Patents

Literature

178results about How to "Good self-adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

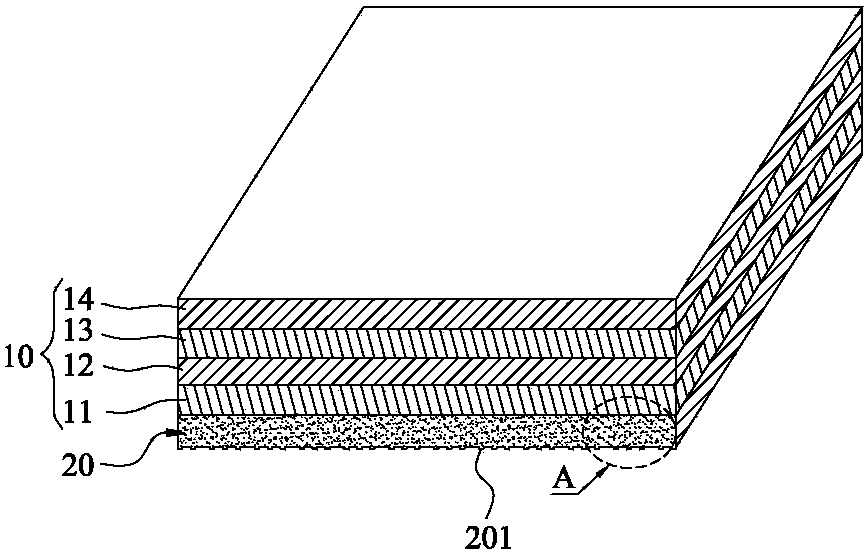

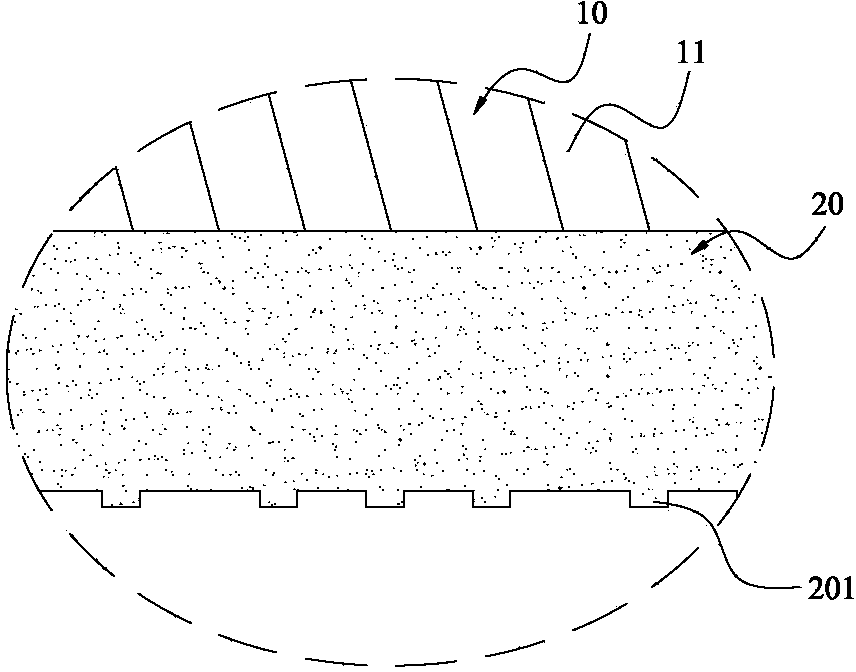

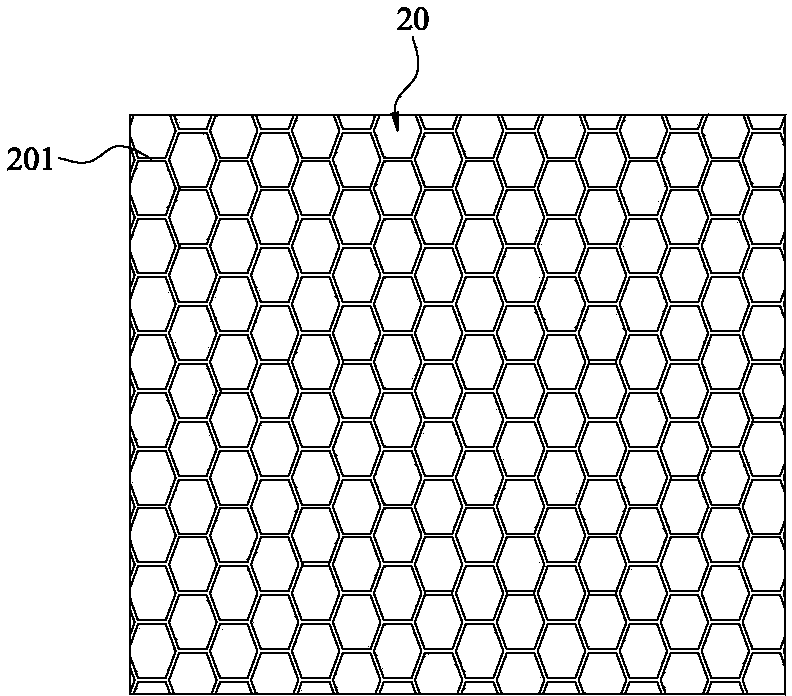

Prepreg fabric and honeycomb sandwich panel

InactiveUS6429157B1Good self-adhesiveReduce porositySynthetic resin layered productsPaper/cardboard layered productsPorosityHoneycomb

A woven fabric prepreg comprising at least [A] a woven fabric as reinforcing fibers, [B] a thermosetting resin or thermosetting resin composition and [C] fine particles of a resin and having a cover factor of 95% or more, and a honeycomb sandwich panel, comprising skin panels fabricated by said woven fabric prepreg and [D] a honeycomb core can be obtained. The woven fabric prepreg little changes in tackiness with the lapse of time and has moderate drapability, being excellent in self adhesiveness to the honeycomb core when used as skin panels of a honeycomb sandwich panel. Furthermore, the honeycomb sandwich panel obtained has a small porosity in the skin panels fabricated by the cured prepreg and has excellent surface smoothness with few pits and depressions on the surfaces of the skin panels.

Owner:TORAY IND INC

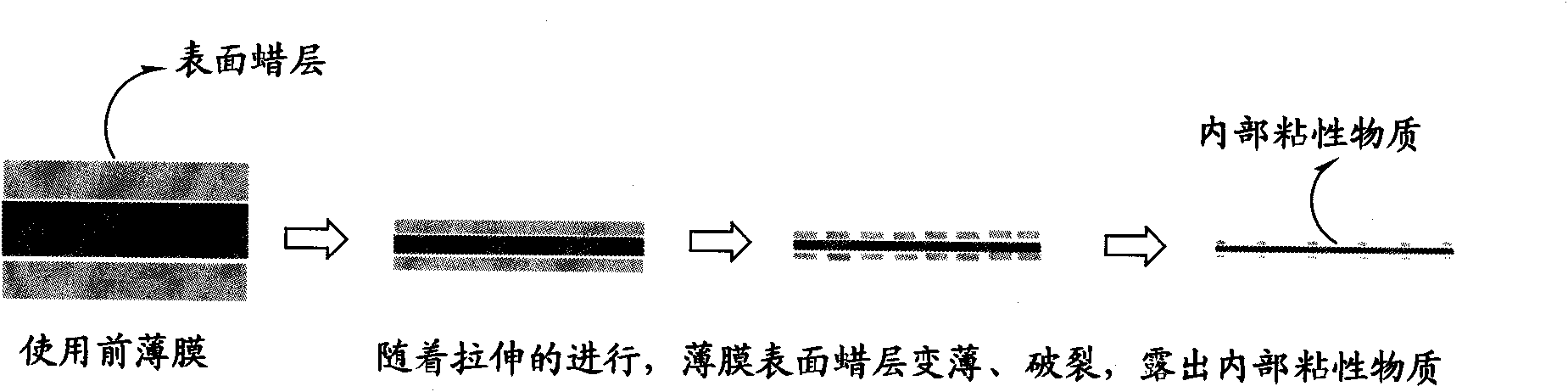

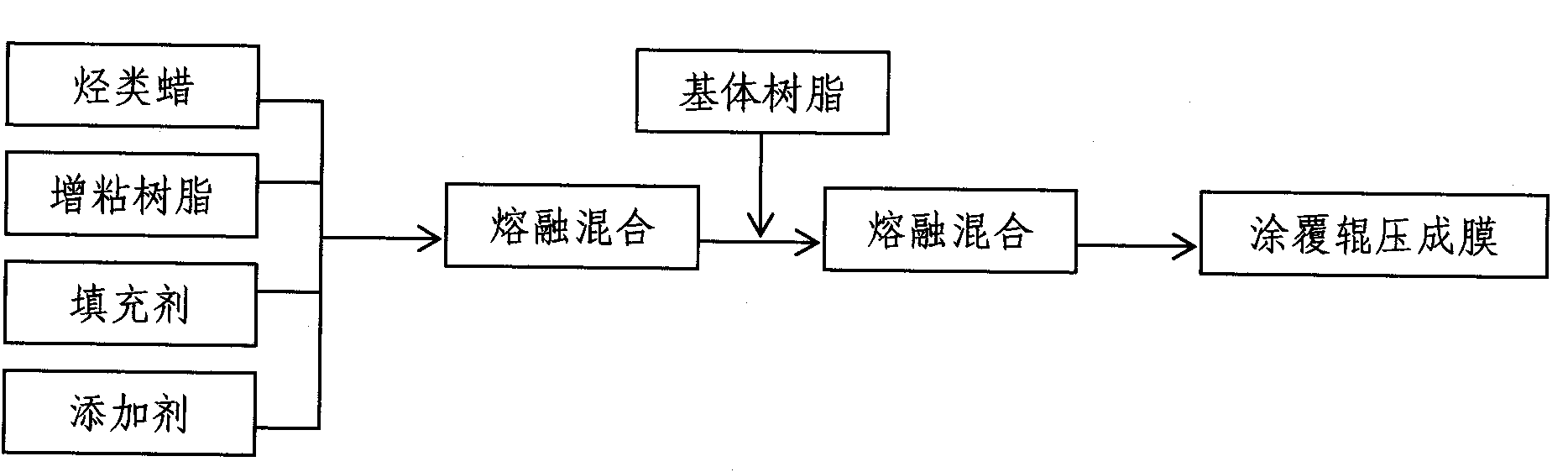

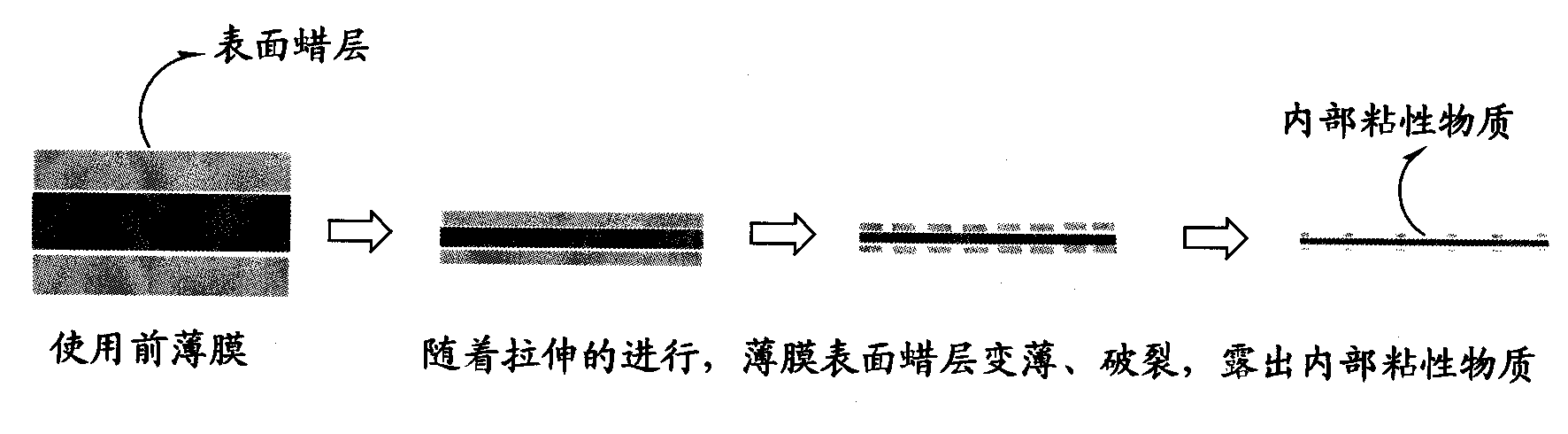

Thermoplastic elastic self-sealing film and preparation method thereof

The invention discloses a thermoplastic elastic self-sealing film and a preparation method thereof. The film is mainly prepared from the following components in part by weight: 100 parts of matrix resin, 100 to 140 parts of wax, 10 to 100 parts of thickening agent and 1 to 30 parts of filler. The preparation method comprises the following steps of: fusing and mixing the components except the matrix resin in a ratio; adding the matrix resin, and performing fusing and mixing; and delivering the obtained melt to a hot melt T-shaped crack die head for coating, rolling and forming the film. The thermoplastic elastic self-sealing film has the advantages of no stickiness on the original surface of the film, easy packaging and transporting, no stickiness to hands, and ideal permeability and resilience; and the preparation process is simple and easy to operate.

Owner:NINGBO QINGHU ELASTOMER SCI & TECH

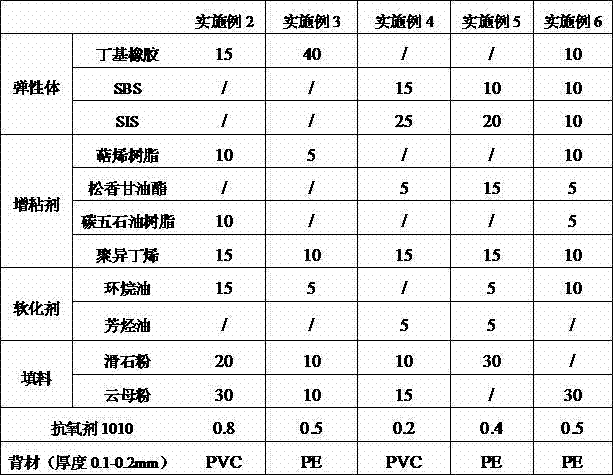

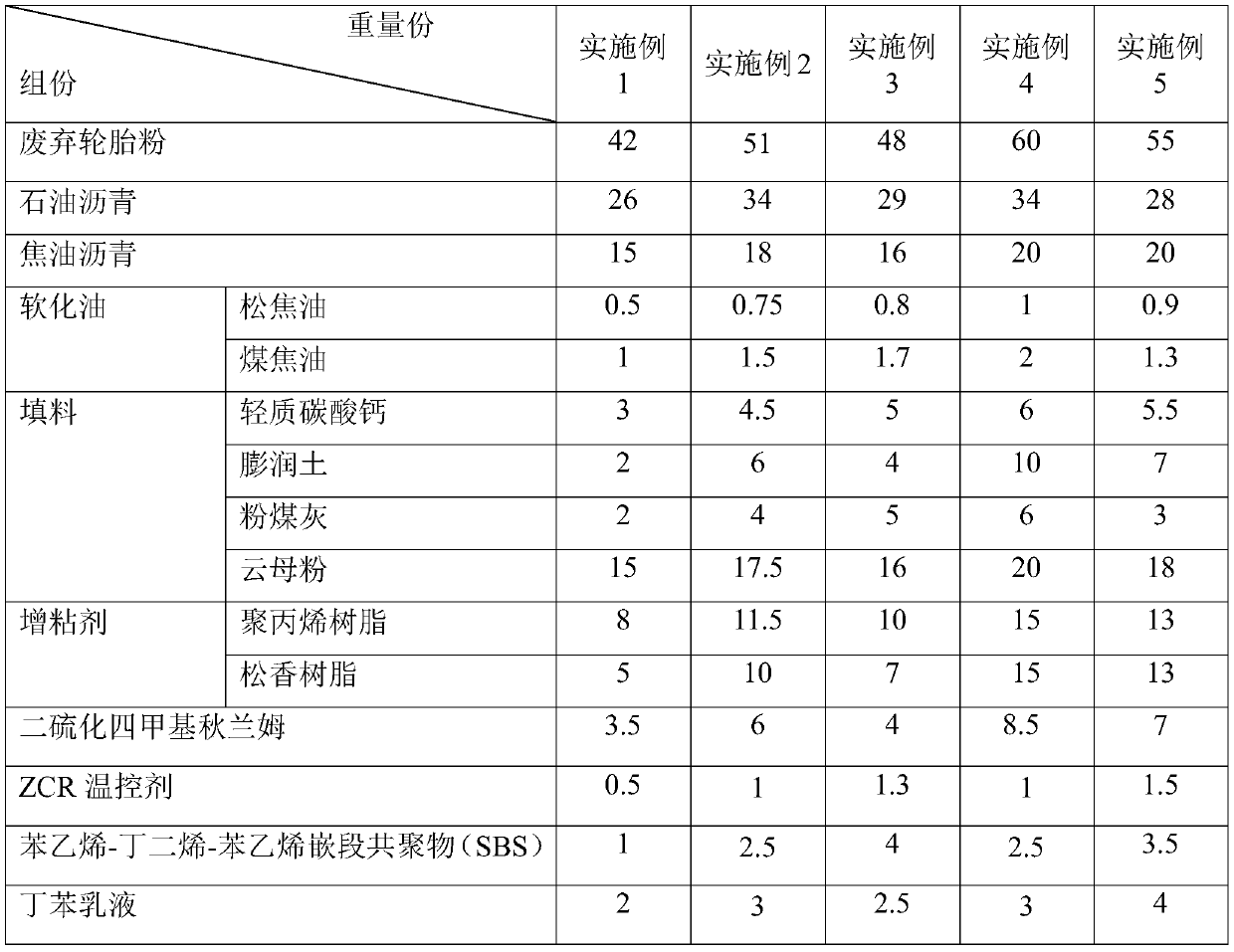

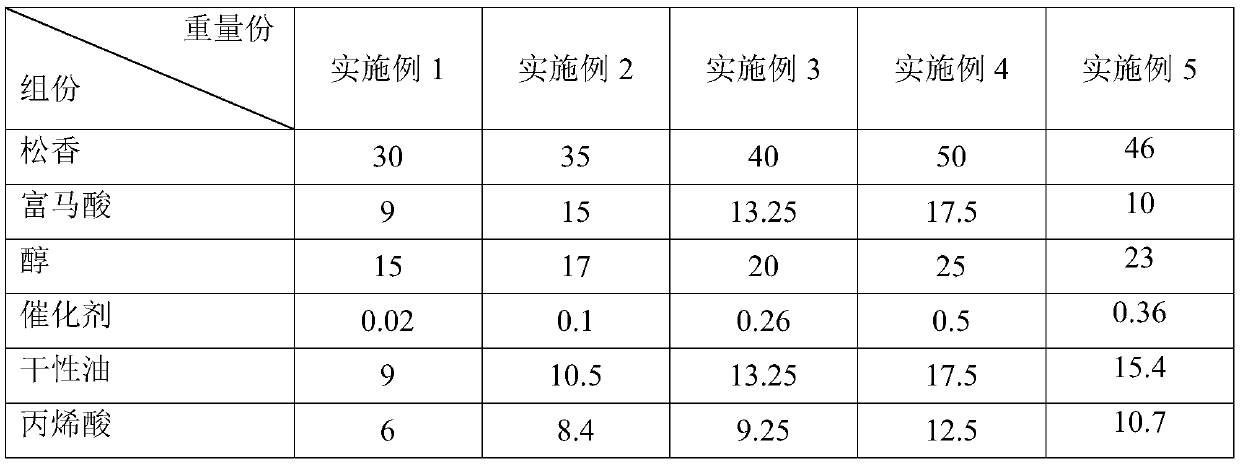

Anticorrosive pressure sensitive adhesive tape and preparation method thereof

InactiveCN102363717AGood self-adhesiveImprove sealingFilm/foil adhesivesCorrosion preventionElastomerPolymer science

The invention discloses an anticorrosive pressure sensitive adhesive tape and a preparation method thereof. The anticorrosive pressure sensitive adhesive tape consists of a back material and pressure sensitive adhesive coated on the back material, wherein the pressure sensitive adhesive consists of the following components in part by weight: 15 to 40 parts of elastomer, 15 to 35 parts of tackifier, 5 to 15 parts of softening agent, 20 to 50 parts of filler, and 0.2 to 0.8 part of anti-aging agent. The preparation method comprises the following steps of: adding the elastomer, the tackifier, the softening agent, the filler and the anti-aging agent into a kneading machine, kneading for 30 to 70 minutes at the temperature of between 130 and 160 DEG C, and obtaining a self-adhesive material; adding the self-adhesive material into a double-screw extruder, performing melt extrusion, and obtaining the pressure sensitive adhesive; and coating the pressure sensitive adhesive on the back material, and thus obtaining the anticorrosive pressure sensitive adhesive tape. The anticorrosive pressure sensitive adhesive tape has good self-adhesive property, high adhesive strength and good sealing performance and durability.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

Preparation method of self-adhesion silicon rubber foam material

The invention provides a preparation method of a self-adhesion silicon rubber foam material. The method comprises the following steps: mixing silicon rubber, a foaming agent, a vulcanizing agent, a reinforcing agent and micromolecular silicon oil as raw materials, milling and sheeting, and performing heat treatment foaming to obtain the self-adhesion silicon rubber foam material. Compared with an existing preparation method, the method has the characteristics that the used raw materials have few varieties and are simple and easy to prepare, low in cost and free of environmental pollution; moreover, by adopting the heat treatment foaming technology, the prepared silicon rubber material is a foam material for foaming, which is high in foaming efficiency, light in weight, excellent in heat insulation property, high and low-temperature resistance, chemical stability and physiological inertia and good in self-adhesion performance, and the force of adhesion between the foam material and an aluminum plate is 10-25N / mm.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Antibacterial hydrocolloid dressing and preparation method thereof

ActiveCN104225663AStrong antibacterialAvoid Potential Biosafety RisksAbsorbent padsBandagesElastomerAntioxidant

The invention provides antibacterial hydrocolloid dressing and a preparation method thereof, and belongs to the technical field of medical dressing. The preparation method of the antibacterial hydrocolloid dressing is as follows: firstly, elastomers, tackifying resin, a plasticizer and an antioxidant are added into an internal mixer and mixed to prepare a hot-melt pressure-sensitive adhesive; hydrocolloid particles, polyvinyl alcohol, chitosan derivative and an antibacterial agent are added into the hot-melt pressure-sensitive adhesive and mixed; and the mixture is placed in a press vulcanizer for treatment, a waterproof polyurethane backing is coated with the treated mixture, release paper is covered, and a finished product is prepared after irradiation sterilization. The anti-bacterial hydrocolloid dressing prepared with the method has good antibacterial performance and has no safety risk; and the polyvinyl alcohol ingredient added in the preparation process is crosslinked during irradiation to form physical gel, the integrity of the dressing is effectively maintained, and the corrosion resistance of the dressing is improved.

Owner:HENAN HUIBO MEDICAL CO LTD

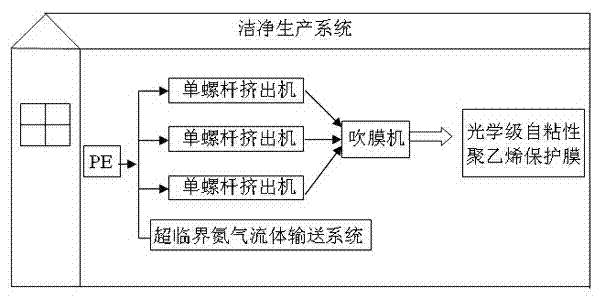

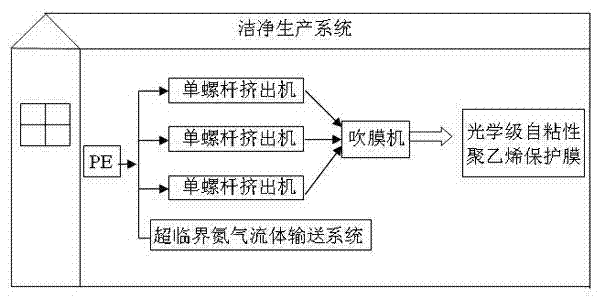

A kind of optical grade self-adhesive polyethylene protective film and preparation method thereof

ActiveCN102294867AHigh transparencyGood self-adhesiveSynthetic resin layered productsPolymer scienceComposite film

The invention belongs to a preparation method of a self-adhesive polyethylene protective film with optical-grade transparency. The protective film of the invention comprises three layers of a self-adhesive layer, an interlayer, and a back-material layer, and is a composite film obtained by coextrusion film blowing. Thereinto, the self-adhesive layer accounts for 10%-20% of the composite film in thickness; the interlayer accounts for 60%-80% of the composite film in thickness; and the back-material layer accounts for 10%-20% of the composite film in thickness. The self-adhesive layer is compounded by low density polyethylene and metallocene low density polyethylene with a ratio of 20 / 80-40 / 60 wt%; the interlayer is compounded by low density polyethylene and medium density polyethylene witha ratio of 20 / 80-40 / 60 wt%; and the back-material layer is composed of low density polyethylene. Three coextrusion film blowing units are all single screw machines with a length-diameter ratio of 28;the plastification extrusion process adopts a supercritical nitrogen fluid conveying system; and the extrusion film blowing process is performed in a dust-free and clean workshop. With the method of the invention, a self-adhesive polyethylene protective film with optical-grade transparency can be prepared.

Owner:佛山新长盛塑料薄膜有限公司

Polyvinyl chloride electrostatic film and preparation method thereof

InactiveCN106046626AHigh static resistanceImprove anti-static effectFlat articlesPlasticizerPolyvinyl chloride

The invention relates to the technical field of electrostatic film, and in particular, relates to a polyvinyl chloride electrostatic film and a preparation method thereof, wherein the polyvinyl chloride electrostatic film comprises the following raw materials in parts by weight: 80-120 parts of PVC resin, 46-73 parts of a plasticizer, 1-3 parts of a heat stabilizer, 3-7 parts of an anti-electrostatic agent, 0.3-0.7 part of a gelatinizing agent, 0.02-0.03 part of a pigment powder, and 0.1-0.3 part of other auxiliary agents. The polyvinyl chloride electrostatic film has high electrostatic resistance, has high anti-electrostatic effect and protection functions, has high self-adhesive performance, and has excellent stable performance under high temperature conditions; the polyvinyl chloride electrostatic film also has the advantages of being ultra thin, tough, transparent, self-adhesive, good in transparency, small in watermarks and the like, has fewer crystal points and low-temperature resistance, and has excellent comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

High-strength heat-resistant modified silicon rubber power cable sheath material

InactiveCN104292836AHigh strengthImprove heat resistanceRubber insulatorsInsulated cablesPolymer scienceBenzoyl peroxide

The invention discloses a high-strength heat-resistant modified silicon rubber power cable sheath material which is prepared from the following raw materials in parts by weight: silicone rubber, fluorine rubber, nano calcium carbonate, modified silica, potassium titanate whiskers, aluminum hydroxide, ferric oxide, tin oxide, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, methyltris(methylethylketoximino)silane, benzoyl peroxide, hydroxyl silicone oil, an amino silane coupling agent, dibutyltin dilaurate, magnesium oxide, a hydroxy stearic acid, an accelerant, an antiager, and a plasticizer. The high-strength heat-resistant modified silicon rubber power cable sheath material disclosed by the invention is high in strength and good in heat resistance, and a cable sheath prepared by using the high-strength heat-resistant modified silicon rubber power cable sheath material is good in comprehensive performance and long in service life.

Owner:ANHUI CONSTANT CRYSTAL CABLE GROUP

Asphalt strip and preparation and construction methods thereof

ActiveCN104109399AEasy to carryImprove ductilityPaving detailsBuilding insulationsAntioxidantDust control

The invention discloses an asphalt strip and preparation and construction methods thereof, belonging to the technical field of asphalt pavement construction. The asphalt strip is characterized by comprising the following components in parts by weight: 70-90 parts of asphalt, 2-10 parts of a styrene-butadiene copolymer, 8-15 parts of solvent naphtha, 1-5 parts of a filler, 1-5 parts of a stabilizer and 0.1-0.3 part of an antioxidant, wherein the solvent naphtha is one of aromatic hydrocarbon oil, coal tar, diesel oil or kerosene; and the asphalt is petroleum asphalt or coal tar pitch. The construction method of the asphalt strip comprises the following steps: flushing, dedusting, caulking and welting. The asphalt strip has high viscidity and extensibility, filling of a pavement crack can be finished without heating, the construction method of the asphalt strip is short in used time, and can be finished without an assist of crack sealing equipment, and the construction effect is firm and lasting.

Owner:淄博恒信路面材料有限公司

Rubber self-adhering type composite damping material for motorcycles and method of manufacturing the same

InactiveCN101112807AImprove damping performanceImprove sound insulationLaminationLamination apparatusRubber materialPolymer science

A locomotive-used rubber system self-adhesive composite damp material and the manufacture method thereof at least comprises a layer of self-adhesive damp material layer; one surface of the self-adhesive damp material layer is attached with a protection layer for protecting the self-adhesive damp material; the other surface of the self-adhesive damp material layer is attached with a layer of installation isolation paper. The damp material layer is a composite rubber material layer with the rubber dosage ranging from 50 to 100 measured by weight, liquid colophony dosage ranging from 100 to 300 and the flame retardant and other filling material dosage ranging from 100 to 300. The rubber can be butyl rubber, halogenated butyl rubber and acrylonitrile-butadiene rubber; the liquid colophony can be polybutylene liquid glue and butyronitrile liquid glue; the flame retardant is the normal flame retardant; the other inorganic filling material is isinglass powder, calcium carbonate and aluminum hydroxide; the protection layer is a flexible layer which can not be torn, made of the aluminium foil, glass fiber cloth, leatheroid or paper material. The installation isolation paper can be the paper layer which can be torn.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

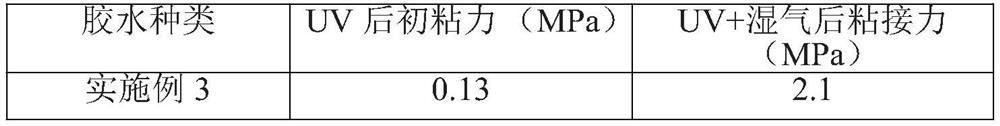

Quick-bonding UV/moisture dual-curing adhesive and preparation method thereof

PendingCN112920762ASolve problems that cannot be curedSolve the problem of fixture pressure keepingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention discloses a quick-bonding UV / moisture dual-curing adhesive and a preparation method thereof. The adhesive is prepared from the following components in parts by mass: 10.0 to 50.0 parts of polyurethane acrylic resin, 10.0 to 50.0 parts of ultraviolet / moisture dual-curing polyurethane acrylic resin, 5 to 30.0 parts of reactive diluent, 0.1 to 8.0 parts of a photoinitiator, 0.01 to 2.0 parts of a moisture curing catalyst, 0 to 15 parts of tackifying resin and 0.5 to 10 parts of a thixotropic agent. According to the UV / moisture dual-curing adhesive provided by the invention, a pressure-sensitive adhesive can be formed on site after ultraviolet light is cured, initial adhesion can be formed immediately, and clamp pressure maintaining is not needed, so that the problem that clamp pressure maintaining is needed in electronic product assembly is solved,electronic product assembling can be accelerated, and the efficiency is improved. In addition, the adhesive prepared from the monofunctional polyurethane acrylic resin has higher autohension.

Owner:HANGZHOU BAOMING NEW MATERIAL TECH CO LTD

Modified ethylene propylene rubber and preparation method thereof

The invention provides a modified ethylene propylene rubber. The modified ethylene propylene rubber comprises, by weight, 70-100 parts of ethylene propylene rubber, 130 parts of a modified polyoctene polymer, 6-13 parts of an activator, 5-100 parts of a strengthening agent, 5-100 parts of a filler, 0-50 parts of a plasticizer, 1-5 parts of an antioxidant, 3-5 parts of a processing assistant, 0.3-5 parts of a vulcanizing agent, and 1-5 parts of a vulcanizing promoter. The invention also provides a preparation method of the modified ethylene propylene rubber. The modified ethylene propylene rubber has a very good extension effect, can well improve the autoadhesion and the mutual viscosity of the ethylene propylene rubber, has an obvious non-polar liquid resistance, has an obvious effect in the modification of other polar rubbers, and well realizes the performance complementation of polar rubber and the non-polar rubber.

Owner:BYD CO LTD

Light-weight shock-absorption rubber plastic foamed material and preparation method thereof

The invention belongs to the technical field of organic high-molecular compounds, and particularly relates to a light-weight shock-absorption rubber plastic foamed material and a preparation method thereof. The preparation method comprises the following steps: carrying out banburying, open mixing and granulation on EVA (ethylene-vinyl acetate), butyl rubber, ethylene-octylene copolymer, a solubilizer, a foaming agent, a crosslinking agent, nano zinc oxide, zinc stearate, stearic acid, an aging accelerator and an inorganic filler to obtain rubber plastic granules, and carrying out one-step injection molding to obtain the light-weight shock-absorption rubber plastic foamed material. The light-weight shock-absorption rubber plastic foamed material has the characteristics of light weight, high shock absorptivity, favorable yellowing resistance, high dimensional stability, excellent tensile strength, excellent tear strength and the like, can be used in automobile vibration absorbers, various shock absorption pieces, shoe sole materials and the like, is especially suitable to be used as a midsole for jogging shoes, can absorb counterforce from the ground, and can well protect the feet from hurt.

Owner:MAOTAI FUJIAN SOLES CO LTD

Rubber composite applicable to inside liner of tubeless tire

The invention discloses a rubber composite applicable to an inside liner of a tubeless tire. The composite comprises the following components in parts by weight: 70 to 100 parts of halogenated butyl rubber, 0 to 30 parts of natural rubber, 30 to 65 parts of carbon black, 20 to 45 parts of inorganic filler, 1 to 4 parts of vulcanizing agent, 1 to 2 parts of accelerant, 1 to 2 parts of active agent, 5 to 15 parts of softening agent and 6 to 10 parts of processing aid, wherein halogenated butyl rubber and natural rubber are blended to form a substrate material. The rubber composite is low in themogenesis, high in self-adhesion performance, outstanding in air impermeability and fatigue resistance, excellent in tensile property and ageing resistance, and applicable to the inside liner of the tubeless tire.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

Nano silver polyester biodegradable preservative film, preparation and application thereof

ActiveCN104059341AEasy to storeExtended shelf lifeFlexible coversWrappersPolymer scienceModified atmosphere

The invention discloses a nano silver polyester biodegradable preservative film, which is prepared by steps of chain extension and modification of dihydric alcohol copolyester of diacid and fatty group by introducing aromatic group and fatty group, the nano silver polyester biodegradable preservative film has strong antibiosis, anticorrosion and fresh-keeping functions, greatly increases the storage and fresh-keeping period of the food, and has modified atmosphere function; in addition, the nano silver polyester biodegradable preservative film has the advantages of excellent performance, high molecular weight, high branching degree, high crystallization degree, less impurity, no toxicity, and biodegradable performance by burying in soil after discharging.

Owner:新疆康润洁环保科技股份有限公司 +1

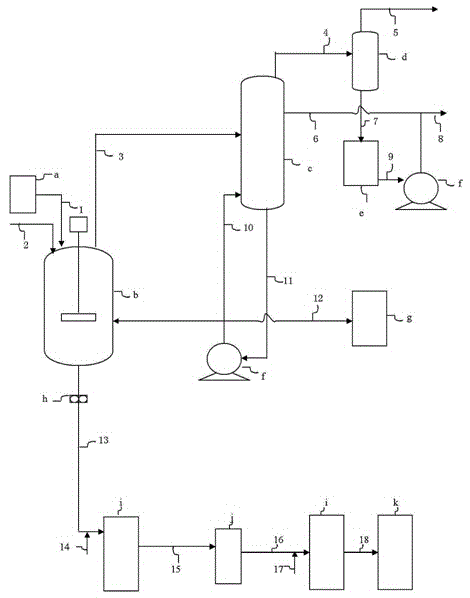

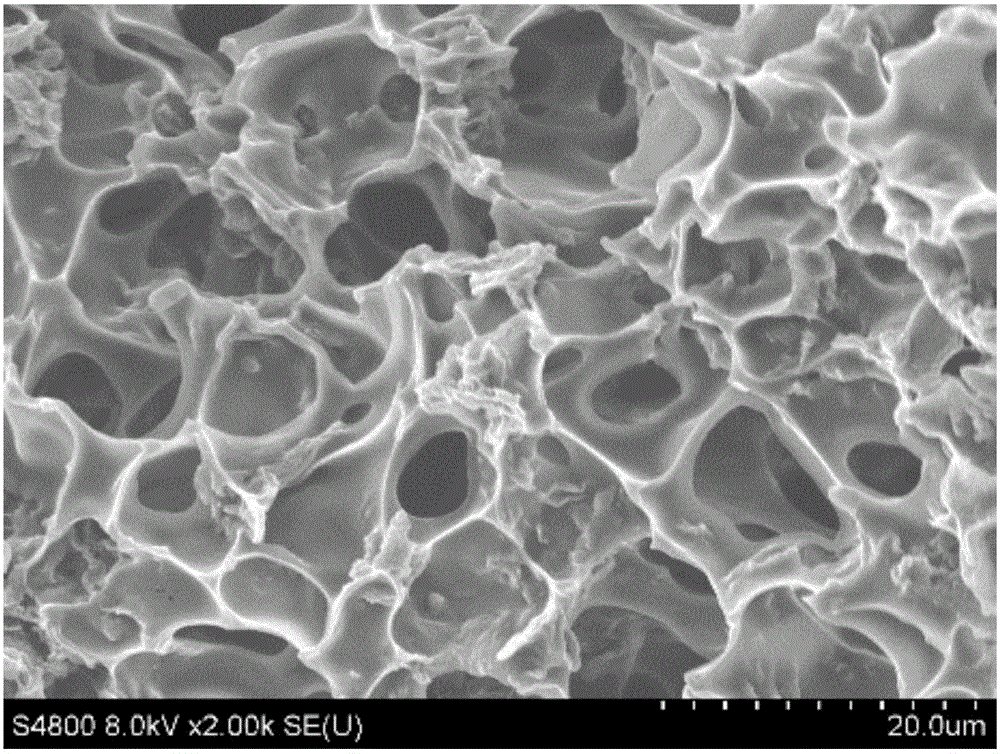

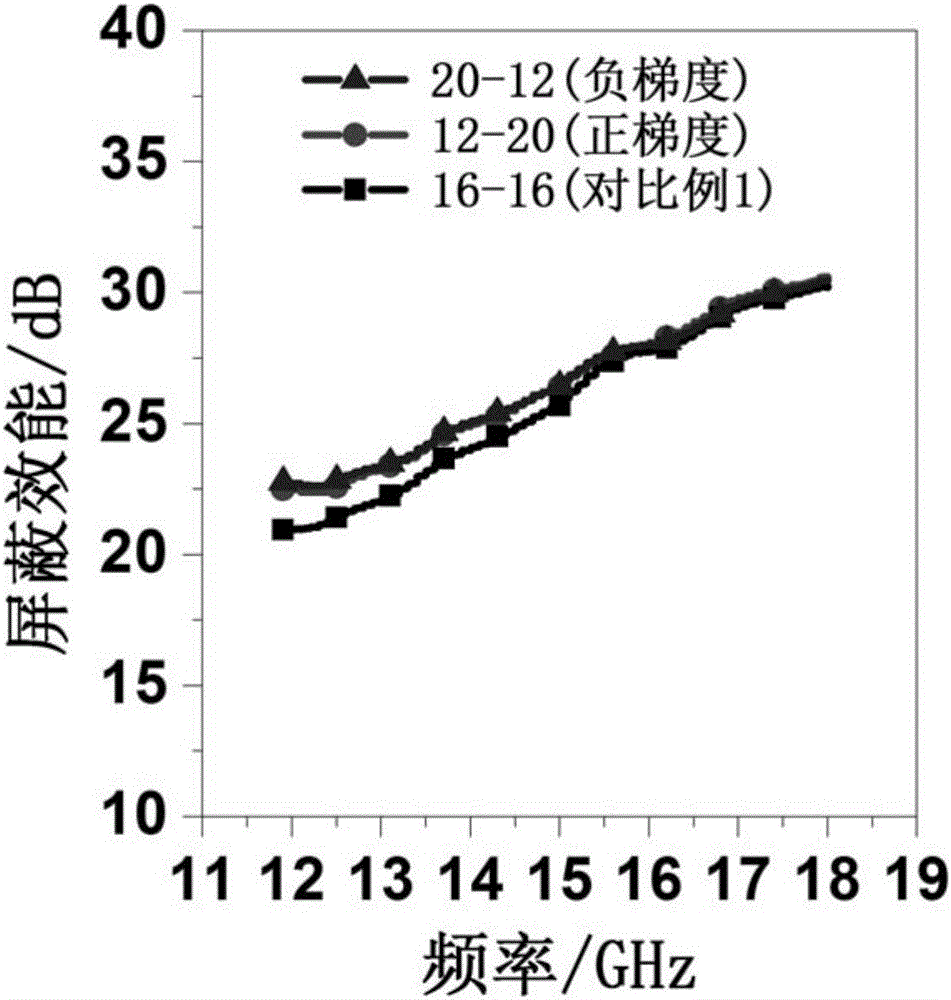

Thermoplastic polyurethane/graphene foam material and preparation method and application thereof

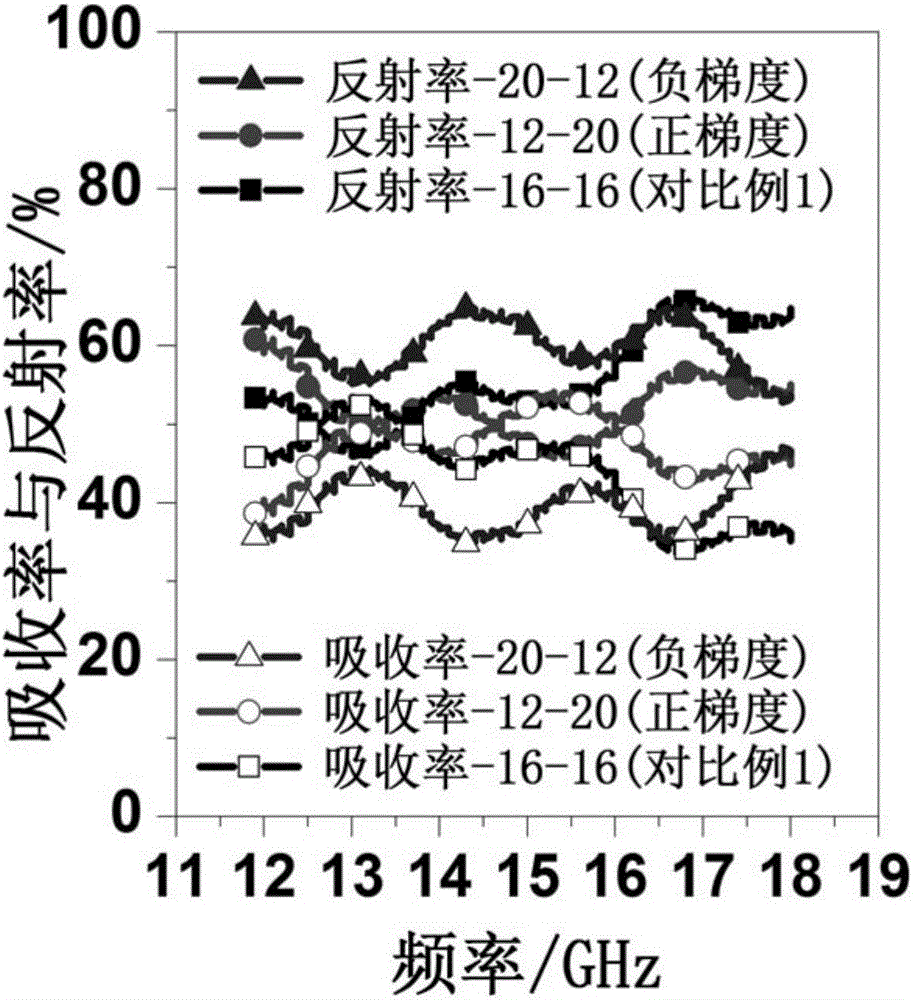

ActiveCN106566226AReduce weight and costIncrease absorption lossLamination ancillary operationsLaminationCvd grapheneGraphene foam

The invention discloses a thermoplastic polyurethane / graphene foam material and a preparation method and application thereof. The thermoplastic polyurethane / graphene foam material has high electromagnetic shielding effectiveness and high wave absorbing performance. According to the method, firstly, single-layer thermoplastic polyurethane / graphene microfoam films are prepared through a phase separation method, then, the single-layer thermoplastic polyurethane / graphene microfoam films with the different graphene contents are bonded into an integrated material through glue, and therefore gradient dispersion of graphene in the thermoplastic polyurethane / graphene foam material is achieved. The gradient structure can endow the thermoplastic polyurethane / graphene foam material with good shielding effectiveness and meanwhile can greatly improve the wave absorbing performance of the material, and the prepared light thermoplastic polyurethane / graphene foam material has good application prospects in the fields of electromagnetic shielding and wave absorbing materials.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Novel foam structural adhesive and preparation method thereof

InactiveCN101935514AGood self-adhesiveSimple to useNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceFoaming agent

The invention discloses a foam structural adhesive and a preparation method thereof and relates to a foam adhesive and a preparation method thereof, which solves the problems that the foam adhesive prepared by the prior art has low heat resistance, mechanical property, impact insistence and dielectrical property and the like. The high-property structural adhesive is prepared from a cyanate prepolymer, a catalyst, a foaming agent, a thixotropic agent, a toughening agent and a filler. The preparation method of the novel foam structural adhesive comprises the following steps of: 1, preparing the cyanate prepolymer; 2, preparing the catalyst; 3, mixing the cyanate prepolymer, the catalyst, the foaming agent, the thixotropic agent, the toughening agent and the filler to prepare an adhesive block and then press the adhesive block to be an adhesive film to obtain the foam structural adhesive. The novel foam structural adhesive can be applied in the fields of military and civil machines and electric manufacturing.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

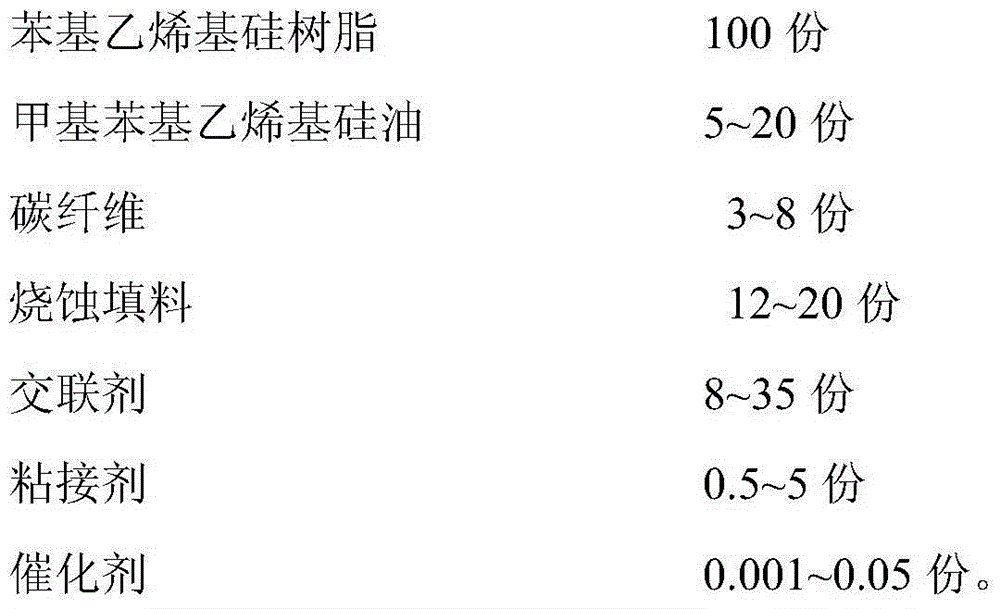

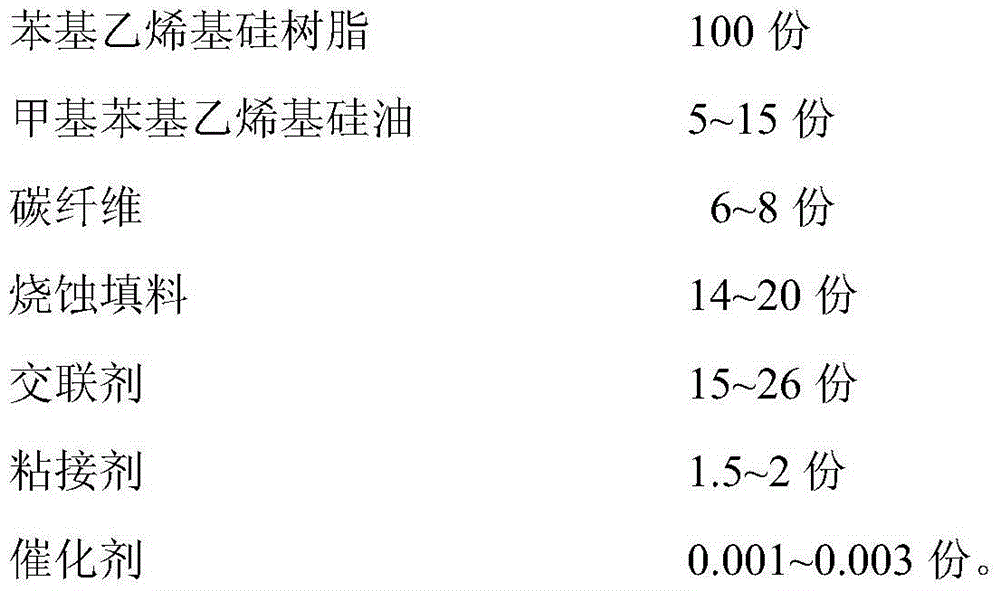

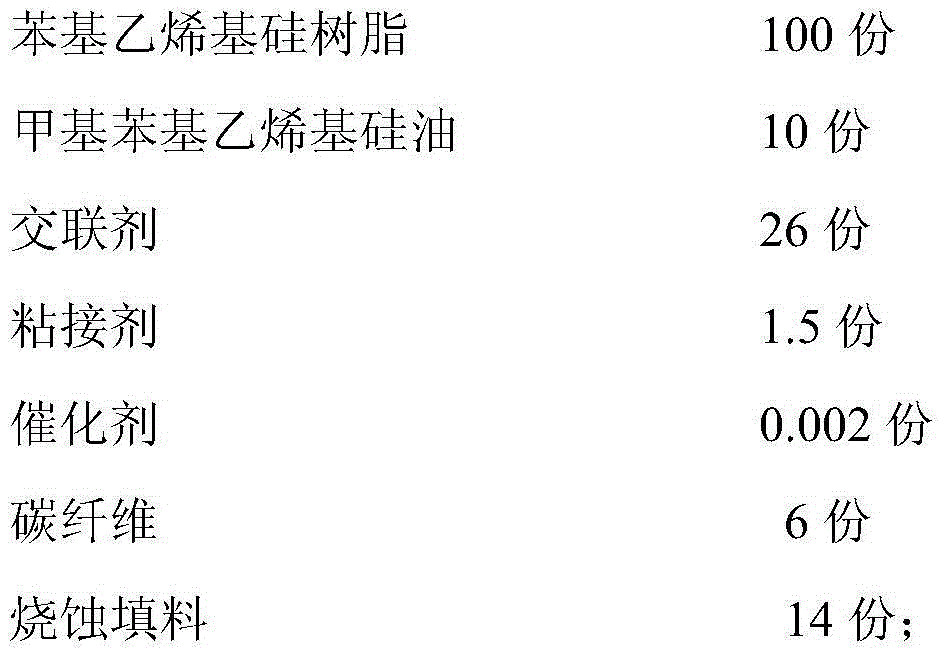

Silicon resin coating layer material as well as preparation method and use method thereof

The invention relates to a silicon resin coating layer material as well as a preparation method and a use method thereof. The silicon resin coating layer material is prepared by mixing the following raw materials in parts by weight: 100 parts of phenyl vinyl silicon resin, 5-20 parts of methyl phenyl vinyl silicone oil, 3-8 parts of carbon fibers, 12-20 parts of ablative fillers, 8-35 parts of a cross-linking agent, 0.5-5 parts of an adhesive and 0.001-0.05 parts of a catalyst. The coating layer material prepared from the silicon resin as a base material does not need to be reinforced with white carbon black and is excellent in mechanical property and ablation resistance; in addition, the compatibility of the adhesive and a sizing material is good; the coating layer material can be stored for a long term after being prepared, does not need priming during use and is an ideal propellant coating material.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Novel self-adhesive waterborne polyurethane dispersion material

The invention relates to a novel self-adhesive waterborne polyurethane dispersion material, which is prepared through the following steps: 1, putting a polymer glycol, a hydrophilic monomer and a cosolvent into a reaction kettle, and carrying out vacuum dehydration for over 1 h at a temperature of over 100 DEG C, wherein the polyether glycol is polyether glycol with a molecular weight of 1000-10000; 2, reducing the temperature of the reaction kettle to below 90 DEG C, adding diisocyanate, raising the temperature, and reacting; 3, reducing the temperature to below 55 DEG C, and adding a neutralizing agent and a diluting solvent; and 4, adding deionized water while stirring, continuously stirring for over 10 min, heating to 45-75 DEG C, carrying out vacuum solvent extraction for over 1 h, cooling, and filtering, so that a self-adhesive waterborne polyurethane dispersion is obtained. The self-adhesive waterborne polyurethane dispersion material provided by the invention is good in self-adhesion effect, soft in texture and low in cost, and does not stick to the skin and hairs, therefore, the self-adhesive waterborne polyurethane dispersion material further has the application value in the aspect of medical elastic bandages.

Owner:SHANGHAI KB MATERIAL TECH CO LTD

Tulobuterol adhesive patch

InactiveCN1905866AExcellent Adhesive PropertiesFacilitated releaseOrganic active ingredientsPharmaceutical non-active ingredientsPermeationSkin irritant

Owner:NIPRO PATCH

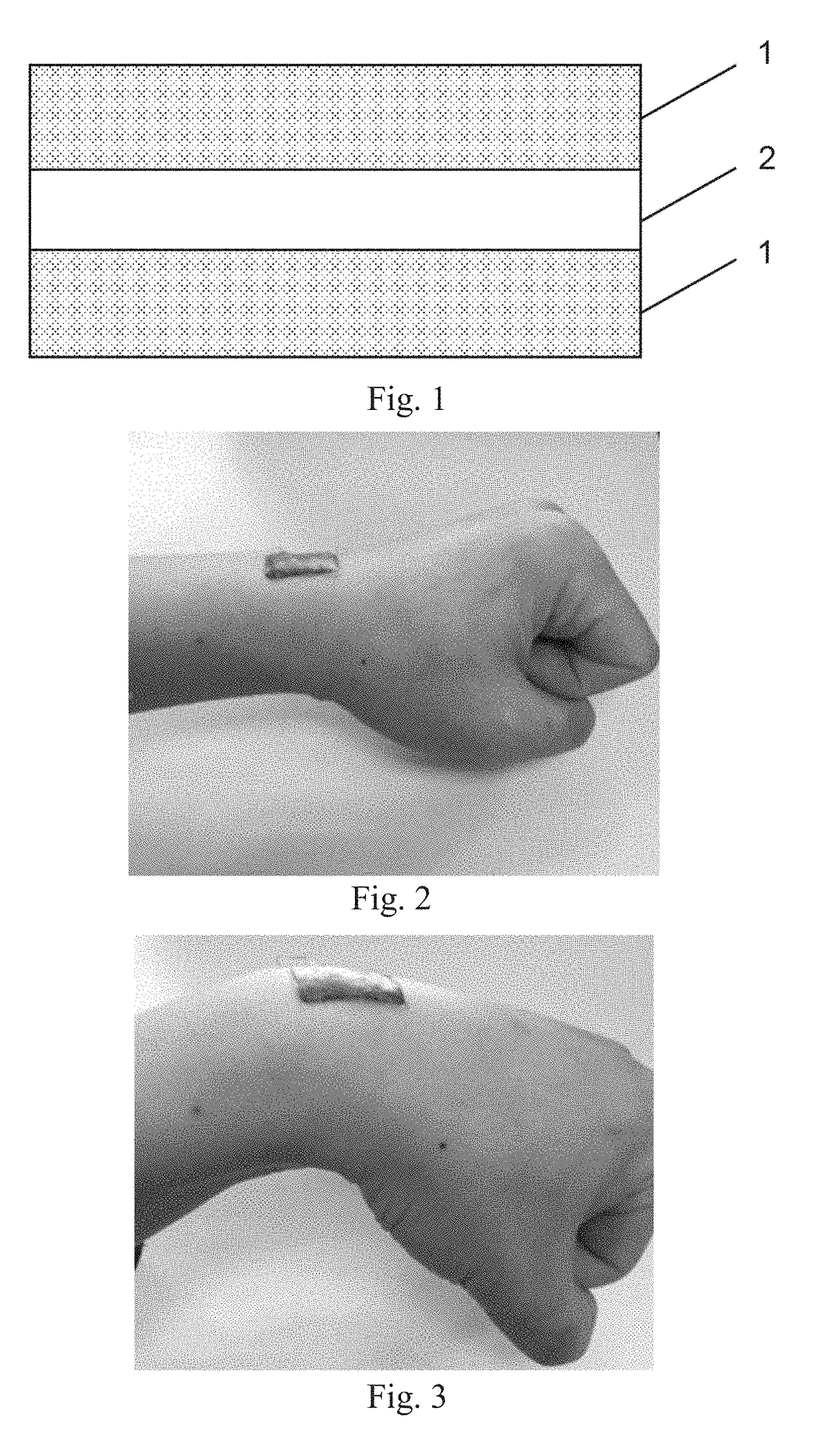

Hydrogel flexible strain sensor and preparation method thereof

ActiveCN112724339AHigh sensitivityGood self-adhesiveElectrical/magnetic solid deformation measurementHuman bodyMeth-

The invention discloses a hydrogel flexible strain sensor and a preparation method thereof. The preparation method comprises the following steps: 1, mixing and dissolving monomer acrylamide, calcium chloride, sodium caseinate and a polydopamine solution in deionized water to obtain a mixed solution; 2, adding a chemical cross-linking agent N, N '-methylene bisacrylamide into the mixed solution, stirring, adding a single-layer graphene oxide dispersion liquid, and stirring at room temperature to obtain a pre-polymerization solution; 3, adding an initiator and a catalyst into the pre-polymerization solution; 4, injecting the polymerization solution into a reaction mold to obtain hydrogel; and 5, cleaning and drying the hydrogel, installing a conductive copper electrode, and packaging to form the flexible strain sensor. The prepared hydrogel strain sensor has high stretchability, high sensitivity and adhesiveness, and can be directly attached to the skin of a human body to realize real-time monitoring of tiny or large-amplitude human motion.

Owner:SHENZHEN HAIPAI TECH

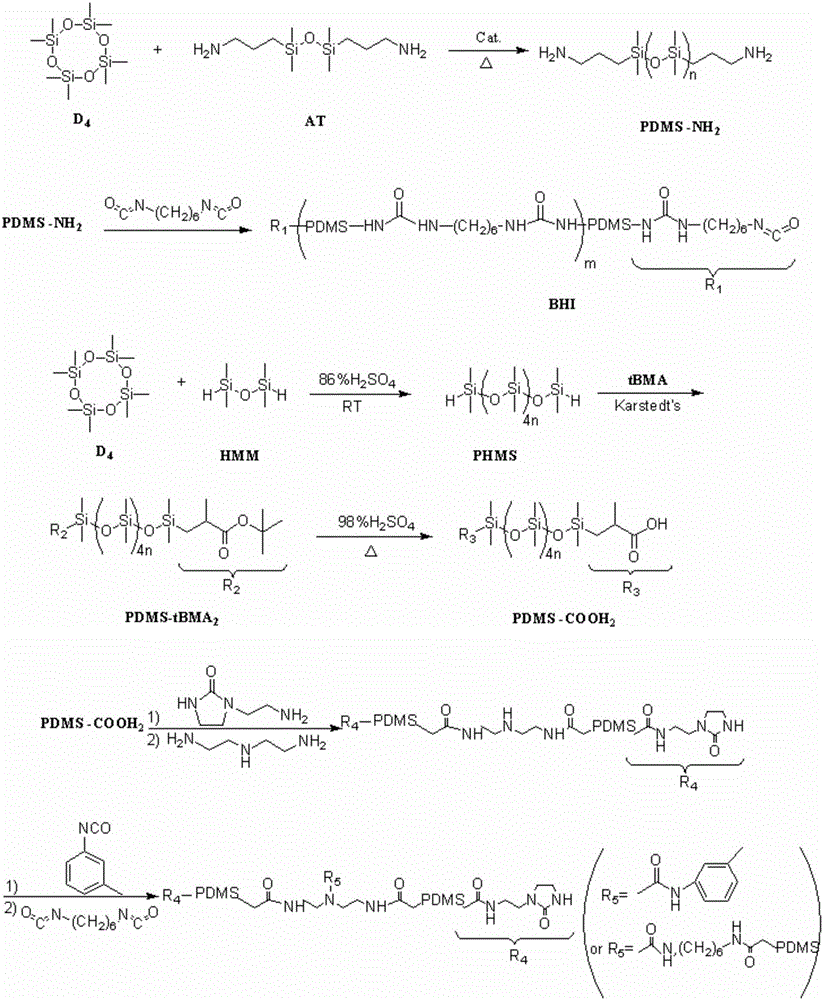

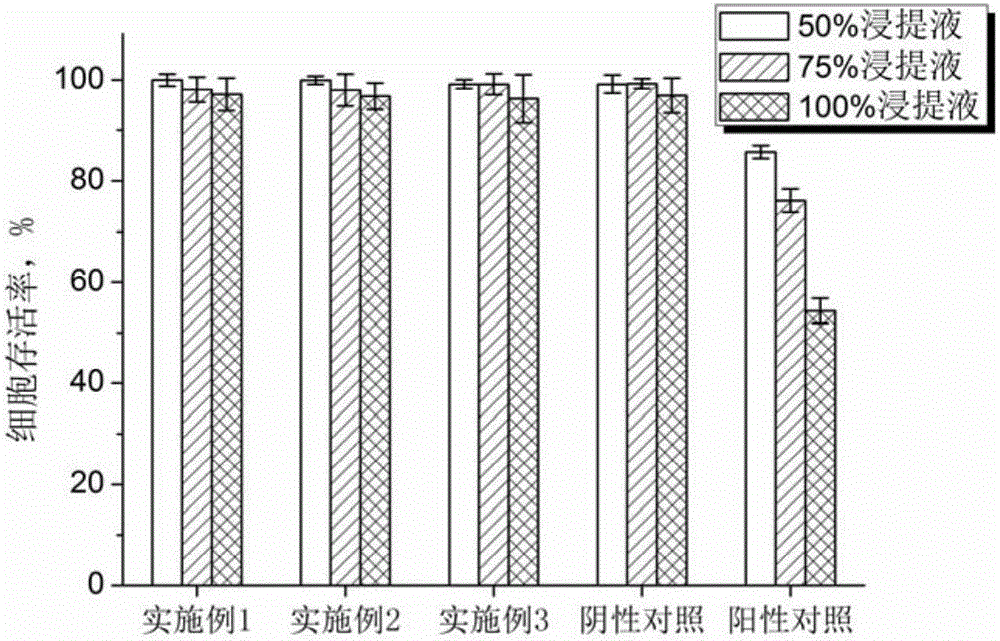

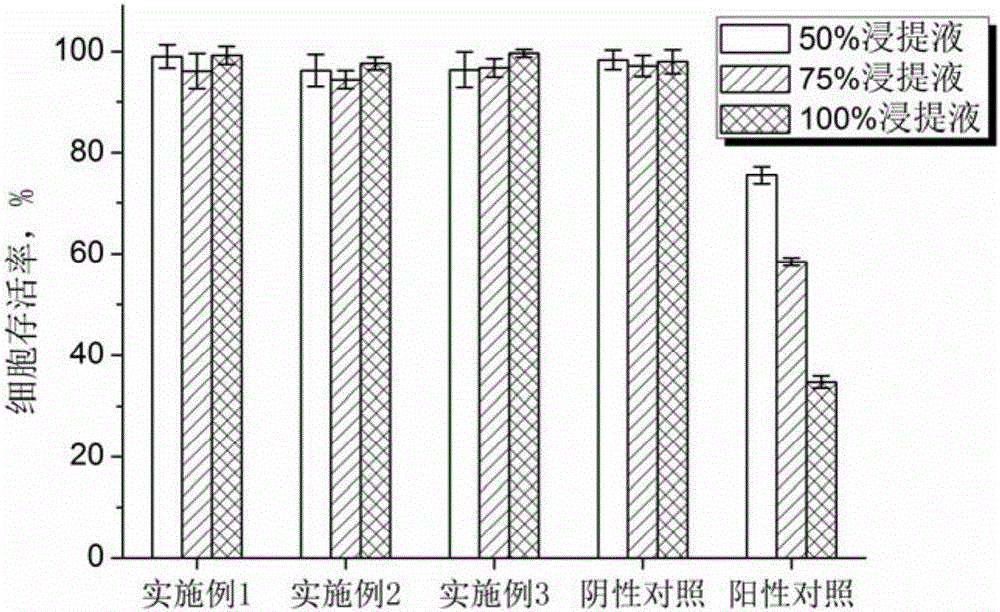

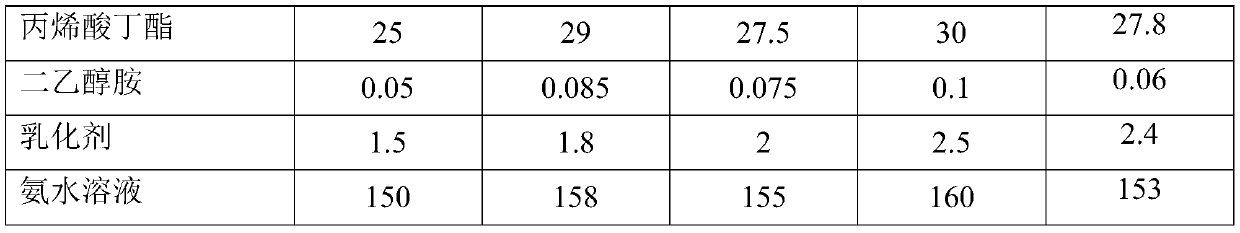

Double-layer structural skin wound dressing based on polysiloxane supra-molecular elastomers and preparation method of skin wound dressing

ActiveCN106038065AHigh transparencyIncrease elasticityAdhesive dressingsAbsorbent padsElastomerBiocompatibility Testing

The invention discloses a double-layer structural skin wound dressing based on polysiloxane supra-molecular elastomers and a preparation method of the skin wound dressing. The method comprises the following steps: promoting a reaction between amino-terminated polysiloxane and hexamethylene diisocyanate, so that the polysiloxane supra-molecular elastomer which serves a flexible substrate layer is obtained; making the amino-terminated polysiloxane sequentially react with mono-functionality and dual-functionality primary amino compounds, so that a siloxane oligomer containing a secondary amine group is obtained; sequentially reacting the siloxane oligomer with m-toluene isocyanate and hexamethylene diisocyanate, so that a polysiloxane supra-molecular elastomer which serves as a binding layer is obtained; and conducting hot-press and cold-press molding processes, so that the double-layer polysiloxane supra-molecular elastomer thin-film dressing is obtained. The thin-film dressing is good in air permeability and hydroscopicity, and the thin-film dressing, when used as a chronic wound dressing, is conducive to the growth and the regeneration of wound surface tissues and is capable of accelerating healing of wounds. The method, which takes polysiloxane as a raw material, can avoid cytotoxicity and skin irritation and can guarantee good biocompatibility.

Owner:SOUTH CHINA UNIV OF TECH

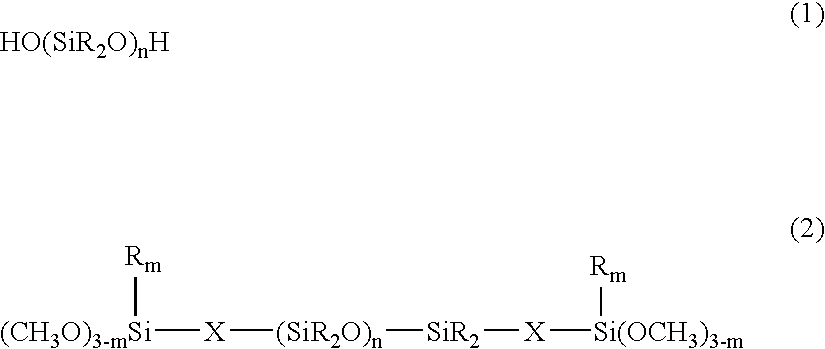

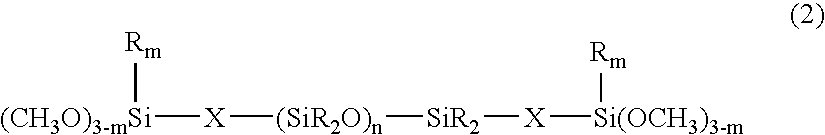

Organopolysiloxane composition for bonding to magnesium alloy

ActiveUS20050228091A1Good self-adhesivenessGood self-adhesiveNon-macromolecular adhesive additivesSpecial tyresOxygen atomSilane coupling

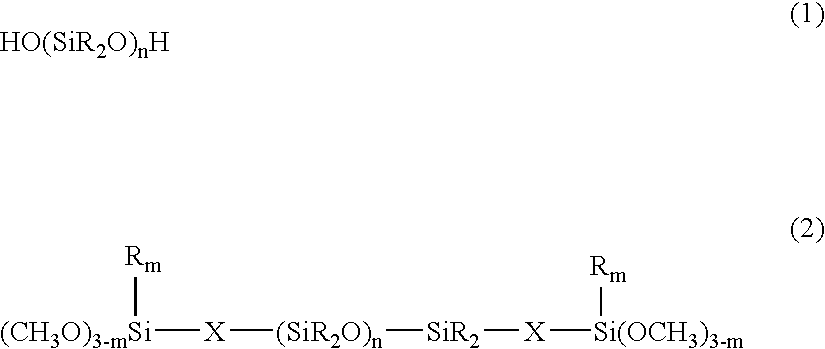

An organopolysiloxane composition for bonding to magnesium alloys comprises (A) 100 parts by weight of an organopolysiloxane of the following general formula (1) and / or (2) wherein R may be the same or different and represents a substituted or unsubstituted monovalent hydrocarbon group having 1 to 10 carbon atoms, and n is an integer of at least 10, X represents an oxygen atom or an alkylene group having 2 to 5 carbon atoms, and m independently represents an integer of 0 or 1, (B) 0.1 to 50 parts by weight of an organosilicon compound having at least three hydrolyzable groups bonded to silicon atoms in one molecule and / or a partial hydrolyzate thereof, and (C) 0.1 to 15 parts by weight of an acidic silane coupling agent.

Owner:SHIN ETSU CHEM IND CO LTD

Neodymium-based homogeneous phase rare earth catalyst and preparation method and application thereof

The invention relates to a rare earth catalyst used for conjugation alkadiene polymerization, a preparation method thereof and a method for combining a high cis-form gathering conjugate alkadiene elastic body. The rare earth catalyst is composed of carboxylic acid neodymium, alkyl aluminum, halogen-containing compound and conjugate alkadiene, can be prepared under the condition that the molar ratio of the alkyl aluminum and the carboxylic acid neodymium is smaller than or equal to 10, has relatively higher catalytic activity and enables polymerization conversion rate of the conjugate alkadiene to be larger than 80%. The catalyst has the advantages of homogeneous phase, good stability and high directionality. The catalyst is used for conjugate alkadiene polymerization and can prepare the gathering conjugate alkadiene elastic body with the cis-form structure content larger than 98%.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inorganic fiber paper

ActiveCN101098998AGood self-adhesiveHigh mechanical strengthInorganic fibres/flakesHybrid capacitor separatorsPhysical chemistryLaser scattering

This invention provides an inorganic fiber paper that consists essentially of inorganic materials and has a basis weight of less than 100 g / m<2> and has been mainly produced by a wet sheet making method. The inorganic fiber paper comprises inorganic fibers and an inorganic binder as materials, wherein the inorganic fibers have been bound to each other with the inorganic binder. In the inorganic fiber paper, the content of impurities during wet sheet making is low, the water resistance and flexibility are good, and satisfactory strength and high porosity can be realized. The inorganic fiber paper is produced from a material comprising 60 to 97% by mass of inorganic fibers having an average fiber diameter of not more than 5 [mu]m and 3 to 40% by mass of an inorganic binder composed mainly of a silica-based flaky inorganic material that has a hydroxyl group content per specific surface area of not less than 20 [mu]mol / m<2> as measured by a BET method, an average particle diameter of not more than 2 [mu]m as measured by a laser scattering method and an aspect ratio of not less than 10.

Owner:ENTEK ASIA INC

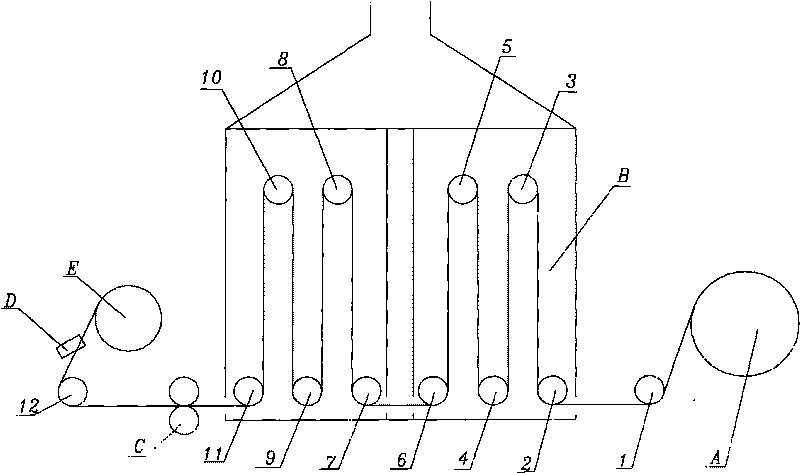

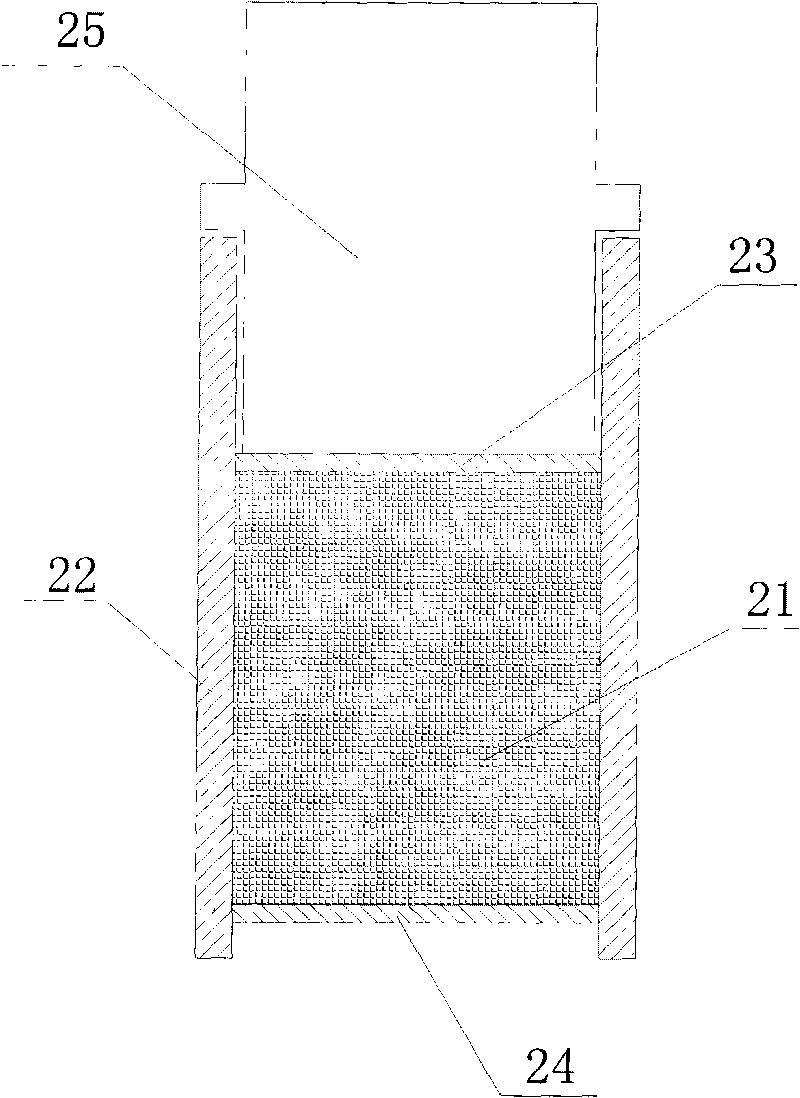

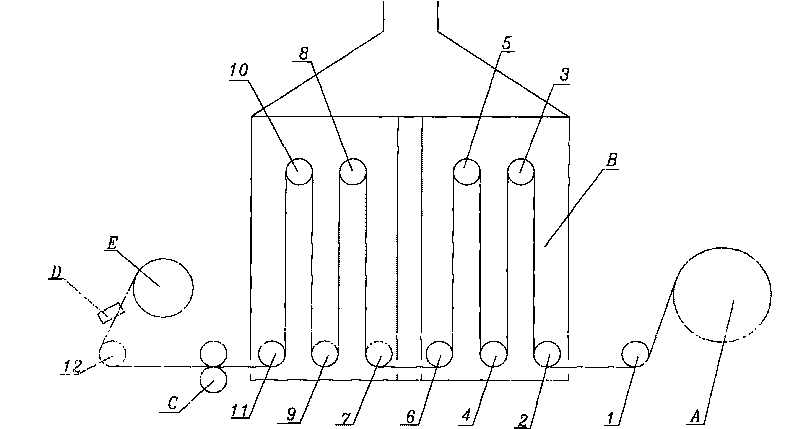

Manufacturing method of self-adhesive elastic bandage and self-adhesive elastic bandage

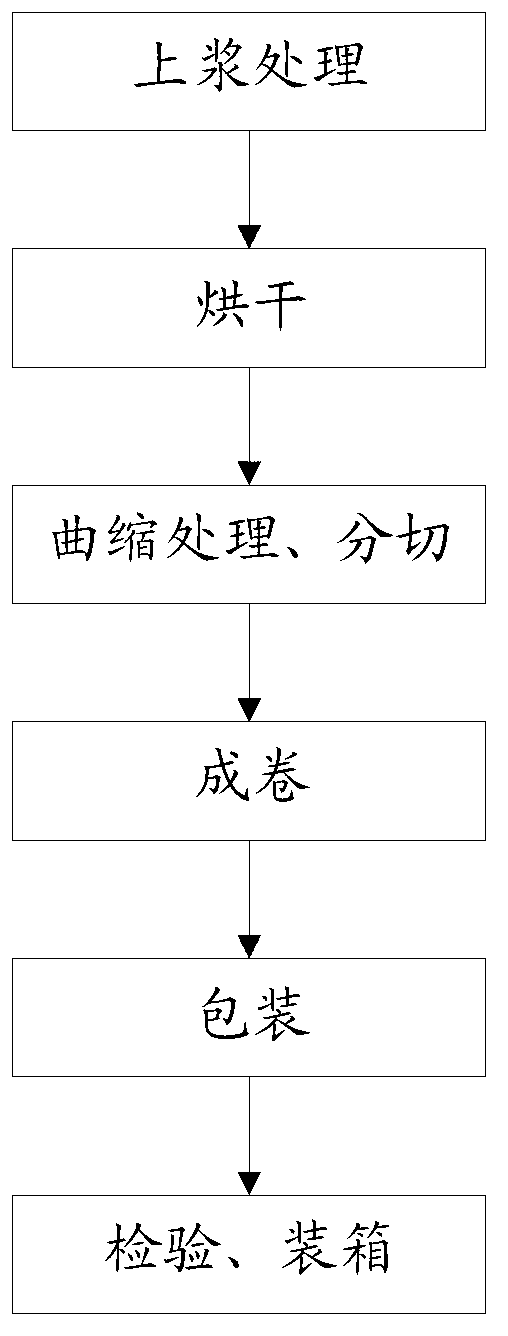

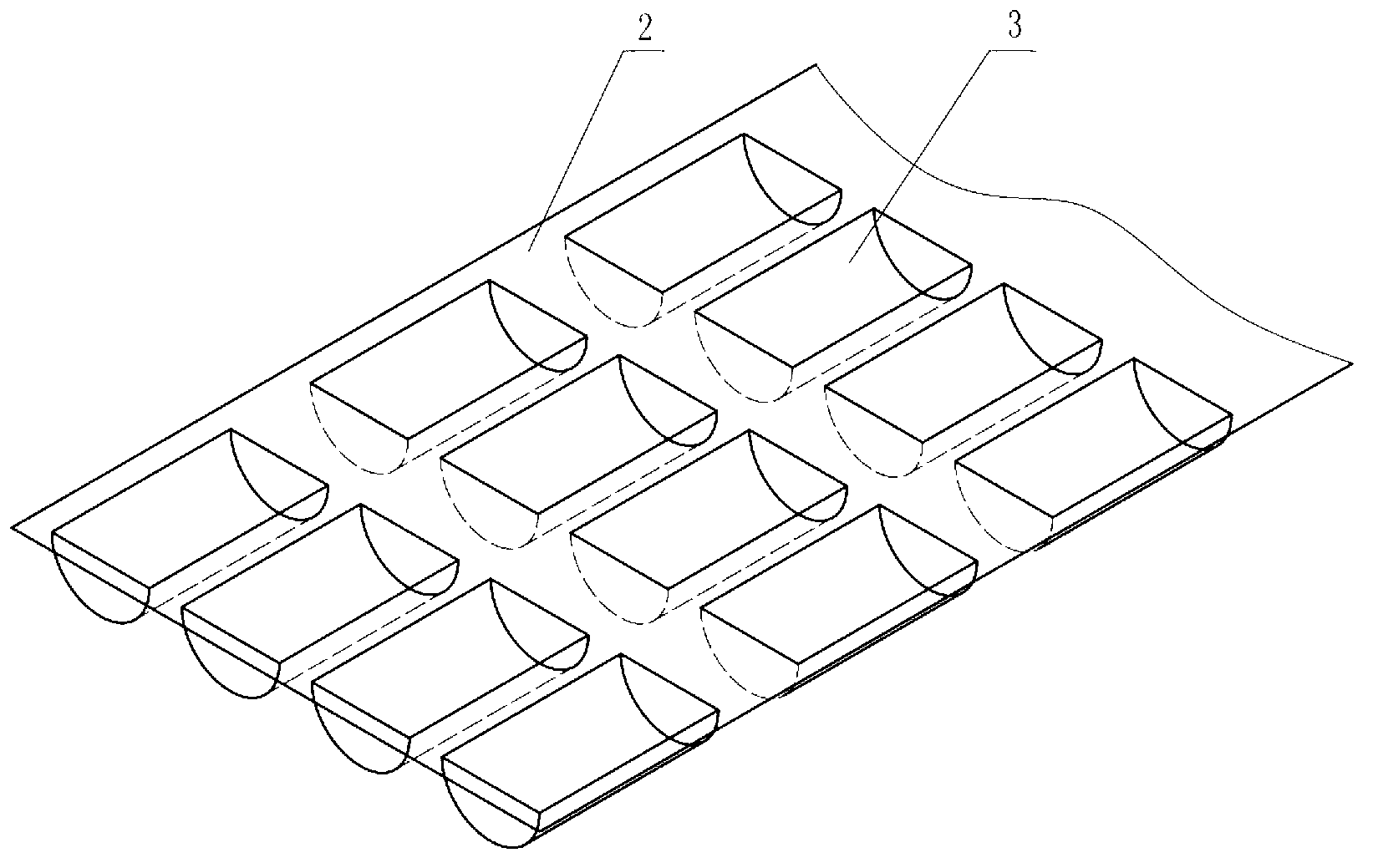

ActiveCN102793607AImprove flexibilityGood self-adhesionAbsorbent padsBandagesBiomedical engineeringSelf adhesive

The invention discloses a manufacturing method of a self-adhesive elastic bandage and the self-adhesive elastic bandage. The method comprises the following steps of: sizing, i.e., sizing a non-woven fabric base material, wherein the pulp for the sizing treatment comprises an adhesive agent, a penetrating agent and a solvent; drying, i.e., drying the sized non-woven fabric base material; and coiling, i.e., coiling the dried non-woven fabric base material to obtain the self-adhesive elastic bandage. Through sizing and coiling of the non-woven fabric base material, the elastic and self-adhesive non-woven fabric bandage is obtained; the production process and equipment structure are simple; and the material cost and the process cost are reduced.

Owner:AOMEI MEDICAL SUPPLIES CO LTD

Non-cured rubber asphalt paint and self-adhesion coiled material composite construction method

InactiveCN110409513AImprove flatnessTight bondOther rubber coatingsUnderground chambersComposite constructionBond properties

The invention relates to the field of waterproof engineering construction methods, in particular to a non-cured rubber asphalt paint and self-adhesion coiled material composite construction method. The non-cured rubber asphalt paint and self-adhesion coiled material composite construction method comprises the following steps of S1, waterproof paint treatment; S2, base layer treatment; S3, joint reinforcing treatment; S4, self-adhesion coiled material pre-trial paving; S5, first bonding layer construction; S6, self-adhesion coiled material paving and lap joint; and S7, close-up seal. The methodhas the beneficial effects that a composite waterproof layer made through the construction method has the good anti-aging property, and even if the composite waterproof layer is used for a long time,the composite waterproof layer can still keep good structural strength and bonding property.

Owner:东莞市卓宝建筑工程有限公司

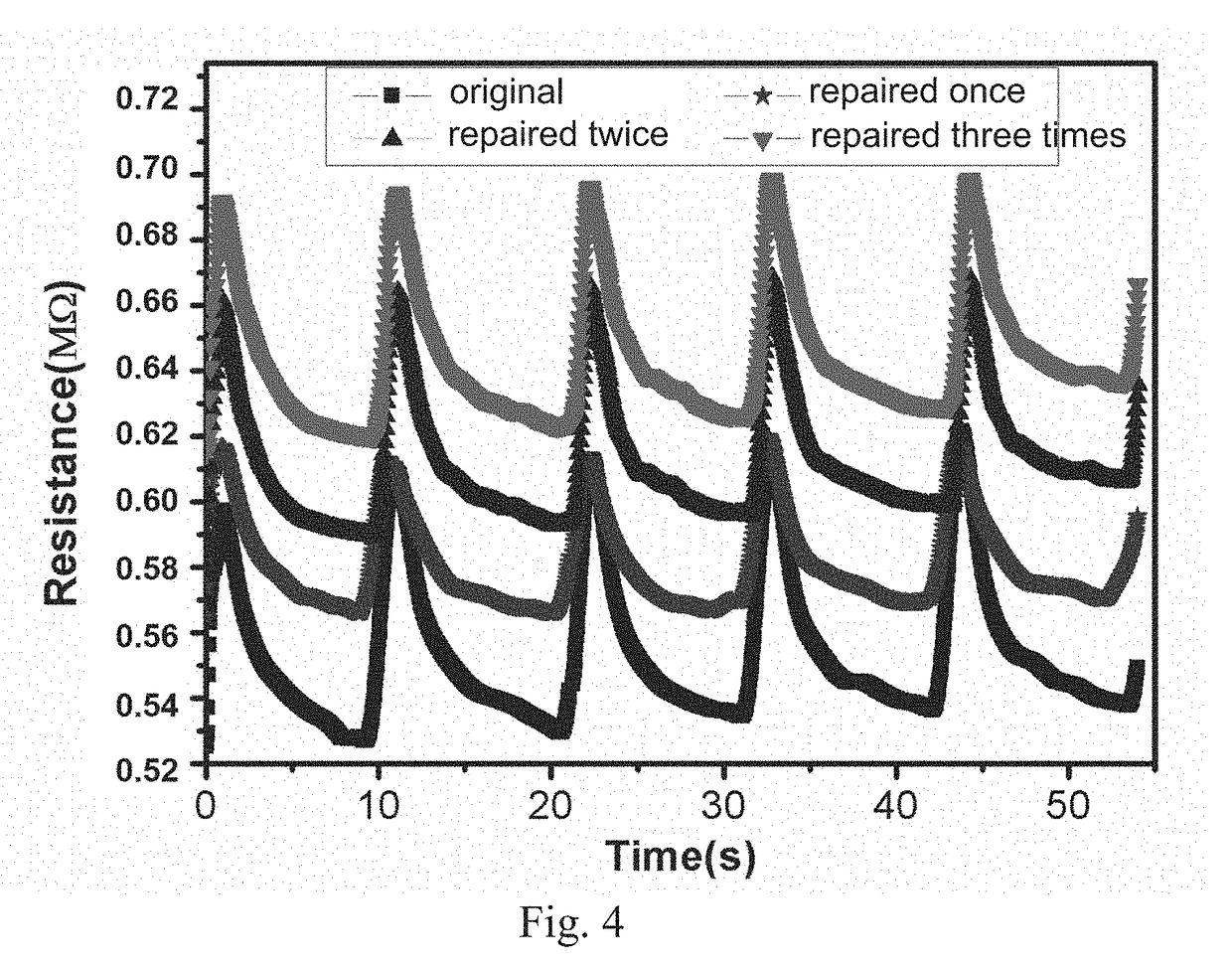

Three-layer self-healing flexible strain sensor and preparation method thereof

ActiveUS20180340848A1Good restorativeEasy maintenanceLayered productsForce measurementRoom temperatureEngineering

A three-layer self-healing flexible strain sensor includes: a self-healing sensitive layer, wherein a self-healing encapsulating layer is respectively placed on an upper surface and a lower surface of the self-healing sensitive layer. The self-healing sensitive layer comprises a doped carbon material or a conductive composite. The three self-healing layers of the self-healing strain sensor can quickly repair the internal and external damage caused by the layered structure in a short period of time after the external damage, and does not require external stimulation. The three-layer self-healing structure strain sensor is simple in preparation without using a repair agent, which can achieve rapid self-repair at the room temperature, and can be repeatedly repair. The three-layer self-healing structure increases the strength and modulus of the strain sensor as well as increases the ability of the strain sensor to resist external damage.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Making method of non-inflammable self-adhesion insulation tape

ActiveCN101705059AImprove performanceNon-flammableFilm/foil adhesivesElectrical resistance and conductanceAdhesive belt

The invention relates to a making method of a non-inflammable self-adhesion insulation tape. The making method comprises the following steps: by making colored polytetrafluoroethylene dispersion resin, sieving the colored polytetrafluoroethylene dispersion resin after cold storage, then mixing with propellant as paste shape and finally making the insulation tape through the steps of curing, preforming, thrusting, rolling, removing the propellant and the like. The made non-inflammable self-adhesion insulation tape is excellent in comprehensive performance with limited oxygen index up to over 95 and has non-flammable property, volume resistance no less than 1 multiplied by 1, 017 ohm / cm, good insulating performance, good self-adhesion without use of pressure sensitive adhesive, reliable adhesion between tape layers and at a port, water absorption rate less than 0.01 percent and good moisture resistance. The insulation tape can be used within the temperature range of -65-250 DEGC for long time with the dielectric strength not less than 40kV / mm, can resist strong acid, alkali and oxidant, is an ideal insulating material and promotes the replacement of insulating materials of traditional electrician equipment with new generations.

Owner:四会市生料带厂有限公司

Non-slip floor

ActiveCN103410296ARemove security concernsEasy to installSynthetic resin layered productsFloor coveringsSlip coefficientPressure sense

The invention discloses a non-slip floor. The non-slip floor comprises a body, a pasting layer is arranged on the bottom surface of the body in a combined and stacked mode, a plurality of protruding ribs are arranged on the bottom surface, in contact with the ground, of the pasting layer in a convex mode, a plurality of closed cavity type suckers are formed by the protruding ribs in an enclosing mode, and the pasting layer is made of pressure-sensing thermosensitive gel. According to the material formula, the pasting layer comprises, by weight, 35-55% of tackifying resin, 10-20% of softener, 2-5% of antioxidant, 10-20% of butyl rubber and 5-10% of naphthenic oil, and the sum of the total amounts of all the above substances is 100%. Thus, the non-slip floor can be used repeatedly, easy to install and convenient to detach by the utilization of the characteristic of being capable of being used repeatedly of the pressure-sensing thermosensitive gel; the non-slip floor can be pasted to the ground through the pasting layer, therefore, the non-slip performance of the non-slip floor is greatly promoted, the non-slip floor has very good self-pasting and absorption effects, the non-slip coefficient of the bottom can reach 1.7-2.0, and safety concerns about the old and children can be relieved in terms of home mat formation.

Owner:DONGGUAN MEI JER PLASTIC PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com