Thermoplastic polyurethane/graphene foam material and preparation method and application thereof

A thermoplastic polyurethane, foaming material technology, applied in chemical instruments and methods, lamination, coating and other directions, can solve the problems of electromagnetic wave reflection enhancement, secondary pollution of the environment, etc., to improve absorption loss, good flexibility and self-adhesion , the effect of high market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

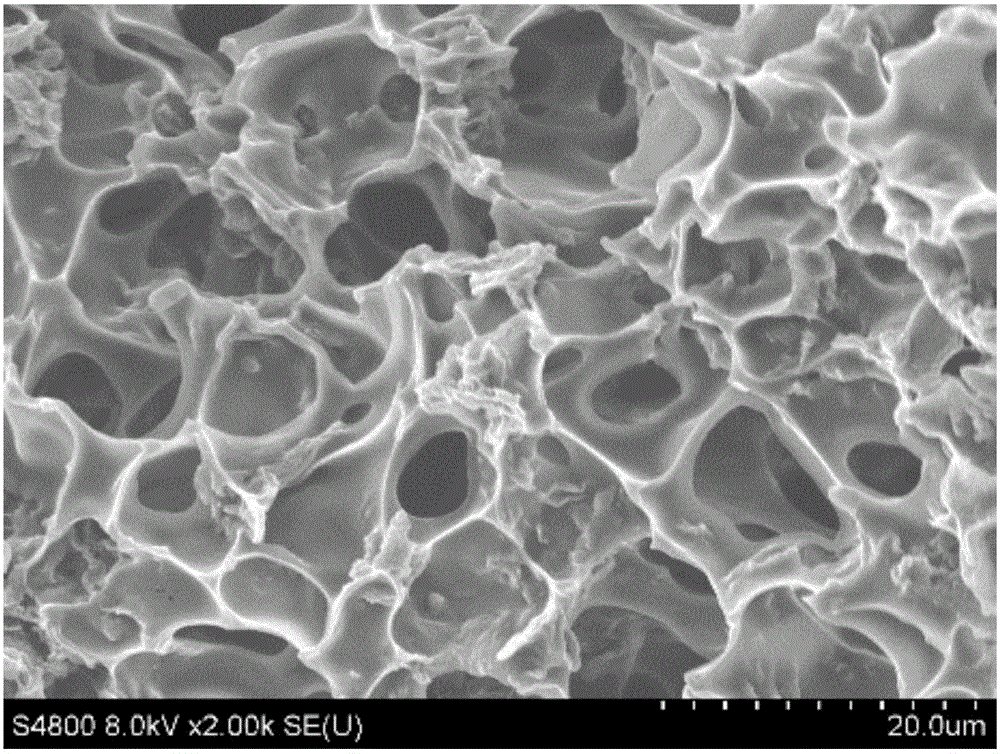

[0036] (1) Add 0.83 g of graphene into 300 mL of DMF and ultrasonically disperse for 10 minutes to obtain a black suspension. 20 g of thermoplastic polyurethane elastomer particles were added to the suspension, stirred and dissolved at a high speed in an oil bath at 60° C. for 5 hours, and then the obtained mixed solution was poured into distilled water for precipitation. Finally, place the precipitated thermoplastic polyurethane / graphene mixture in a vacuum oven at 60°C for 48 hours, take it out and pulverize it for later use;

[0037] (2) Re-dissolve the thermoplastic polyurethane / graphene mixture in step (1) in 100mL of DMF to obtain a mixed casting solution, pour it into the scraper groove of the scraper and coat the film on a clean glass plate, scraper The thickness is set to 4mm. After completion, place it in the air with a relative humidity of 80% at normal temperature for 3 hours, then take it out and dry it in a vacuum oven at 30°C for 24 hours to obtain a thermoplas...

Embodiment 2

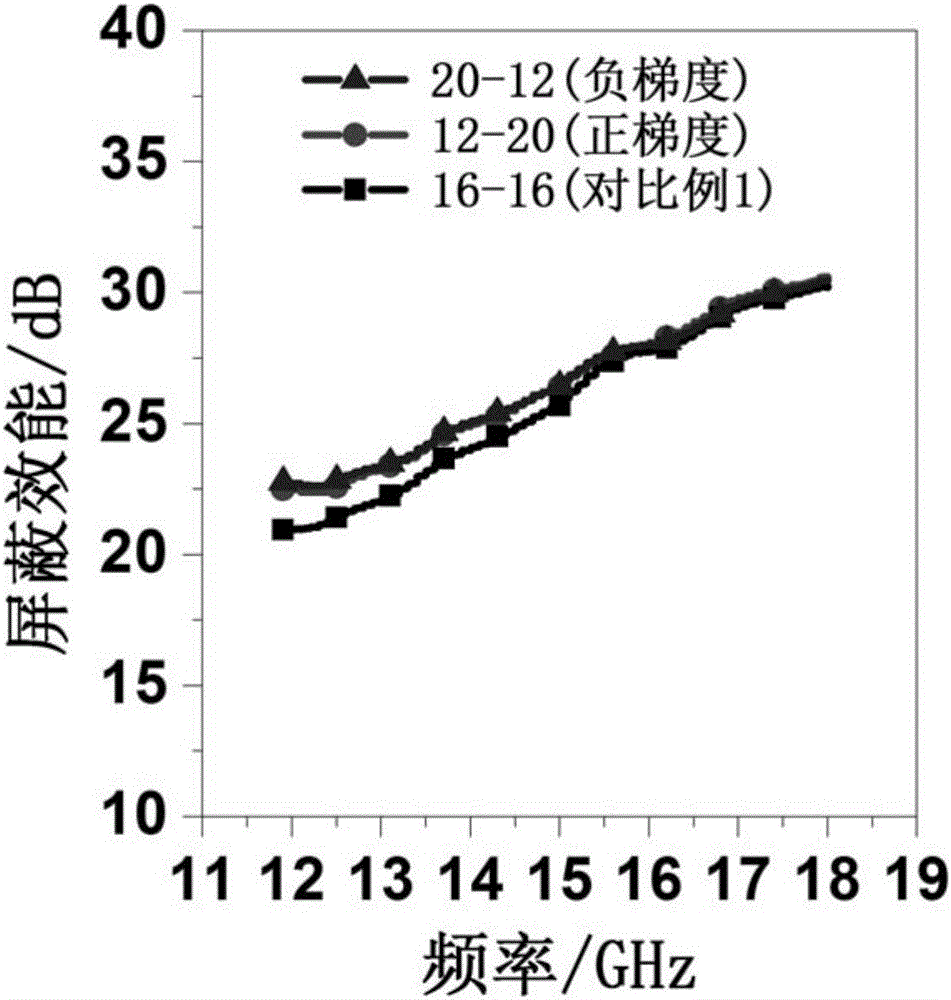

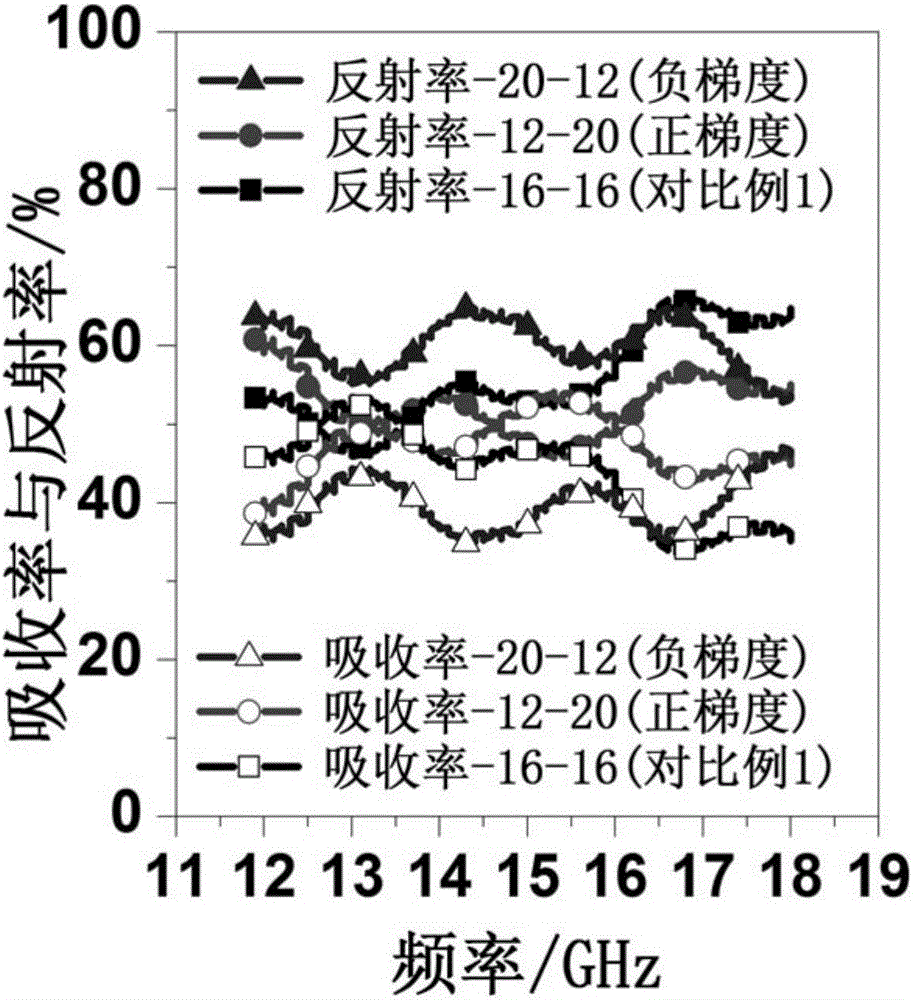

[0048] The materials used in this embodiment are PUG8 and PUG16 prepared in Example 1, they are bonded with PU glue in the order of graphene content from small to large to form a double-layer thermoplastic polyurethane / graphite with graphene concentration gradient vinyl foam.

Embodiment 3

[0053] The materials used in this example are PUG4 and PUG12 prepared in Example 1. They are bonded with PU glue in the order of graphene content from small to large to form a double-layer thermoplastic polyurethane / graphite with a graphene concentration gradient. vinyl foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com