Patents

Literature

42results about How to "Increase absorption loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

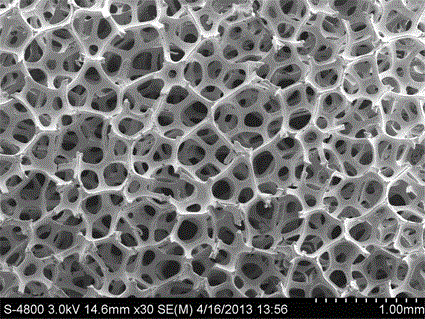

Foam metal-graphene composite material and preparation method thereof

ActiveCN103436939ALarge specific surface areaImprove conductivityElectrophoretic coatingsDielectricElectrophoreses

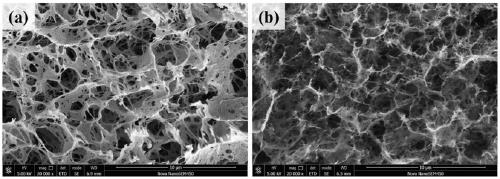

The invention discloses a foam metal-graphene composite material and a preparation method thereof. The composite material comprises a foam metal substrate and a graphene film layer positioned on the substrate. The foam metal-graphene composite material is prepared by means of electrophoresis. Specifically, the preparation method comprises the following steps: removing greasy dirt and oxides from the surface of a foam metal substrate, preparing graphene by the oxidation-reduction method, modifying graphene, and performing electrophoretic deposition on the graphene on the surface of the foam metal substrate. Within a certain of electromagnetic waveband, on one hand, the foam metal-graphene composite material has the structural advantages of light weight and porosity, large specific surface area and good conductivity of a foam metal, and on the other hand, the composite material integrates excellent electrical conductivity and high dielectric constant, a capacity of being more conducive to absorbing electromagnetic waves due to a large amount of defects and functional group residues of the self-made graphene, and other properties of self-made graphene. The composite material has a higher electromagnetic shielding performance and can serve as an excellent electromagnetic shielding material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

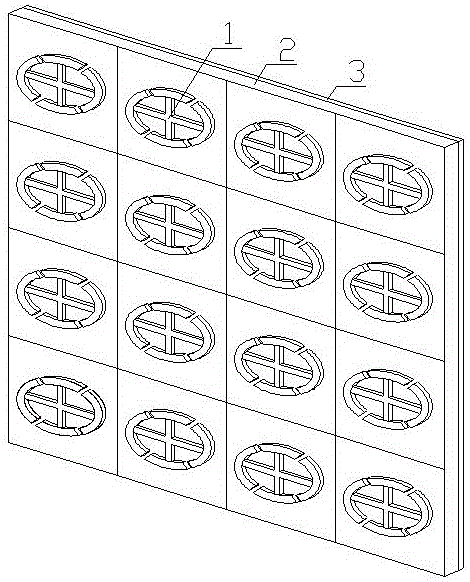

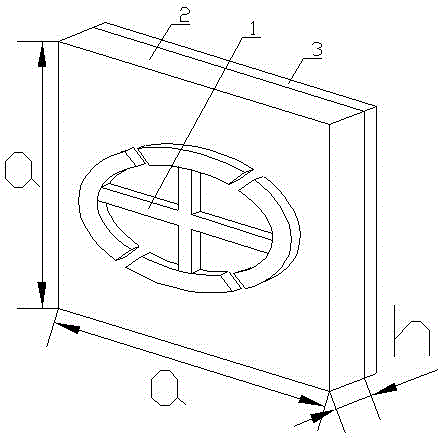

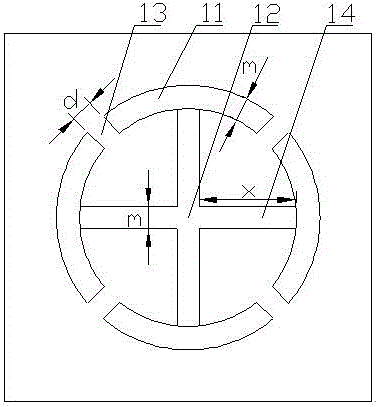

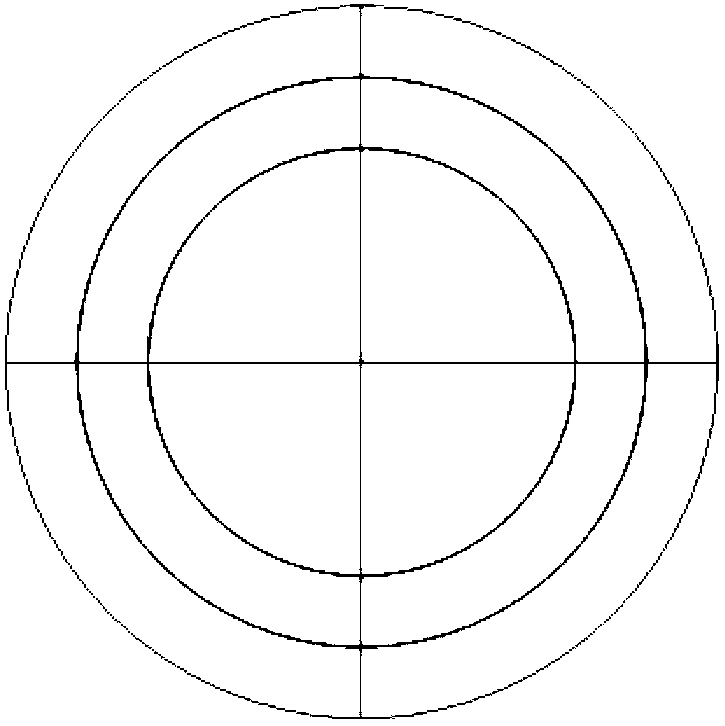

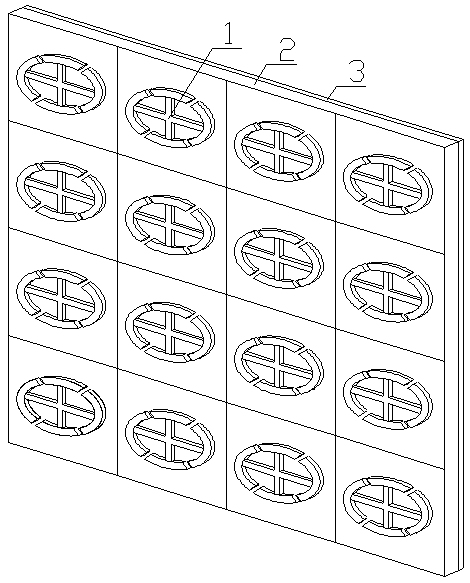

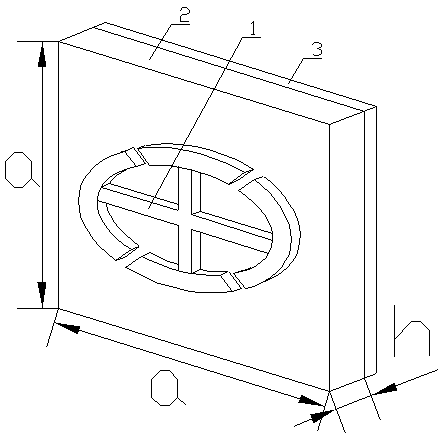

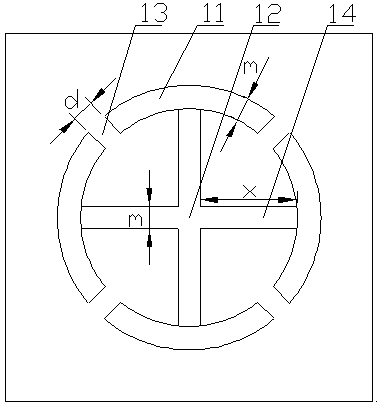

Broadband THz metamaterial absorber based on multi-resonant absorption superposition

ActiveCN105896098AObvious absorption peak characteristicsImprove application efficiencyAntennasTerahertz metamaterialsLine width

The invention discloses a broadband THz metamaterial absorber based on multi-resonant absorption superposition, belongs to a THz absorber in the field of metamaterials and electromagnetic functional technology, and aimed at that the broadband THz metamaterial absorber includes an upper patterned functional material layer, an intermediate medium layer and a lower metal reflective layer; the upper patterned functional material layer is formed by arranging metamaterial unit structures, each metamaterial unit structure includes a circular ring structure in which four parallel openings and a cross arm are disposed, and four connecting arms of each cross arm are connected with four ARC segments of each circular ring structure; the lattice period of a metamaterial unit structure array is a 10um to 100um, each metamaterial unit structure has a line width of 0.5um to 10um, the arm length x of each connecting arm is 3um to 50um, and the width d of each parallel opening is 0.5um to 50um. The invention does not require complicated procedures, a difficult process and high production cost to achieve the purpose of terahertz absorption band spread.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

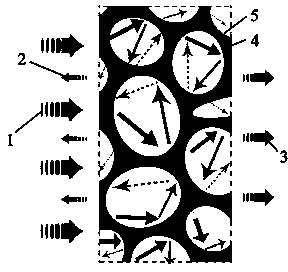

Electromagnetic shielding macromolecule composite material

InactiveCN101050284AGood chemical stabilityIncrease absorption lossEngine sealsMagnetic/electric field screeningElectromagnetic shieldingPore diameter

This invention discloses electromagnetic shielding polymer composite sheets or rolls. The polymer composite is composed of foam metal with pore diameters of 60-6000 mu.m, porosity above 75% and density of 0.03-1.2 g / cm3, and polymer material such as thermoplastic resin, thermosetting resin or rubber. The polymer composite has such advantages as high electromagnetic shielding performance and low cost, and can be used in aviation, aerospace, security communication, electronics, electrics and electrical devices.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

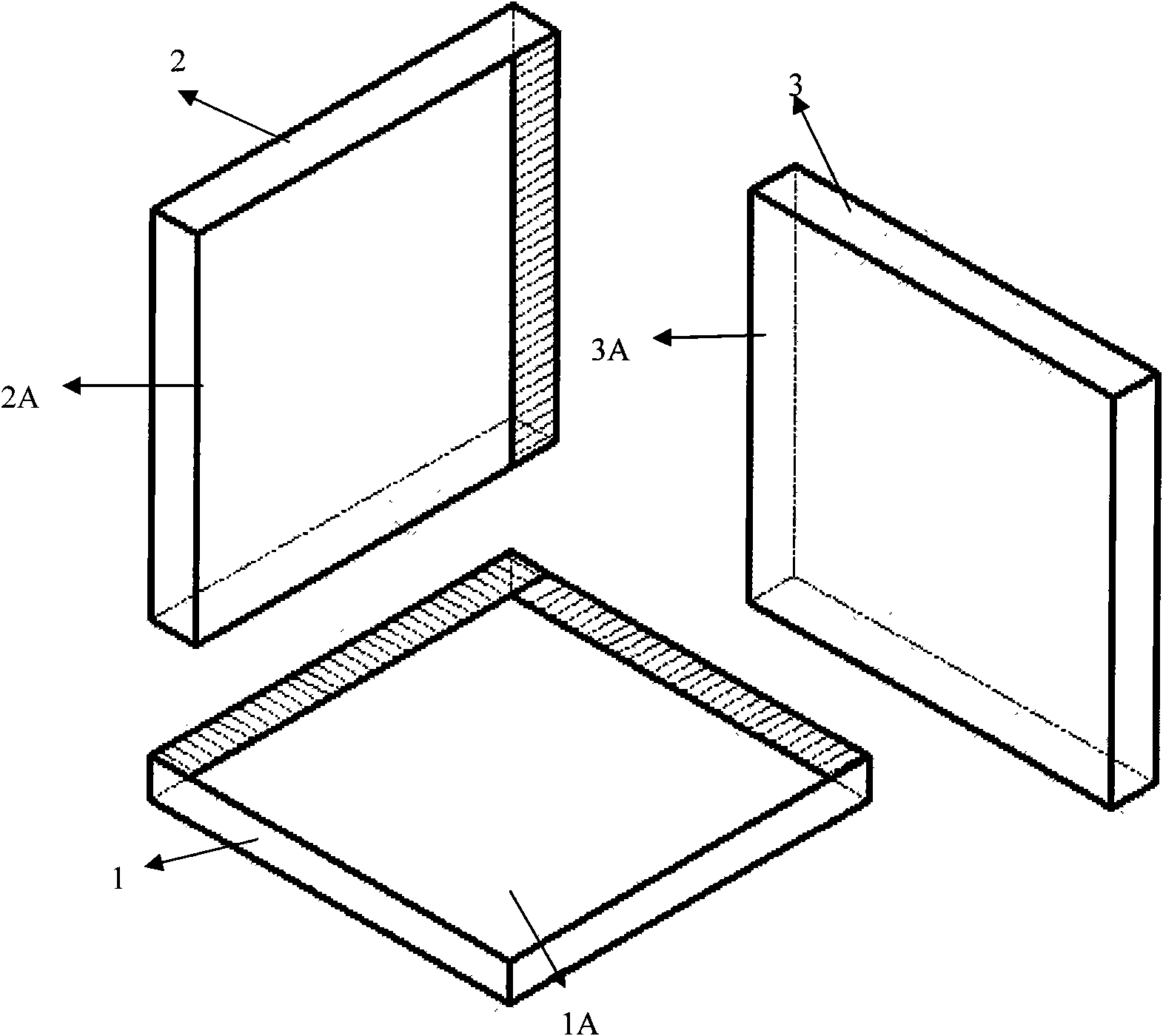

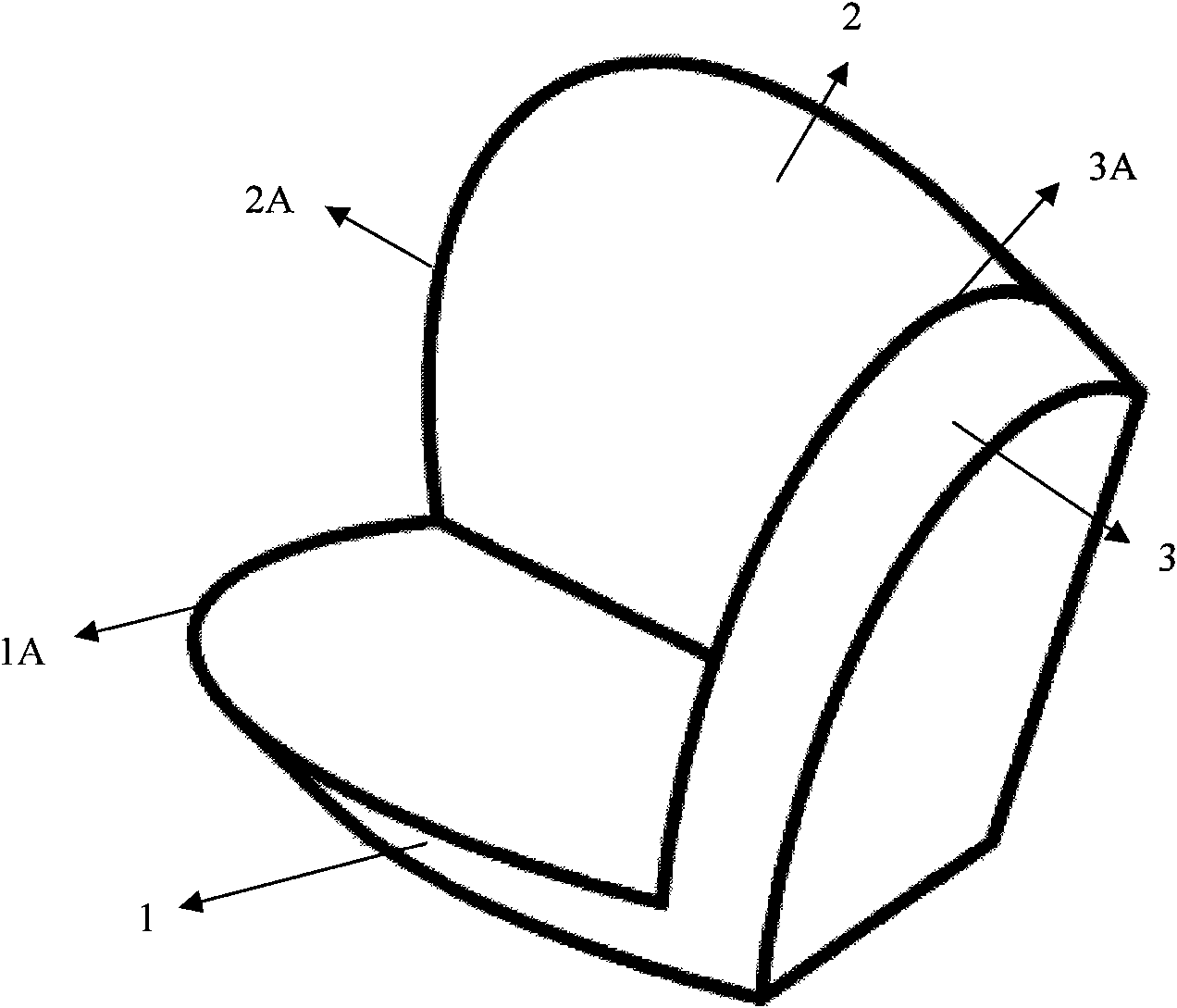

High precision hollow prism reflector

The invention discloses a high precision hollow prism reflector, comprising glass plates and a prism support seat. The high precision hollow prism reflector is characterized in that the three glass plates are in adhesive connection with one another by adhesive bonding so as to form the hollow prism reflector; and after adhesive connection, the glass plates form the shape of a hollow cone, a first glass plate and a second glass plate are in adhesive connection by photosensitive adhesive, a third glass plate is in adhesive connection with the first and the second glass plates by the photosensitive adhesive, an UV Lamp is used for irradiating and solidifying the photosensitive adhesive, corresponding standard faces on the three glass plates are the inner faces of the three glass plates, and the prism support seat is in adhesive connection with the rear face of the standard face of the third glass plate by an epoxy resin adhesive. The invention has the advantages of simple structure and convenient use, the device has light weight and high precision, and the reflectivity of the hollow prism reflector on which film is coated can nearly be higher than 99 percent. The high precision hollow prism reflector is suitable for full-wave band measurement.

Owner:INST OF EARTHQUAKE CHINA EARTHQUAKE ADMINISTRATION +1

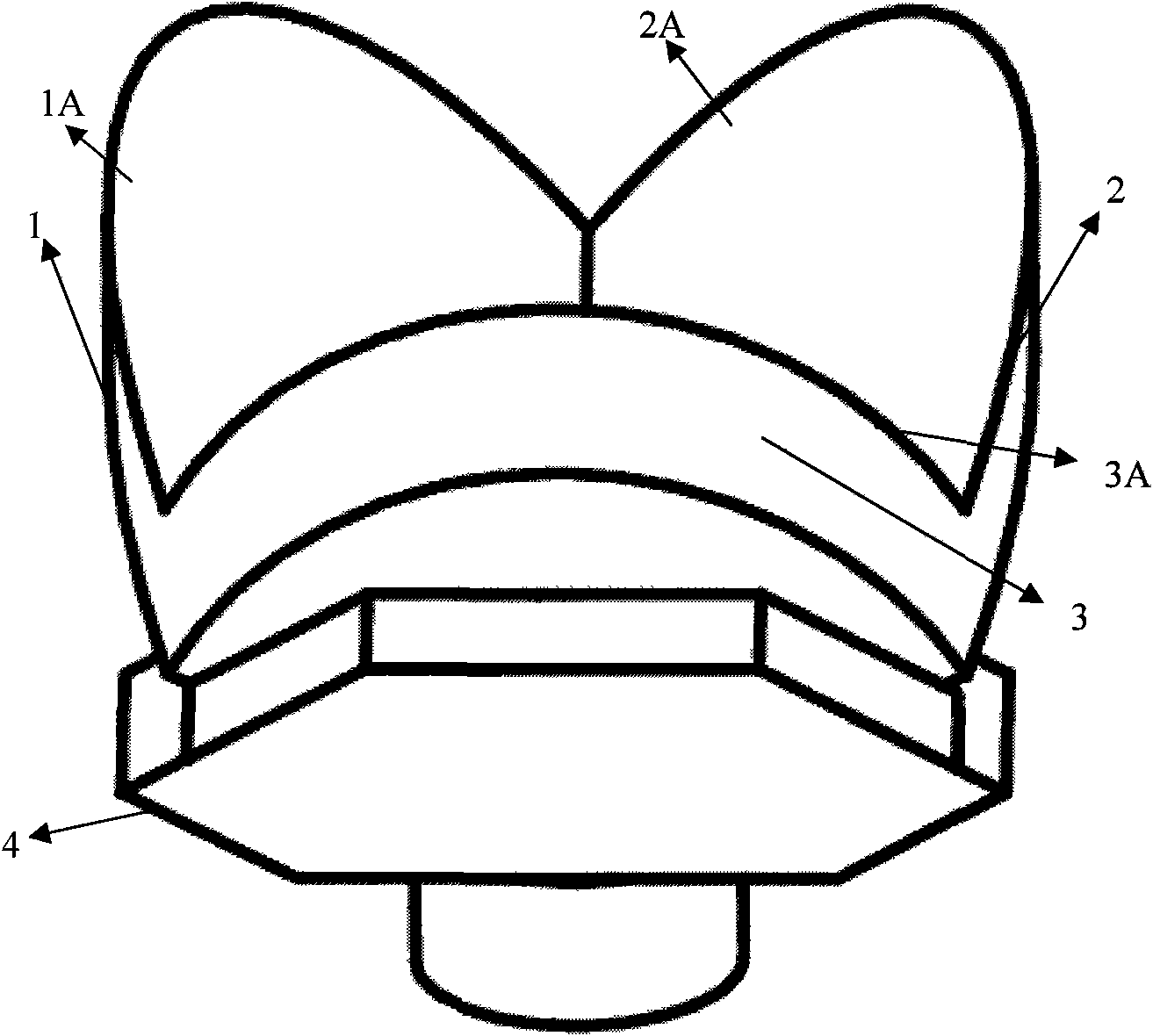

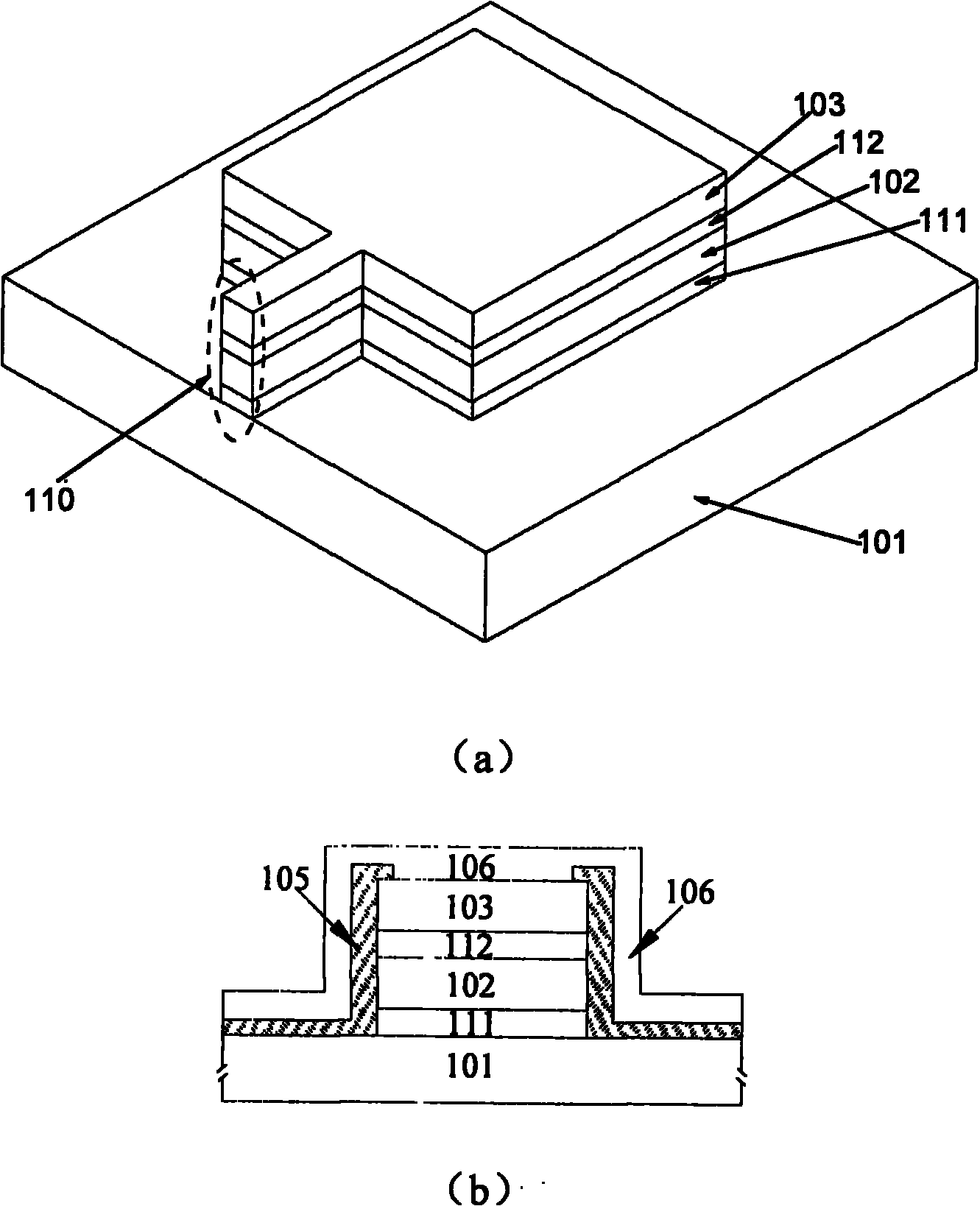

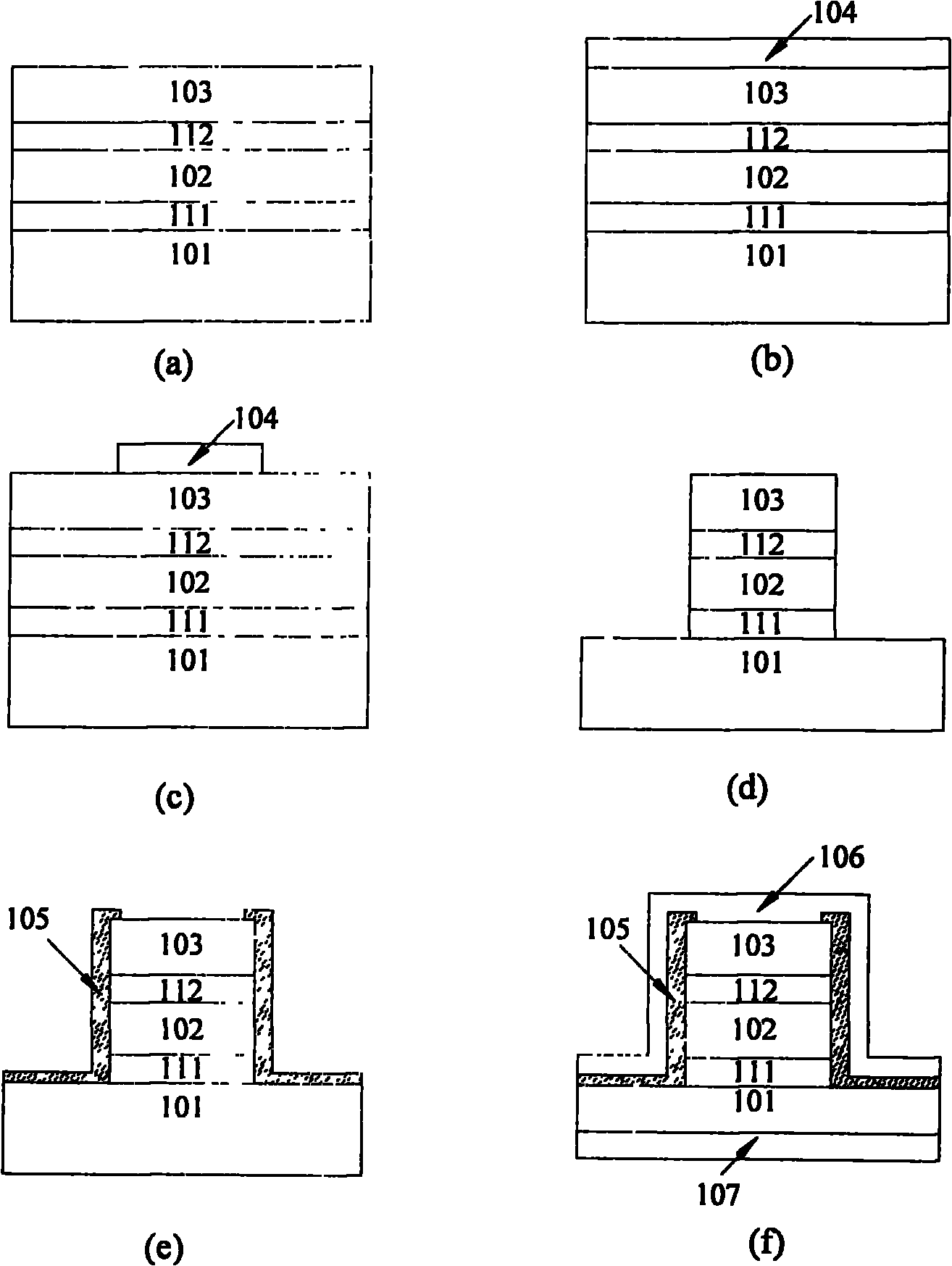

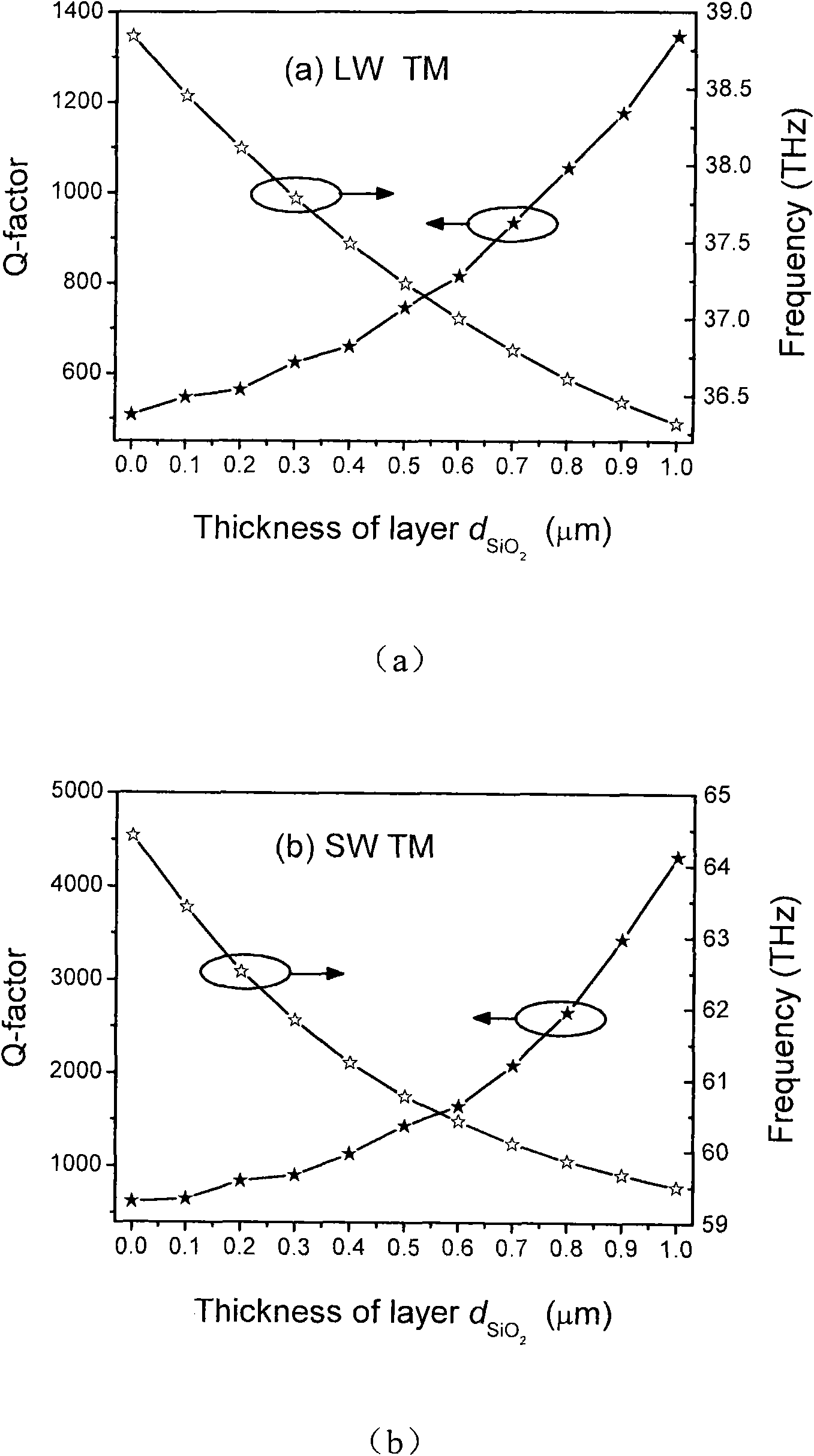

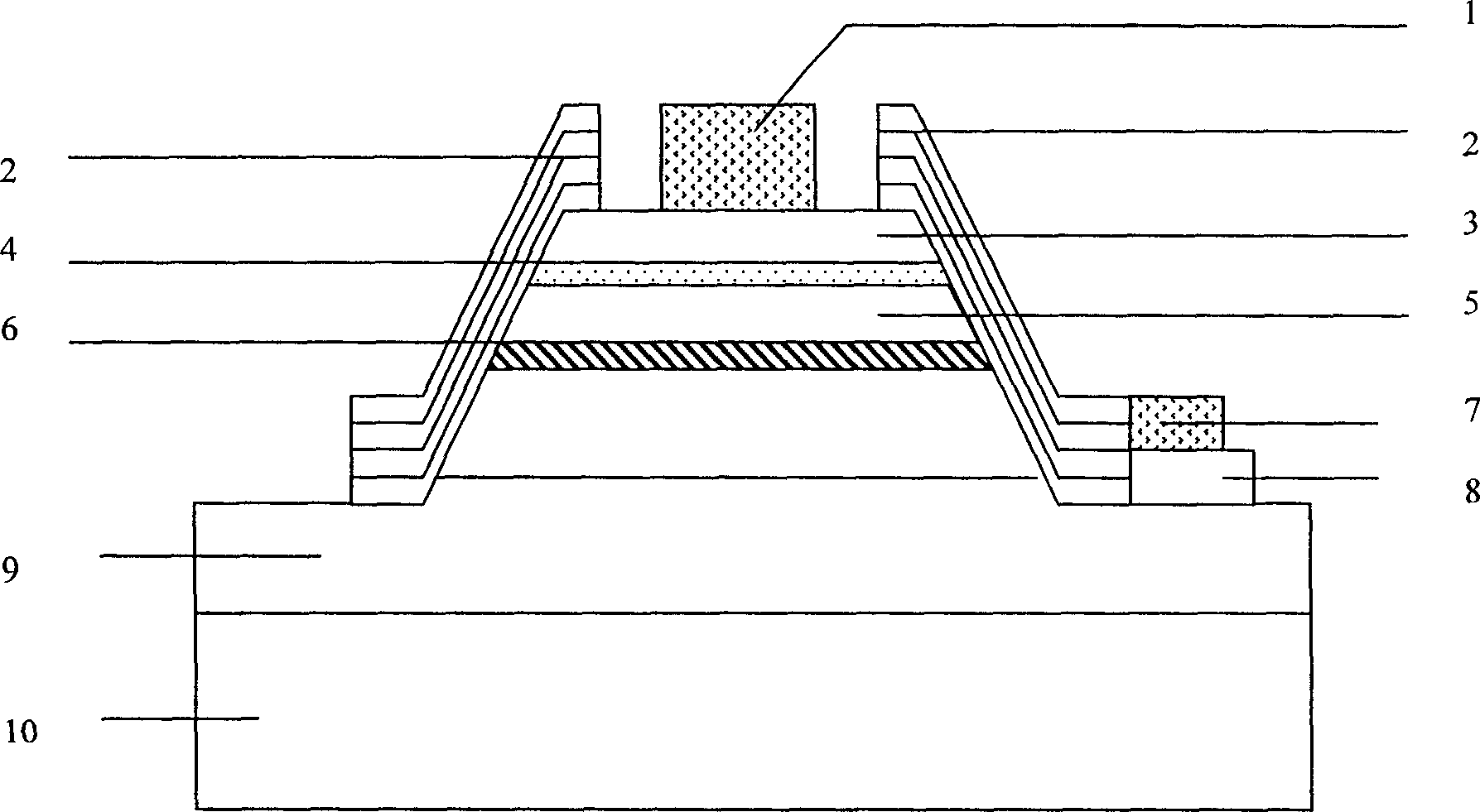

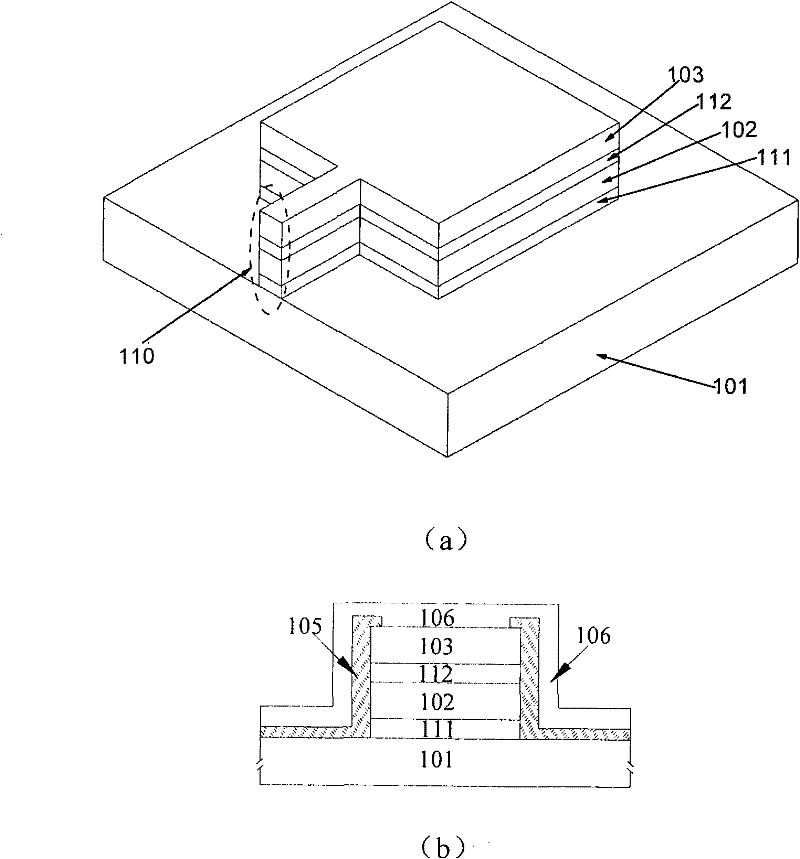

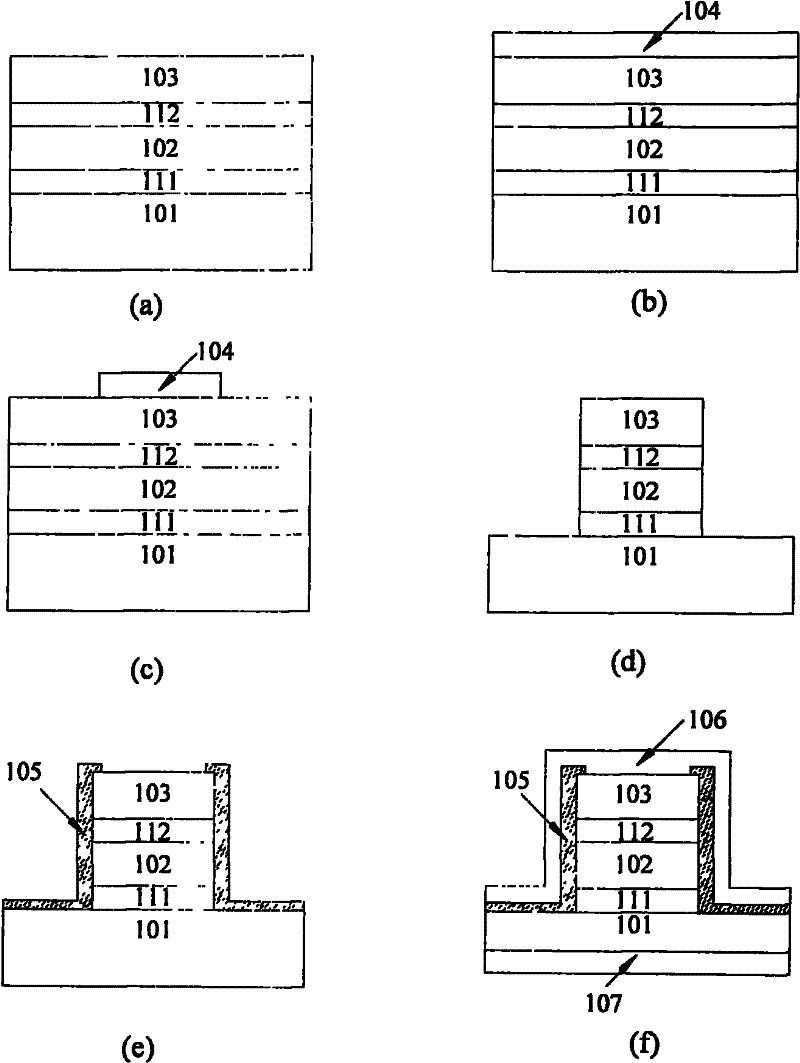

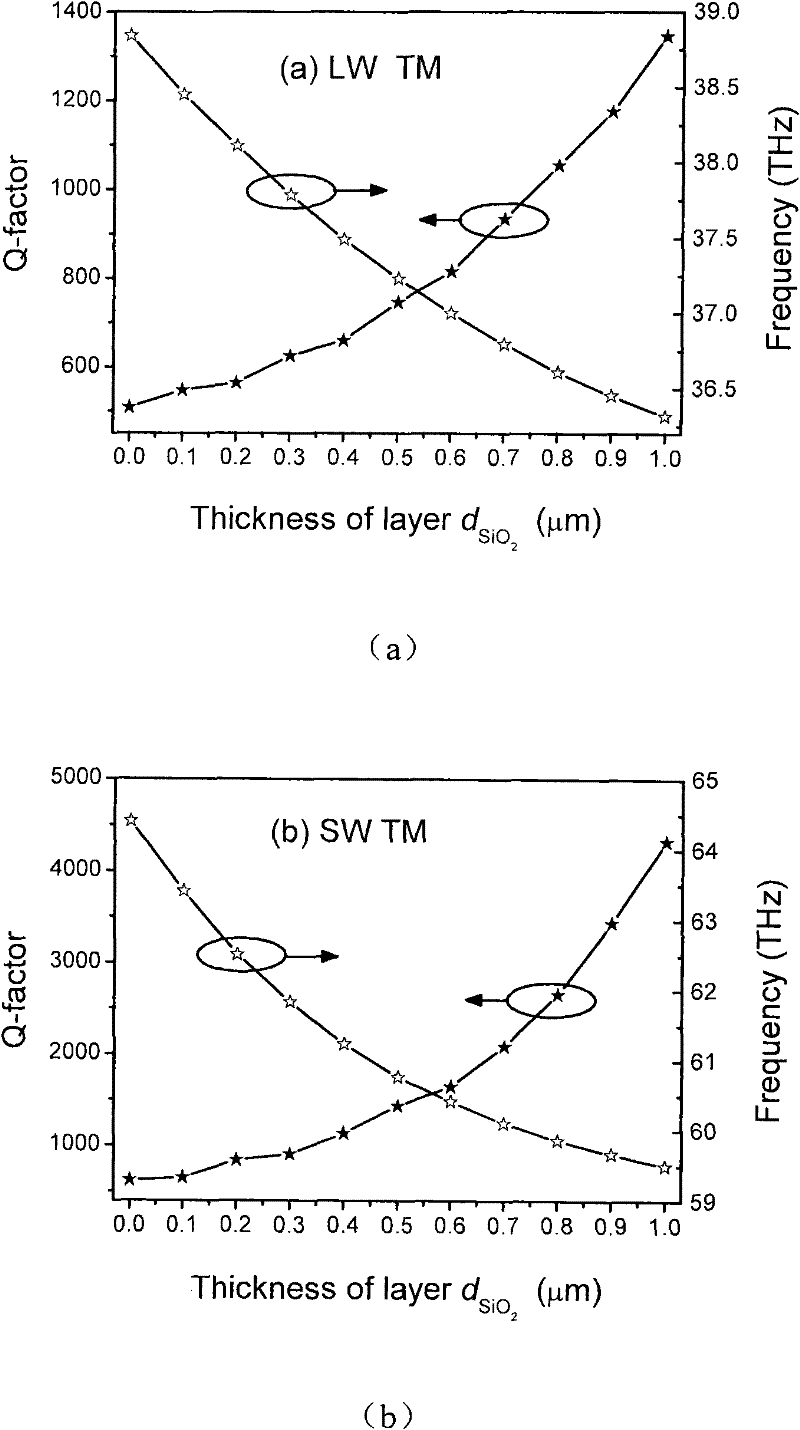

Quantum cascade laser regular polygonal microcavity laser and manufacturing method thereof

InactiveCN101867147ASimple structureSimple preparation processLaser detailsLaser optical resonator constructionLower limitOhmic contact

The invention discloses a quantum cascade laser regular polygonal microcavity laser, comprising a substrate of a quantum cascade epitaxial layer, a lower limiting layer positioned on the substrate, an active area / an injecting area positioned on the lower limiting layer; an upper limiting layer arranged on the active area / an injecting area, and an upper wrapping layer containing an ohmic contact layer, wherein the side walls of the lower limiting layer, the active area / the injecting area, the upper limiting layer and the upper wrapping layer are wrapped by an insulating layer which is wrapped by a front electrode layer. The invention discloses a manufacturing method of the quantum cascade laser regular polygonal microcavity laser simultaneously. The invention uses a SiO2 insulating layer and a Ti / Ag / Au electrode layer to wrap the etched side wall of the quantum cascade laser regular polygonal microcavity laser, thus enhancing the limitation for the light field in a microcavity, and improving the quality factor of the mode in the microcavity; and the laser has simple structure and convenient manufacturing technique.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

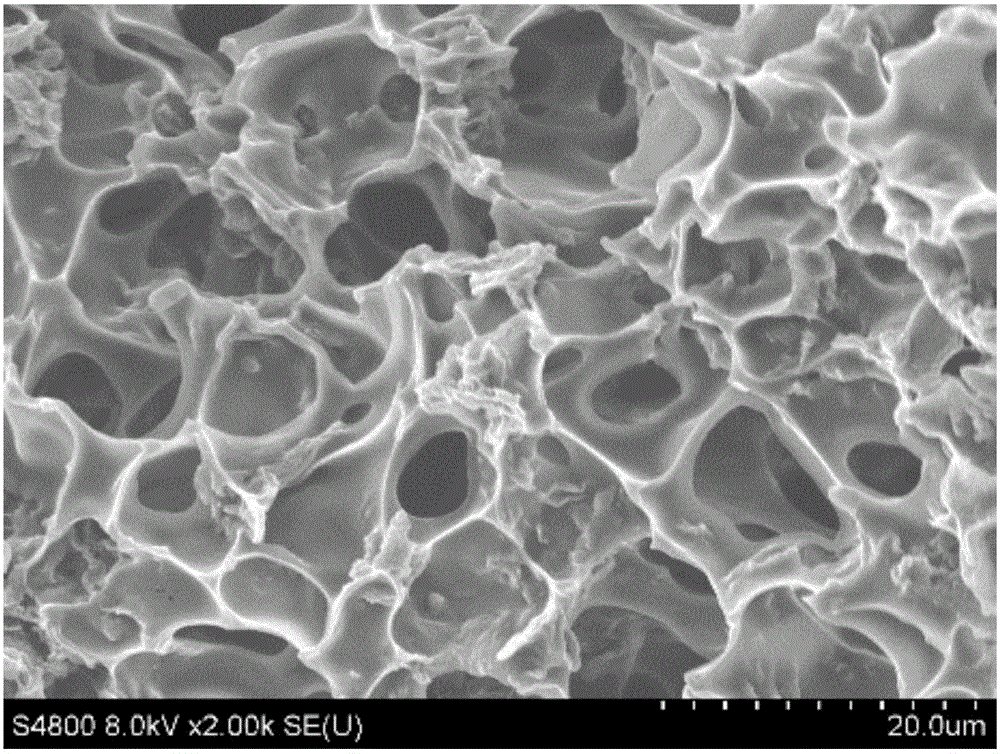

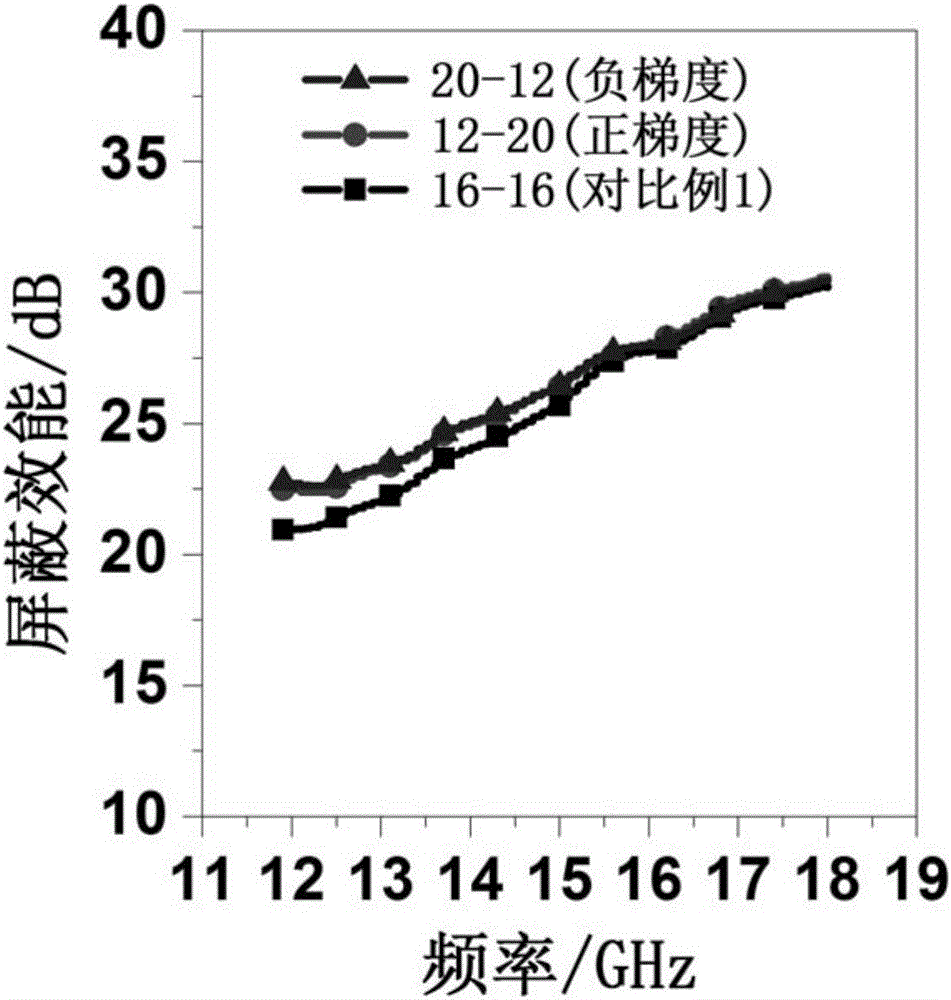

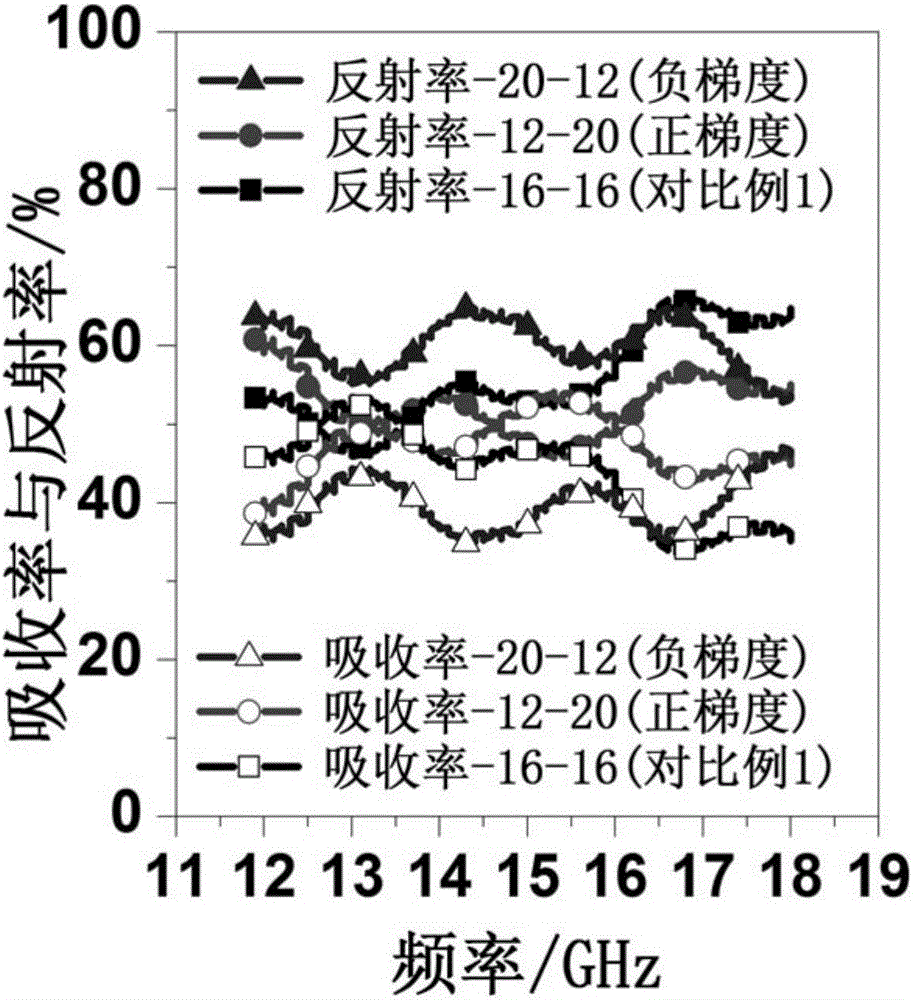

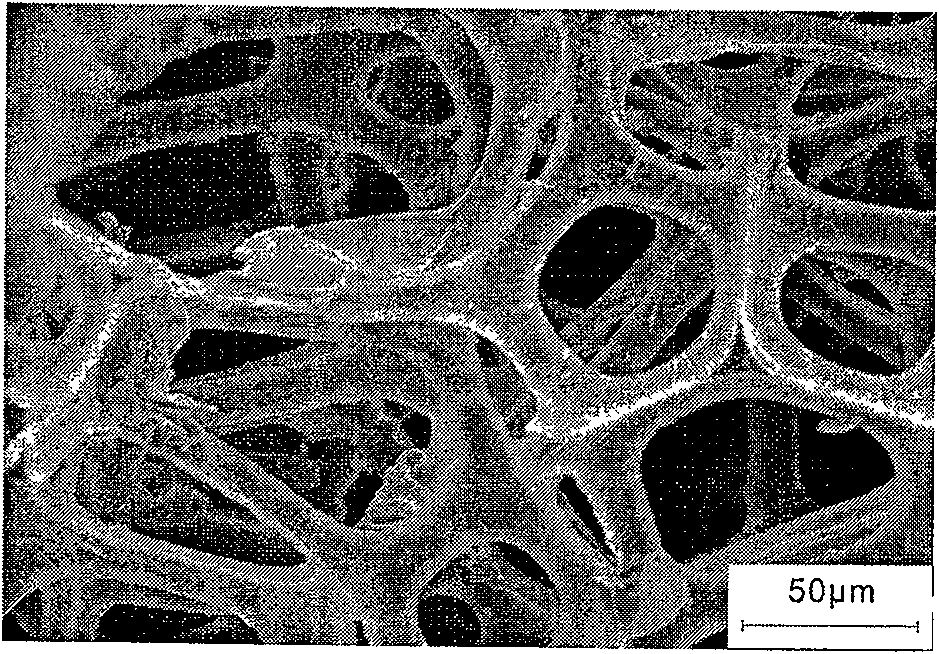

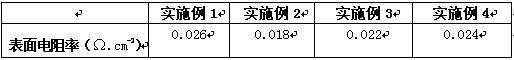

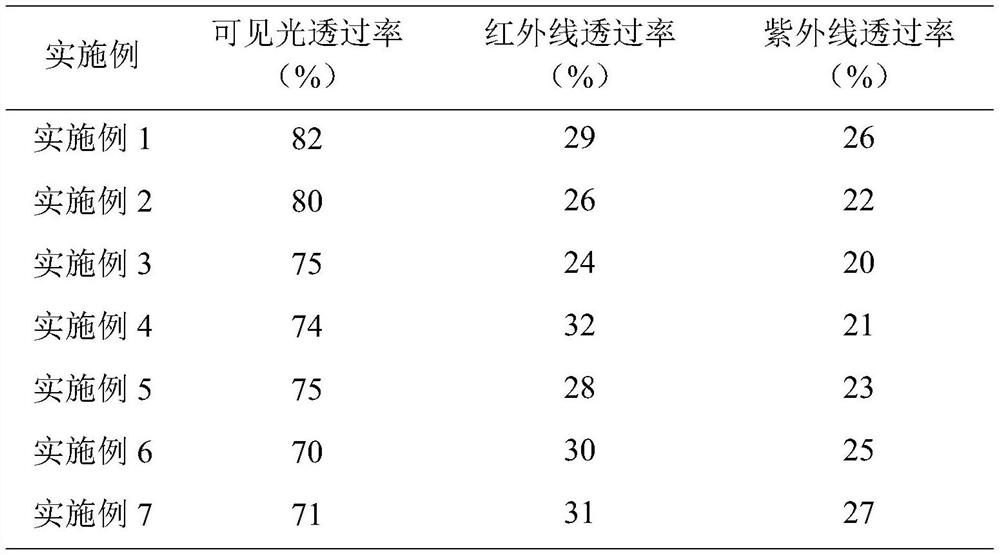

Thermoplastic polyurethane/graphene foam material and preparation method and application thereof

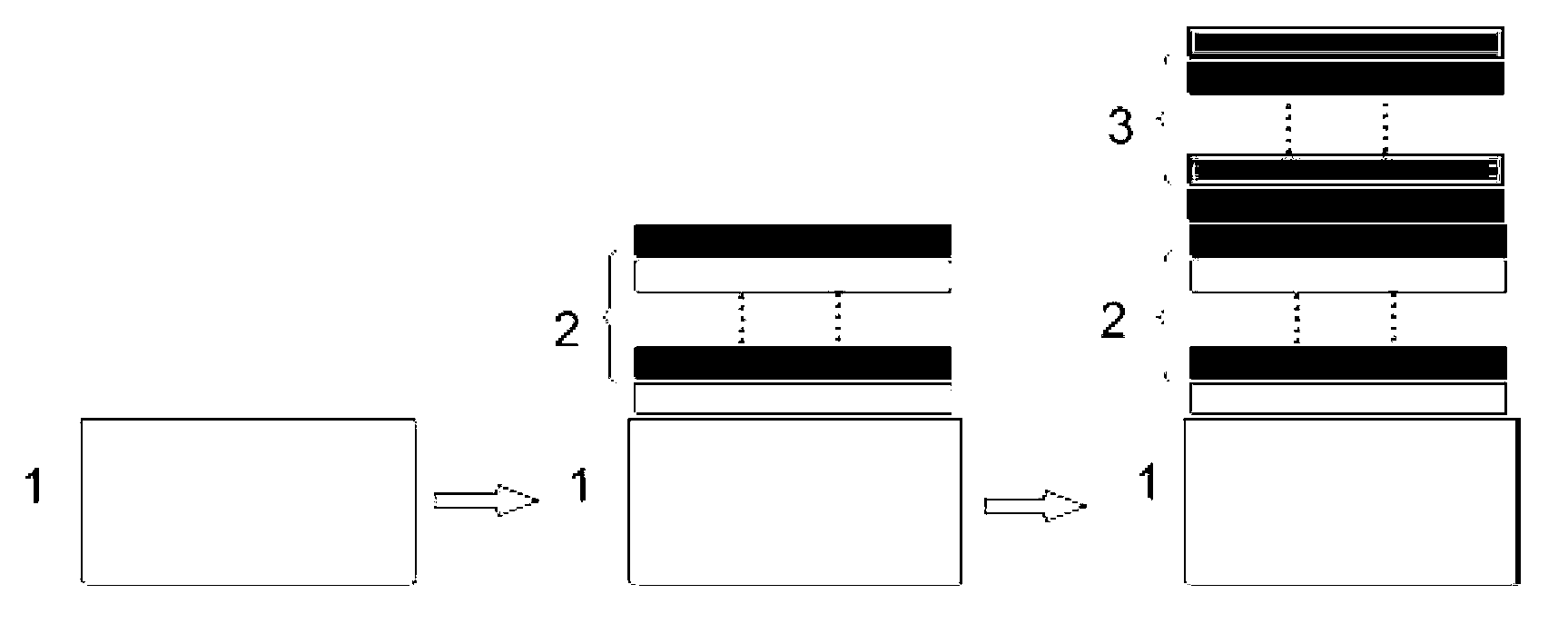

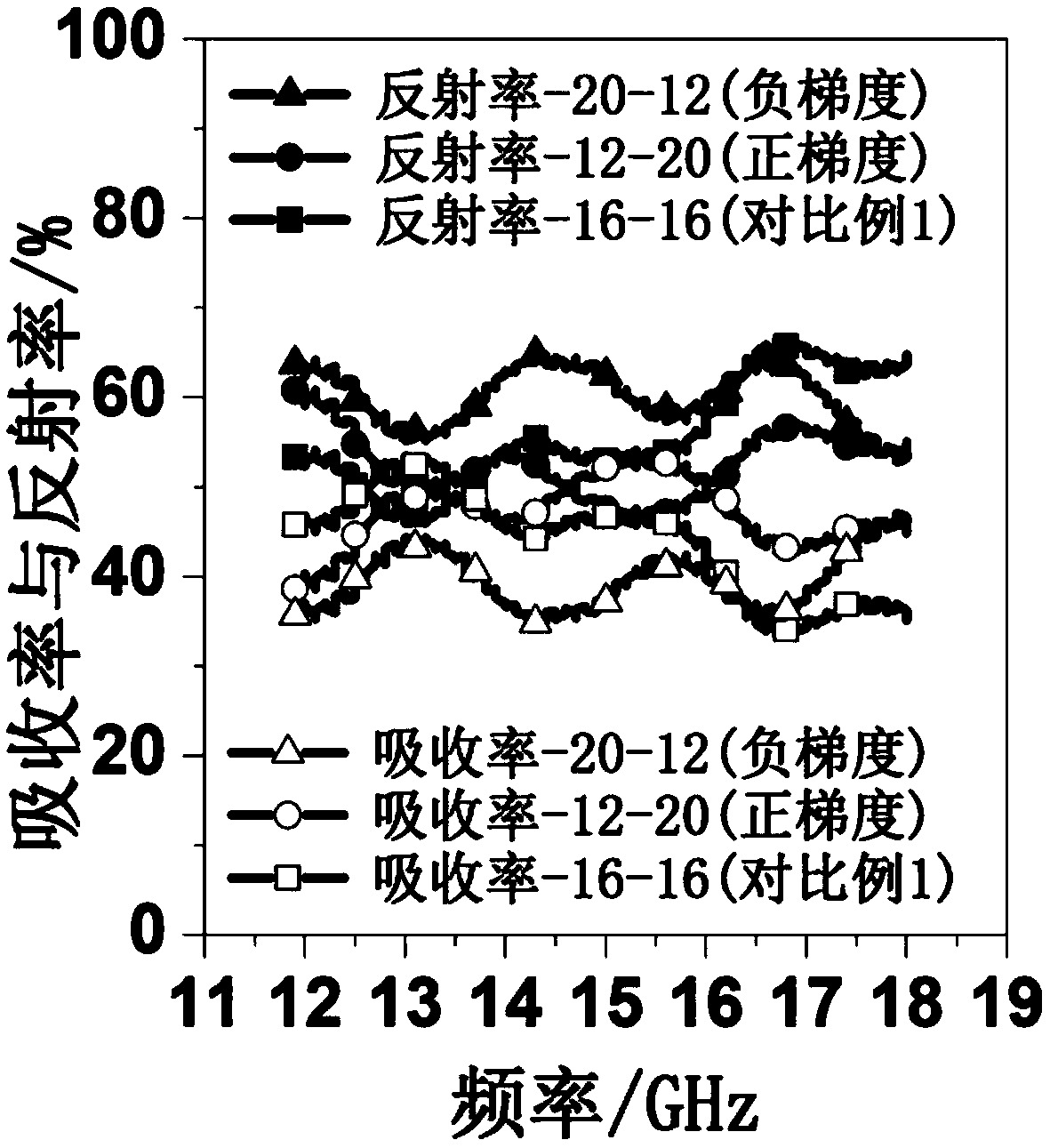

ActiveCN106566226AReduce weight and costIncrease absorption lossLamination ancillary operationsLaminationCvd grapheneGraphene foam

The invention discloses a thermoplastic polyurethane / graphene foam material and a preparation method and application thereof. The thermoplastic polyurethane / graphene foam material has high electromagnetic shielding effectiveness and high wave absorbing performance. According to the method, firstly, single-layer thermoplastic polyurethane / graphene microfoam films are prepared through a phase separation method, then, the single-layer thermoplastic polyurethane / graphene microfoam films with the different graphene contents are bonded into an integrated material through glue, and therefore gradient dispersion of graphene in the thermoplastic polyurethane / graphene foam material is achieved. The gradient structure can endow the thermoplastic polyurethane / graphene foam material with good shielding effectiveness and meanwhile can greatly improve the wave absorbing performance of the material, and the prepared light thermoplastic polyurethane / graphene foam material has good application prospects in the fields of electromagnetic shielding and wave absorbing materials.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

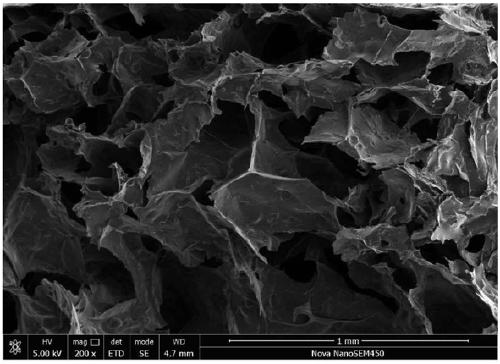

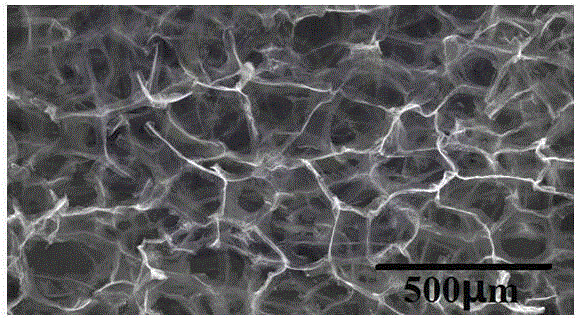

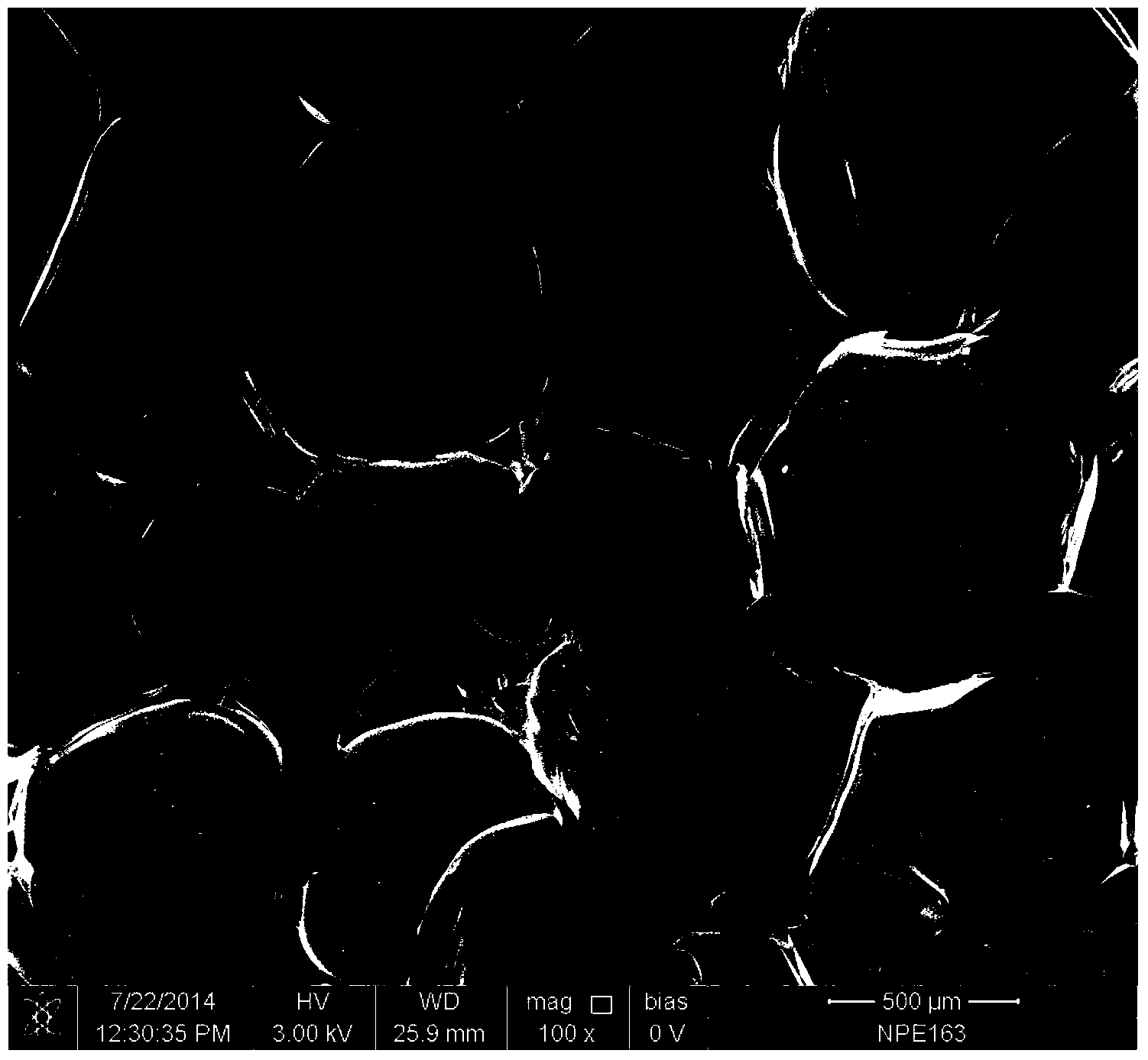

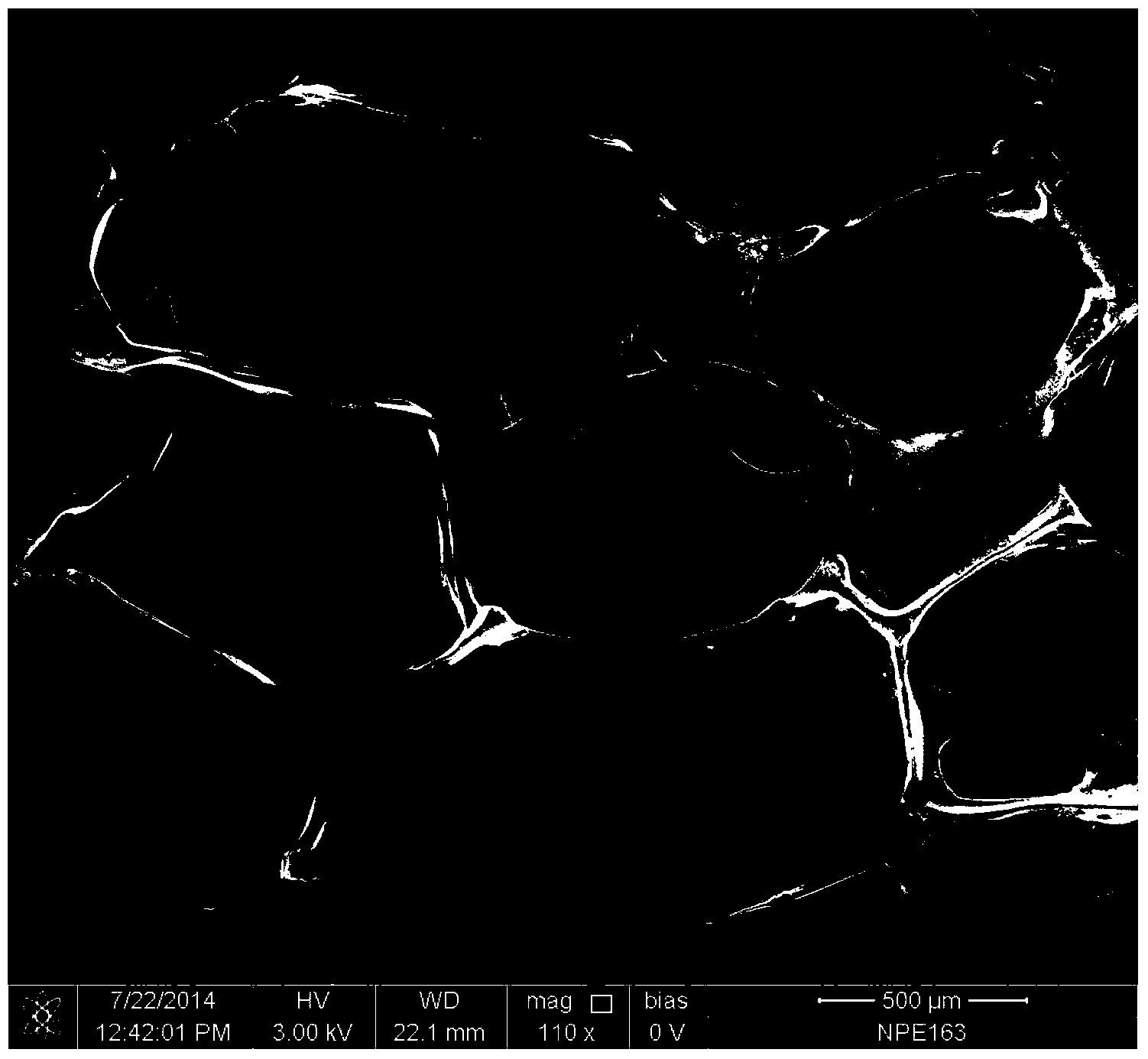

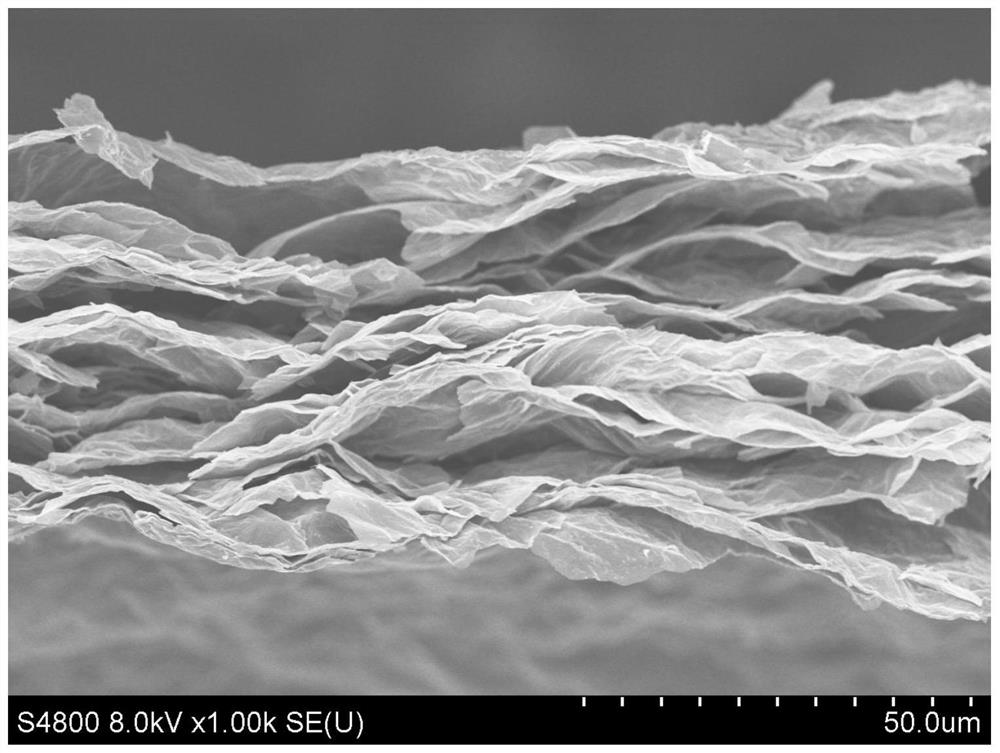

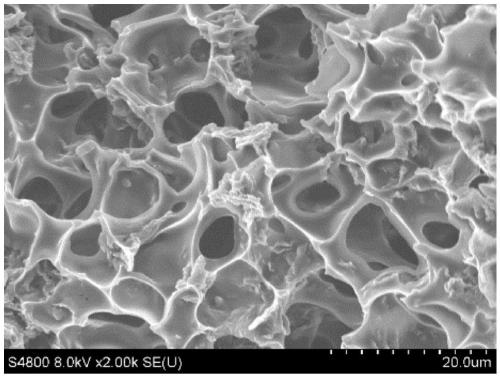

Preparation method of high-electromagnetic-shielding-effectiveness full-biomass-based carbon aerogel

ActiveCN109607509AImprove conductivityGood electromagnetic shielding performanceCarbon preparation/purificationBiomassHigh potential

The invention discloses a preparation method of high-electromagnetic-shielding-effectiveness full-biomass-based carbon aerogel. The required raw materials comprise cellulose. The method comprises thefollowing steps of raw material drying, preparation of a cellulose solution, preparation of cellulose aerogel and preparation of carbon aerogel. According to the method, celluloses is used as a precursor, through dissolution regeneration, cosolvent treatment and freezing drying, a three-dimensional continuous opening sheet layered grid structure of the cellulose aerogel is regulated and controlled, the stable and excellent electric conduction network (592.3 S / m) is constructed through high-temperature carbonization, and the efficient electromagnetic shielding performance (106.3 dB) of the carbon aerogel is achieved. The carbon aerogel has a wide precursor source and is environmentally friendly, a solvent system is nontoxic and low in price, the material preparation process is simple, the technology is easy to control, the production cost is low, and the carbon aerogel has high potential of large-scale production.

Owner:SICHUAN UNIV

Electromagnetic shielding composite coating resistant to information leakage and radiation pollution

InactiveCN102802395AIncrease reflection lossIncrease absorption lossMagnetic/electric field screeningLayered productsReflection lossHigh absorption

The invention relates to an electromagnetic shielding composite coating resistant to information leakage and radiation pollution. The electromagnetic shielding composite coating is characterized in that a composite shielding material with high magnetic loss and high dielectric loss is coated on the first layer on the surface of a PVC (Polyvinyl Chloride) plastic plate to serve as a high-absorption layer; a composite shielding material with high electric conductivity is coated on the second layer on the surface of the PVC plastic plate to serve as a high-reflection layer; a composite shielding material with low magnetic conductivity and high saturation magnetic induction is coated on the third layer on the surface of the PVC plastic plate to serve as a transition layer; and a composite shielding material with high resistivity is coated on the outermost layer on the surface of the PVC plastic plate to serve as a electromagnetic wave impedance matching layer, a filling material is respectively coated among the layers. After being subjected to treatments including component preparation, mixing, diluting, and ball milling dispersion, the materials of the composite coating are sprayed to a PVC plastic matrix material through a spray gun layer by layer, and then are dried to be solidified to form an electromagnetic shielding composite coating layer. According to the invention, a material and structure integrated design technology is adopted, the electromagnetic shielding composite coating can be used to achieve the purposes of high reflection loss, high absorption loss and high shielding effectiveness to electromagnetic waves within a broadband range of 1MHz-1GHz at the same time.

Owner:CHANGSHA TUOZHI METAL MATERIAL TECH

Low-loss deep-ultraviolet multilayer film production method

InactiveCN103018798AImprove compactnessImprove surface roughnessVacuum evaporation coatingSputtering coatingScattering lossEvaporation

The invention relates to a low-loss deep-ultraviolet multilayer film production method, belongs to the application field of the deep-ultraviolet optical technology, and aims at solving the problems of the deep-ultraviolet optical film in the prior art that an optical film system is large in absorption loss by adopting a total oxide film layer and is large in scattering loss by adopting a total fluoride film layer. The low-loss deep-ultraviolet multilayer film production method includes the following steps: 1 an optical substrate needing film plating is subjected to ultrasonic cleaning, slow pulling and dewatering and N2 drying; 2 an oxide film layer stack is prepared on the optical substrate obtained in the step 1 by aid of the ion assisted electron beam evaporation technology according to a film system structure of the film design; and 3 a fluoride film layer stack is prepared on the oxide film layer stack by aid of the thermal evaporation process. The low-loss deep-ultraviolet multilayer film production method overcomes shortcomings of the loose interior structure and large surface roughness of films in a total fluoride multilayer film system and the shortcoming of large absorption loss of a total oxide multilayer film system caused by acting of middle-and-outer-layer oxide films and laser.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

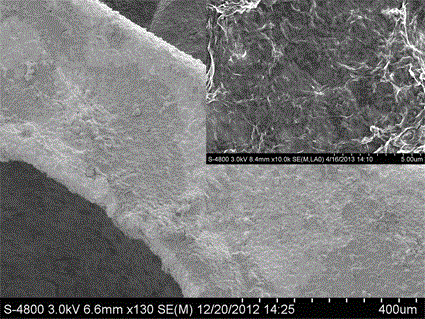

Foam metal-graphene composite material and preparation method thereof

InactiveCN106757283ALarge specific surface areaImprove conductivityElectrophoretic coatingsPorosityElectrophoresis

The invention discloses a foam metal-graphene composite material and a preparation method thereof. The composite material comprises a foam metal substrate layer and a graphene film layer on the substrate layer. The foam metal-graphene composite material is prepared by electrophoresis. The method specifically comprises the following steps of: removing oil stains and oxides on the surface of the foam metal substrate layer, preparing graphene by an oxidation-reduction method, modifying the graphene and performing electrophoretic deposition of the graphene on the surface of foam metal. Within a certain electromagnetic wave band, on one hand, the foam metal-graphene composite material has the structural advantages of light weight, porosity, large specific surface area and favorable conductive properties of the foam metal, and on the other hand, the foam metal-graphene composite material has excellent electrical conductivity and high dielectric constants of self-made graphene, and the properties of the self-made graphene that electromagnetic waves are well absorbed due to a large number of defects and functional group residues. The composite material has a high electromagnetic shielding effect, and can be used as an excellent electromagnetic shielding material.

Owner:CHANGDE LYRUN MATERIAL

Method for wave absorbing material and application of wave absorbing material

InactiveCN104300231AOverall goodHigh thickness controllabilityOther chemical processesMagnetic/electric field screeningAir atmosphereCarbonization

The invention relates to the technical field of wave absorbing materials. A preparation method of a wave absorbing material includes the steps of firstly, dissolving an organic carbon source and metal salt in organic solvent, and conducting stirring to form a solution; secondly, soaking polyurethane foam in the solution obtained in the first step, taking out the polyurethane foam, repeatedly squeezing the polyurethane foam through filter paper, and placing the squeezed polyurethane foam with the solution in air to be dried; thirdly, cooling the dried polyurethane foam to the room temperature after conducting temperature rising, oxidation and solidification on the dried polyurethane foam obtained in the second step under the atmosphere of air; fourthly, conducting temperature rising and carbonization on the oxidized and solidified polyurethane foam obtained in the third step under the protection of the inert atmosphere, and cooling the polyurethane foam to the room temperature so as to obtain the required target material. The preparation process which is adopted is easy to operate, high in carbon yield, short in reaction time and low in material cost and can be directly used for microwave absorbing without conducting secondary processing, and the product has the advantages of being small in density, wide in wave absorbing frequency band, high in absorbing strength, resistant to the high temperature and the like.

Owner:DALIAN UNIV OF TECH

Metal fiber/polymer compound electromagnetic shielding material and its making method

InactiveCN101123864AImprove shielding effectSimple processMagnetic/electric field screeningConductive polymerResin matrix

A metal fibre / polymer composite electromagnetic shielding material and the preparation method of the material relates to a functional composite material of shielding the interfering of electromagnetic wave. The invention consists of electromagnetic shielding components that are compositely formed by metal fibre and conducting polymer and a resin matrix. The preparation method includes the cutting of the metal fibre and acquiring the electromagnetic shielding material through ball milling by mixing the metal fibre with the conducting polymer and the resin mechanically. As the invention makes use of the metal fibre as the metal jointing to replace metal powder and the metal fibre has a certain slenderness ratio which is more beneficial to forming a conducting network, the invention plays a remarkable role on reducing cost as well as the weight of the electromagnetic shielding material. The composition of the metal fibre and polymer increases the bandwidth of shielding efficiency and can acquire a higher shielding efficiency in a wider frequency range. Adopting different metal fibre assemblies or alloy fibre can design the electromagnetic performances of the metal fibre conducting network .and increase the absorption loss in shielding efficiency thereby reducing the secondary pollution caused by reflection. The method has the advantages of easy preparation and operation.

Owner:UNIV OF SCI & TECH BEIJING +1

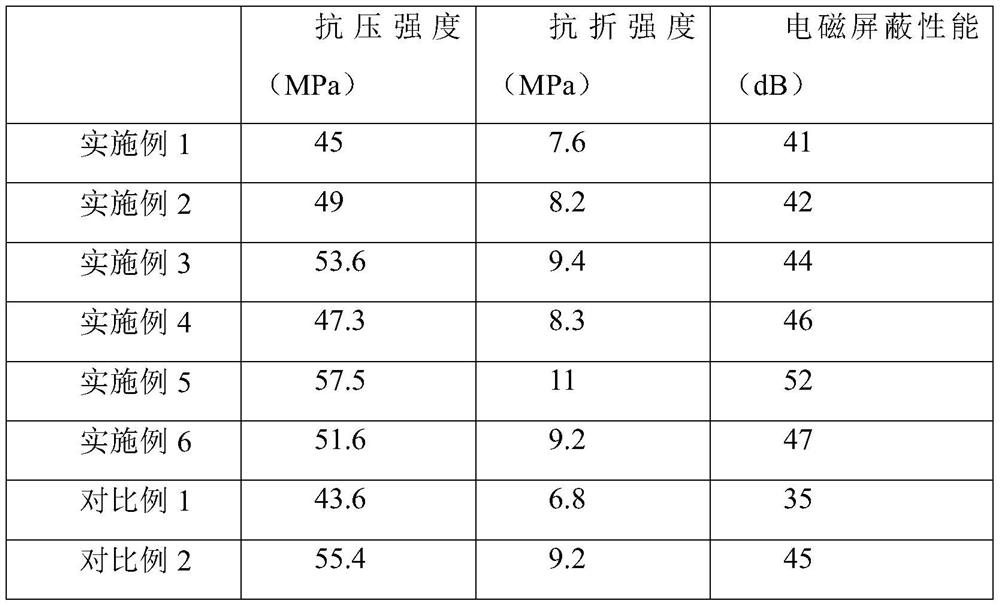

Wet-ground copper slag cement-based electromagnetic shielding composite material and preparation method thereof

InactiveCN112142415AHigh electromagnetic shieldingIncrease absorption lossSolid waste managementMagnetic/electric field screeningCarbon fibersSlurry

The invention relates to a wet-ground copper slag cement-based electromagnetic shielding composite material and a preparation method thereof. The preparation method comprises the following steps: adding water into copper slag for wet grinding, and obtaining wet-ground copper slag slurry for standby application; immersing the recycled carbon fibers into water, uniformly dispersing the recycled carbon fibers into the water, adding a dispersing agent, uniformly stirring, adding a defoaming agent, and carrying out ultrasonic treatment for a period of time to obtain a carbon fiber dispersion liquidfor later use; taking and mixing portland cement, the wet-ground copper slag slurry, waste tire rubber powder, the carbon fiber dispersion liquid and the water reducing agent solution, and evenly mixing to obtain the wet-ground copper slag-based cement-based electromagnetic shielding composite material. According to the invention, industrial wastes such as copper slag, recycled carbon fibers andwaste tires are utilized, so that the mechanical property and electromagnetic shielding property of the cement-based composite material are effectively improved, and the cost is reduced while the green and environment-friendly scientific development concept is realized.

Owner:HUBEI UNIV OF TECH

LED with high light extracting efficiency and preparing method thereof

InactiveCN1825643AQuality improvementPrevent leakageSemiconductor devicesRefractive indexContact layer

The invention is a light-emitting diode (LED) for improving light pickup efficiency, comprising: thickened P electrode, high reflecting metallic mirror, P electrode Ohm contact layer, P-type semiconductor, multi-quantum trap active region, thickened N electrode, N electrode Ohm contact layer, N-type semiconductor, and substrate, where the P-type semiconductor, multi-quantum trap active region, N-type semiconductor compose a table of the LED from the top down, and the substrate is a light outgoing side; and it is characterized by alternatively growing high and low refractivity materials on the LED side wall to form a high reflecting multilayer dielectric film. And the preparing method of the LED is characterized by preparing the high reflecting multilayer dielectric film after preparing the high reflecting metallic mirror. And the invention makes one-time growth of the high reflecting multilayer dielectric film while passivating the side wall. And the process is simple and the light output is improved at least by 20%.

Owner:BEIJING TIMESLED TECH CO LTD

Electromagnetic shielding macromolecule composite material

InactiveCN100577715CGood chemical stabilityIncrease absorption lossEngine sealsMagnetic/electric field screeningEpoxyElectromagnetic shielding

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

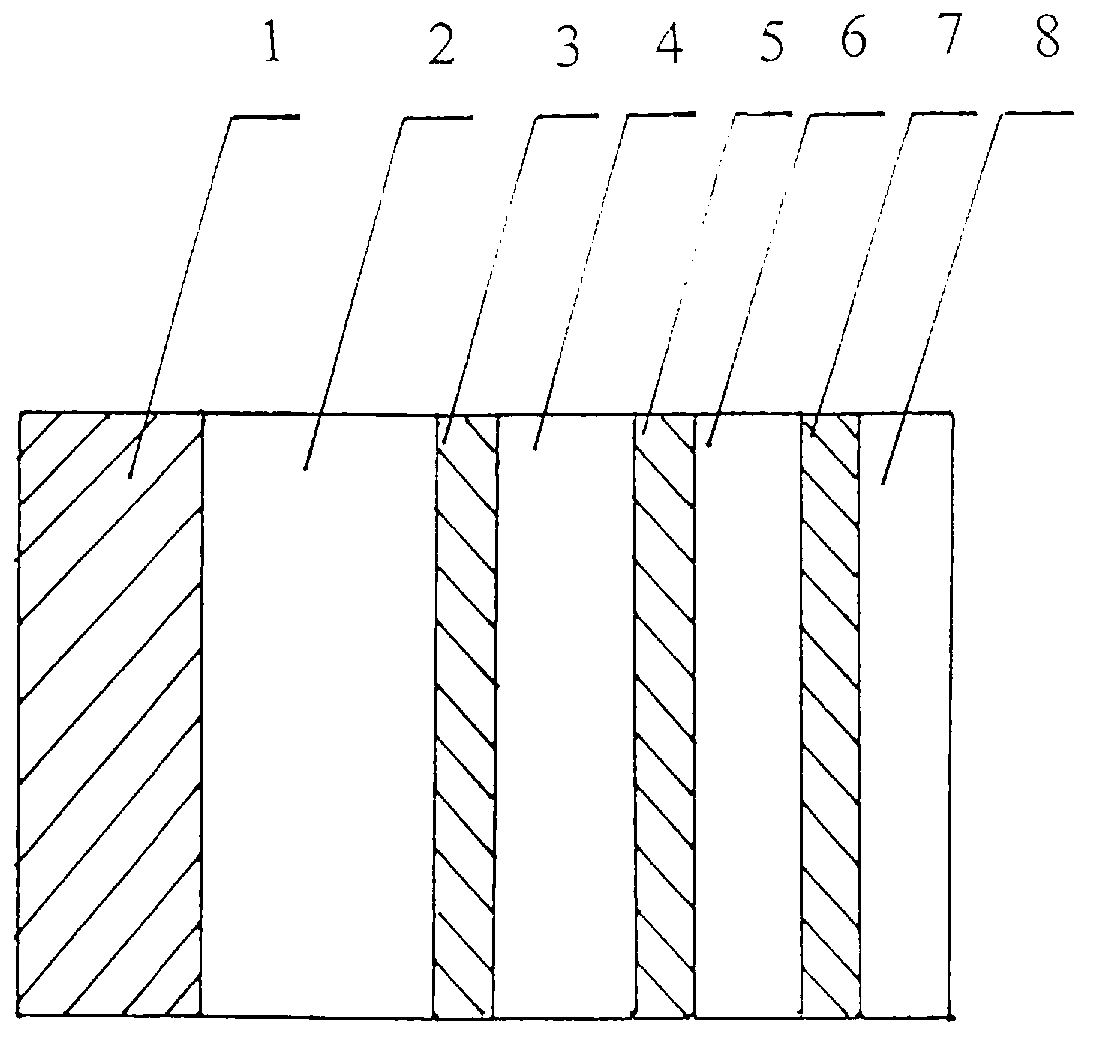

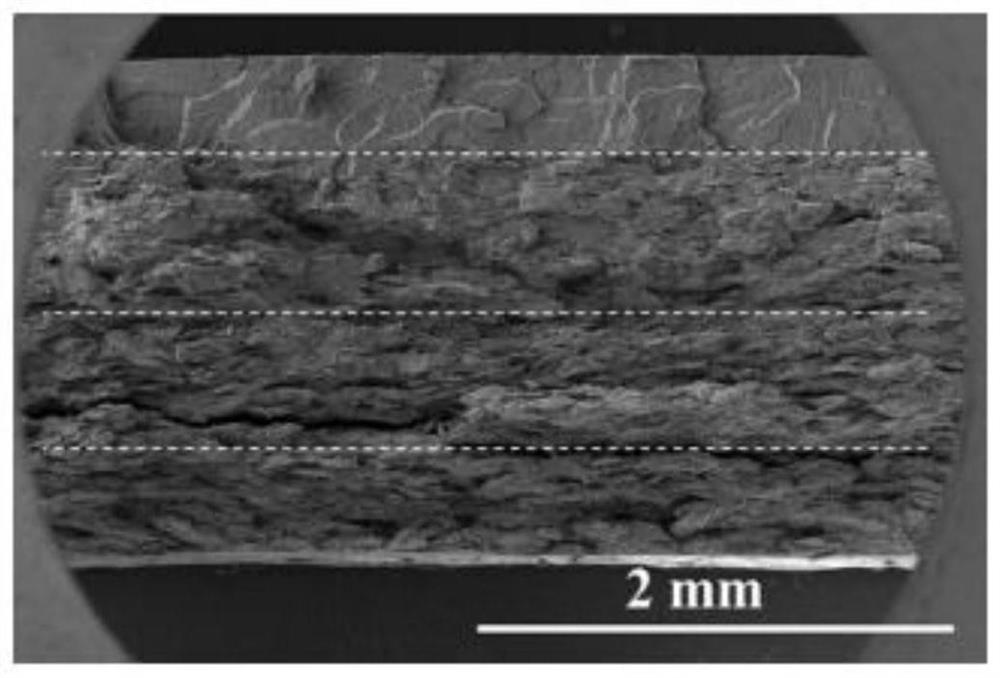

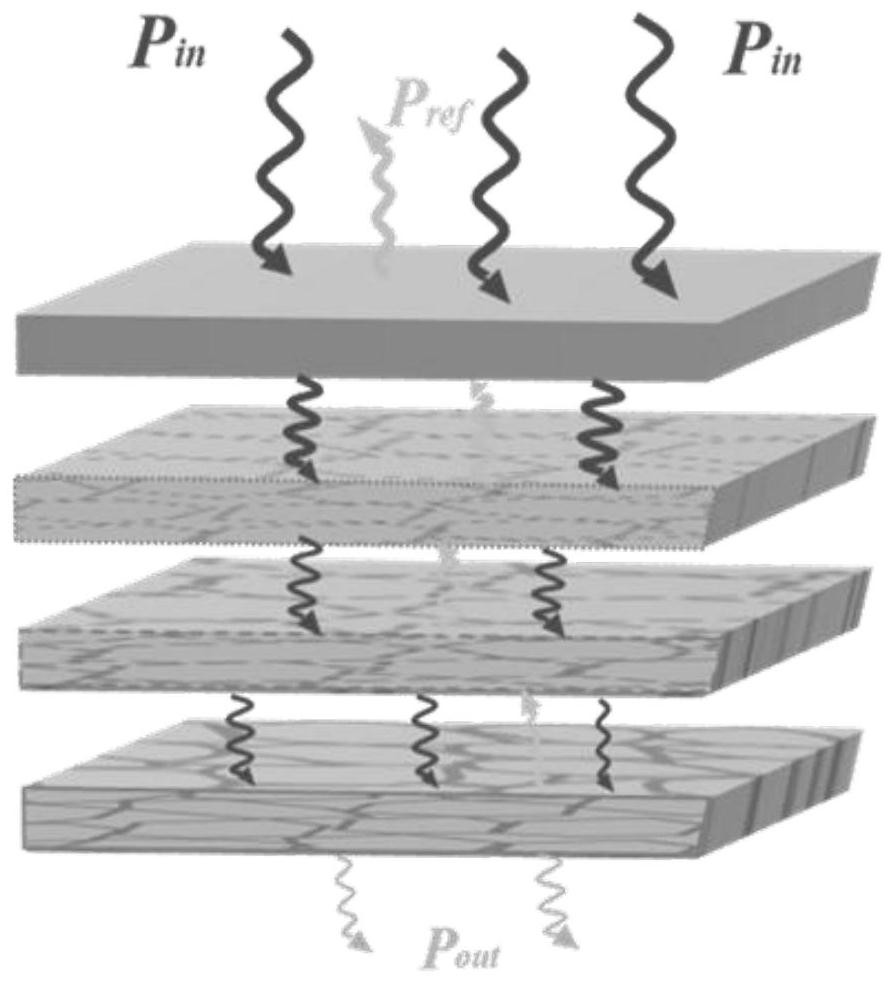

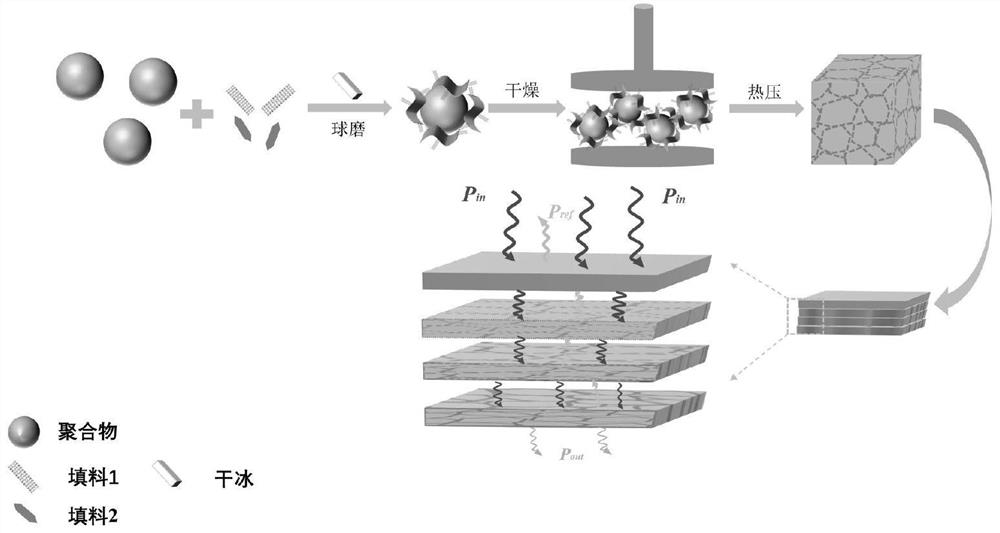

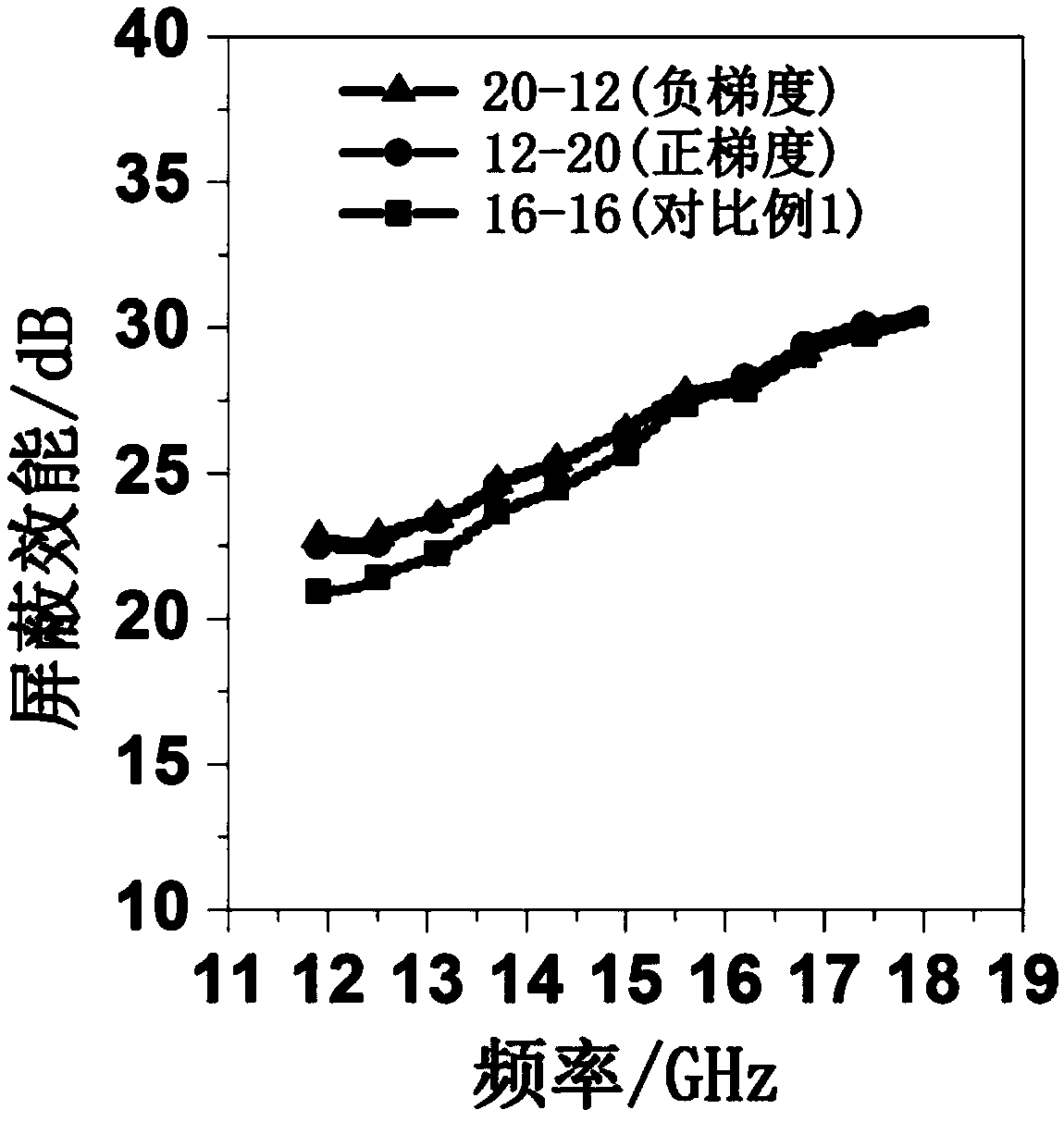

Electromagnetic shielding composite material with multilayer gradient isolation network and preparation method thereof

PendingCN113910718ASmooth entryReduce Impedance MismatchMagnetic/electric field screeningSynthetic resin layered productsDry iceElectromagnetic shielding

The invention discloses an electromagnetic shielding composite material with a multilayer gradient isolation network and a preparation method thereof, and belongs to the technical field of functional composites. The electromagnetic shielding composite material with the multilayer gradient isolation network is characterized in that the composite material comprises a first carbon-based shielding layer, a second carbon-based shielding layer, a third carbon-based shielding layer and an incident layer; the preparation method comprises the following steps: S1, carrying out vacuum drying on polymer particles and a conductive carbon-based filler; S2, ball-milling the pure polymer particles to obtain a first ball-milled product; S3, carrying out ball milling on the mixture of the conductive carbon-based filler, the polymer particles and dry ice; S4, respectively carrying out hot press molding on the premixes obtained in the S2 and the S3; S5, stacking the hot-press forming objects obtained in the step S4 from top to bottom and performing hot pressing to obtain a final product. The composite material prepared by the method can effectively reduce reflection loss and increase absorption loss, and the electromagnetic shielding effectiveness can be greatly improved through combination of the reduced reflection loss and the reduced absorption loss.

Owner:SICHUAN UNIV

Foam metal-graphene composite material and preparation method thereof

ActiveCN103436939BLarge specific surface areaImprove conductivityElectrophoretic coatingsElectrophoresesElectromagnetic shielding

The invention discloses a foamed metal-graphene composite material and a preparation method thereof. The composite material comprises a foamed metal base layer and a graphene film layer on the base. The foamed metal-graphene composite material is prepared by an electrophoresis method. Specifically, it includes removing oil stains and oxides on the surface of metal foam substrates, preparing graphene by redox method, modifying graphene, and electrophoretic deposition of graphene on the surface of metal foam. In a certain electromagnetic wave band, metal foam-graphene composites have the structural advantages of light and porous metal foam, large specific surface area and good conductivity on the one hand, and are compatible with the excellent electrical conductivity and high dielectric strength of self-made graphene on the other hand. The electrical constant and a large number of defects and functional group residues make it more conducive to absorbing electromagnetic waves and other properties. The composite material has high electromagnetic shielding efficiency and can be used as an excellent electromagnetic shielding material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

PC/ABS alloy

ActiveCN111825969AImproves UV resistanceExcellent dielectric propertiesElectromagnetic shieldingAnoxomer

The invention discloses a PC / ABS alloy and a preparation method thereof. The PC / ABS alloy is prepared from the following raw materials in parts by weight: 50 to 65 parts of PC resin, 15 to 45 parts ofABS resin, 10 to 20 parts of an electromagnetic shielding filler, 0.5 to 1 part of a compatilizer, 0.5 to 1 part of an antioxidant and 0.5 to 1 part of a flame retardant. The electromagnetic shielding filler adopts a silicon-coated metal oxide nano material; on one hand, the effective surface area of the electromagnetic shielding filler is increased, and on the other hand, the coated silicon dioxide shell is used as an interface, so that electromagnetic radiation is reflected and scattered for multiple times on the interface, and the electromagnetic shielding efficiency of the PC / ABS alloy isfurther improved.

Owner:浙江华杰材料科技有限公司

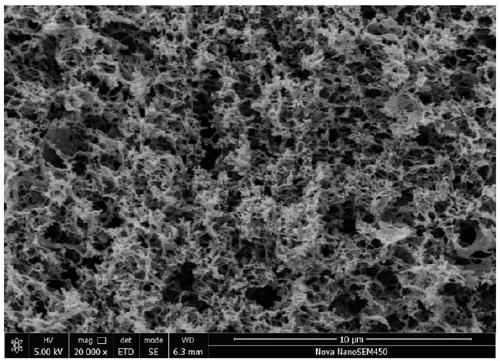

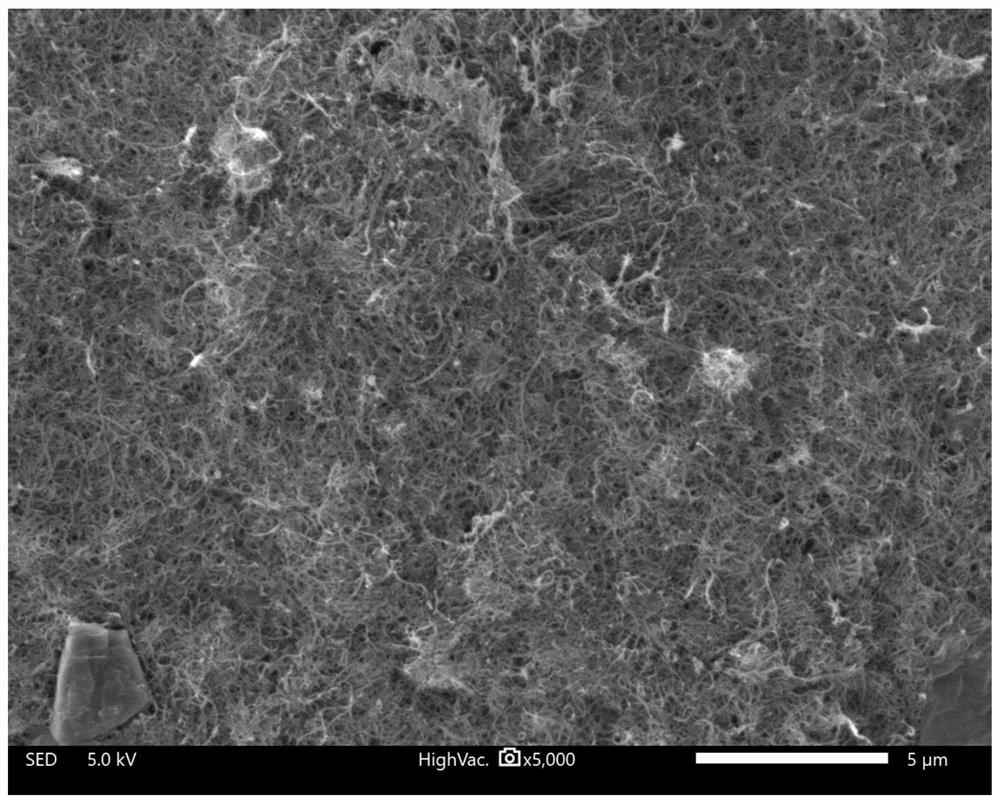

Preparation method and application of graphene/carbon nanotube composite porous membrane

InactiveCN111615318AAchieve low temperatureUniform/non-uniform dispersionMagnetic/electric field screeningGrapheneMicrospherePorous membrane

The invention discloses a preparation method and application of a graphene / carbon nanotube composite porous membrane, and relates to the technical field of preparation of composite porous membranes. The preparation method comprises the steps of (1) dispersing crosslinked polystyrene (PS) microspheres, graphene oxide and carboxylated carbon nanotubes in a solvent to obtain a suspension; (2) carrying out suction filtration on the suspension to obtain a filter membrane; (3) drying the filter membrane to obtain a graphene oxide / carbon nanotube / PS microsphere composite membrane; and (4) clamping the graphene oxide / carbon nanotube / PS microsphere composite membrane between graphite plates, and performing carbonization treatment in an atmosphere furnace to obtain the required graphene / carbon nanotube composite porous membrane. According to the preparation method, polystyrene microspheres are taken as a template, uniform and non-uniform dispersion of the polystyrene microspheres in the graphene / carbon nanotube composite membrane is realized through suction filtration, and then the template is removed through low-temperature carbonization, so that low-temperature and simple preparation of the graphene / carbon nanotube composite porous membrane is realized.

Owner:HUANGHUAI UNIV

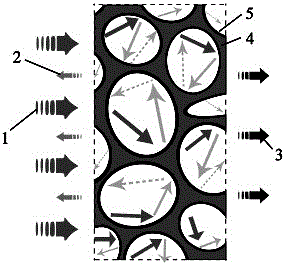

Composite material for shielding electromagnetic radiation

InactiveCN108285604AImprove shielding effectExtended propagation pathMagnetic/electric field screeningReflection lossAcrylic resin

The invention discloses a composite material for shielding electromagnetic radiation, and the composite material is prepared from raw materials of silicon carbide fiber, thermoplastic acrylic resin, aferrocene organic magnet, N-phenyl-beta-naphthylamine, zinc stearate, polyvinyl chloride, a conductive filler, a coupling agent, a filler, a stabilizer and other auxiliary agents; the composite material combines the advantages of a multilayer structural material and a gradient structural material, and has the performances superior to that of the two materials. Due to the impedance mismatch between a material absorption layer and a reflection layer, incident electromagnetic wave may generate multiple reflections, propagation paths of the electromagnetic wave in the material can be increased, and by the increase of multiple-reflection loss and absorption loss, the shielding effectiveness of the material become larger; the difference in impedance between the absorption layer and the reflection layer is reduced, so that the electromagnetic wave may not escape the shielding material too quickly due to reflection, and can enter a next shielding unit more, and the shielding effectiveness ofthe material can be further improved. Therefore, the composite shielding material of the structure has better shielding properties.

Owner:孙奉生

Electromagnetic shielding cement-based composite material prepared from wet-ground titanium slag and preparation method of electromagnetic shielding cement-based composite material

ActiveCN112441796AGood electromagnetic shieldingIncrease absorption lossSolid waste managementFiberCarbon fibers

The invention relates to an electromagnetic shielding cement-based composite material prepared from wet-ground titanium slag and a preparation method of the electromagnetic shielding cement-based composite material. The cement-based electromagnetic shielding composite material prepared from the wet-ground titanium slag is prepared from the wet-ground titanium slag, recycled carbon fibers, a waterreducing agent, water, a dispersing agent, a defoaming agent and Portland cement. The material has the advantages of simple production process, short production period, relatively low cost and good electromagnetic shielding performance, solves the problem of accumulation pollution of industrial wastes such as blast furnace titanium slag and recycled carbon fibers, and is relatively high in comprehensive benefits.

Owner:HUBEI UNIV OF TECH

Foam metal-carbon nano tube composite material and preparation method thereof

InactiveCN106757282AExcellent dimensional propertiesLarge specific surface areaElectrophoretic coatingsPlatinumOrganic solvent

The invention relates to a foam metal-carbon nano tube composite material and a preparation method thereof. The foam metal-carbon nano tube composite material comprises a foam metal base layer and a carbon nano tube film layer on the foam metal base layer, wherein the thickness of the carbon nano tube film layer is 0.1-10 nm. The preparation method of the foam metal-carbon nano tube composite material particularly comprises the following steps: cleaning the foam metal base layer; adding carbon nano tubes into an electrolyte and an organic solvent to obtain a mixed electrolyte, and performing ultrasonic treatment for 1-5 h; then taking a platinum electrode as an anode and foam metal as a cathode, and placing in the mixed electrolyte; switching on a DC power supply; depositing for 1-50 min under the voltage of 80-160 V; and taking out a cathode material, and drying to obtain the foam metal-carbon nano tube composite material, wherein the concentration of the electrolyte in the mixed electrolyte is 0.1-0.6 mg / ml; and the parallel space between the anode and cathode is 1-3 cm. The foam metal-carbon nano tube composite material has high electromagnetic shielding effectiveness and can serve as an electromagnetic shielding material.

Owner:CHANGDE LYRUN MATERIAL

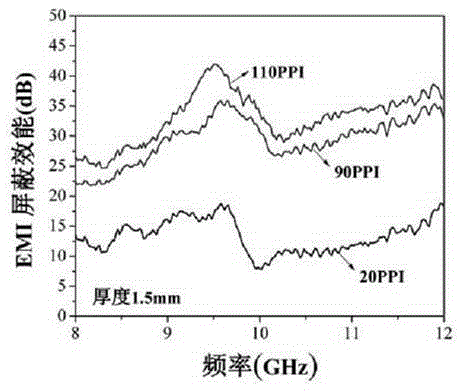

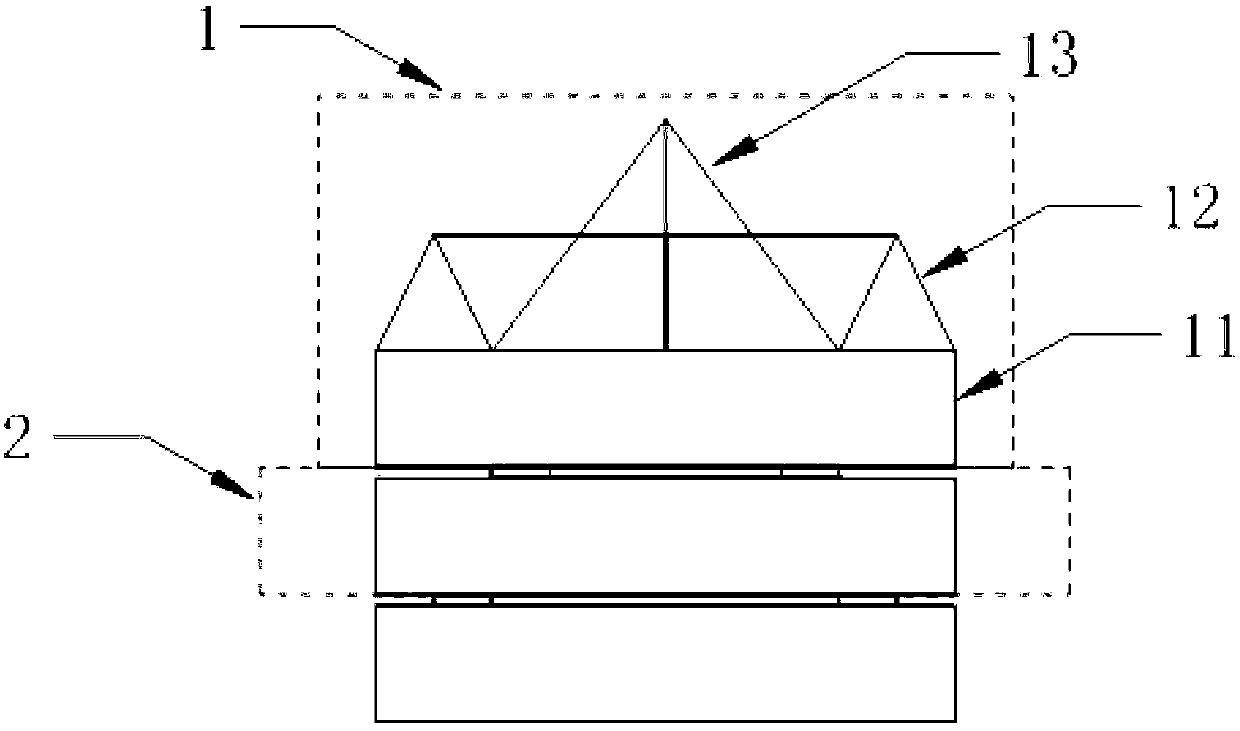

Thin composite multiple-layer band gap microwave dark chamber wall body liner

ActiveCN102995863AReduce the amount of reflectionIncreased path lossCovering/liningsUnderlayReflection coefficient

A thin composite multiple-layer band gap microwave dark chamber wall body liner is composed of microwave absorbing units arranged according to arrays. Each microwave absorbing unit comprises one layer or multiple layers of overlaid magnetic band gap structures, wherein a foam pointed cone is arranged on the magnetic band gap structure on an upmost layer and comprises a foam base arranged on the magnetic band gap structure on the upmost layer, and conical foam is arranged on the foam base. In the thin composite multiple-layer band gap microwave dark chamber wall body liner, a conical foam ring is arranged on the foam base, and the conical foam is arranged in the conical foam ring. The height of the conical foam is larger than that of the conical foam ring. The number of multiple layers of overlaid magnetic band gap structures is two to four. A simulation result shows that at least -15dB of reflection coefficient can be achieved in a range from 0.6GHz to 3GHz under the condition that the overall liner thickness does not exceed 5cm.

Owner:SOUTHEAST UNIV

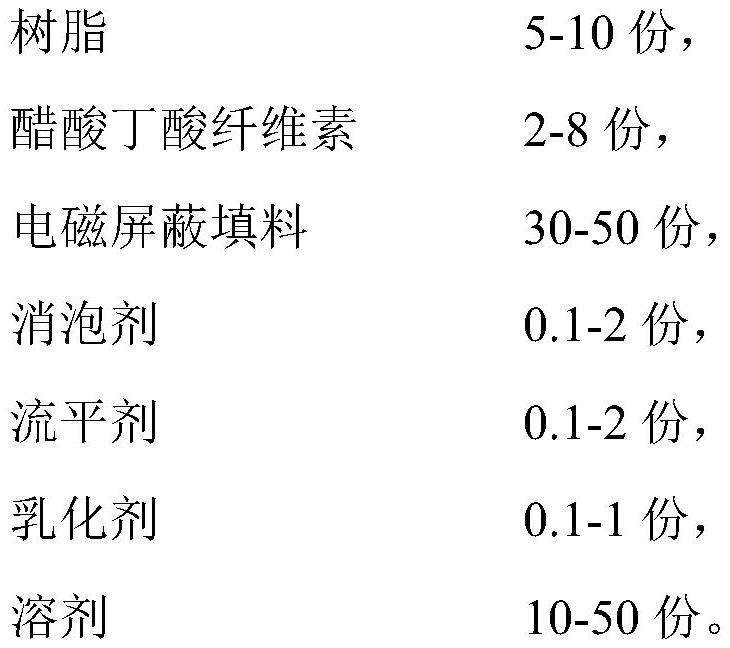

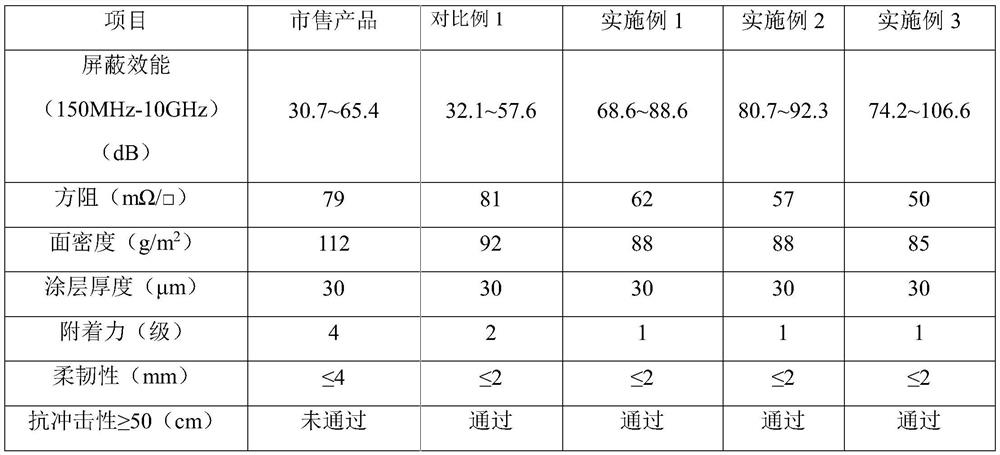

Lightweight broadband electromagnetic shielding coating and preparation method thereof

PendingCN113621299AReduce bulk paddingReduce the probability of uneven dispersionEpoxy resin coatingsElectrically-conductive paintsCelluloseMicrosphere

The invention belongs to the technical field of functional coatings, and particularly relates to a lightweight broadband electromagnetic shielding coating and a preparation method thereof, the lightweight broadband electromagnetic shielding coating comprises the following components in parts by weight: 5-10 parts of resin, 2-8 parts of cellulose acetate butyrate, 30-50 parts of an electromagnetic shielding filler, 0.1-2 parts of an antifoaming agent, 0.1-2 parts of a leveling agent, 0.1-2 parts of an emulsifier, and 10-50 parts of a solvent. The lightweight broadband electromagnetic shielding coating is designed and prepared through a PS microsphere / silver powder / silver coated copper powder composite electromagnetic shielding filler, and the problems that a traditional electromagnetic shielding coating is uneven in dispersion, small in shielding and absorption frequency range, low in shielding effectiveness and large in coating density are effectively solved.

Owner:青岛九维华盾科技研究院有限公司

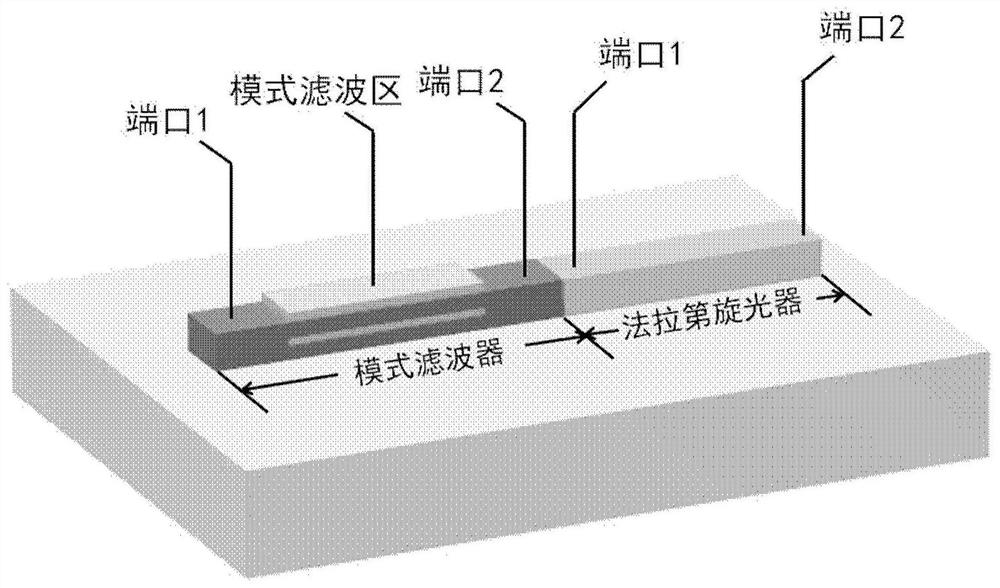

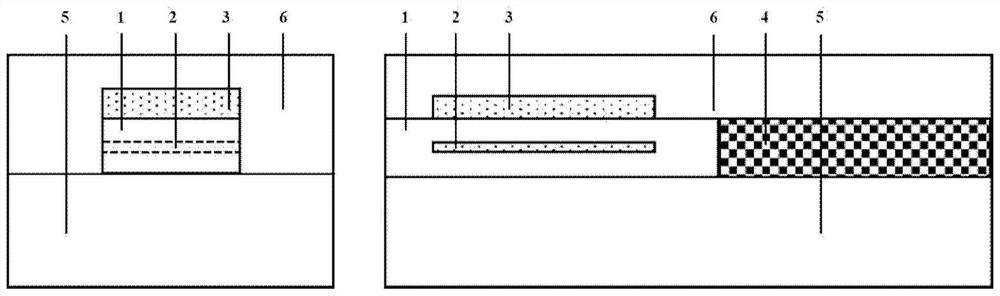

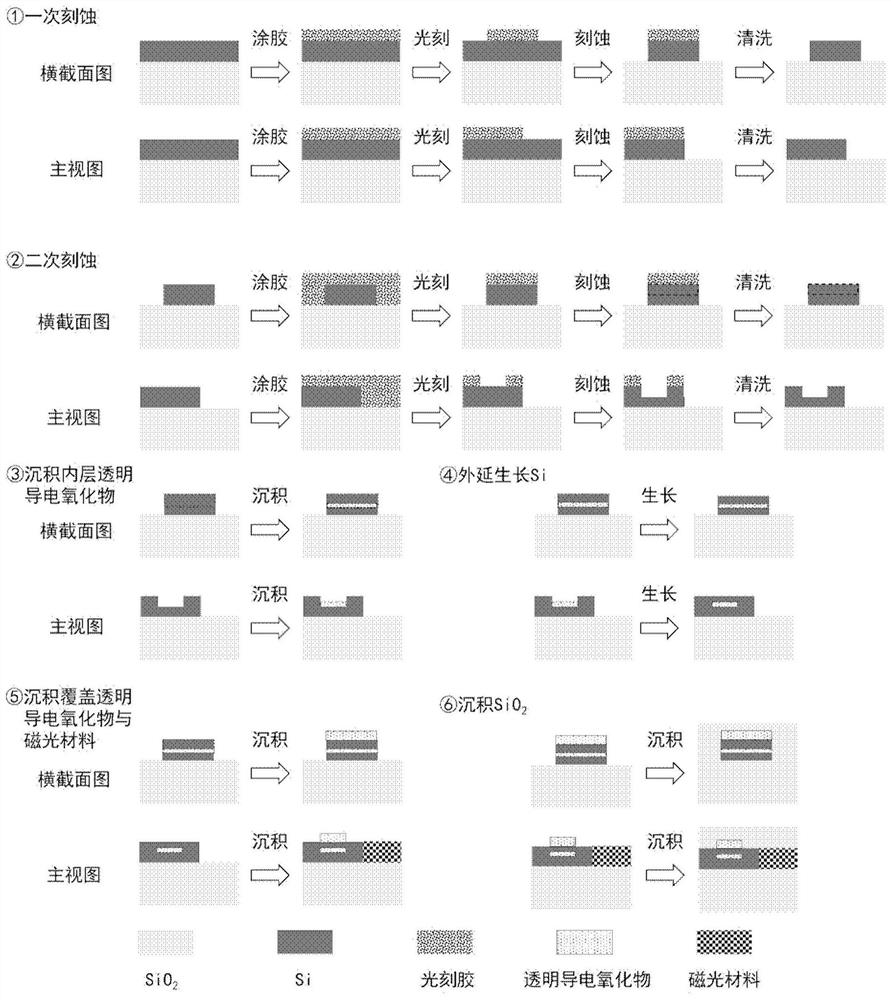

Silicon-based magneto-optic isolator based on mode filter and preparation method

ActiveCN111856791AImprove isolationIncrease absorption lossOptical waveguide light guideNon-linear opticsTransverse magnetic fieldWaveguide

The invention provides a silicon-based magneto-optic isolator based on a mode filter. The isolator comprises the mode filter and a Faraday rotator, the mode filter adopts a strip-shaped silicon waveguide structure embedded with a transparent conductive oxide layer, and the Faraday rotator adopts a strip-shaped magneto-optic material structure; an input signal of a transverse electric field mode transmitted in the forward direction is input from the mode filter, enters the Faraday rotator after passing through the mode filter area, and is output after 45-degree polarization rotation is achieved. Reflected reverse transmission light is input from the Faraday rotator, enters the Faraday rotator and continues to rotate by 45 degrees in the original direction, the reverse transmission light ischanged into a transverse magnetic field mode from the transverse electric field mode after rotating by 90 degrees in total, the reverse transmission light is lost by a transparent conductive oxide layer when entering the filter area of the mode filter, and therefore isolation of the reverse transmission light is achieved. The isolator provided by the invention has the characteristics of high isolation, low insertion loss, small device size, easy CMOS integration and the like.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI +1

A quantum cascade regular polygon microcavity laser and its manufacturing method

InactiveCN101867147BSimple structureSimple preparation processLaser detailsLaser optical resonator constructionLower limitOhmic contact

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Microcellular foaming HIPS electromagnetic shielding material as well as preparation method and application thereof

ActiveCN111961305AImprove electromagnetic shielding performanceExcellent electromagnetic shielding performance and stabilityMagnetic/electric field screeningSocial benefitsFoaming agent

The invention discloses a microcellular foaming HIPS electromagnetic shielding material and a preparation method and application thereof, and belongs to the technical field of preparation of functional polymer materials. The electromagnetic shielding material is prepared by the following steps: carrying out melt blending on HIPS, a foaming agent and a cross-linking agent to prepare a blend I; subjecting HIPS, a compatilizer, an electromagnetic shielding aid, an antioxidant, an activating agent, a nucleating agent and a lubricating agent to melt blending to prepare a blend II, and finally, mixing the blend I and the blend II and subjecting a product to microcellular foaming to prepare the material. The microcellular foaming HIPS electromagnetic shielding material prepared by the invention has high electromagnetic shielding effectiveness and excellent electromagnetic shielding effectiveness stability, can be widely applied to linings of shells of electric appliances such as household appliances, medical electric appliances, outdoor electric appliances, industrial and mining electric appliances and the like, and has relatively high economic value and social benefit. And the method plays a key role in a forced authentication requirement of each export country.

Owner:VIEW ELECTRONICS

Double-silver low-emissivity coated glass and preparation method thereof

The invention discloses double-silver low-emissivity coated glass and a preparation method thereof. The silver nanowires are used as the material of the silver functional layer to form a network structure, so that the infrared radiation loss is effectively increased, and the infrared radiation resistance of the glass is improved; acetone doping and sulfuric acid post-treatment are utilized to increase the conductivity of the conductive adhesive layer and increase dielectric loss radiation; by utilizing an electronic channel provided by the conductive adhesive layer and a three-dimensional structure of the middle dielectric layer, the radiation absorption loss and reflection loss of the glass are synergistically increased; nano-zinc oxide is uniformly distributed by utilizing the dispersitypromoting property of complex protein acid salt in the intermediate dielectric layer so that the light transmittance is improved, and sodium ions are inhibited from diffusing into the film layer in the toughening process; the damage to the surface of the glass is reduced by utilizing the super-hydrophobicity and self-repairability of the protective layer, namely, the N-boroxane-PDMS; by utilizinga three-dimensional structure formed in multiple layers, the toughness of the surface of the glass is effectively improved, and the impact strength is improved.

Owner:墨光新能科技(苏州)有限公司

A kind of thermoplastic polyurethane/graphene foam material and its preparation method and application

ActiveCN106566226BReduce weightLow costLamination ancillary operationsLaminationThermoplastic polyurethaneElectromagnetic shielding

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A broadband terahertz metamaterial absorber based on multiresonance absorption superposition

ActiveCN105896098BObvious absorption peak characteristicsImprove application efficiencyAntennasLine widthUnit structure

The invention discloses a broadband THz metamaterial absorber based on multi-resonant absorption superposition, belongs to a THz absorber in the field of metamaterials and electromagnetic functional technology, and aimed at that the broadband THz metamaterial absorber includes an upper patterned functional material layer, an intermediate medium layer and a lower metal reflective layer; the upper patterned functional material layer is formed by arranging metamaterial unit structures, each metamaterial unit structure includes a circular ring structure in which four parallel openings and a cross arm are disposed, and four connecting arms of each cross arm are connected with four ARC segments of each circular ring structure; the lattice period of a metamaterial unit structure array is a 10um to 100um, each metamaterial unit structure has a line width of 0.5um to 10um, the arm length x of each connecting arm is 3um to 50um, and the width d of each parallel opening is 0.5um to 50um. The invention does not require complicated procedures, a difficult process and high production cost to achieve the purpose of terahertz absorption band spread.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com