Thin composite multiple-layer band gap microwave dark chamber wall body liner

A technology of microwave anechoic chamber and wall lining, applied in the field of microwave anechoic chamber, can solve the problems of high cost, reduce material volume and weight, etc., and achieve the effects of increasing resonance loss, reducing reflection amount, and increasing low-frequency resonance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the purpose and effect of the present invention will become more obvious.

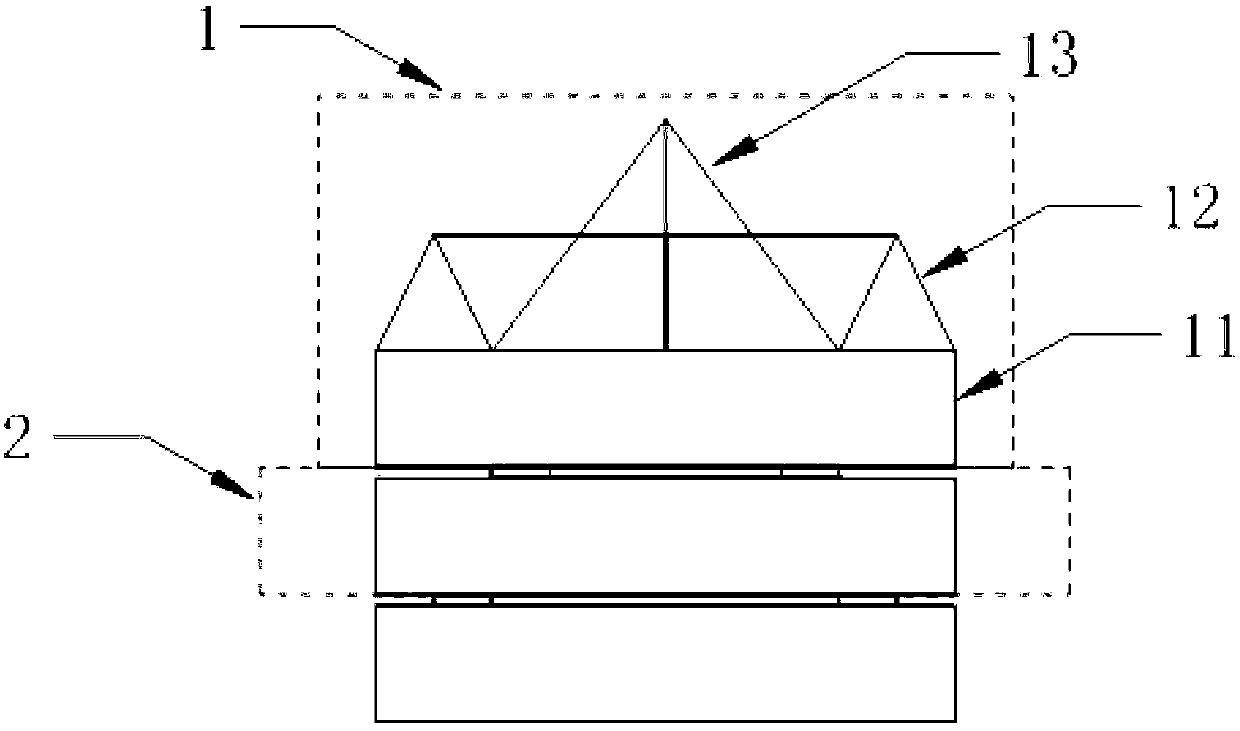

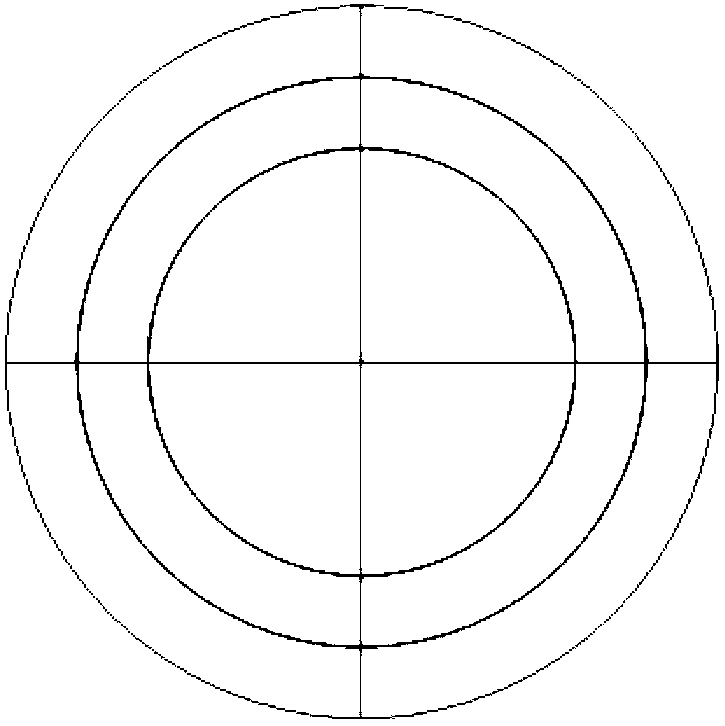

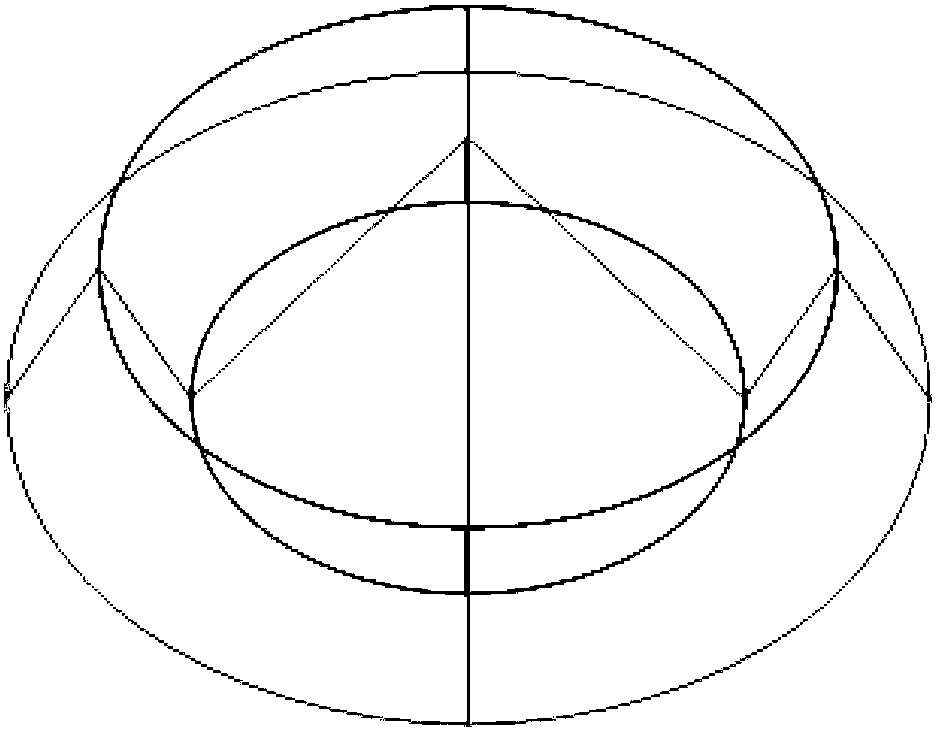

[0035] A thin composite multilayer bandgap microwave anechoic chamber wall lining, the thin composite multilayer bandgap microwave anechoic chamber wall lining is composed of wave-absorbing units arranged in an array, and the wave-absorbing units include one layer or stacked Multi-layer electromagnetic bandgap structure 2, on the electromagnetic bandgap structure of the uppermost layer, be provided with foam cone 1, described foam cone 1 comprises the foam base 11 that is arranged on the electromagnetic bandgap structure of uppermost layer, on foam base 11 is provided with conical foam 13. In this embodiment, a tapered foam ring 12 is provided on the foam base 11 , and the tapered foam 13 is disposed inside the tapered foam ring 12 . The height of the tapered foam 13 is great...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com