Low-loss deep-ultraviolet multilayer film production method

A deep-ultraviolet multi-layer film and low-loss technology, which is applied in the field of deep-ultraviolet optical technology applications, can solve the problems of large absorption loss and large scattering loss of optical thin film systems, and overcome the relatively loose internal structure and avoid absorption loss Great effect of reducing absorption loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

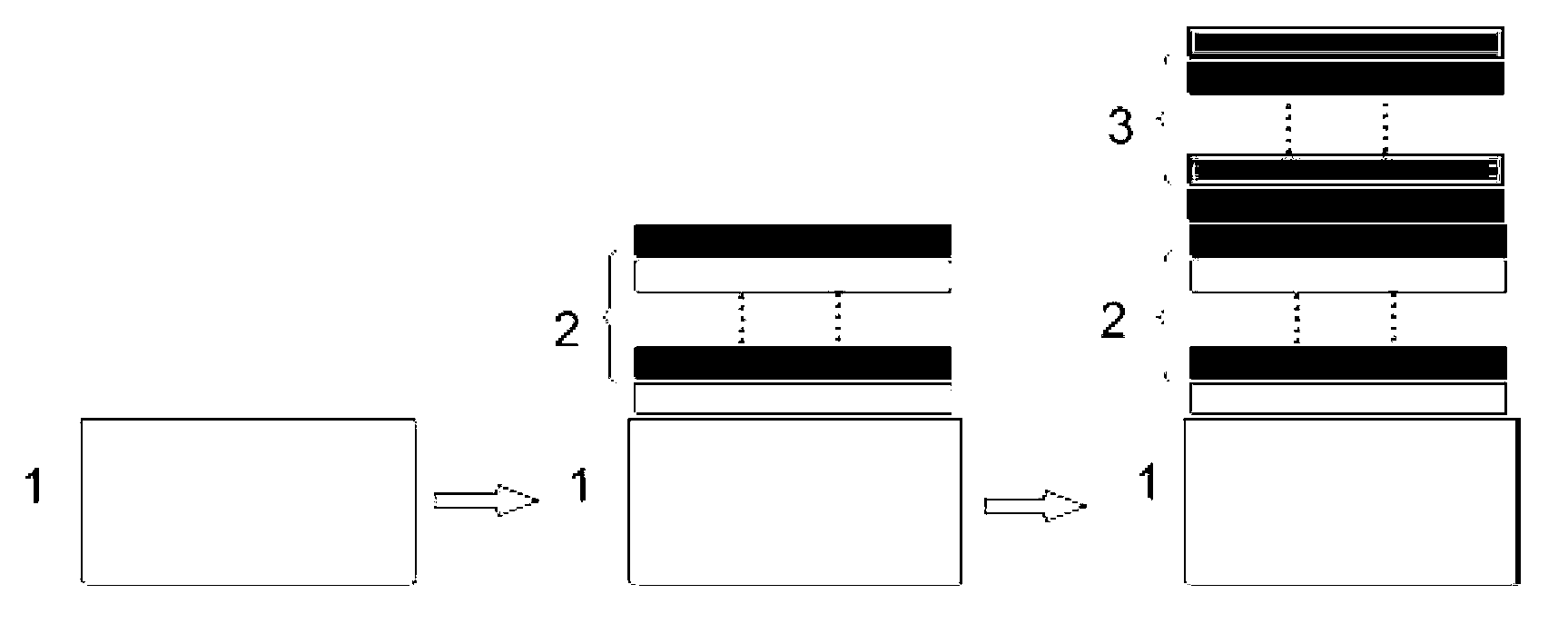

[0014] Such as figure 1 Shown, the preparation method of low-loss deep ultraviolet multilayer film of the present invention, this preparation method comprises the following steps:

[0015] Step 1. Ultrasonic cleaning, slow dehydration, and N 2 drying;

[0016] Step 2. According to the film system structure in the thin film design, on the optical substrate 1 after the completion of step 1, the oxide film layer stack 2 is prepared by ion-assisted electron beam evaporation process, so as to realize a denser and smoother inner side in the multilayer film system The film system can effectively reduce the scattering loss of the multi-layer film system;

[0017] Step 3. Due to the introduction of process gas in the ion-assisted electron beam evaporation process, the background vacuum degree of the coating chamber will be reduced. The thermal evaporation process needs to be deposited under a relatively high degree of vacuum, so it is necessary to wait for the vacuum degree of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com