Silicon-based magneto-optic isolator based on mode filter and preparation method

A mode filtering and filter technology, applied in the field of silicon-based optoelectronics integration, can solve the problems of lack of optical isolator integration methods and integration obstacles, and achieve the effect of high absorption loss and high isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

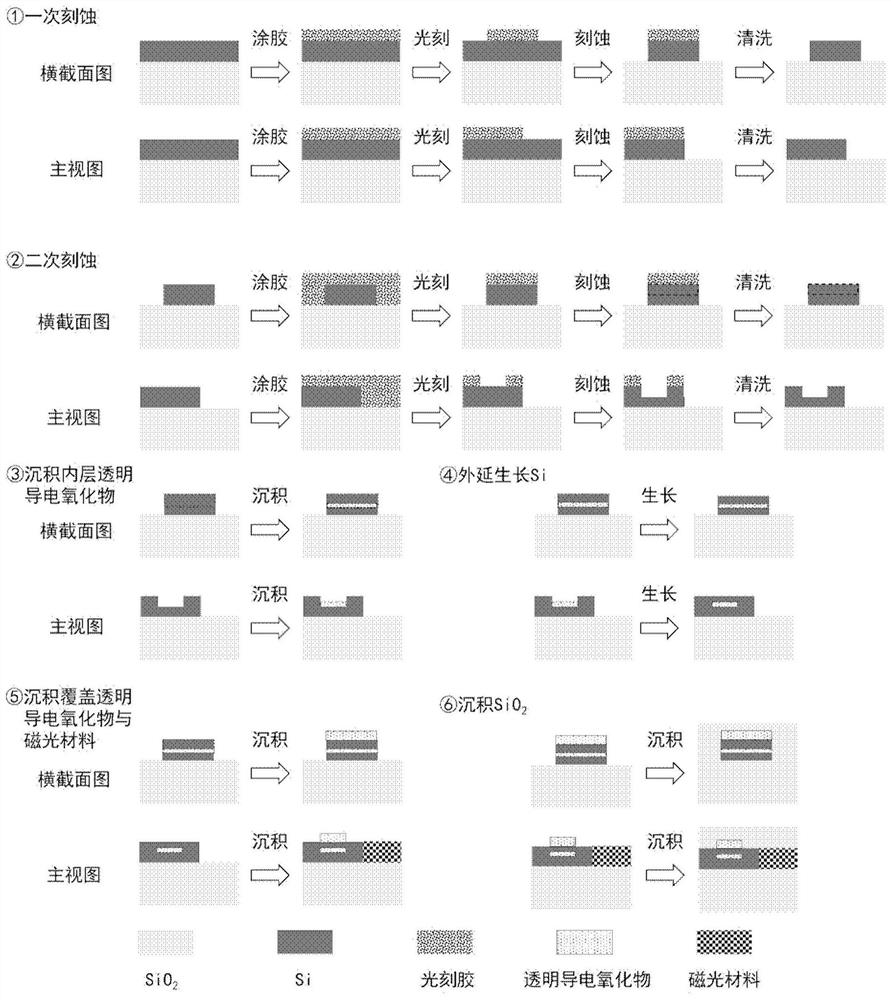

[0043] The invention also discloses a method for preparing a silicon-based magneto-optical isolator based on a mode filter, which includes the following steps:

[0044] Etching on SOI silicon wafer to form a strip-shaped silicon waveguide structure;

[0045] Forming the mode filter area through the secondary photolithography and etching process;

[0046] Depositing a transparent conductive oxide layer on the etched waveguide structure;

[0047] Epitaxially grow a layer of silicon film;

[0048] Depositing a transparent conductive oxide layer on the top layer of the mode filter area, and depositing an iron garnet film on the back end of the strip-shaped silicon waveguide structure to prepare a magneto-optical polarization Faraday rotator;

[0049] Deposit a layer of SiO 2 The thin film serves as the cladding layer on the device.

[0050] Preferably, the strip-shaped silicon waveguide is a rectangular waveguide;

[0051] Preferably, the strip-shaped silicon waveguide has a width of 400-2000 ...

Embodiment 1

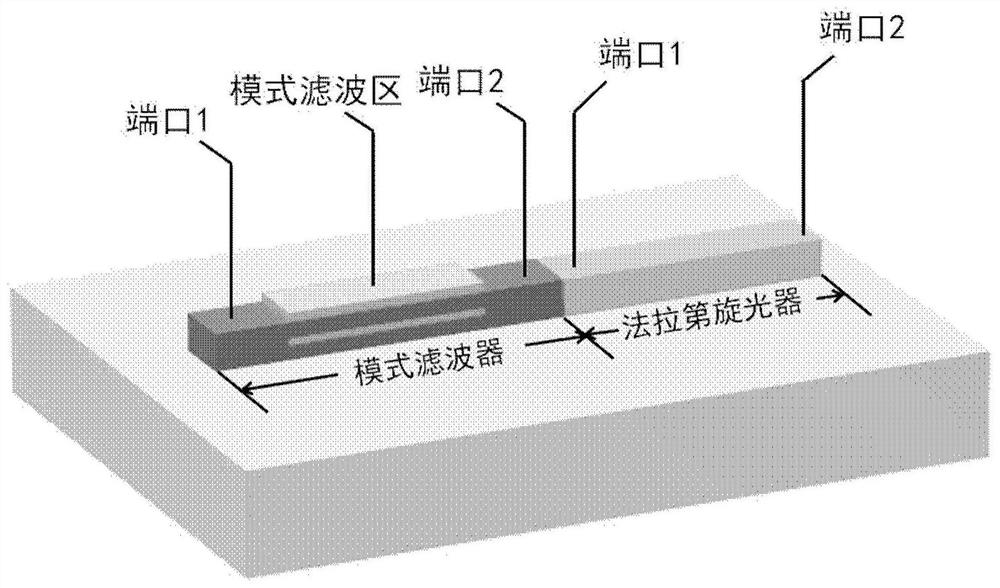

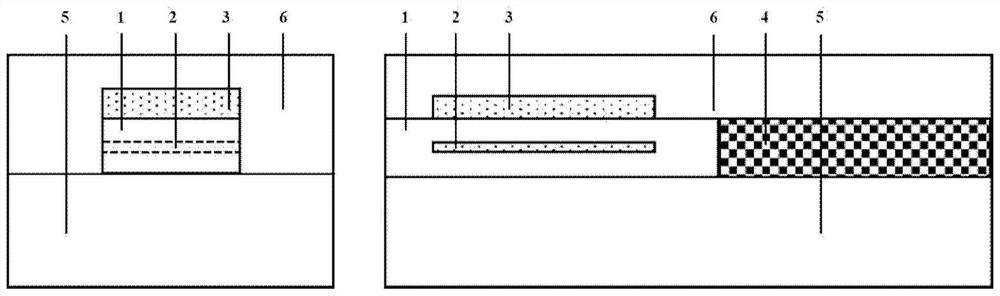

[0061] Such as figure 1 As shown, the present invention includes a mode filter and a Faraday rotator. The mode filter adopts a strip-shaped silicon waveguide structure embedded and covered with a transparent conductive oxide layer. The Faraday rotator adopts an iron garnet strip with a magneto-optical material doped with rare earth elements. The mode filter is divided into port 1 (ie the first port), the mode filter area, and port 2 (ie the second port) along the length direction; the Faraday rotator is divided into port 1 (ie the third port) along the length direction Port) and port 2 (ie the fourth port);

[0062] The input signal including the transverse electric field mode transmitted in the forward direction is input from port 1 of the mode filter. After entering the mode filter area, it is output from port 2 and enters port 1 of the Faraday rotator, which is implemented in the Faraday rotator. 45° polarization rotation is output from port 2; the reflected reverse transmissi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com