Electromagnetic shielding macromolecule composite material

A technology of polymer materials and composite materials, applied in the field of new electromagnetic shielding materials, can solve the problems of increased cost of electromagnetic shielding plastics or coatings, easy sedimentation of fillers, and difficult dispersion, etc., to achieve high electromagnetic shielding efficiency, large absorption loss, and low weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

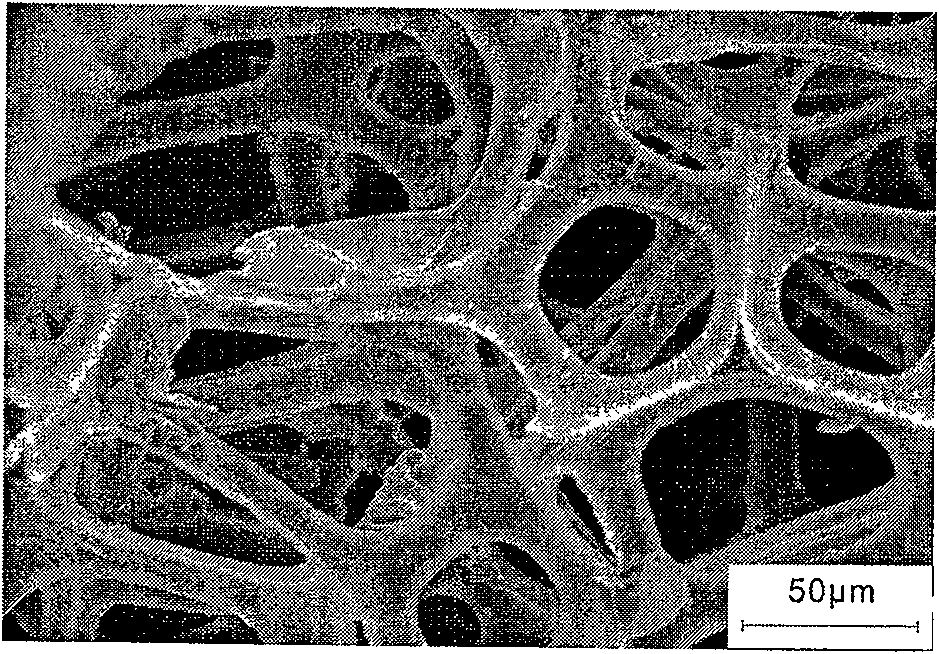

[0020] Nickel foam is used. The surface density of nickel foam is 320g / m2, the thickness is 1.6mm, and the pore diameter is 110ppi; the metal foam has a metallic luster in appearance, connected pores, a porosity of more than 95%, and a three-dimensional network structure. figure 1 It is a scanning electron micrograph of the surface morphology of nickel foam.

[0021] Using one-component acrylic resin + 6% ferrite, fully diluted, soak nickel foam, apply ultrasonic vibration to the outside, take it out after 1 minute, blow off the excess paint in the hole with high-pressure air, only leave a gap on the nickel skeleton Afterwards, according to China Aerospace Industry Corporation's aerospace industry industry standard "QJ2809-96 Test Method for Shielding Effectiveness of Planar Materials", the porous electromagnetic shielding sheet was tested for electromagnetic shielding effectiveness by point frequency method, and the frequency range was 100kKHz -1GHz, the material has an avera...

Embodiment 2

[0022] Embodiment 2 Molding method prepares foamed copper / ABS resin electromagnetic shielding plastic

[0023] The main raw materials required: copper foam is used as filler, the specification is 200×200×1.8, the surface density is 350g / m2, the pore diameter is 90PPI, and the thermoplastic resin ABS is selected as the matrix material.

[0024] Preparation process:

[0025] First mix ABS resin and pigment evenly, spread it on the bottom of the flat mold, then spread the resin-treated foamed copper with a certain strength, then add resin to fill the mold, and heat-press at a temperature of 300°C. The resulting product has a specification of 200×200×2.5.

[0026] The mechanical properties and electromagnetic shielding properties of the obtained electromagnetic shielding plastic were carried out.

[0027] In the electromagnetic shielding plastic, since the metal network of the nickel foam is not damaged, the copper foam is sandwiched in the middle of the ABS resin matrix materia...

Embodiment 3

[0028] Embodiment 3 injection method prepares foam metal nickel powder / PE resin electromagnetic shielding plastic

[0029] The main raw material needed: nickel foam, crush it into 50-500μm powder with a pulverizer, and use thermoplastic resin polyethylene (PE).

[0030] Preparation process:

[0031] 60wt% PE resin, 30wt% foam metal nickel powder treated with coupling agent, 5wt% pigment and 5% Fe 3 o 4 (Ferrite) powder is mixed evenly, passed through the injection machine, and injection molded at a temperature of 200°C.

[0032] Because the foam metal nickel powder has a porosity of more than 95% and a three-dimensional network structure, the pulverized foam metal nickel powder has a dendritic structure and is uniformly dispersed in the polyethylene resin (PE) matrix to form a conductive network. The low density and light weight of nickel powder has little effect on the density and mechanical properties of polyethylene resin (PE).

[0033]The electromagnetic shielding effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com