Foam metal-carbon nano tube composite material and preparation method thereof

A foam metal, carbon nanotube technology, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of poor spraying method, complicated instrument operation, limited application scope, etc., to broaden design ideas, conductivity performance Good, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

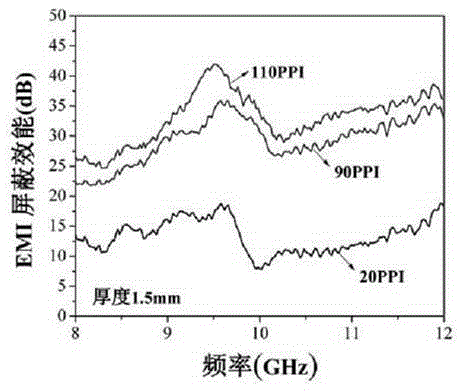

[0024] (1) Clean the foamed nickel substrate: immerse three foamed nickels with PPI of 20, 90, 110 and a thickness of 1.51 mm in a mixed solution of acetone and ethanol with a volume ratio of 1:1, ultrasonic cleaning for 30 minutes, and then in 6mol Soak in 1 / L HCl solution for 30 minutes to remove surface oxides, and finally wash with deionized water and dry;

[0025] (2) Modified carbon nanotubes: Weigh 45mg of multi-walled carbon nanotubes with a diameter of 20-30nm and 150mg of 60% dimethyldiallyl ammonium chloride aqueous solution, add 150ml of methanol to prepare carbon nanotubes with a concentration of 0.3mg / ml of electrolyte solution, sonicate for 3 hours at room temperature.

[0026] (3) Electrophoretic deposition: use the molybdenum electrode as the anode, the nickel foam cleaned in step 1 as the cathode, the distance between the parallel cathode and anode is 2cm, the size of the cathode foam nickel is 22.9mm*10.0mm, put it into the above mixed electrolyte , connec...

Embodiment 2

[0029] Select aperture to be 110PPI, thickness is respectively 0.5mm, 1.0mm, the nickel foam of 1.5mm is research object, prepares foam Ni-CNTs composite material, other is the same as embodiment 1, carbon nanotube film thickness is 1Mm. The specific experimental steps are as follows:

[0030] (1) Clean the foamed nickel substrate: Soak three kinds of foamed nickel with a PPI of 110 and a thickness of 0.5mm, 1.0mm, and 1.5mm in a mixed solution of acetone and ethanol with a volume ratio of 1:1, ultrasonic cleaning for 30 minutes, and then Soak in 6mol / L HCl solution for 30 minutes to remove surface oxides, and finally wash with deionized water and dry;

[0031] (2) Modified carbon nanotubes: Weigh 45mg of multi-walled carbon nanotubes with a diameter of 20~30nm and 150mg of 60% dimethyldiallylammonium chloride aqueous solution, add 150ml of methanol to prepare carbon nanotubes with a concentration of 0.3mg / ml of electrolyte solution, ultrasonic at room temperature for 3h.

...

Embodiment 3

[0035]The specification PPI of two groups of nickel foams is selected to be 20, and the thickness is 1.5mm. The concentration of carbon nanotubes in the electrolyte is changed to 0.1mg / ml and 0.6mg / ml respectively, the voltage is 120V, and the electrophoresis time is 60min. Others are the same as in Example 1. The experimental steps are as follows:

[0036] (1) Clean the foamed nickel substrate: soak the foamed nickel with a PPI of 20 and a thickness of 1.5 mm in a mixed solution of acetone and ethanol with a volume ratio of 1:1, ultrasonically clean it for 30 minutes, and then soak it in a 6mol / L HCl solution Remove surface oxide for 30 minutes, finally wash with deionized water and dry;

[0037] (2) Modified carbon nanotubes: Weigh 15mg of multi-walled carbon nanotubes with a diameter of 20-30nm and 50mg of 60% dimethyldiallyl ammonium chloride aqueous solution, add 150ml of methanol to prepare carbon nanotubes with a concentration of 0.1mg / ml of electrolyte solution; anot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com