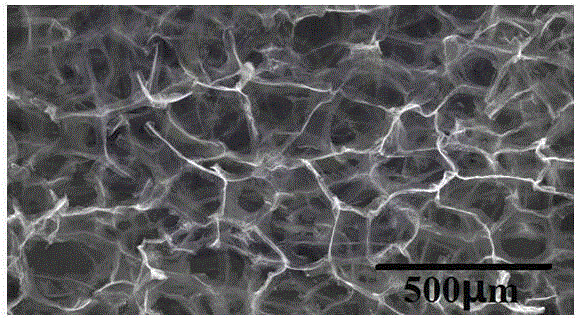

Foam metal-graphene composite material and preparation method thereof

A foam metal and composite material technology, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of high price and complicated instrument operation, and achieve the effects of low cost, good conductivity and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Cleaning the foamed nickel substrate: three kinds of foamed nickel with PPI of 20, 90, 110 and a thickness of 1.5 mm were immersed in a mixed solution of acetone and ethanol with a volume ratio of 1:1 and ultrasonically cleaned for 30 minutes. Soak in HCl solution for 30 minutes to remove surface oxides, and finally wash with deionized water and dry for later use;

[0024] (2) Prepare graphene: adopt improved hummer's method, add the vitriol oil of 50ml 98% in the 250ml beaker, oil bath is heated to 90 ℃, adds 10g K thereto 2 S 2 o 8 and 10g P 2 o 5 After dissolving, cool down to 80°C, add 12g of graphite powder to react for 4-5h, then cool to room temperature, add 2L of deionized water overnight, filter with suction, and dry at room temperature to obtain pre-oxidized graphite powder. Add 6g of pre-oxidized graphite powder to a beaker containing 230ml of concentrated sulfuric acid, stir in an ice bath for 30min, then gradually add 30g of KMnO 4 powder, heated t...

Embodiment 2

[0031] Select foamed nickel with a pore size of 110PPI and a thickness of 0.5mm, 1.0mm, and 1.5mm as the research object to prepare a foamed nickel-graphene composite material. The specific experimental steps are as follows:

[0032] (1) Clean the foamed nickel substrate: PPI is 110, and three kinds of foamed nickels with thicknesses of 0.5mm, 1.0mm, and 1.5mm are immersed in a mixed solution of acetone and ethanol with a volume ratio of 1:1 and ultrasonically cleaned for 30 minutes, and then cleaned in 6mol Soak in 1 / L HCl solution for 30 minutes to remove surface oxides, and finally wash with deionized water and dry for later use;

[0033] (2) prepare graphene with embodiment 1;

[0034] (3) Modified graphene: Weigh 45mg of graphene and 45mg of Mg(NO 3 ) 2 *6H 2 O electrolyte is added in isopropanol, and the concentration of preparation graphene is the electrophoretic liquid of 0.3mg / ml, and ultrasonic 3h is obtained at room temperature, obtains electrophoretic liquid;

...

Embodiment 3

[0037] Replace the nickel foam with PPI20, the thickness is 1.5mm, the experimental steps are as follows:

[0038] (1) Clean the foamed nickel substrate: PPI is 20, and the foamed nickel with a thickness of 1.5mm is immersed in a mixed solution of acetone and ethanol with a volume ratio of 1:1 and ultrasonically cleaned for 30 minutes, and then soaked in 6mol / L HCl solution for 30 minutes To remove surface oxides, finally wash with deionized water and dry for later use;

[0039] (2) prepare graphene with embodiment 1;

[0040] (3) Modified graphene: Weigh 15 mg of graphene and 30 mg of Mg(NO 3 ) 2 *6H 2 O electrolyte is added in isopropanol, and the concentration of preparation graphene is the electrophoresis fluid of 0.1mg / ml, ultrasonic 3h under room temperature, obtains electrophoresis fluid;

[0041] (4) Electrophoretic deposition: The above-mentioned cleaned nickel foam is used as the cathode, and the molybdenum electrode is used as the anode. Put it into the electrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com