Patents

Literature

495 results about "Vitriol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, vitriol is an archaic name for a sulfate, and vitriol names have the obvious meaning: for example, vitriol of lead is lead sulfate, and so on. The word vitriol comes from the Latin word "vitriolum" for "glassy", as crystals of several metallic sulfates resemble pieces of colored glass.

Compound decarburization solution for recovering carbon dioxide in gas mixture

ActiveCN101091864APromote absorptionIncrease desorptionProductsCarbon compoundsChemical industryAbsorption capacity

The invention belongs to the gas separation technology area, it relates to a decarbonization solution which recycles or removes the carbon dioxide gas from the mixed gas which contains carbon dioxide, said invention specially relates to an ethoxyl ethylenediamine decarbonization solution. Its characteristic lies in: the invention has designed a new compound decarbonization solution which is composed of the main absorption component, the aid absorption component, the activation component, the corrosion inhibitor, the oxidation inhibitor and the water. Among, the main absorption component is AEE, the aid absorption component is AMP, MDEA and TEA, the activation component is MEA, DEA and PZ, the corrosion inhibitor is vitriol sour sodium, the oxidation inhibitor is the sodium sulfite and the cupric acetate. The effect and the profit of the invention are that it can be used in recycling many kinds of chemical industry reaction exhaust, the carbon dioxide of the combustion flue gas and the mixed gas, may also used in removing the carbon dioxide of town gas, the natural gas and so on, the merit of the decarbonization fluid is that the absorption capacity is big, purification is high, desorption rate is big, regeneration energy consumption is low.

Owner:DALIAN UNIV OF TECH

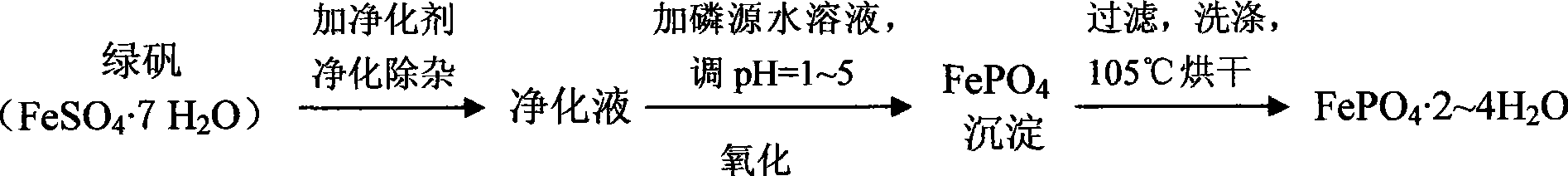

Method for preparing high purity ferric phosphate using ferrous sulfate as by-product of white titanium pigment

InactiveCN101531355AEasy to oxidizeSolve the use problemPhosphorus compoundsLithium iron phosphateGlaze

The invention relates to a preparation method of pure ferric phosphate, characterized in that: iron vitriol, phosphorus source as by-product of white titanium pigment are used as reactant and purificant and oxidant are added into the reactant and the reaction temperature is controlled at 25-100 DEG C and the reaction time is 0.5-10 hours, thus white ferric phosphate powder (FePO[4]2-4H[2]O) with 2-4 crystal water is obtained. The technological process has features of simple process, low production cost, high product purity, increased added value of ferrous sulfate as by-product of white titanium pigment and the product can be used as ceramic metal glaze-color glaze material and raw material for producing lithium iron phosphate as lithium ionization cell anode material.

Owner:GUANGXI UNIV +1

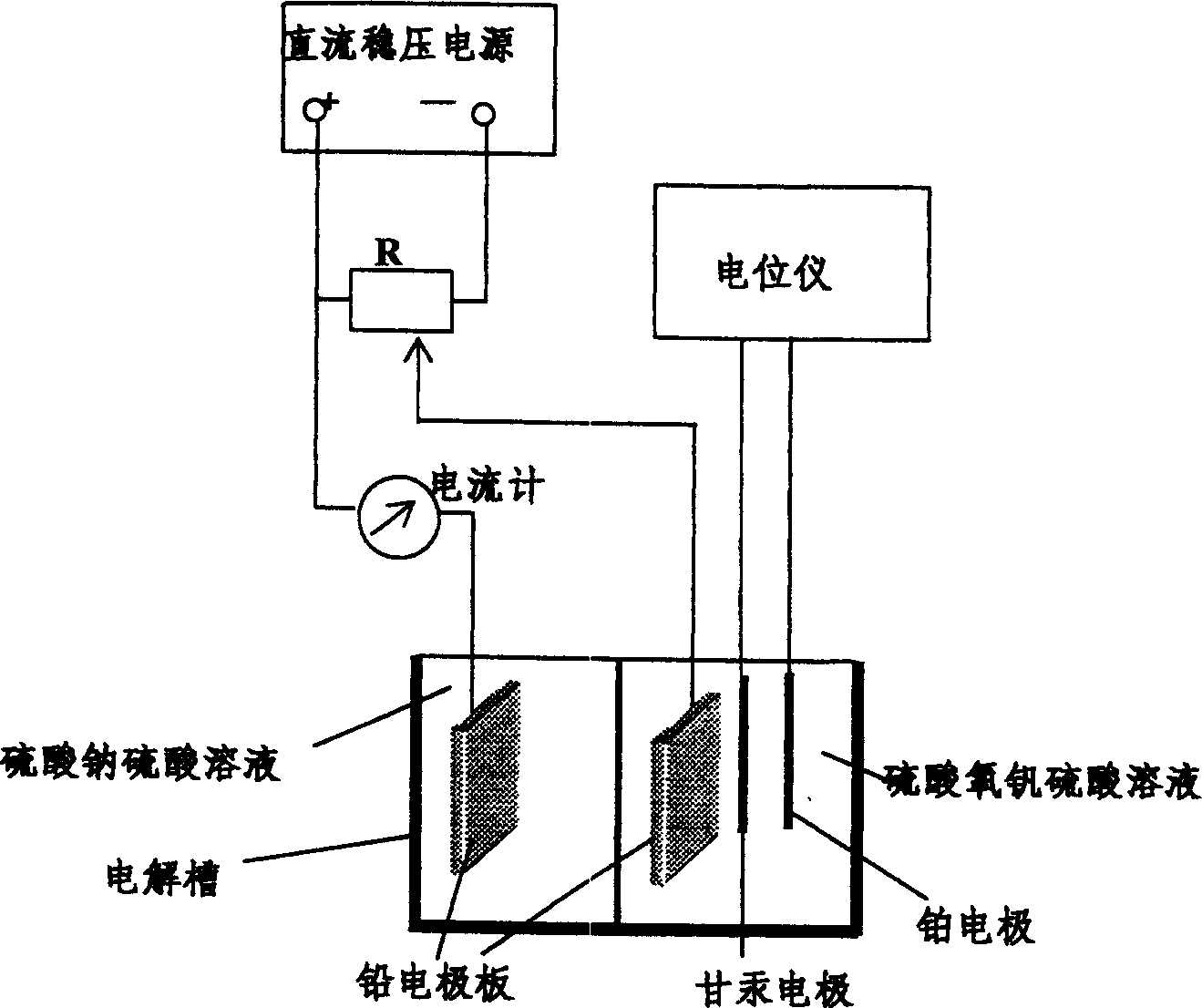

Process for electrolyzing preparing electrolyte of full vanadium ion flow battery

InactiveCN1598063ASimplify the assembly processExtended service lifeElectrolysis componentsLead-acid accumulatorsLiquid cellVanadyl sulfate

The invention relates to the field of the cell manufacturing and especially relates to a method of preparing the electrolyte of the vanadium ion liquid cell, making the 1:1 thin vitriol from the thick vitriol, adding the trioxid bi-vanadium and then the five-trioxid bi-vanadium to get the vitriol oxide vanadium; adding the Na2SO4, emulsification agent OP and other additive, placing the vitriol oxide vanadium at the cathode of the electrolytic cell and the same ion intension at the anticathode and electrolyse, getting the vitriol electrolyte used for vitriol batteries which includes half quadrivalence vanadium and half tervalent vanadium. The invention simplyfy the equipment of vitriol batteries and chemical procedure, enhance the work efficiency, extend the use time of the functional materials of vitriol batteries, such as the electrode and the dissepiment, needn't change the electrolyte of the anode, avoid wasting raw material, avail the producing by large scale.

Owner:攀枝花钢铁有限责任公司钢铁研究院 +1

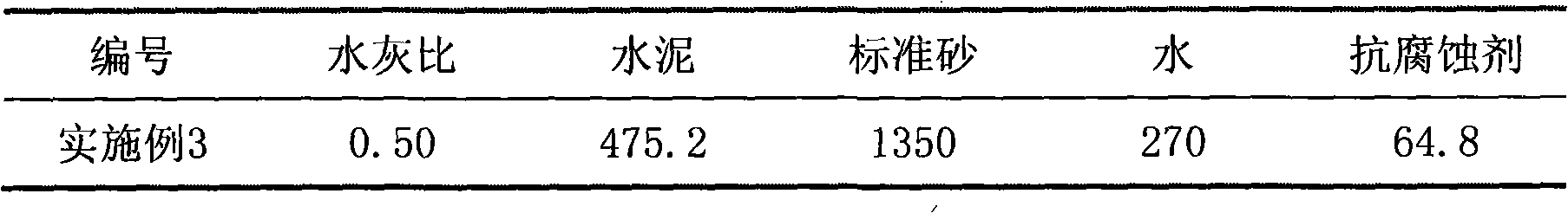

Concrete corrosion resistant additive for sea construction

InactiveCN101337787AAchieve high performanceImprove corrosion resistanceSolid waste managementCrack resistanceHazardous substance

The invention relates to a concrete corrosion proof additive for maritime work. The concrete corrosion proof additive is characterized in that the concrete corrosion-proof additive is prepared with the following components by weight: 40 to 80 percent of a sulfoaluminate micro-expanding agent, 0.1 to 2.0 percent of synthetic fiber, 1 to 10 percent of anticorrosive composition, 10 to 40 percent of fleur, and 0 to 12 percent of a water reducer. In the invention, the sulfoaluminate micro-expanding agent, the synthetic fiber, the anticorrosive composition, the fleur, the water reducer and so on are matched and compounded properly, thus forming the mutual superimposed effect. In this way, the crack resistance and the impermeability of concrete can be significantly improved; and chloride ions, vitriol and other hazardous substance can be effectively prevented from entering the concrete, thus preventing seawater and hazardous substance contained in seawater from eroding the concrete, protecting steel bars from being eroded, and improving the service life of concrete structure in maritime work.

Owner:南京派尼尔科技实业有限公司

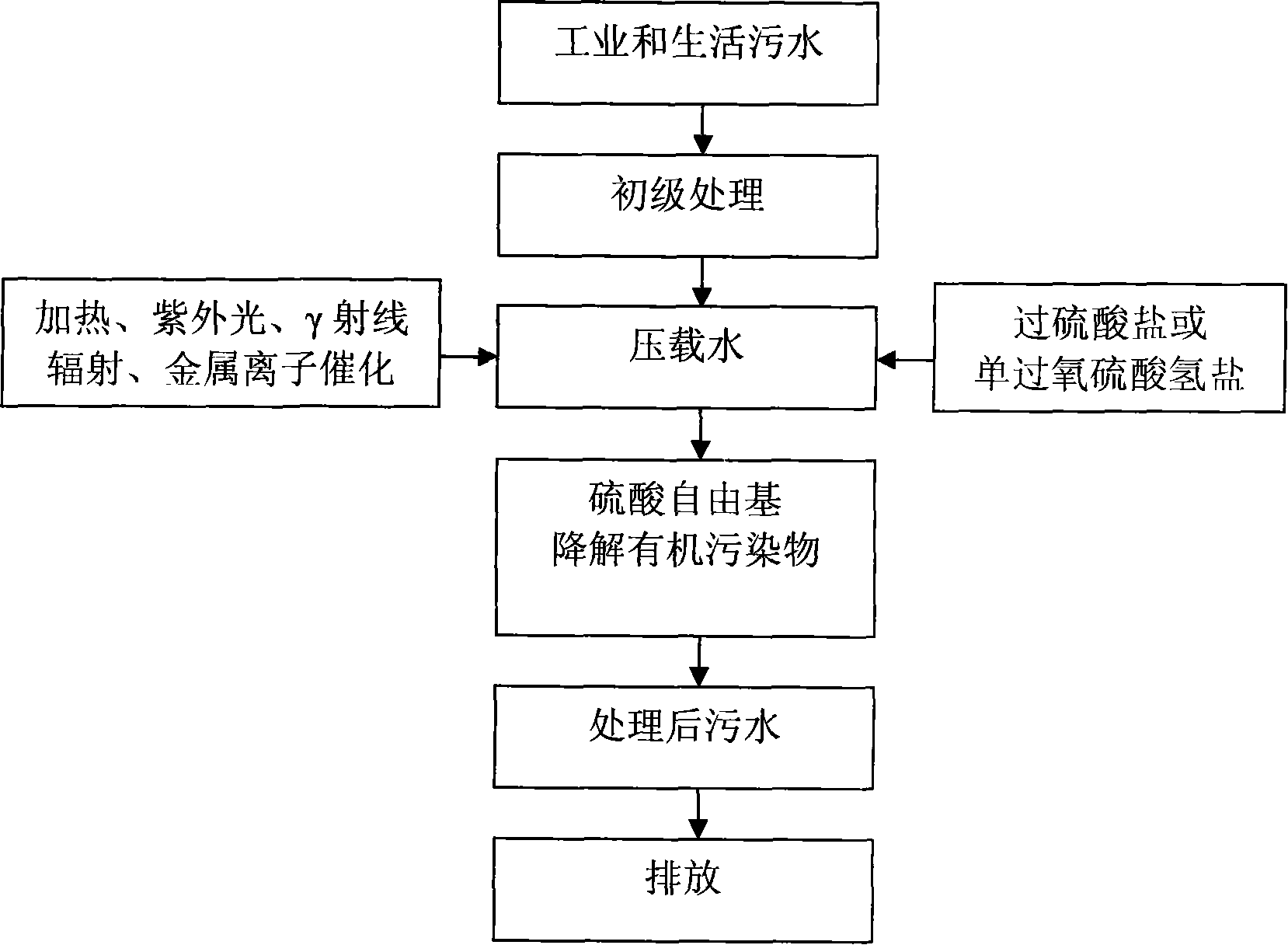

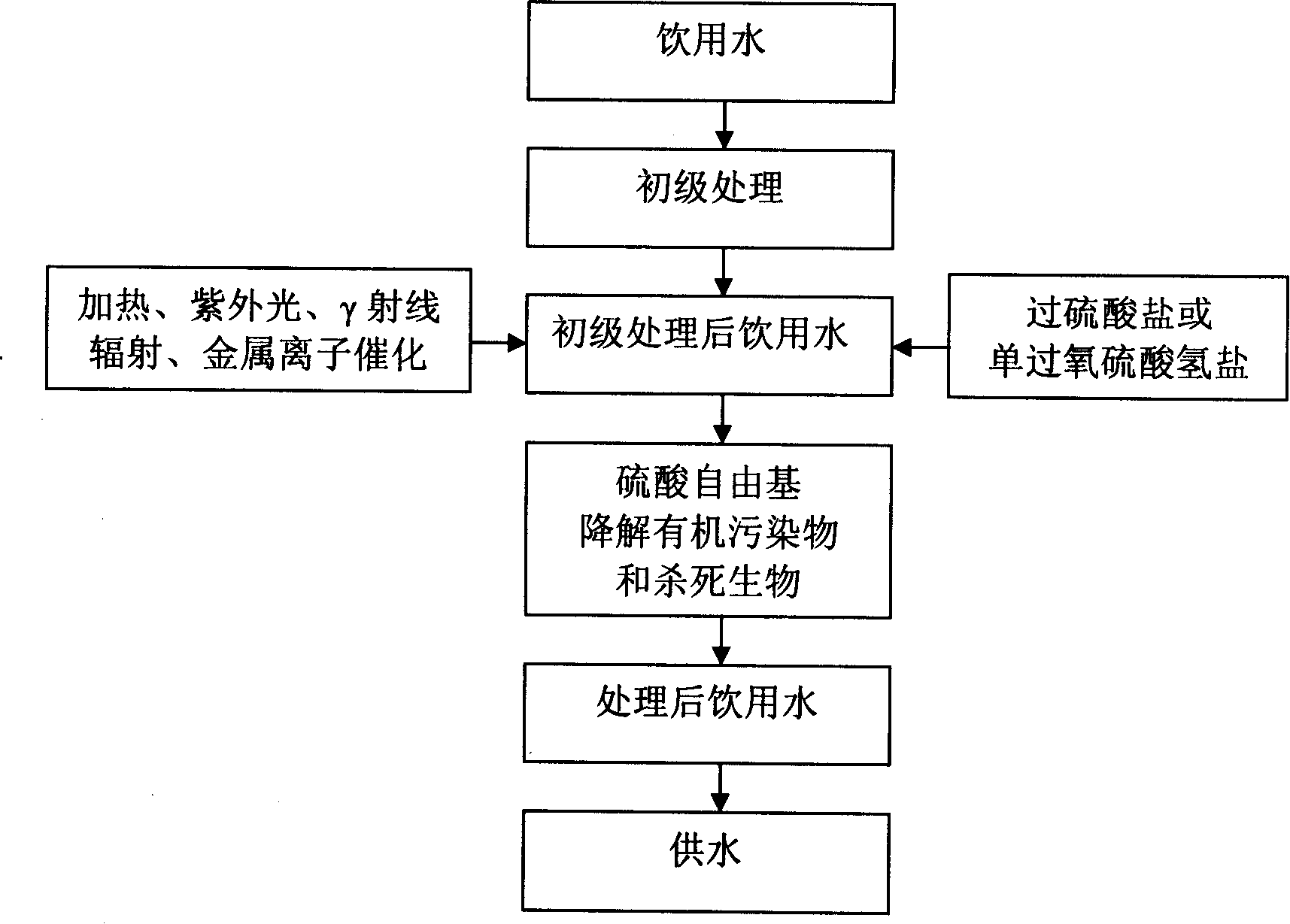

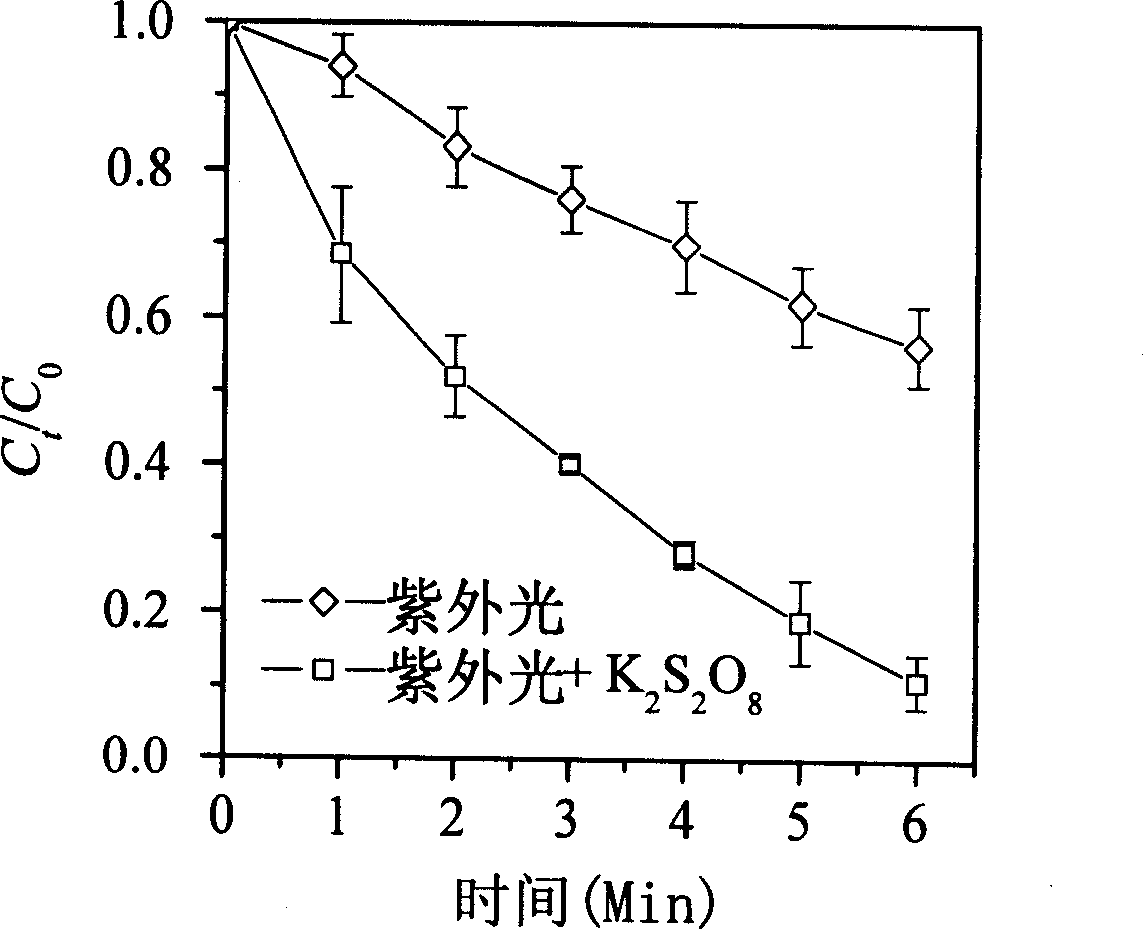

Method for processing sulphuric acid free radical oxidized water

InactiveCN101172691ANo secondary pollutionImprove processing efficiencyWater/sewage treatment by irradiationWater/sewage treatment by oxidationDecompositionFenton reagent

Owner:DALIAN MARITIME UNIVERSITY

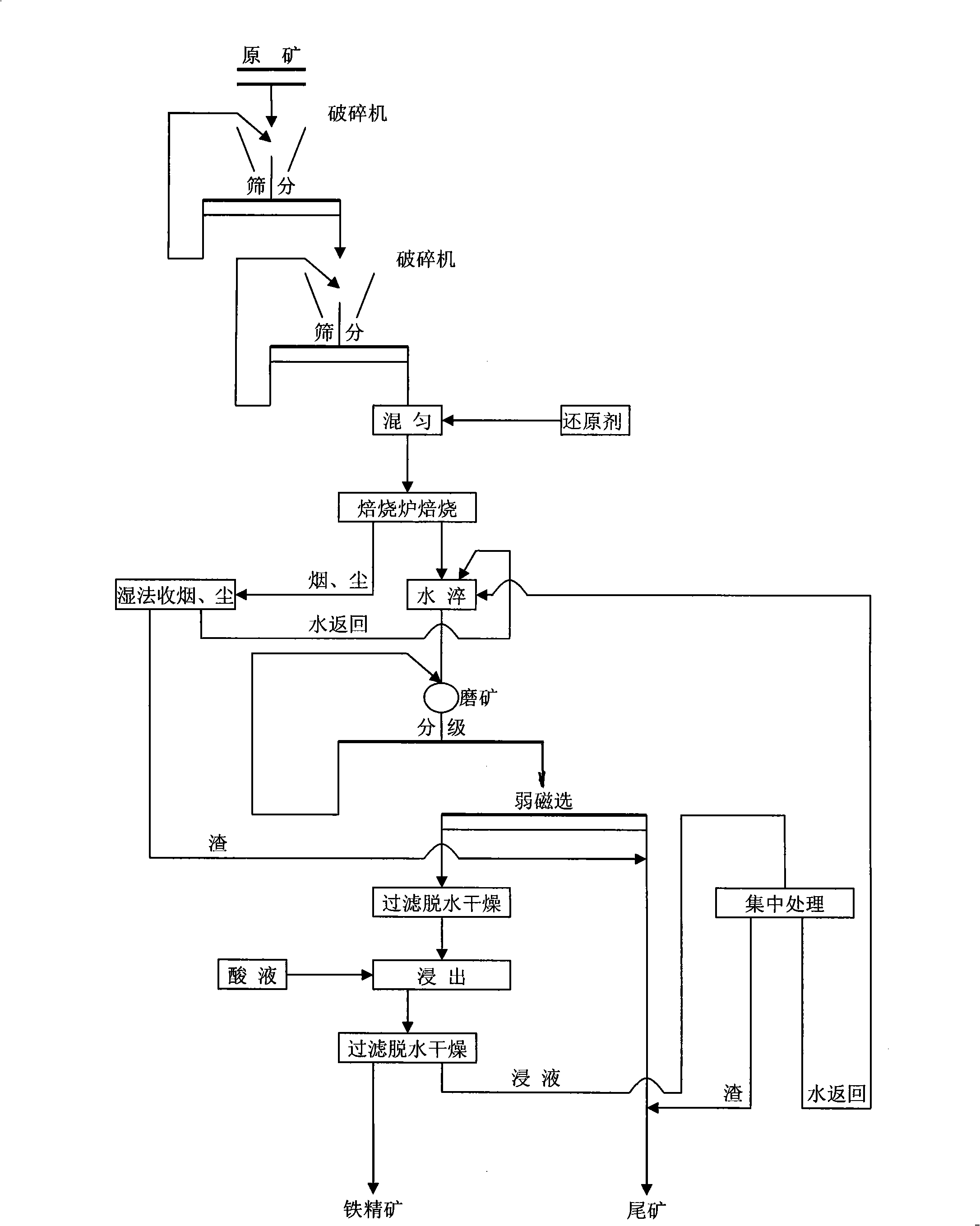

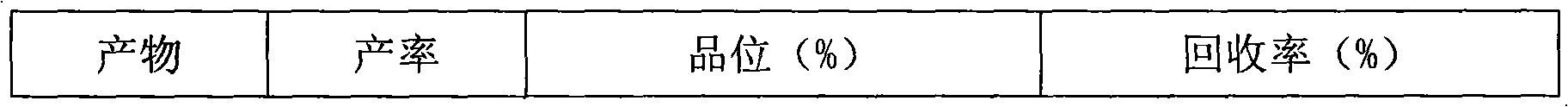

Method for reducing phosphorus in high phosphorus haematite or hematite and limonite ore by magnetization roasting-leaching method

InactiveCN101338361AReduce phosphorus contentProcess efficiency improvementMagnetic separationIronstoneMagnetization

The invention relates to a high phosphorus hematite-hematite-limonite magnetic roasting-extraction phosphorous reduction method, in particular applicable for an extraction phosphorous reduction method for the iron ores which mainly include the hematite-hematite and the limonite and accompany with magnetite, pyrrhotite, iron pyrites, etc. The method of the invention adopts magnetic roasting-wet extraction to reduce phosphorous; after carrying out modifying on high phosphorus iron ore, muriatic acid or vitriol is selected to carry out extraction phosphorous reduction on the iron concentrate obtained by a weak electromagnetic separator which not only can obtain the iron concentrate with an iron grade to be larger than 56 percent; simultaneously the content of the phosphorous in the iron concentrate is lower than 0.30 percent.

Owner:昆明晶石矿冶有限公司

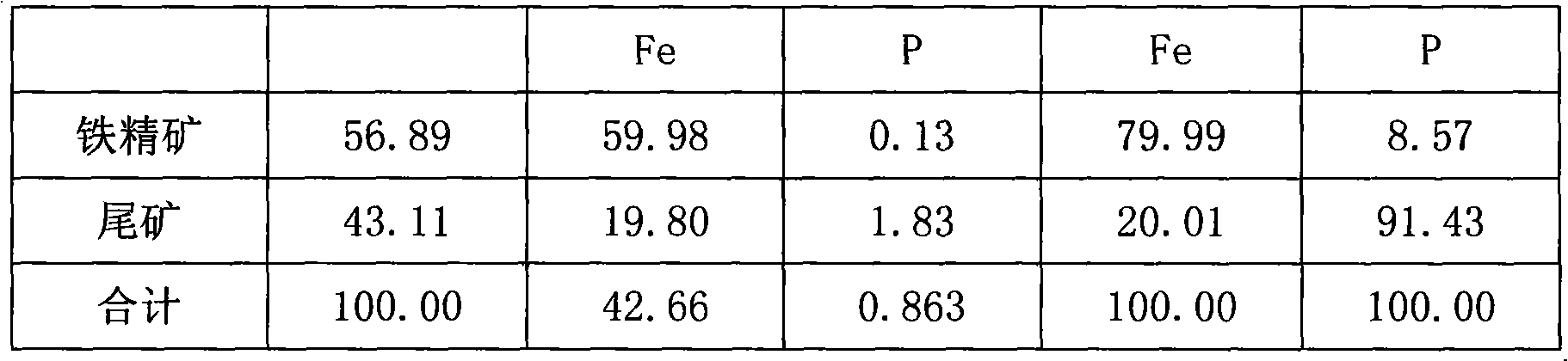

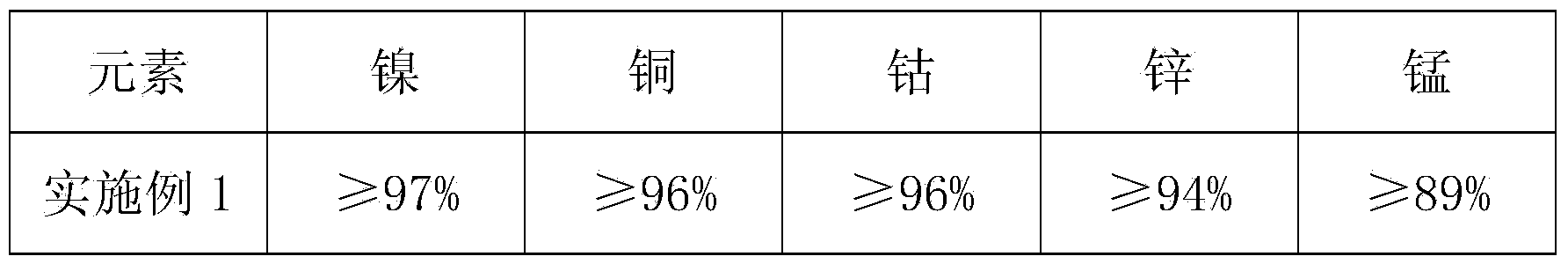

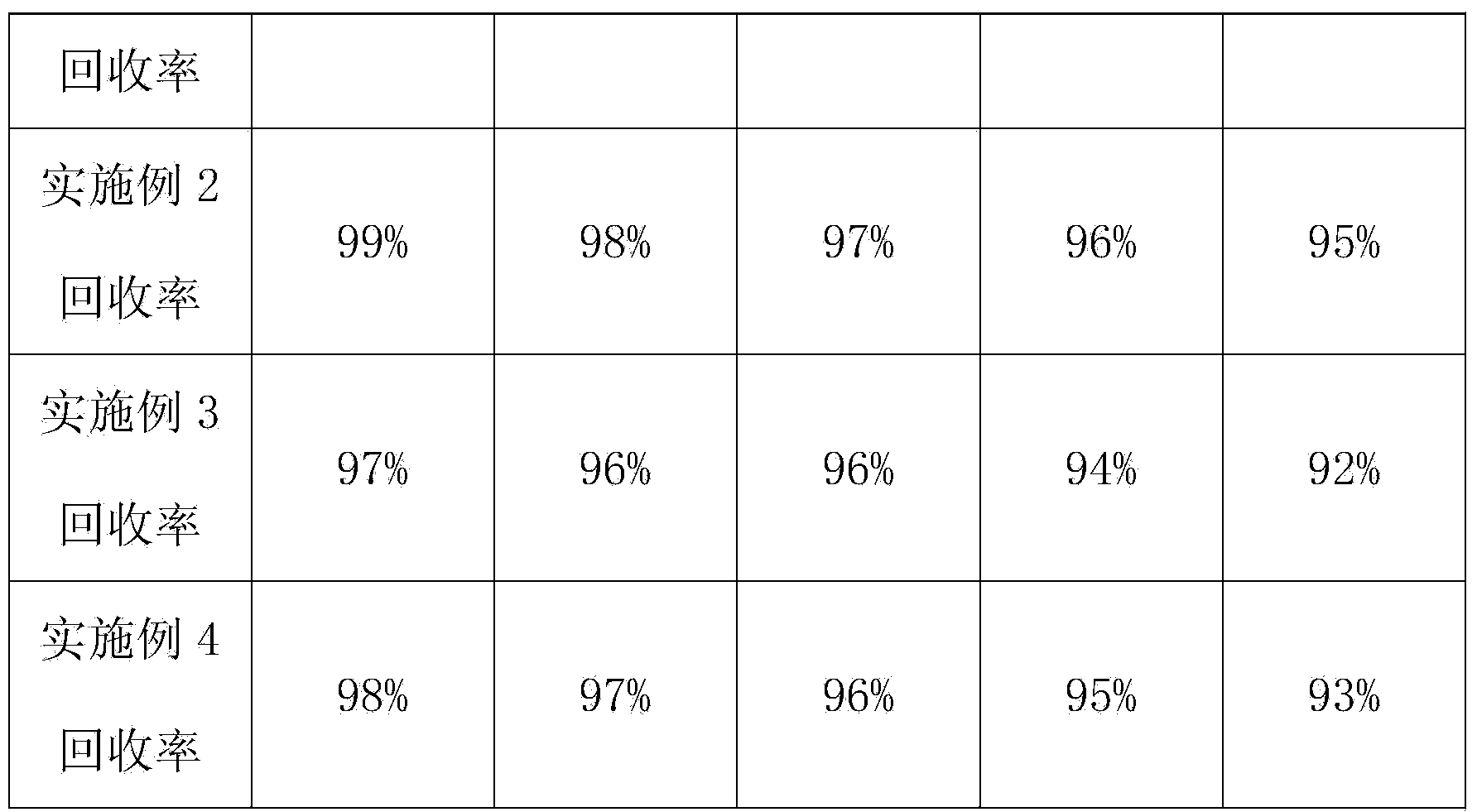

Separating and recycling method of nickel, cobalt, copper manganese and zinc in electroplating sludge

The invention provides a separating and recycling method of nickel, cobalt, copper manganese and zinc in electroplating sludge. The method comprises the steps that acid leaching is performed on the electroplating sludge to obtain leaching agents for fractional extraction, organic phases and nickel-rich raffinate are obtained, four steps of reverse extraction are performed on the organic phases by sequentially adapting hydrochloric acid, vitriol, the vitriol and the hydrochloric acid, and four kinds of corresponding strip liquor are achieved; then follow-up recycle is performed on the nickel-rich raffinate and the four kinds of strip liquor, and separation and recycle of the nickel, the cobalt, the copper manganese and the zinc are completed. According to the method, the complete extraction mode is adopted, the nickel, the cobal, calcium, magnesium, the copper, manganese and the zinc are sequentially extracted step by step and then recycled respectively, a technology procedure is short, production efficiency is high, the equipment investment is small, operation cost is low, the environment is protected, recycling of the nonferrous metal is achieved, and good social benefits and economical benefits are obtained.

Owner:JIANGXI GUANGDE ENVIRONMENTAL PROTECTION TECH CO LTD

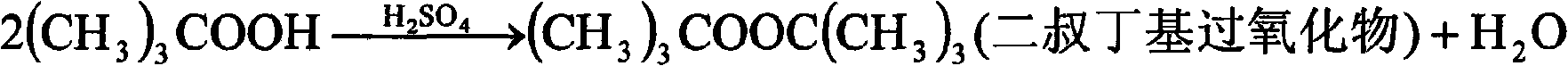

Preparation of tert-butyl hydrogen peroxide and di-tert-butyl peroxide

ActiveCN101298429AMild reaction conditionsHigh yieldOrganic chemistryDi-tert-butyl peroxideOil phase

The invention discloses a preparation method of tert-butyl hydroperoxide and di-t-butyl peroxide which includes the following steps: after mixing vitriol, oxyful and phosphotungstic acid with certain concentration, adding tertiary butyl alcohol into a mixed liquor or adding the mixed liquor into the tertiary butyl alcohol; reacting for 0.5 to 5 hours under 20 to 60 DEG C; obtaining an oil phase after carrying out liquid separation on the crude product of the reaction; obtaining the tert-butyl hydroperoxide and di-t-butyl peroxide products by carrying out decompressing and rectifying on the oil phase; the method has the advantages of simple and convenient operation, low manufacture cost, safety, high efficiency and high yield; in addition, the method of the invention can adjust the relative content of the two reaction products by changing the reaction conditions. The reaction products of tert-butyl hydroperoxide and di-t-butyl peroxide are separated by decompressing and rectifying, thus avoiding the working procedures of acid cleaning and caustic wash in the traditional technique, solving the defect of overlarge waste water amount in the traditional technique, being beneficial to protecting the environment, reducing the manufacture cost and being capable of greatly increasing the enterprise benefits.

Owner:ZHEJIANG JINKE CHEM

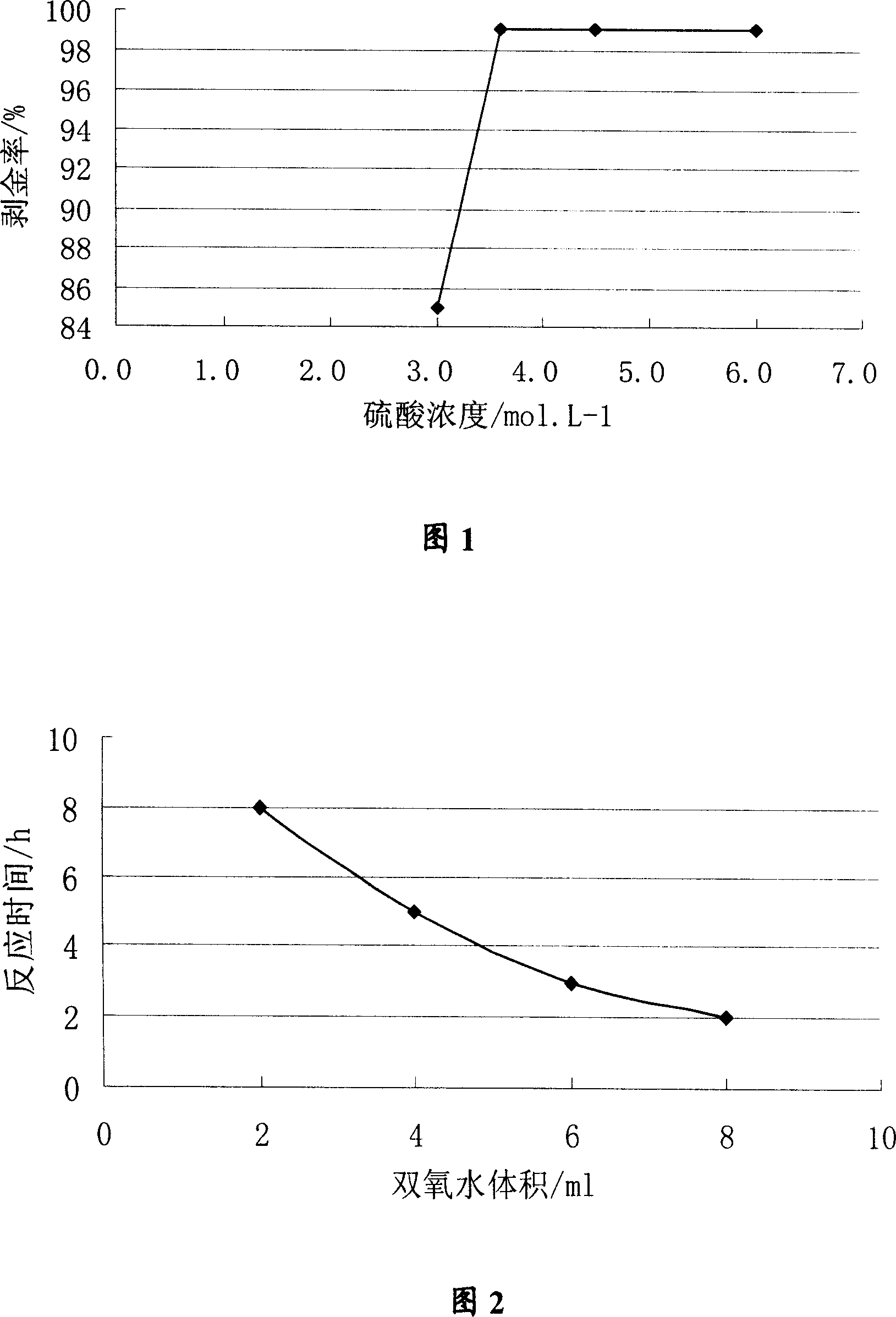

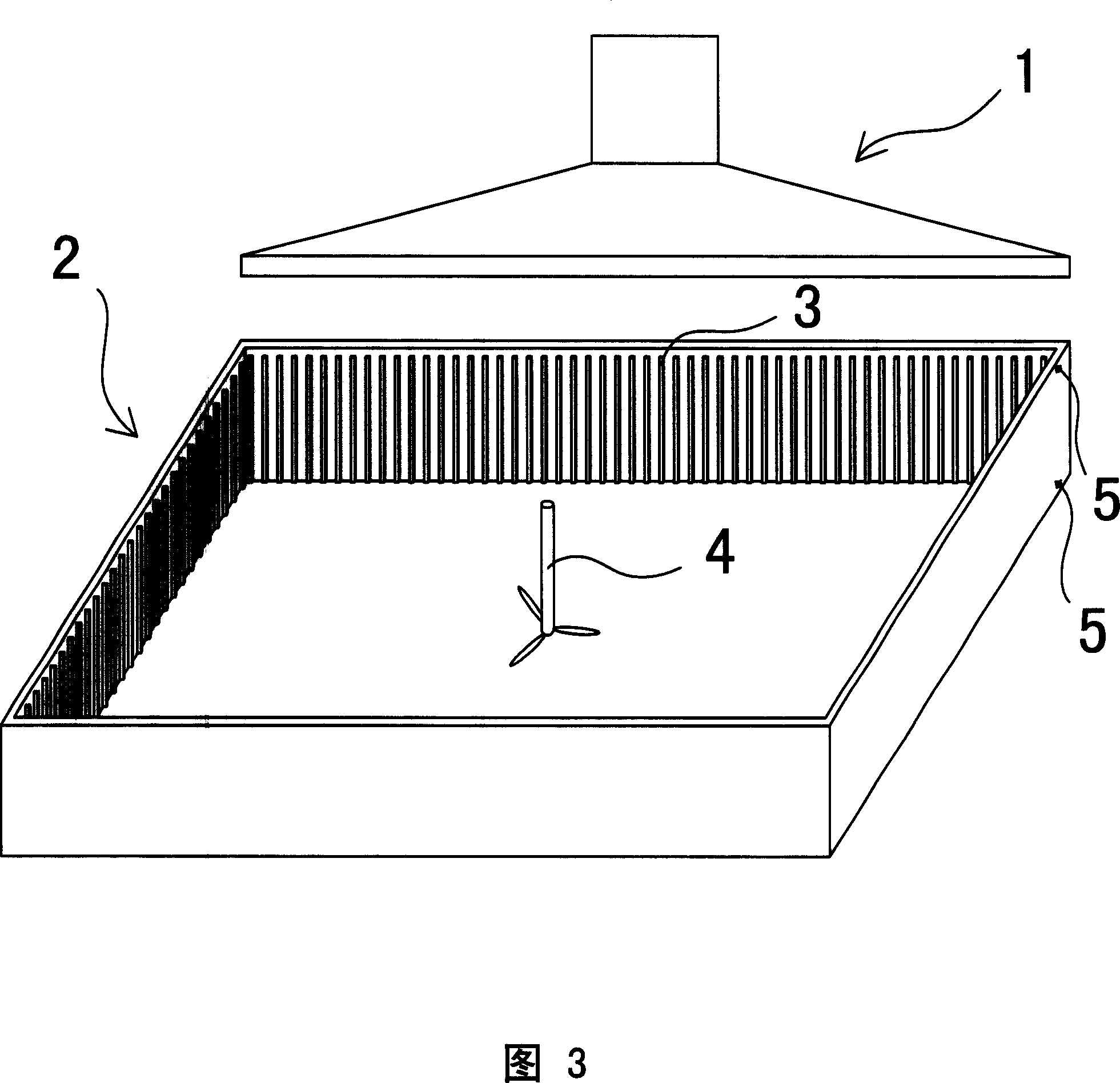

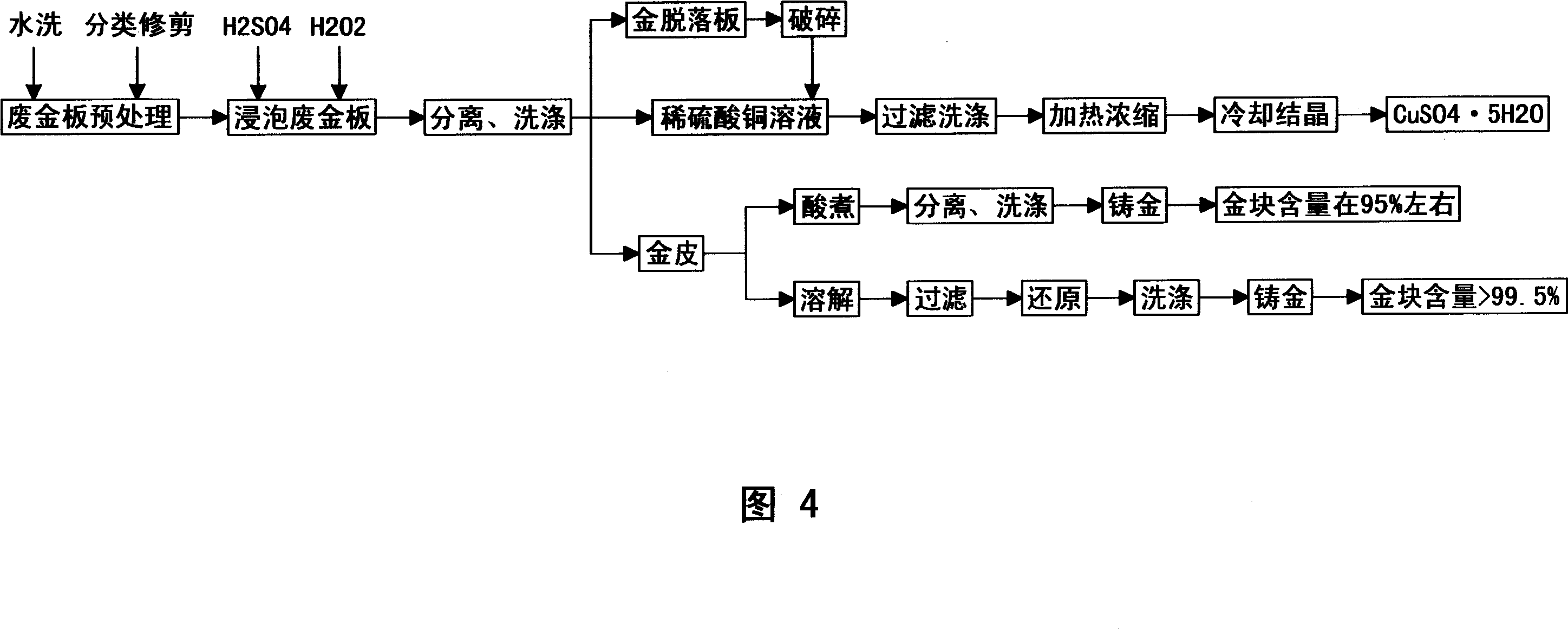

Method for recovering gold and copper from gold-plated printed circuit board waste material

InactiveCN101024864ASuitable for industrial productionGood effectProcess efficiency improvementSocial benefitsTime aspect

The invention is a method for recovering Au and Cu from Au-plated PCB waste, adopting oxydol and vitriol as reacting reagent to recover Au and Cu from the Au-plated PCB waste. And it researches the effect of concentration and utilization of vitriol, oxydol utilization, reacting conditions, and reacting time on the results. And the experimental result indicates that both overhigh and overlow acidity are detrimental to the Au and Cu recovery. Considering from the cost and time aspects, it advances the optimum concentration and utilization of vitriol. And the Au peeling ratio can be 99% and the Cu recovery rate can be 99%; after purified, the obtained Au has purity up to 99%, and the obtained bluestone can crystallize to obtain bluestone products. And the used reagent is nontoxic, cheap and easy to obtain; no harmful matters are generated in the experiment course; and the invention has better economic and social benefits and wide development future.

Owner:苏州天地环境科技有限公司

Silicon waste-slice surface metal removal and noblemetal silver-platinum-gold recovery method

InactiveCN1851016AEfficient removalEasy to recycleProcess efficiency improvementCleaning using liquidsRecovery methodMetal impurities

The invention discloses the method of wiping off the exterior metal of the silicon abandoned piece and reclaiming the noble metal platinum. The semiconductor parts of an apparatus and the semiconductor integrate circuit abandoned silicon piece are dipped in the hydrochloric acid or the dilute vitriol to wipe off the metal alive than the hydrogen, the nitric acid is used to melt the cooper or the silver on the silicon piece, the combination of thick hydrochloric acid and the thick nitric acid is used to melt the gold and the platinum on the surface of the silicon piece, then the combination of the hydrofluoric acid and the nitric acid is used to melt the metal silicon material on the surface of the silicon piece, the material silicon piece is gained with the cleaning, the drying or the setting off. The metal alive than the hydrogen is added in the said silver nitrate solution to gain the silver by the permutation, the aqua regia containing the gold and the platinum is heated or is added the alkali to get rid of the excessive hydrochloric acid and the nitric acid, the copper is added in the residual solution to gain the gold or the platinum by the permutation. The invention can wipe off the metal impurity and the metal silicon material on the surface of the abandoned silicon piece effectively, the disposed silicon piece can be used for the material of the sun energy silicon single crystal, the solar cell silicon piece can be gained by the more process, the noble metal is reclaimed, so it is useful for circle utilize of the resource.

Owner:浙江东源电子有限公司

Production of ethanol from agronomic crop fibre castoff

The invention belongs to a method for preparing ethyl hydrate by improved agronomic crop fabric wastes which is more economy for preparing ethyl hydrate by integrated utilization. The improved method comprises acid and caustic pretreating the agronomic crop wastes, color removing and concentrating crystal the xylose, enzyme treatmenting the ligno-cellulose, alcohol(ic) fermentation and rectification the hydrolytic decomposition sugar. The chemical pretreatment process comprises using 0.1-10alcaine, vitriol oil, phosphoric acid, volatility organic acid and mixture of the above acid, and 1-5Óalcarea lime, ammonia spirit and mixture of the above alkali in order to carry out in moment. The temperature of acid pretreatment is from normal temperature to 120 DEG C, and time is 1-8 hours. The pretreatment final liquor is used for color removing, concentrating and crystallization. The pretreatment final slag is hydrolyzed by cellulase and cellase at the temperature of 40 to 60 DEG C for 12-14 hours. The fermentation time of prehydrolysis or prehydrolysis while fermentation are 48 hours or so.

Owner:徐佳珊 +3

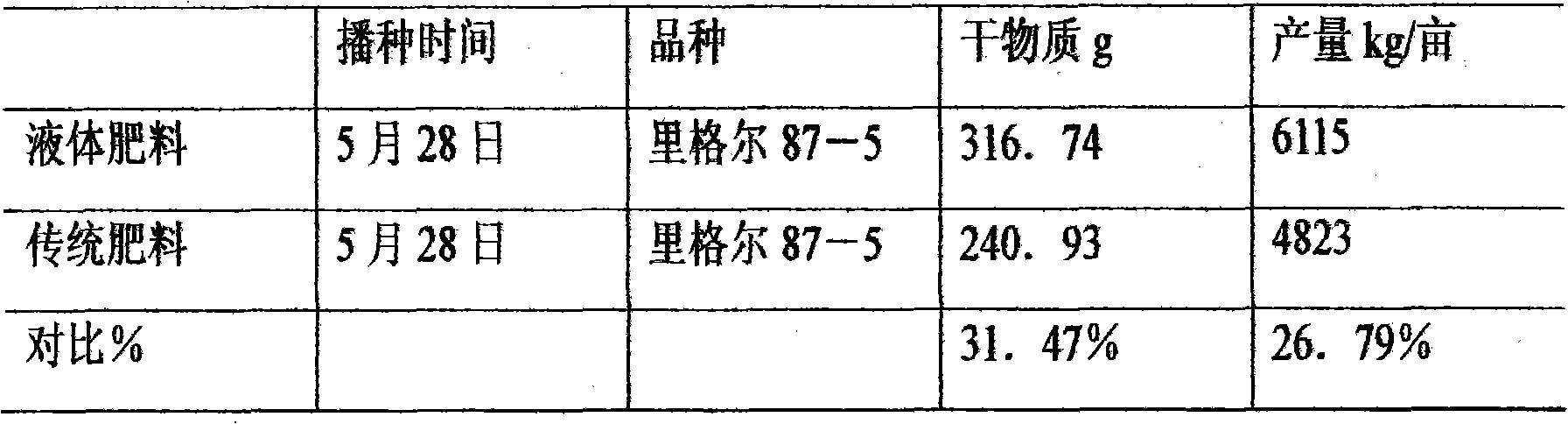

Clear liquid complex fertilizer special for high concentration drip irrigation and method of preparing the same

ActiveCN101318858ALower pHImprove utilizationOrganic fertilisersUrea compound fertilisersHigh concentrationPhosphoric acid

The invention relates to a high-concentration clear liquid compound fertilizer special for drop irrigation and a production method thereof. The fertilizer is prepared by dissolving urea, liquid phosphoric acid and potassium chloride, green vitriol, zinc vitriol, boric acid and fulvic acid in water with different temperatures in two steps and then mixing the compositions. The liquid compound fertilizer has the advantages that: the liquid compound fertilizer has good physical characteristics, can not deposit for long-term storage, has full nutrients to fully supplement various elements required by crops, can accelerate the growth of a crop root system and prevent precipitation reaction from blocking drop holes, in particular, the liquid compound fertilizer can obviously activate inorganic phosphorus pool of soil and reduce pH value of limy soil so as to greatly improve utilization efficiency of nitrogen and phosphorus nutrient resources. The clear liquid compound fertilizer can be separately applied for basal application and dressing, also can be used as a foliar fertilizer after diluted, and also can be mixed with other fertilizers for application, in particular has wide application respect in drop irrigation areas with the limy soil.

Owner:沃达农业科技股份有限公司

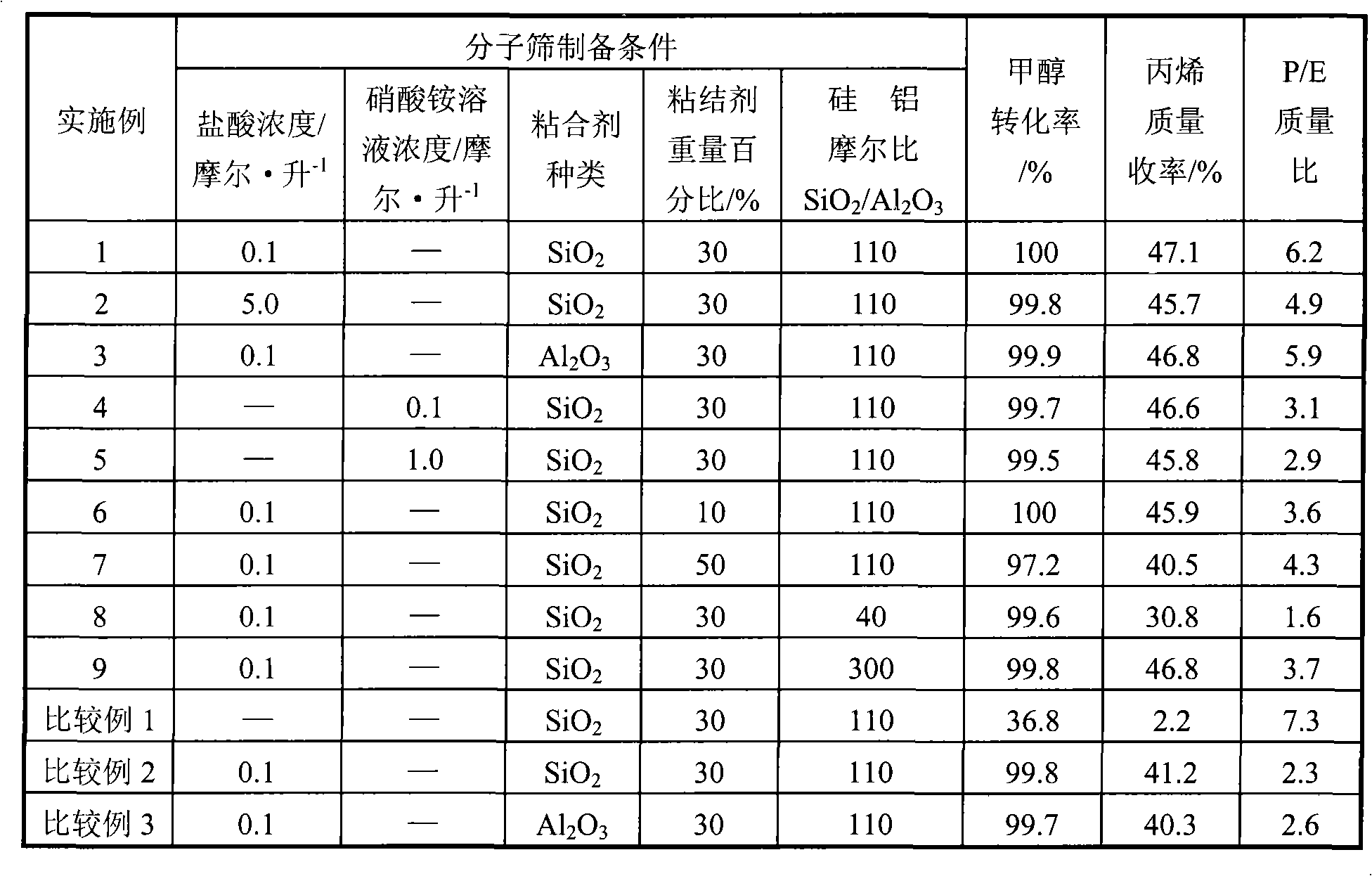

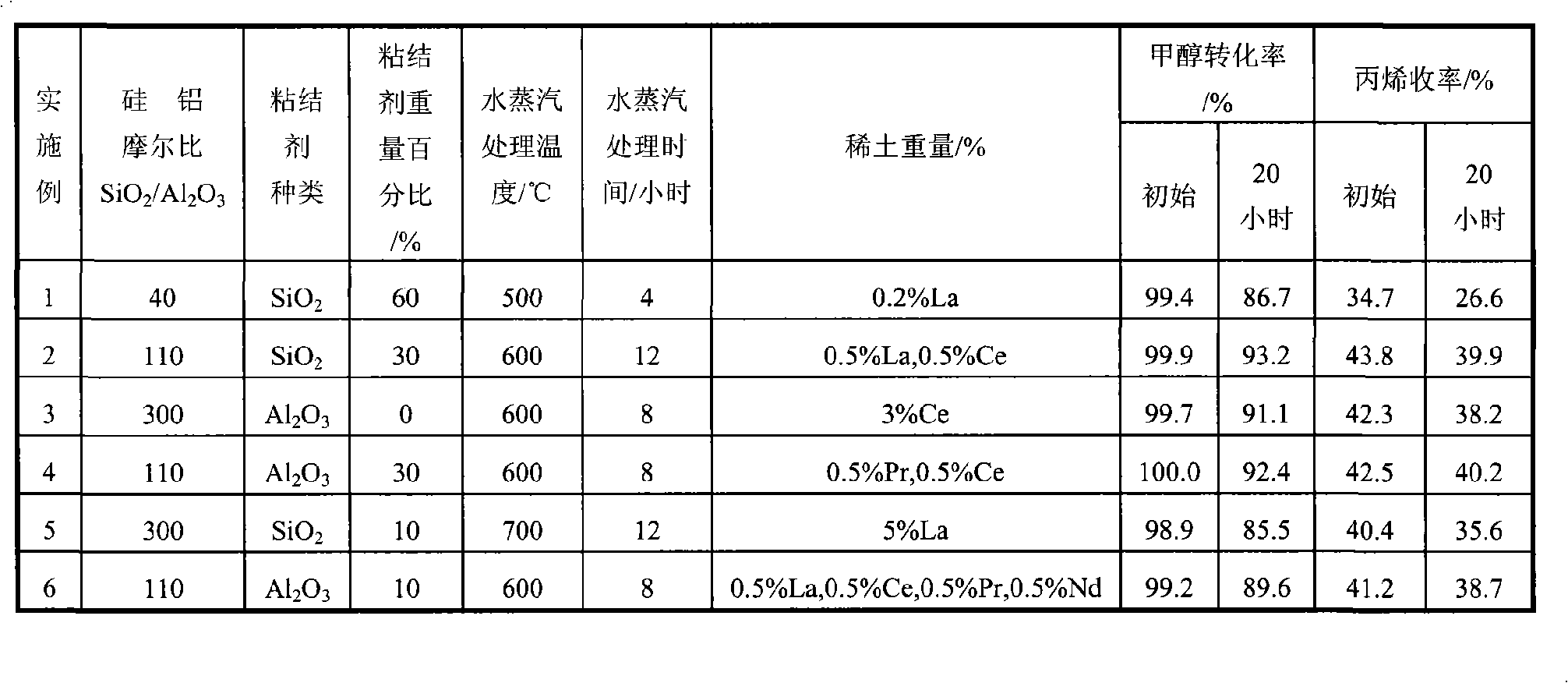

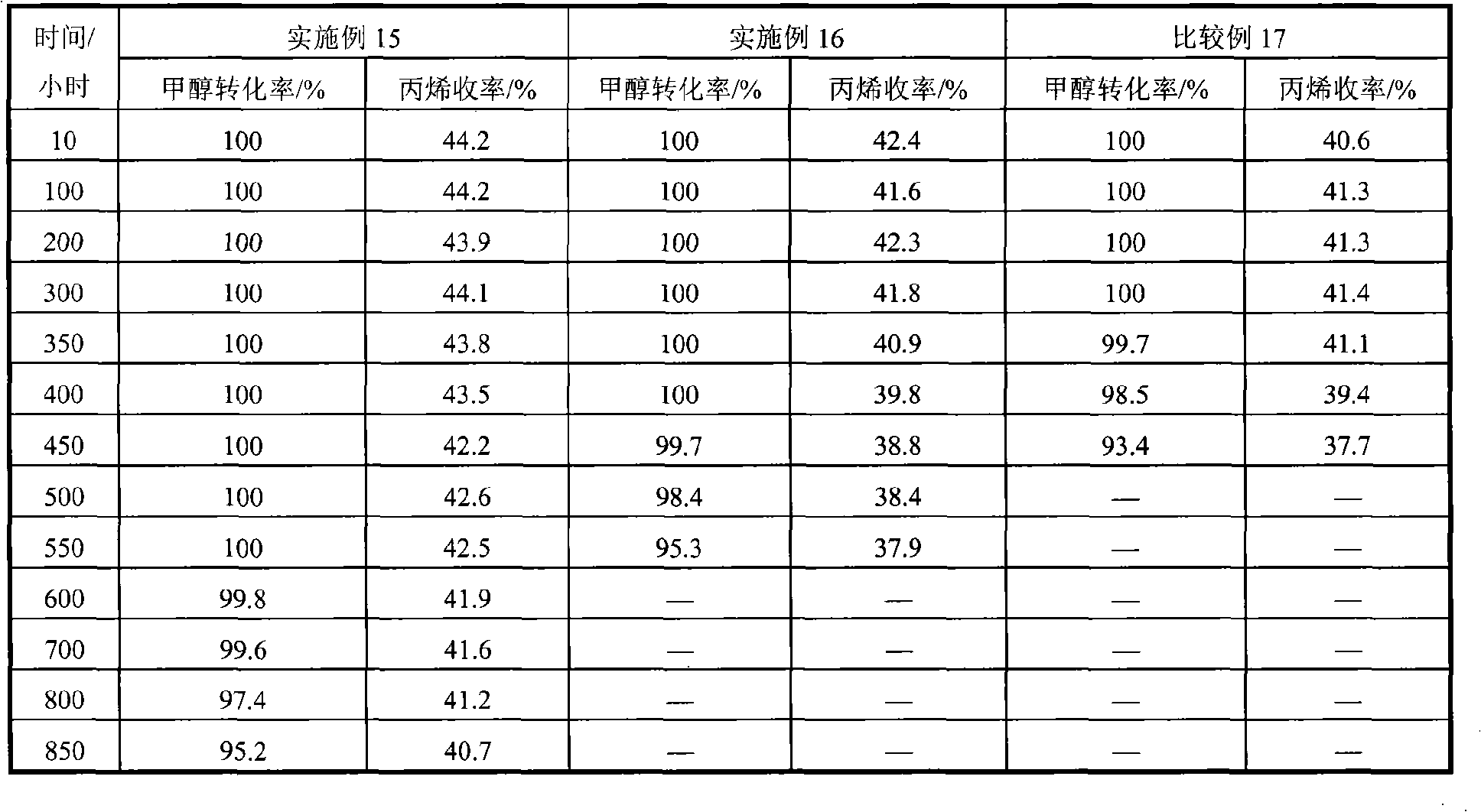

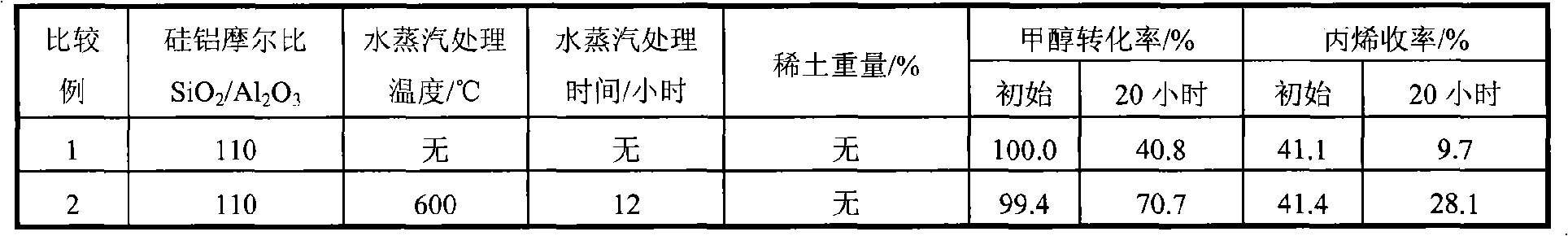

Catalyst for preparing propylene transformed from methanol

ActiveCN101279280AHigh hydrothermal stabilityHigh yieldMolecular sieve catalystsHydrocarbon from oxygen organic compoundsPhosphoric acidAmmonium nitrate

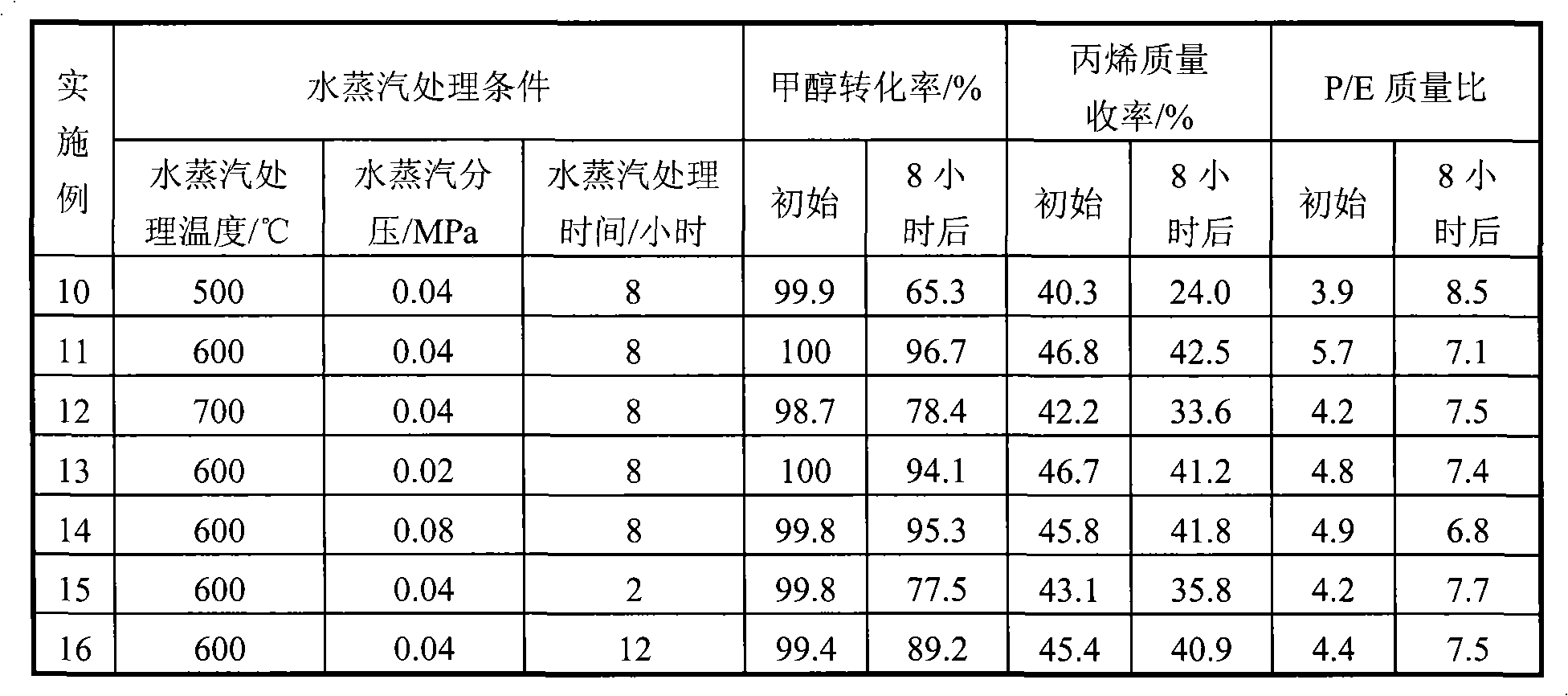

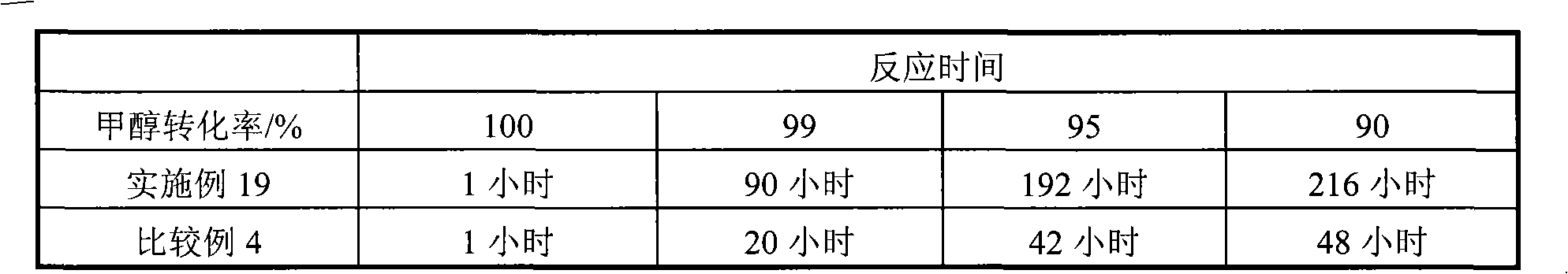

The present invention relates to a catalyst for manufacturing propylene by being converted from methanol which mainly solves the problems of low yield of the target product propylene, low P / E( the mass ratio of propylene to ethane) and poor water thermal stability of catalyst in the prior art. The present invention adopts the technical proposal for adopting 30 to 100 percent of molecular sieve raw powder with a silicon-aluminum mol ratio SiO2Al2O3 of 20 to 1000 ZSM-5 calculated by weight percentage and at least one caking agent from SiO2, clay and Al2O3 to compose a catalyst; then treating the catalyst for 1 to 5 hours by 0.1 to 3 mol / l of at least one ammonium liquor from ammonium nitrate, ammonium chloride or ammonium sulphate or 0.1 to 8.5 mol / l of at least one acid liquor from muriatic acid, nitric acid, vitriol or acetic acid before in use; then using steam to treat for 1 to 15 hours under the conditions that the temperature is 400 to 700 DEG C, the partial pressure of the steam in inertia atmosphere is 0.01 to 0.1MPa and the empty speed of the water liquid phase weight is 0.1 to 10hour<-1> and selecting at least one of oxalic acid, citric acid, phosphoric acid and ortartaric acid under a temperature condition of 20 to 90 DEG C to obtain the modified molecular sieve catalyst, thus better solving the problems. The present invention can be used in the industrial production of propylene by being converted from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

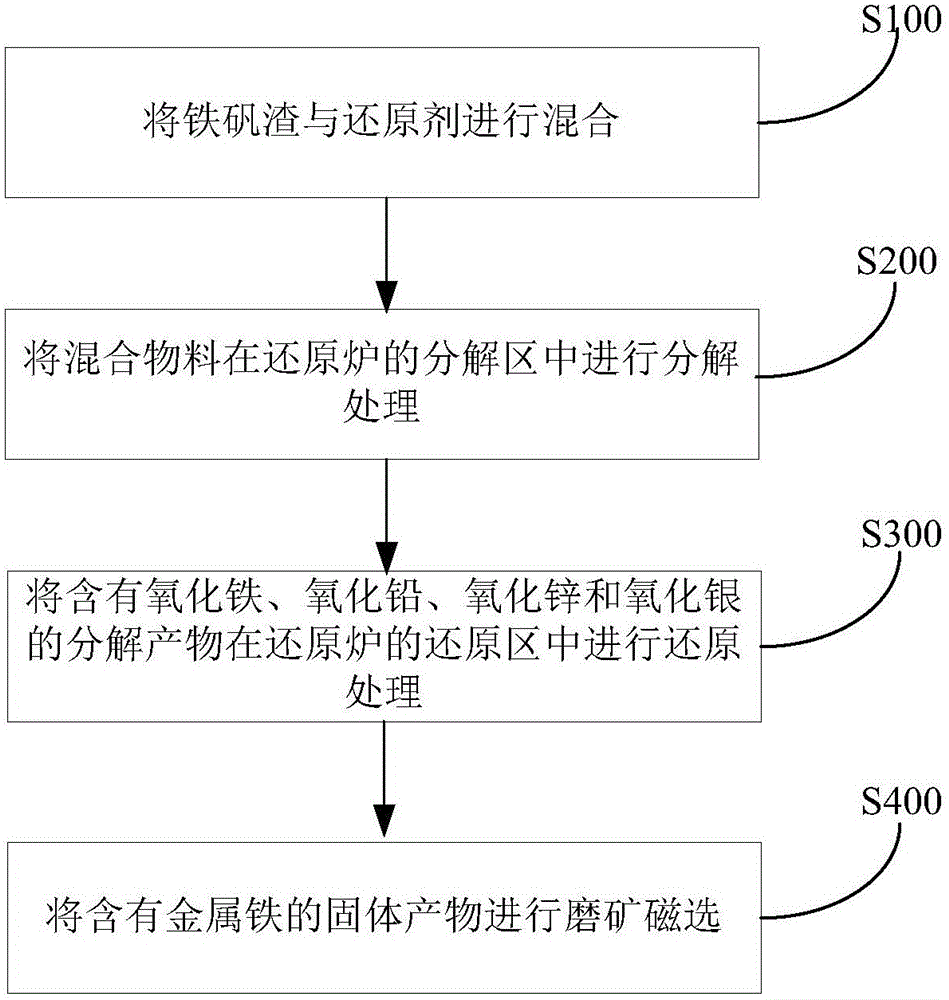

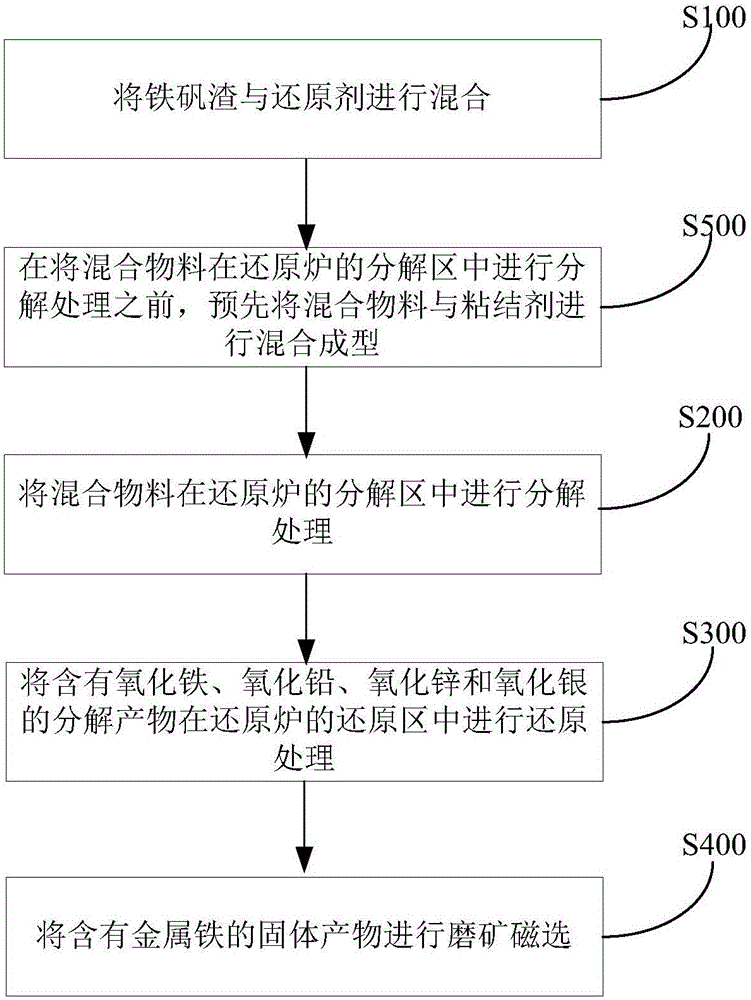

Iron vitriol slag treatment method

InactiveCN106011489ASolve the problem that cannot be recycledEfficient recyclingProcess efficiency improvementSlagReducing agent

The invention discloses an iron vitriol slag treatment method. The iron vitriol slag treatment method comprises the following steps: (1) iron vitriol slag is mixed with a reducing agent to obtain a mixture; (2) the mixture is decomposed in a decomposing area of a reducing furnace to obtain sulfur dioxide and a decomposed product containing iron oxide, lead oxide, zinc oxide and silver oxide; (3) the decomposed product containing iron oxide, lead oxide, zinc oxide and silver oxide is reduced in a reducing area of the reducing furnace to obtain a gaseous product containing lead, zinc and silver and a solid product containing metal iron; and (4) the solid product containing metal iron is grinded and magnetically separated to obtain the metal iron and tailings. The method can effectively recover iron, lead, zinc and silver in the iron vitriol slag, solves the difficulty of incapability of recovering iron in the iron vitriol slag in the prior art, and can reach the recovery rates of iron, lead, zinc and silver of above 90%.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

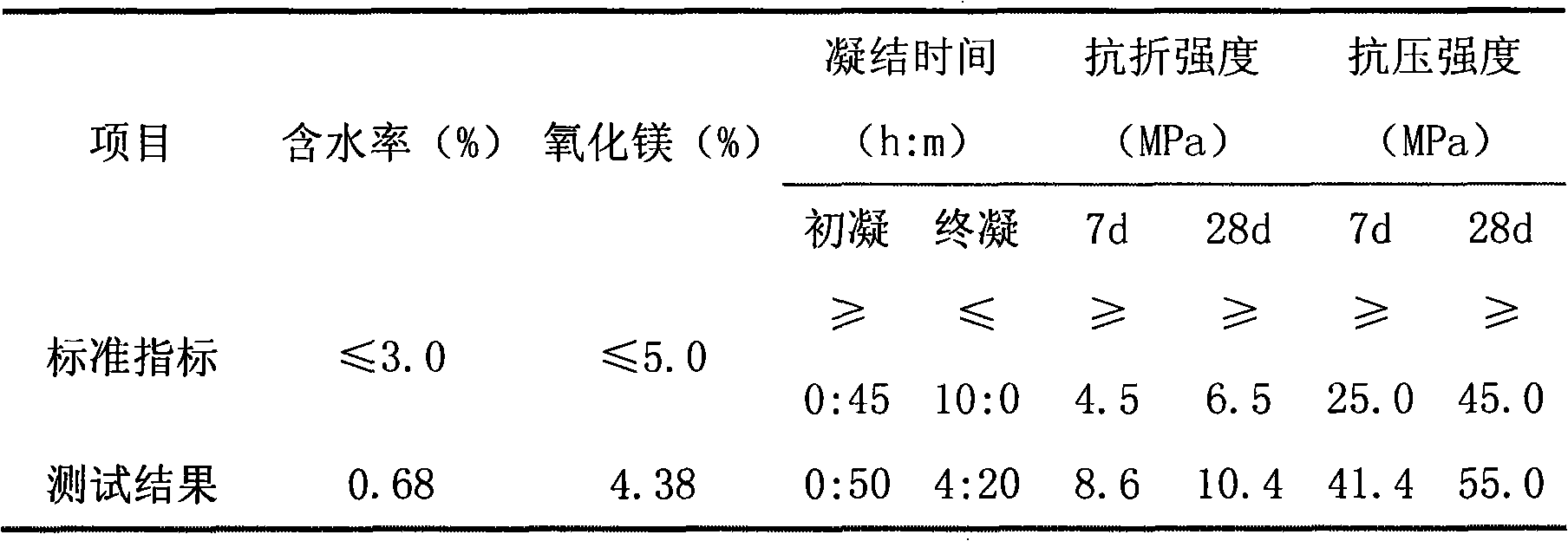

Process for preparing modified ardealite by water-free calcining

The invention relates to a method for preparing modified phosphogypsum through calcination without water scrubbing. The method is as follows: firstly, composite excitant and modifier are added into phosphogypsum and uniformly mixed, wherein, the weight percent of the phosphogypsum is between 85 and 95 percent; the weight percent of the composite excitant is between 2 and 5 percent; the weight percent of the modifier is between 3 and 10 percent; the composite excitant is green vitriol and aluminum sulphate, and the modifier is calcium oxide and cement; secondly, after uniform mixing, the mixture is dried at a drying temperature of between 100 and 110 DEG C, and the moisture of the phosphogypsum is lower than 8 percent; thirdly, the mixture enters into a calciner, is calcined for 0.5 to 1 hour at a temperature of between 150 and 300 DEG C, and is naturally cooled to prepare the modified phosphogypsum. The method decomposes and volatilizes harmful substances such as phosphor, fluorine, organic substances and so on contained in the phosphogypsum or converts the harmful substances into inert substance calcium pyrophosphate which is harmless to products, thereby not only avoiding secondary pollution but also reducing or avoiding influence of harmful chemical microconstituents contained in the phosphogypsum on the quality and the performance of the products. Moreover, the method shortens the processing time by 15 to 20 percent, saves the investment by 3 to 8 percent and reduces the energy consumption by 10 to 20 percent.

Owner:KUNMING UNIV OF SCI & TECH

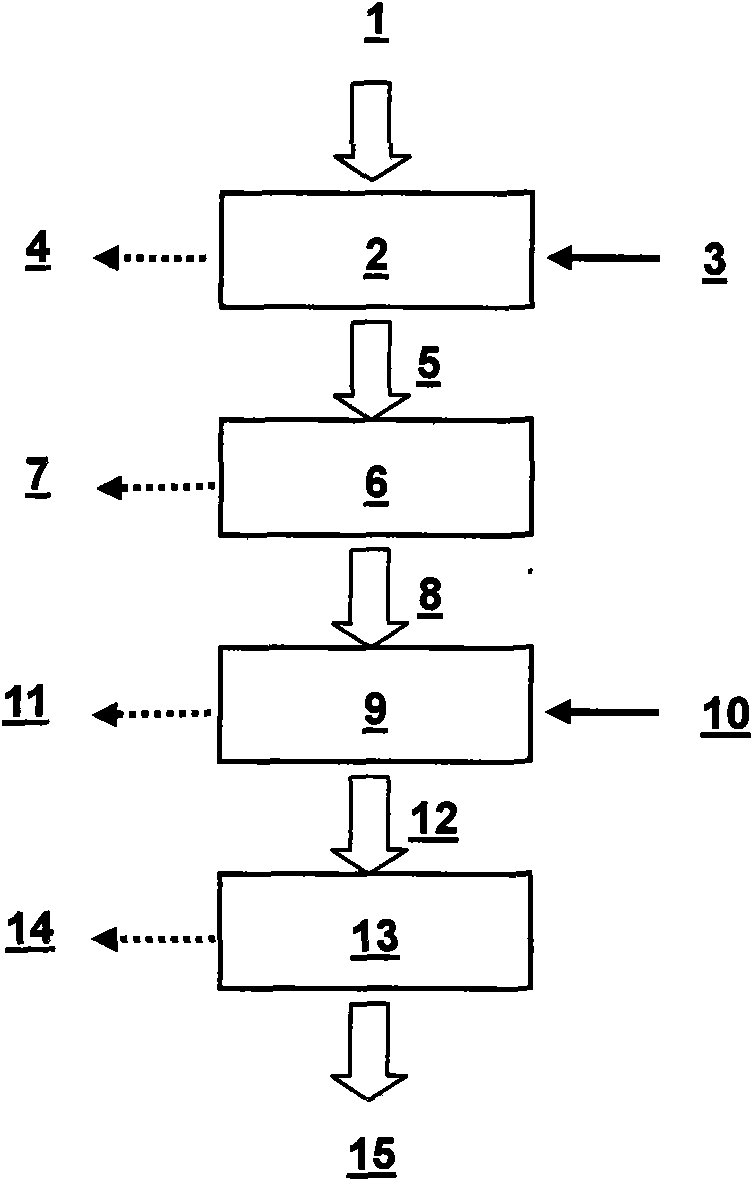

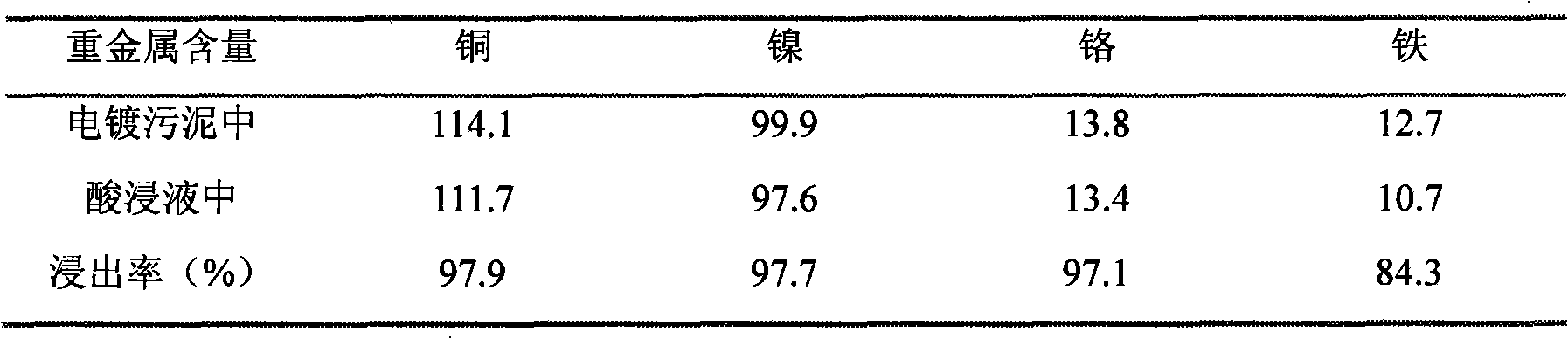

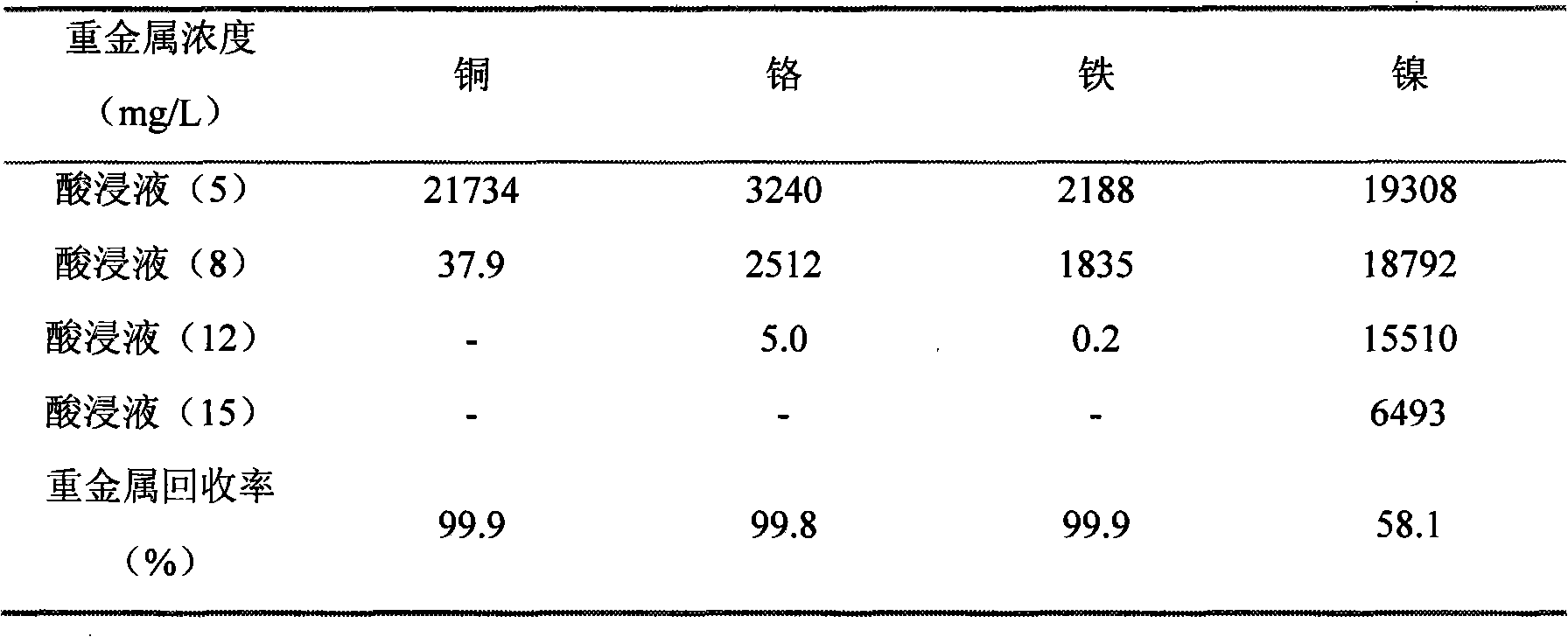

Method for realizing resource recovery of electroplating sludge

The invention relates to a treatment method for realizing resource recovery of electroplating sludge, which comprises the following steps: firstly, valuable metals in electroplating sludge are leached out by acid at normal temperature; secondly, filtered acid immersion liquid is poured into a copper electrolytic bath to recover and obtain electrolytic copper; thirdly, ferrum and chromium in copper acid immersion liquid are removed by ammonium jarosite through sedimentation, and iron-chromium residue and acid immersion liquid containing nickel are separated through filtration; and finally, the acid immersion liquid containing nickel is poured into an electrolytic bath of nickel to recover part of electrolytic nickel, and the rest nickel vitriol solution is taken as material for plating solution to be reused by a plating workshop. The method adopts a step-processing technique of acid dipping, electrolysis, sedimentation and electrolysis, so that electrolytic copper with high purity, iron-chromium residue and electrolytic nickel can be obtained. In addition, the method has simple process, low investment and operation cost, and higher economic benefit and environmental benefit.

Owner:OCEAN UNIV OF CHINA

Compound clarifying agent for high-aluminum alkali-free borosilicate glass

The invention discloses a compound clarifying agent for high-aluminum alkali-free borosilicate glass and belongs to the field of glass manufacturing. The compound clarifying agent comprises the following components by weight percent: 80-89% of thinning agents, 3-6% of sulfates, 4-6% of chlorine alkaline earth salts and 4-10% of stannous oxides. The invention provides a better clarifying agent for a fusing process of the high-aluminum alkali-free borosilicate glass, so as to facilitate the discharging of air bubbles during the glass fusing process and increase the yield.

Owner:成都中光电科技有限公司 +1

High stability molecular sieve catalyst for preparing propylene transformed from methanol and preparation thereof

ActiveCN101279281AStay acidicImprove anti-coking performanceMolecular sieve catalystsHydrocarbon from oxygen organic compoundsCerium nitratePhosphoric acid

The present invention relates to a high stability molecular sieve catalyst for preparing propylene by being converted from methanol and a preparation method thereof which mainly solve the problems of poor molecular sieve stability and water thermal stability as well as easy coking and deactivation in the prior art. The present invention adopts the technical proposal of adopting the molecular sieve raw powder with a silicon-aluminum mol ratio SiO2Al2O3 of 20 to 1000 and a weight percentage of 25 to 99.9 percent as well as at least one caking agent from SiO2, clay and Al2O3 to extrude, tablet or spray ball to shape; then treating for 1 to 8 hours by 0.1 to 3 mol / l of at least one ammonium liquor from ammonium nitrate, ammonium chloride or ammonium sulphate or 0.1 to 8.5 mol / l of at least one acid liquor from muriatic acid, nitric acid, vitriol, phosphoric acid or acetic acid under a temperature of 20 to 90 DEG C; then using 0.1 to 5 percent of at least one liquor selected from lanthanum, cerium nitrate or chloride calculated by weight percentage to treat for 4 to 8 hours under a temperature of 20 to 90 DEG C; then using steam to treat for 2 to 15 hours under the temperature condition of 400 to 700 DEG C; using a liquor of 0.1 to 3mol / l selected from at least one of oxalic acid, citric acid, phosphoric acid and maleic acid under a temperature condition of 20 to 90 DEG C to dip for 2 to 5 hours to obtain the modified molecular sieve catalyst, thus better solving the problems. The present invention can be used in the industrial production of propylene by being converted from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

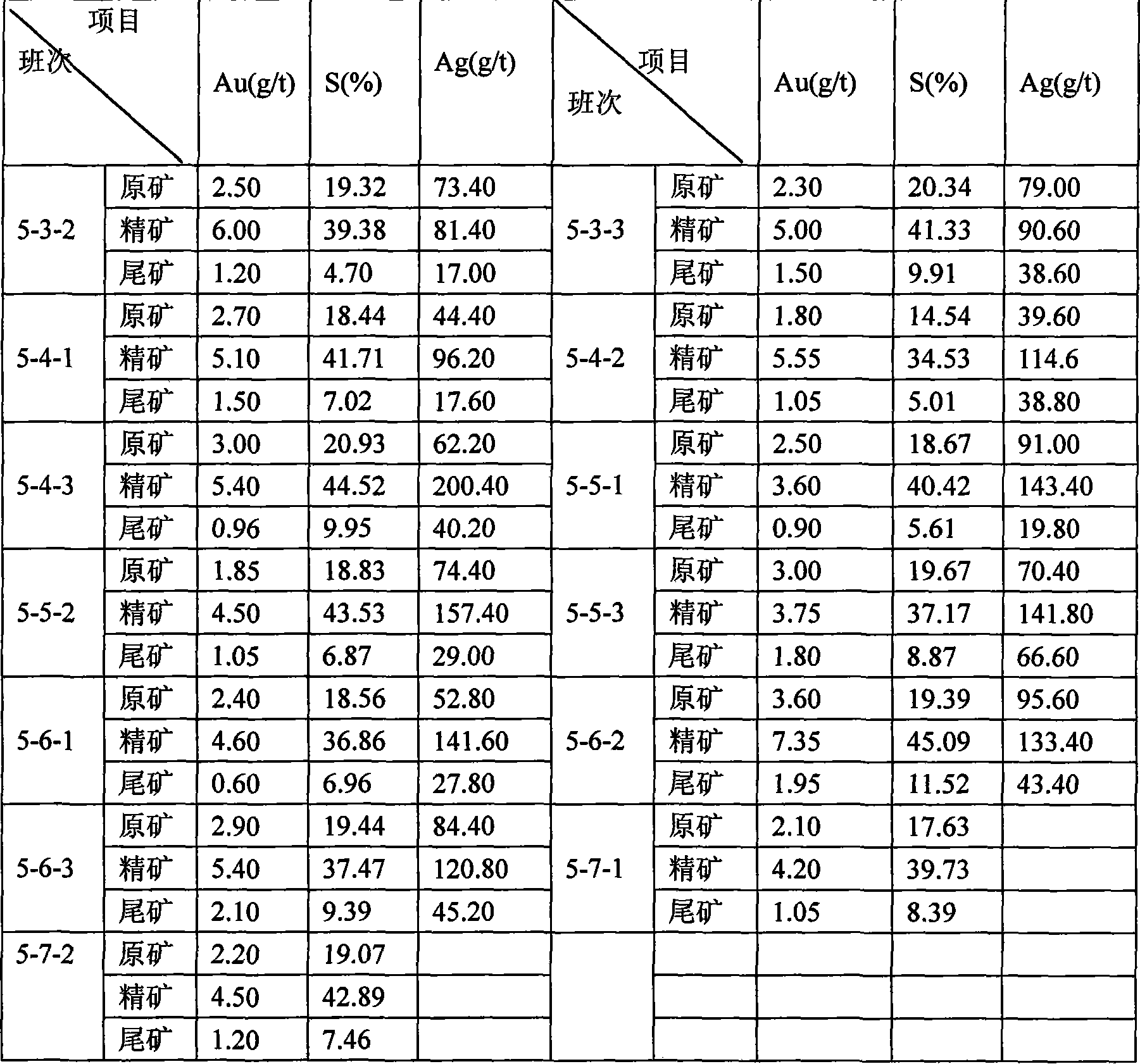

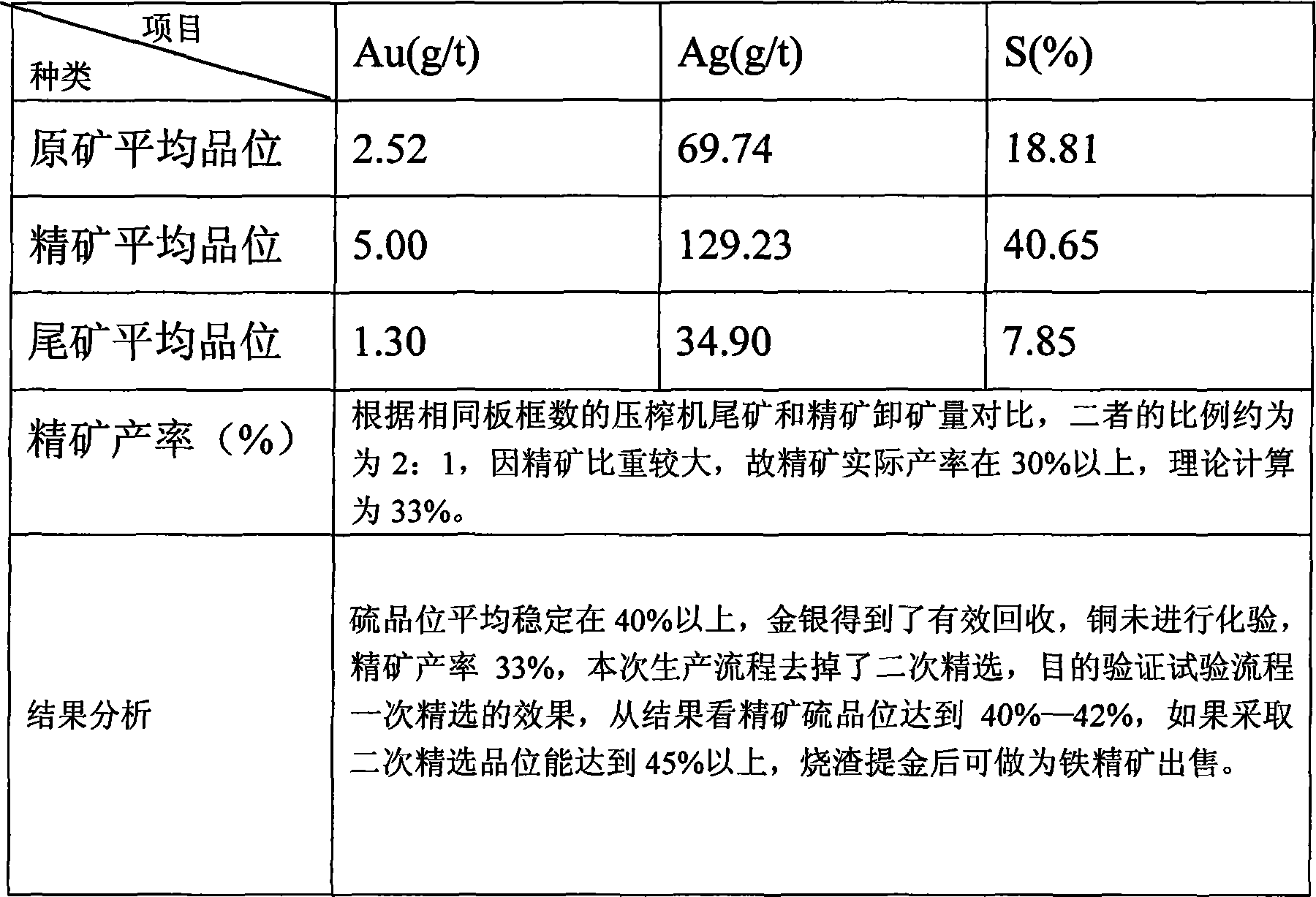

Method of extracting valuable element from waste water and waste slag

ActiveCN101078056ASimple configurationAdaptablePhotography auxillary processesSolid waste managementBrickSlag

A method to extract charge elements with drain water and waster slag, It contains the following technology steps: a To acidulate; the cyanide tailings and blended with acid drain water. b To add protection alkali; To enter the agitated tank before floatation, and add protection alkali to neutralize and precipitate the ion of impurity. C To recover by flotation; the beneficiated ore will be produced out after a rude choice, two scavengings, and a choice. d To floatate the smelting end product of beneficiated ore; to produce out end product: vitriol, copper, bullion bar, sycee, and iron ore concentrate, the remained tailings will be sell to produce brick, the arrangement of the technology equipment is simple, and the operation is stable and easy to control, It' s adaptability to the cyanide tailings produced by different technology is very high, It not only eliminates the pollution to environment caused by the pile-up of tailings, but also further accelerates the reclaim of the useful element, and at the same time, it saves a part of cost spend in dealing with the drain water.

Owner:SHANDONG HUMON SMELTING

Micro-arc oxidation electrolyte and micro-arc oxidation method

InactiveCN101445949AImprove stain resistanceImprove compactnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention provides a micro-arc oxidation electrolyte which is aqueous solution containing phosphate and silicate and has the pH value of 6-12, wherein, the electrolyte also contains color toner which comprises one or a plurality of sodium sulfate, rose vitriol, ammonium metavanadate, copper sulphate and potassium permanganate. The micro-arc oxidation electrolyte and a micro-arc oxidation method provided by the invention can lead a micro-arc oxidation film made of light metal materials to obtain multiple colors which are very even to ensure the light metal products to have beautiful decorative effects. Meanwhile, the stain resistance and compactness of the micro-arc oxidation film obtained on the light metal materials are excellent; therefore, the added value and actual use value of aluminium alloy are greatly enhanced.

Owner:BYD CO LTD

Ni-W-P alloy plating solution for chemical plating and chemical plating method employing the same

InactiveCN101225516AFast platingLittle change in pHLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention relates to a plating solution for chemical plating nickel-tungsten-phosphor alloy, comprising nickel vitriol of 24 to 28 g / l, sodium citrate of 40 to 70 g / l, gluconic acid sodium salt of 20 to 30 g / l, ammonium sulfate of 30 to 40 g / l, sodium pyroborate of 5 to 15 g / l, sodium tungstate of 30 to 50 g / l, sodium hypophosphite of 20 to 28 g / l, potash iodate of 10 to 20 mg / l, thiourea of 0.5 to 1.5 mg / l and sodium dodecyl sulfate of 5 to 15 mg / l. The plating solution is characterized in that: the chemical plating method using the plating solution comprises the following steps that: the pH value of the plating solution is adjusted to 8 to 9, and then the plating solution is heated to 80 to 90 degree centigrade, and then the processed plating articles are dipped into the plating solution; the time of dip plating is determined by the required plating layer thickness. The plating solution for chemical plating nickel-tungsten-phosphor alloy has the advantages of higher stability and higher plating speed.

Owner:罗森鹤

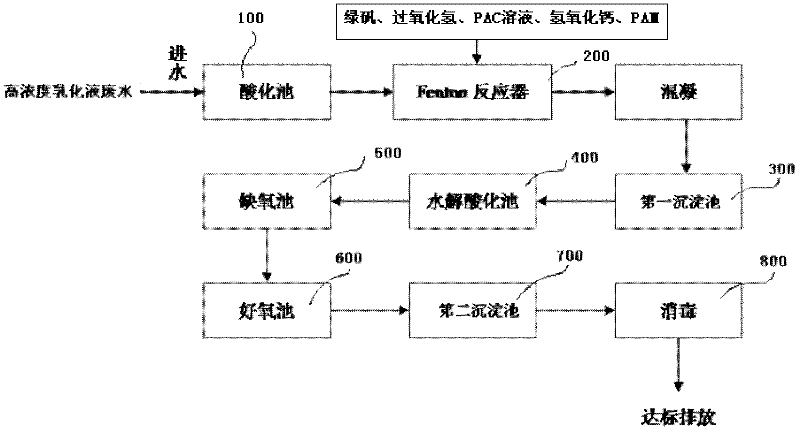

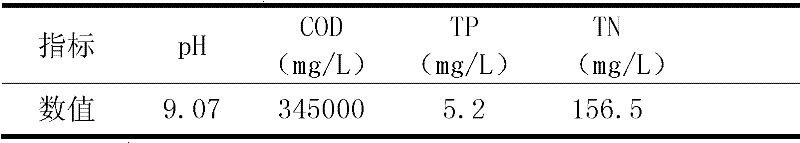

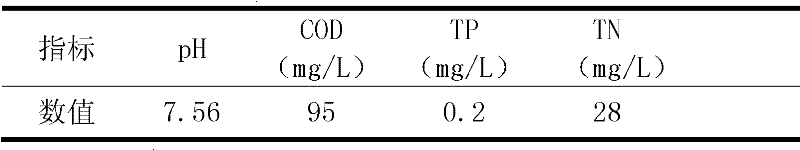

Treatment method of high-concentration emulsion waste water

The invention discloses a treatment method of high-concentration emulsion waste water. The method comprises the following steps of: pumping a high-concentration emulsion into an acidifying pond, adjusting the pH value to acid, standing, and isolating upper layer floating oil; pumping into a Fenton reactor, adding green vitriol, aerating, dissolving, slowly adding a hydrogen peroxide solution, adding a PAC (Poly Aluminum Chloride) solution for reacting, and adjusting the pH value of waste water to neutral after a reaction is completed; aerating, adding a flocculating agent to produce a flco, pumping into a first precipitating pond for precipitating, and introducing water discharged from the first precipitating pond into an anaerobic acidifying pond for performing anaerobic acidifying treatment; introducing water discharged from the anaerobic acidifying pond into an anoxic pond for performing anoxic treatment; introducing water discharged from the anoxic pond into an aerobic pond for performing aerobic treatment; and introducing water discharged from the aerobic pond into a second precipitating pond for precipitating, introducing water discharged from the second precipitating pond into a disinfecting tank for performing disinfecting treatment, and discharging disinfected discharged water within controlling index of the national standard. After a high-concentration emulsion is treated with the treatment method disclosed by the invention, various indexes of discharged water can reach the grade B standard of the Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002).

Owner:SHANGHAI JIHUI REMONDIS ENVIRONMENT PROTECTION TECH DEV

Nanometer silicon oxide colloid electrolyte for lead-acid storage battery and its preparing method

InactiveCN1738092AReduce adverse effectsImprove rheologyLead-acid accumulatorsSilicon oxideAgglutination

Disclosed a nanometer monox colloid electrolytic solution of lead-acid storage battery and its preparing method, relates to the manufacturing technique of lead-acid storage battery colloid electrolytic solution special for the electric bicycle. The invention prepares the nanometer monox colloid electrolytic solution by using the lead-acid analytical pure vitriol, vapor phase silica dioxide nanometer powder, salt cake, and the deionized water as main material, which are mixed to be added polyacrylamide and poly-sodium acrylate as gel modifying agent; then, adding litter lanthanum sulfate, cerous sulfate, tungsten oxide, and molybdenum oxide. The invention avoids the disadvantage effect of using sodium silicate colloid; uses vapor phase silica dioxide nanometer powder as gel agent; adds little chemical components, to form the new colloid electrolytic solution which can improve the agglutination property, increase the capacity of accumulator, and prolong the service life of deep discharging cycle. In addition, the invention can be used as electrolytic solution to replace present vitriol water electrolytic solution, to improve the rheological property of colloid electrolytic solution, and control the electrolytic process of water.

Owner:江苏华富能源有限公司

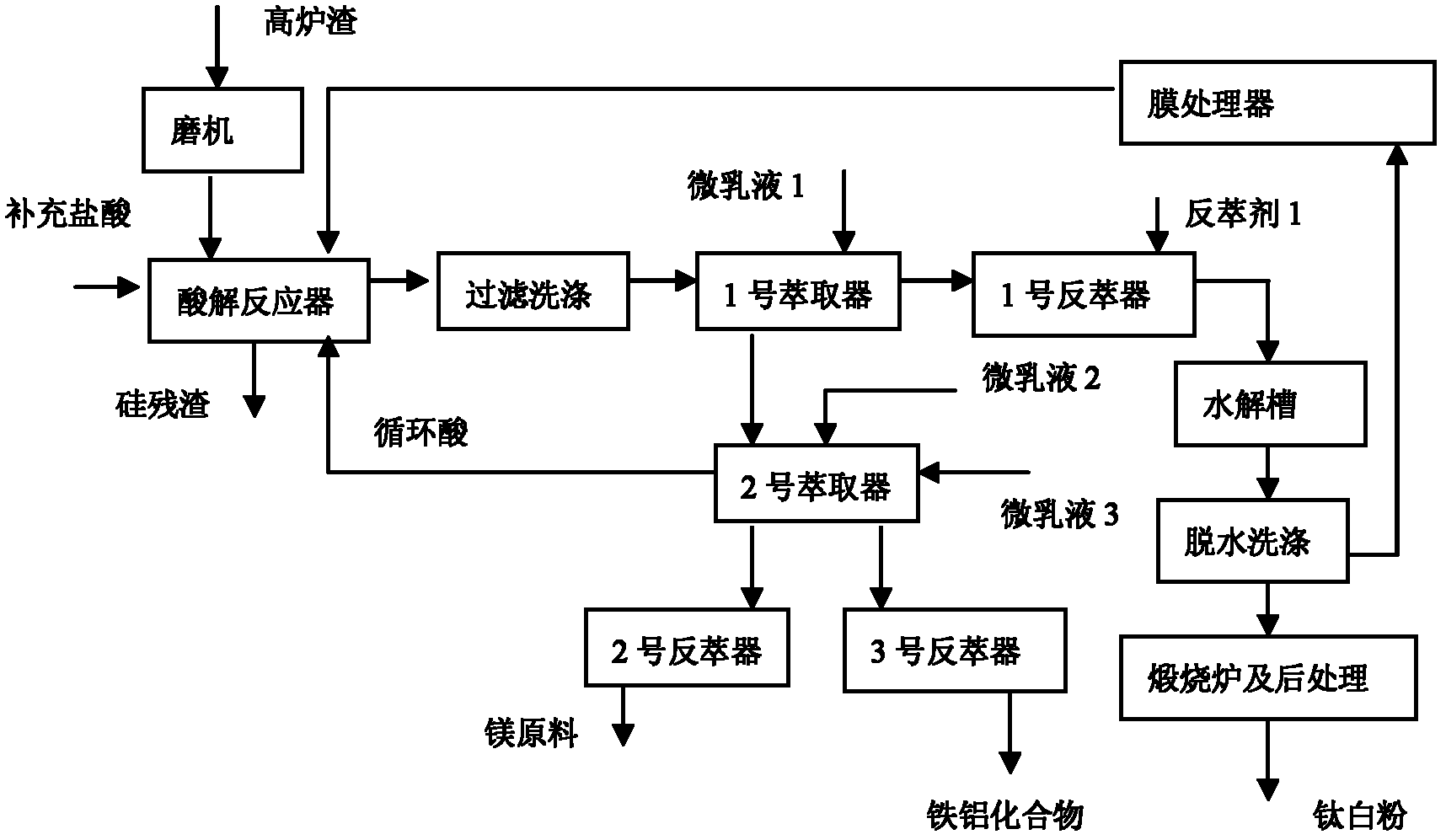

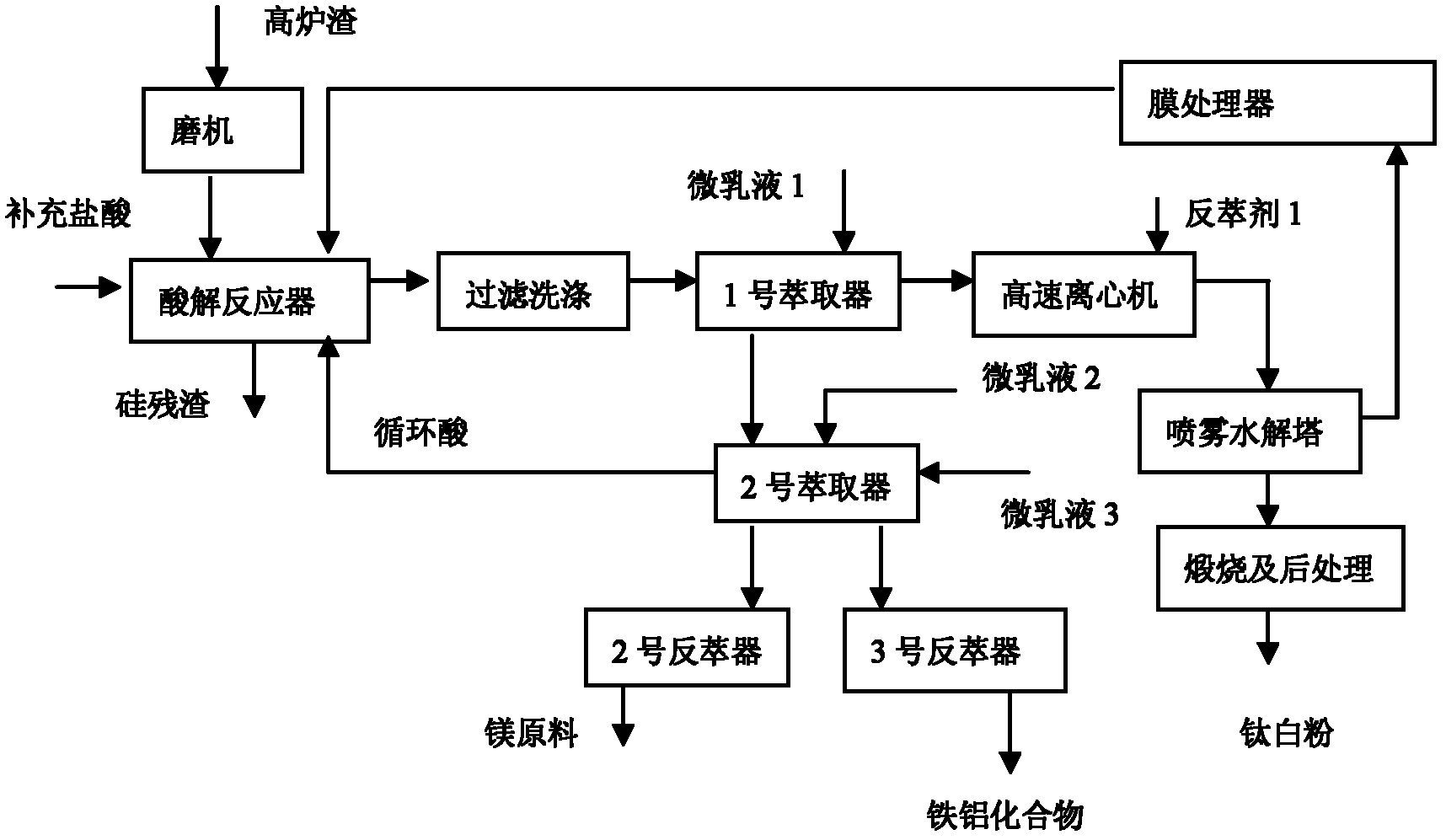

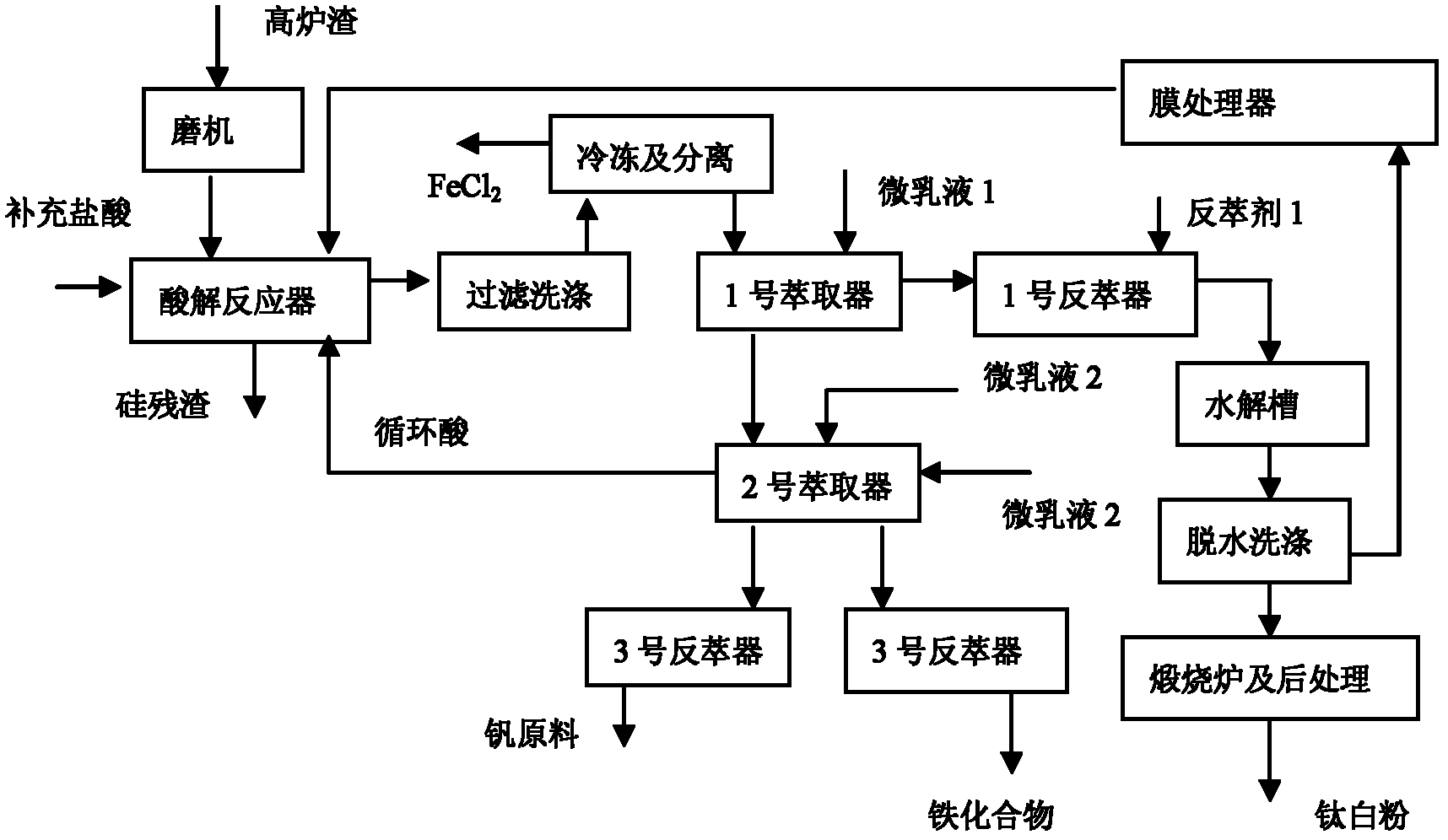

Preparation method of pigment-level titanium dioxide powder by cyclic hydrochloric acid micro emulsion method

InactiveCN102602991AOvercoming decomposition difficultiesSolve pollutionTitanium dioxideSlagRaffinate

The invention discloses a preparation method of pigment-level titanium dioxide powder by a cyclic hydrochloric acid micro emulsion method. The preparation method mainly comprises the following steps of: carrying out acidolysis on titanium-enriched blast furnace slag or ilmenite by utilizing hydrochloric acid to obtain a clear acidolysis liquid; extracting titanium with an organic micro emulsion; collecting titanium in the clear acidolysis liquid by superfine liquid ball formed by a micro emulsion film in the organic micro emulsion; separating organic micro emulsion into organic extract liquor and raffinate; carrying out reextraction on the obtained organic extract liquor with reextraction agent to remove titanium; and hydrolyzing and calcining the obtained reextraction titanium liquid to obtain rutile type titanium dioxide, extracting and removing the impurities, such as iron, aluminum, magnesium and vanadium, in the raffinate by the organic micro emulsion, and returning obtained regenerated hydrochloric acid back to the acidolysis process. By using the method of the invention, the problems that the preparation method of the titanium dioxide powder in the prior art is high in vitriol cycle energy consumption and industrialization is hard to realize can be overcome, various byproducts can be prepared while the titanium dioxide powder is prepared, and resources in raw materials can be comprehensively recycled, so that the pollution problem of blast furnace slag on environment can be basically solved.

Owner:SICHUAN UNIV

Superhigh intensity electric ceramic formulation

The invention discloses a hyperhigh-strength electric porcelain formula, which comprises the following parts: 8-12% Fraxinus mandshurica clay, 9-13% feldspar powder, 37-47% sintered vitriol powder and 6-10% zhangwu clay, 5-10% faku clay, 4-8% kuancheng clay, 5.5-8.5% baofeng clay, 4-8% yongji clay and 0.5-1.5% modified alta-mud. Each property of electric porcelain reaches and exceeds V-typed standard in the GB8411 with transverse strength at 165-170Mpa without glaze or 221 231Mpa with glaze, which supplements the blank of this kind of product in our country.

Owner:抚顺高科电瓷电气制造有限公司

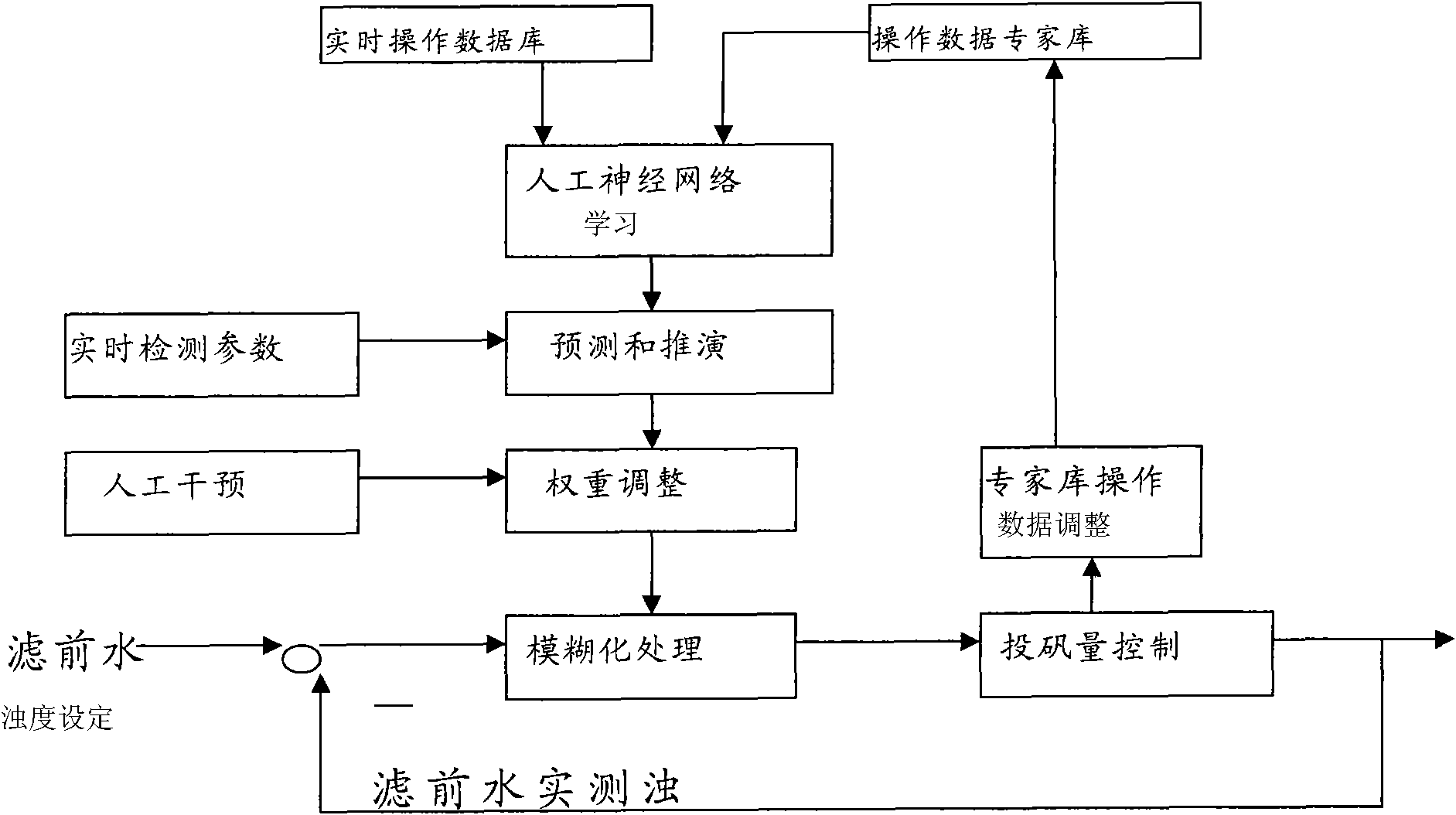

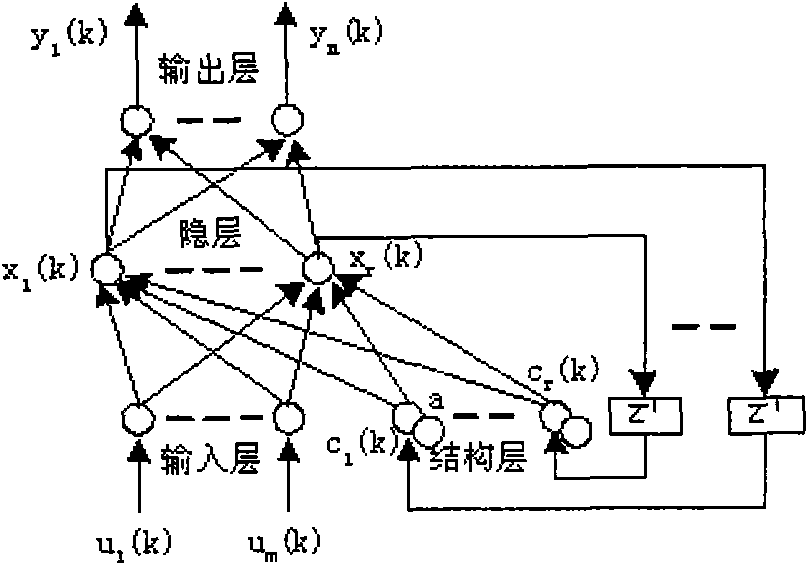

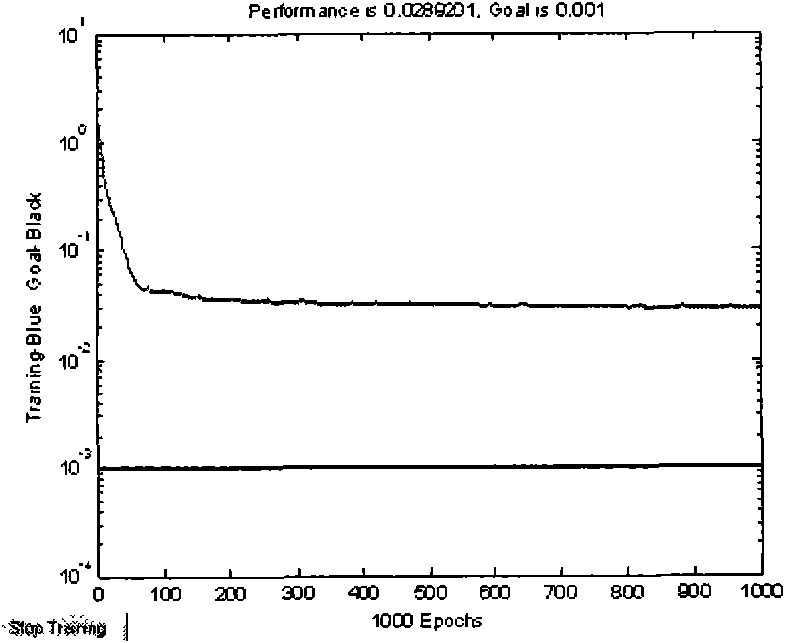

Automatic control algorithm for feeding vitriol in tap water by coagulation

InactiveCN101556458AEnsure safe productionAchieving energy saving will consumeEnergy industryWater/sewage treatment by flocculation/precipitationAutomatic controlFeedback control

The invention discloses an automatic control algorithm for carrying out feed-forward control based on an artificial neural network and feeding vitriol in tap water by coagulation on the basis of fuzzy feedback control, comprising the following steps of: learning the process parameters of vitriol-feeding control by the artificial neural network, identifying the internal corresponding relationships in the system parameters, thus predicting the control value of the detection source water parameters of a core; subsequently correcting the prediction value by a method of fuzzy control feedback; and finally obtaining a vitriol-feeding control quantity meeting the requirement to control the operation of a metering pump, thus completing the full process of vitriol-feeding control. The algorithm can ensure the safety production and stable operation of water industries under the condition of variable source water references and achieves the objects of saving energy, reducing consumption, downsizing staffs and improving efficiency.

Owner:JIANGHAN UNIVERSITY

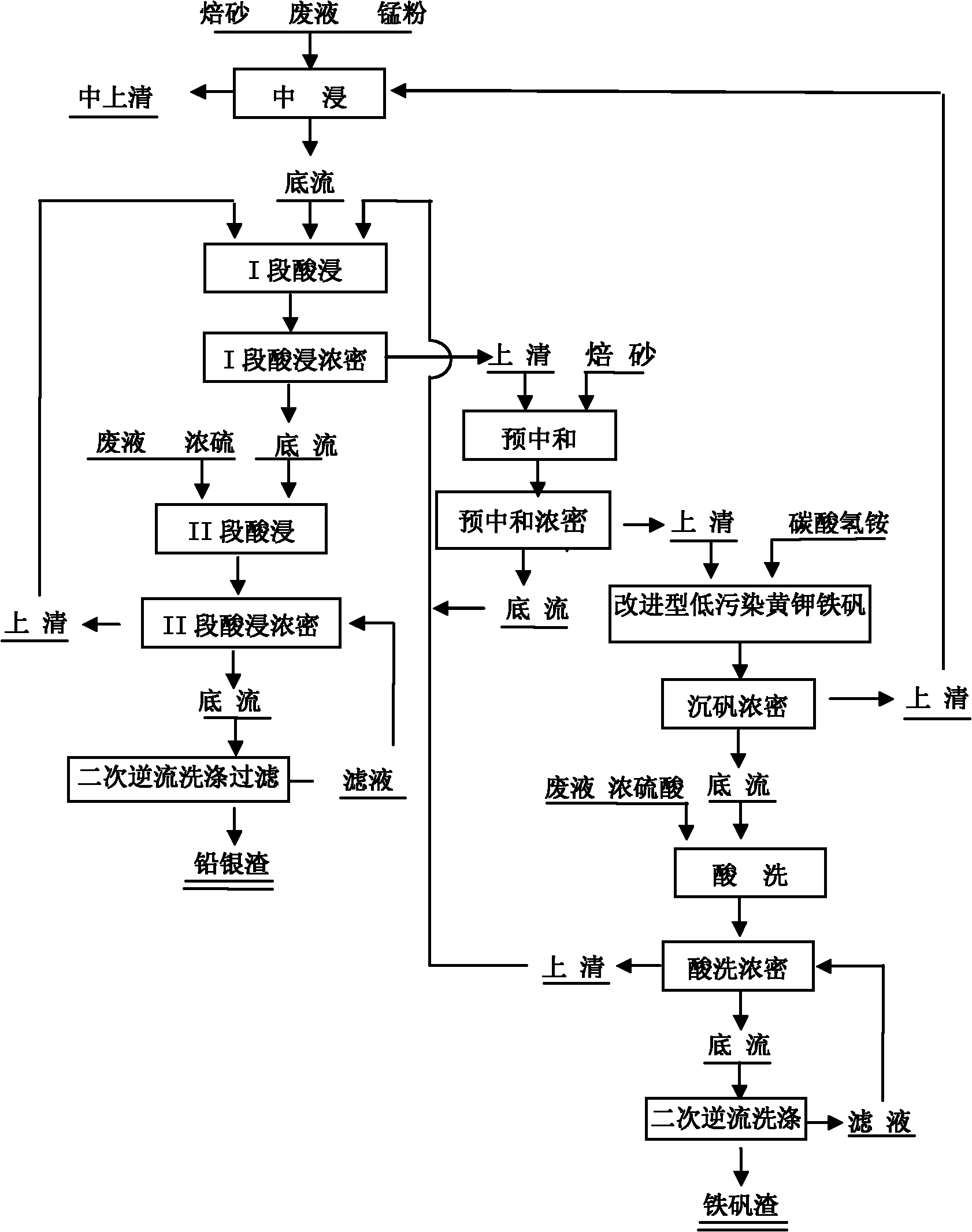

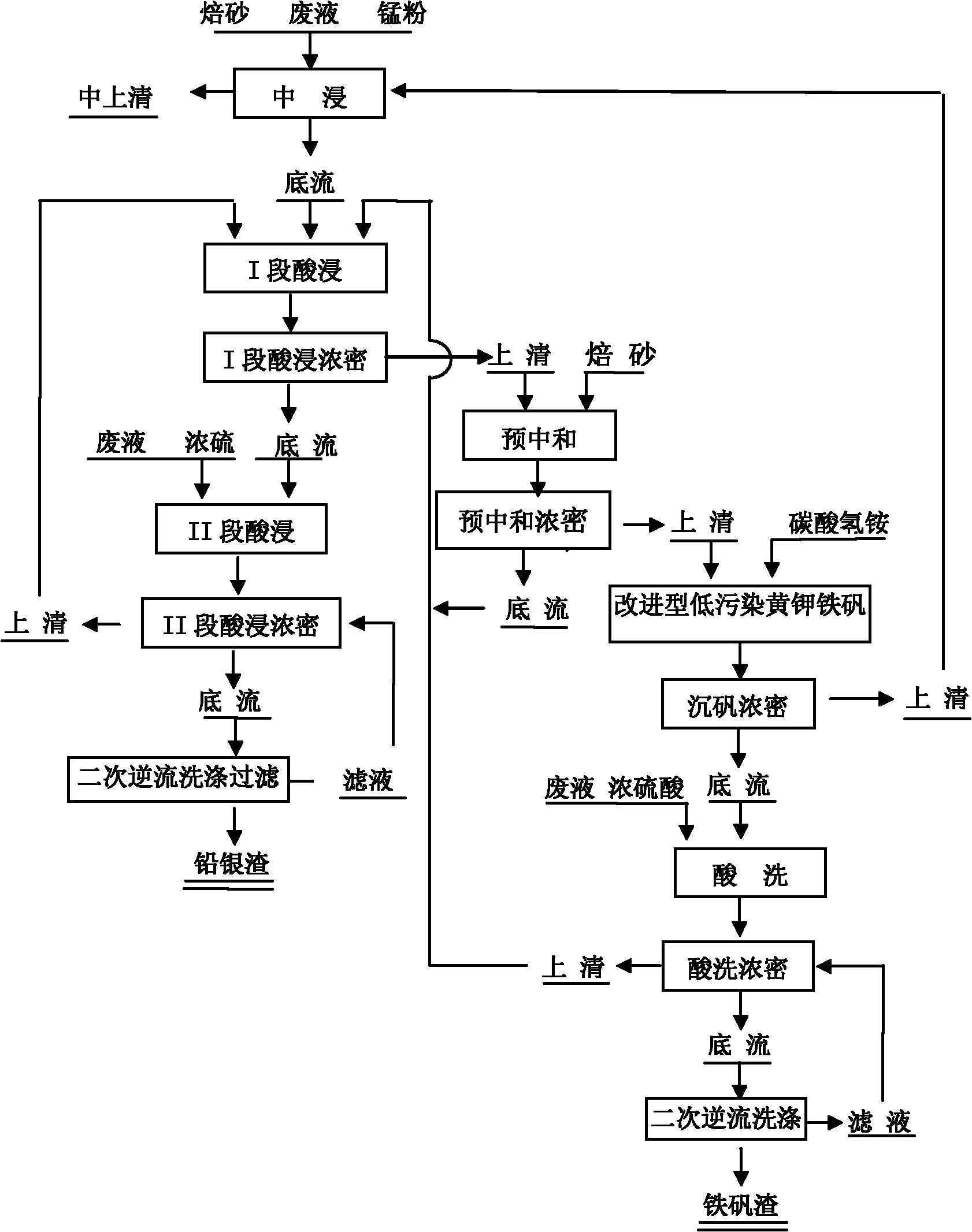

Process for smelting zinc with wet method of high temperature and high acid-jarosite iron removing-iron vitriol slag pickling by two stages

InactiveCN102094126AImprove leaching rateHigh recovery rateProcess efficiency improvementSlagZinc metal

The invention provides a process for smelting zinc with a wet method of high temperature and high acid-jarosite iron removing-iron vitriol slag pickling at two stages, belonging to the technical field of non-ferrous metal smelting. The process comprises the following steps of neutral leaching, acid leaching at the first stage, acid leaching at the second stage, pre-neutralizing, settling vitriol and pickling to obtain zinc metal with a high recovery rate. The total recovery rate of zinc metal is 94.45%. The loss of valuable metal in iron vitriol slag is less, the recovery rate of metal is high, and the pollution of vitriol slag to the environment is improved.

Owner:BAIYIN NONFERROUS GROUP

Method for preparing ultra hydrophobic surface on surface of metal copper

InactiveCN101091947ASuperhydrophobicSupersulfuric acidAntifouling/underwater paintsPretreated surfacesAir atmosphereSulfur water

The invention publics a method of preparing super sulfur-water surface on the metal copper surface, especially involves a method that it can prepare super sulfur-water surface, super vitriol surface and super sulfur-alkalescence surface simultaneously. The method puts the metal copper plate in the oversaturation solution full of vitriol copper for 10-15 days,and cleans with the deionized water, and has a air-dry; smearing the ethylene-dimethyl siloxanes on the metal copper plate surface reelingly, and drying 1-2 hours in air atmosphere 100-120deg.c.Then dropping the pure water, the acid or the alkali on the copper sign surface to make a determination of the contact angle which needs to be bigger than 150deg.The invention simultaneously has the super sulfur-water, super vitriol and super sulfur-alkalescence on the copper surface, it may help to prevent the metal copper surface from being polluted and rusted and so on.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

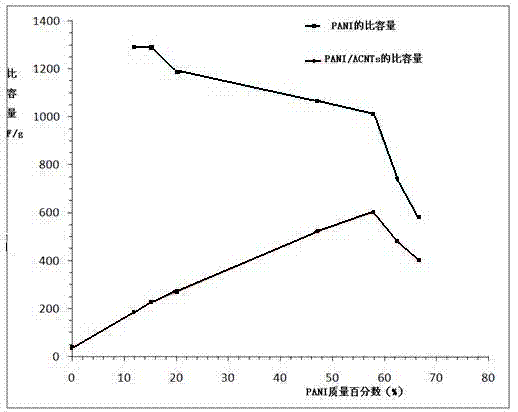

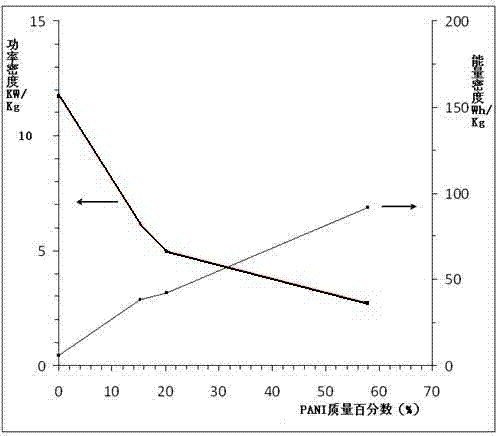

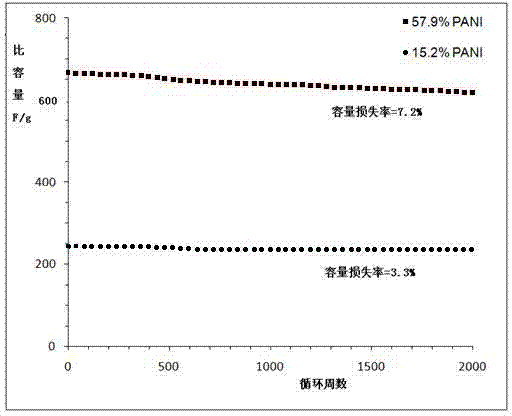

Electrode of capacitor and preparation method thereof

InactiveCN102306552ASimple manufacturing processReduce pollutionHybrid capacitor electrolytesHybrid capacitor electrodesGas phaseHigh energy

The invention discloses an electrode of a capacitor and a preparation method thereof, and relates to a mixed super capacitor electrode based on polyaniline / directional carbon nanotube composite material and a preparation method thereof. The electrode is characterized by comprising a conductive matrix material and a polyaniline / directional carbon nanotube composite material; and the polyaniline / directional carbon nanotube composite material directly grows on one side or both sides of the conductive matrix material. In the preparation process, by selecting reaction gas and conductive matrix material and controlling chemical gas phase deposition technology, the directional carbon nanotube directly grows on a conductive matrix; then, electrochemical deposition of the directional carbon nanotube is carried out in vitriol solution of prepared hydrochloric acid aniline; and a polyaniline / directional carbon nanotube composite electrode with large power density, good multiplication rate performance, high energy density and long service life for a super capacitor is prepared. The invention has the characteristics of simple preparation process, low cost, easy large-scale production and the like.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for preparing fertilizer containing humic acid concentrated chelating trace elements

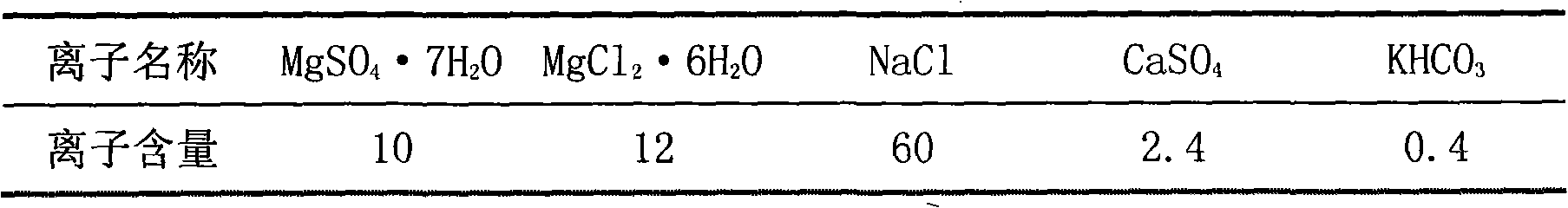

InactiveCN104478574AIncrease concentrationReduce dosageOrganic fertilisersFertilizer mixturesZINC SULFATE HEPTAHYDRATEPlant growth

The invention relates to a method for preparing a fertilizer containing trace elements, and particularly relates to a method for preparing a fertilizer containing humic acid concentrated chelating trace elements. The method comprises the following steps of firstly, adding supernate containing humic acid, ethylene diamine tetraacetic acid and sodium hydroxide sequentially into a reaction kettle, and stirring until dissolving; then adding heptahydrate, manganese sulfate monohydrate, blue copperas and iron vitriol sequentially into the reaction kettle, chelating, and stirring until dissolving; and then adding boric acid, ammonium molybdate, citric acid, caprylyl / capryl glucoside APG0810 into a reaction kettle, and stirring until dissolving. The invention provides a plant growth adjusting agent which is high in nutritional element concentration, is stable and uniform in solution, contains biochemical humic acid and the like, is beneficial to plant absorption, is high in biodegradability and is low in blade and soil pollution.

Owner:NINGXIA KOCEL BIOLOGICAL CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com