Treatment method of high-concentration emulsion waste water

A treatment method and high-concentration technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as high energy consumption, poor biochemical properties, and large amount of treated water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

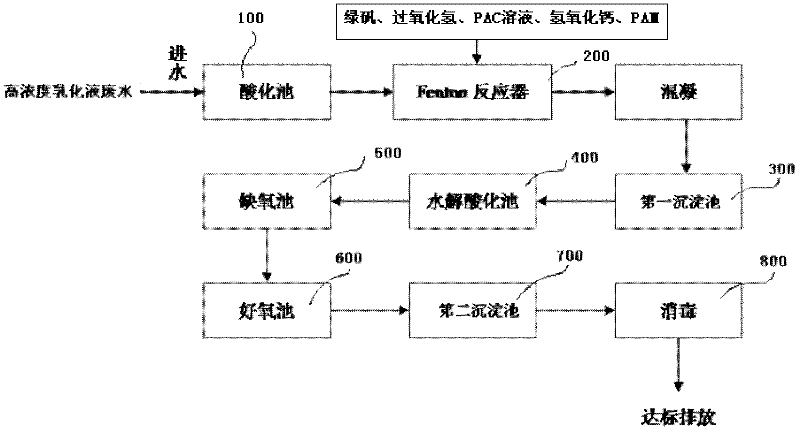

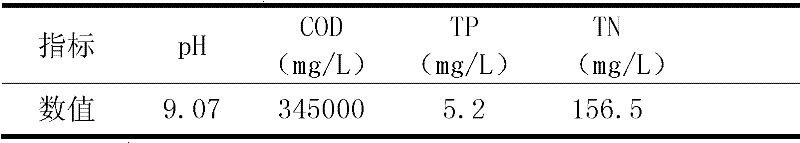

[0030] The present invention is described by taking the treatment of high-concentration emulsion wastewater produced by a mechanical processing plant as an example. The high-concentration emulsion wastewater produced by this mechanical processing plant is 1500 tons per year, and the water quality is shown in Table 1.

[0031] Table 1 Wastewater quality of a mechanical processing plant (except for pH, other indicators are in mg / l)

[0032]

[0033] Specific steps are as follows:

[0034] 1. Pump the high-concentration emulsion into the acidification tank 100, add sulfuric acid to adjust the pH value of the high-concentration emulsion wastewater to 3, and after standing for 6 hours, remove the oil slick from the upper layer to obtain the lower-layer degreasing wastewater;

[0035] 2. Pump the degreasing waste water after the degreasing treatment in step 1 into the Fenton reactor 200, add the catalyst green vitriol with a mass percentage of 5.6% of the degreasing waste water ...

Embodiment 2

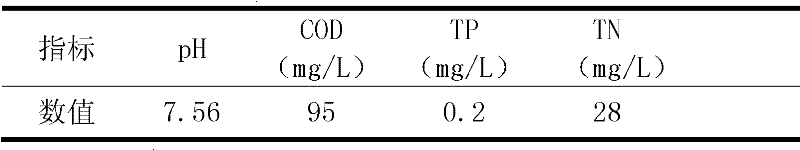

[0044] The present invention is described by taking the treatment of high-concentration emulsion wastewater produced by a mechanical forging plant as an example. The high-concentration emulsion wastewater produced by the mechanical forging plant is 700 tons per year, and the water quality is shown in Table 1.

[0045] Table 1 Waste water quality of a mechanical forging plant (except for pH, other indicators are in mg / l)

[0046]

[0047] Specific steps are as follows:

[0048] 1. Pump the high-concentration emulsion into the acidification tank, add sulfuric acid to adjust the pH value of the high-concentration emulsion wastewater to 3, and after standing for 12 hours, remove the oil slick in the upper layer to obtain the degreasing wastewater in the lower layer;

[0049]2. Pump the oil-removing waste water after the degreasing treatment in step 1 into the Fenton reactor, add the catalyst green vitriol with a mass percentage of 5.6% of the oil-removing waste water to aerate...

Embodiment 3

[0058] The present invention is described by taking the treatment of high-concentration emulsion wastewater produced by a mechanical processing plant as an example. The high-concentration emulsion wastewater produced by this mechanical processing plant is 1200 tons per year, and the water quality is shown in Table 1.

[0059] Table 1 Wastewater quality of a mechanical processing plant (except for pH, other indicators are in mg / l)

[0060]

[0061] Specific steps are as follows:

[0062] 1. Pump the high-concentration emulsion into the acidification tank, add sulfuric acid to adjust the pH value of the high-concentration emulsion wastewater to 3.0, and let it stand for 12 hours to separate the upper layer of oil slick to obtain the lower layer of degreasing wastewater;

[0063] 2. Pump the oil-removing waste water after the degreasing treatment in step 1 into the Fenton reactor, add the catalyst green vitriol with a mass percentage of 5.6% of the oil-removing waste water to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com