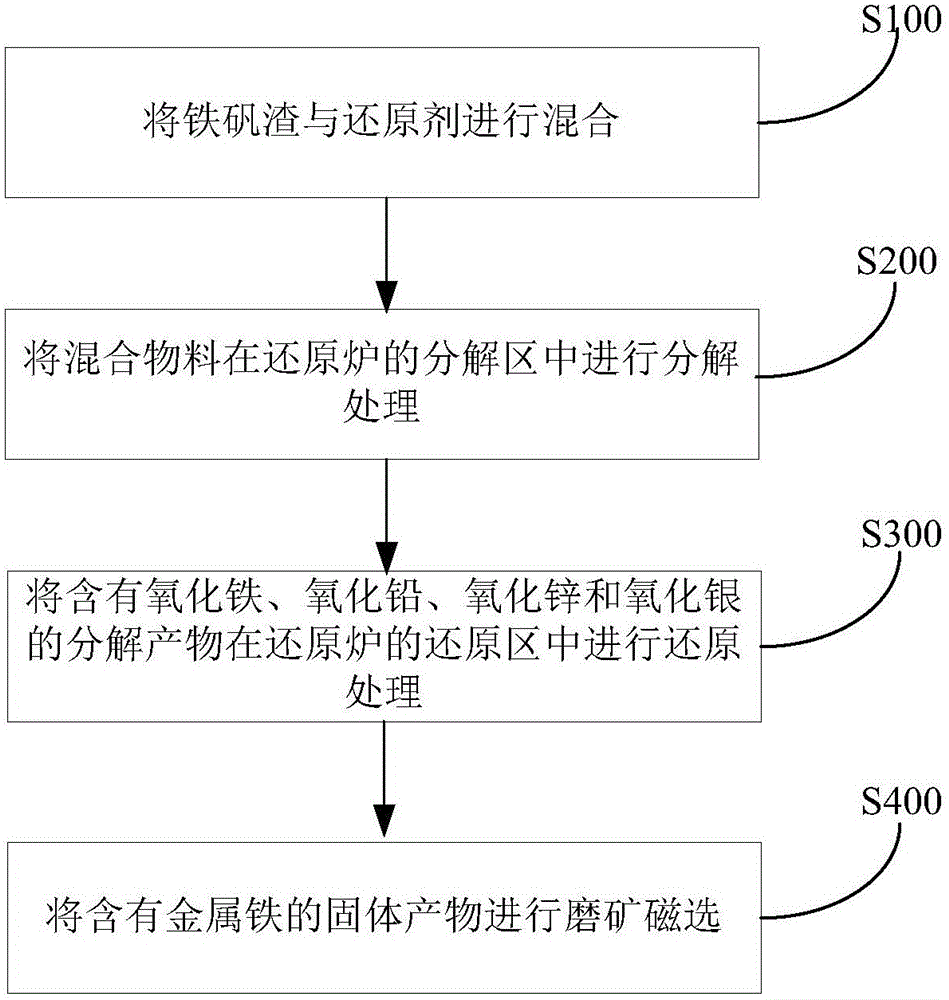

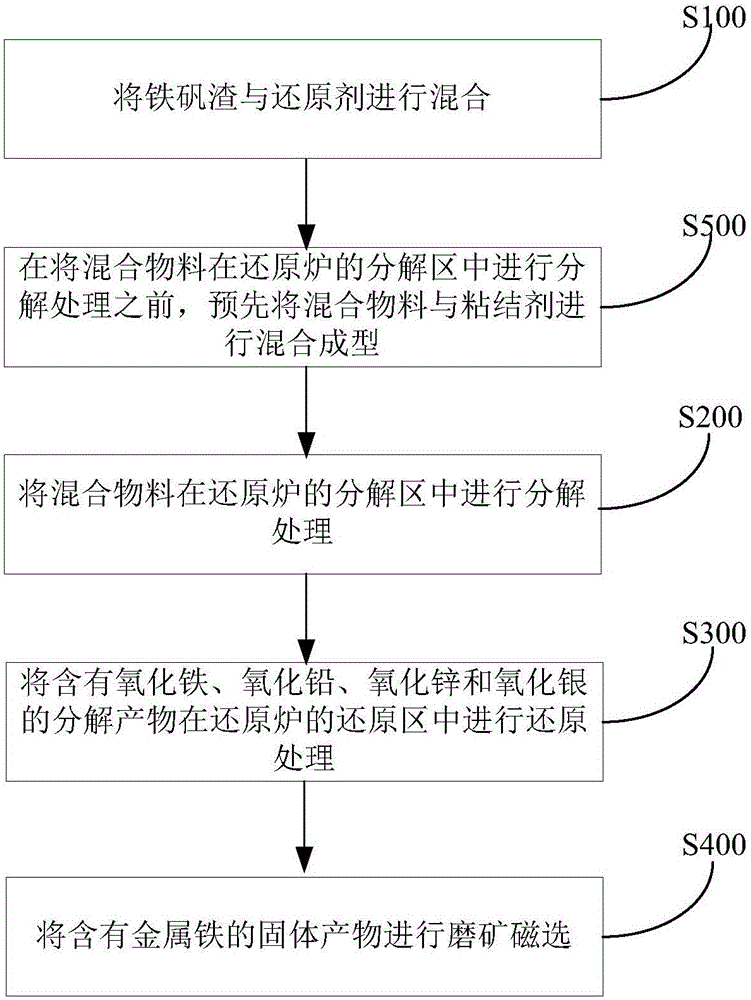

Iron vitriol slag treatment method

A technology of jarosite slag and ferric sulfate, applied in directions such as the improvement of process efficiency, can solve the problems such as the inability to recover iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Auxinite slag (13.2% S content, 5.2% zinc content, 3.2% lead content) and anthracite (below 4mm in particle size) are mixed according to the mass ratio of 100:8, and the mixed material is sent to the sub-distributor through the distribution device In the stage reduction furnace, the reduction furnace is divided into two temperature zones: the decomposition zone and the reduction zone. The temperature in the decomposition zone is 750°C, the residence time of the material is 2h, and the decomposition zone needs to be fed with CO to adjust the atmosphere to ensure that the CO concentration is Above 2000ppm, iron sulfate, lead sulfate, zinc sulfate and silver sulfate in the iron slag are decomposed to obtain sulfur dioxide and decomposition products containing iron oxide, lead oxide, zinc oxide and silver oxide, and the sulfur dioxide is discharged through the flue, and the obtained The decomposition product is transported to the reduction area, the reduction temperature is ...

Embodiment 2

[0052] Mix the alum slag (with S content of 13.2%, zinc content of 5.2%, and lead content of 3.2%) with semi-coke (with a particle size below 4mm) at a mass ratio of 100:8, and the mixed material is sent into the In the segmented reduction furnace, the reduction furnace is divided into two temperature zones: the decomposition zone and the reduction zone. The temperature in the decomposition zone is 800°C, the residence time of the material is 3h, and the decomposition zone needs to be fed with CO to adjust the atmosphere to ensure the CO concentration. It is more than 2000ppm, so that iron sulfate, lead sulfate, zinc sulfate and silver sulfate in the alumina slag undergo decomposition reactions to obtain sulfur dioxide and decomposition products containing iron oxide, lead oxide, zinc oxide and silver oxide, and the sulfur dioxide is discharged through the flue. The obtained decomposition products are transported to the reduction area, the reduction temperature is 1230 ° C, and...

Embodiment 3

[0054]Mix jarosite slag (13.2% S content, 5.2% zinc content, 3.2% lead content, ground to 200 mesh) and anthracite (below 1mm particle size) according to the mass ratio of 100:8, and the mixed material It is sent into the segmented reduction furnace through the material distribution device. The reduction furnace is divided into two temperature zones: the decomposition zone and the reduction zone. The temperature in the decomposition zone is 800°C, and the material residence time is 2.5h. The atmosphere is adjusted to ensure that the CO concentration is more than 2000ppm, so that iron sulfate, lead sulfate, zinc sulfate and silver sulfate in the alumina slag undergo decomposition reactions to obtain sulfur dioxide and decomposition products containing iron oxide, lead oxide, zinc oxide and silver oxide, and Sulfur dioxide is discharged through the flue, and the resulting decomposition products are transported to the reduction zone. The reduction temperature is 1200°C, and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com