Patents

Literature

60results about How to "Solve the problem that cannot be recycled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

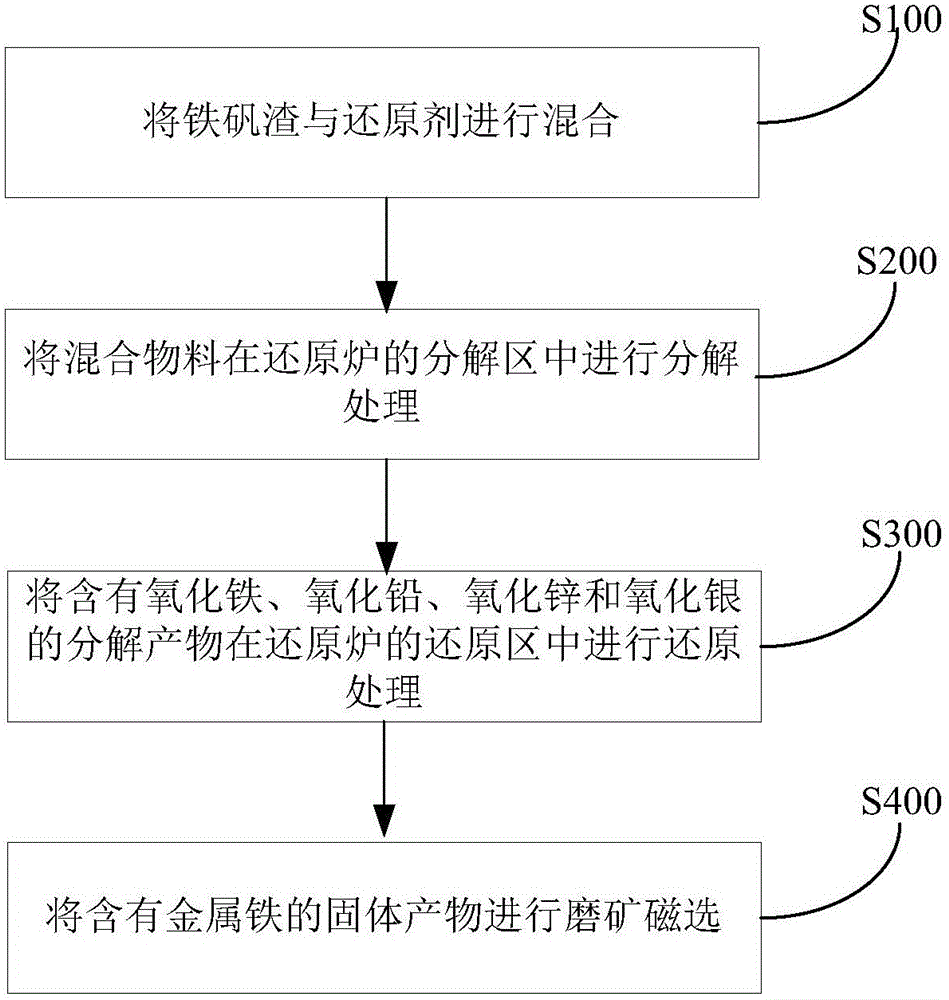

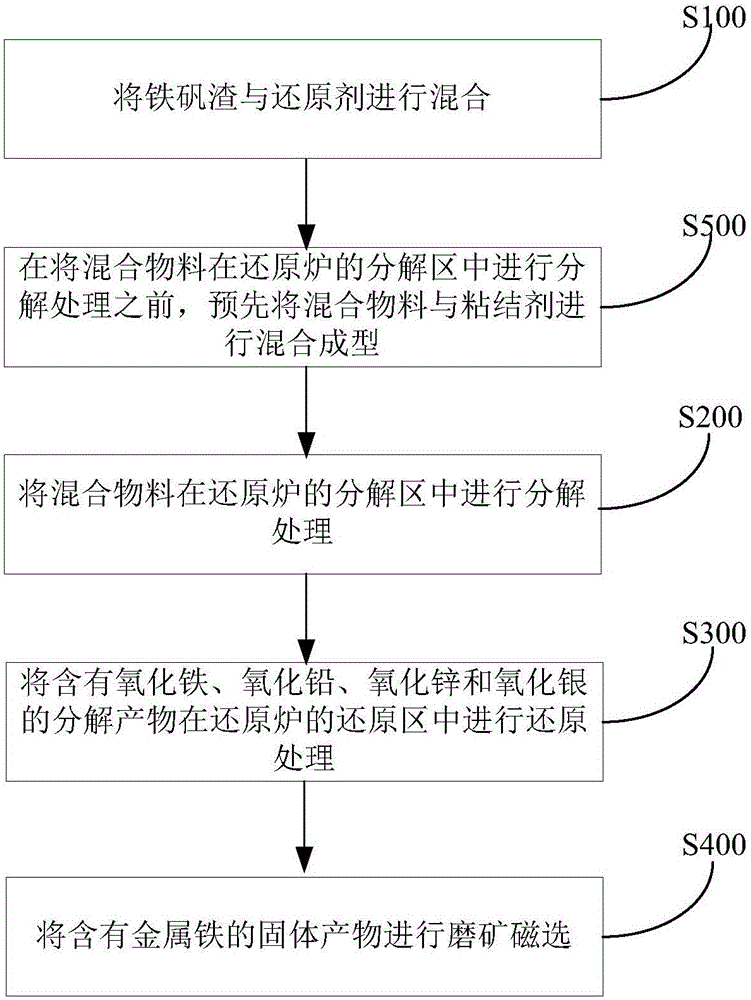

Iron vitriol slag treatment method

InactiveCN106011489ASolve the problem that cannot be recycledEfficient recyclingProcess efficiency improvementSlagReducing agent

The invention discloses an iron vitriol slag treatment method. The iron vitriol slag treatment method comprises the following steps: (1) iron vitriol slag is mixed with a reducing agent to obtain a mixture; (2) the mixture is decomposed in a decomposing area of a reducing furnace to obtain sulfur dioxide and a decomposed product containing iron oxide, lead oxide, zinc oxide and silver oxide; (3) the decomposed product containing iron oxide, lead oxide, zinc oxide and silver oxide is reduced in a reducing area of the reducing furnace to obtain a gaseous product containing lead, zinc and silver and a solid product containing metal iron; and (4) the solid product containing metal iron is grinded and magnetically separated to obtain the metal iron and tailings. The method can effectively recover iron, lead, zinc and silver in the iron vitriol slag, solves the difficulty of incapability of recovering iron in the iron vitriol slag in the prior art, and can reach the recovery rates of iron, lead, zinc and silver of above 90%.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

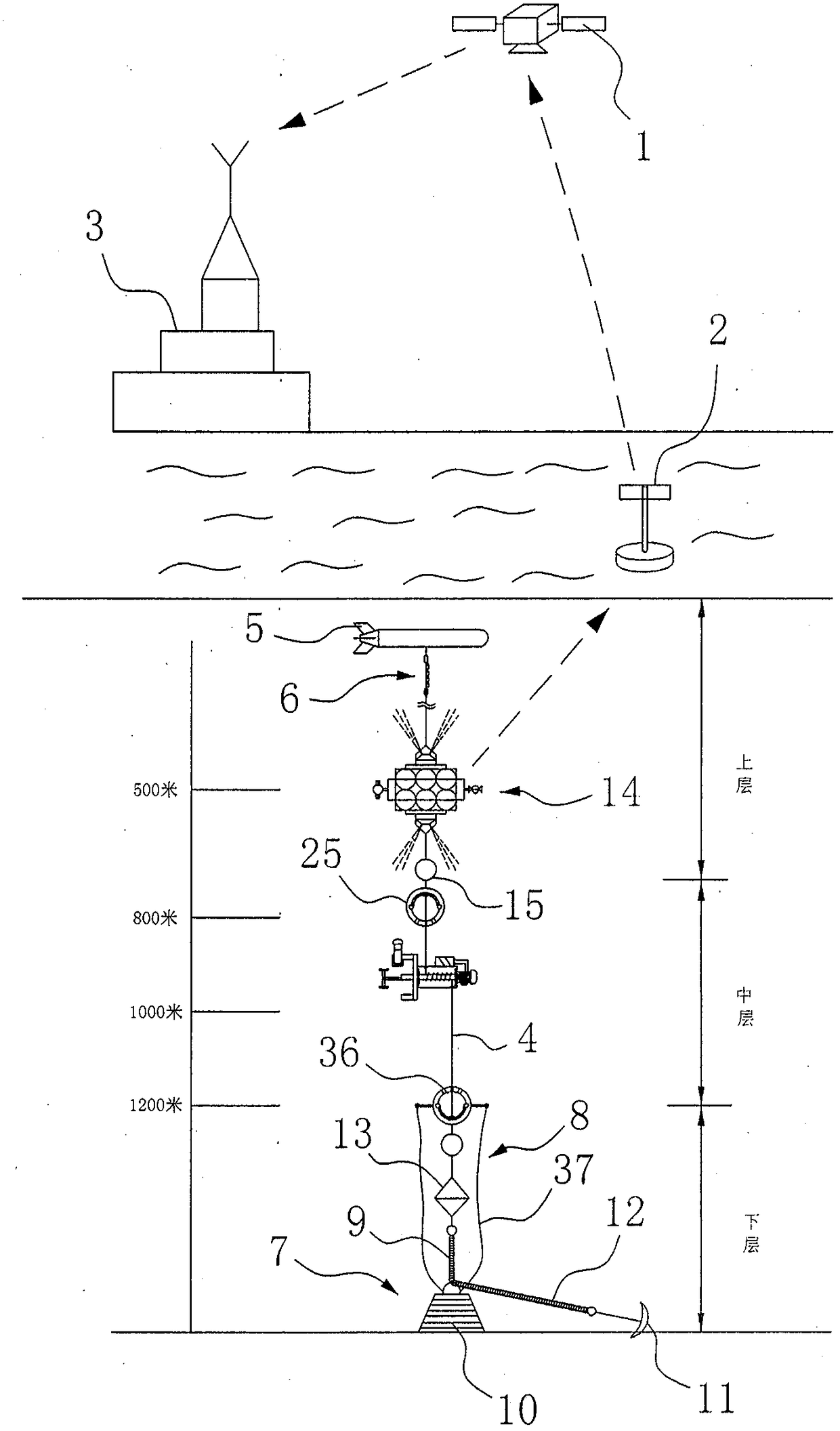

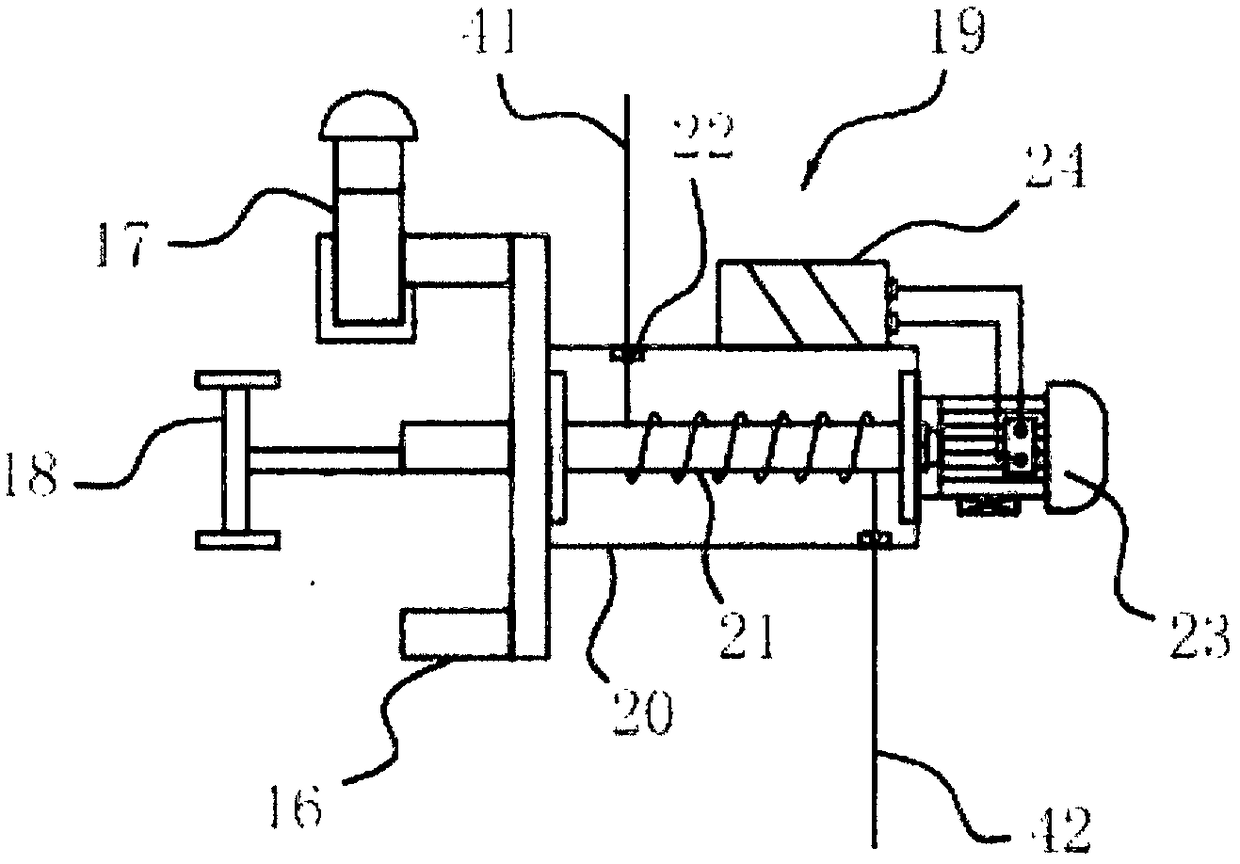

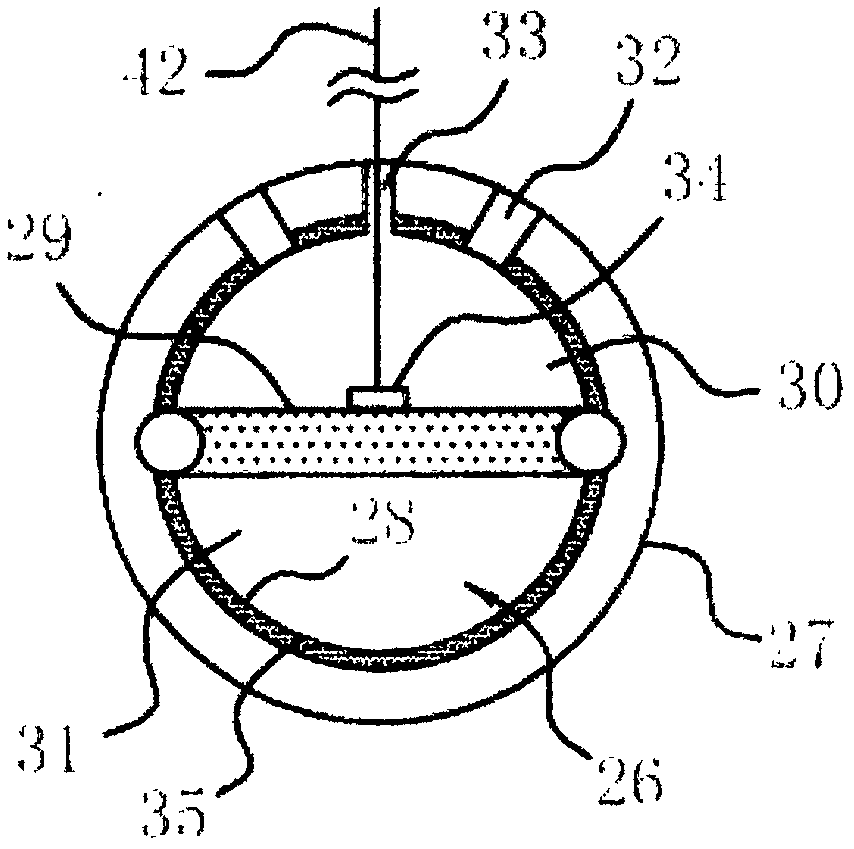

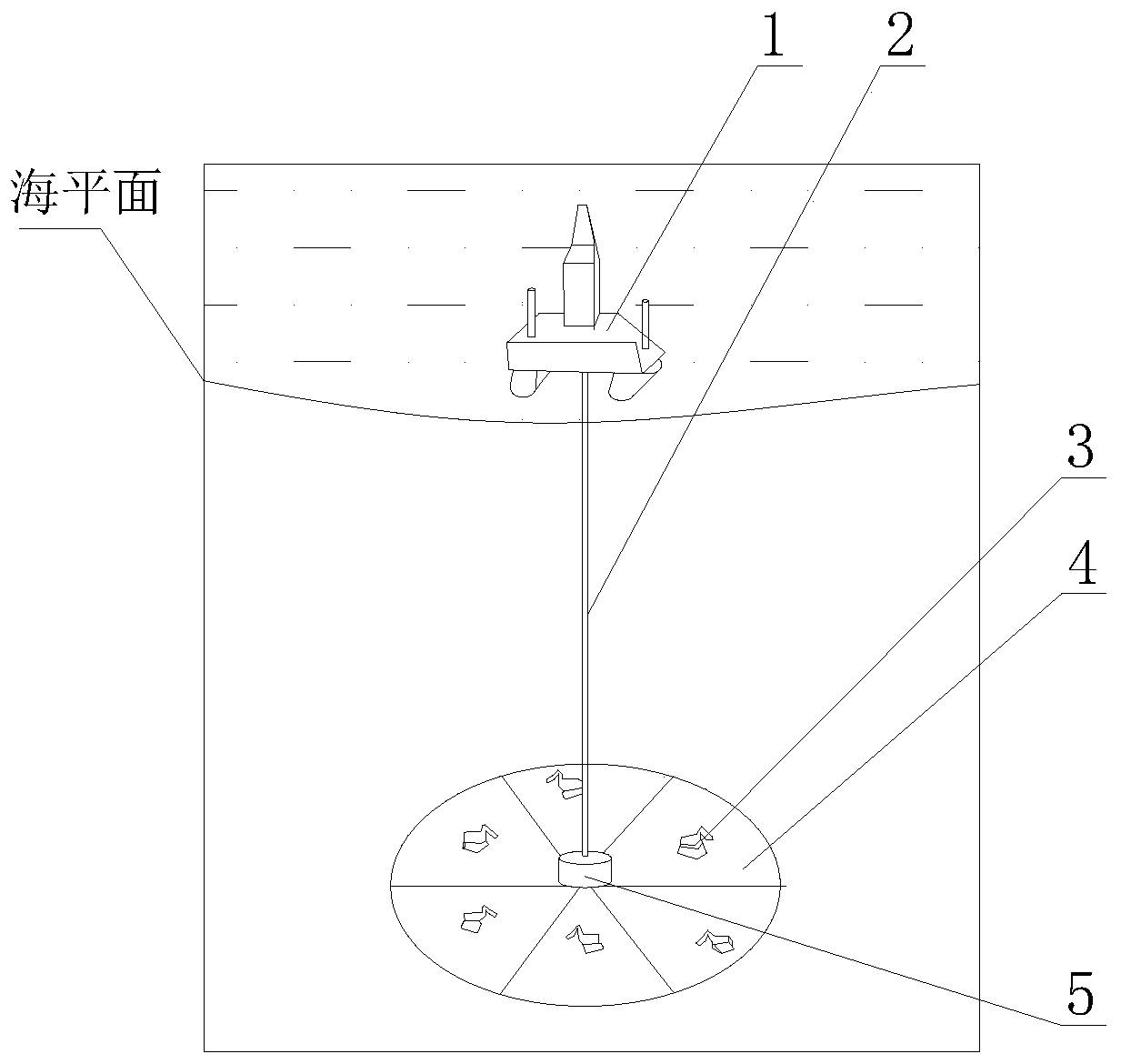

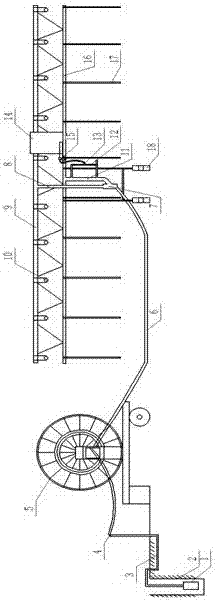

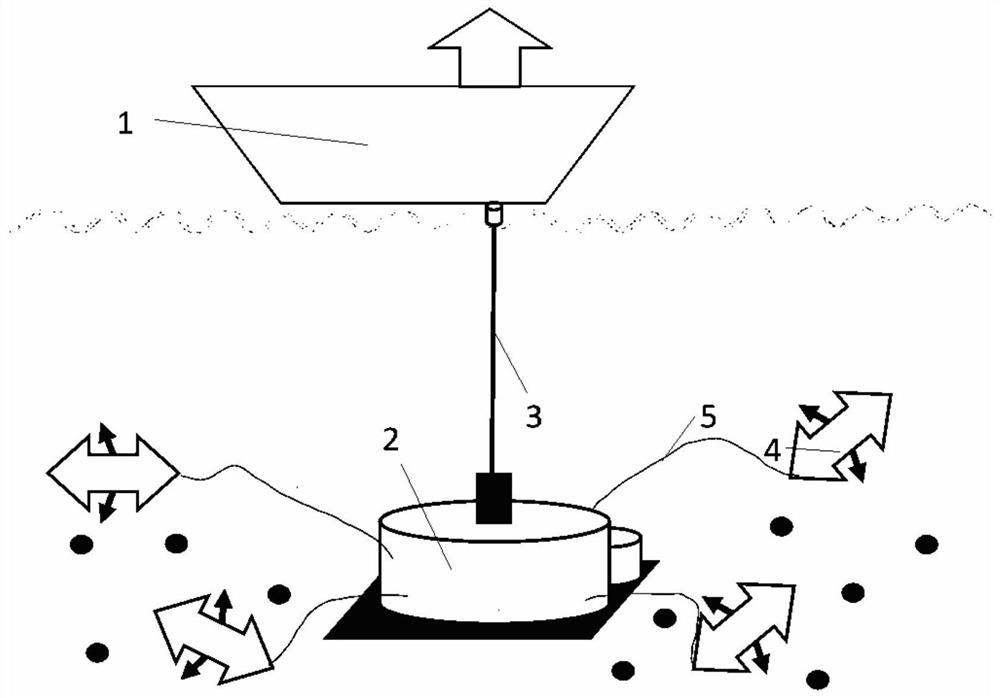

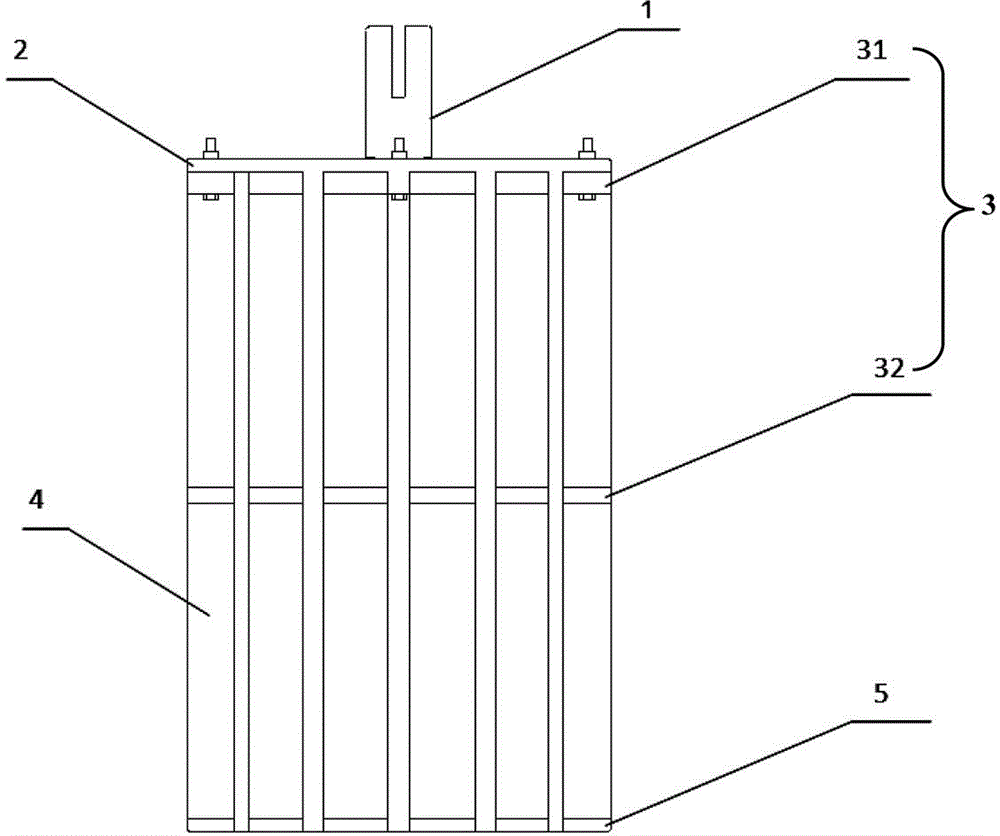

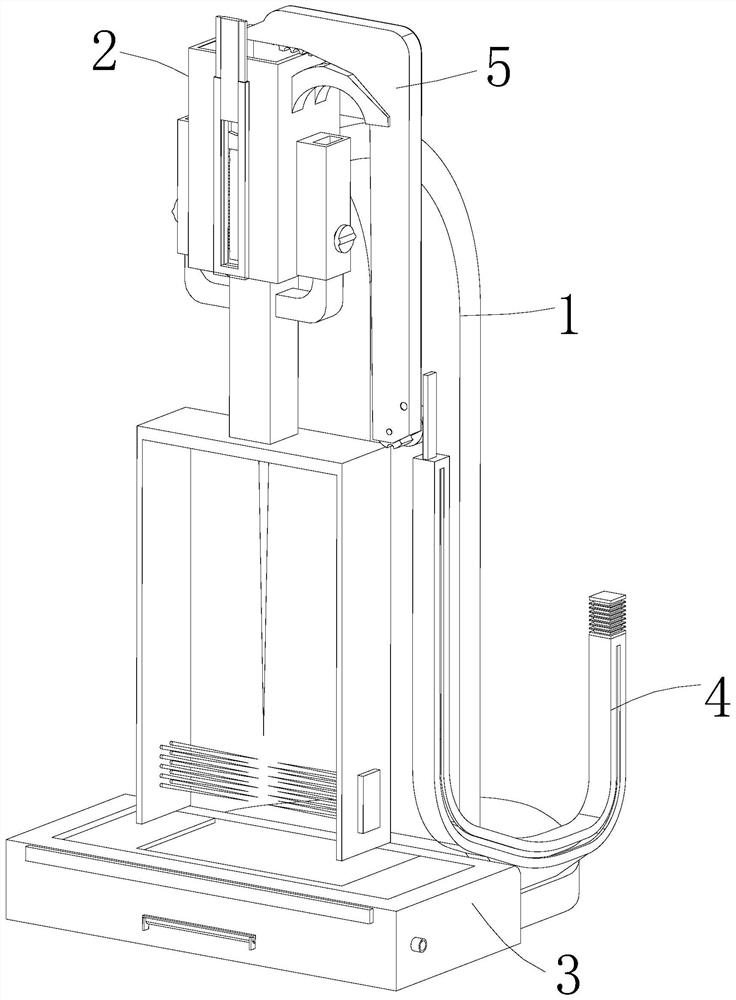

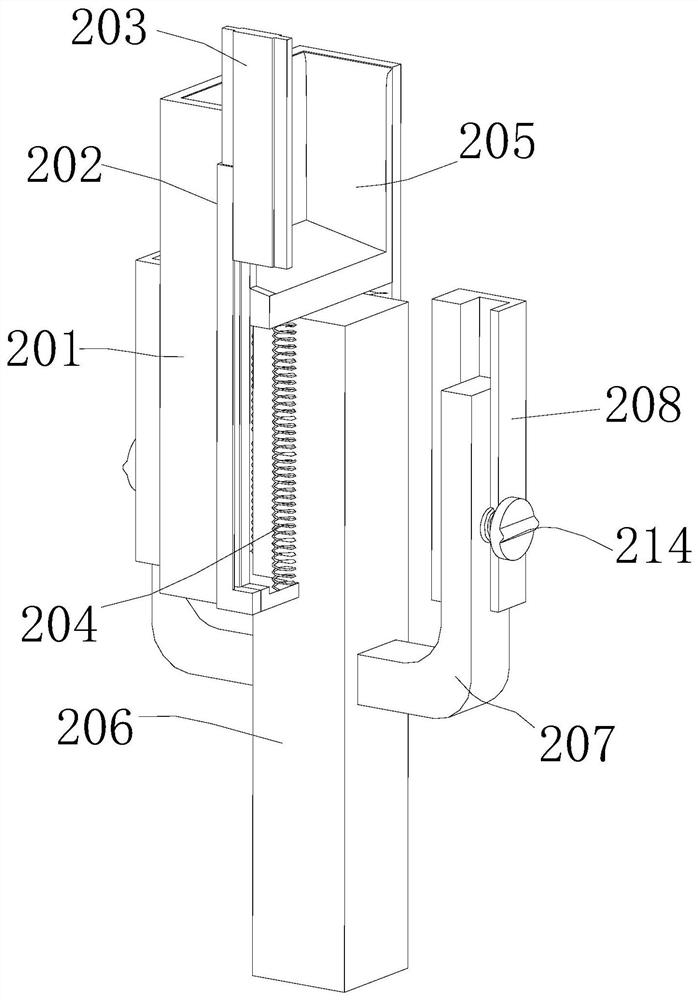

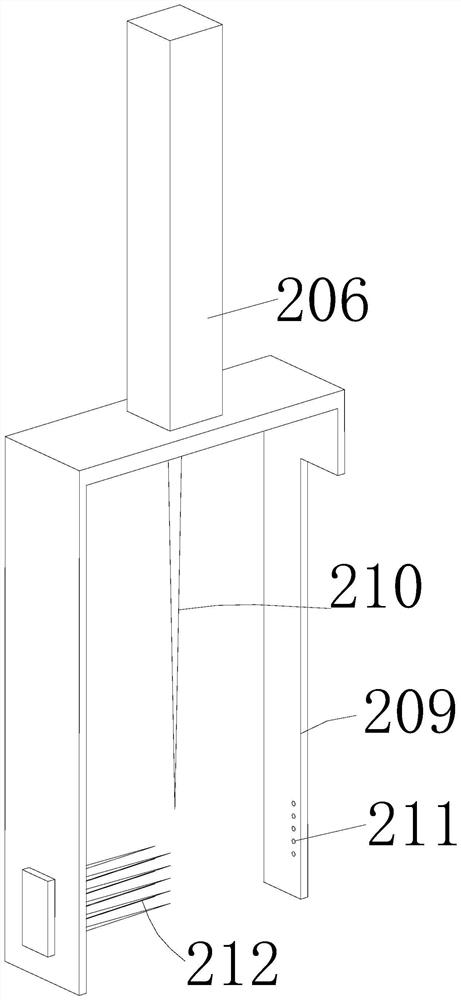

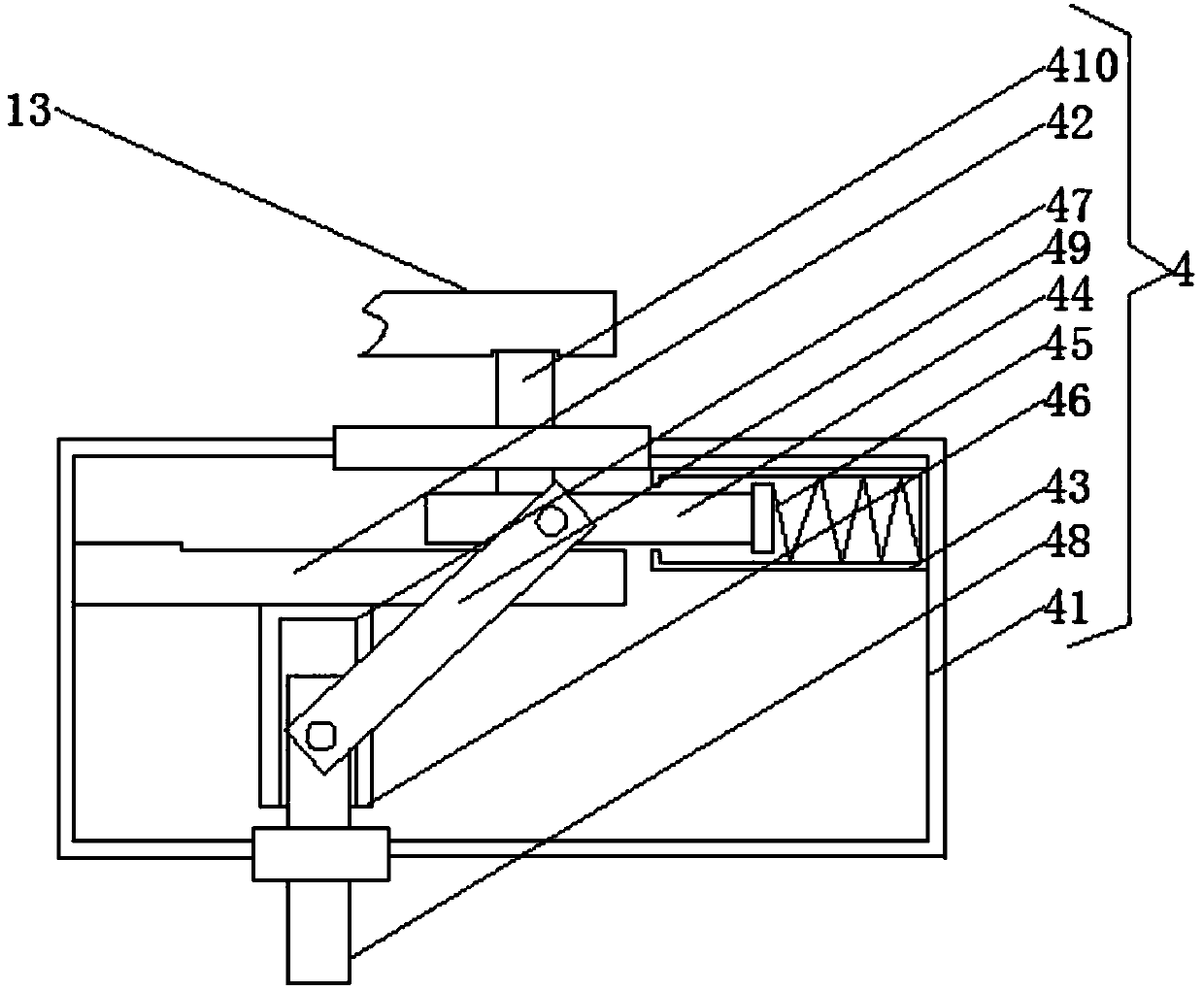

Deep-sea anchor-system subsurface-buoy system based on satellite communication data real-time transmission

ActiveCN108189969AReasonable structureRun smoothlyMeasurement devicesWaterborne vesselsAutomatic controlWater depth

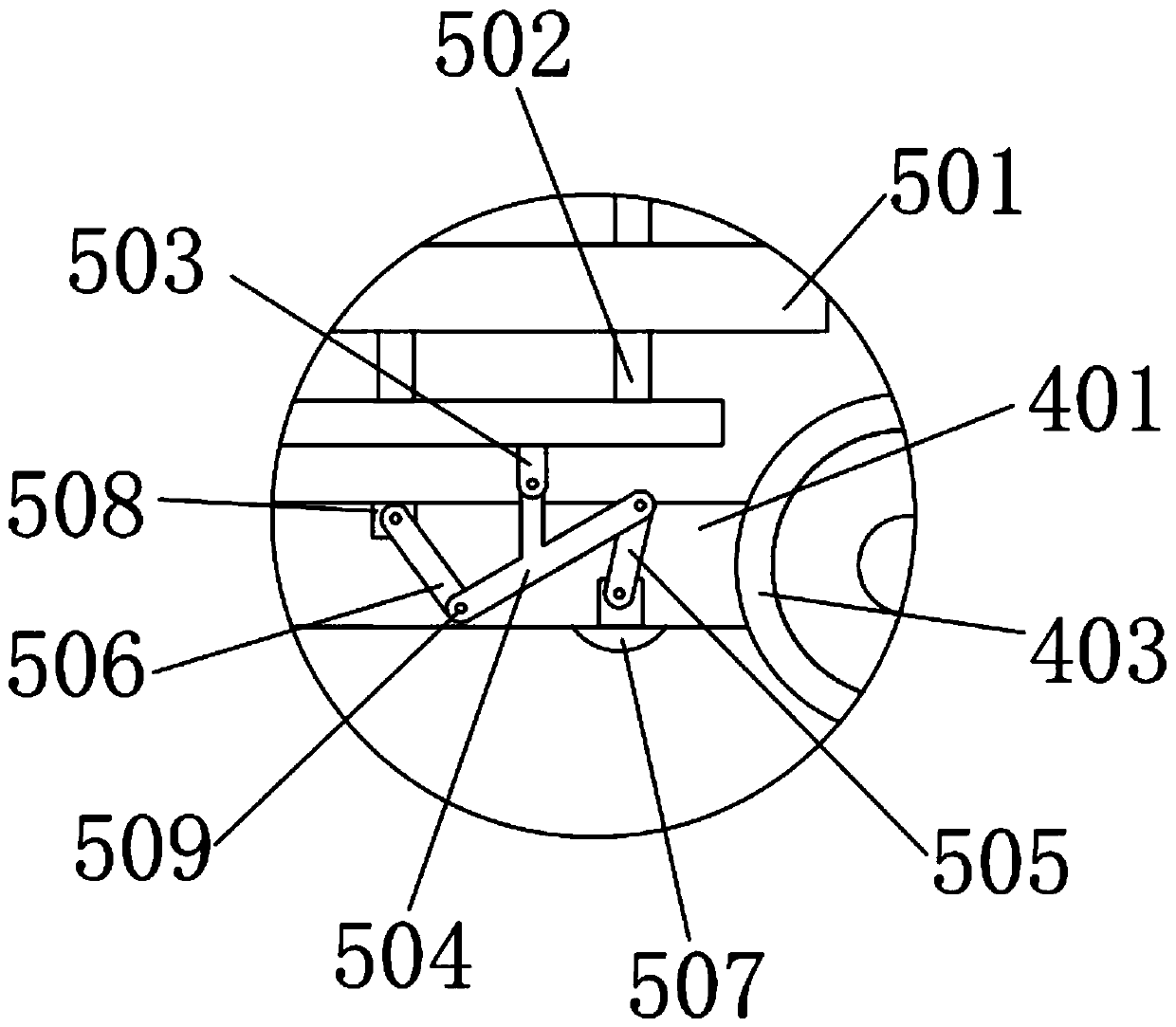

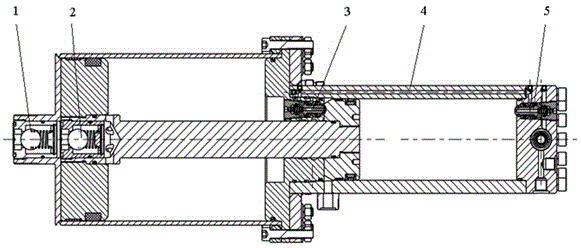

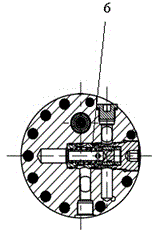

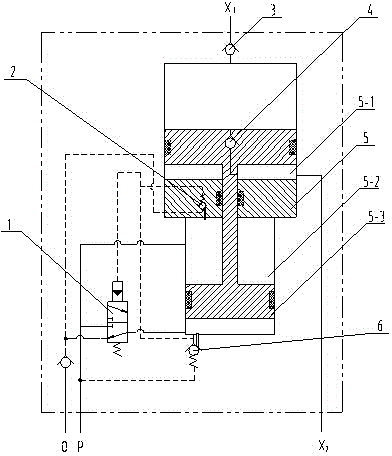

The invention discloses a deep-sea anchor-system subsurface-buoy system based on satellite communication data real-time transmission. The deep-sea anchor-system subsurface-buoy system comprises a water-surface buoy system, a vertically-arranged plastic covered steel cable, a secondary floating body, an anchoring mooring part, a releasing unit, a primary floating body and a plurality of glass floating balls, and the deep-sea anchor-system subsurface-buoy system also comprises a frame body arranged between the main floating body and the releasing unit and used for carrying deepwater measuring apparatuses; a lifting adjusting mechanism for driving all the deepwater measuring apparatuses to move up and down along the plastic covered steel cable to measure measurement data of sections at different water-depth portions is arranged on the frame body. Through the lifting adjusting mechanism, continuous data monitoring of underwater preset depth distance sections can be achieved, and the void that continuous collection of section information under all temperature-salinit deepwater in different water depths cannot be carried out at present is filled; automatic control is achieved through a controller, the structure is reasonable, and running is stable; through an arranged lifting-adjusting auxiliary part, the resistance of the frame body in the ascending or descending process along the plastic covered steel cable is smaller, and running is more stable.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

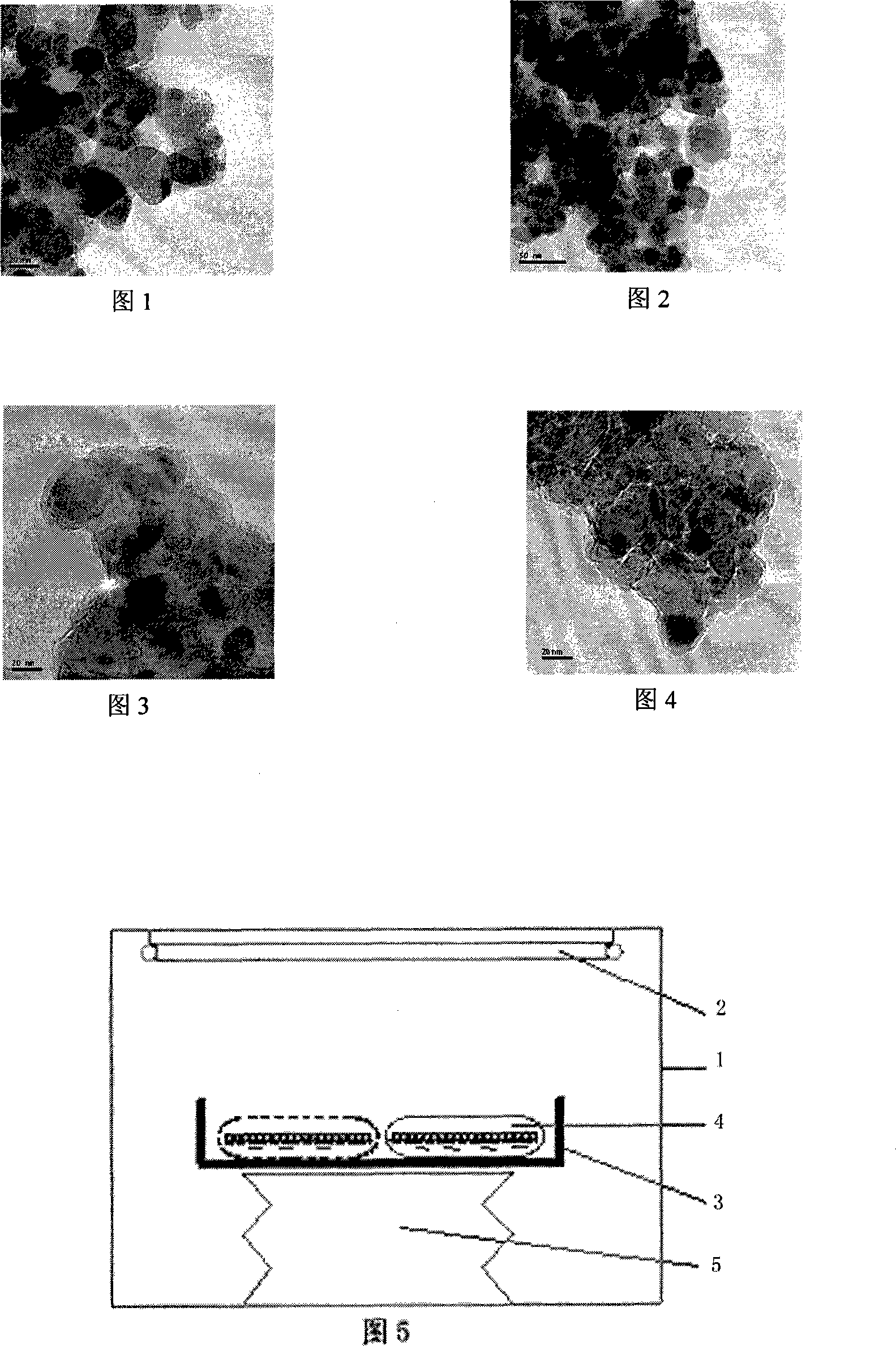

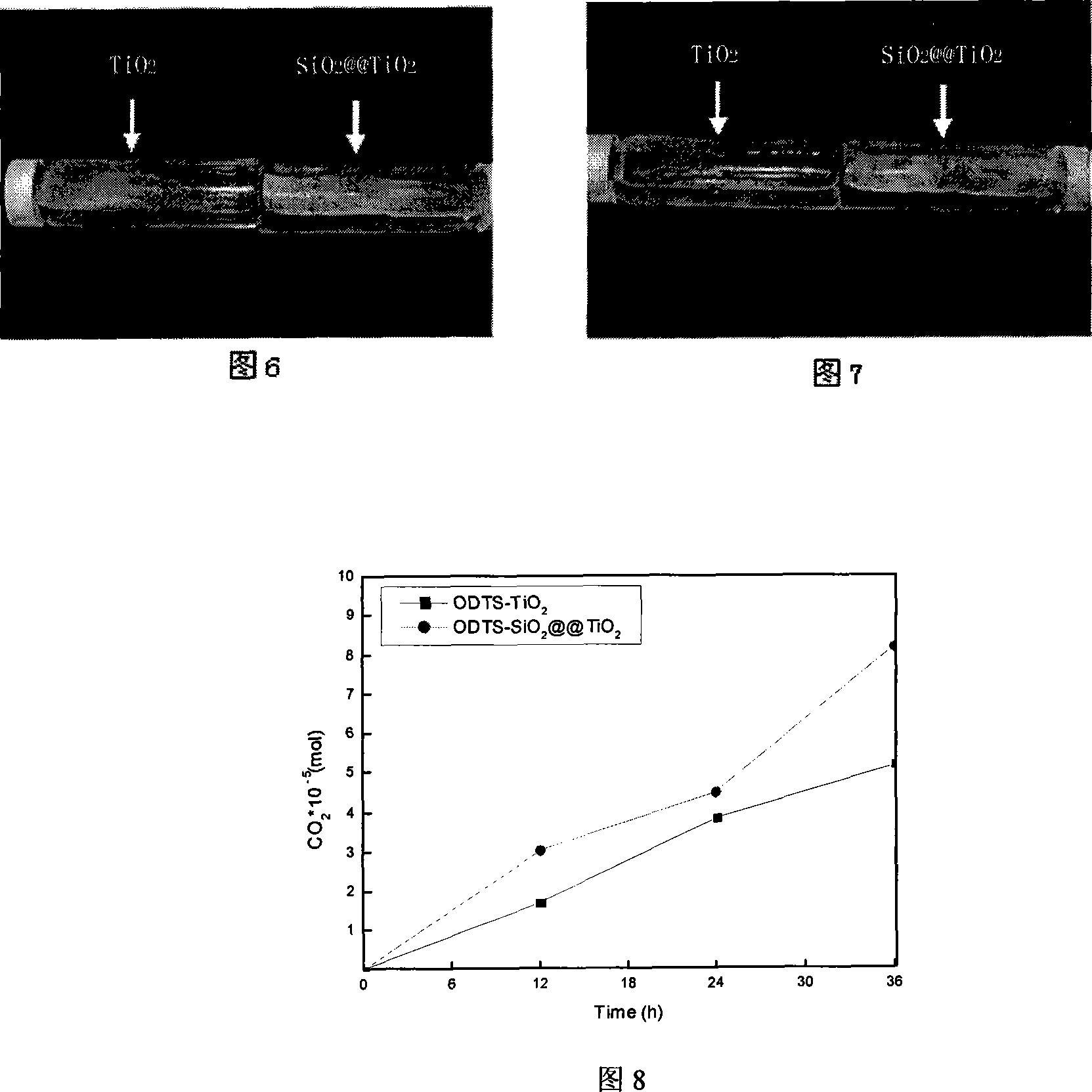

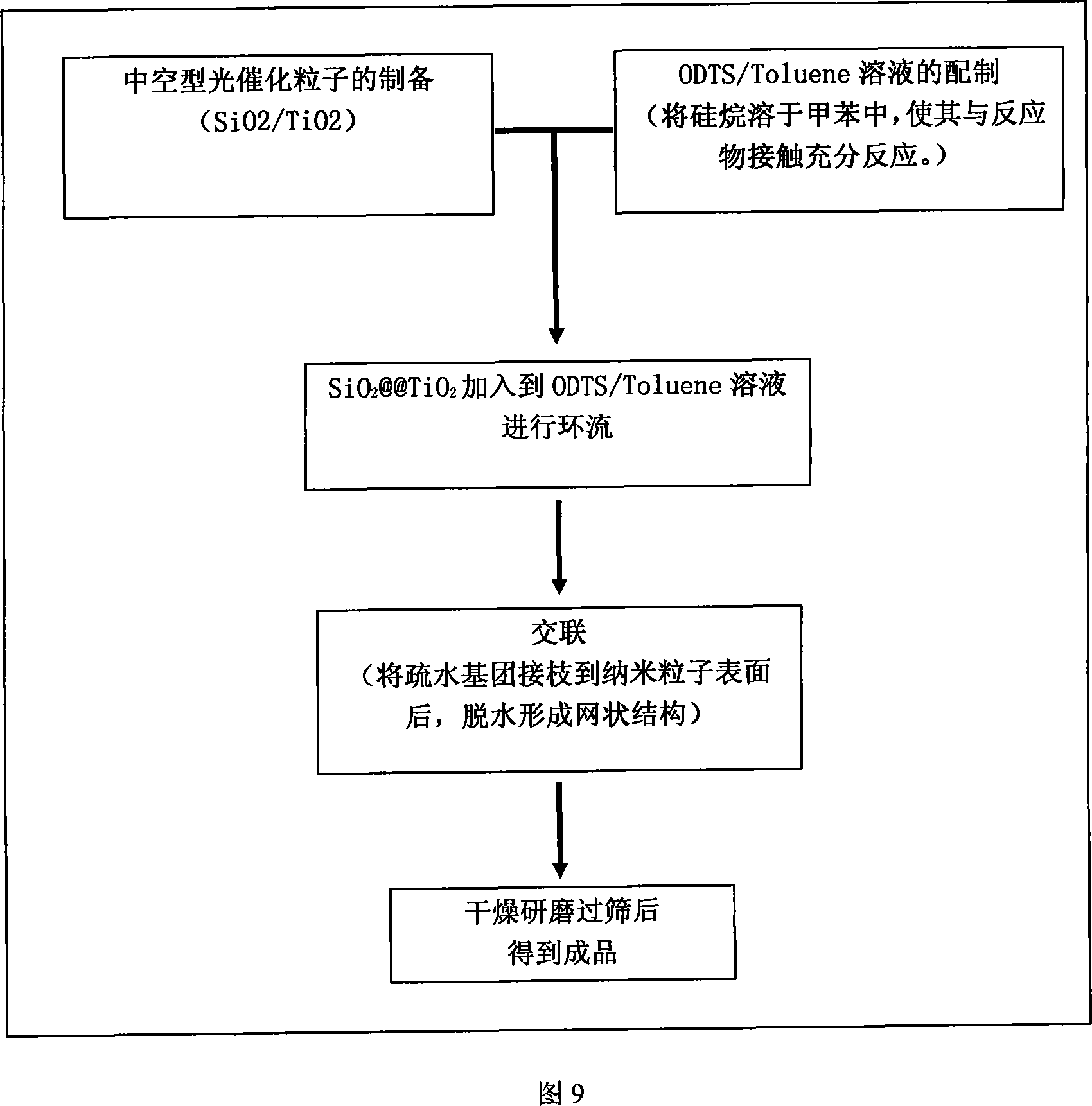

Method for preparing interface optical catalyst

ActiveCN101099929AAvoid direct contactSpread as soon as possibleCatalyst activation/preparationCross-linkPhotocatalytic reaction

The present invention relates to one kind of interface photocatalyst, and solves the technological problem of preparing one interface photocatalyst capable of floating on water surface for photocatalytic reaction and with lasting photocatalytic activity. The interface photocatalyst floating on water surface can utilize sunlight well for photocatalysis to decompose pollutant and may be recovered easily, with the decomposition produced CO2 being dispersed to the air directly. It is prepared through the following steps: 1. preparing photocatalyst particle in SiO2-hollow layer-TiO2 structure and with nanometer core; 2. preparing hydrophobic solution; 3. preparing hydrophobic hollow nanometer photocatalyst particle; and 4. cross-linking hydrophobic groups of hollow nanometer photocatalyst particle. The present invention is applied in degrading toxic pollutant to protect environment.

Owner:ZHEJIANG SCI-TECH UNIV

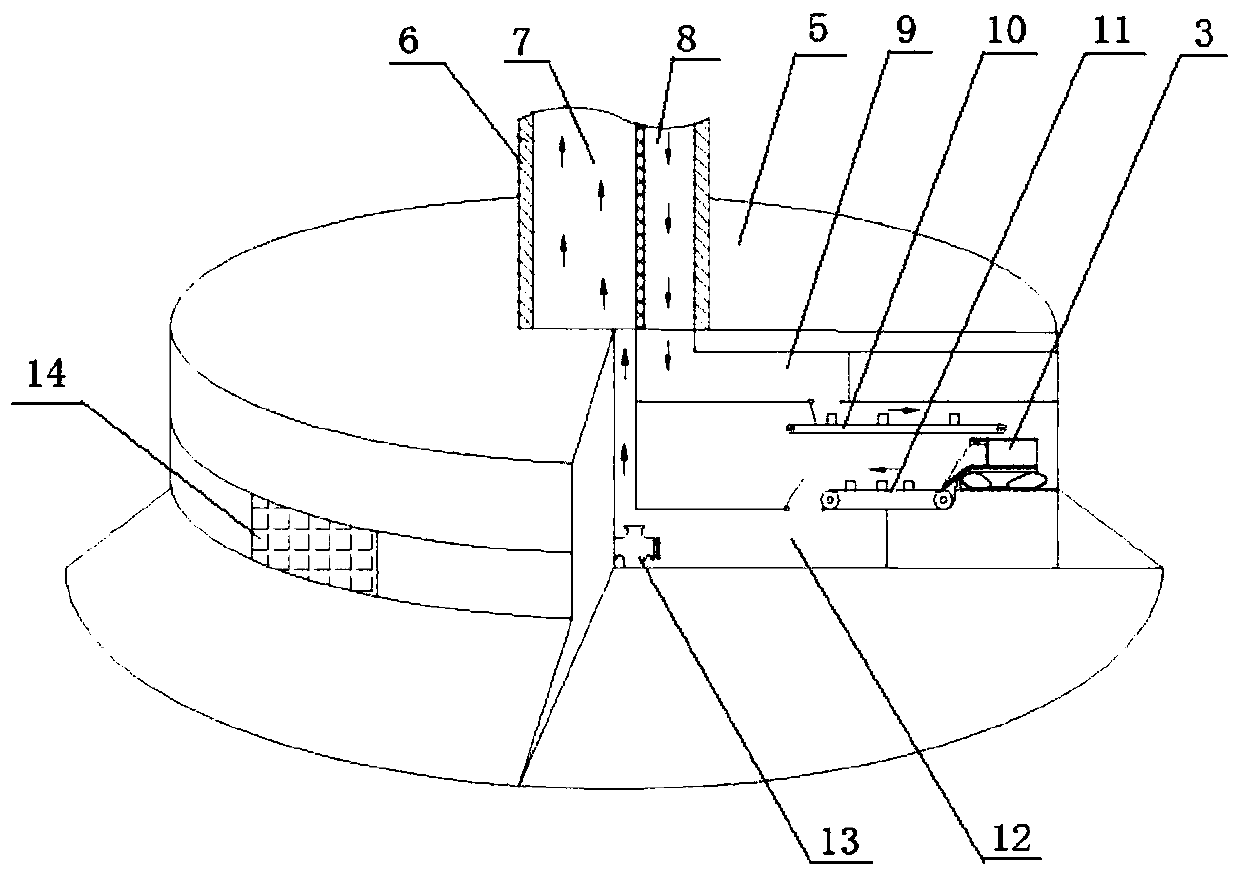

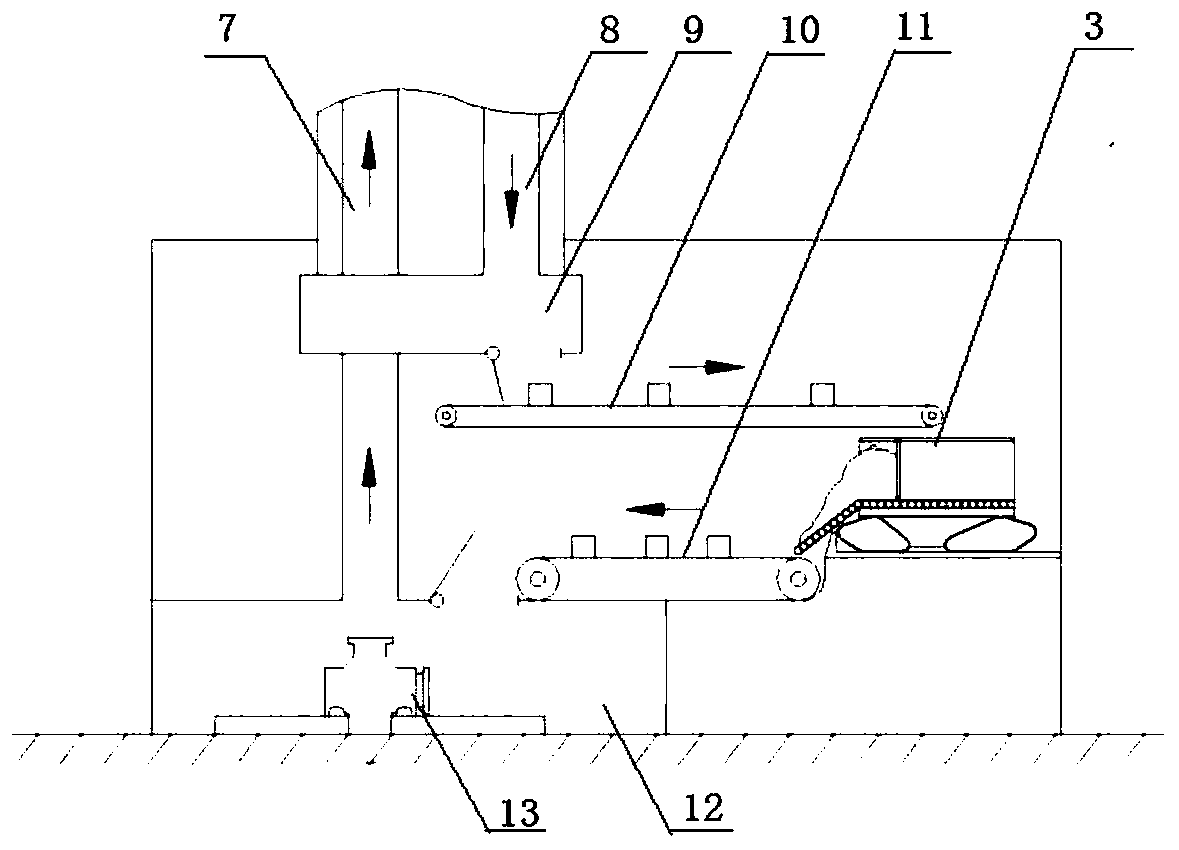

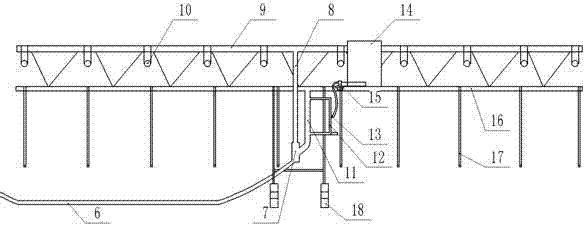

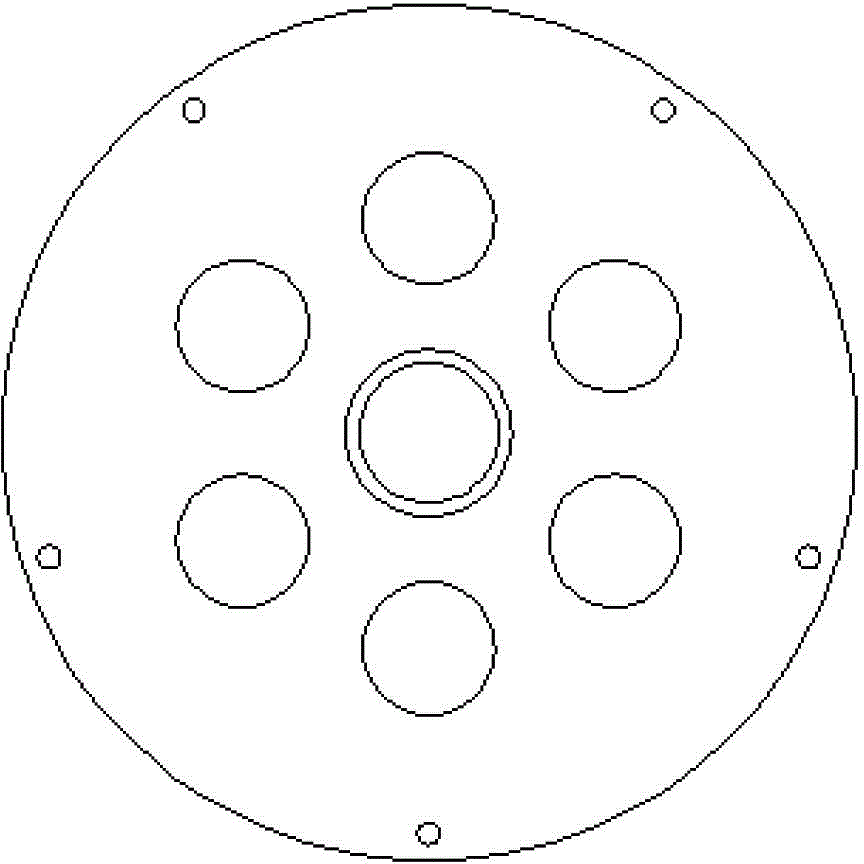

Deep-sea multi-metal nodule mining operation system

PendingCN109973096ARealize communicationSolve the problem that cannot be recycledMineral miningUniversal jointMulti degree of freedom

The invention discloses a deep-sea multi-metal nodule mining operation system. A mine-lifting vertical pipe system comprises a mine-lifting vertical pipe and a mud pump; the top end of the lifting vertical pipe is connected with a mining platform, and the bottom end of the lifting vertical pipe is connected with a bottom-supported mineral connection processing center through universal joints; a multi-degree-of-freedom platform is arranged in the bottom-supported mineral connection processing center, a waste material warehouse and a fresh material warehouse are sequentially arranged on the multi-degree-of-freedom platform from top to bottom, and the end parts, positioned at an outlet of the waste material warehouse and an inlet of the fresh material warehouse, of an upper conveyer belt anda lower conveyer belt are connected through mining robots; and a plurality of fan-shaped mining areas are correspondingly arranged right below the multi-degree-of-freedom platform, and the mining robots operate in the fan-shaped mining areas. Connecting and mineral lifting are carried out, DSAMV mineral unloading is realized while ballast is provided, power supply and two-way data communication are achieved; the relationship between gravity and buoyancy of DSAMV is balanced; and a plurality of DSAMV work in parallel without interfering with each other, umbilical cables and mineral conveying hoses are omitted, and the deep-sea multi-metal nodule mining operation system is capable of adapting to the dynamic change of the mining vertical pipe in real time and adapting to the real-time state of the DSAMV during connection.

Owner:OCEAN UNIV OF CHINA

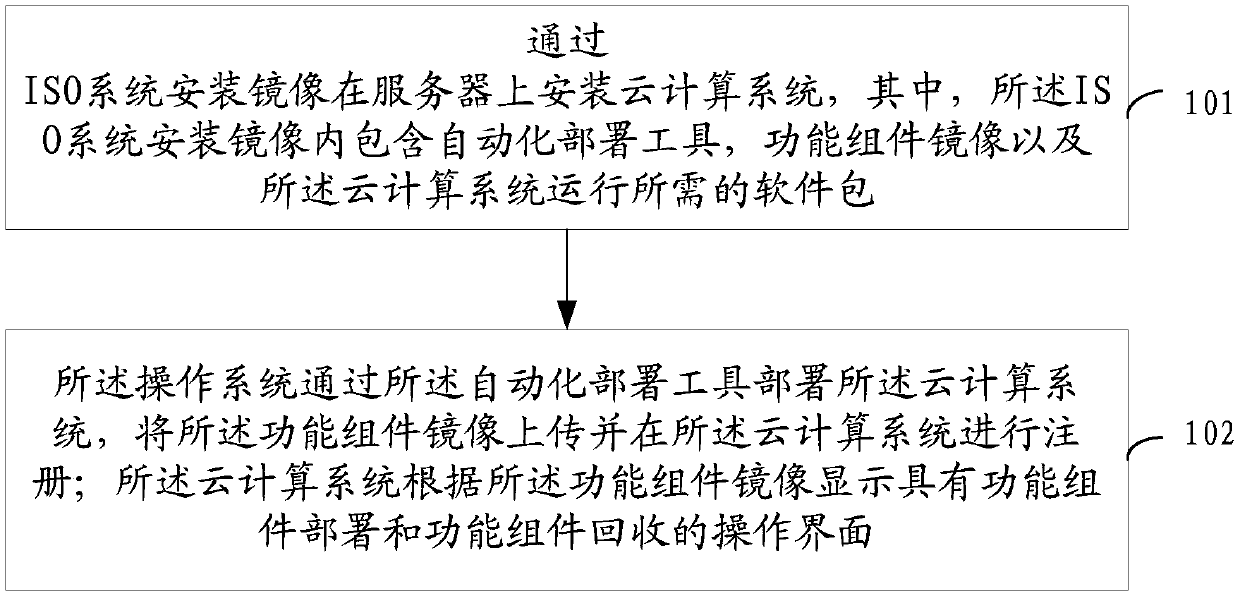

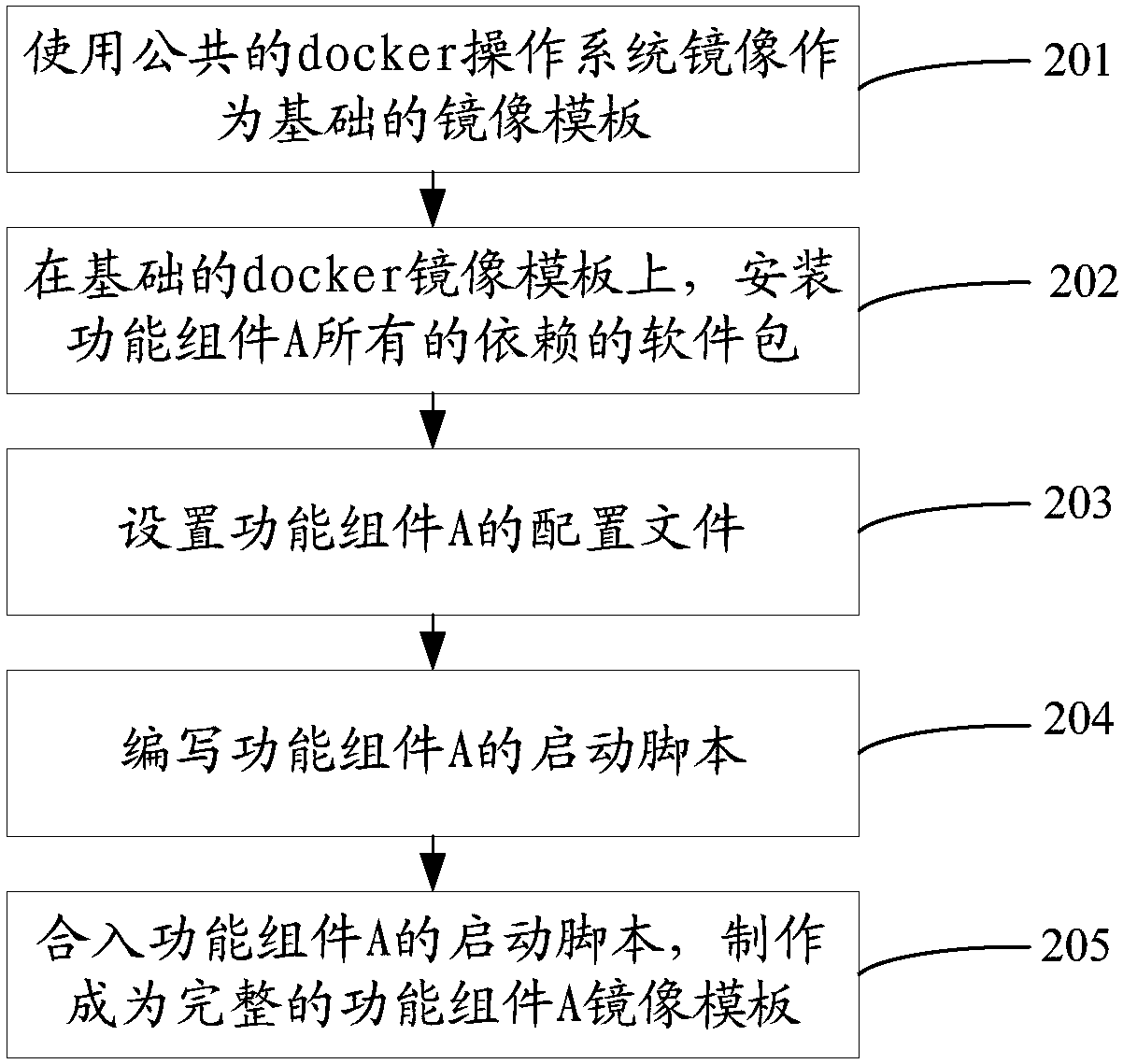

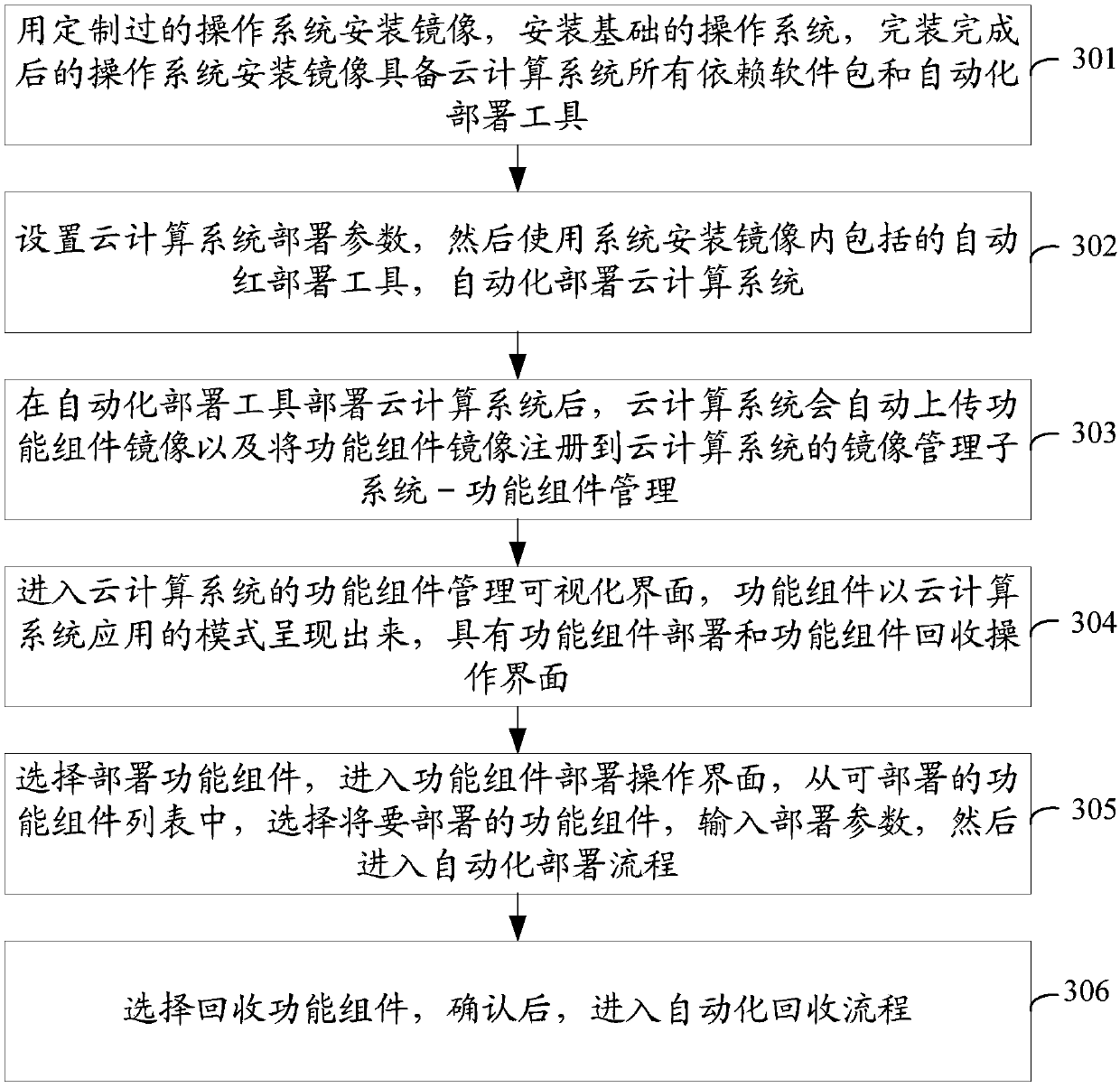

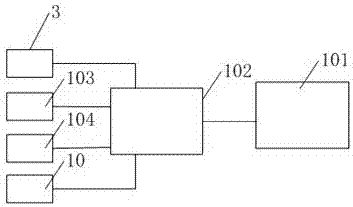

Deployment method and device for function components in cloud computing system

ActiveCN107733985AHigh functional flexibilityHigh degree of automationTransmissionMirror imageComputing systems

The invention discloses a deployment method and device for function components in a cloud computing system, belongs to the technical field of communication and is used for solving the problem that theexisting deployment method for a cloud computing platform is complex in configuration and excessively tedious in manual operation and the recycling cannot be carried out after the components are deployed. The method comprises the steps of installing the cloud computing system on a server through an ISO system installation mirror image, wherein the ISO system installation mirror image comprises anautomatic deployment tool, function component mirror images and a software packet required for operation of the cloud computing system; deploying the cloud computing system by an operating system through the automatic deployment tool, uploading the function component mirror images and registering with the cloud computing system; and displaying an operation interface with function component deployment and function component recycling functions by the cloud computing system according to the function component mirror images.

Owner:GUANGZHOU VCMY TECH CO LTD

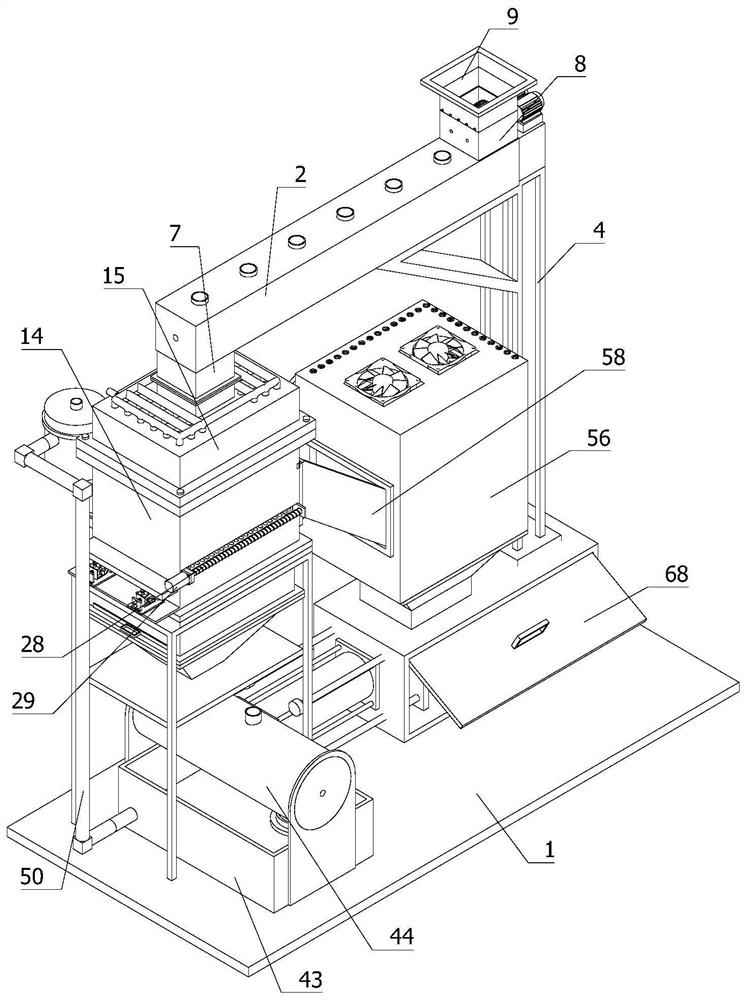

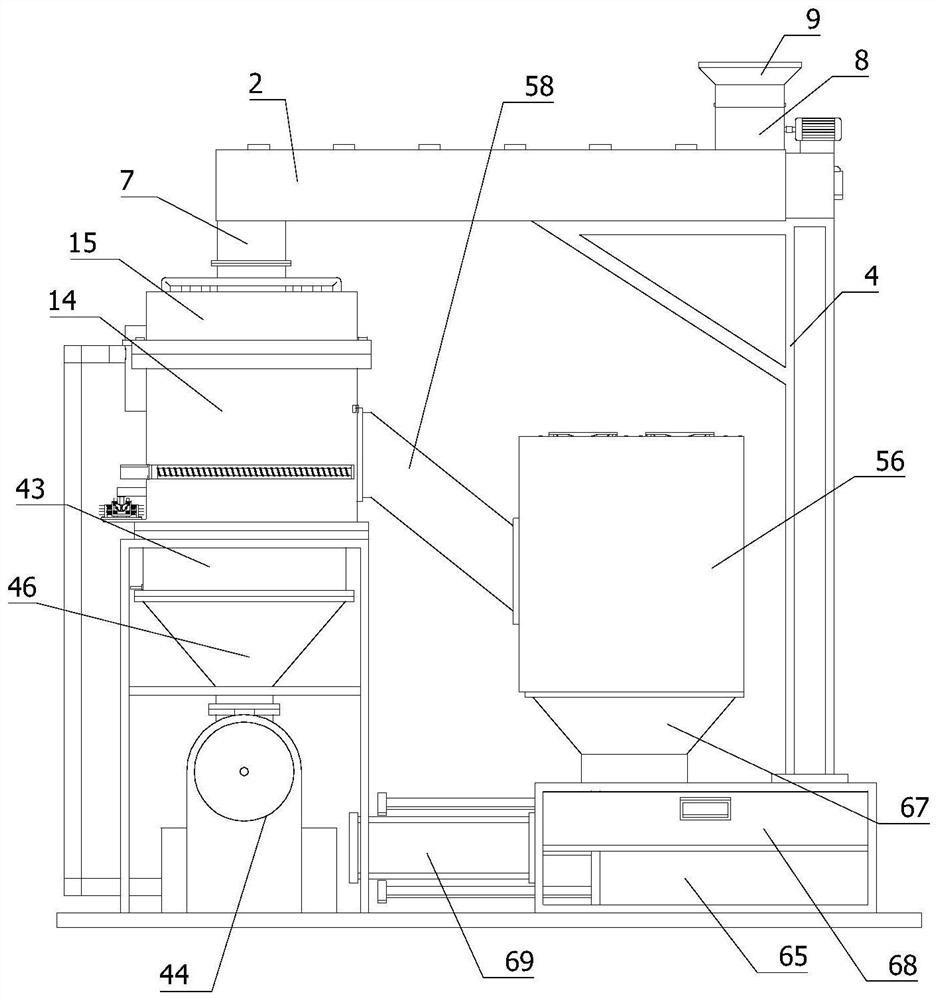

Environment-friendly cleaning equipment for solid waste treatment

InactiveCN111906121AShorten the timeGuaranteed to be environmentally friendlySpecific water treatment objectivesSolid waste disposalProcess engineeringWaste treatment

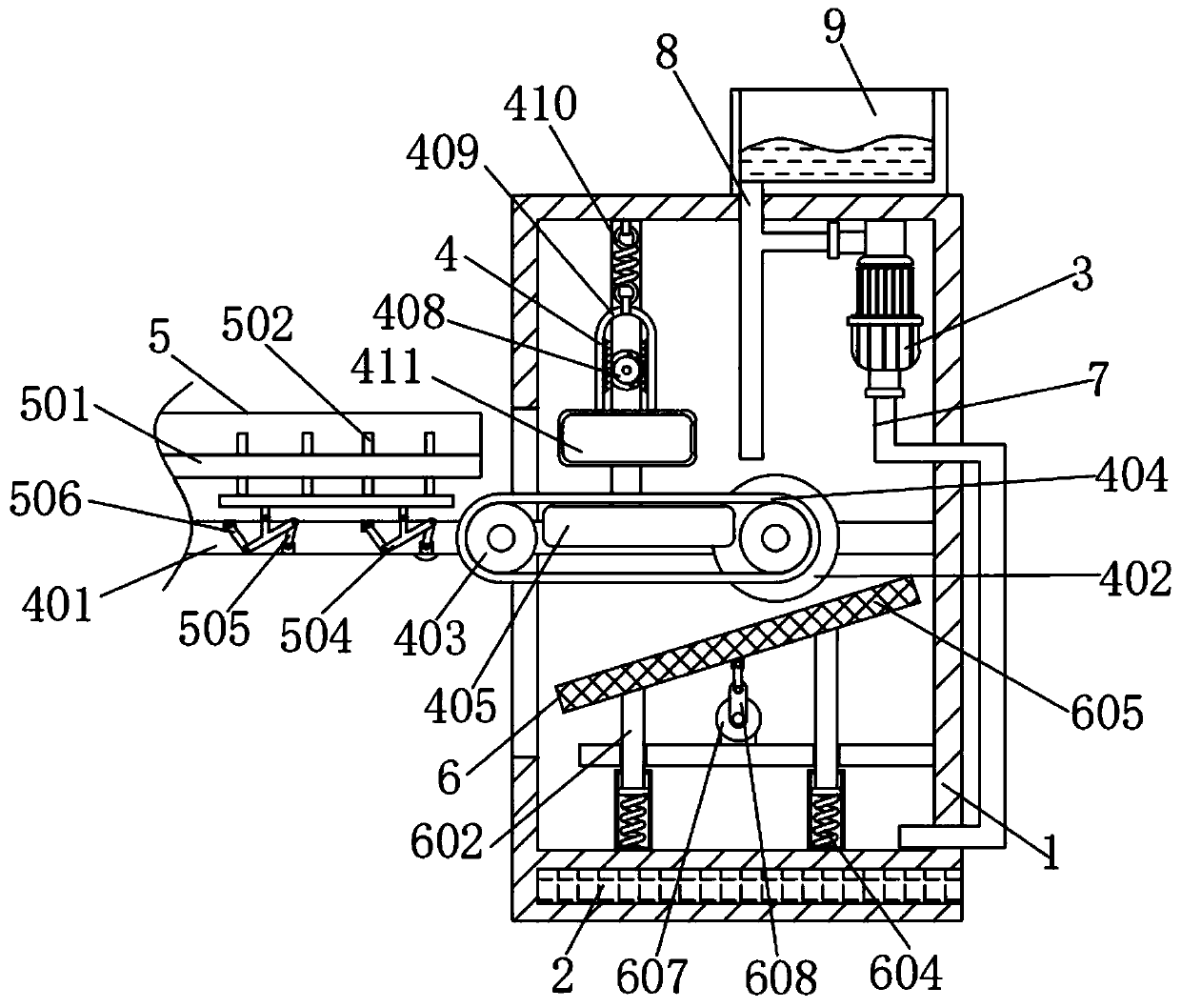

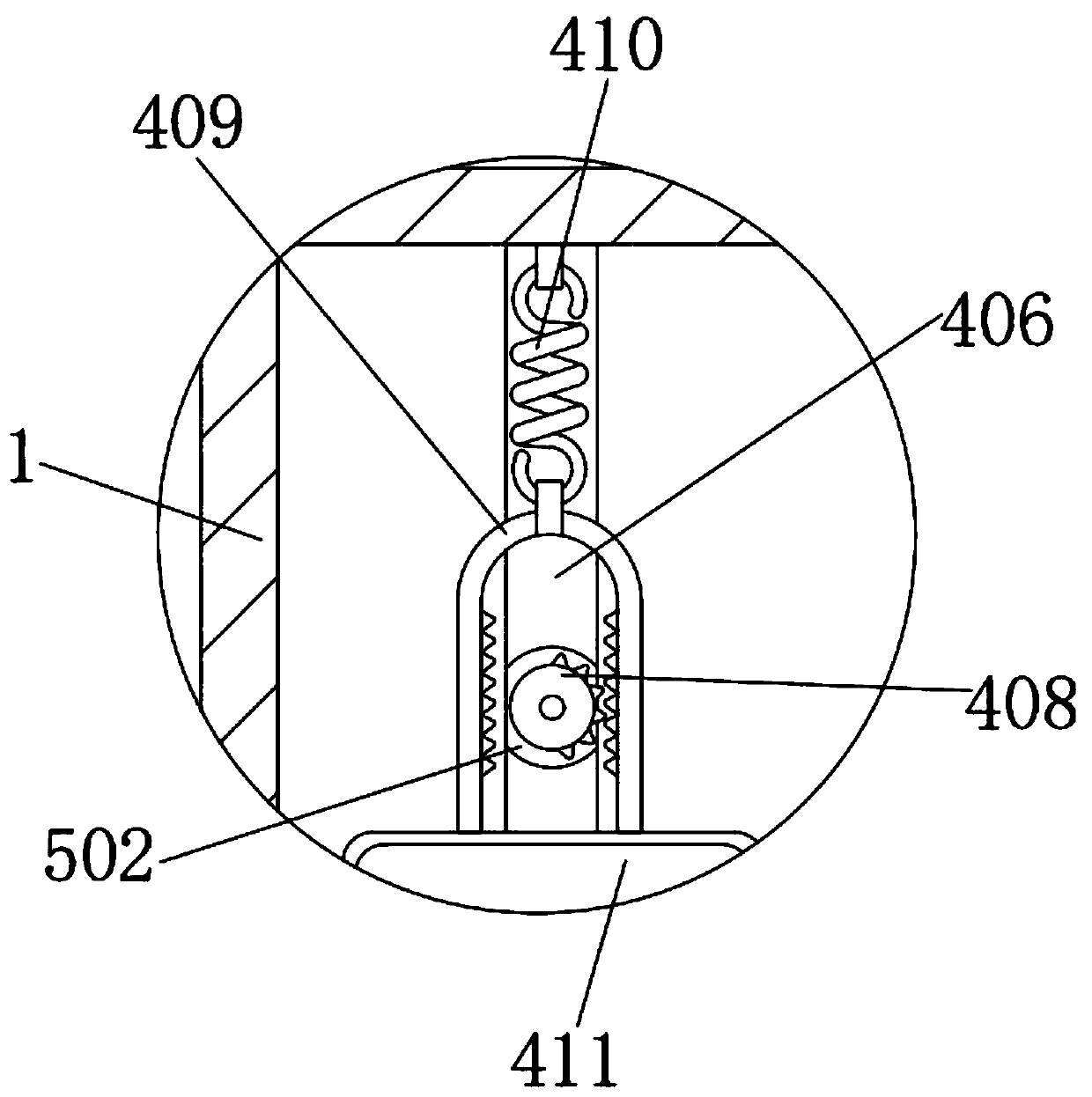

The invention relates to the field of solid waste treatment, in particular to environment-friendly cleaning equipment for solid waste treatment. The environment-friendly cleaning equipment comprises abottom plate, a crushing assembly, a conveying assembly, a cleaning assembly, a filtering assembly, a drying assembly and an extrusion assembly; the crushing assembly is used for crushing solid wastegarbage, the conveying assembly is used for conveying the crushed solid waste garbage, the cleaning assembly is used for cleaning the solid waste garbage, the filtering assembly is used for filteringwaste water generated after the solid waste garbage is cleaned, the drying assembly is used for drying the solid waste garbage, and the extrusion assembly is used for extruding the solid waste garbage into blocks; and the cleaning assembly is fixed to the top of the bottom plate through a support, the filtering assembly is arranged below the cleaning assembly, the conveying assembly is arranged above the cleaning assembly, the crushing assembly is arranged at the top of the conveying assembly, the drying assembly is arranged on one side of the cleaning assembly, and the conveying assembly comprises a conveying box and a spiral extrusion rod. According to the environment-friendly cleaning equipment for solid waste treatment, the problem that waste liquid generated in the solid waste treatment and cleaning process cannot be recycled is solved, the solid waste treatment time is shortened, and the environmental protection performance of solid waste treatment is guaranteed.

Owner:WUHAN CITY VOCATIONAL COLLEGE

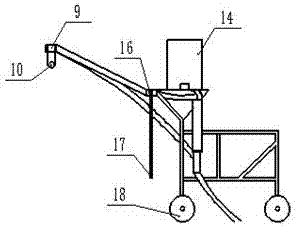

Dual-pipeline water and fertilizer integrated spray irrigation machine unit for spray irrigation machine

InactiveCN107396674ASolve the problem that cannot be recycledSolve the problem that only foliage fertilization can be usedPressurised distribution of liquid fertiliserInsect catchers and killersWater sourceIntegrated operations

The invention provides a dual-pipeline water and fertilizer integrated spray irrigation machine unit for a spray irrigation machine. According to the dual-pipeline water and fertilizer integrated spray irrigation machine unit, the water and fertilizer integrated operation can be finished once. The dual-pipeline water and fertilizer integrated spray irrigation machine unit comprises a submersible electric pump, a water irrigation device, a fertilizer applying device and a fertilizer liquid storage bucket, wherein one end of the submersible electric pump is connected with a water source, and the other end of the submersible electric pump is connected with the water irrigation device through a pipeline, a hydrant, a spray irrigation machine and a water conveying pipe; the water irrigation device is connected with an inlet of a t-branch pipe, one outlet of the t-branch pipe is connected with a main water pipe, and the other outlet of the t-branch pipe is connected with an auxiliary water pipe; and the main water pipe is connected with a main applying pipe, a plurality of main applying pipe branched pipes are arranged on the main applying pipe, the auxiliary water pipe is connected with an auxiliary applying pipe, a plurality of auxiliary applying pipe branched pipes are arranged on the auxiliary applying pipe, the auxiliary water pipe is further connected with the fertilizer applying device, and a fertilizer suction pipe of the fertilizer applying device is connected with the fertilizer liquid storage bucket.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

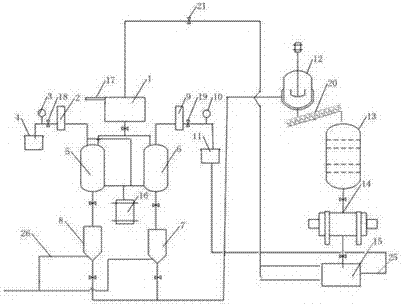

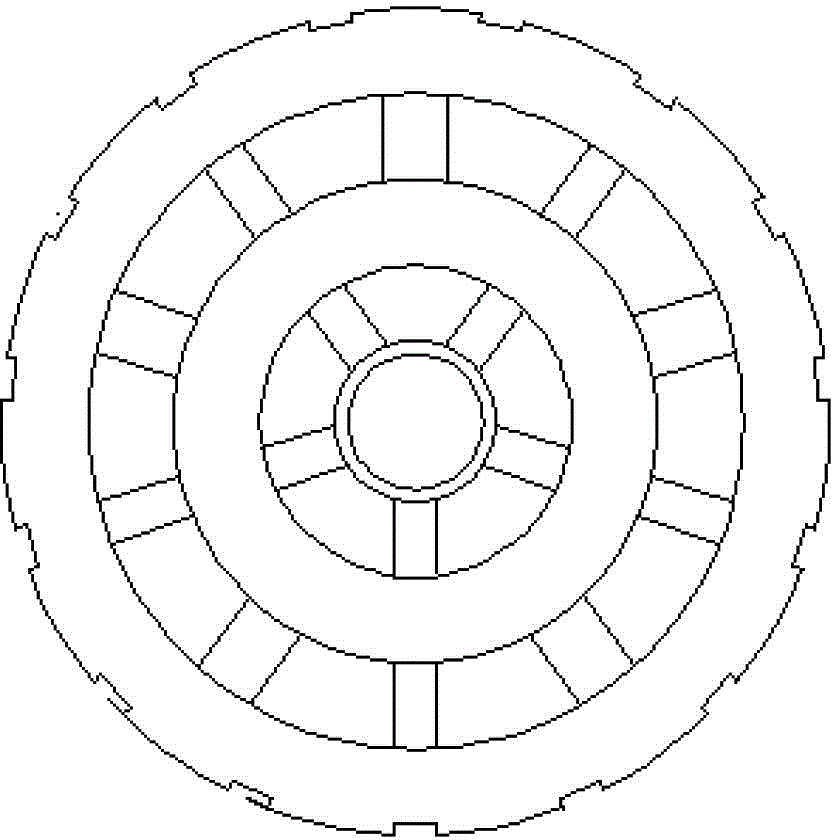

Method for treating grease through granular activated carbon in reproducible mode and system thereof

PendingCN107474949ASolve the problem that cannot be recycledReduce dosageFatty-oils/fats refiningOil and greasePhysical chemistry

The invention belongs to the technical field of grease decoloring, and particularly relates to a method for treating grease through granular activated carbon in a reproducible mode and a system thereof. The method comprises the following steps that 1, grease is subjected to decoloring treatment through granular activated carbon in an adsorption tower; 2, saturated carbon formed after adsorption treatment enters a flushing tank to be flushed, then enters a carbon feeding tank, and then is conveyed into a reproduction multi-hearth furnace to be subjected to reproduction treatment; 3, carbon obtained after reproduction treatment is cooled through a quenching groove, received by a blowing groove and then conveyed into a header tank, some novel carbon supplemented to the header tank enters the adsorption tower, and the grease continues to be subjected to decoloring adsorption treatment. The problem that existing activated carbon / granular activated carbon cannot be recycled or reproduced after decoloring is solved, by arranging the reproducible system, carbon obtained after grease adsorption is stripped, burnt and reproduced, the reproduction loss ratio of the granular activated carbon is controlled within 5%, the consumption of the activated carbon is greatly lowered, and the running cost is lowered.

Owner:青岛瑞发恩环保科技有限公司

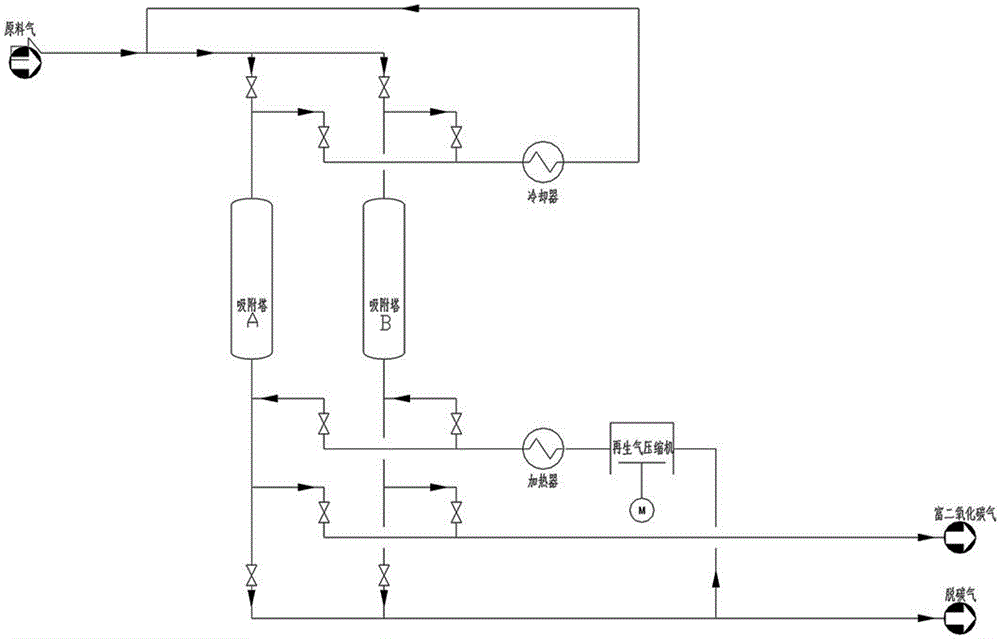

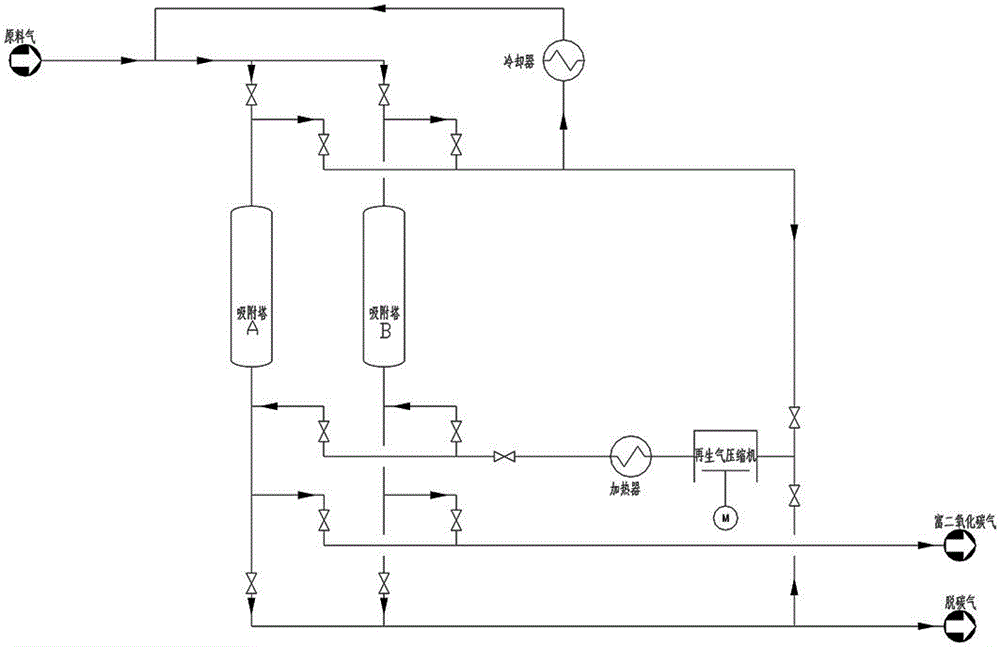

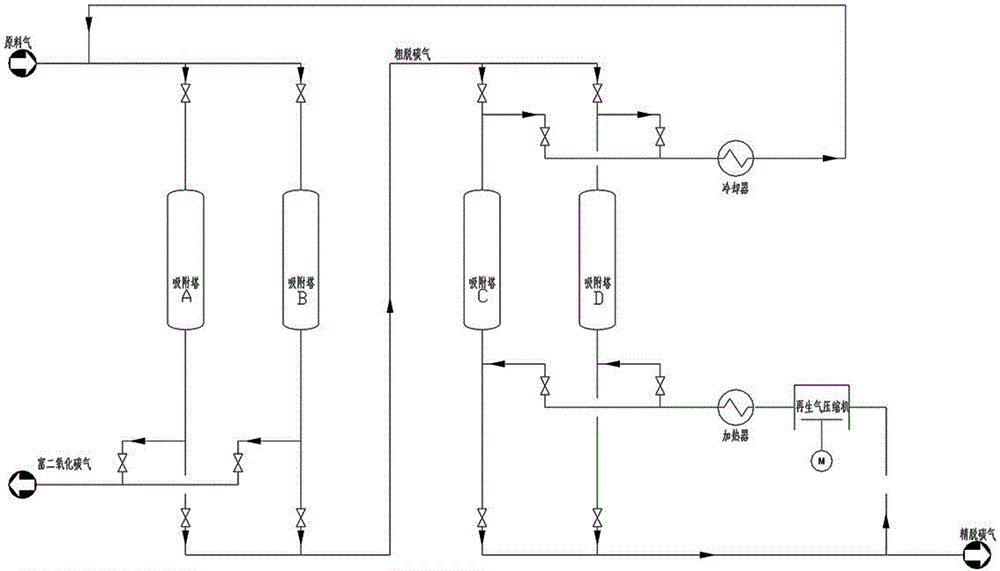

Solid adsorbent regeneration process

InactiveCN104888741ASolve the problem that cannot be recycledAvoid wastingCombustible gas purificationFilter regenerationThermodynamicsSorbent

The invention discloses a solid adsorbent regeneration process specifically including the steps: A) a carbon dioxide-containing raw material gas is allowed to pass through a first adsorption tower, carbon dioxide in the raw material gas is adsorbed by the first adsorption tower, so as to obtain decarbonized gas having carbon dioxide removed; and B) regeneration gas is adopted for making a second adsorption tower regenerated: a) in a pressure reduction stage, the second adsorption tower is subjected to pressure reduction, b) in a hot blowing stage, gas heated by a heating device is allowed to enter the second adsorption tower to heat the second adsorption tower, and c) in a cold blowing stage, the regeneration gas not heated by the heating device enters the second adsorption tower to cool the second adsorption tower to room temperature. The solid adsorbent regeneration process has the beneficial effects that with adopting of the pressure reduction way, the majority of adsorbed carbon dioxide is desorbed, then by means of hot blowing, the adsorbed residual carbon dioxide is desorbed, and the process is suitable for working conditions requiring lower percentage of carbon dioxide in product gas.

Owner:税建平

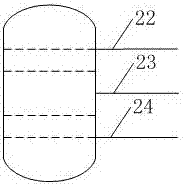

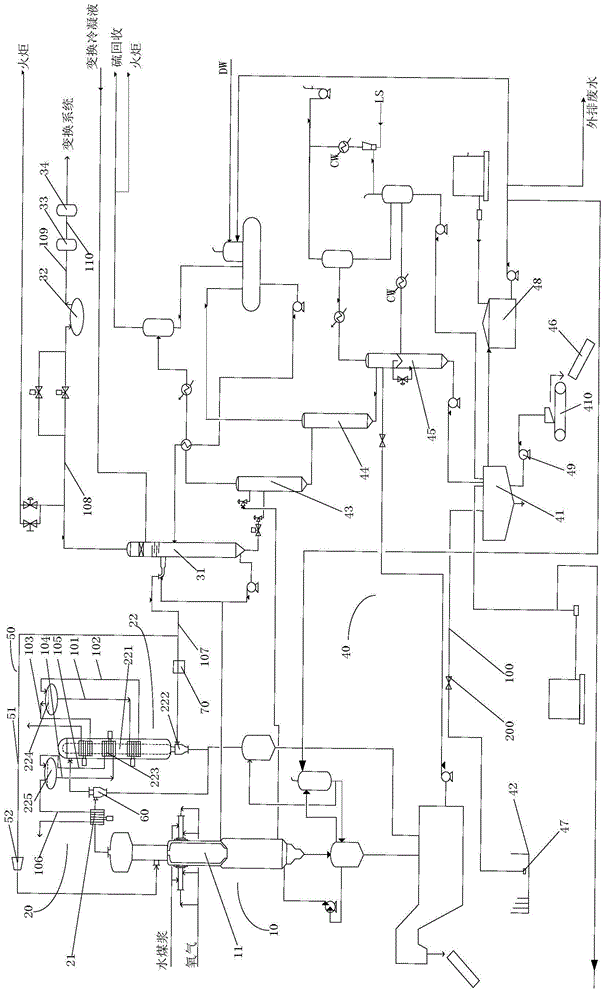

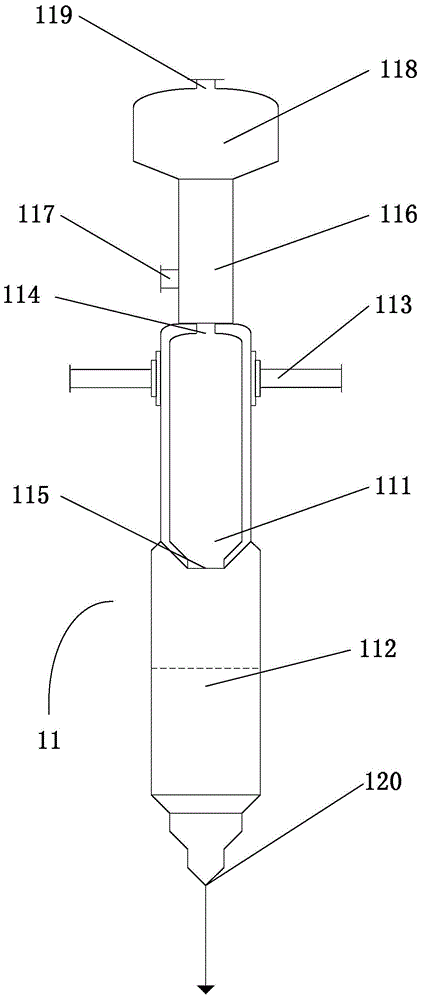

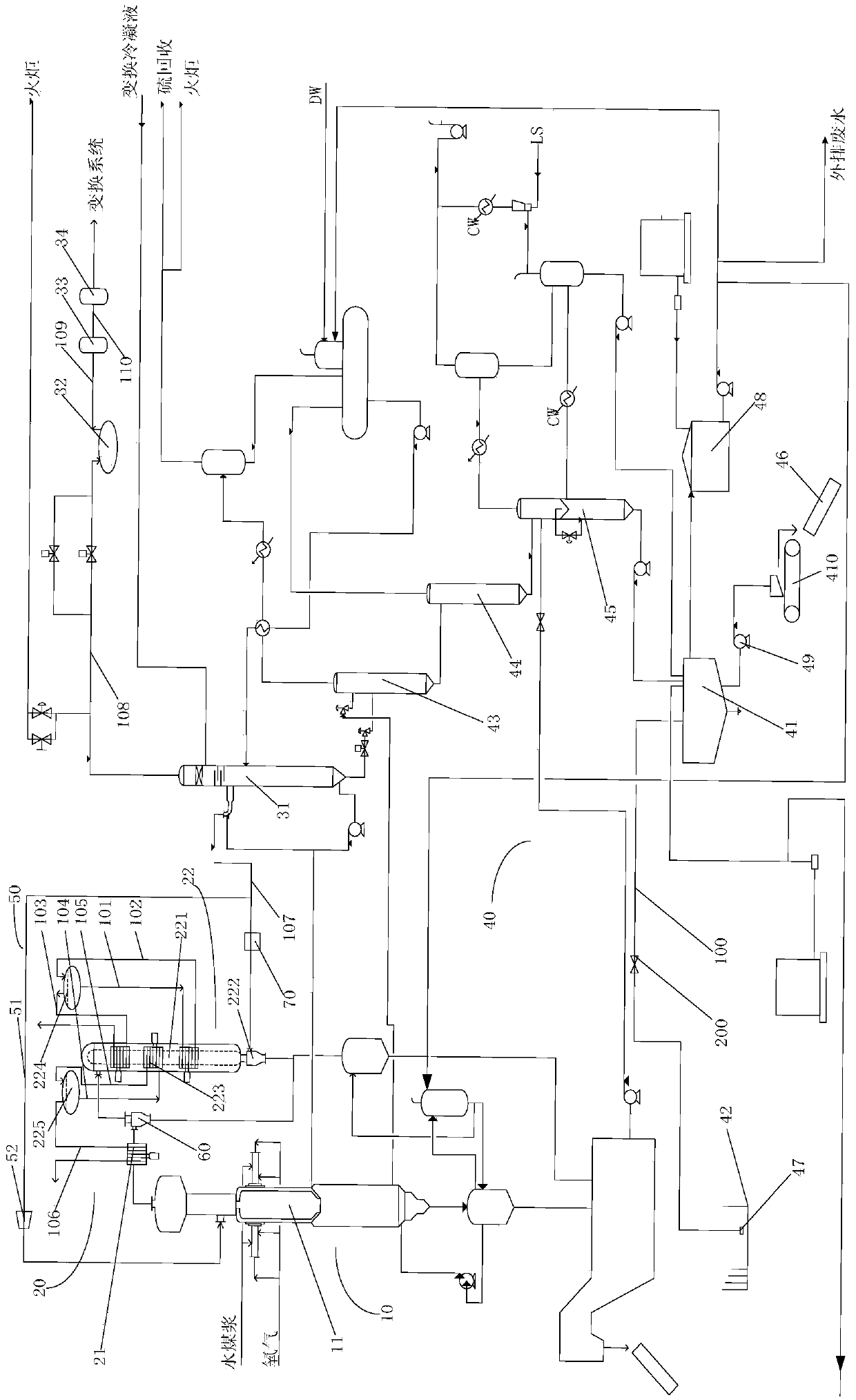

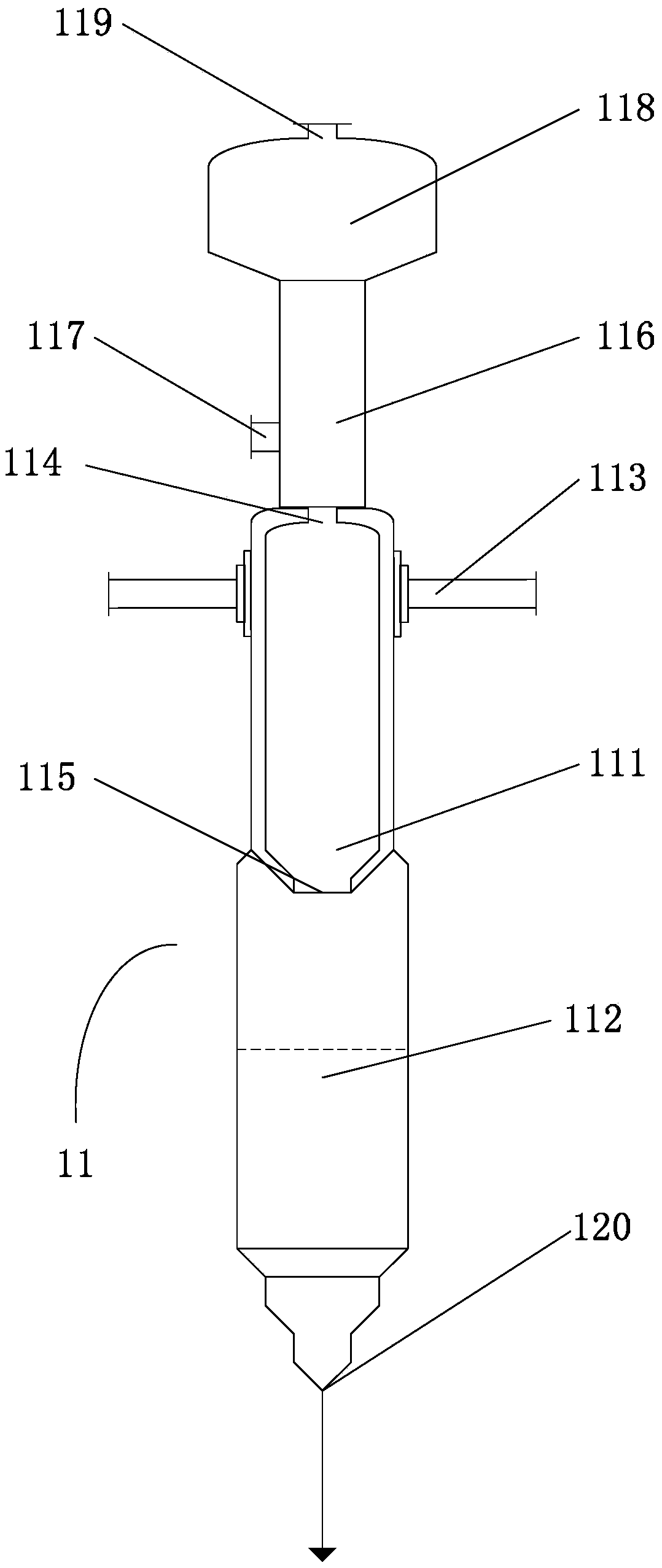

Coal water slurry gasification process system

ActiveCN104017606ASolve the problem that cannot be recycledChemical industryGranular/pulverulent flues gasificationWaste heat recovery unitCoal water

The invention provides a coal water slurry gasification process system. The coal water slurry gasification process system comprises a gasification unit and a heat recovery unit, wherein the gasification unit comprises a coal gasifier; the heat recovery unit comprises a heat exchanger and a cooling device, wherein the air inlet of the heat exchanger is connected with the first air outlet of the coal gasifier, the air inlet of the cooling device is connected with the air outlet of the heat exchanger, and each of the heat exchanger and the cooling device is provided with a heat exchange pipe; a cooling medium is filled in both the heat exchange pipe of the heat exchanger and the heat exchange pipe of the cooling device and is used for recovering heat carried by synthetic gas flowing through the heat exchanger and the cooling device. By using the coal water slurry gasification process system provided by the invention, the heat in the synthetic gas can be recovered again.

Owner:CHINA SHENHUA ENERGY CO LTD +2

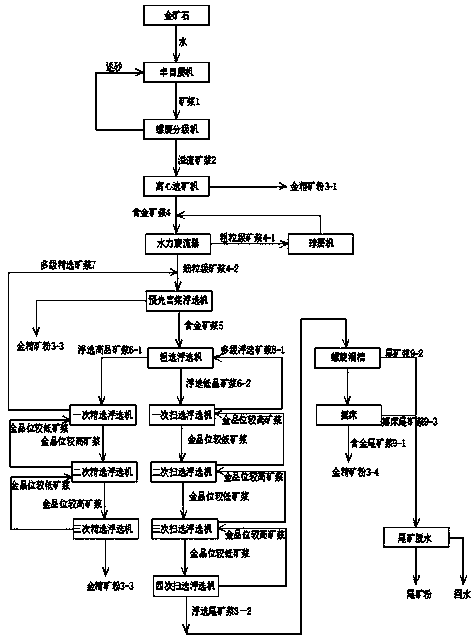

Beneficiation method suitable for alterated rock type gold ores

ActiveCN111229452ANo pollution in the processFull recoverySolid separationMining engineeringGold ore

The invention discloses a beneficiation method suitable for alterated rock type gold ores, and belongs to the technical field of gold ore beneficiation. The problems that a traditional beneficiation method for the alterated rock type gold ores is serious in pollution, high in energy consumption and low in gold-bearing ore recovery rate are solved. The method comprises the four steps of ore grinding, centrifugal reselection, flotation and tailing reselection. According to the beneficiation method, the reselection process of combining centrifugal reselection, a flotation process, a spiral chuteand a table concentrator, namely, the technological process of combining reselection, flotation and reselection is adopted, and after the gold-bearing ores with the grade of 1.5-5 g / t are subjected tobeneficiation process enrichment and separation, finally the gold-bearing grade in final gangue is about 0.10 g / t, and the recovery rate of the gold-bearing ores reaches 97%; and the method is extremely efficient, and the beneficiation process is environmentally friendly and free of pollution in the whole process.

Owner:甘肃省天水李子金矿有限公司

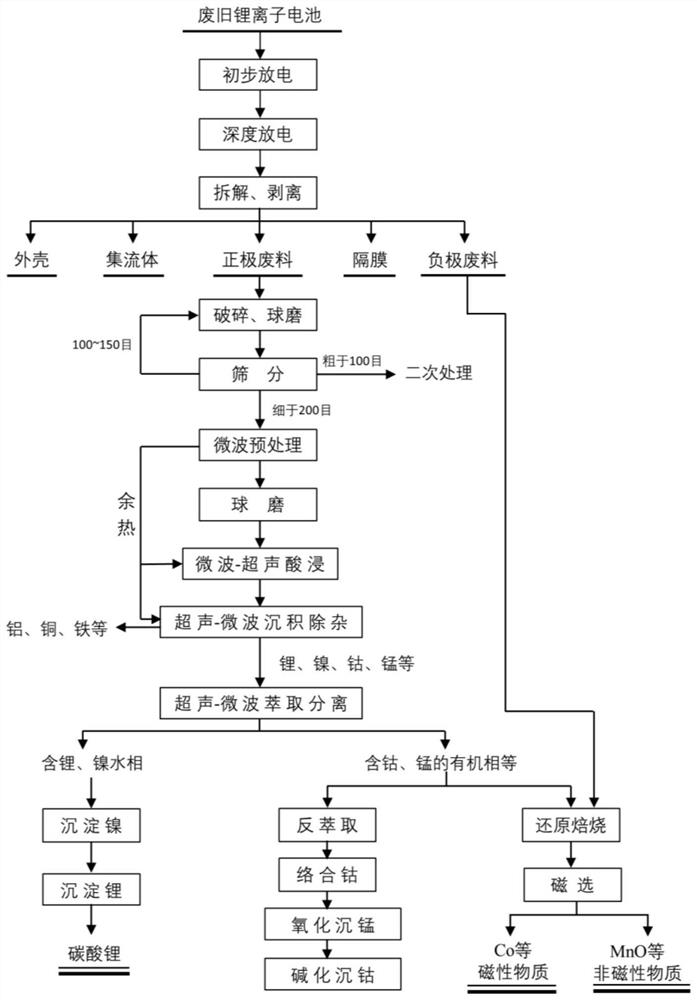

Ultrasonic-microwave assisted lithium ion battery recovery method

InactiveCN111961860AIncrease mixing powerAdd Brownian motionWaste accumulators reclaimingBattery recyclingPhysicsChemistry

The invention discloses an ultrasonic-microwave assisted lithium ion battery recovery method, and belongs to the technical field of waste lithium ion battery recovery. Microwave heating, ultrasonic heating and a rotary furnace body are combined, the pretreatment time of materials is shortened by utilizing the excellent wave absorbing performance of the materials, meanwhile, micro-gas nuclear cavitation bubbles in the acid leaching and extraction processes vibrate and burst instantly by utilizing the mechanical effect and cavitation effect of ultrasonic waves, so that the reaction process is accelerated. On one hand, waste heat generated in the microwave pretreatment process can provide reaction conditions for the subsequent acid leaching and extraction process, the production cost is saved, on the other hand, a rotary furnace body matches with a spiral stirrer inside a furnace chamber to enable a solution to move in the longitudinal direction and the transverse direction, liquid dropsin a container are cut, the effective contact area of a water phase and an organic phase is increased, and the extraction efficiency is greatly improved.

Owner:KUNMING UNIV OF SCI & TECH

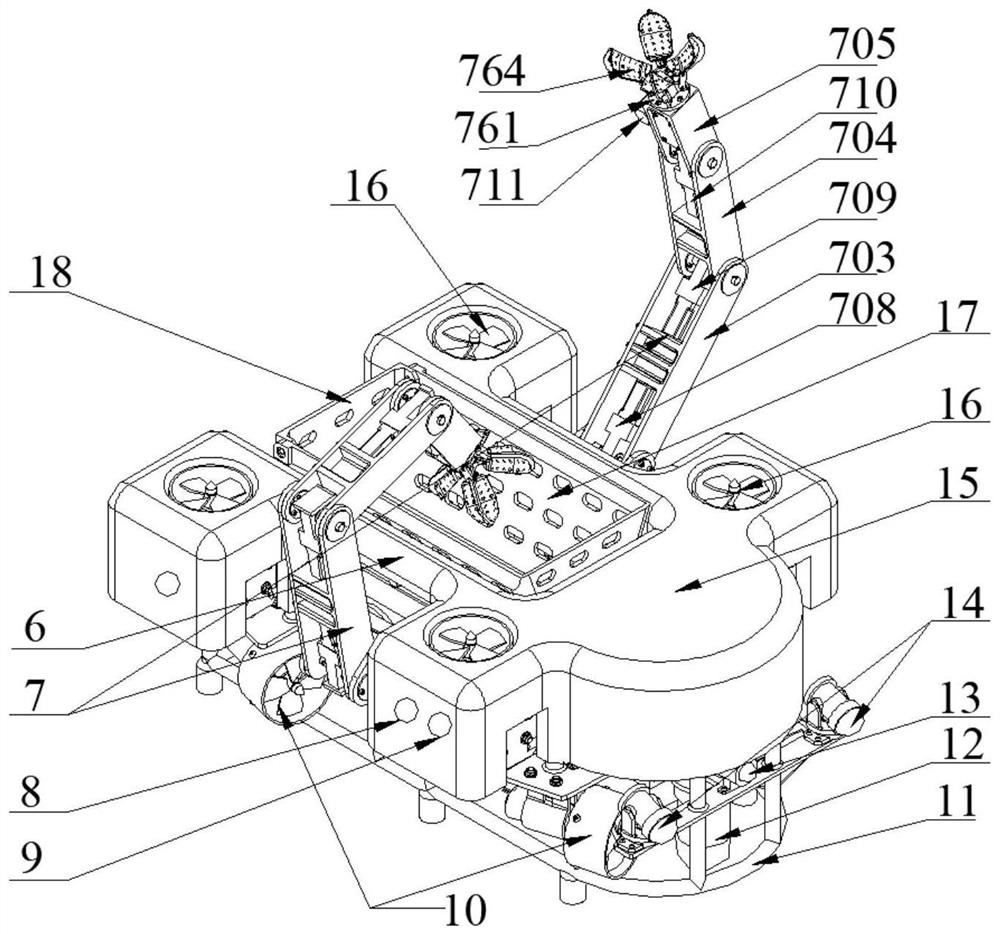

Deep-sea seabed multi-metal nodule low-disturbance mining system

PendingCN113374479AReduce volumeReduce disturbanceMineral miningManipulatorMining engineeringMineralogy

The invention discloses a deep-sea seabed multi-metal nodule low-disturbance mining system. The deep-sea seabed multi-metal nodule low-disturbance mining system comprises a mother ship, an ore concentration station, an ore lifting system and mining devices; the mother ship is located on the sea surface, the ore concentration station and the mining devices are located on the seabed, the mother ship is connected with the ore concentration station, the ore lifting system and the mining devices through umbilical cables, and power supply and communication of the ore concentration station, the ore lifting system and the mining devices are achieved; the ore concentration station is connected with the mining devices through communication power supply cables; and the mining devices are used for collecting ore along the seabed and then pouring the ore into the ore concentration station, the ore concentration station is provided with a container for containing the ore, and the container can be lifted to the mother ship on the sea surface through the ore lifting system. The multiple mining devices are arranged, can work in a designated area in parallel, do not interfere with one another and are high in mining efficiency. The mining devices are small in size, posture control is conducted through propellers, disturbance to the seabed environment is small, and damage to the seabed environment is small.

Owner:HUNAN UNIV OF SCI & TECH

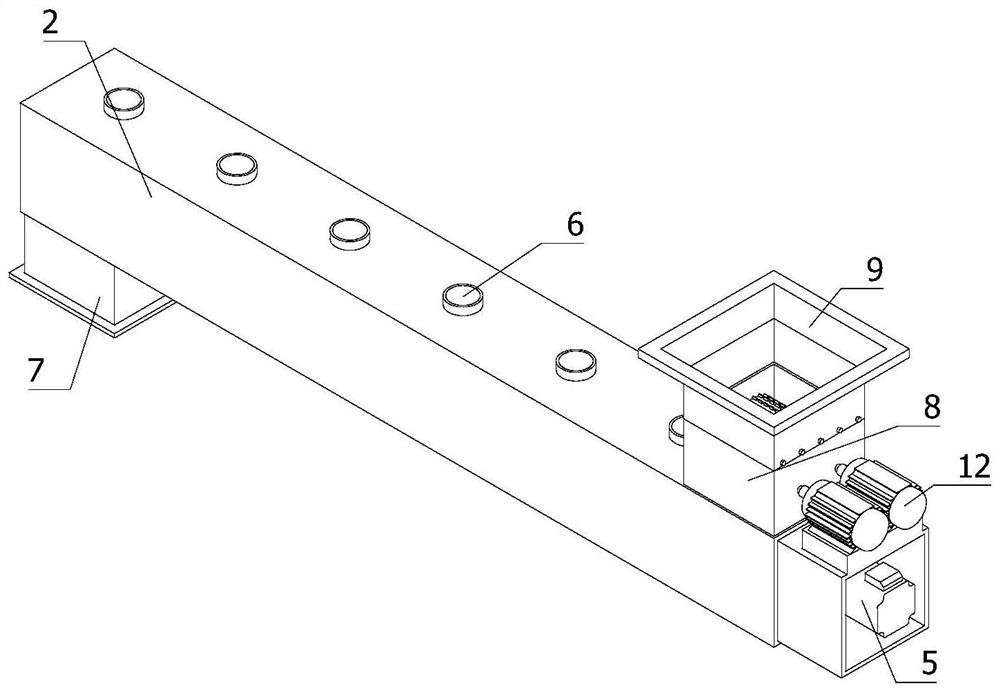

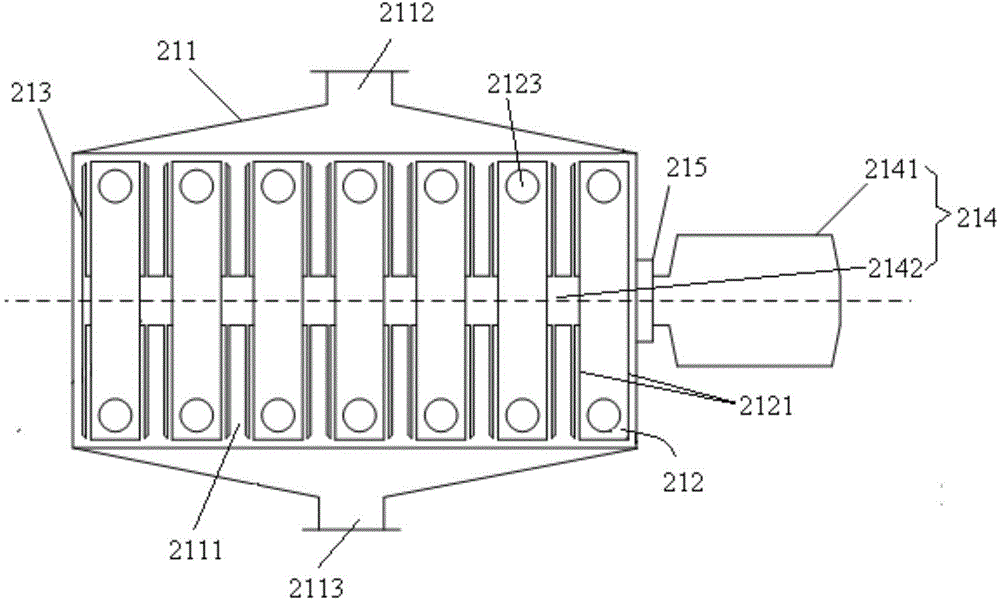

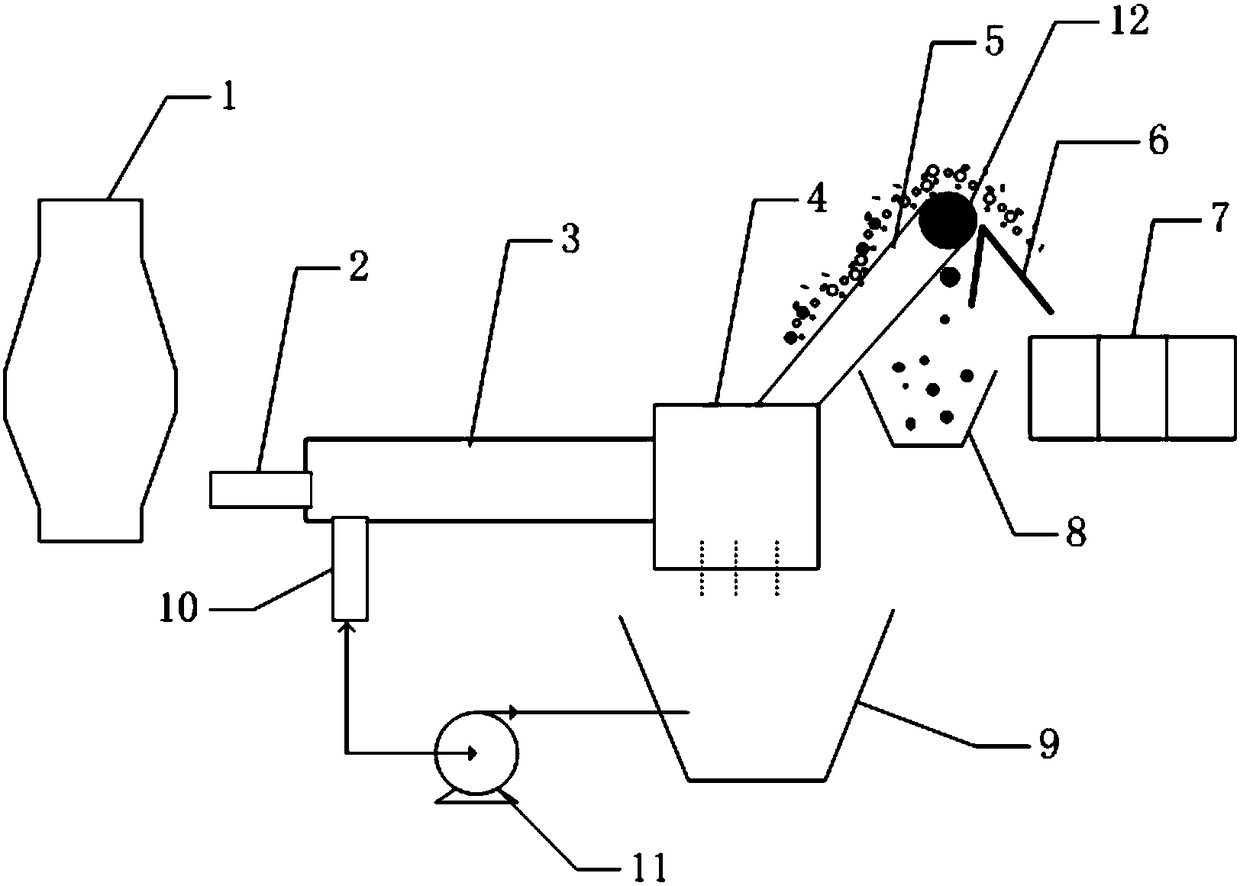

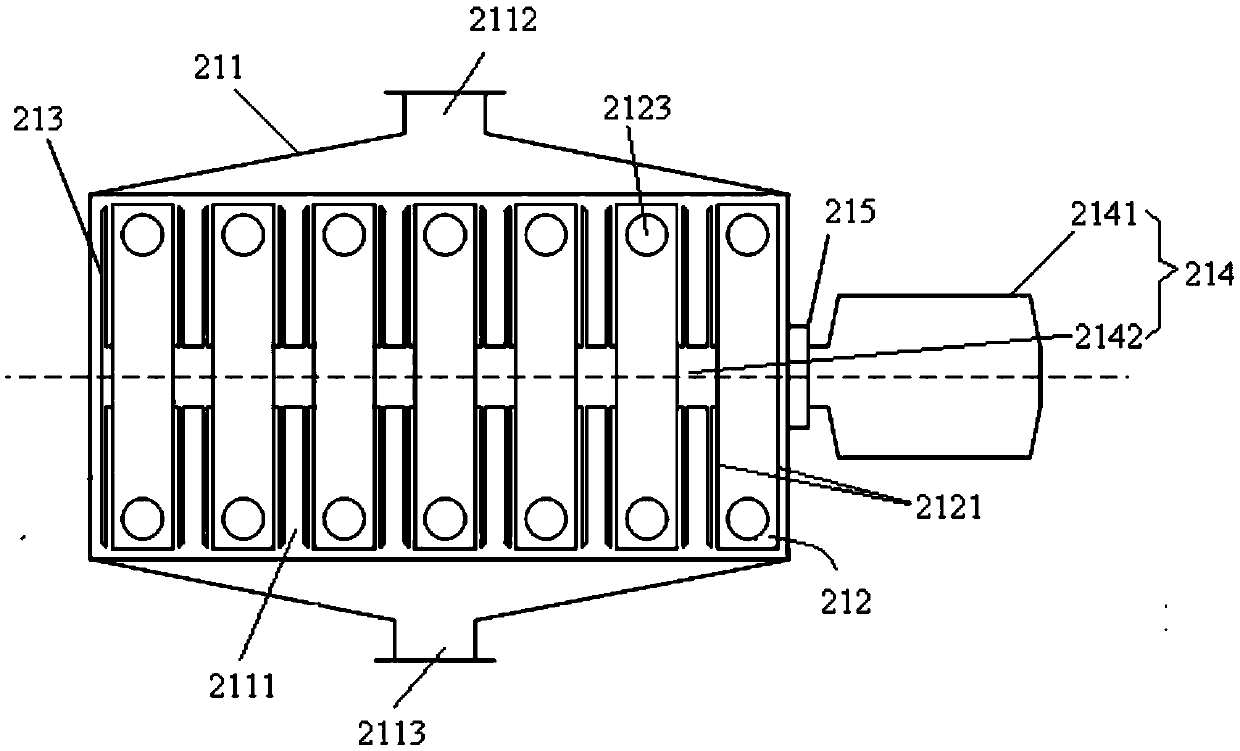

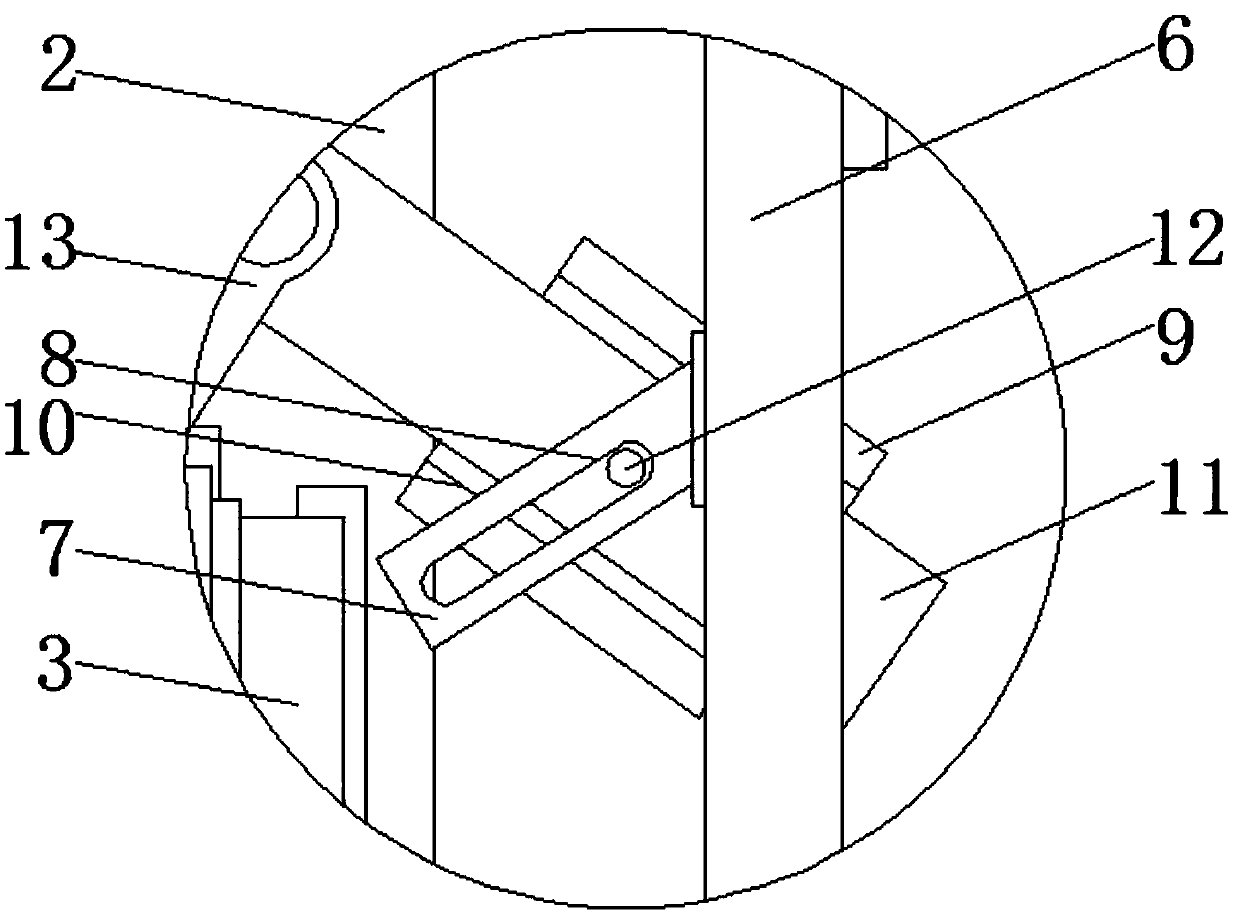

Blast furnace water slag iron removal device

PendingCN108554626AEfficient recyclingSolve the problem that cannot be recycledRecycling and recovery technologiesMagnetic separationSlagWater pipe

The invention discloses a blast furnace water slag iron removal device. The device comprises a slag melting ditch, a slag flushing water pipe, a water slag ditch, a slag collecting tank, a belt conveyor, a separating device, an iron collecting tank, a water slag conveying device, a water collecting tank and a circulating water pump, wherein the slag collecting tank is used for receiving the waterslag and the slag flushing water which is discharged from the water slag ditch, moreover, on one hand, the slag flushing water is filtered and discharged into the water collecting tank, and on the other hand, the water slag is transferred to the belt conveyor; the separating device is arranged at the tail end of a belt of the belt conveyor, the separating device is provided with magnetism, iron particles mingled in the water slag are separated from the water slag and fall into the iron collecting tank, and other impurities are transferred to the water slag conveying device; the water in the water collecting tank is pumped to the circulating water pump, so that the water is recycled; and the separating device separates the slag iron in the water slag at the tail end of the belt, so that effective recovery of the iron particles mingled in the water slag is realized. The blast furnace water slag iron removal device is additionally arranged on the basis of the existing process and invention, and the cost can be saved.

Owner:SHANDONG IRON & STEEL CO LTD

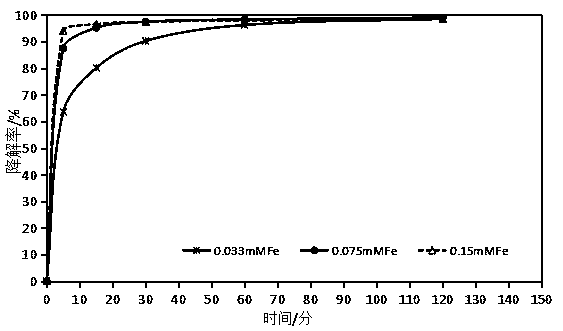

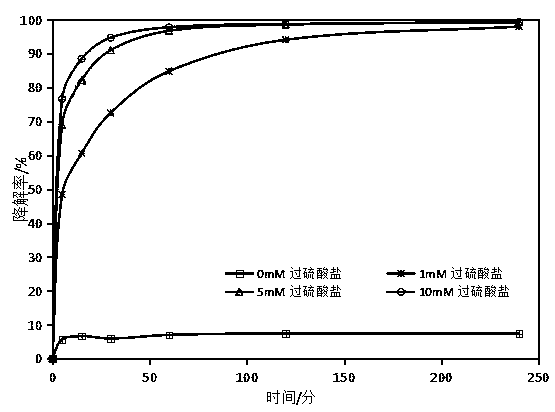

Chemical for activating persulfate system by using green tea nano iron to repair organic polluted water body

ActiveCN110526311AHigh cost of preparationEasy reunionWater treatment compoundsWater contaminantsIron saltsFiltration

The invention discloses a chemical for activating a persulfate system by using green tea nano iron to repair an organic polluted water body. The chemical comprises a green tea nano iron suspension andpersulfate. A preparation method of the green tea nano iron suspension comprises the following steps: preparing a green tea extract, namely putting green tea into deionized water, performing a reaction under a sealed condition, performing standing to room temperature, and performing vacuum suction filtration so as to obtain the green tea extract; preparing a ferrous sulfate solution, namely dissolving a solid, namely ferrous sulfate heptahydrate, into deionized water so as to obtain the ferrous sulfate solution; and preparing the green tea nano iron suspension, namely adding dropwise the green tea extract into the ferrous sulfate solution, performing stirring continuously, and reducing ferrous ions in the ferrous sulfate solution, so as to obtain the green tea nano iron suspension. By adopting the chemical, the amount of ferrous sulfate can be remarkably reduced, the repairing efficiency is high, the chemical has the characteristics of being high in efficiency, free of selectivity, environmentally friendly and free of secondary pollution when being applied to organic polluted water bodies, and the problems that a great number of iron salts are used and the iron salts cannot be recycled in a conventional process that persulfate is activated by using ferrous ions can be solved.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

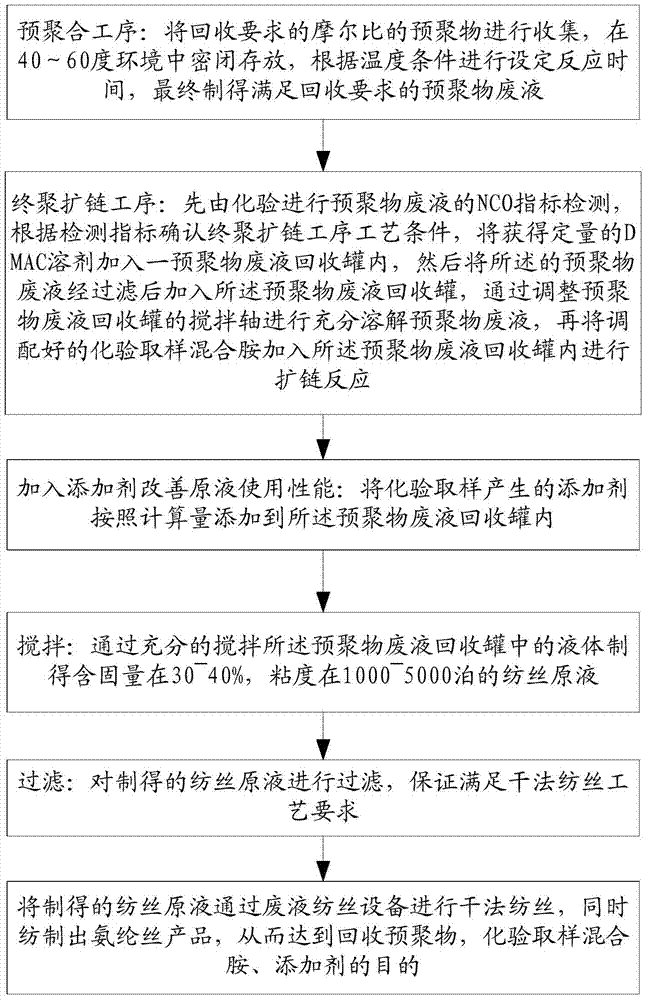

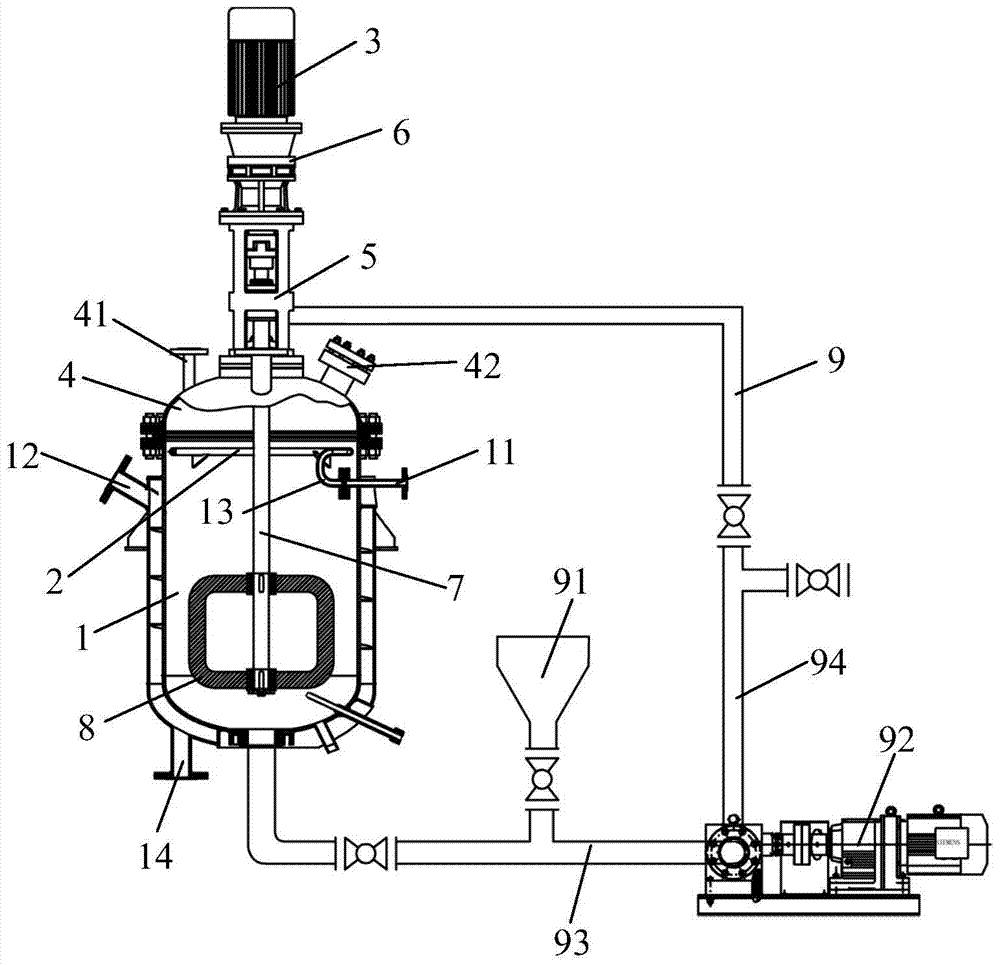

A method for producing spandex yarn by using spandex prepolymer waste liquid

ActiveCN105483855BSolve the problem that cannot be recycledEasy to useProductsReagentsPrepolymerPollution

The invention provides a method for producing spandex filaments by utilizing a spandex prepolymer waste liquid. The method comprises the steps: 1 performing prepolymerization process; 2 performing final polymerization chain extension process; 3 adding an additive to improve use performance; 4 stirring; 5 filtering; and 6 spinning. According to the method for producing spandex filaments by utilizing the spandex prepolymer waste liquid, prepolymers which are not reacted completely can be recycled, so that secondary environment pollution is not caused, and thus the goal of recycling prepolymer and testing sampling mixed amine and additives is achieved.

Owner:CHANGLE HENGSHEN SYNTHETIC FIBER

Coal water slurry gasification process system

ActiveCN104017606BSolve the problem that cannot be recycledChemical industryGranular/pulverulent flues gasificationProcess systemsCoal water

The invention provides a coal water slurry gasification process system. The coal water slurry gasification process system comprises a gasification unit and a heat recovery unit, wherein the gasification unit comprises a coal gasifier; the heat recovery unit comprises a heat exchanger and a cooling device, wherein the air inlet of the heat exchanger is connected with the first air outlet of the coal gasifier, the air inlet of the cooling device is connected with the air outlet of the heat exchanger, and each of the heat exchanger and the cooling device is provided with a heat exchange pipe; a cooling medium is filled in both the heat exchange pipe of the heat exchanger and the heat exchange pipe of the cooling device and is used for recovering heat carried by synthetic gas flowing through the heat exchanger and the cooling device. By using the coal water slurry gasification process system provided by the invention, the heat in the synthetic gas can be recovered again.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Molecular sieve synthesis mother solution using method

ActiveCN108128789ASolve the problem that cannot be recycledChanging environmental hazardsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationMolecular sieveSuspended matter

The invention discloses a molecular sieve synthesis mother solution using method. The molecular sieve synthesis mother solution using method comprises the following steps: 1, conducting settling separation on a suspended matter of a mother solution to obtain a supernatant liquor, wherein the content of the suspended manner in the supernatant liquor is less than 0.1 g / L; 2, adding lime milk into the supernatant liquor obtained in the step 1), desiliconizing, wherein the content of SiO2 in the desiliconized supernatant liquor is less than or equal to 0.5 g / L; 3, taking the supernatant liquor desiliconized in the step 2) as a clinker in the sintering-process aluminum oxide production technique to dissolve out a regulating solution. The molecular sieve synthesis mother solution using method has the following beneficial effects: the problem that the caustic alkali in the molecular sieve synthesis mother solution cannot be recycled is solved, and the problems of the environment risks that the caustic alkali is directly neutralized by sulfuric acid and is discharged are changed. The method directly combines the production process of a molecular sieve with the production process of aluminum oxide, by removing the silicon in the solution, the molecular sieve synthesis mother solution is desiliconized to dissolve out the clinker, and the dissolved sodium metaaluminate solution is taken as a raw material in the synthesis of the molecular sieve, so that the purposes of recycling of the resources and zero emission are fulfilled.

Owner:中铝智能数维(杭州)工程设计研究院有限公司

Novel adsorption column for removing heavy metals and preparation method of adsorption column

ActiveCN104801288AAvoid secondary pollutionImprove business valueOther chemical processesIonChemistry

The invention discloses a novel adsorption column for removing heavy metals and a preparation method of the adsorption column. Recovered waste sodium alginate gel and environment-friendly resin are combined, artificial stones are formed, and the adsorption column is further prepared. The adsorption column has the effect of adsorbing heavy metal ions, the adsorption column which has certain space and is formed by a top cover, a strip-shaped cage body and a bottom plate can be filled with other adsorption gel capsule materials for removing the heavy metal ions, and the problem that the gel capsule materials cannot be recovered after heavy metal adsorption is solved. Tightening ring parts of the adsorption column are used for fixing the body of the adsorption column so as to prevent the adsorption column from falling apart. Recovery, regrinding and sample preparation can be performed after the adsorption column is damaged during adsorption, and recycling is realized. The novel adsorption column for removing the heavy metals has excellent performance such as high mechanical strength, good pollution resistance, acid and alkali corrosion resistance and the like and has very high commercial exploitation value, and secondary pollution can be avoided fundamentally.

Owner:山西阳中新材有限责任公司

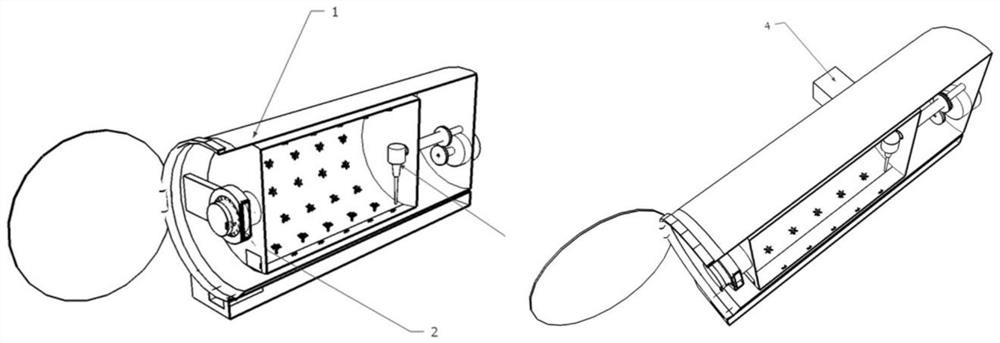

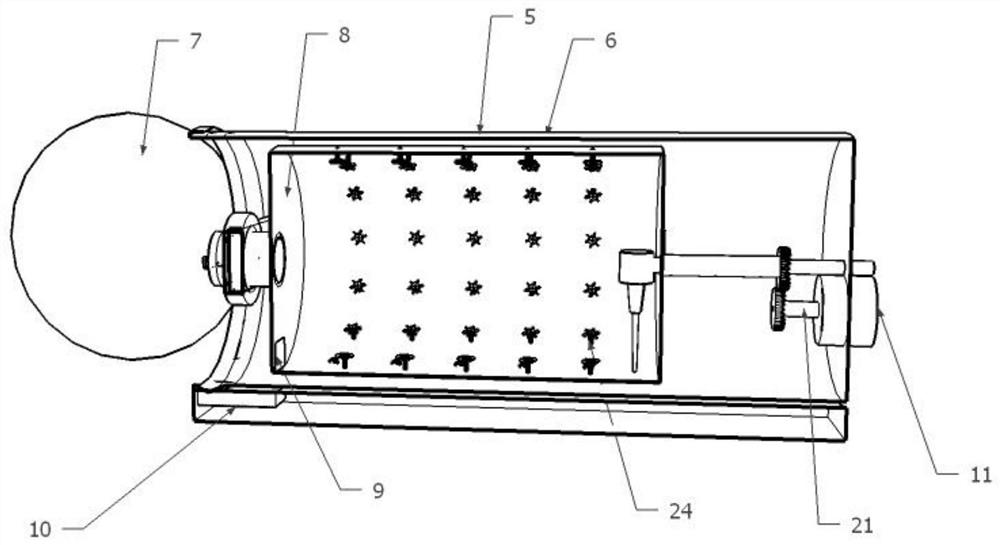

Freezing type slicing device for biological experiment

InactiveCN113029640ASave spaceSolve small and difficult-to-observe problemsWithdrawing sample devicesPreparing sample for investigationEngineeringOrganism

The invention provides a freezing type slicing device for biological experiments, and relates to the field of biological experiment equipment. The freezing type slicing device for the biological experiment comprises a supporting frame, a depth control mechanism is fixedly installed in front of the top end of the supporting frame, a freezing mechanism is fixedly installed in front of the supporting frame and located under the depth control mechanism, and a power mechanism is fixedly installed above the supporting frame and located on one side of the depth control mechanism. According to the freezing type slicing device for the biological experiment, the air bag can be controlled by pressing to drive the rack belt to rotate, so that a certain number of balance weight balls fall into the inner sleeve; then the amount of the biological sample immersed in the freezing tank is changed through the counterweight ball, and the biological sample is frozen in cooperation with the freezing tank; after freezing, the biological sample obtained through freezing is separated from the unfrozen biological sample through the scraper, so that the problems that in the prior art, the slicing thickness of the biological sample is not easy to control, and wrinkles are likely to be generated in the slicing process can be solved.

Owner:吕然然

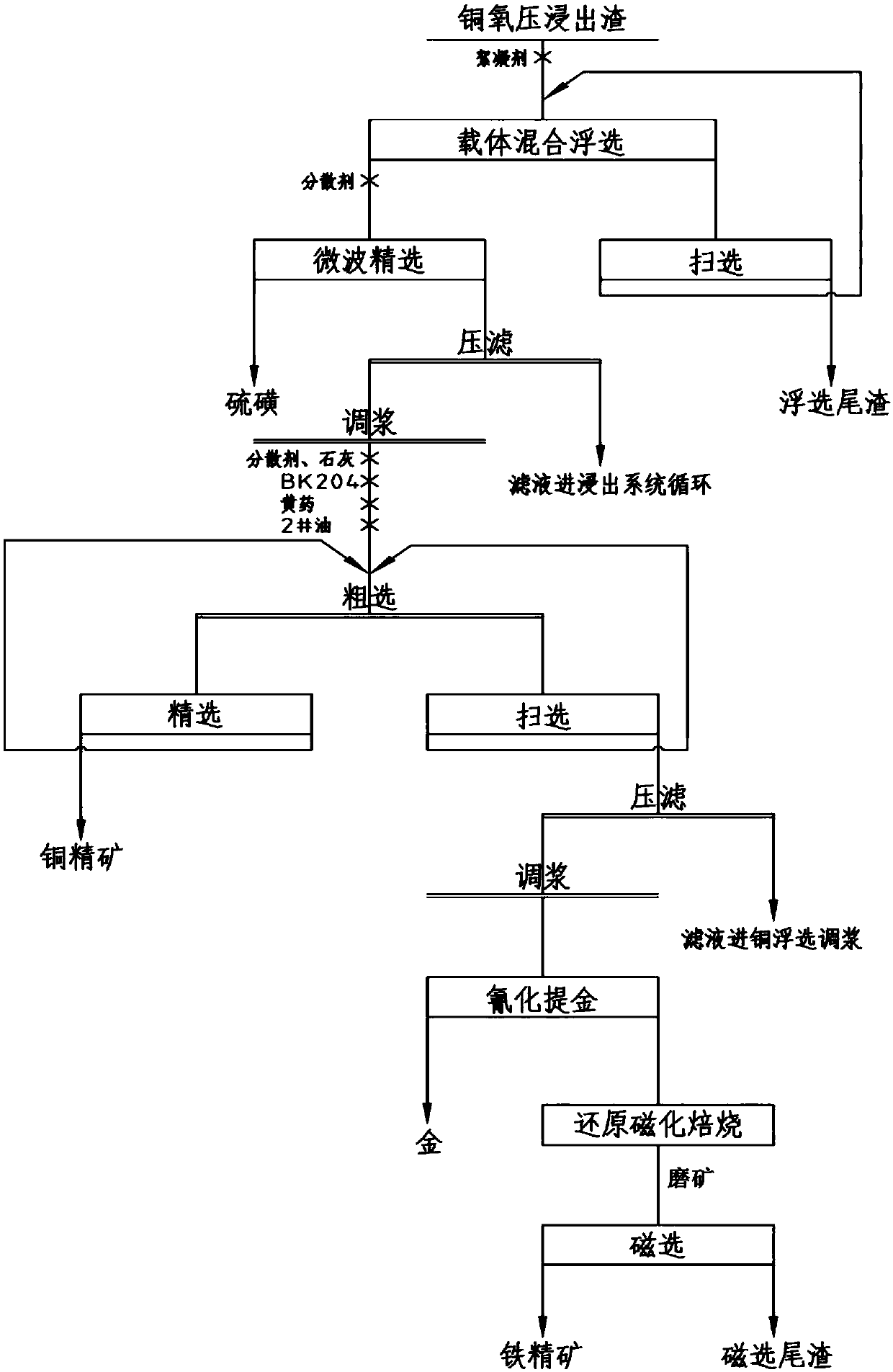

Technology for recycling sulfur and valuable metal from copper oxidative pressure leaching residues

ActiveCN109590107ARealize harmless treatmentSolve the problem that cannot be recycledProcess efficiency improvementWet separationFiltrationSulfur

The invention discloses a technology for recycling sulfur and valuable metal from copper oxidative pressure leaching residues and belongs to the technical field of non-ferrous metal recycling. According to the technology for recycling the sulfur and the valuable metal from the copper oxidative pressure leaching residues, through carrier flotation, selective mixed flotation of sulfur, iron, copperand metal in the copper oxidative pressure leaching residues is achieved, the problem that precious metal in the copper oxidative pressure leaching residues cannot be recycled is effectively solved, and the problem of influence of the iron element in the copper oxidative pressure leaching residues on the flotation recovery rate is also solved; addition of flocculant is mainly used for increasing the particle size of sulfur and reducing the ore pulp viscosity caused by iron colloid in the copper oxidative pressure leaching residues, and it is achieved that the sulfur in the leaching residues isused as the flotation carrier of the copper, the iron, the gold and the like. Segmented pressure filtration achieves segmented backwater utilization, it is avoided that agents intervene in the copperoxidative pressure leaching process and the residue processing full procedure, and the utilization rate of recycling treatment and the stability of the procedure are improved. After flotation recycling of copper concentrate, cyaniding gold extracting is conducted, the interference of the copper ions is lowered, effective enrichment of gold is achieved, and effective economic benefits are createdfor cyaniding gold extracting.

Owner:CINF ENG CO LTD

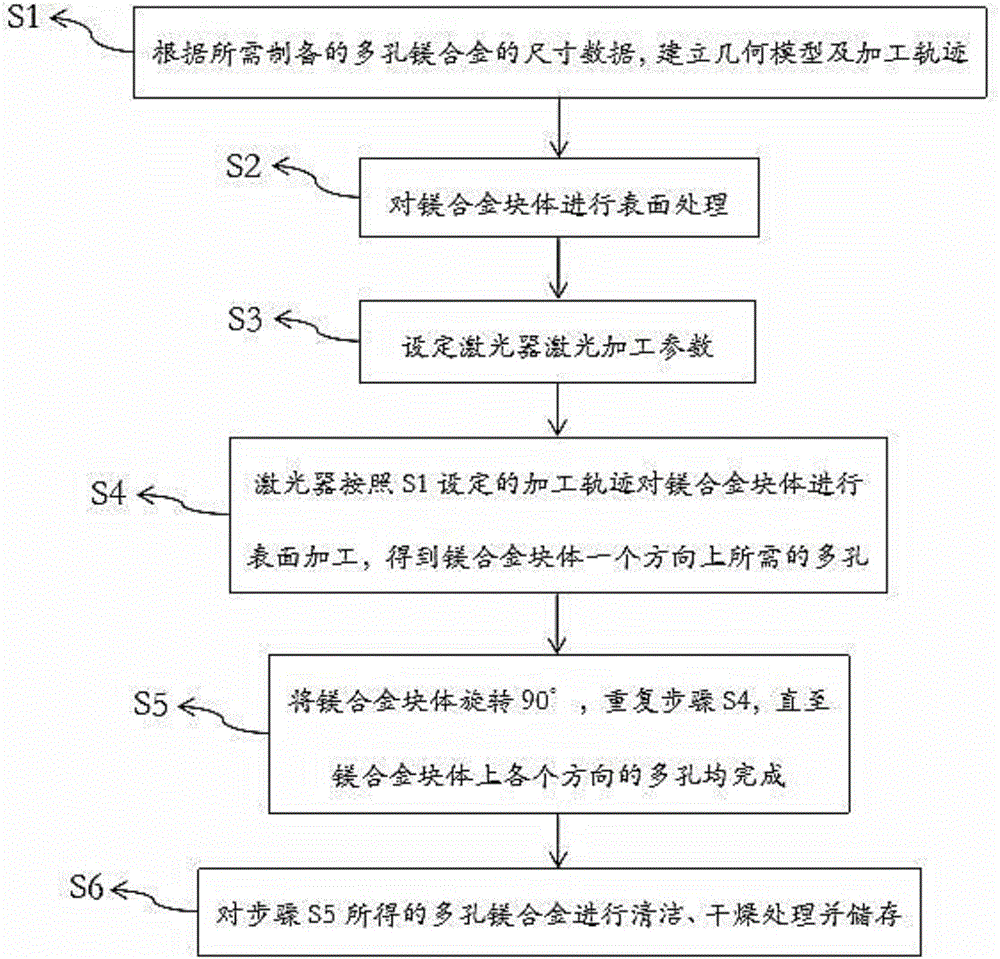

Preparation method for biological porous magnesium alloy

The invention discloses a preparation method for a biological porous magnesium alloy. The preparation method comprises the following steps: S1, establishing a geometric model and a machining track according to dimension data of the porous magnesium alloy which is required to be prepared; S2, conducting surface treatment on a magnesium alloy block body; S3, setting laser machining parameters of a laser; S4, conducting surface machining on the magnesium alloy block body according to the machining track which is set in S1 to obtain a plurality of pores required by one direction of the magnesium alloy block body; S5, rotating the magnesium alloy block body by 90 degrees, and executing the S4 again until a plurality of pores in each direction of the magnesium alloy block body are all completed; S6, conducting drying treatment and storing the porous magnesium alloy obtained in the S5. According to the preparation method for the biological porous magnesium alloy, the magnesium alloy is molten directly by adopting the laser, so that the biological porous magnesium alloy is prepared; the conventional method of adding a pore-forming agent for performing sintering or vapour deposition by utilizing powder is abandoned; the problem of recycling a magnesium alloy waste material is solved; and meanwhile, the problems of environmental pollution and harmful material residues caused by preparing by the conventional method are also solved.

Owner:SUZHOU UNIV

Food processor with improved ice breaking function

PendingCN110771774ASolve the problem that cannot be recycledSolve the problem of incomplete ice breakingFood preservationPhysicsElectric machinery

The invention discloses a food processor with an improved ice breaking function. The processor comprises a box body, an ice crushing device is installed in the center of the interior of the box body,a conveying device is installed in the middle of the left side of the box body, and a lifting device is installed on the lower portion of the interior of the box body. According to the food processorwith the improved ice breaking function, through cooperation of a second motor, a gear, an arc-shaped rack, a third transverse plate, an inclined plate, a fourth motor and a fifth connecting rod, thesecond motor is started, the second motor drives the gear to rotate, and therefore the arc-shaped rack drives the third transverse plate to do reciprocating motion. The fourth motor is started, and the fourth motor drives a fifth connecting rod to move, so that the fifth connecting rod drives the inclined plate to move, and the problem of incomplete ice breaking in the prior art is solved. Throughcooperation of a water pump, a first water pipe and a second water pipe, the water pump is started, and water at the bottom is pumped up through the first water pipe and flows out of the second waterpipe, so that the problem that water cannot be recycled in the prior art is solved.

Owner:吴淑艳

Residual oil recovery device for port loading arm

InactiveCN104555879ASolve the problem that cannot be recycledReduce economic lossLiquid transferring devicesReciprocating motionResidual oil

The invention relates to a residual oil recovery device for a port loading arm. The recovery device comprises a double-piston hydraulic cylinder, a two-position three-way hydraulic operated directional valve, two ejector rod type one-way valves and a group of suction and discharge one-way valves, wherein the two-position three-way hydraulic operated directional valve is mounted on the double-piston hydraulic cylinder. Automatic reciprocating movement of piston rods of the double-piston hydraulic cylinder is controlled by the two-position three-way hydraulic operated directional valve and the two ejector rod type one-way valves, and oil is sucked and discharged by the aid of the suction and discharge one-way valves. The device can realize residual oil recovery required by the port loading arm.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

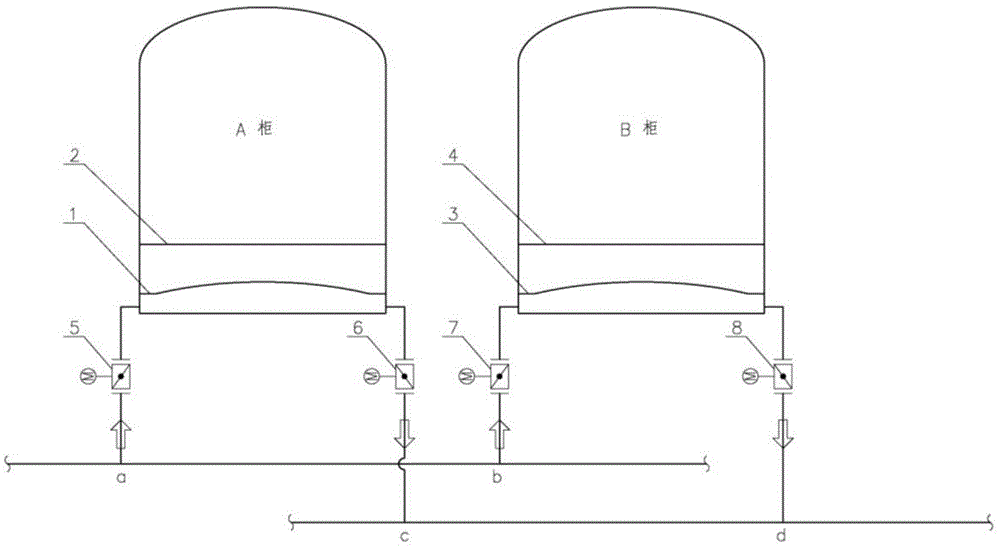

Control method for relay network connection of two gas chambers

Provided is a control method for relay network connection of two gas chambers. The two gas chambers are connected to the same gas pipe network and jointly play gas peak removal, valley filling and pressure stabilization effects, and meanwhile the gas recovery problem during in-turn overhauling of the gas chambers is solved. The control method specifically comprises the following steps of 1 comparing inlet gas pressures of the two gas chambers and defining the near-end chamber and the far-end chamber according to the pressures, 2 comparing resistance values of inlet and outlet pipe networks of the two gas chambers and regarding the larger resistance value as pipe network resistance DeltaP, and 3 setting the pressures of pistons and T-shaped baffles of the two gas chambers according to the principles of the gas inlet chamber and the gas outlet chamber. The relay network connection operation of the two gas chambers is achieved by reasonably setting the pressures of the pistons and T-shaped baffles of the two gas chambers, the problem that the gas chambers are successively established and connected to the network is solved, and the gas buffering and pressure stabilization demands are met. In addition, optional switching between a double-chamber relay operation mode and a single-chamber operation mode can be further performed, and the problem that gas cannot be recovered during gas chamber overhauling is effectively solved.

Owner:WISDRI ENG & RES INC LTD

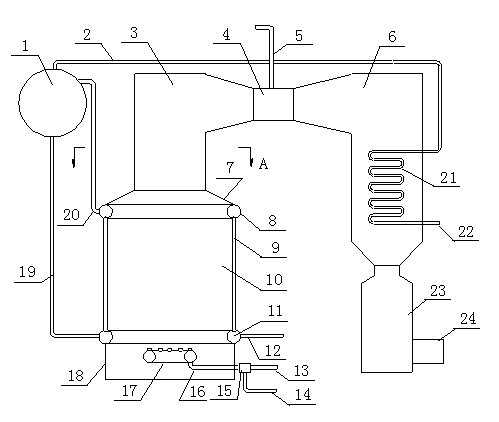

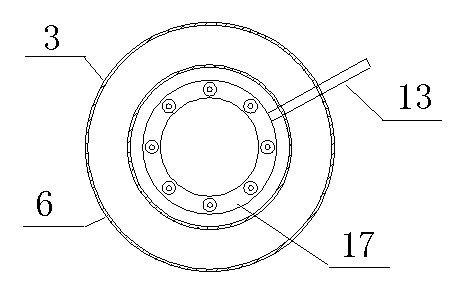

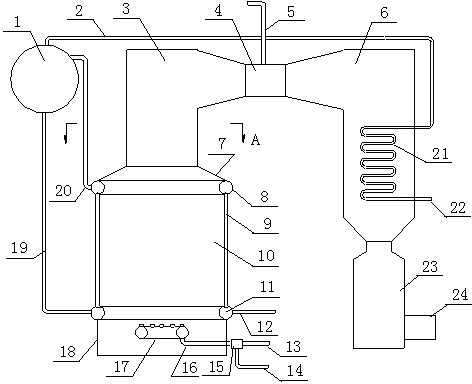

Yellow phosphorus tail gas combustion boiler

The invention relates to a yellow phosphorus tail gas combustion boiler, which recovers heat energy by combustion of a boiler. The boiler comprises a combustion chamber (10), an intake cover (18), a gas spray gun (17), a steam drum (1), a smoke guide cover (7) and a flue, wherein the combustion chamber (10) is composed of a membrane type wall heat exchanger consisting of a membrane type wall (9), an upper header (8) and a lower header (11); the intake cover (18) is connected with the bottom of the lower header (11); the gas spray gun (17) is arranged in the intake cover (18); the inlet of the smoke guide cover (7) is connected with the top of the upper header (8), and the outlet thereof is connected with the flue; a deacidification device is arranged in the middle of the flue and divides the flue into a left flue (3) and a right flue (6); the right flue (6) is connected with a desulfurizing tower (23); and the center lines of the gas spray gun (17), the combustion chamber (10) and the smoke guide cover (7) are on the same center line. In the invention, the heat exchange surface of the boiler is effectively isolated from smoke containing corrosive materials by a protection gas, thus preventing the heat exchanger from being corroded by the corrosive materials.

Owner:王志凯

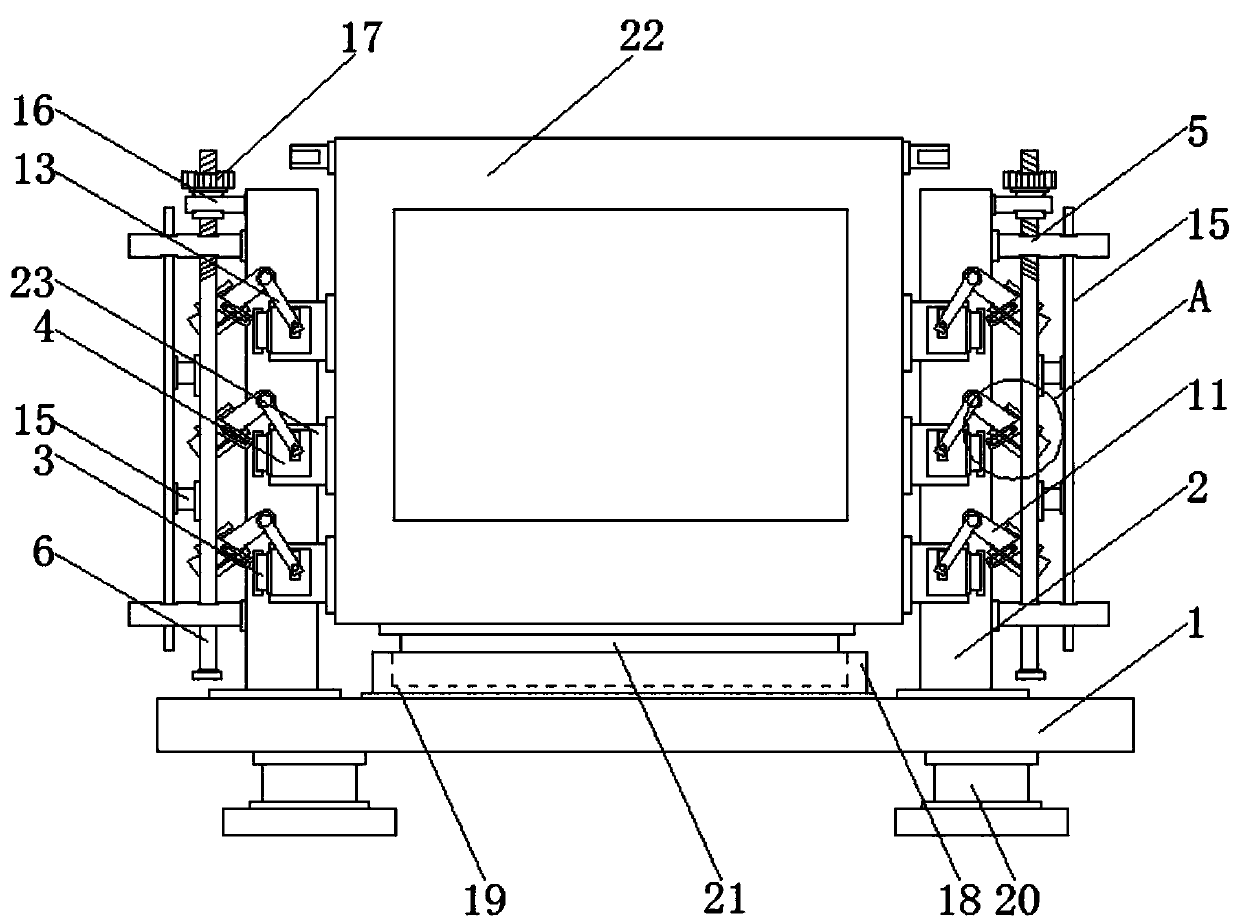

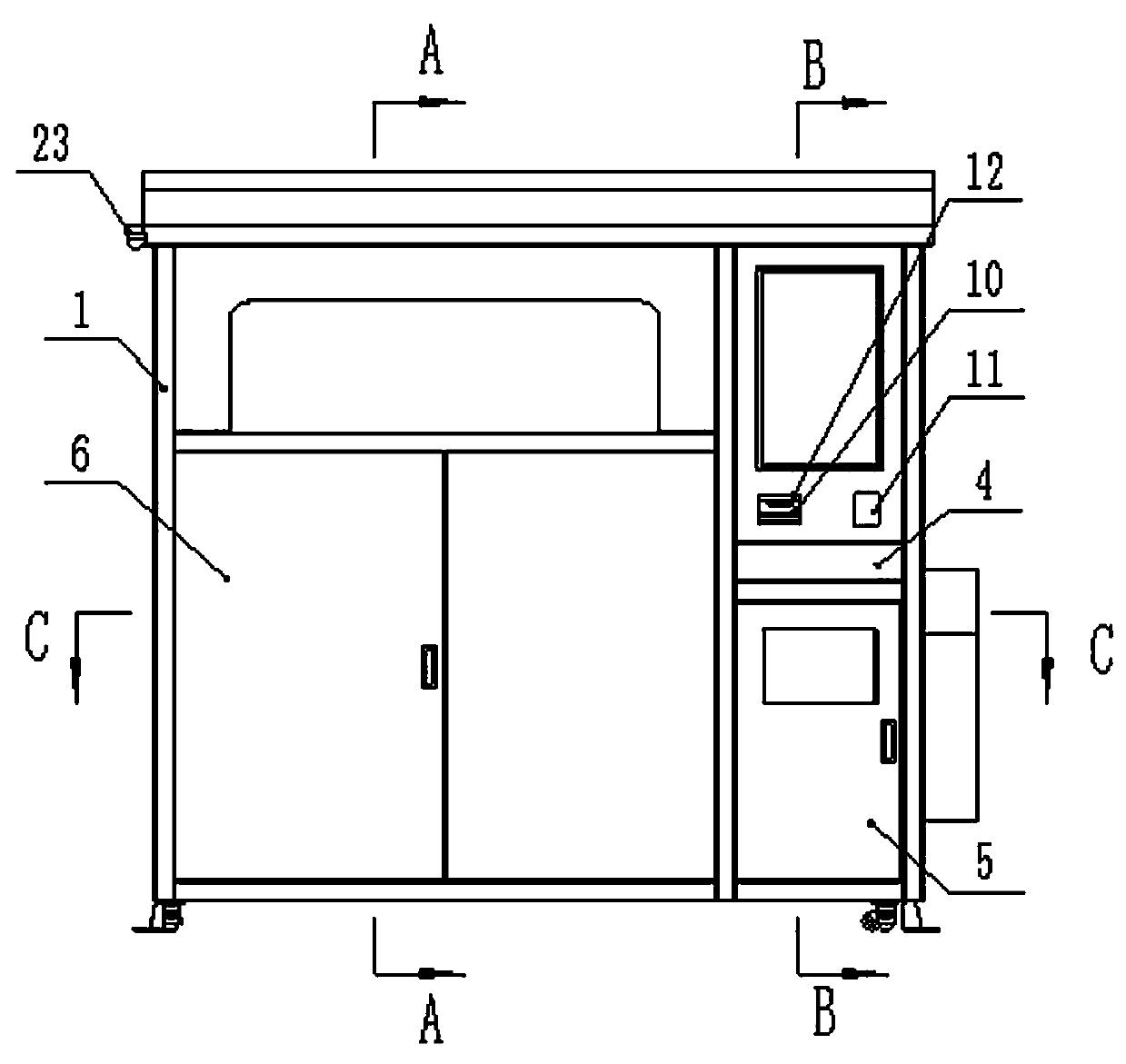

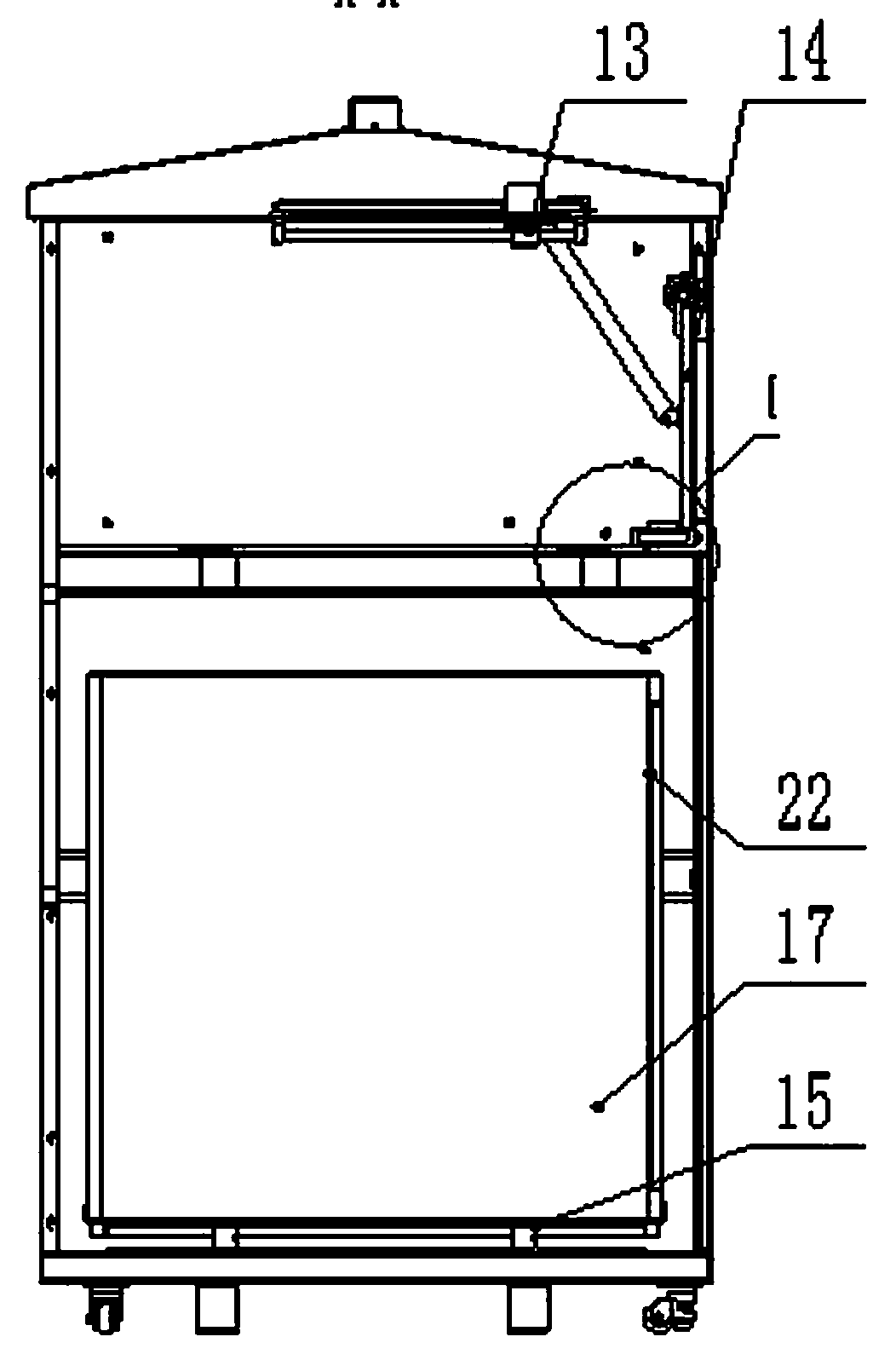

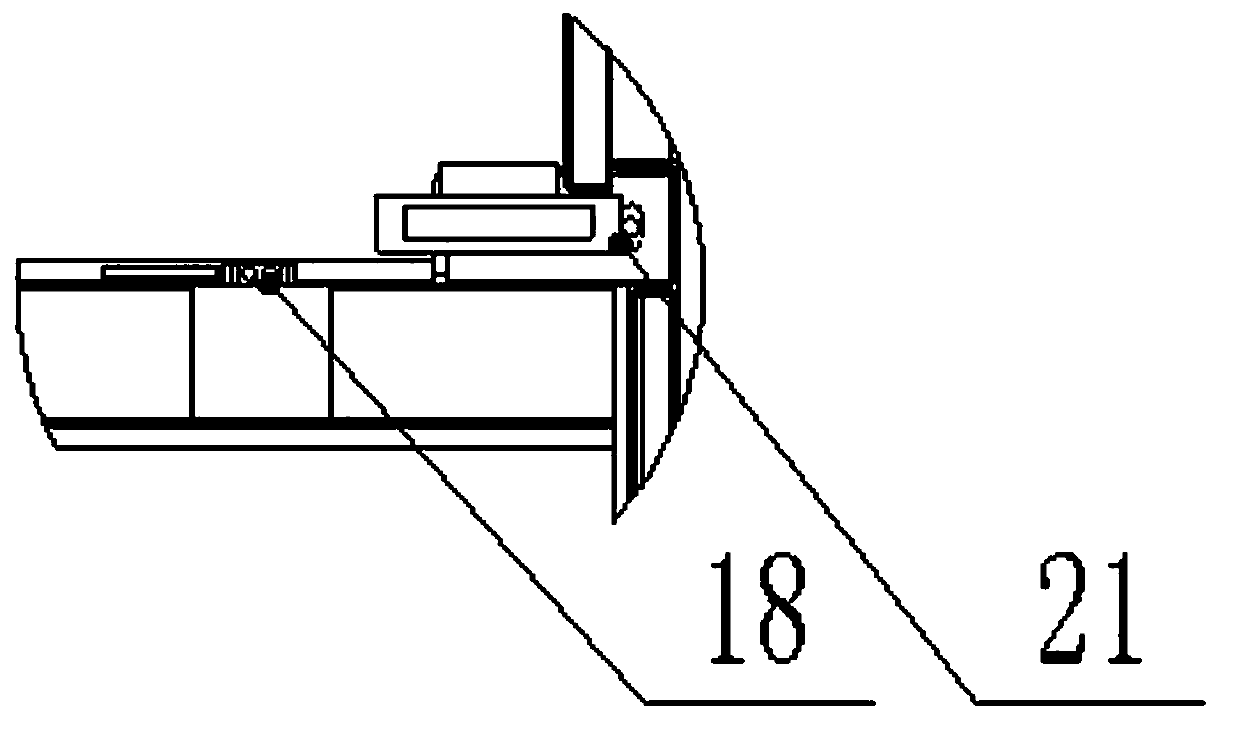

Intelligent recycling machine for renewable resources

InactiveCN111301903AIncrease motivationIncrease profitAcutation objectsWaste collection and transferProcess engineeringRenewable materials

The invention discloses an intelligent recycling machine for renewable resources. The intelligent recycling machine is technically characterized by comprising an integrated machine and an operation terminal, wherein the integrated machine is used for the packaging, sorting and throwing of renewable materials; and the operation terminal is used for user data information processing and management. Through the integrated machine, the renewable materials are sorted, packaged and thrown, thereby solving the problem that recyclable materials in household waste cannot be recycled; after disassembling, recognizing and screening the packaged, sorted and thrown renewable materials, the operation terminal sends the confirmed final weight and final points to a user as well as sends a message about screened-out materials of other types to the user; in addition to the reward points, the user can acquire the correct sorting types and disposal modes of the renewable materials; and consequently, the initiative in sorting the renewable materials of the user can be improved, the user can be guided to correct sorting, and the purpose of preventing the renewable materials from being polluted can be fulfilled finally. The intelligent recycling machine has the beneficial effects that the occupied area is small, the manufacturing cost is low and the price-performance ratio is high.

Owner:辽宁佳创环保设备有限公司

Method for separating alcohol-salt mixture by supercritical carbon dioxide extraction

InactiveCN106977374ASolve the problem that cannot be recycledSolve environmental problemsOrganic compound preparationHydroxy compound preparationPolyolAlcohol

The invention provides a method for separating an alcohol-salt mixture by supercritical carbon dioxide extraction. The method comprises a) feeding supercritical carbon dioxide into an extraction tank, extracting polyol in an alcohol-salt mixture and transferring the polyol into a primary separation tank, b) reducing the temperature and pressure in the primary separation tank, keeping a carbon dioxide supercritical state, separating the extracted polyol from carbon dioxide and feeding the supercritical carbon dioxide containing a small amount of polyol into a secondary separation tank, and c) pre-adding a defoamer into the secondary separation tank, reducing pressure so that the supercritical state of the carbon dioxide is changed into a common gaseous state and further separating polyol so that polyol in the alcohol-salt mixture can be completely separated.

Owner:WANHUA CHEM GRP CO LTD

Method for adjusting balance of carbon-alkali materials in production technology of aluminum oxide

ActiveCN106745122ASolve imbalanced puzzlesAchieve deliveryAluminium oxides/hydroxidesAlkaline waterChemical composition

The invention relates to a method for recycling carbon and alkali systematically during production of aluminum oxide, in particular to a method for adjusting balance of carbon-alkali materials in a production technology of the aluminum oxide. The method is characterized by sequentially including the steps that 1, CO2 gas is injected into sintering method carbonated mother liquor, in this way, caustic alkali in the sintering method carbonated mother liquor completely reacts with CO2, CO2 gas is injected into a solution, and then the aluminum oxide is sufficiently separated out; 2, slurry which the CO2 gas is injected into is filtered one time, filtrate stands and is cooled, and remaining aluminum oxide in the filtrate and other metal ions are further separated out and precipitate; secondary filtering is carried out, the pH value of secondary filtrate is determined, and chemical components of the solution are analyzed; 4, sodium hydroxide or solid sodium hydroxide is added into the secondary filtrate to obtain the pH value of the solution through blending so that requirements for alkaline water used for ore dressing can be met; 5, after the pH value is qualified through blending, the secondary filtrate is delivered to a floatation process of an ore dressing Bayer method.

Owner:中铝中州铝业有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com