Yellow phosphorus tail gas combustion boiler

A yellow phosphorus tail gas and boiler technology, which is applied in the field of combustion boilers, can solve problems such as high cost, complicated process, and inability to ensure safe operation, and achieve the effect of avoiding corrosion and solving the problem of non-recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

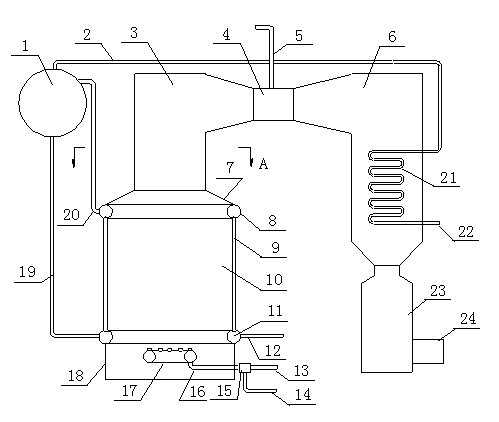

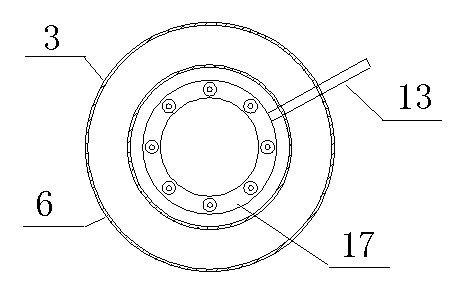

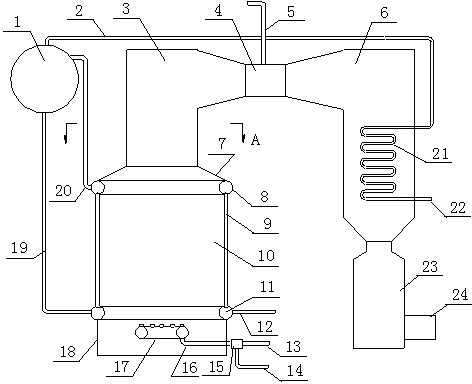

[0014] see figure 1 and figure 2 , figure 1 It is a structural schematic diagram of the yellow phosphorus tail gas combustion boiler of the present invention. figure 2 for figure 1 A-A cut-away diagram. Depend on figure 1 and figure 2 It can be seen that the yellow phosphorus tail gas combustion boiler of the present invention is mainly composed of a combustion chamber 10, an intake hood 18, a gas spray gun 17 (ring), a steam drum 1, a smoke guide hood 7 and a flue. The combustion chamber 10 is formed by a membrane wall heat exchanger, and the membrane wall heat exchanger is composed of a membrane wall 9, an upper header 8 and a lower header 11, and the upper header 8 and the lower header 11 are fixedly connected to the membrane respectively. The top and bottom of the formula wall 9. The lower header 11 is connected with a water supply pipe 12 . The air intake cover 18 is connected to the bottom of the lower header 11, the gas spray gun 17 is arranged in the intake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com