Novel adsorption column for removing heavy metals and preparation method of adsorption column

A heavy metal and adsorption column technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of complex production process, poor mechanical properties, easy aging and deformation, etc., achieve simple preparation process, low cost, and avoid secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method for removing a novel adsorption column for heavy metals, comprising the steps of:

[0036] 1) crushing and grinding the recovered biogel material of 5-10 parts by mass;

[0037] 2) Put 20-48 mass parts of environmentally friendly resin into a clean mixing tank, stir at a speed of 900-1500rpm for 5-10min, keep the stirring speed constant, add the above-mentioned ground sodium alginate gel material, continue Stir for 10-15 minutes, keep the stirring rate constant, add 20-48 parts by mass of composite powder, continue stirring for 15-20 minutes, keep the stirring rate constant, add 0.1-1 parts by mass of color paste and 0.1-1 parts by mass of Accelerator, continue to stir for 5-10 minutes, keep the stirring rate constant, add 0.1-1 mass part of curing agent, continue to stir for 5-10 minutes, and form a mixed raw material;

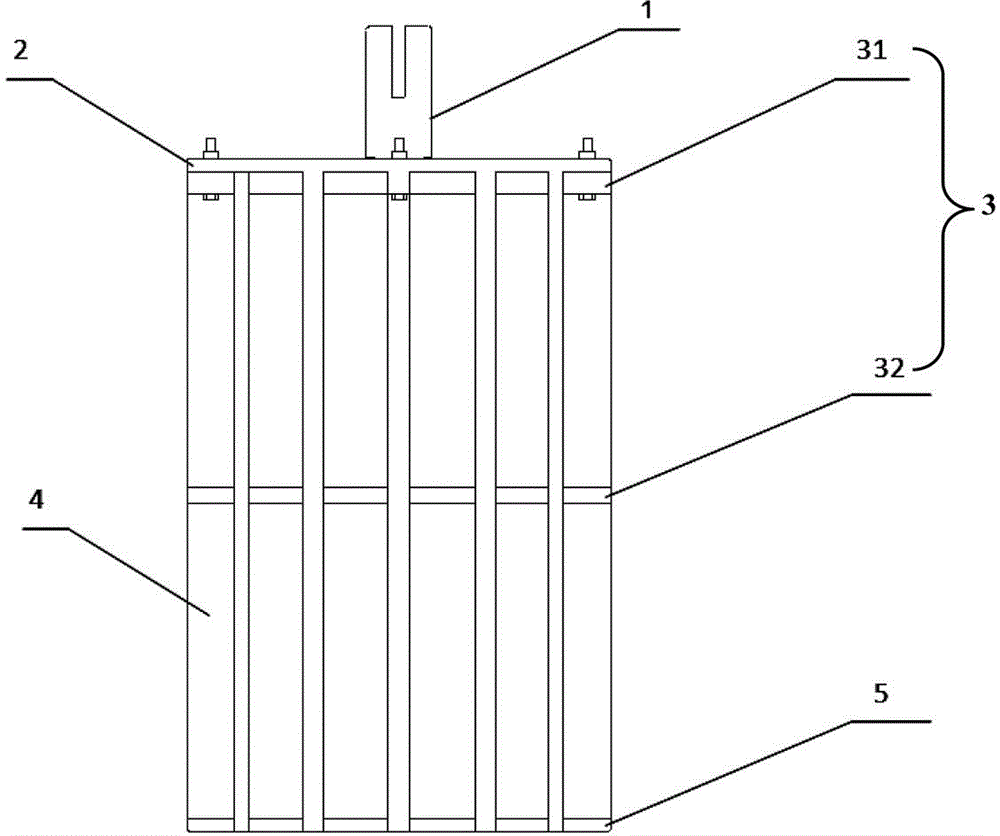

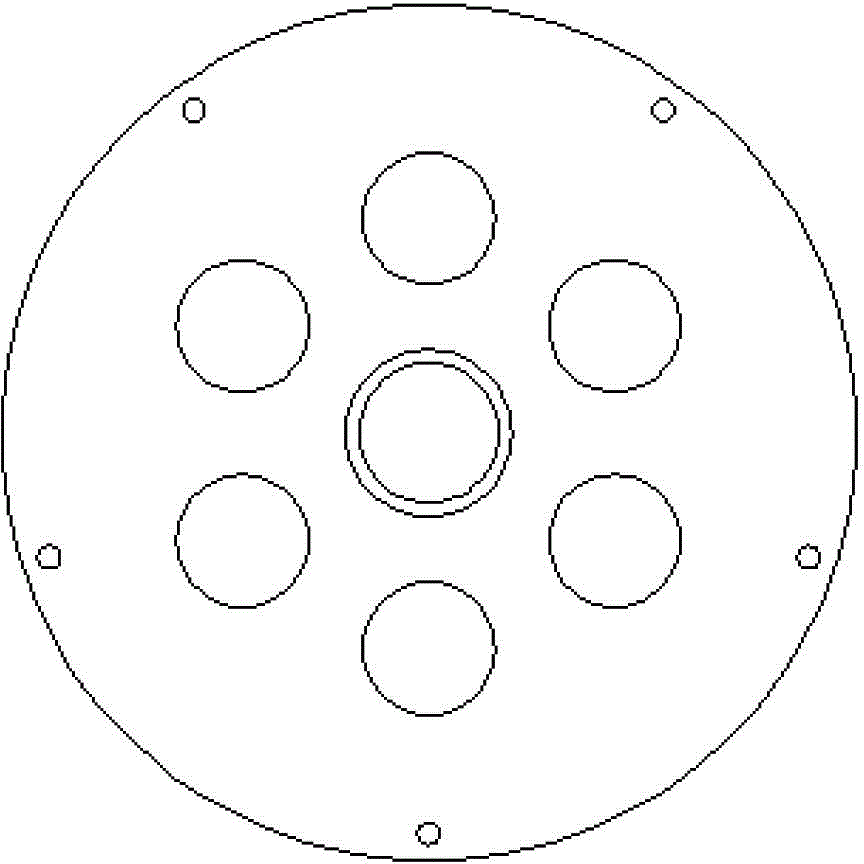

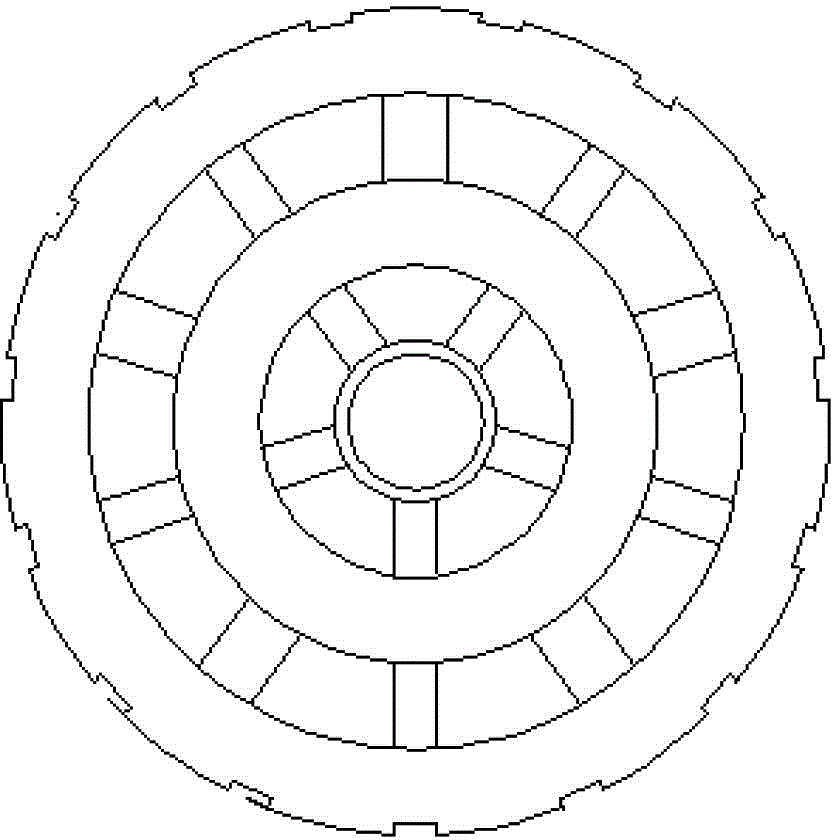

[0038] 3) Open the mold corresponding to each part of the adsorption column, place the glass fiber in each mold, the shape and s...

Embodiment 1

[0056] Environmentally friendly resin includes the following components: 25% phthalic anhydride, 20% maleic anhydride, 15% glycerin, 10% diethylene glycol, 10% ethylene glycol, 2% benzoic acid, and 18% styrene.

[0057] The preparation method for removing heavy metal novel adsorption column comprises the following steps:

[0058] 1) Grinding and grinding the sodium alginate gel material of 6 parts by mass;

[0059] 2) Put 26 parts by mass of environmentally friendly resin into a clean mixing tank, stir for 5 minutes at a speed of 1000 rpm, keep the stirring rate constant, add the above-mentioned ground and crushed sodium alginate gel material, continue stirring for 10 minutes, and keep stirring Speed is constant, add and the calcium carbonate of 25 mass parts, continue stirring 15min, keep stirring speed constant, add the color paste of 0.24 mass part and the cobalt isooctanoate of 0.24 mass part, continue stirring 5min, keep stirring speed constant, add 0.30 parts by mass ...

Embodiment 2

[0065] Environmentally friendly resin includes the following components: 25% phthalic anhydride, 20% maleic anhydride, 15% glycerin, 10% diethylene glycol, 10% ethylene glycol, 2% benzoic acid, and 18% styrene.

[0066] A kind of preparation method for removing heavy metal novel adsorption column comprises the following steps:

[0067] 1) Grinding and grinding the sodium alginate gel material of 10 parts by mass;

[0068] 2) Put 46 parts by mass of environmentally friendly resin into a clean mixing bucket, stir at a speed of 1000rpm for 10 minutes, keep the stirring rate constant, add the above-mentioned ground and pulverized sodium alginate gel material, continue stirring for 10 minutes, and keep stirring Speed is constant, add the calcium carbonate of 45 mass parts, continue stirring 20min, keep stirring speed constant, add the color paste of 0.4 mass part and the copper naphthenate of 0.4 mass part, continue stirring 10min, keep stirring speed constant, add The methyl et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com