Ultrasonic-microwave assisted lithium ion battery recovery method

A lithium-ion battery, ion battery technology, applied in battery recycling, recycling technology, waste collector recycling and other directions, can solve the problems of long wet process cycle, non-recycling, complex process, etc., to shorten the leaching-extraction time, Brownian motion effect increase, the effect of improving the degree of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

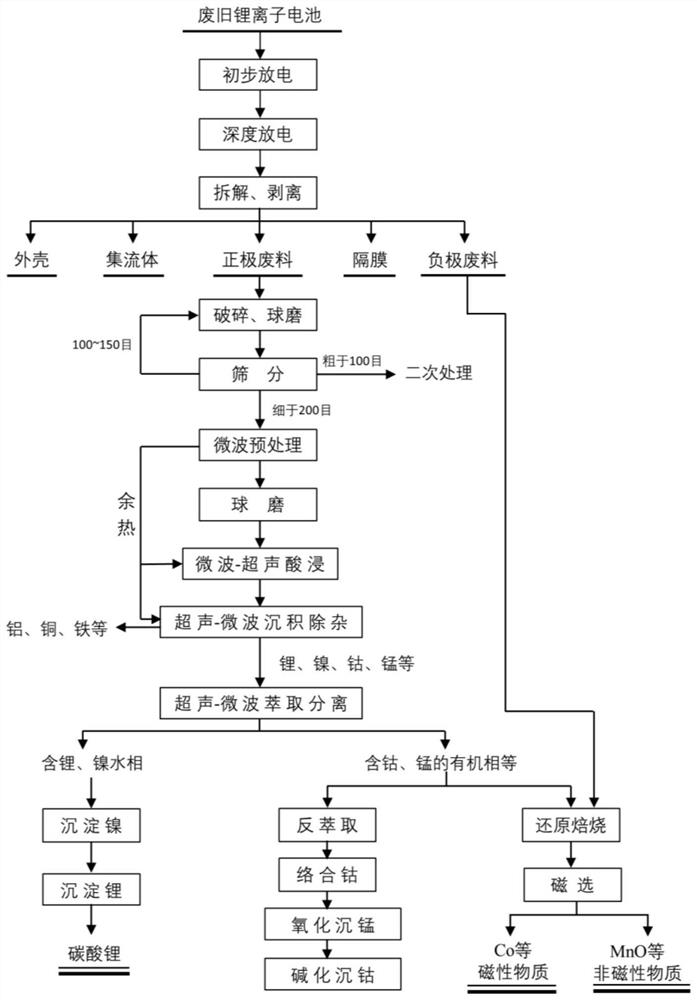

[0041] see figure 1 , a method for ultrasonic-microwave assisted recovery of lithium-ion batteries, comprising the following steps:

[0042] S1. Carry out preliminary discharge and deep discharge on the used lithium-ion battery to make it reach the condition that it can be safely disassembled;

[0043] S2. Disassemble the lithium-ion battery to obtain the battery shell, current collector, diaphragm, and battery electrodes, and peel off the battery electrodes to obtain the positive and negative electrode materials; crush, sieve, ball mill, and sieve the positive electrode materials to obtain them for recycling. positive electrode powder;

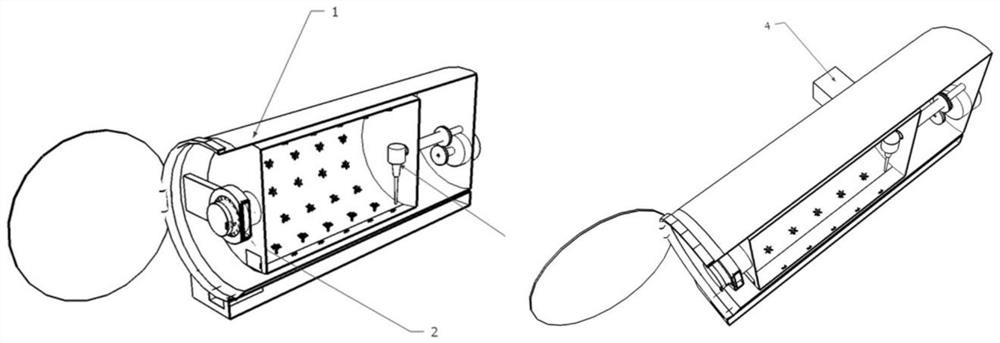

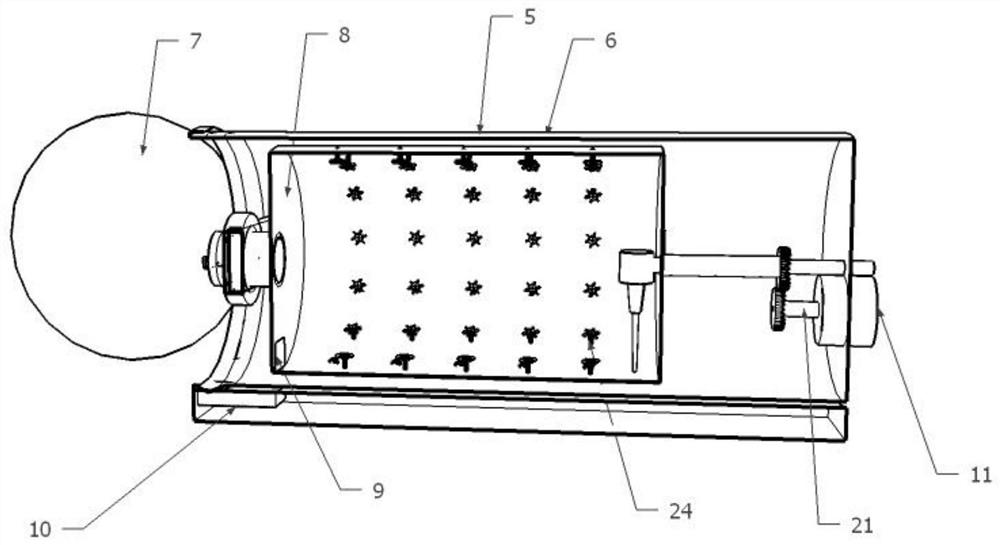

[0044] S3. Perform microwave pretreatment on the positive electrode powder, add the positive electrode powder into the ultrasonic-microwave rotary equipment and blow in oxygen for a period of time, then close the furnace body and turn on the microwave generator 4, under the condition that the furnace body rotates at a speed of 10r / min Heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com