Convection-type sticky candy stirring device

A stirring device and brown sugar technology, applied in confectionary, confectionery industry, food science, etc., can solve the problems of small contact surface and low stirring force, achieve the effect of increasing mixing force, mixing evenly, and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

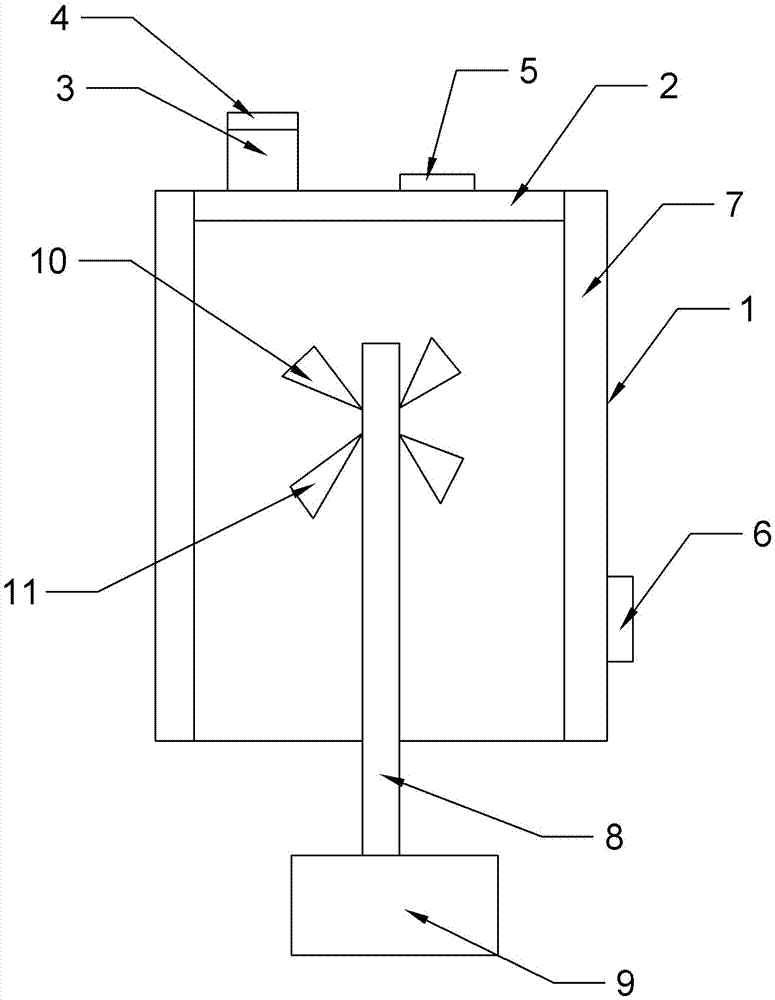

[0014] Such as figure 1 As shown, the convective brown sugar stirring device includes a housing 1, the housing 1 is a cylindrical structure, the upper end of the housing 1 is provided with a sealing cover 2, and sealing rings are provided around the sealing cover 2 to facilitate sealing it. The sealing cover 2 is provided with an explosion-venting opening 3, and an explosion-venting membrane 4 is fixed on the explosion-venting opening 3, and the explosion-venting membrane 4 is made of aluminum foil. A material inlet 5 is provided on the top of the sealing cover 2, a material outlet 6 is arranged on one side of the housing 1, and a collecting bucket is arranged at the outlet 6. The side wall of housing 1 is provided with heating layer 7, and heating wire is installed in the heating layer 7, is convenient to heating brown sugar liquid. A rotating shaft 8 is vertically arranged in the housing 1, and the rotating shaft 8 passes through the bottom of the housing 1 and is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com