Patents

Literature

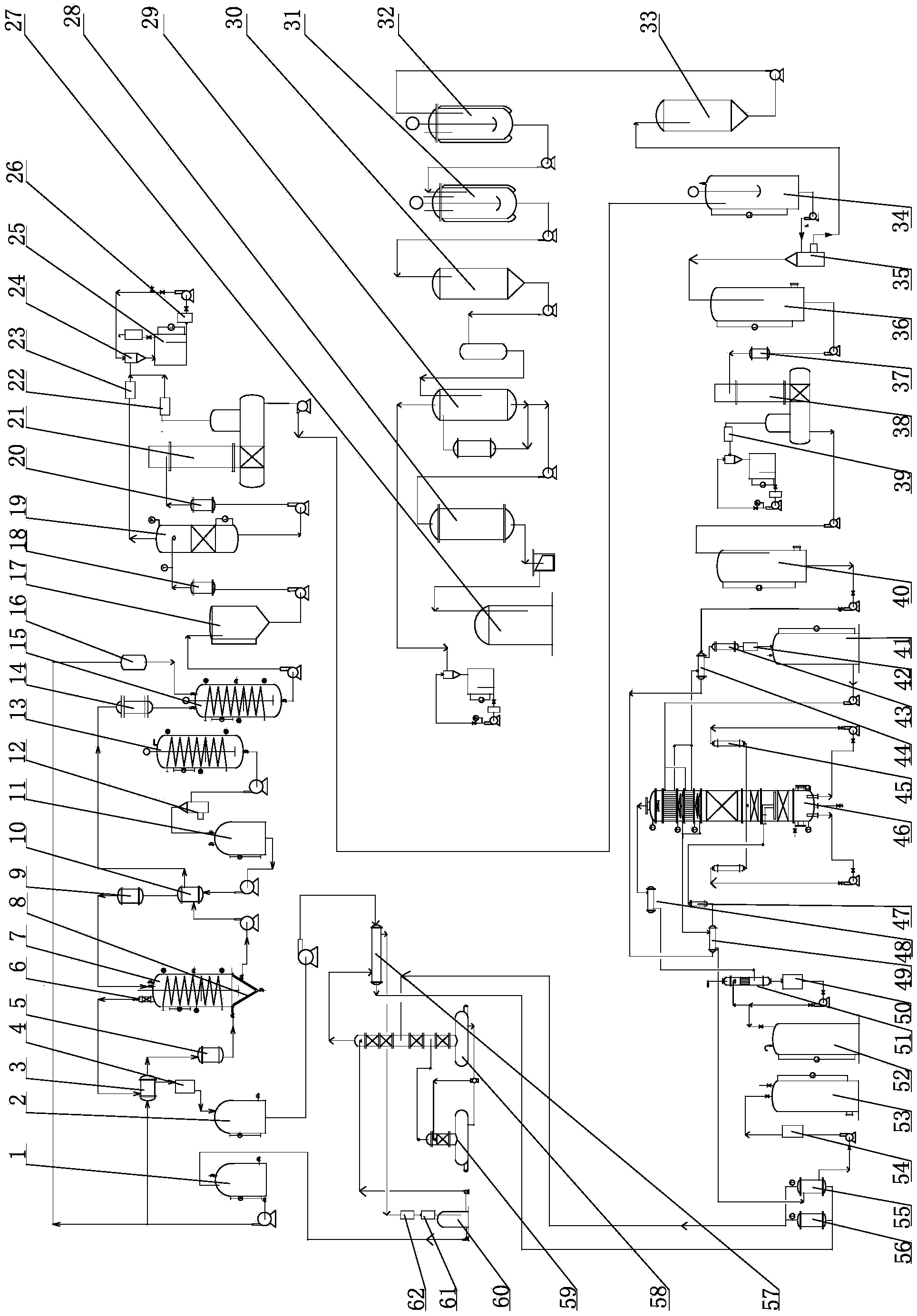

1227results about How to "Increase the degree of mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

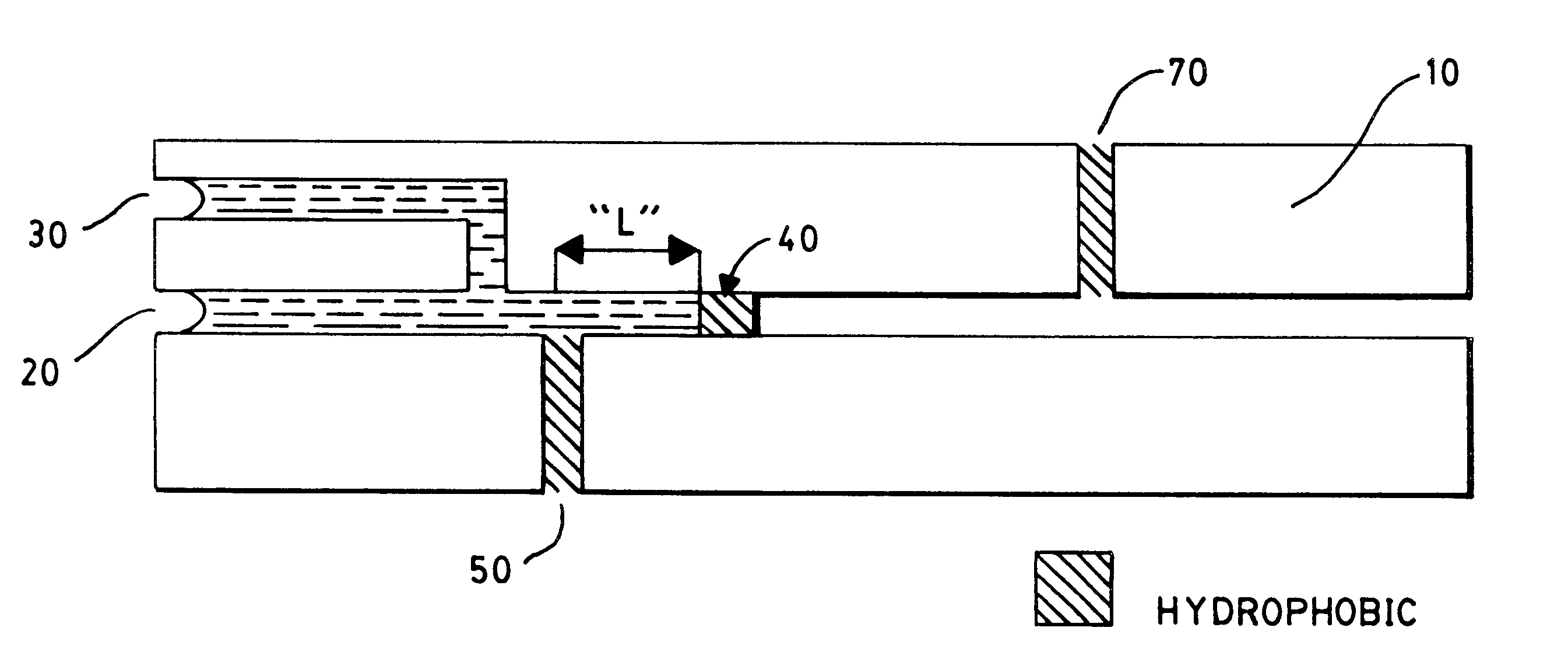

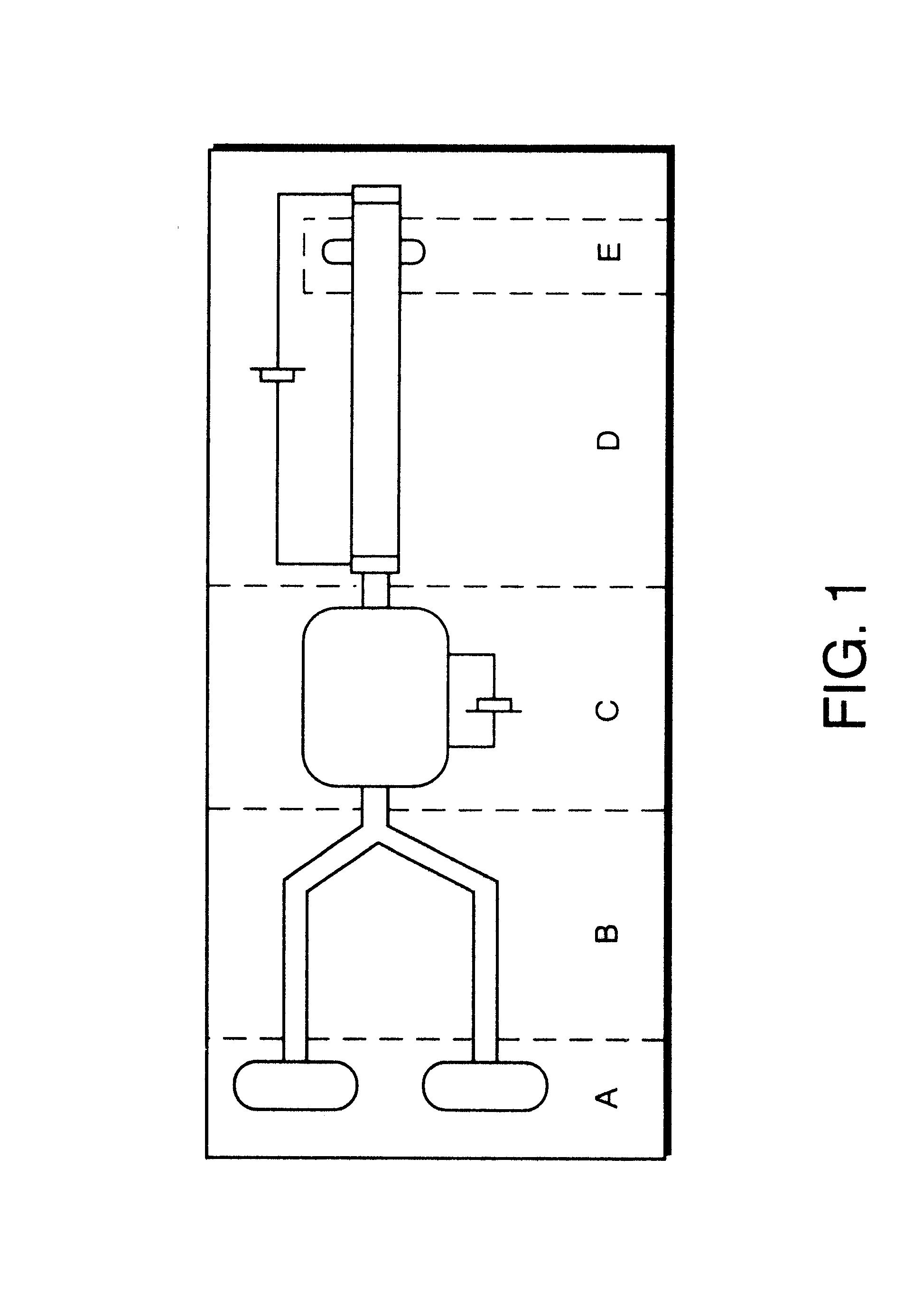

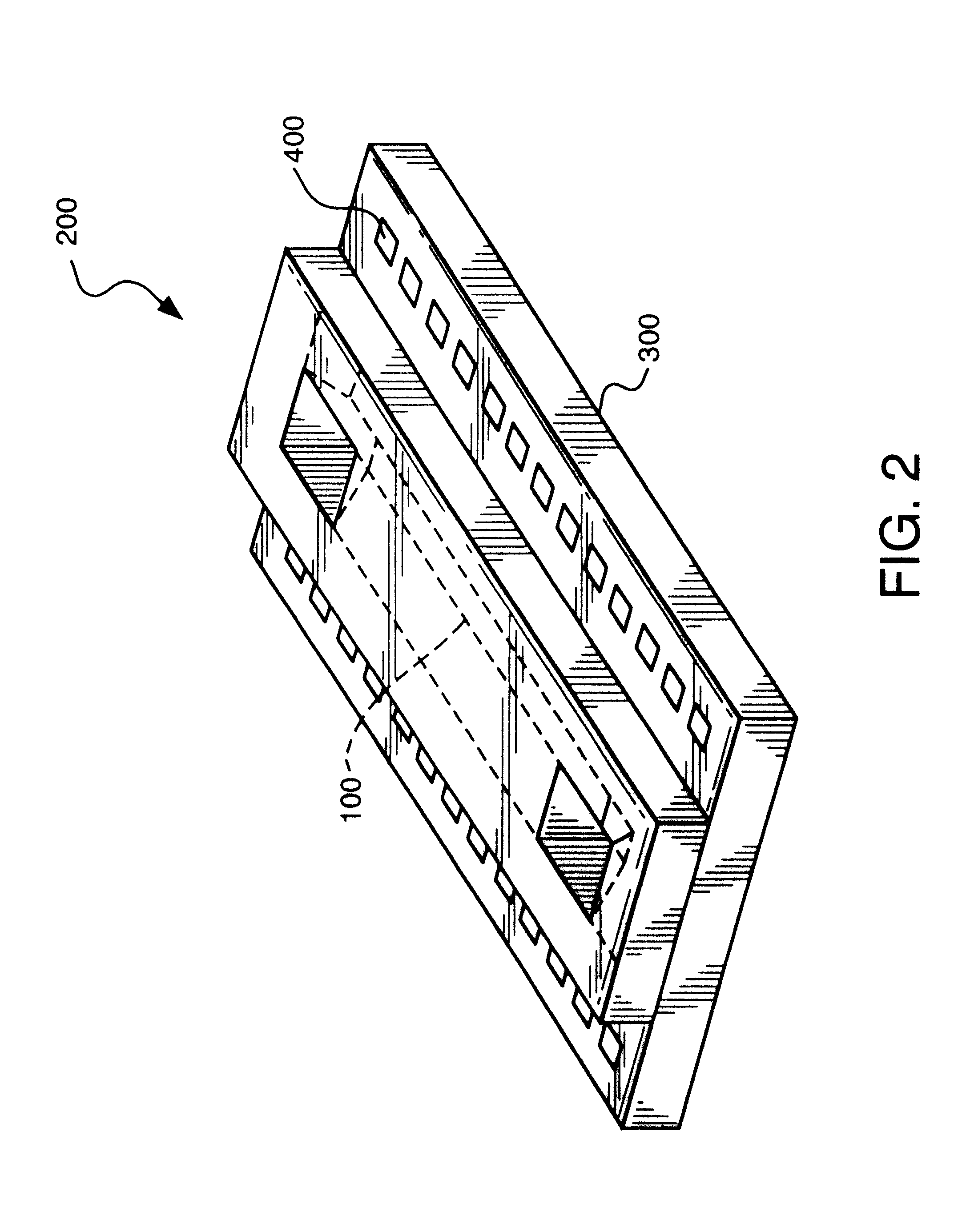

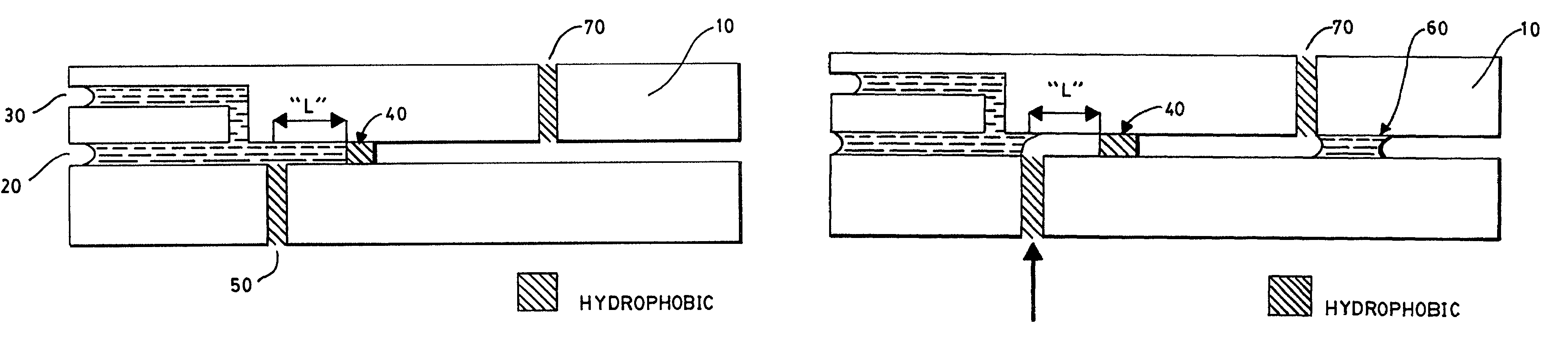

Moving microdroplets

InactiveUS6911183B1Easy to assembleIncrease the degree of mixingMaterial nanotechnologyValve arrangementsElectrophoresisOptoelectronics

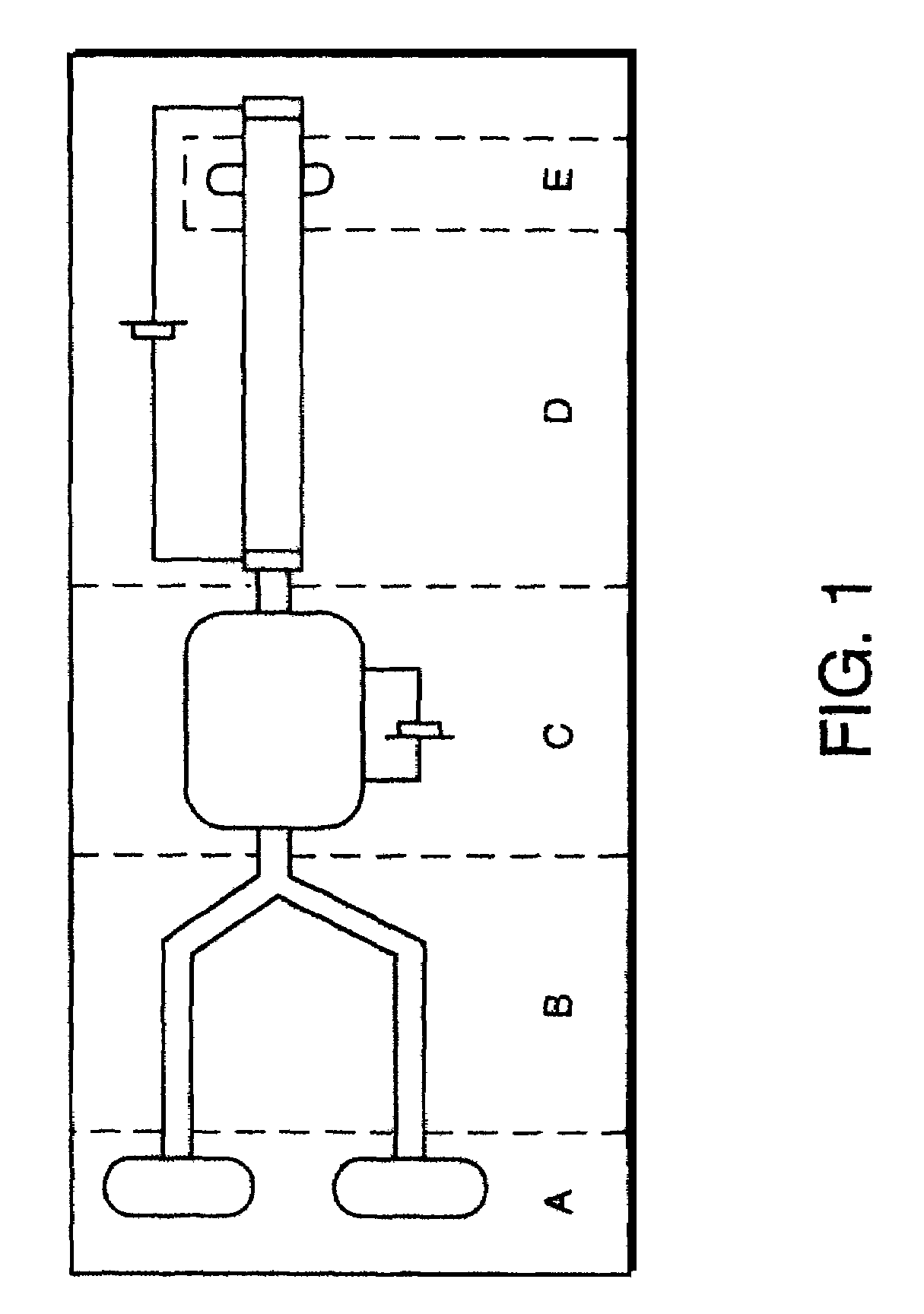

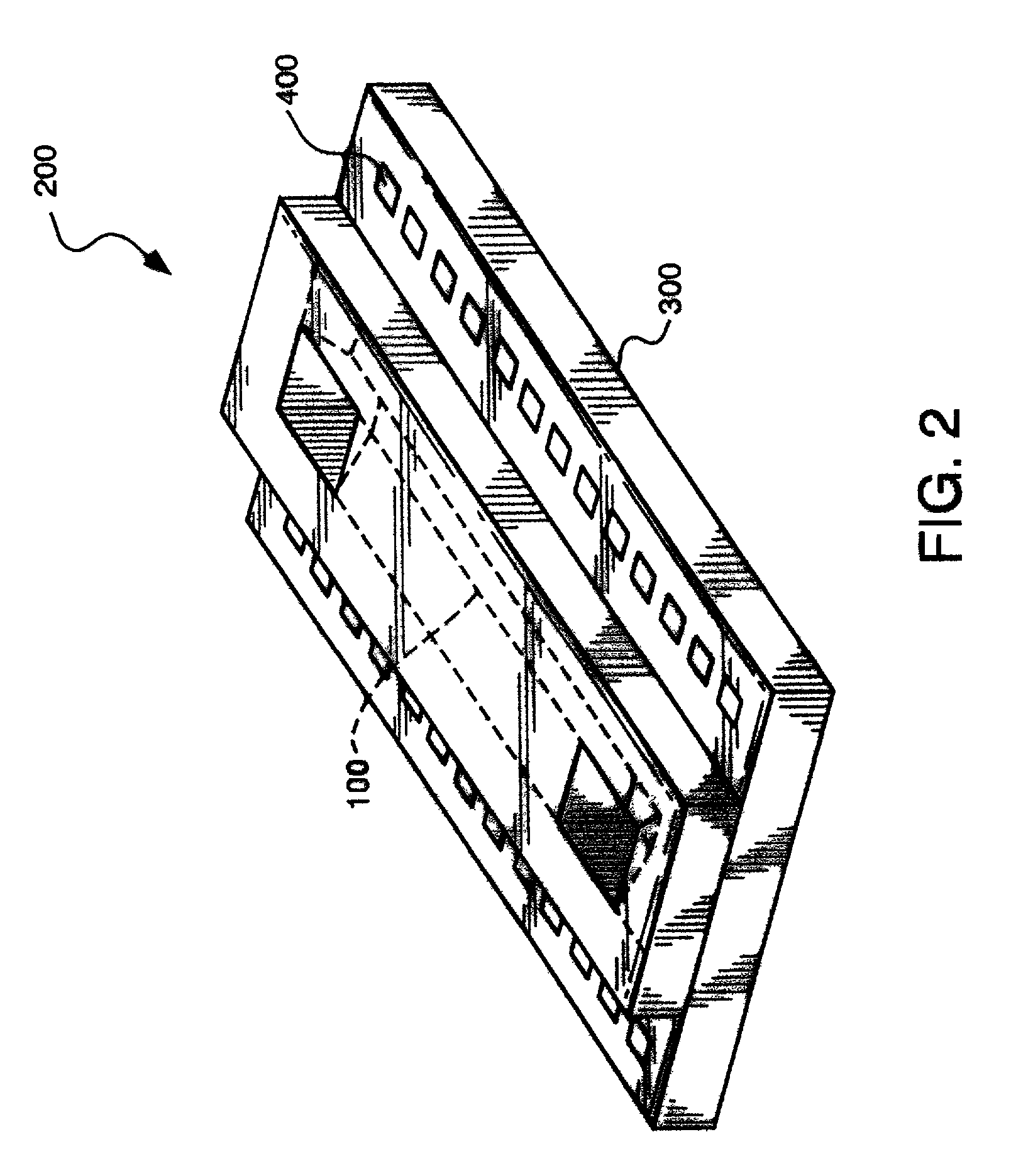

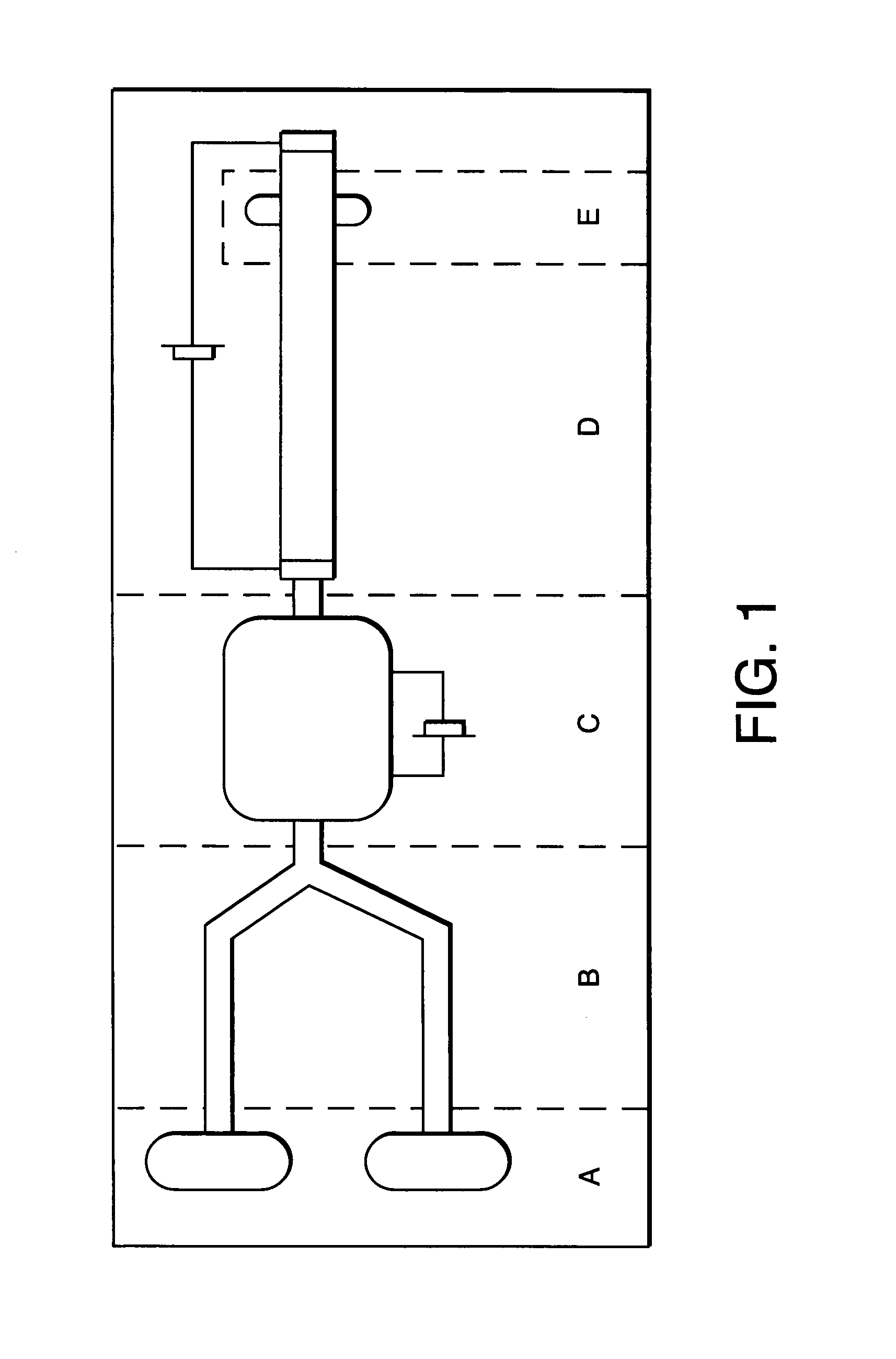

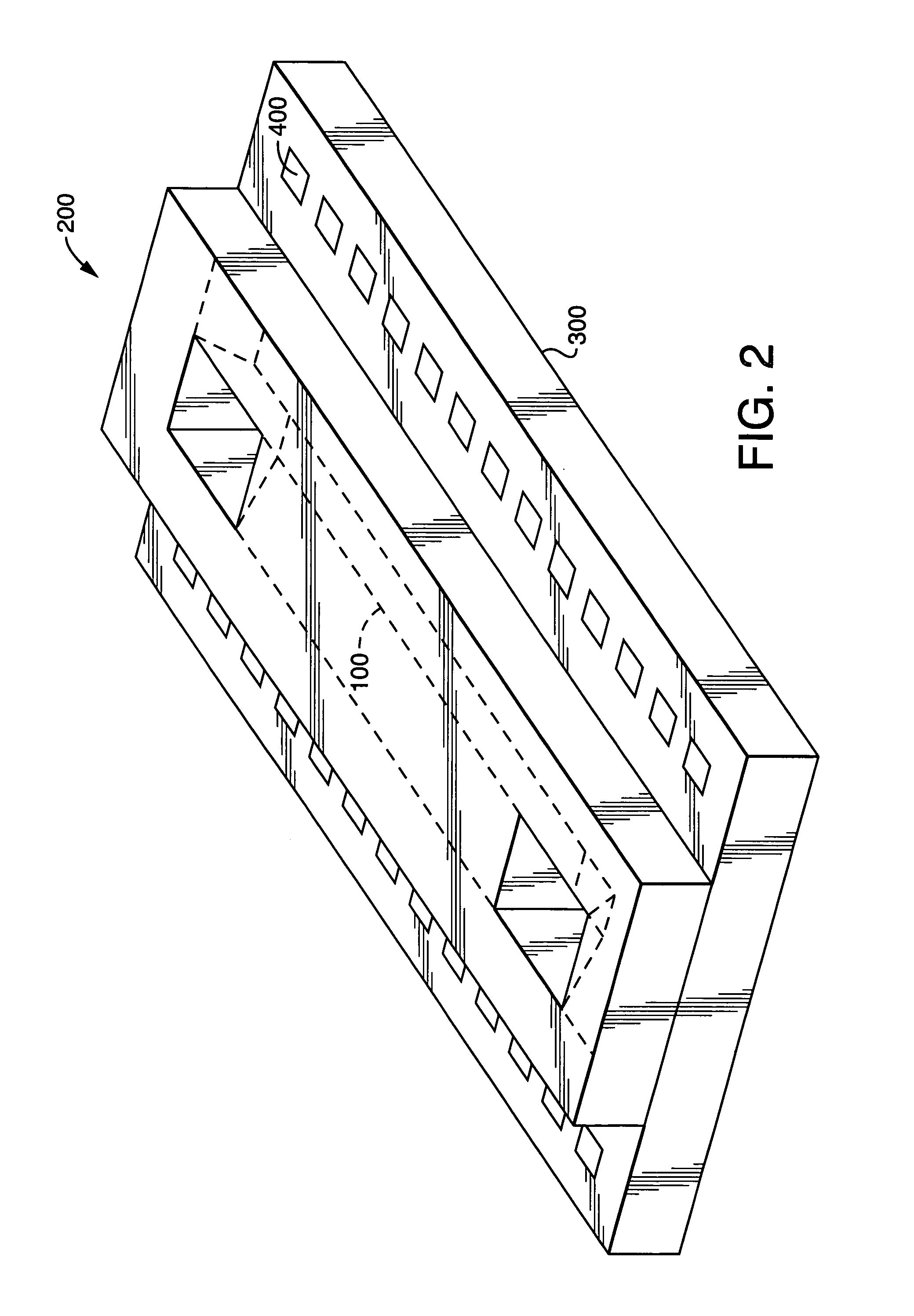

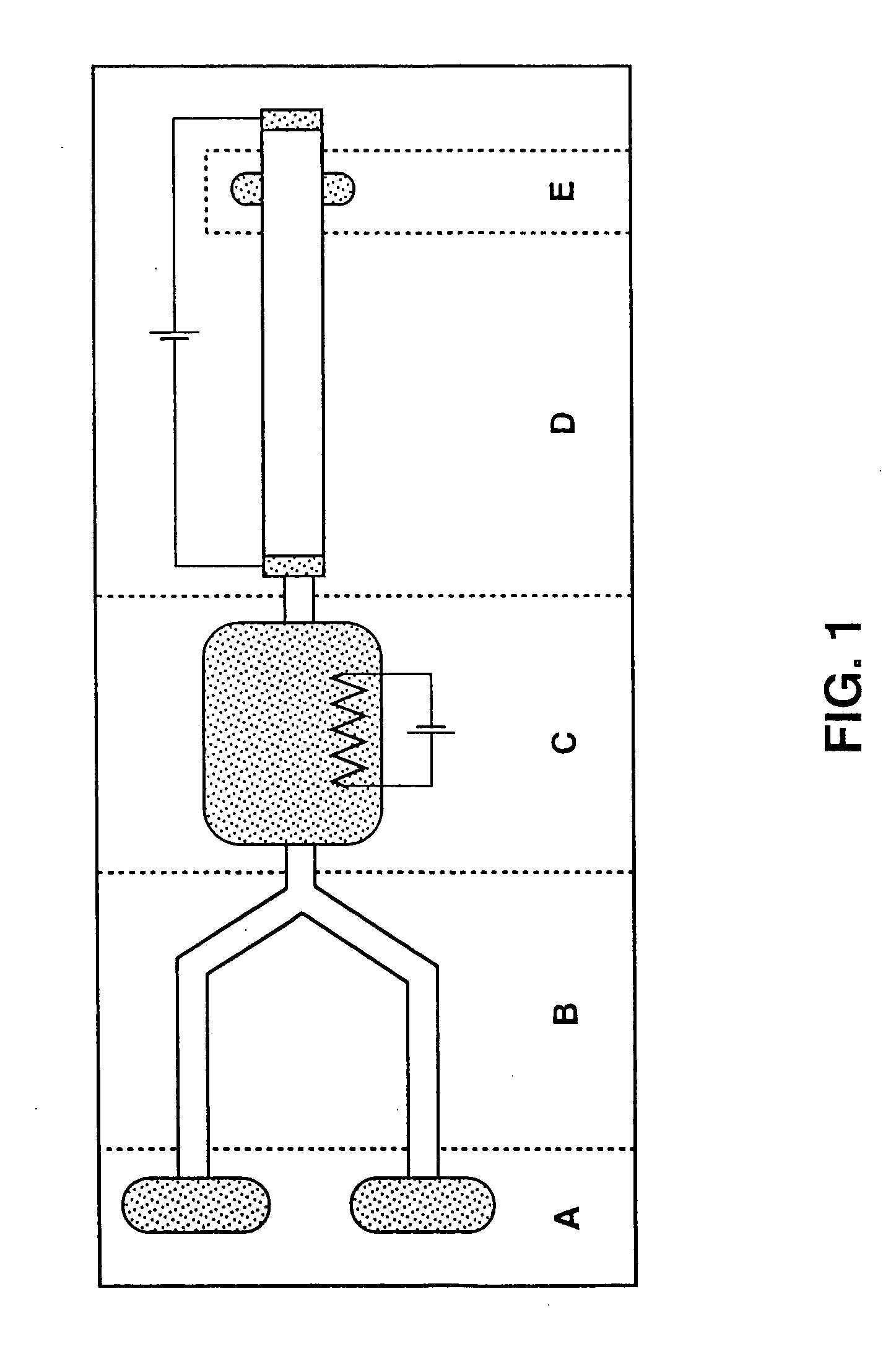

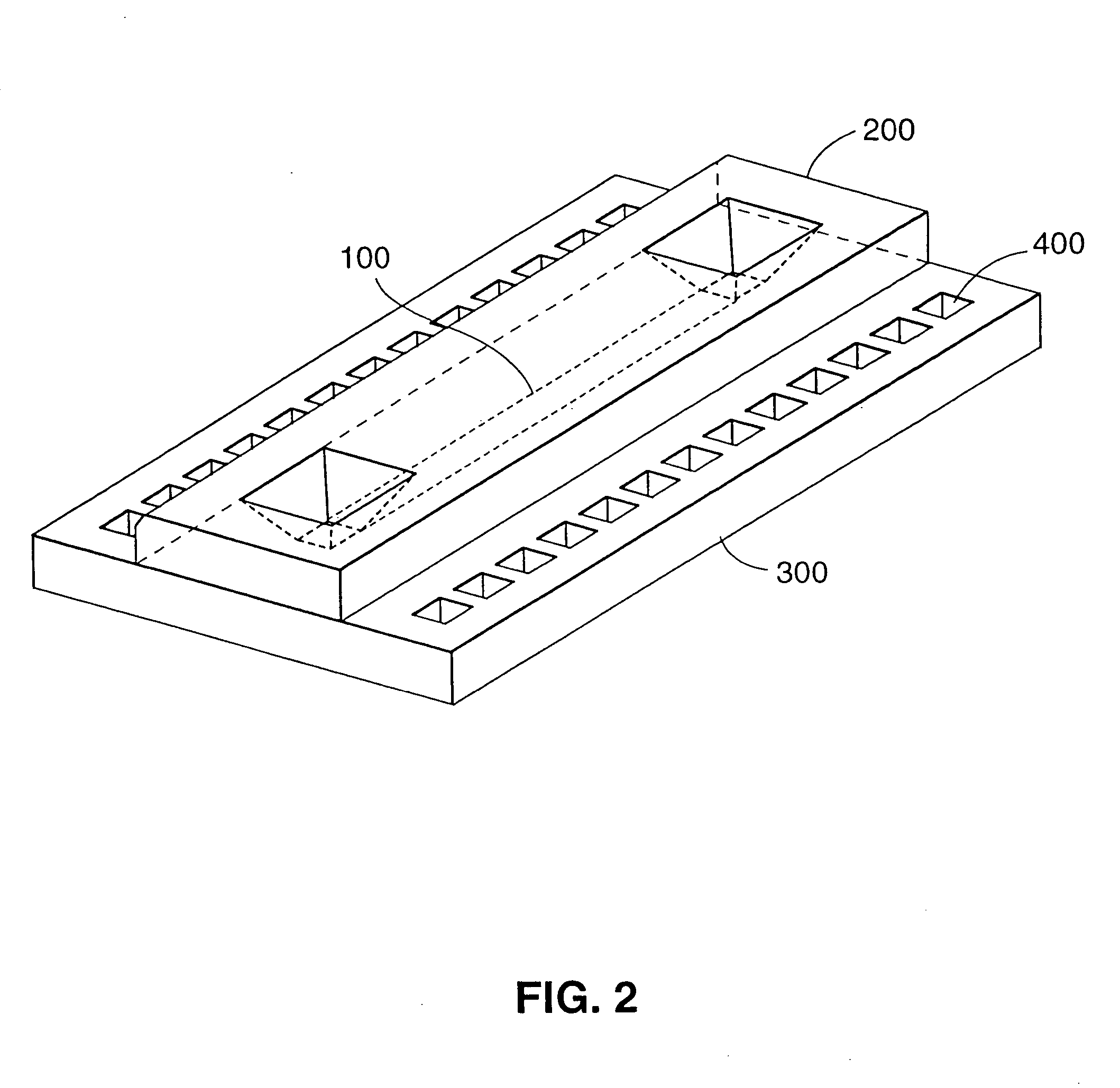

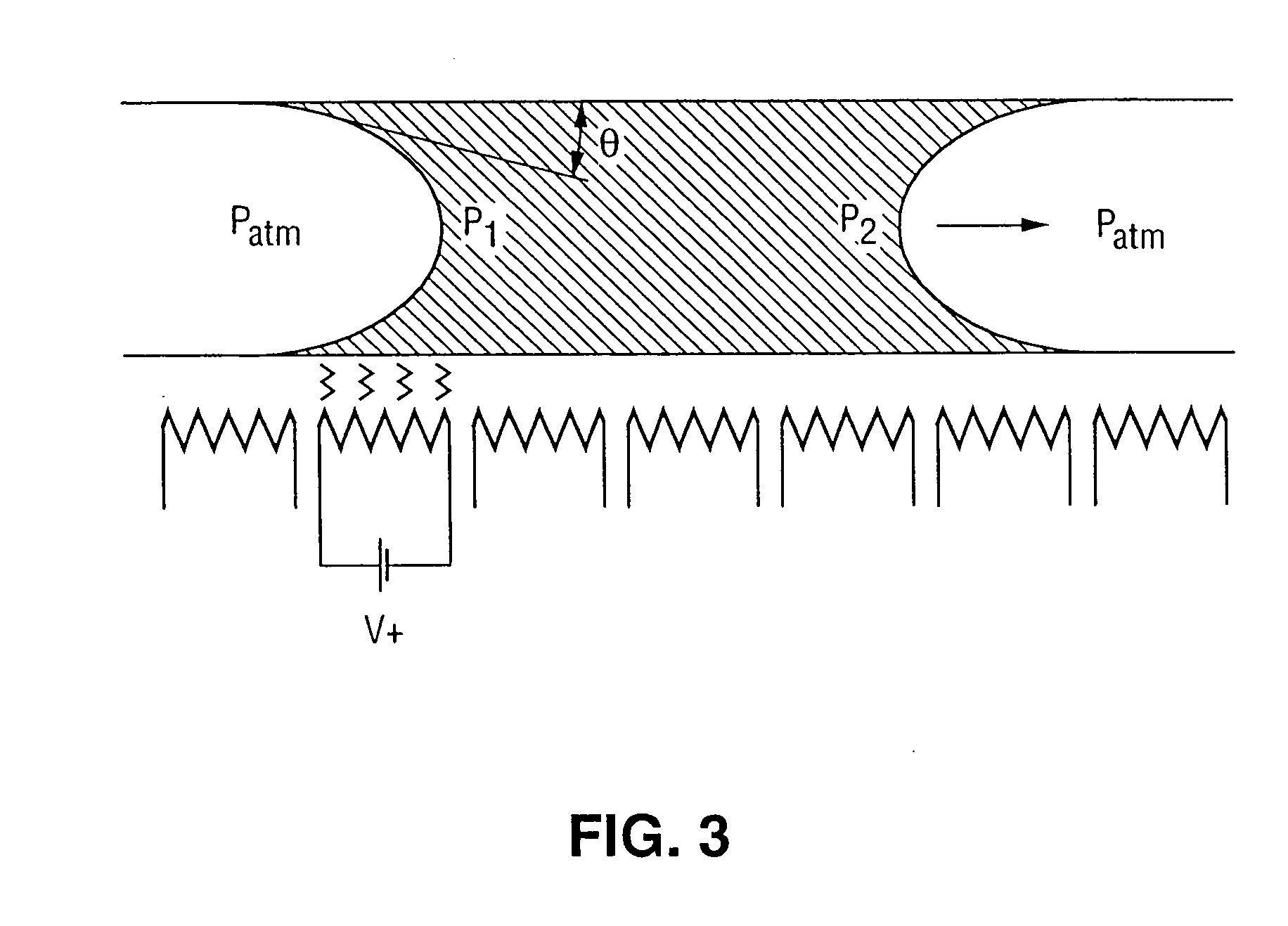

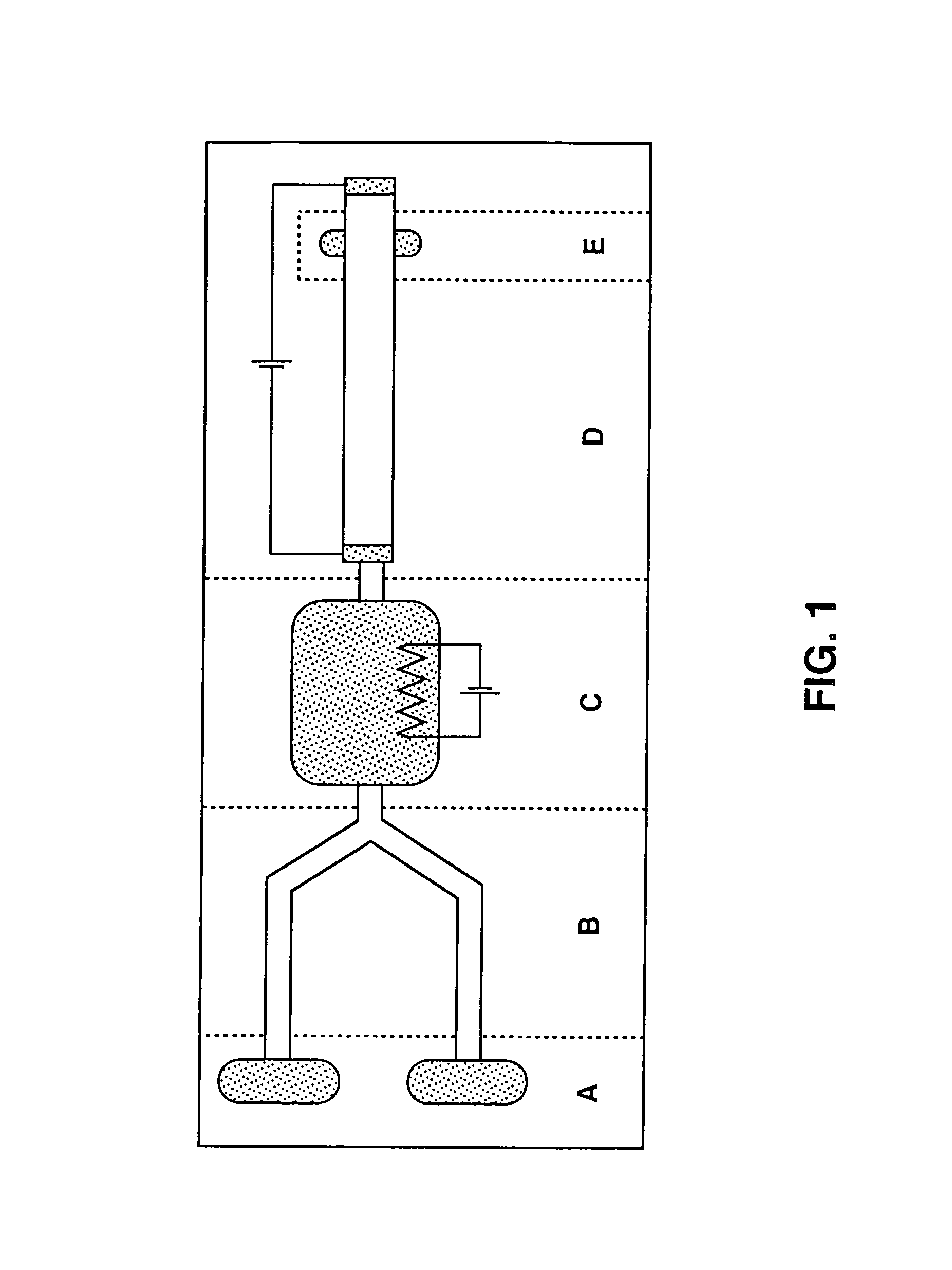

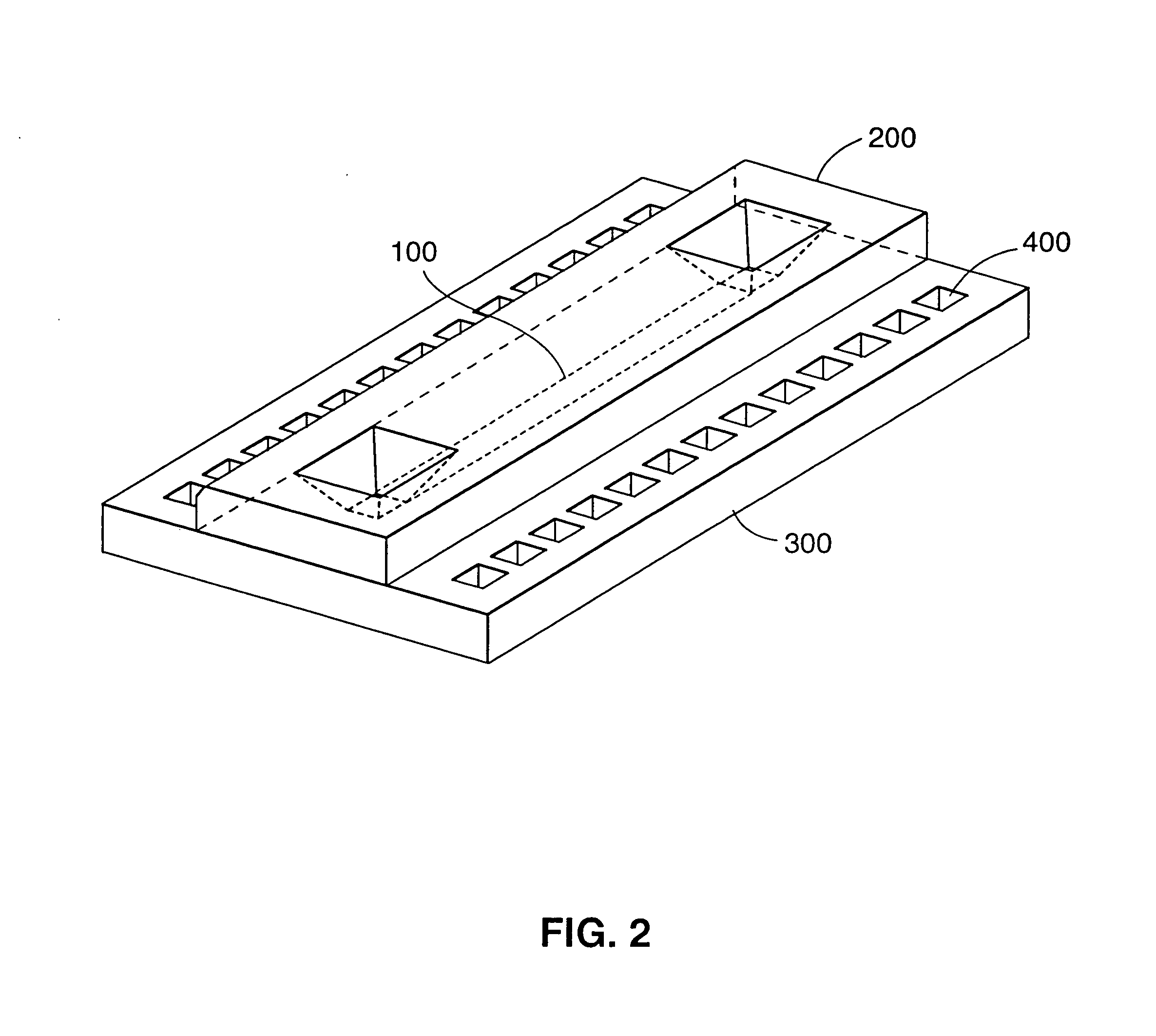

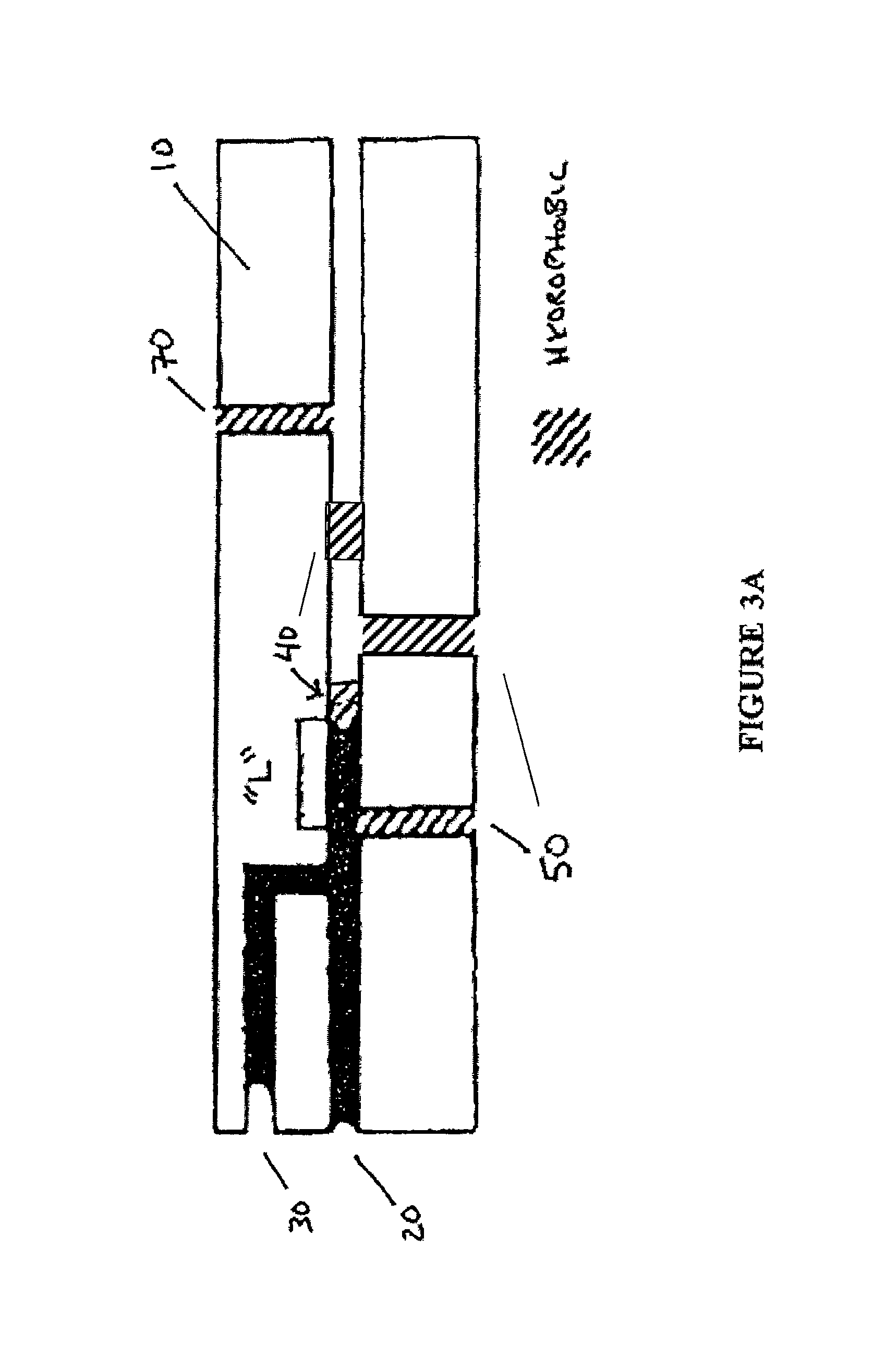

The movement and mixing of microdroplets through microchannels is described employing microscale devices, comprising microdroplet transport channels, reaction regions, electrophoresis modules, and radiation detectors. The discrete droplets are differentially heated and propelled through etched channels. Electronic components are fabricated on the same substrate material, allowing sensors and controlling circuitry to be incorporated in the same device.

Owner:RGT UNIV OF MICHIGAN

Compositions and methods for liquid metering in microchannels

InactiveUS7004184B2Easy to assembleIncrease the degree of mixingMaterial nanotechnologyShaking/oscillating/vibrating mixersElectrophoresisComputer module

The movement and mixing of microdroplets through microchannels is described employing microscale devices, comprising microdroplet transport channels, reaction regions, electrophoresis modules, and radiation detectors. Microdroplets are metered into defined volumes and are subsequently incorporated into a variety of biological assays. Electronic components are fabricated on the same substrate material, allowing sensors and controlling circuitry to be incorporated in the same device.

Owner:RGT UNIV OF MICHIGAN

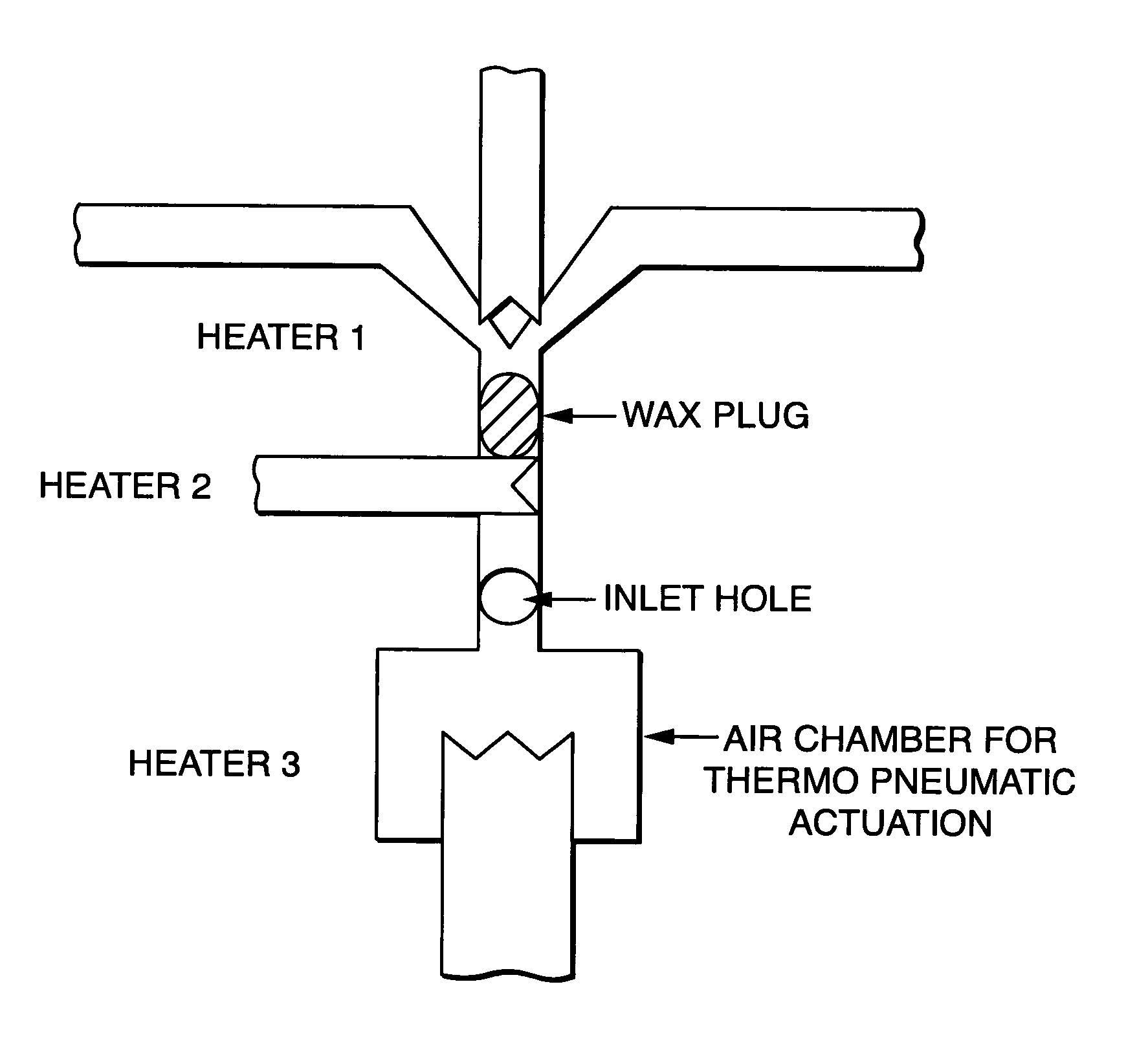

Thermal micro-valves for micro-integrated devices

ActiveUS7195036B2Prevents short circuitAvoid damageOperating means/releasing devices for valvesCircuit elementsElectrophoresisComputer module

The movement and mixing of microdroplets through microchannels is described employing silicon-based microscale devices, comprising microdroplet transport channels, reaction regions, electrophoresis modules, and radiation detectors. The discrete droplets are differentially heated and propelled through etched channels. Electronic components are fabricated on the same substrate material, allowing sensors and controlling circuitry to be incorporated in the same device.

Owner:RGT UNIV OF MICHIGAN

Thermal microvalves

InactiveUS20050272079A1Easy to assembleQuick identificationBioreactor/fermenter combinationsMaterial nanotechnologyElectrophoresisEngineering

The movement and mixing of microdroplets through microchannels is described employing silicon-based microscale devices, comprising microdroplet transport channels, reaction regions, electrophoresis modules, and radiation detectors. The discrete droplets are differentially heated and propelled through etched channels. Electronic components are fabricated on the same substrate material, allowing sensors and controlling circuitry to be incorporated in the same device.

Owner:RGT UNIV OF MICHIGAN

Compositions and methods for liquid metering in microchannels

ActiveUS8936945B2Easy to assembleIncrease the degree of mixingBioreactor/fermenter combinationsMaterial nanotechnologyElectrophoresisComputer module

The movement and mixing of microdroplets through microchannels is described employing microscale devices, comprising microdroplet transport channels, reaction regions, electrophoresis modules, and radiation detectors. Microdroplets are metered into defined volumes and are subsequently incorporated into a variety of biological assays. Electronic components are fabricated on the same substrate material, allowing sensors and controlling circuitry to be incorporated in the same device.

Owner:RGT UNIV OF MICHIGAN

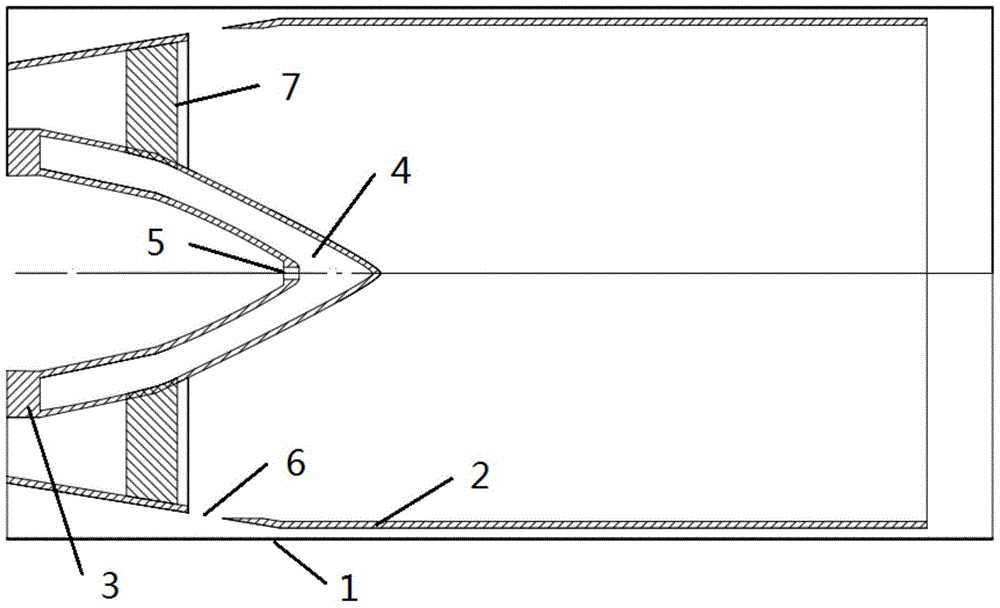

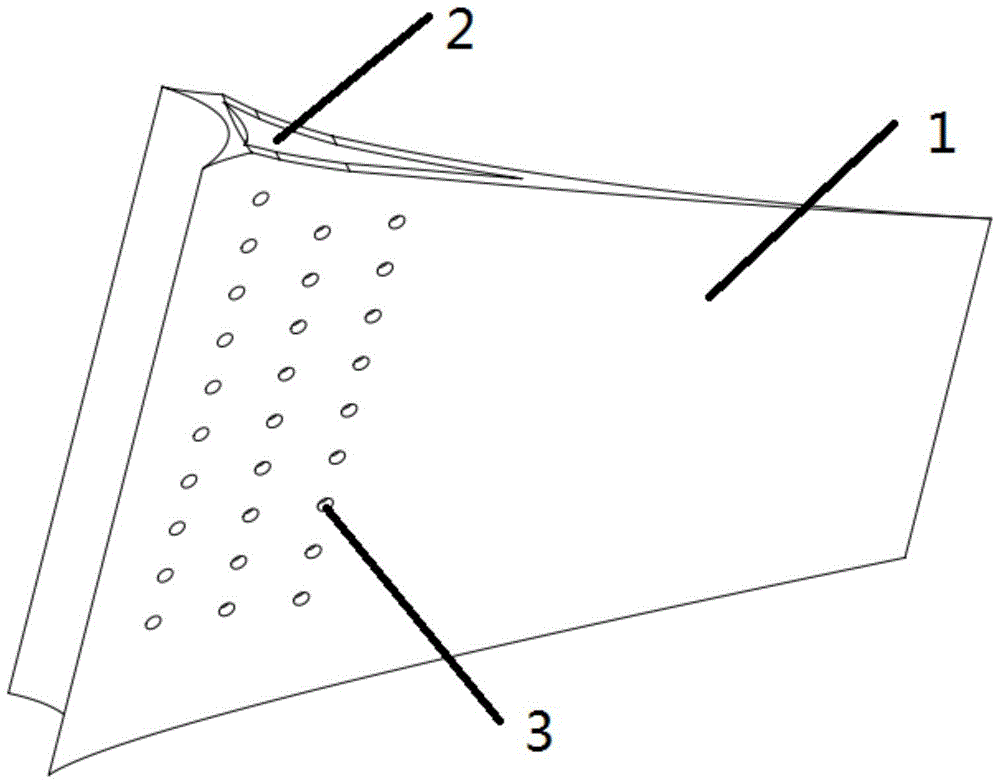

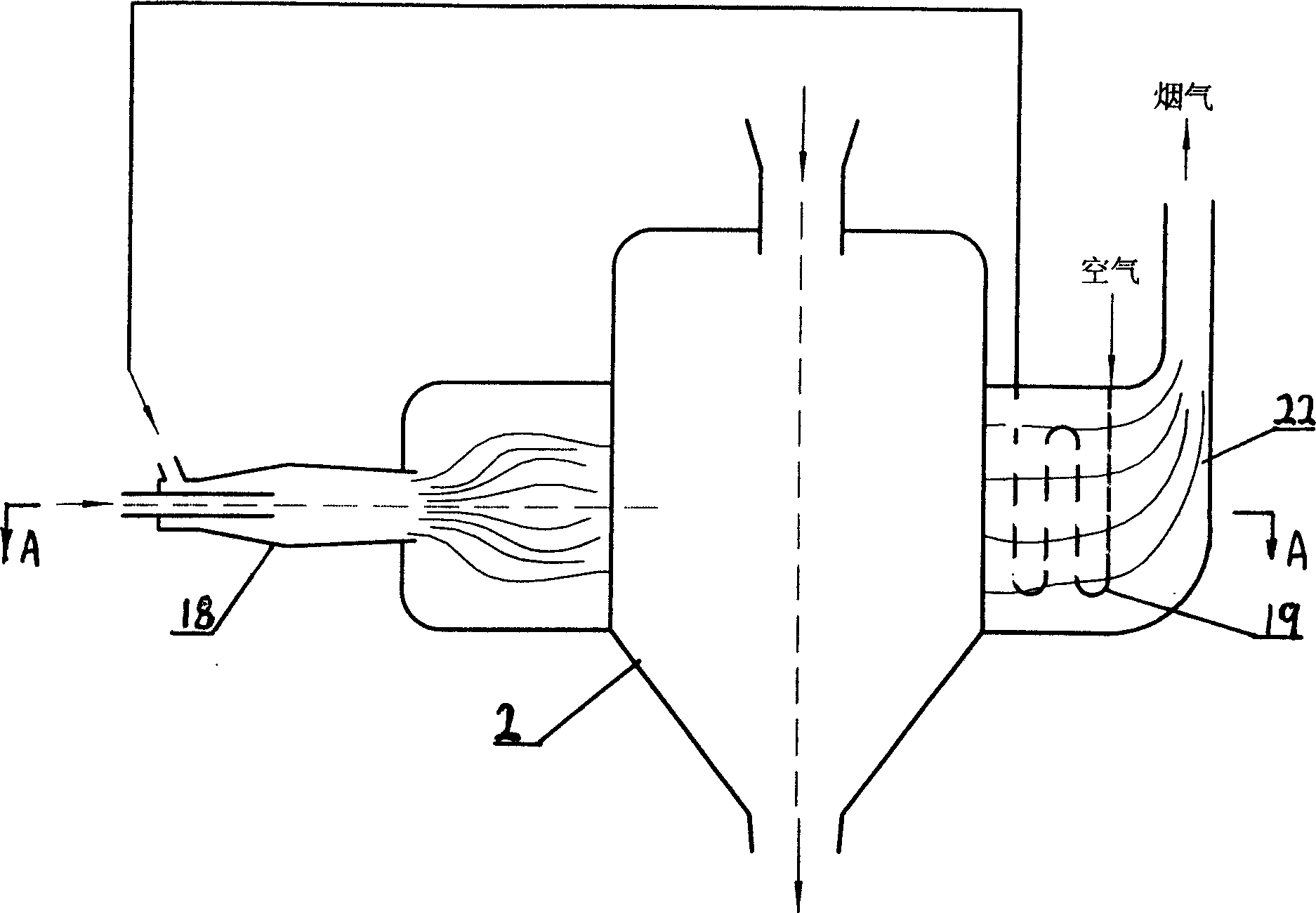

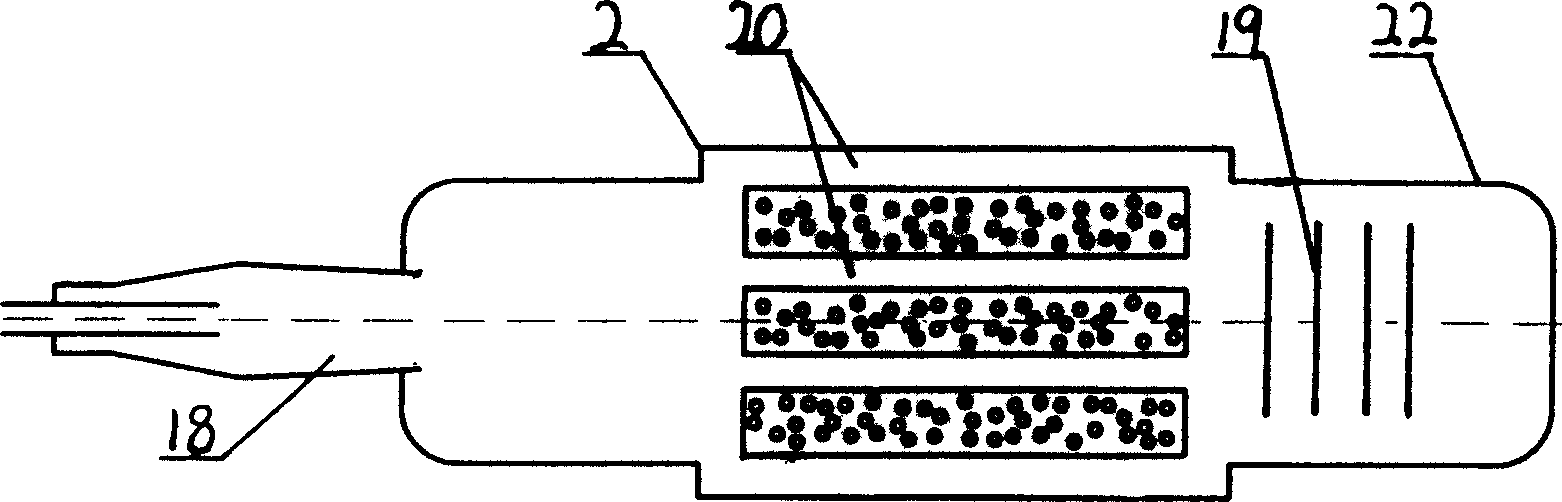

Pre-evaporation type integrated afterburner

InactiveCN105674332AIncrease the degree of mixingReduce the temperatureContinuous combustion chamberCombustion chamberEvaporation

The invention provides a pre-evaporation type integrated afterburner. An oil cavity is formed inside an afterburning inner cone, and is connected with a fuel oil channel inside a rectification support plate flame stabilizer. Fuel oil is heated in the oil cavity to become gas or a supercritical body, and then the gas or the supercritical body enters the fuel oil channel inside the rectification support plate flame stabilizer and is sprayed out from direct-injection type spraying nozzle small holes in the two sides. The spraying nozzle small holes are reasonably formed so that the mixing effect of the fuel oil and the gas can be effectively improved, and the burning efficiency is improved. In addition, a large amount of heat is transmitted to the fuel oil through the afterburning inner cone, so that the self temperature is decreased, and the infrared stealth performance is effectively improved. The pre-evaporation type integrated afterburner has the beneficial effects that on the basis of an integrated afterburner structure, by reasonably leading in the structure of the oil cavity inside the afterburning inner cone and the structure of the fuel oil channel inside the rectification support plate flame stabilizer and reasonably forming the direct-injection type spraying nozzle small holes, the burning efficiency is effectively improved, and the infrared stealth performance is effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Production method of biodiesel

ActiveCN103468413AReduce moistureReduce impuritiesFatty acid esterificationFatty acids production/refiningWater bathsDistillation

The invention provides a production method of biodiesel. The production method comprises the steps of preprocessing of raw oil, esterification reaction, transesterification, dealcoholization, washing, distillation and deodorization, methanol distillation and recycling, glycerin purification and recycling and other steps. The production method has the advantages that the utilization rate of raw oil is high; few esterifying catalysts are needed; the catalytic activity is high; the esterification reaction is performed within a short time; a water-bath heating system is adopted, so that the temperature of heating a medium can be controlled effectively, and the generated unsaponifiable matters can be effectively decreased; in addition, the heat produced in reaction can be recycled, thus the energy consumption is reduced; the unreacted methanol can be recycled that the production cost is reduced. The biodiesel has acid value up to 0.5mgKOH / g and yield up to more than 92%, has the quality meeting BD100, and is suitable for industrial production.

Owner:四川惠盛新能源有限公司

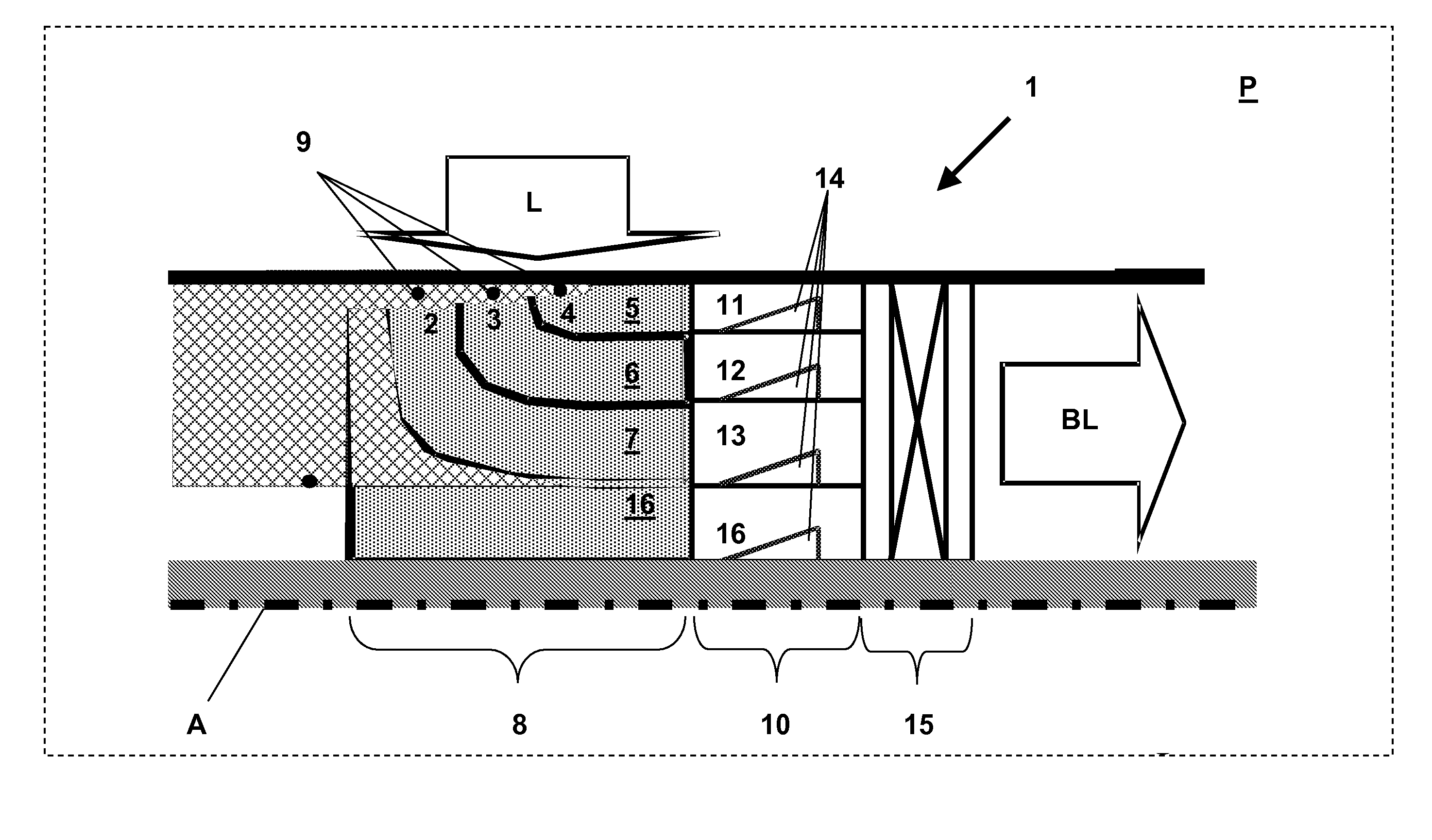

Mixer Assembly

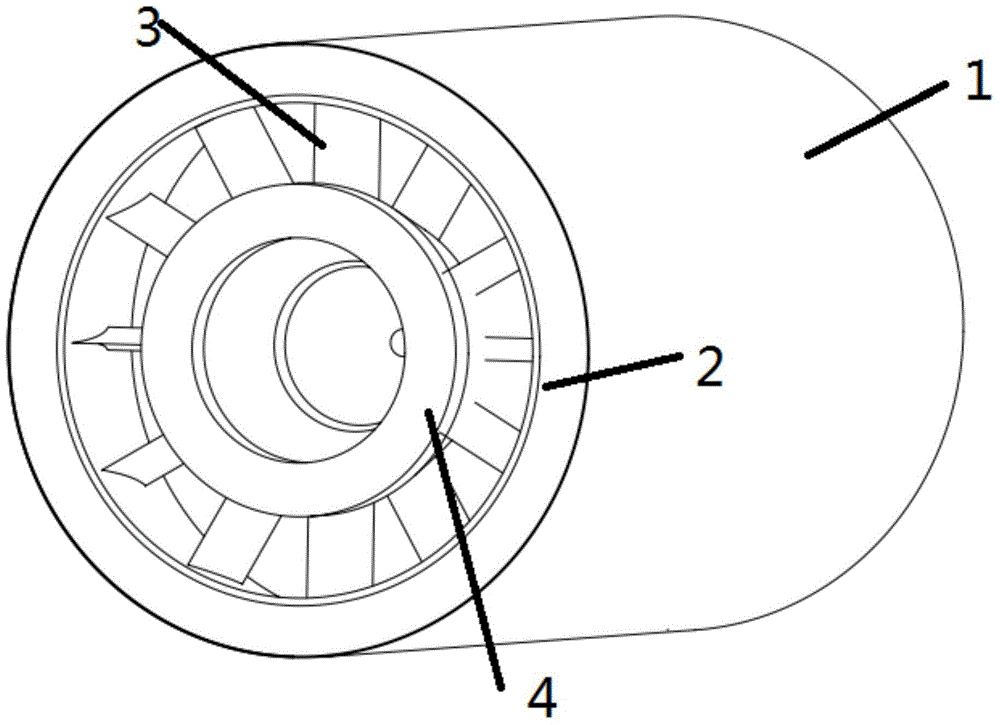

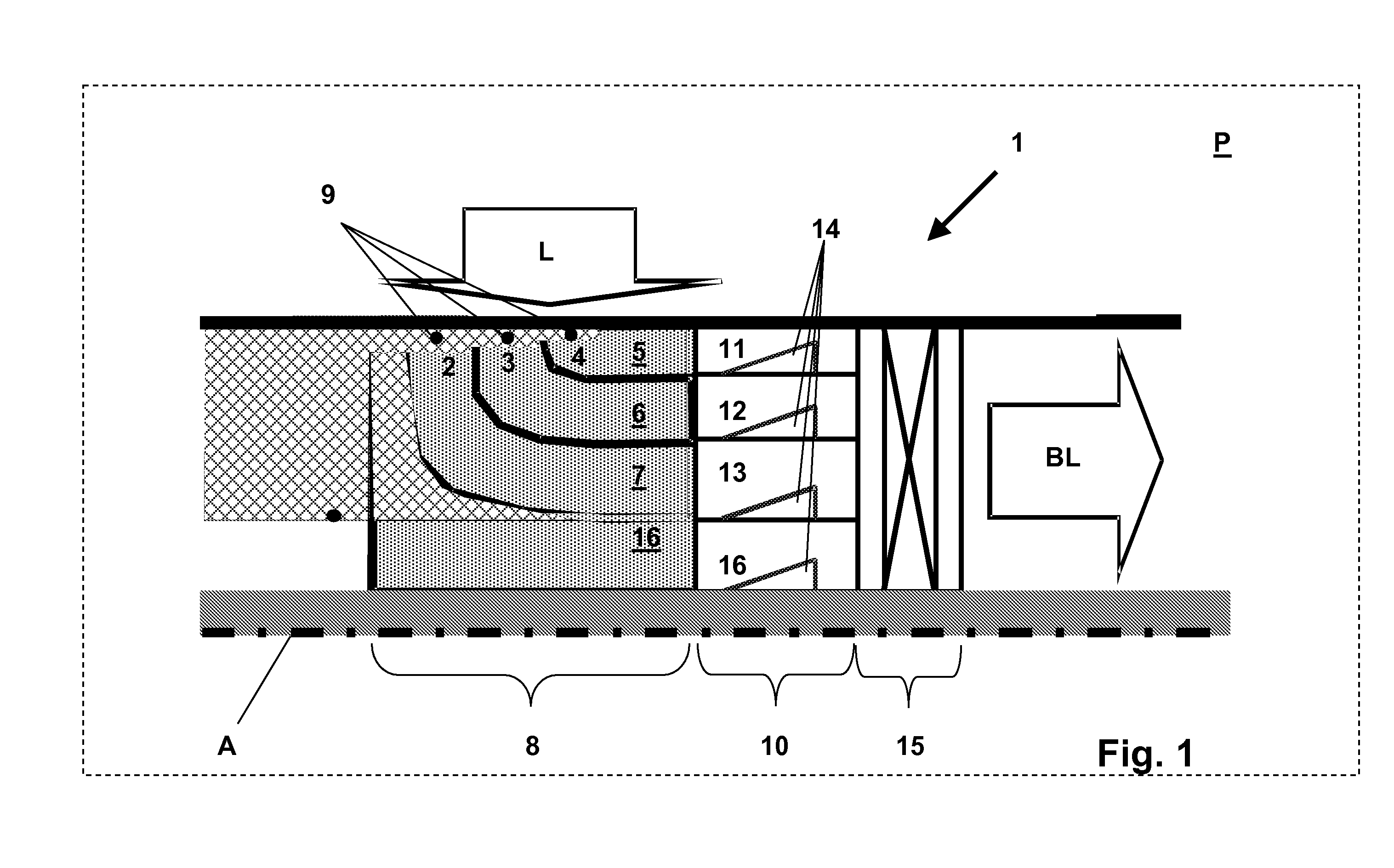

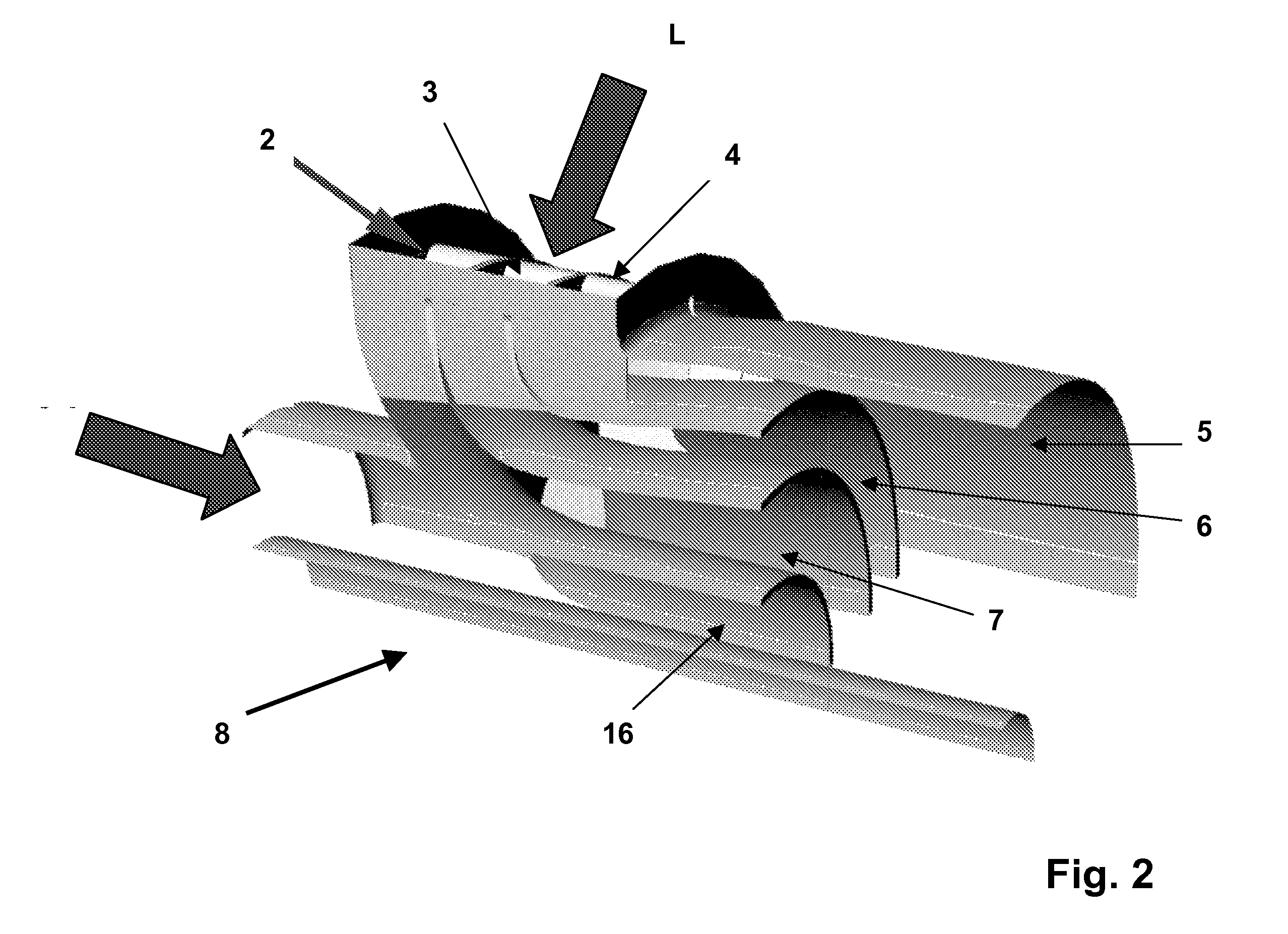

InactiveUS20070113555A1Uniform velocity profileIncreased riskContinuous combustion chamberUsing liquid separation agentEngineeringGas turbines

A mixer assembly and a method for forming a fuel-air mixture is combinable with a burner system of a heat engine, especially a gas turbine plant. A flow-through component (1) provides a flow deflecting region (8) which provides at least two air inlet openings (2, 3, 4) to which is each connected a flow passage section (5, 6, 7), which flow deflecting region deflects the airflow which enters the respective flow passage section (5, 6, 7) by a deflection angle β≠0O, and each has an outlet opening, and that a mixing passage section (11, 12, 13) is connected to each of the outlet openings of the flow passage sections (5, 6, 7), in each of which mixing passage section is provided at least one flow vortex generating structure (14), and which each provides an outlet opening; or that a fine mixing region (15) is connected to the outlet openings of the flow passage sections (5, 6, 7), which fine mixing region has a multiplicity of individual flow passages (23) which, in each case, have a passage cross section which is dimensioned smaller than the passage cross section of the flow passage sections (5, 6, 7) in the region of their outlet openings; or that a mixing passage section (11, 12, 13) is connected to the outlet openings of the each of flow passage sections (5, 6, 7), in each of which mixing passage section at least one flow vortex generating structure (14) is provided, and each of which provides an outlet opening, to which is connected the fine mixing region (15) which has a multiplicity of individual flow passages (23) which have a passage cross section which is dimensioned smaller than the passage cross section of the mixing passage sections (11, 12, 13) in the region of their outlet openings.

Owner:ANSALDO ENERGIA SWITZERLAND AG

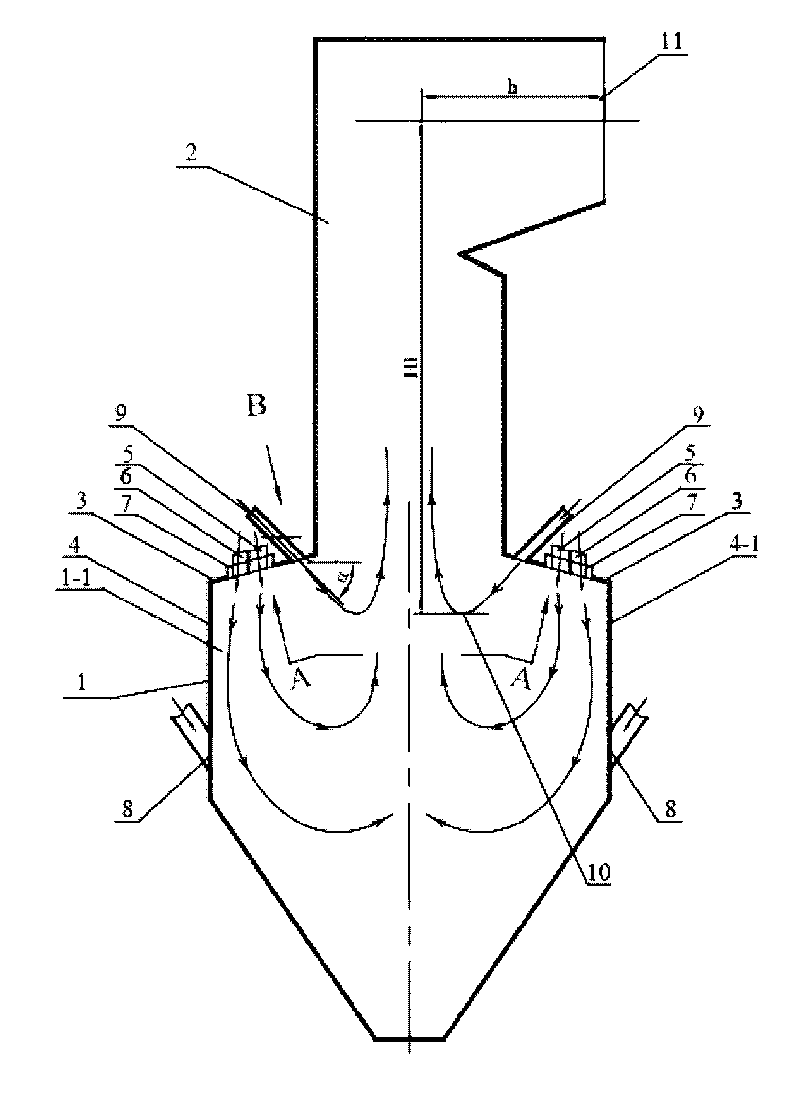

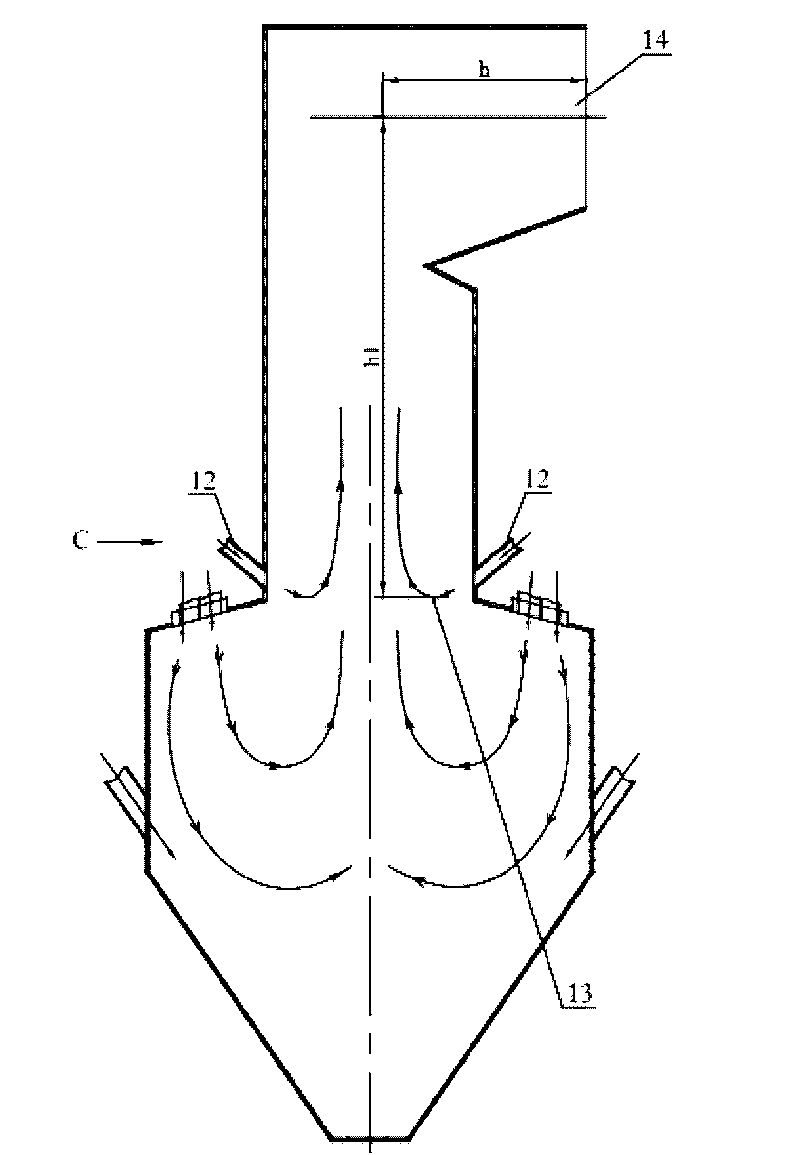

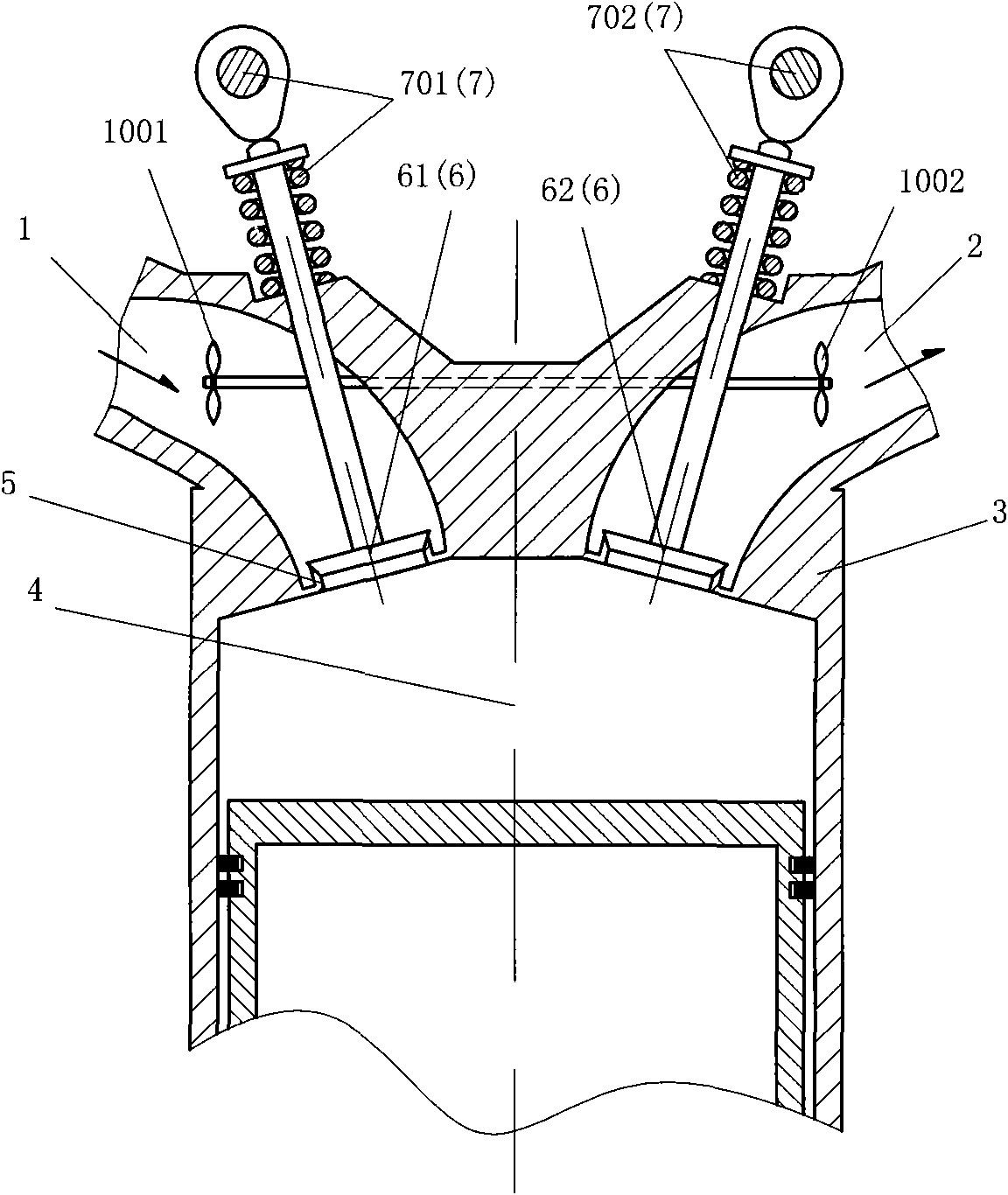

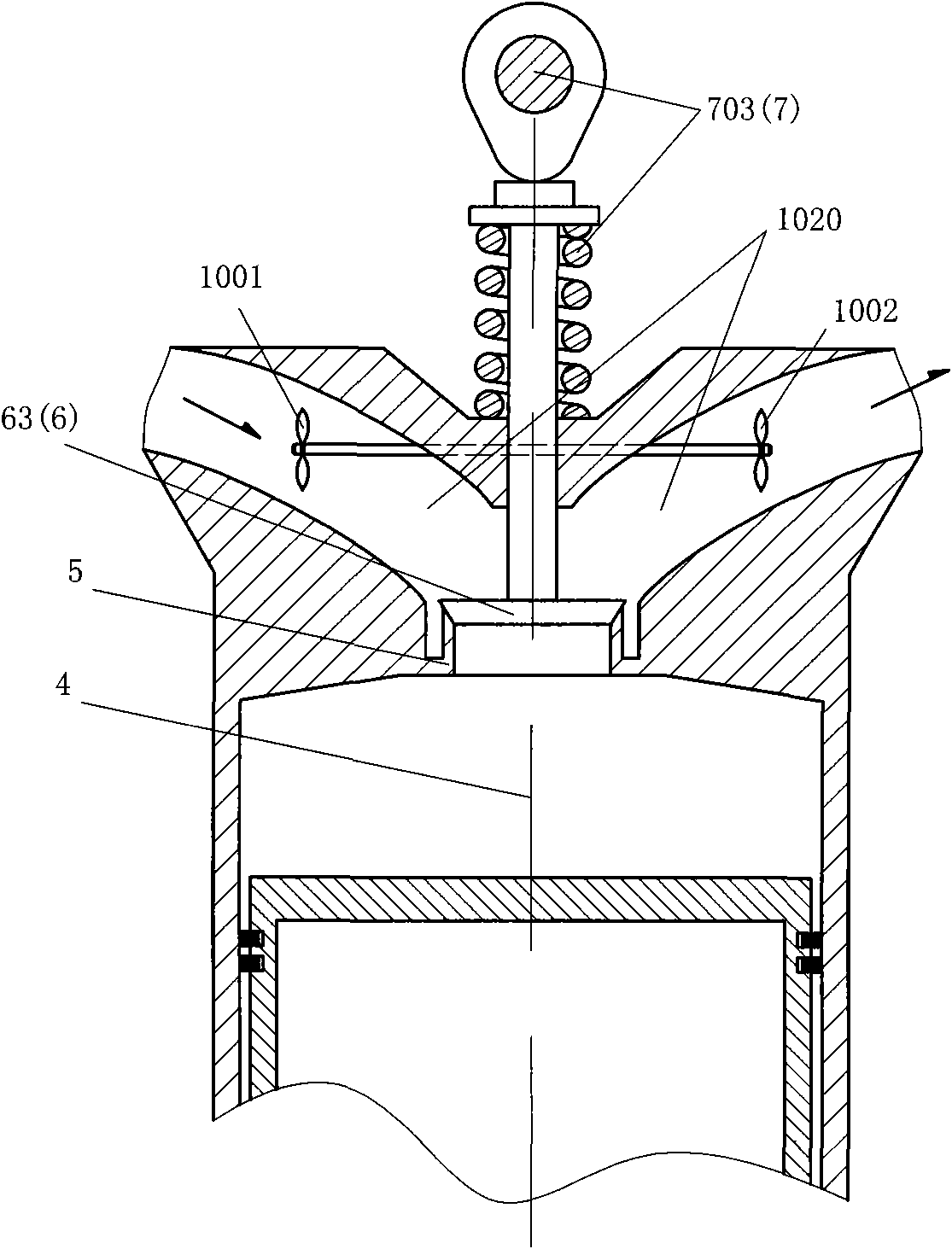

W-shaped flame boiler disposing aperture type over-fire air spouts on stove arch

ActiveCN101694295AExtended reaction timeImprove combustion efficiencyAir/fuel supply for combustionNon-combustible gases/liquids supplyHearthControl theory

A W-shaped flame boiler disposing aperture type over-fire air spouts on a stove arch relates to a W-shaped flame boiler. The invention aims at solving the problems of existing W-shaped flame boilers that the burnout degree of coal powder is low, and the efficiency of the boiler is reduced when simultaneously increasing over-fire air and reducing the discharge of NOx. A plurality of the aperture type over-fire air spouts are divided into two groups, the two groups of the aperture type over-fire air spouts are symmetrically arranged along the central line of a boiler body, a group of aperture type over-fire air spouts are correspondingly arranged on each stove arch near the neck aperture of a hearth, one group of the aperture type over-fire air spouts are arranged in parallel along the length direction and are all communicated with a lower hearth of the lower boiler body, the sections of the aperture type over-fire air spouts are rectangles with the ratio of length to width is (5-7):1, and the central line of each aperture type over-fire air spout and the horizontal line form an included angle of 20-35 degrees. The distance between adjacent aperture type over-fire air spouts is 100 mm. The setting of the aperture type over-fire air spouts prolongs the reacting time between uncombusted coal powder granules and the over-fire air, and enables the combustion to be more compete.

Owner:HARBIN INST OF TECH

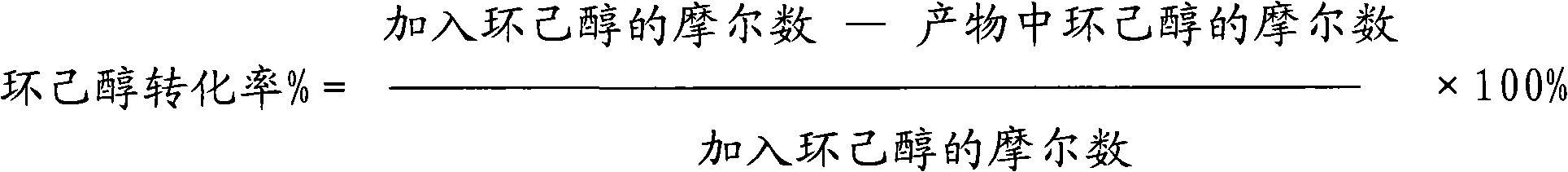

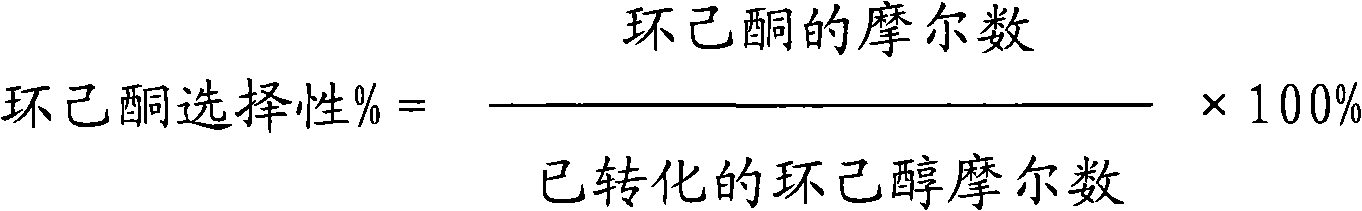

Method for catalytically oxidizing cyclohexane

ActiveCN102079695AIncrease the degree of mixingExtend your lifePreparation by oxidation reactionsMolecular sieve catalystsHysteresisDesorption

The invention discloses a method for catalytically oxidizing cyclohexane, which is characterized in that cyclohexane, hydrogen peroxide and a catalyst are in contact for reacting, the mol ratio of the cyclohexane to the hydrogen peroxide is 0.5-8, the concentration of the catalyst in a reaction system is 0.005-0.1g / min, the reaction temperature is 40-150 DEG C, the catalyst is a titanium-silicon molecular sieve with an MFI structure, a hysteresis loop exits between an adsorption isotherm and a desorption isotherm of low-temperature nitrogen absorption of the molecular sieve, a crystalline grain is a single hollow crystalline grain or an aggregated crystalline grain formed by the aggregation of a plurality of hollow crystalline grains, the radial length of the cavity part of the hollow crystalline grains is 5-300nm, and the benzene adsorption capacity of the sample of the molecular sieve, measured under the conditions that the absorption time is 1h, the temperature is 25 DEG C and P / P0 is equal to 0.10, is at least 70mg / g. The method has the advantages of high selectivity of a target product and environment protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

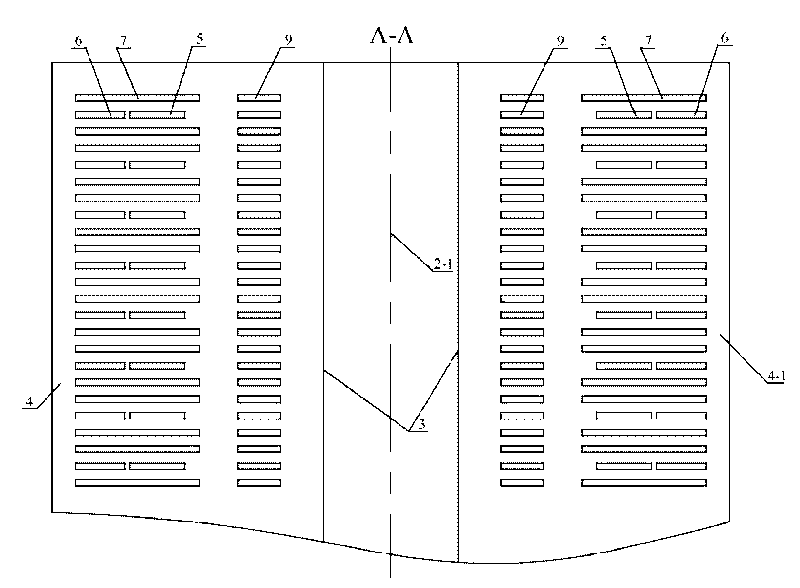

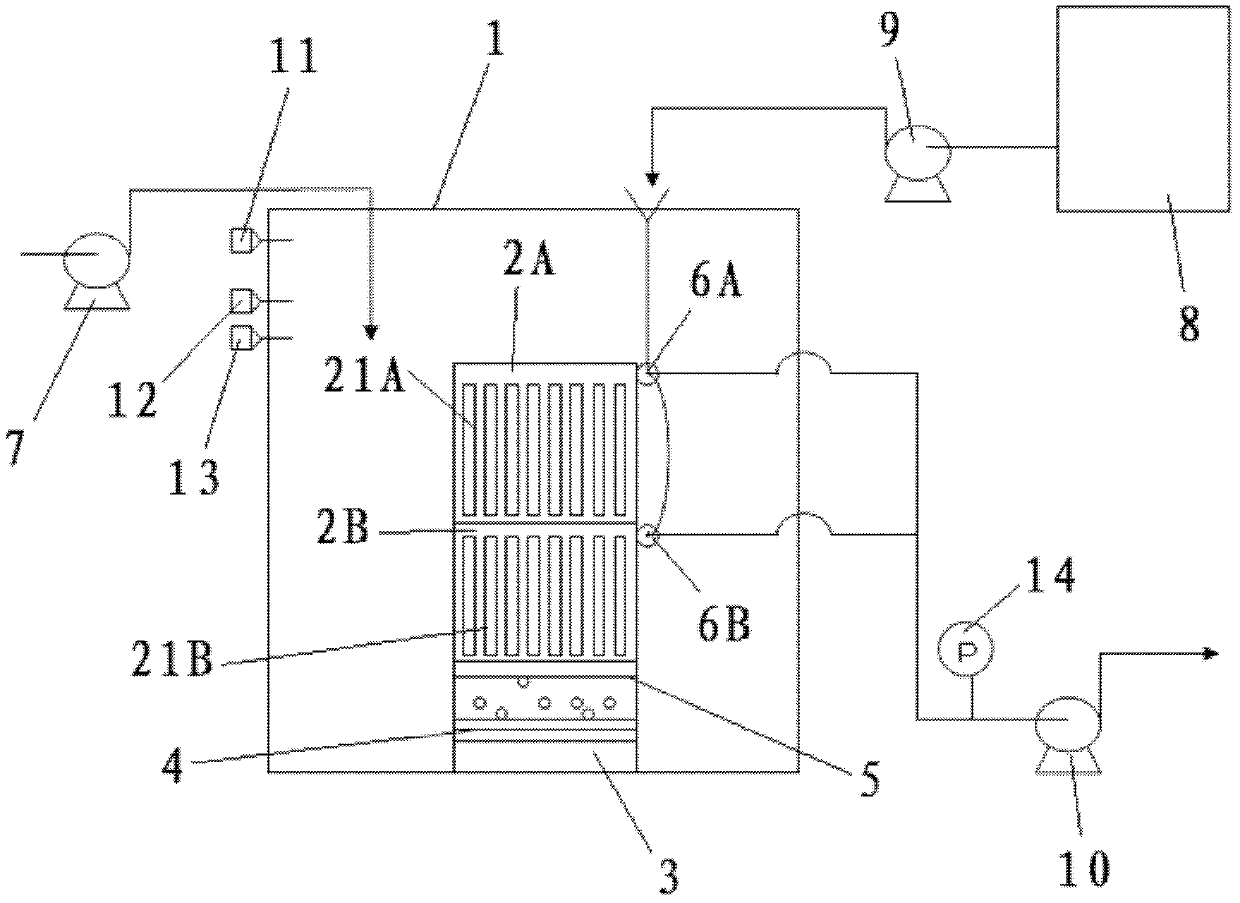

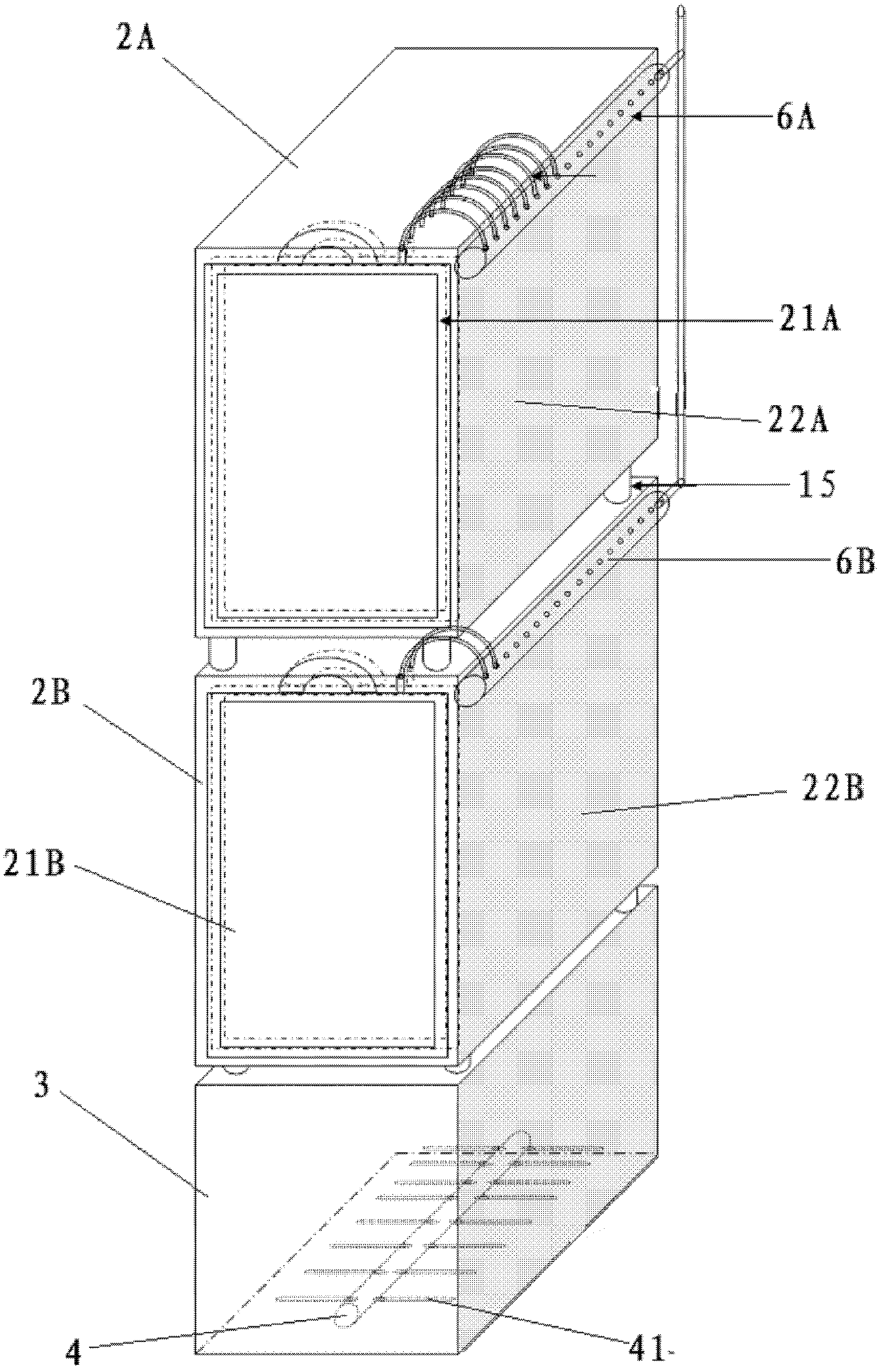

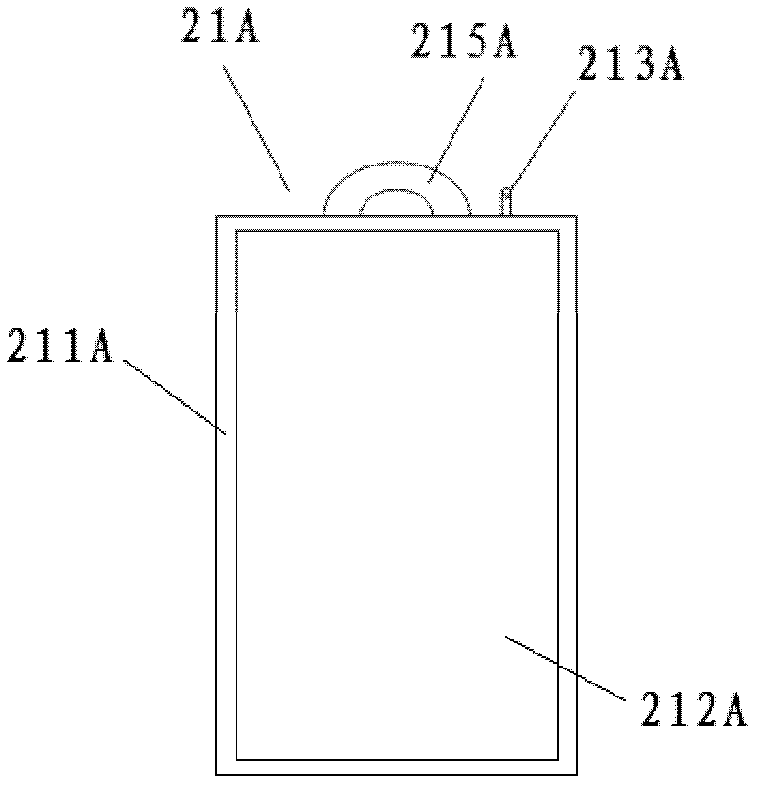

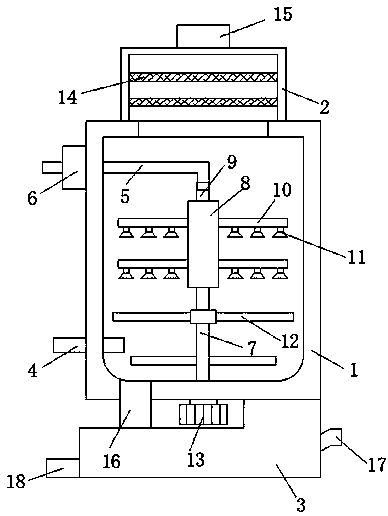

High-flux contamination-resisting type flat membrane bioreactor and flat MBR (Membrane Bioreactor) device

ActiveCN102580544AReduce areaIncrease the number ofSemi-permeable membranesSustainable biological treatmentHigh fluxMembrane bioreactor

The invention discloses a high-flux contamination-resisting type flat membrane bioreactor and a flat MBR (Membrane Bioreactor) device. The flat membrane bioreactor comprises an aerating box, at least two membrane boxes and at least two water collecting tubes, wherein the aerating box is provided with an aerating tube for supplying gas to the aerating box; one end of the aerating tube extends into the aerating box; the at least two membrane boxes are overlapped on the aerating box along the vertical direction; two adjacent membrane boxes are connected with each other; the aerating box is connected with the downmost membrane box; each of the membrane boxes comprises a frame and multiple flat membrane elements arranged in the frame at intervals; a water purifying space is defined in each flat membrane element; each flat membrane element is provided with a water-generating tube communicated with the corresponding water purifying space; the at least two water collecting tubes respectively correspond to the at least two membrane boxes one by one; each water collecting tube is connected with the water-generating tubes of the multiple flat membrane elements in the corresponding membrane box. According to the high-flux contamination-resisting type flat membrane bioreactor disclosed by the invention, the high-flux contamination-resisting type flat membrane bioreactor has the characteristics of high flux, excellent contamination-resisting performance, long service life and low cost.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Environment-friendly sewage treatment device and sewage treatment method

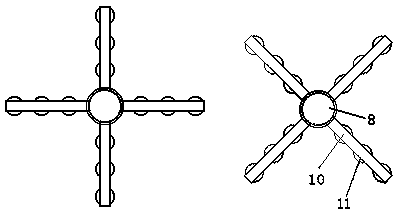

InactiveCN111620471AIncrease the degree of mixingOpposite direction of rotationRotary stirring mixersTransportation and packagingSludgeElectric machine

The invention relates to an environment-friendly sewage treatment device and a sewage treatment method in the technical field of sewage treatment. The environment-friendly sewage treatment device comprises a box body, the box body is provided with a cover plate, the cover plate is provided with a mounting frame and a square water inlet cylinder, the water inlet cylinder is provided with a supporting plate, the supporting plate is provided with a filter plate, the mounting frame is provided with a rotating motor, the rotating motor is provided with an upper rotating shaft, the upper rotating shaft is provided with a second bevel gear, and the second bevel gear is provided with a cleaning structure; the cleaning structure is provided with a flocculant uniform spraying structure; the upper rotating shaft is provided with a third bevel gear, the third bevel gear is provided with a fourth bevel gear, the fourth bevel gear is provided with a cross rod, the cross rod is connected with the boxbody, the fourth bevel gear is provided with a fifth bevel gear, the fifth bevel gear is provided with a lower rotating shaft, the lower rotating shaft and the upper rotating shaft are provided withstirring frames, each stirring frame is provided with a straight scraper blade, the straight scraper blade at the lowest end is provided with a transverse scraper blade, the box body is provided witha water outlet pipe with a control valve, and the box body is provided with a sludge pipe, so that the sewage stirring directions in the box body are opposite, the sewage stirring mixing degree is improved, and rapid flocculation treatment is realized.

Owner:CRYSTAL WATER & BLUE SKY ENVIRONMENTAL ENG

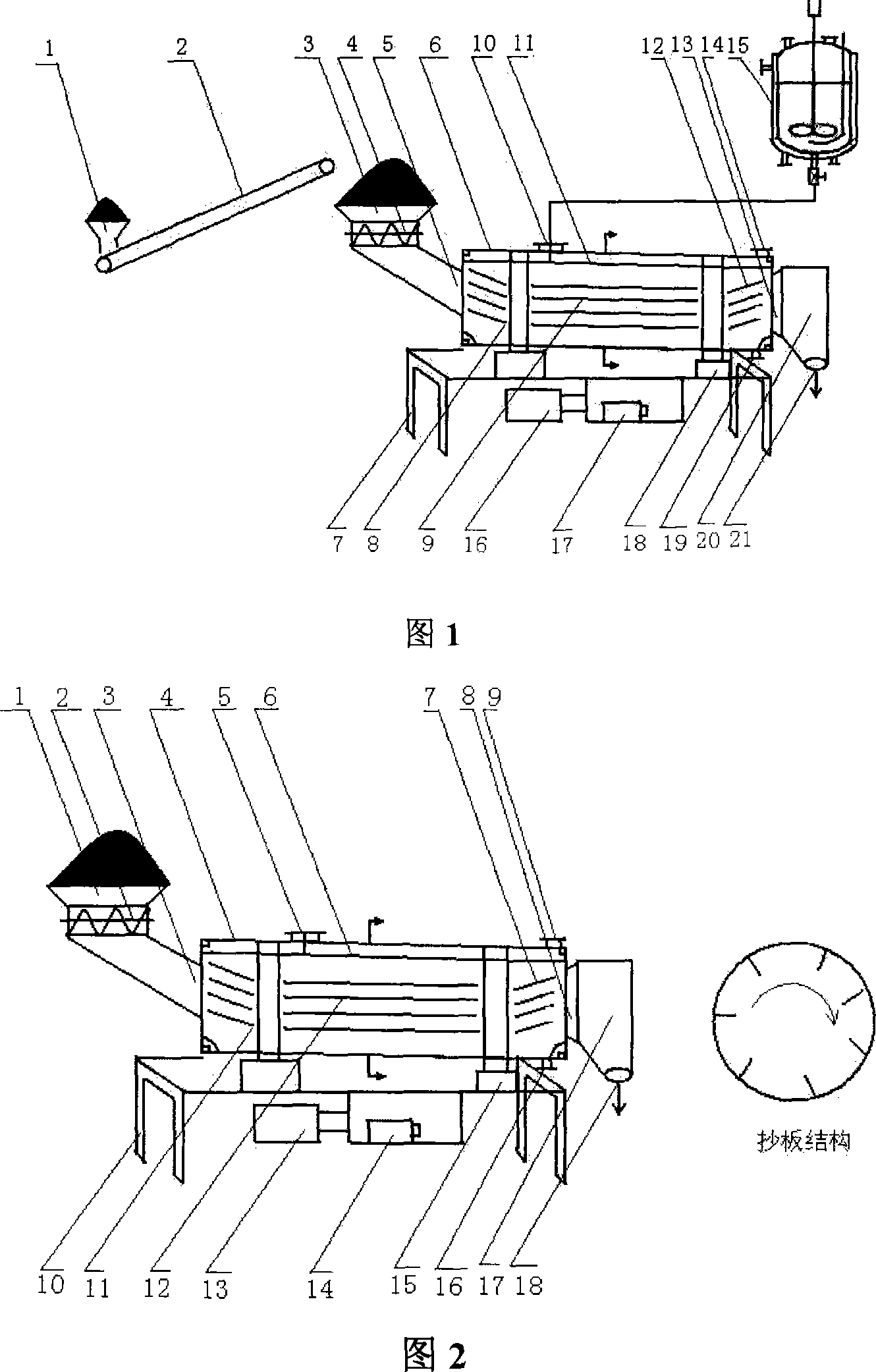

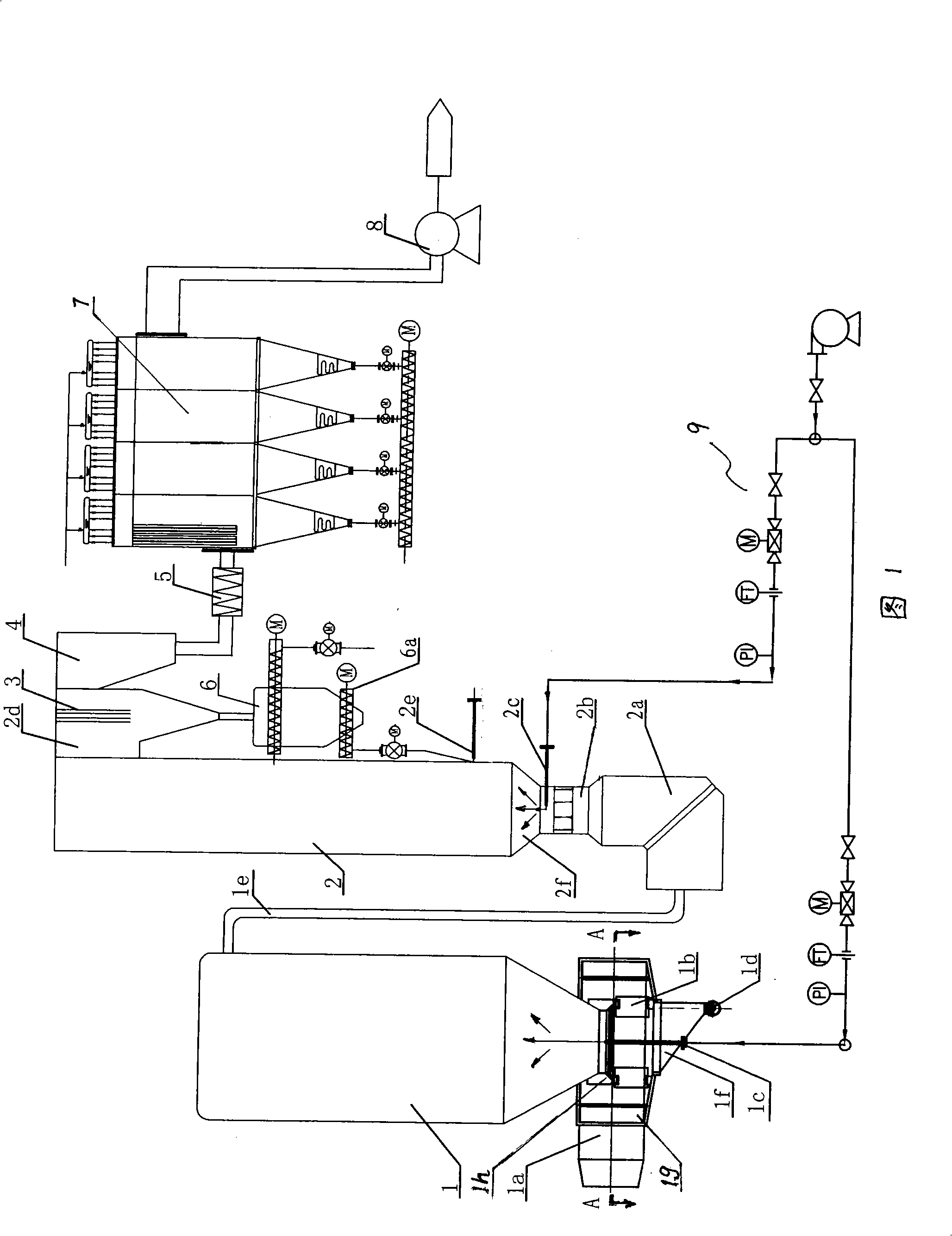

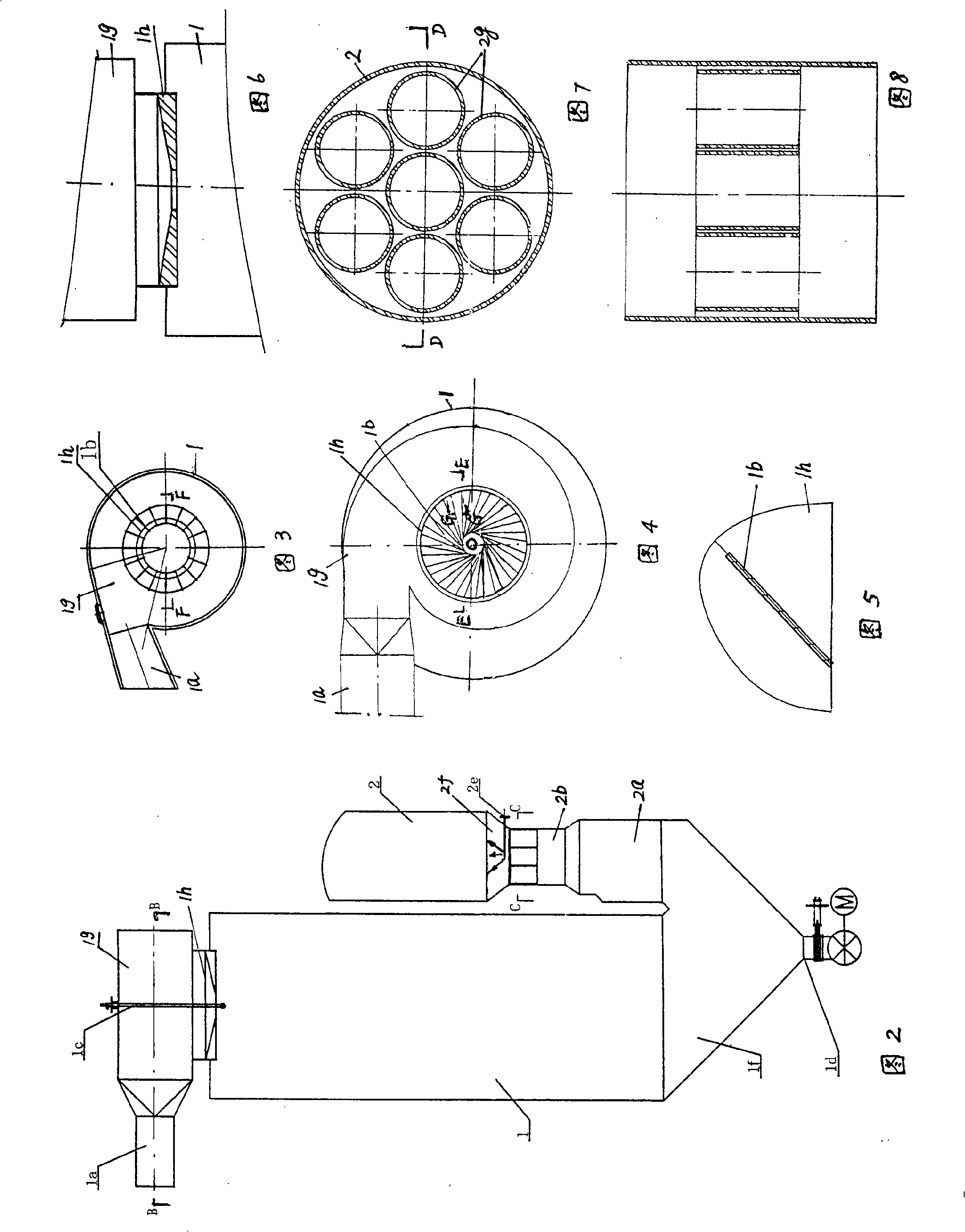

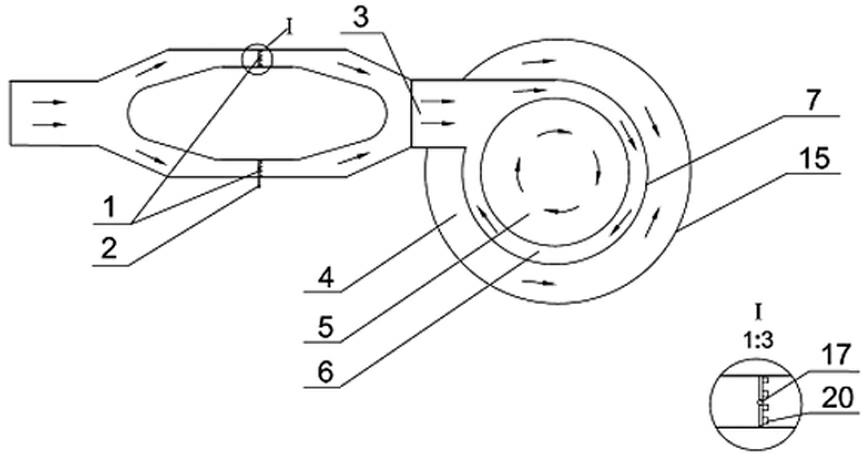

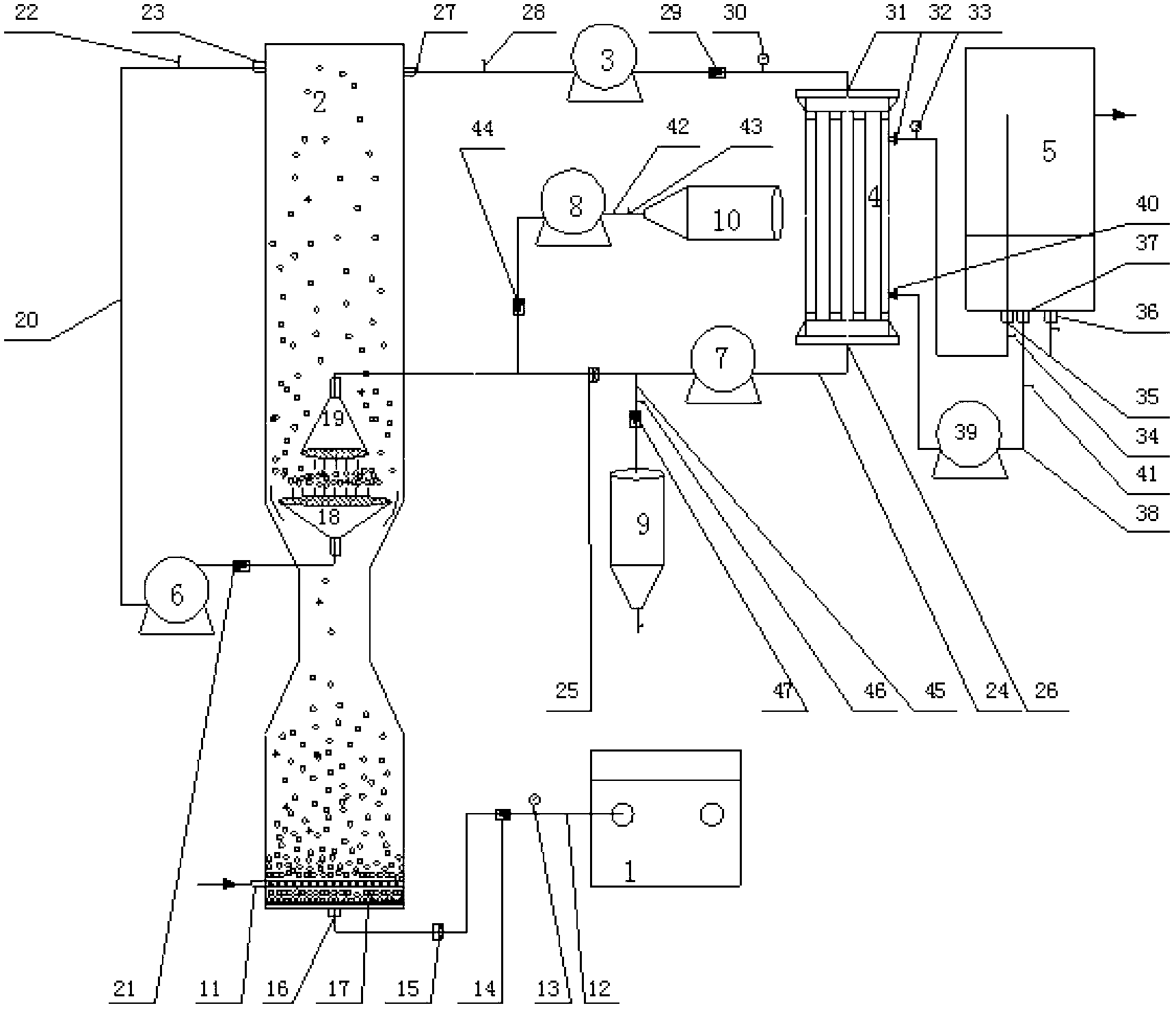

Solid-state fermentation method and system for producing ethyl alcohol based on sugariness raw material

InactiveCN101220378AEfficient conversionHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsSprayerLiquid fuel

The invention relates to a solid-state fermentation method for ethanol production based on sweet sorghum stalks (including other sugar raw materials, such as, sugar beet, sugar cane, Jerusalem artichoke, etc) and a system, which pertains to the technical field of the processing of biomass liquid fuel. The method mainly includes the following key processes and core equipments: (1) smashed materials are fed into a tank with the help of the rotary motion of a cylinder body of a rotating drum type solid-state fermentation tank and the dual-function of the inclined angle of the tank body (1 to 15 degrees) and a feeding stirring board so as to be evenly mixed with the high-yield ethanol TSH-Sc-1 yeast liquid which is prayed from a sprayer; (2) the solid-state fermentation is carried out in the facultative oxygen environment, the fermentation tank is rotated at an even speed to promote the mixing of materials and the strengthening of heat transfer, thus the fermentation is always in a best condition and the fermentation time is shortened; (3) on-line monitoring is carried out: the solid-state fermentation is affected by a plurality of factors, such as, the distribution of the on-line regulation temperature of a computer, spray amount, the concentration of dissolved O2, filling factors, the mixing degree of the smashed materials and the yeast liquid, the pH value of yellow slurry, CO2 concentration, ethanol concentration, the migration of bacteria species and other parameters so as to ensure that the solid-state fermentation is carried out under a best working condition; (4) the automatic discharge of the fermentation material from the tank is realized with the help of the rotation of the tank body and the push of a discharging stirring board, and a closed tunnel belt is adopted for conveying the fermentation material to an ethanol-dreg separation unit.

Owner:TSINGHUA UNIV

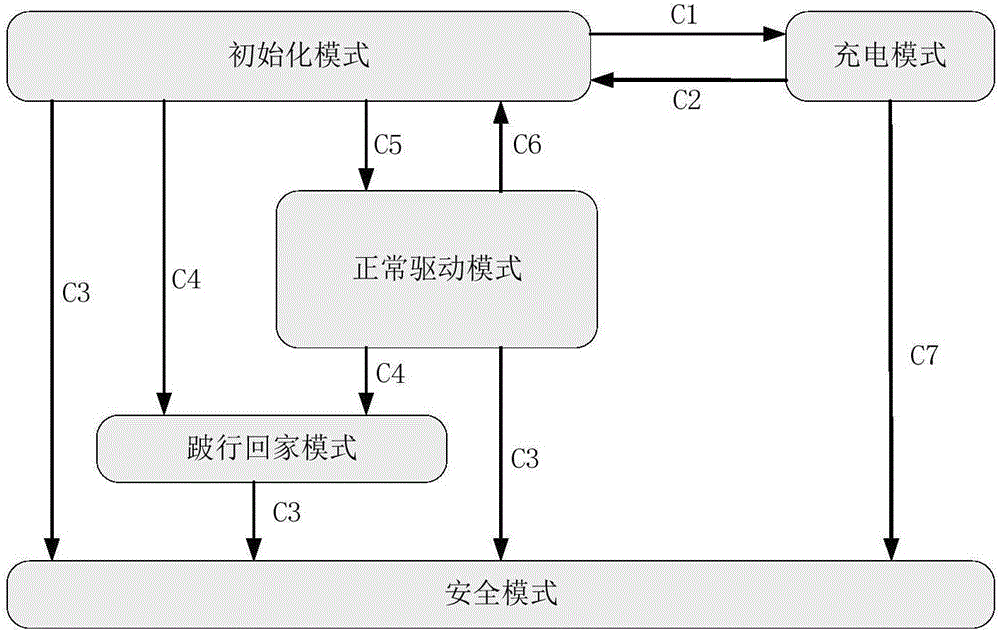

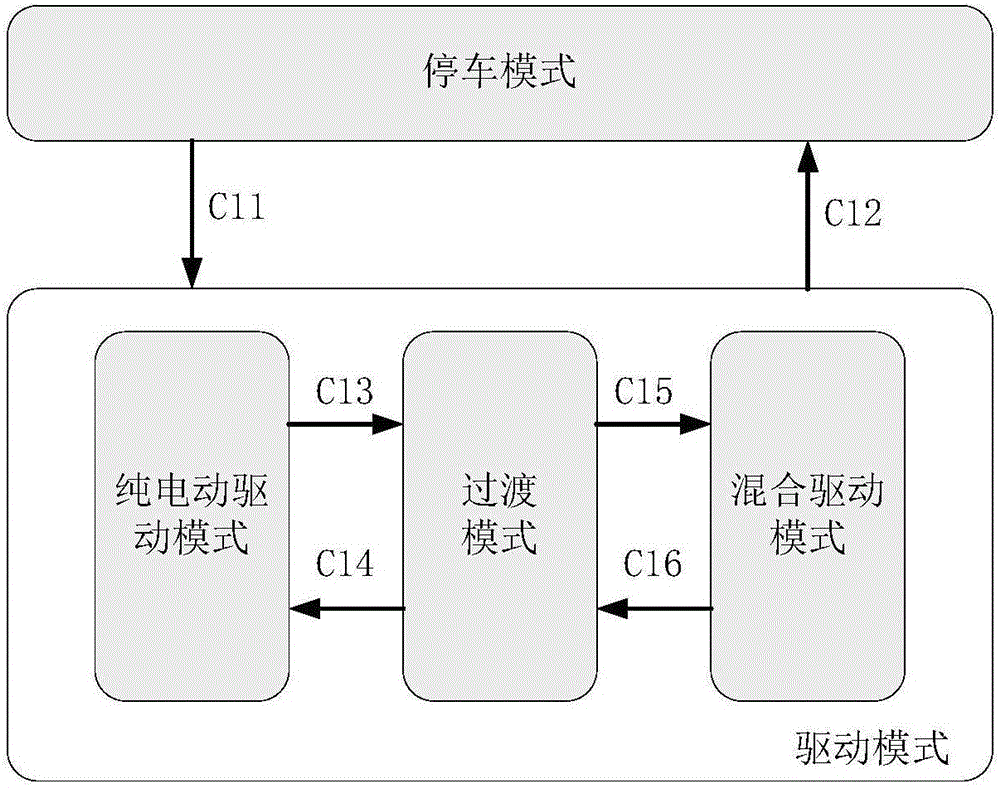

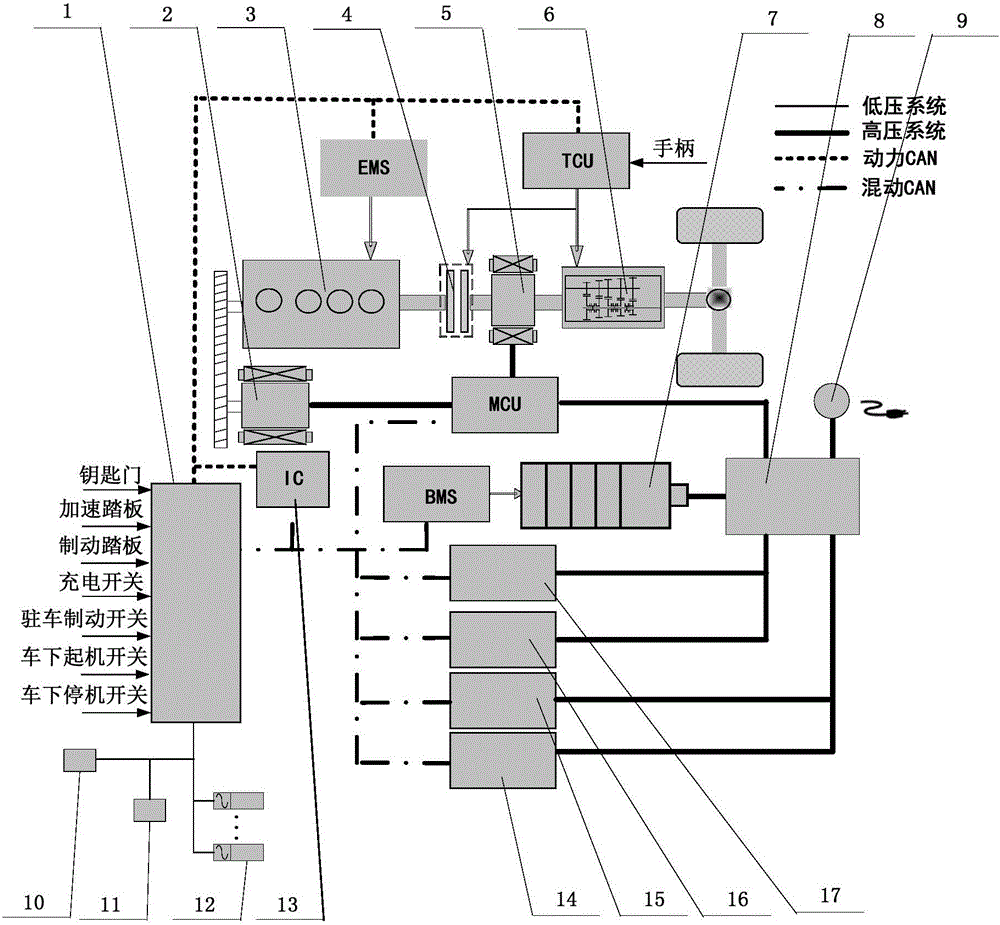

Vehicle control system of plug-in gas-electric hybrid power bus and control method of vehicle control system

ActiveCN105966226AIncrease the degree of mixingVersatileHybrid vehiclesCharging stationsReduction driveElectrical battery

The invention provides a vehicle control system of a plug-in gas-electric hybrid power bus and a control method of the vehicle control system. The vehicle control system comprises a vehicle controller, an engine, a controller of the engine, a clutch, a driving motor, a controller of the driving motor, an auxiliary motor, a controller of the auxiliary motor, a gearbox, a controller of the gearbox, a high-voltage battery, a management system of the high-voltage battery, a high-voltage block terminal, a high-pressure steering system, a high-pressure gas pump system, a high-pressure air conditioner, a direct current / direct current converter, an instrument controller, a starter, a motor water pump, a high voltage control relay and a charging port. The engine is a gas engine. The auxiliary motor is arranged in front of the engine and connected with the engine through a belt. The driving motor is arranged between the engine and the gearbox. A gearbox system is additionally installed behind the driving motor, and a main speed reducer and a vehicle wheel are connected behind the gearbox system. According to the vehicle control system with the vehicle controller as the core, information of a full vehicle and all assemblies is synthesized, on the basis of vehicle and power assembly system modes, the control method is switched and coordinated, the advantages of all subsystems of the plug-in gas-electric hybrid power bus can be fully achieved, and optimal vehicle performance is achieved.

Owner:CHINA FIRST AUTOMOBILE

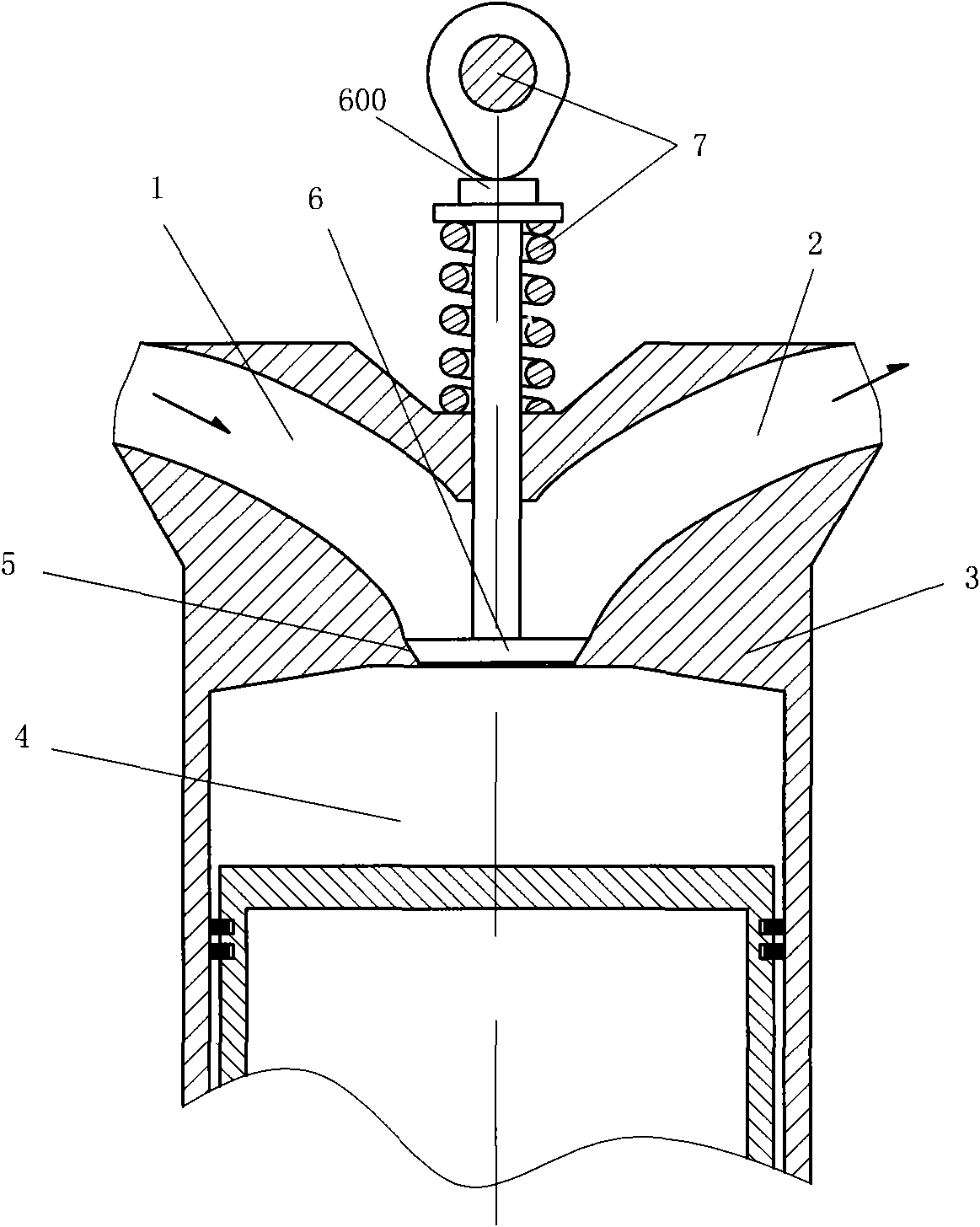

Valve body external-open air distribution engine

InactiveCN101571068ASimple structureReduce volumeInternal combustion piston enginesLift valveInlet channelCombustion chamber

The invention discloses a valve body external-open air distribution engine which comprises an air inlet channel, an exhaust passage, a combustion chamber outer wall and a combustion chamber; the combustion chamber outer wall is provided with one or a plurality of external-open air distribution seat openings which cause the air inlet channel and the exhaust passage to be respectively or simultaneously communicated with the combustion chamber; each external-open air distribution seat opening is correspondingly provided with an external-open air distribution valve body; the external-open air distribution valve body is directly controlled or through a connecting piece by a valve body timing control device. The external-open air distribution seat opening corresponding to the external-open air distribution valve body is opened or closed according to the timing requirement of the engine. The engine can reduce the loss of air distribution and flow restriction and causes the degree of air current flowing and flue gas mixing in an air cylinder to be increased, thus increasing the efficiency of the engine.

Owner:靳宇男

Semi-dry process smoke eliminator with independent temperature-reducing column

ActiveCN101342458AEnhanced rectificationImprove current sharing effectDispersed particle separationEvaporationInlet manifold

The invention relates to a smoke gas purification device by a semidry process, which is provided with an independent desuperheating tower, comprising a reaction tower provided with an smoke inlet box, a smoke gas outlet, a venturi tube type tower wall arranged on a tower bottom, a water injector arranged on the tower wall and a nozzle for lime dry powder and revert dust; and the smoke gas outlet is connected with an inertia separator, an activated carbon mixer, a bag-type dust remover and a draught fan. The invention is characterized in that the invention is also provided with the desuperheating tower which is provided with a boiler smoke gas inlet manifold, a single-stage water injector, an ash bucket with an ash hole and a gas flue; the gas flue of the desuperheating tower is connected with the smoke inlet box into one unit. The boiler smoke gas disperses within the two towers for cooling, thereby improving the adaptability of a system to a load; the boiler smoke gas particularly can be cooled down urgently to a set temperature in the desuperheating tower; and the reaction tower can be humidified only by evaporation with a little water to complete a deacidifying reaction and remove dioxin, thereby avoiding the disadvantages of scale formation on the tower wall of the prior reaction tower and bag burning of the bag-type dust remover, guaranteeing a sustaining and stable smoke purification process and having the advantages of good purification effect and low energy consumption.

Owner:HANGZHOU NEW CENTURY ENERGY ENVIRONMENTAL PROTECTION ENG CO LTD

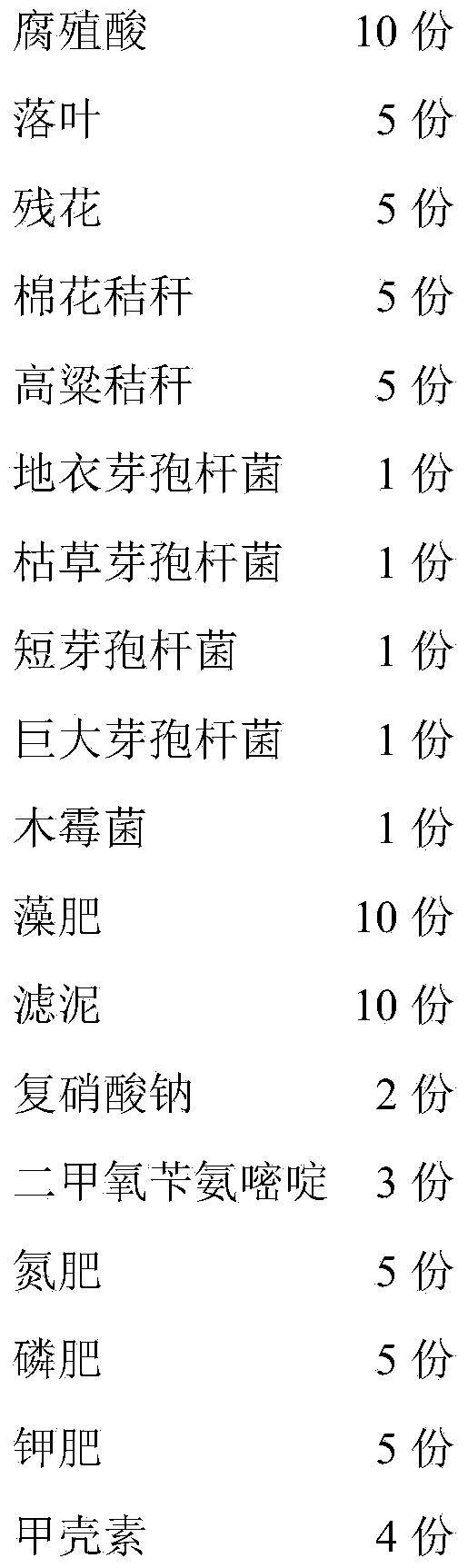

Bioorganic compound fertilizer and preparation method thereof

InactiveCN104030751AReduce manufacturing costAvoid breedingBiocidePlant growth regulatorsMicrobial agentAgricultural pollution

The invention discloses a bioorganic compound fertilizer and a preparation method thereof. The bioorganic compound fertilizer comprises, by weight, 10-15 parts of humic acid, 20-25 parts of crop waste, 5-10 parts of a biological agent, 10-15 parts of algae fat, 10-15 parts of filter mud, 5-15 parts of a synergist, 5-10 parts of a nitrogen fertilizer, 5-10 parts of a potassium fertilizer and 4-10 parts of chitin. The preparation method of the bioorganic compound fertilizer includes the following steps: preparing raw material mixture powder; fermenting to prepare a bioorganic compound fertilizer; and drying, granulating, screening, and carrying out aluminum foil vacuum packaging. Agricultural wastes are fermented by the microbial agent, and the fermented wastes are mixed with nutrients required by plants, so the prepared bioorganic compound fertilizer has the advantages of increase of the fertility of soil, the promotion of planting and the growth of plants on the soil, full recycling of the agricultural waste, reduction of the agricultural pollution, and promotion of the agricultural development.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

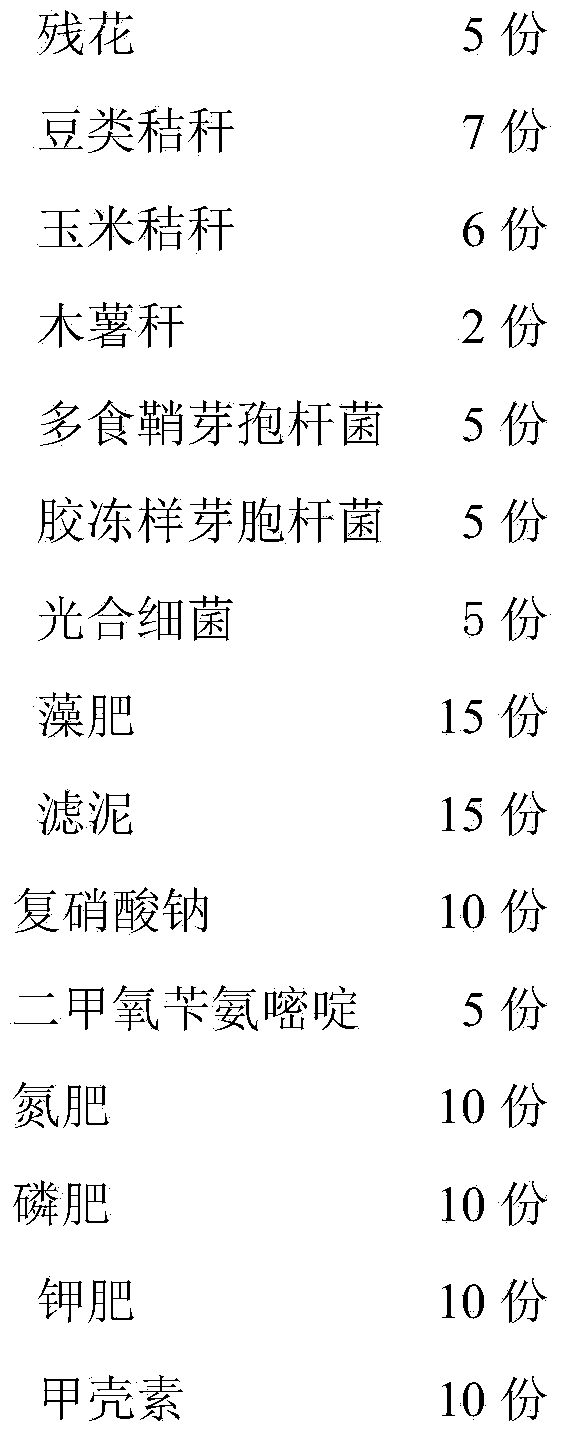

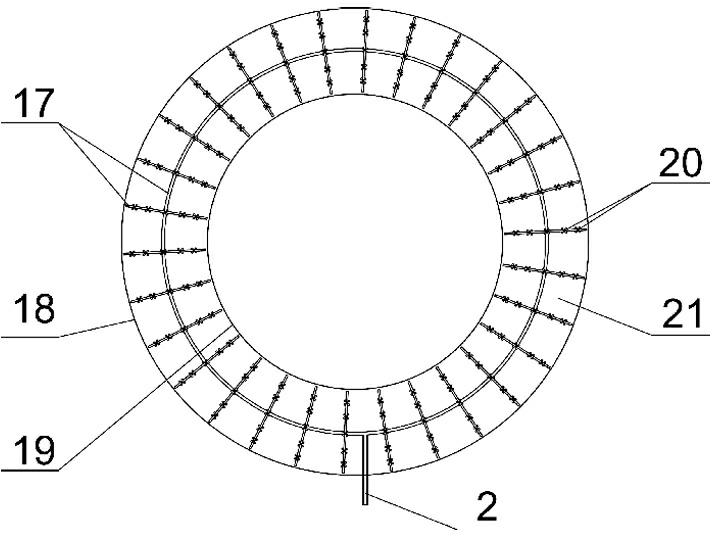

Dedusting-denitrating integrated device

ActiveCN102614779ASimple structureSimple control systemDispersed particle filtrationFlue gasProcess engineering

The invention discloses a dedusting-denitrating integrated device which comprises a flue gas channel, a mixed flue gas inlet and a shell consisting of an outer cylinder and an inner cylinder, and a ash hopper at the bottom of the shell, wherein the inner cylinder is mainly used for dedusting and ammonia mixing, the outer cylinder is mainly used for containing a denitrating catalyst bed, the crosssection of the flue gas channel is ring-shaped, and ammonia spray grilles are distributed in the flue gas channel in a radial manner so that the required NH3-to-NO ratio can be reached more easily. The device provided by the invention can be used for dedusting before carrying out denitrating, a catalyst can be effectively prevented from being worn, poisoned and blocked and the service life of thecatalyst can be prolonged. Under the condition that the length of the device is not increased, the ammonia mixing time is prolonged and ammonia mixing can be performed fully; heat absorbing spiral plates and cooling rectifier plates are arranged in both the inner cylinder and the outer cylinder to share heat of flue gas at the inlet, and therefore the heat loss of flue gas can be reduced, the denitrating efficiency can be improved and the catalyst is prevented from being sintered and inactivated under the action of superheated flue gas.

Owner:HUNAN UNIV

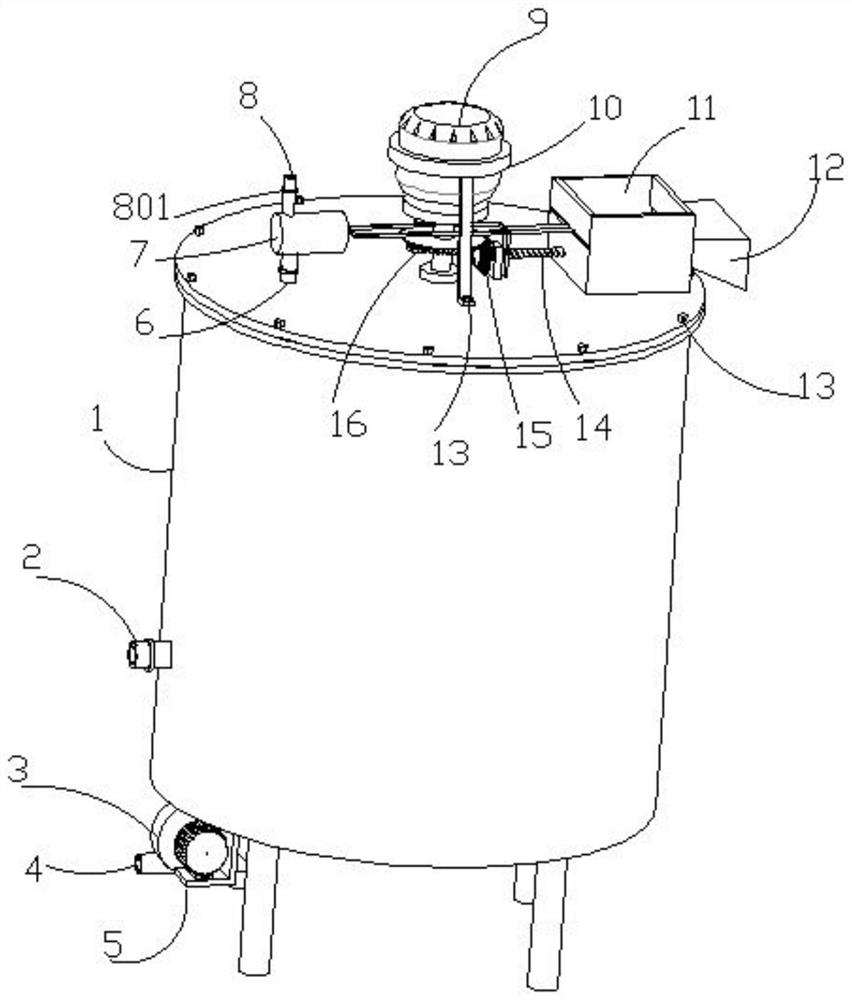

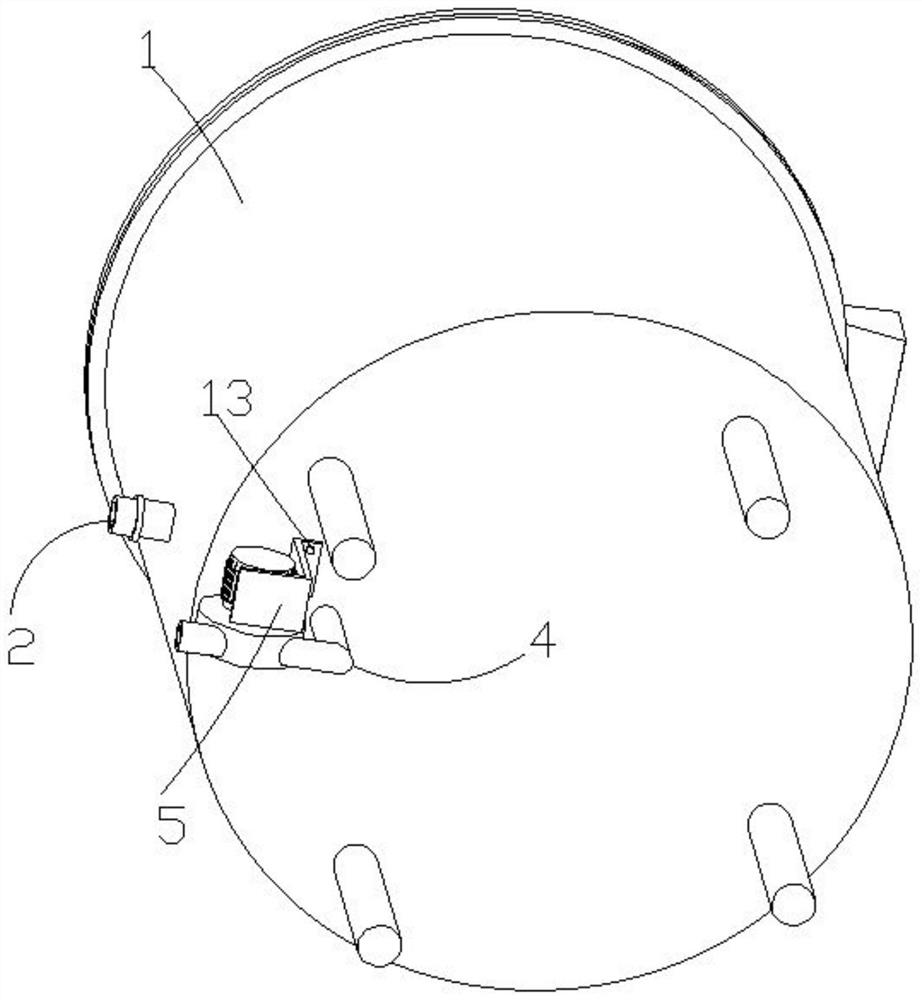

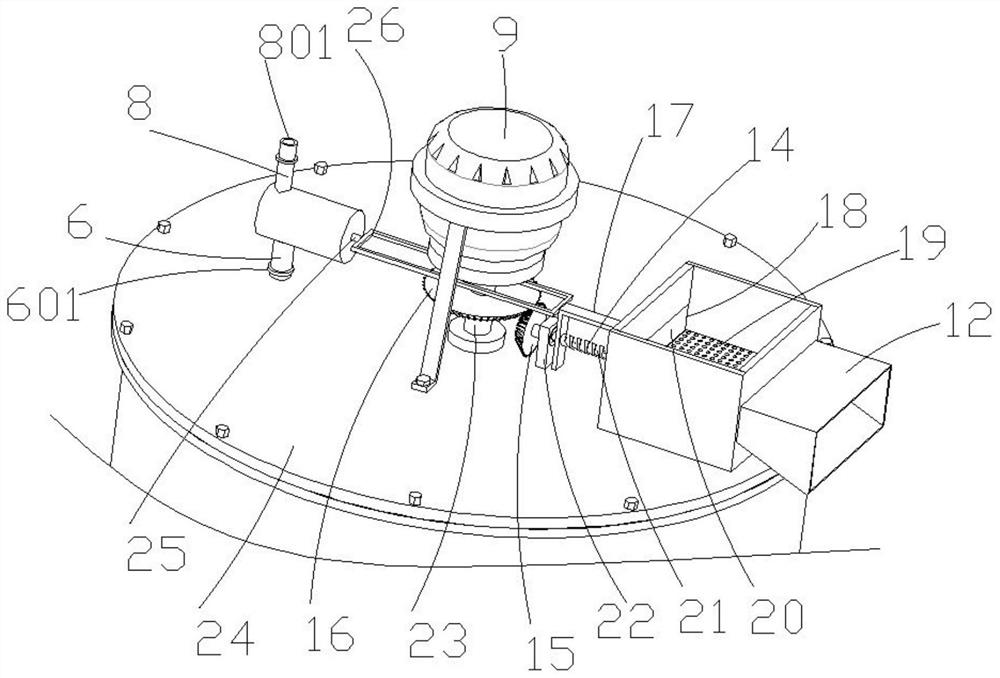

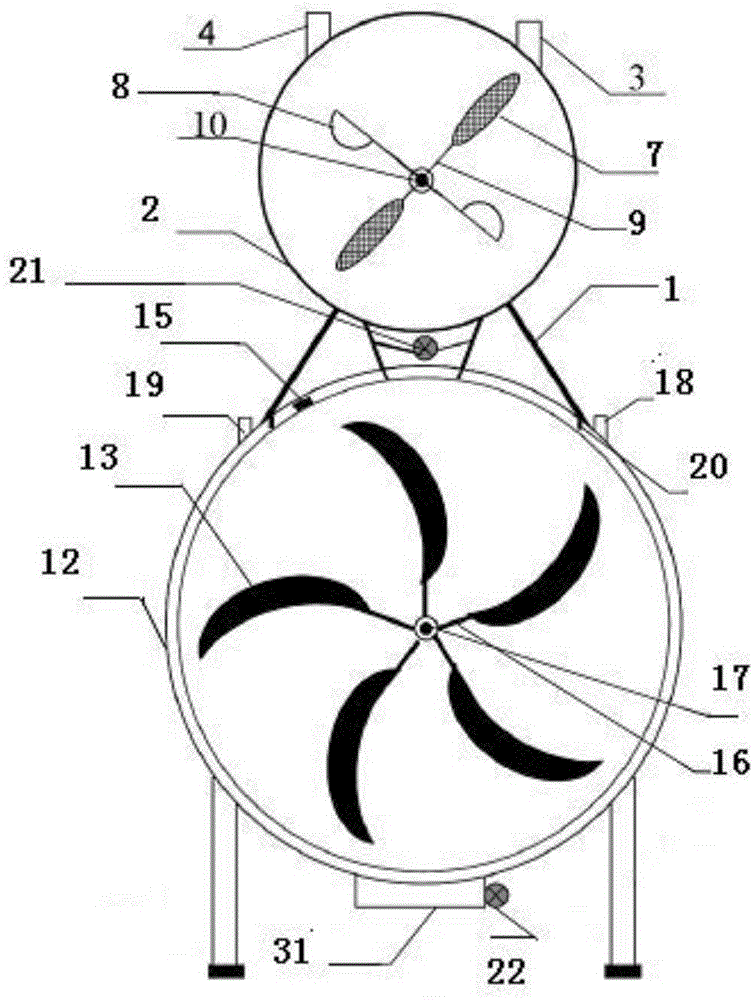

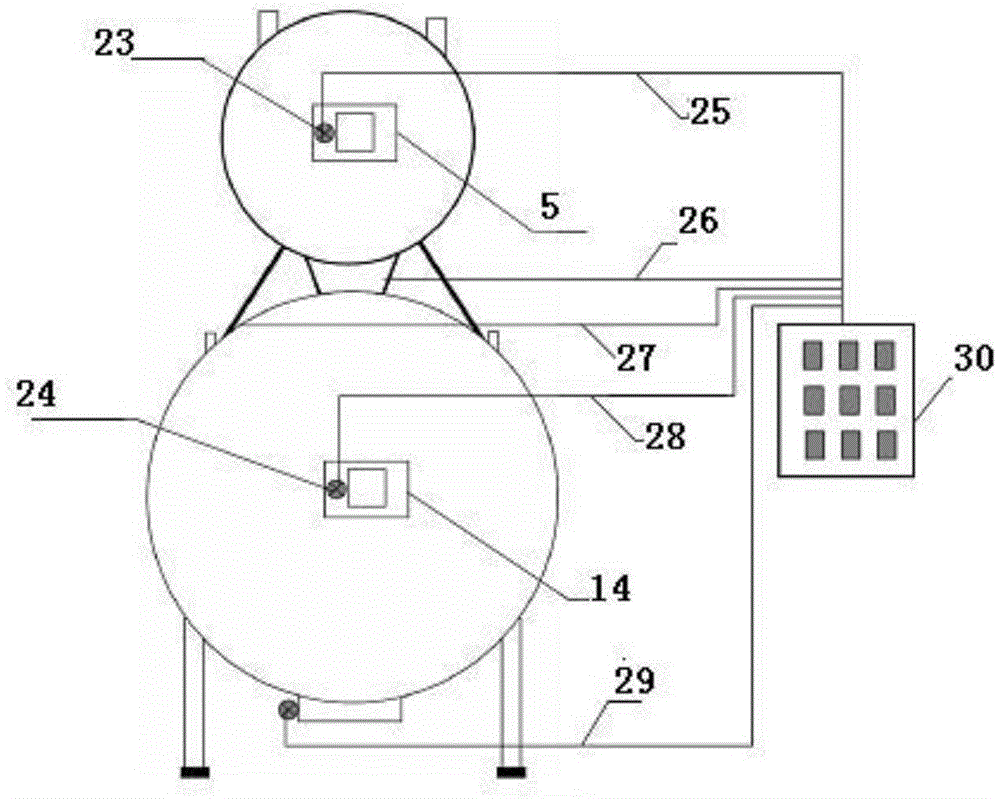

Automatic mixing device for mixed feed additive

ActiveCN105536586AImprove the tightnessQuality improvementFeeding-stuffTransportation and packagingHybrid typeAutomatic control

The invention discloses an automatic mixing device for a mixed feed additive. The automatic mixing device comprises four parts, namely a premixing system, a mixing system, a temperature control system and an automatic control system, wherein the premixing system comprises a premixing bin body, a main and auxiliary material feeding hole, a mixing blade, an adjustable motor and a fixed sealing flange; the mixing system comprises a mixing bin body, a mixing blade, an adjustable motor and a vibrator; the temperature control system comprises an internally inlet / outlet, a seal sheet and an interlayer; and the automatic control system comprises a relay switch gear, a connecting circuit and an automatic control board. The automatic mixing device has the characteristics of high automation, convenience in use, high main / auxiliary material mixing strength and obviously improved mixing degree, is high in device sealing degree, is capable of lowering the pollution rate and the material loss rate, reducing damage to human bodies, decreasing heat produced by machine operation and improving the activity and heat-labile component quality of the mixed feed additive, and is beneficial to quality stability of products in different batches.

Owner:FUJIAN BRADY PHARMA CO LTD

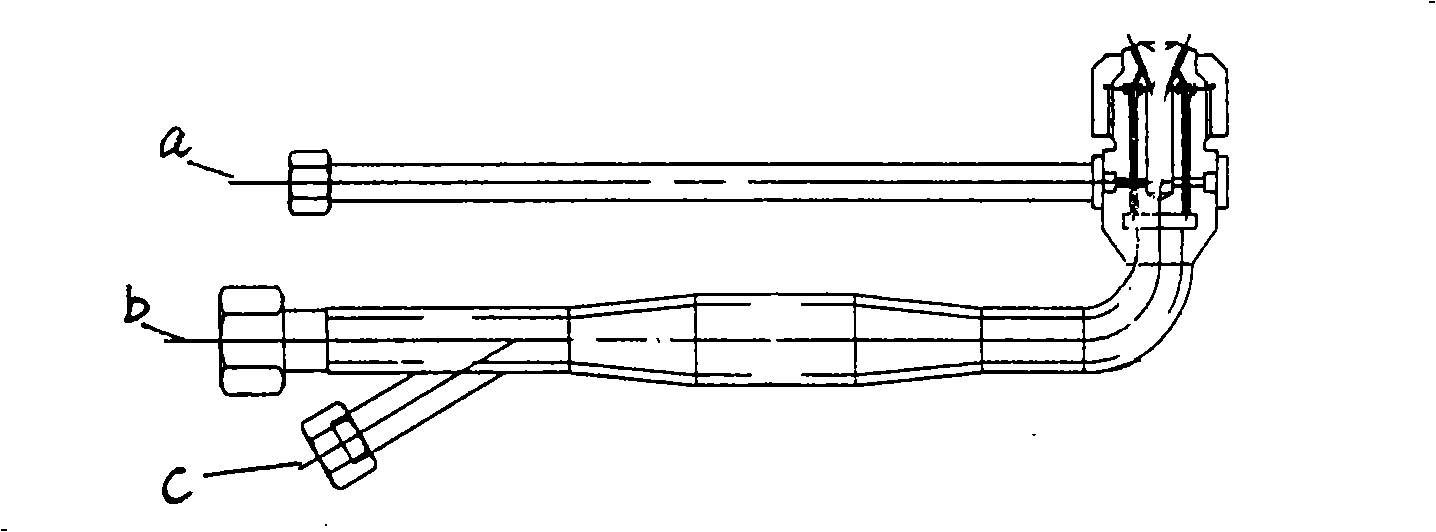

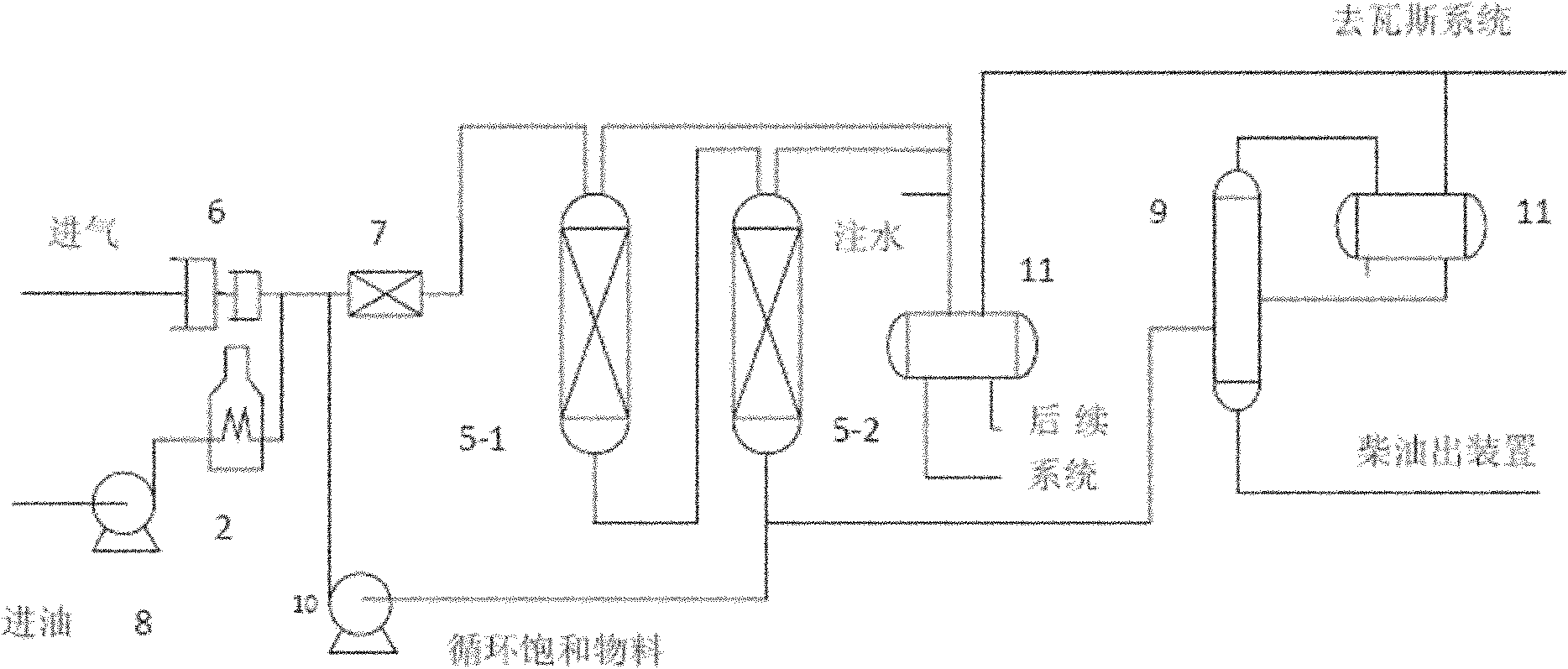

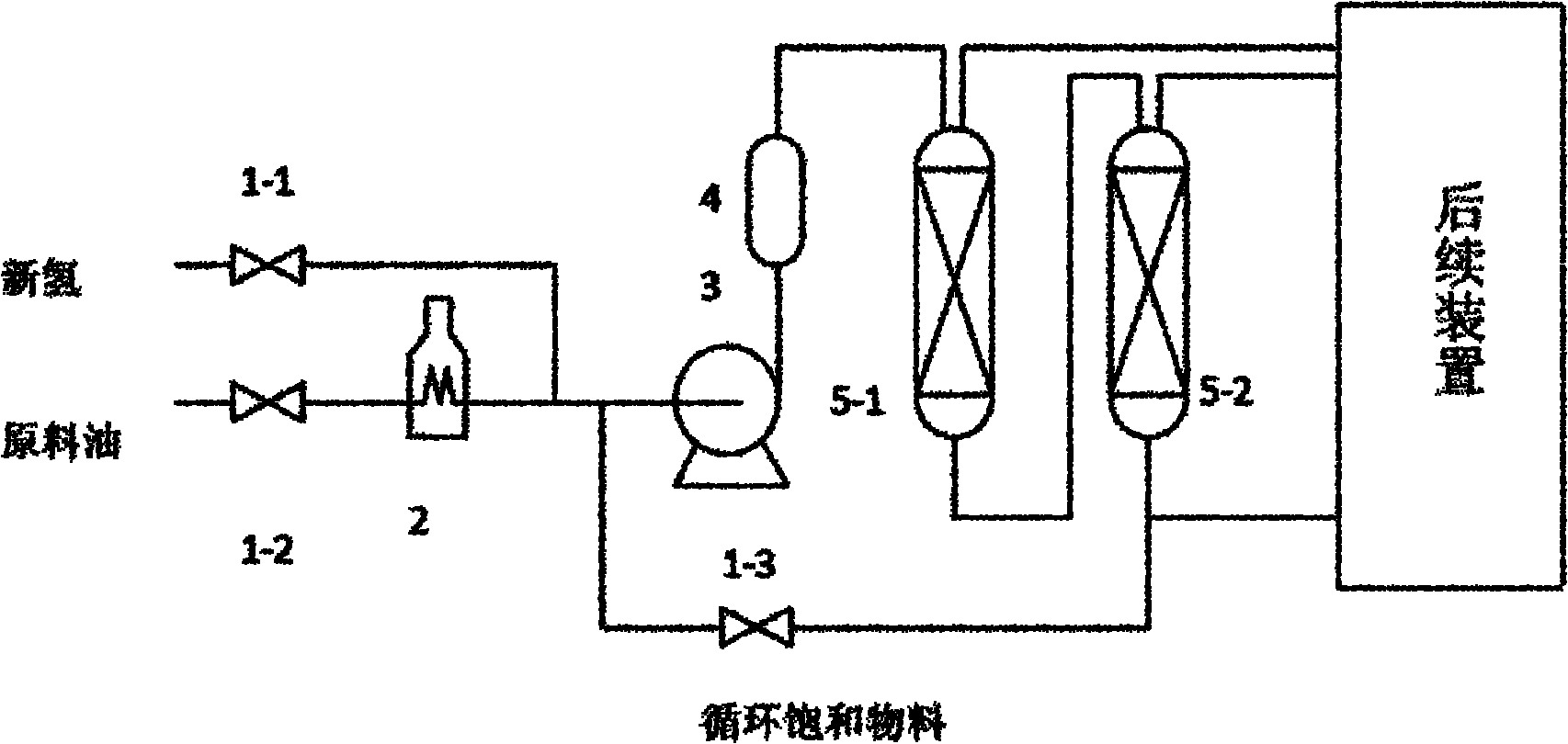

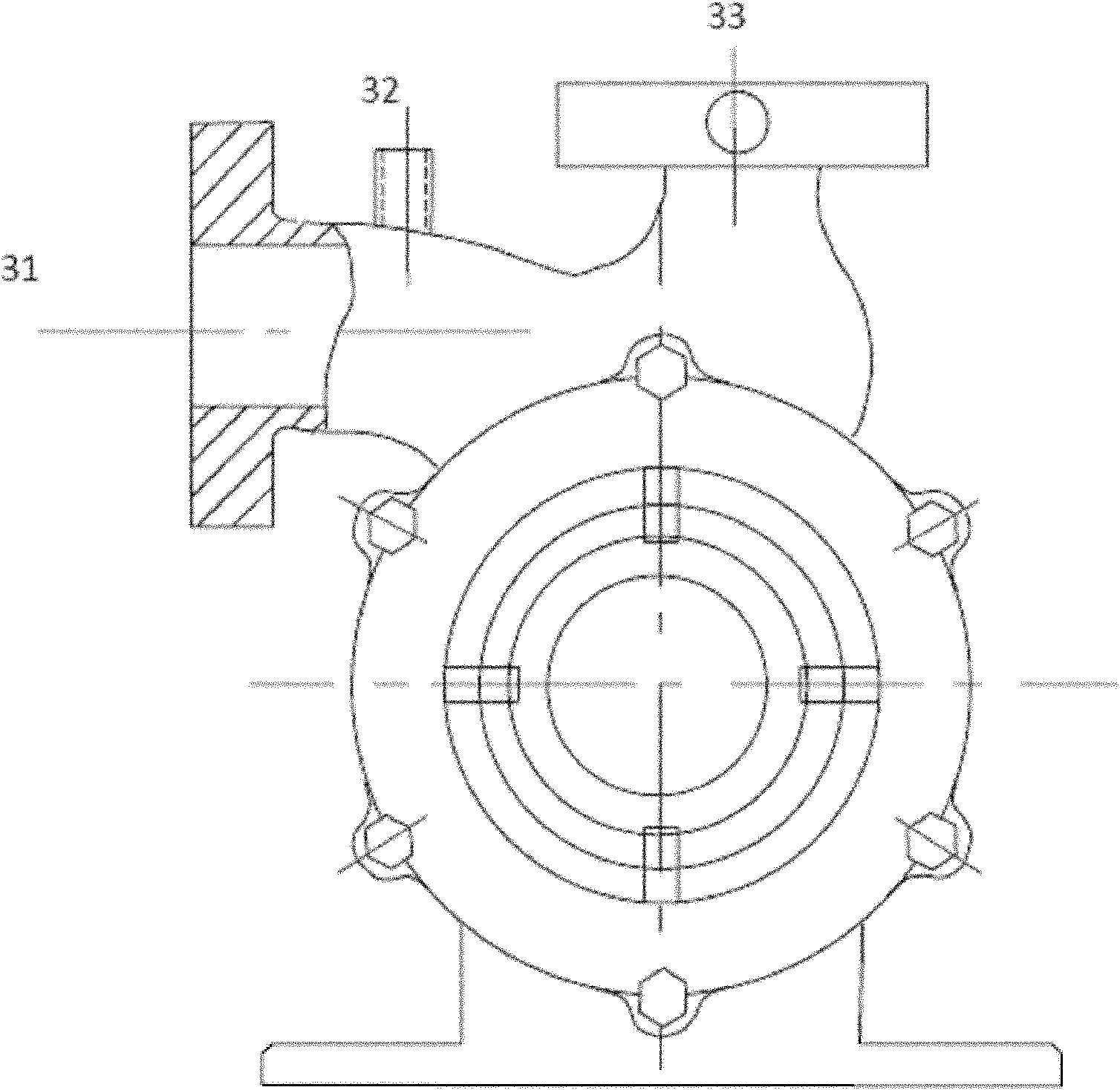

Method and device for dissolving gas in liquid-phase circulating hydrodesulfurization system

ActiveCN102002395AIncrease the degree of mixingEvenly mixedTreatment with hydrotreatment processesChemistryLiquid phase

The invention relates to a method and a device for dissolving gas in a liquid-phase circulating hydrodesulfurization system, and provides a method for dissolving gas in a liquid-phase circulating hydrodesulfurization system, which comprises the following steps of: introducing new hydrogen, raw oil and circulating saturated oil refluxed from a hydrogenation reactor into a gas-liquid mixing pump, and fully mixing under the strong turbulence state; introducing the mixed materials into a gas-liquid separation tank, collecting big bubbles, removing the big bubbles, and introducing the mixed materials into the hydrogenation reactor for hydrogenation; and introducing the circulating saturated oil refluxed from the hydrogenation reactor into the gas-liquid mixing pump again, mixing with the raw oil and the new hydrogen entering the gas-liquid mixing pump, and introducing the mixture into the hydrogenation reactor again. The invention also provides a device for dissolving gas in the liquid-phase circulating hydrodesulfurization system.

Owner:EAST CHINA UNIV OF SCI & TECH

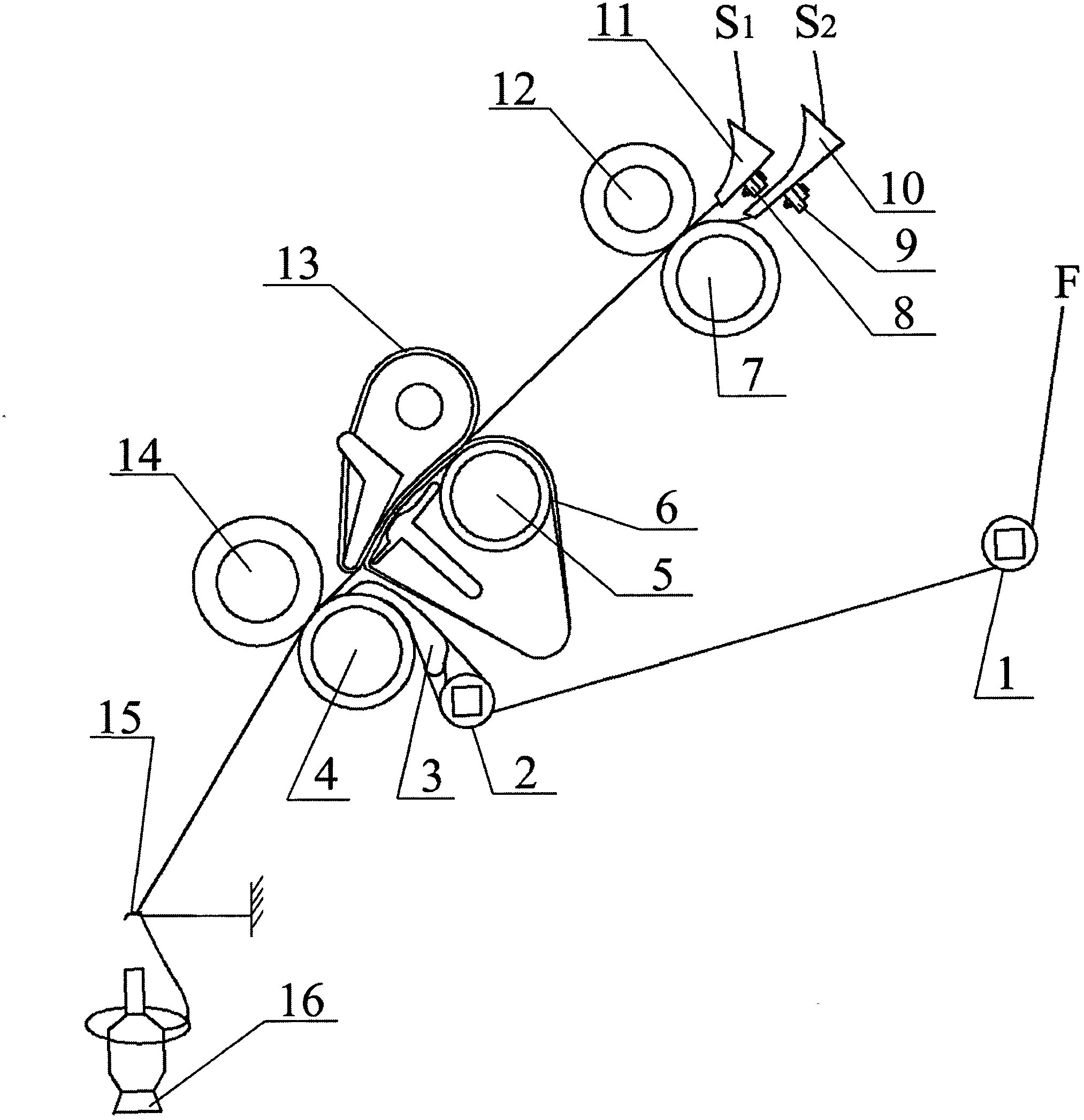

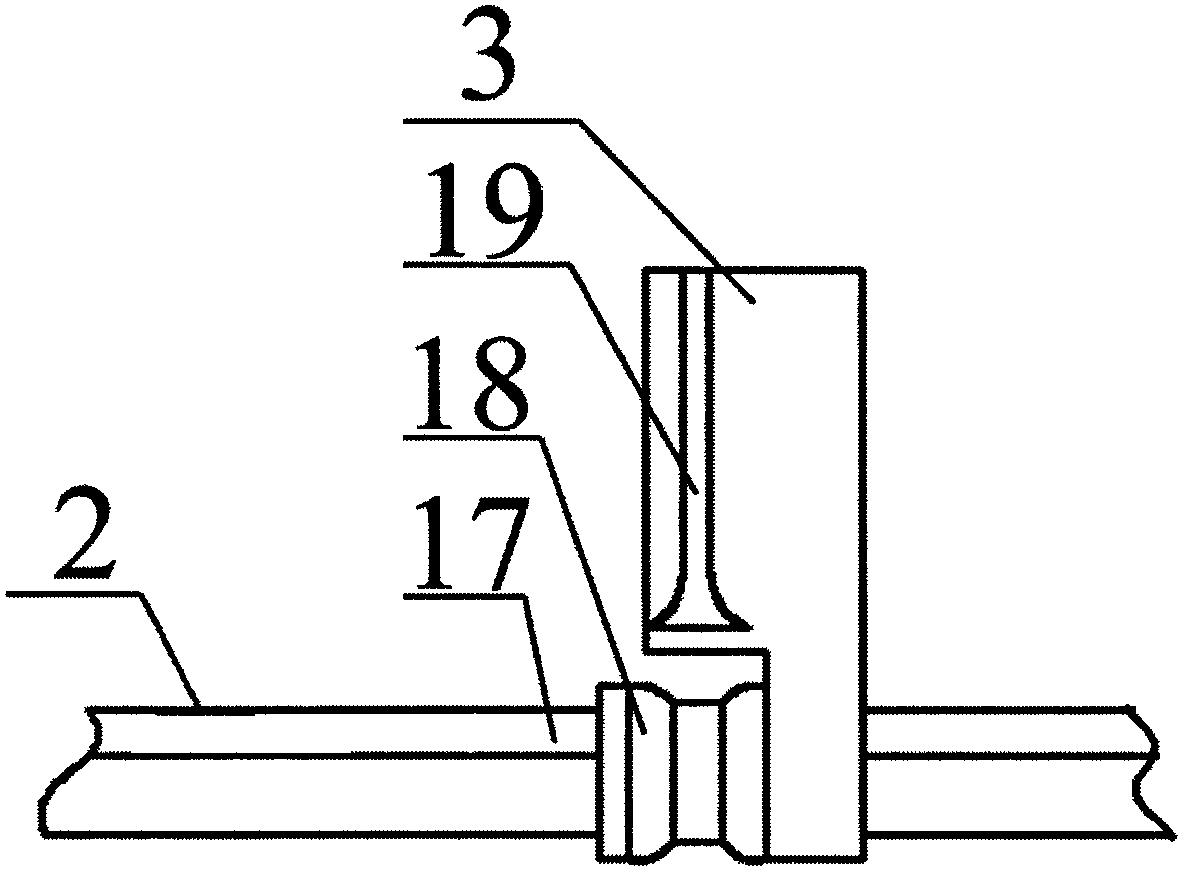

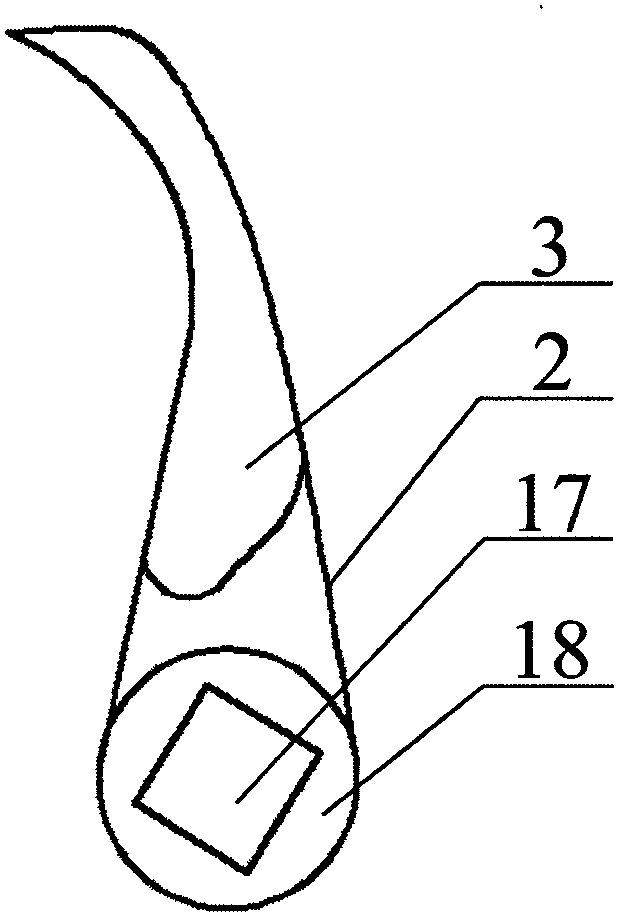

Forced internal and external transfer type composite ring spinning method for filament

InactiveCN102677248AIncrease the degree of mixingIncreased intermixingDrafting machinesYarnYarnTextile processing

The invention relates to a forced internal and external transfer type composite ring spinning method for a filament, which belongs to the technical field of textile processing. The technical scheme disclosed by the invention is that: a first yarn guide trumpet and a second yarn guide trumpet are adopted to do reversed reciprocating motion so as to respectively drive two short fibre rovings to do reversed reciprocating motion on each traction mechanism of a ring spinning frame; a forced yarn guide device feeds the filament into a front jaw in a reciprocating motion form, and is twisted with two short fibres output by a drafting system to form the yarn so as to realize full internal and external transferring of the filament in the finally produced composite yarn; and the filament in the composite yarn body and the fibres are naturally and uniformly mixed and tightly adhered so as to eliminate the relative sliding between the filament and the short fibres in subsequent processing of the yarn. According to the forced internal and external transfer type composite ring spinning method for the filament disclosed by the invention, electric fiber splitting and extra power are not related in actual production, the cost is low, a hidden trouble of igniting of static sparks in production can not be generated, simultaneously the device is simply reformed, and the operation and the use are convenient.

Owner:HUBEI HENGDA TEXTILE CO LTD

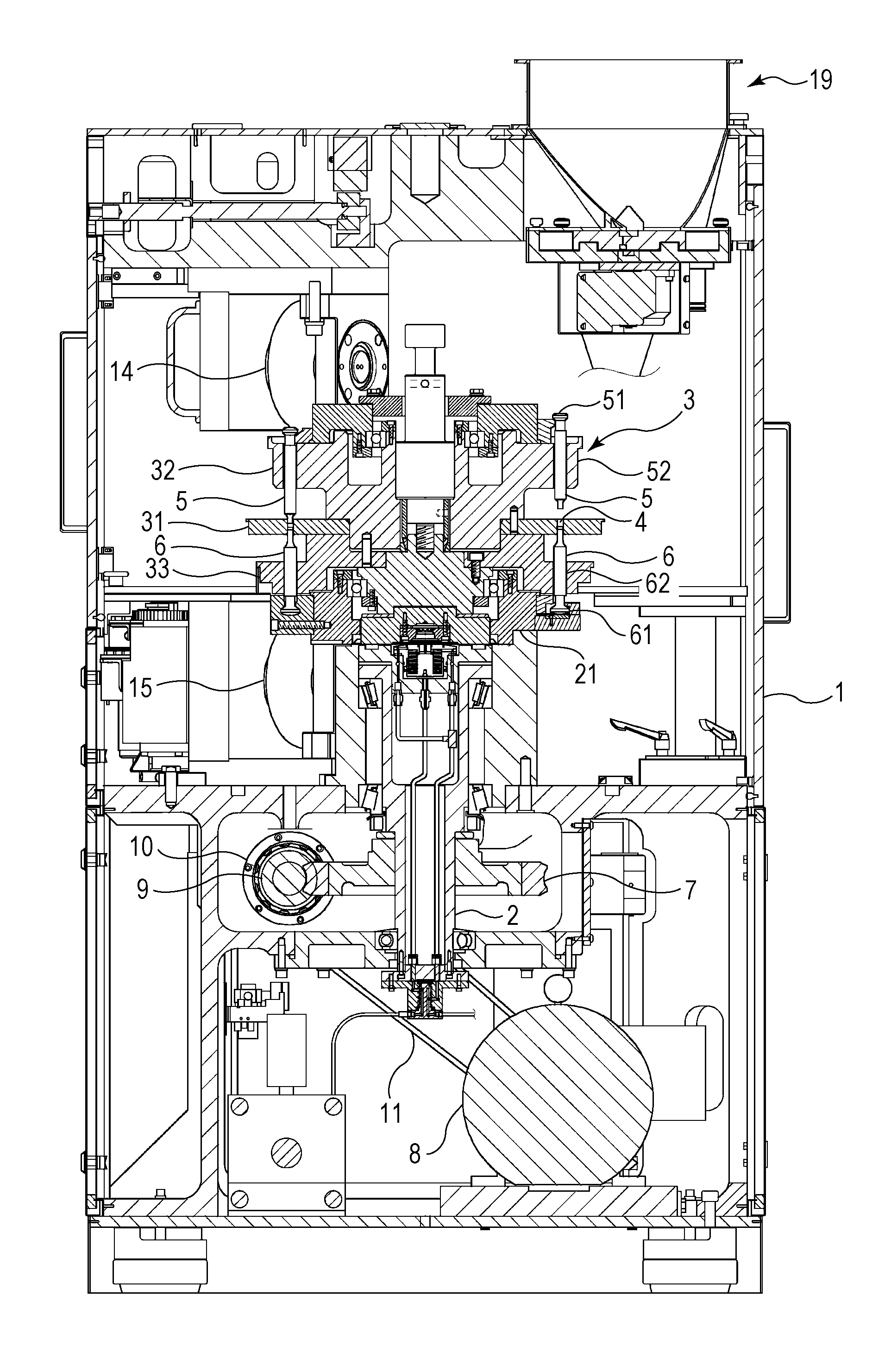

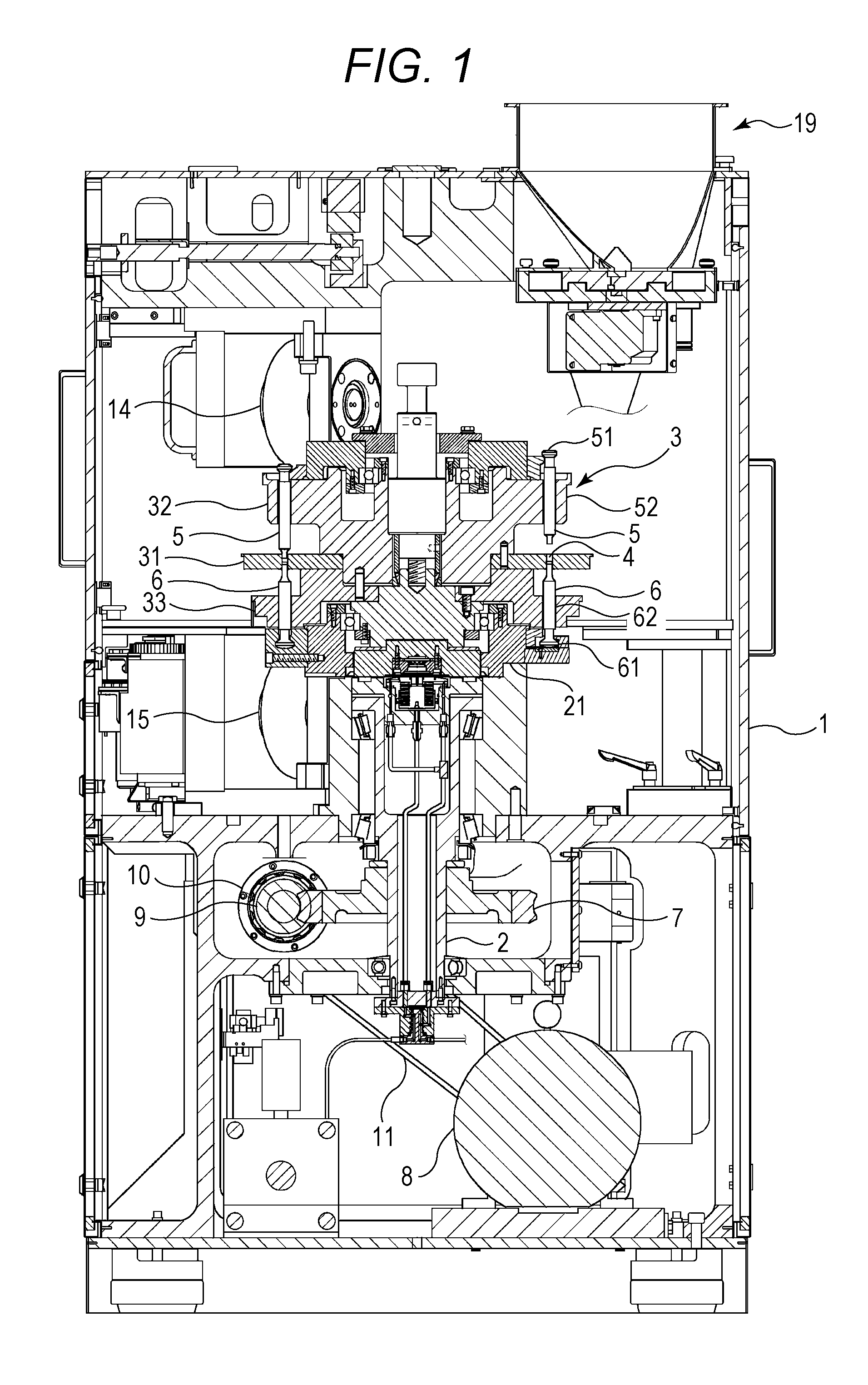

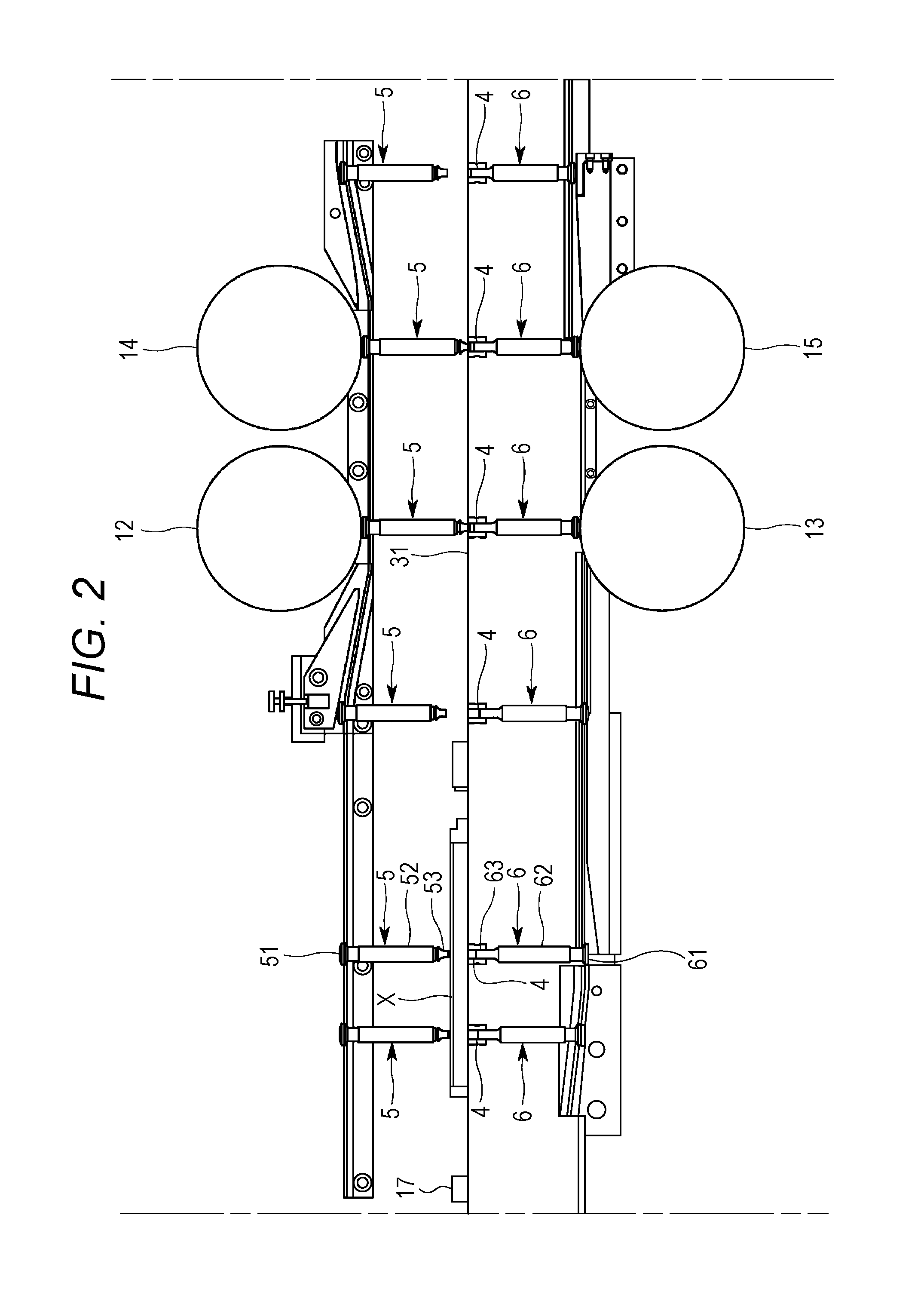

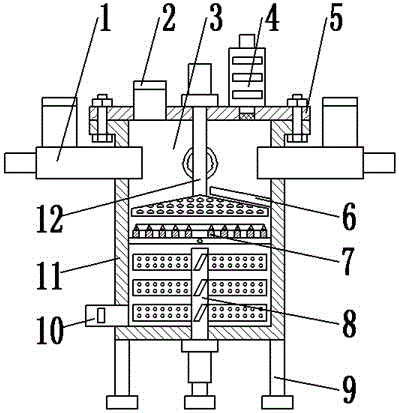

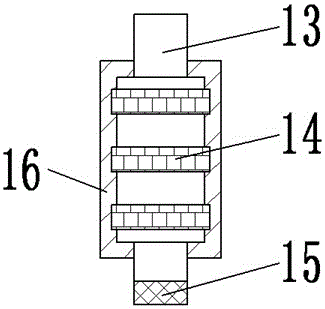

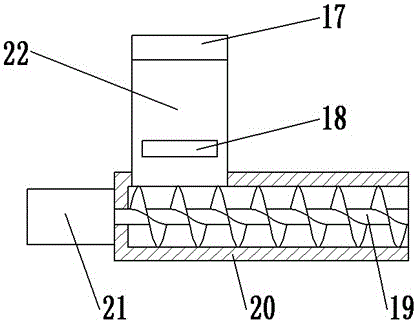

Powdery material mixing and feeding device and compression-molding machine including the same

ActiveUS20160361885A1Enhanced mixing processIncrease the degree of mixingRotary stirring mixersTransportation and packagingCompression moldingEngineering

A powdery material mixing and feeding device is configured to mix at least two types of powdery materials and to feed a compression-molding machine with the mixed powdery materials. The powdery material mixing and feeding device includes a first mixer configured to rotate about a substantially vertical shaft and to mix the powdery materials, and a reservoir configured to reserve at least a part of the powdery materials, and a second mixer configured to rotate about a substantially horizontal shaft and to mix the powdery materials.

Owner:KIKUSUI SEISAKUSHO LTD

System for deep treatment of coking wastewater by means of catalytic ozonation-ceramic membrane filtration

InactiveCN102849875AStrong upward impactInhibition falls intoMultistage water/sewage treatmentParticulatesChemical oxygen demand

The invention discloses a system for deep treatment of coking wastewater by means of catalytic ozonation-ceramic membrane filtration, mainly consisting of an ozone generator, an ozone oxidation reactor, a booster pump, a ceramic membrane component, a gas-liquid separator, a tail gas absorbing device, a wastewater reflowing pump, a catalyst reflowing pump, a catalyst adding pump, a catalyst outflowing groove, a catalyst adding groove and corresponding pipe fittings, valves and instruments. According to the system, the application of a powder catalyst in a dynamic reactor can be realized due tothe combination of the catalytic ozonation and the ceramic membrane separation; the ozonation and the catalytic ozonation can be guaranteed to be carried out in a single reactor in a segmental way due to the convection current of the reflowing wastewater and the catalyst slurry and the impact of upcurrent; the mass transfer resistance when the ozonation and the catalytic ozonation are independently used can be reduced; the use ratio of hydroxyl free radical and the removal rate of organic matters can be improved; the aims, such as the COD (chemical oxygen demand), the chroma and the turbidityof the deeply-treated coking wastewater, can be achieved; and the problems that the activity is suddenly reduced when the powder catalyst is formed into particulates, the running needs to be suspended when the mass transfer resistance is increased due to the use of the particulate catalyst and the particulate catalyst is changed and the like can be solved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Energy-saving and emission-reducing exhaust gas desulfurization tower

InactiveCN108722160AAids in spray coverageIncrease the degree of mixingDispersed particle separationSeparation devicesExhaust fumesPulp and paper industry

The invention discloses an energy-saving and emission-reducing exhaust gas desulfurization tower. The energy-saving and emission-reducing exhaust gas desulfurization tower comprises a tower body, a demisting tank and a waste liquid treatment tank, wherein the demisting tank is fixedly connected to the upper end of the tower body, the waste liquid treatment tank is fixedly connected to the lower end of the tower body, a gas inlet pipe is arranged on the side wall close to the lower end of the tower body, a liquid inlet pipe is arranged on the side wall close to the upper end of the tower body,one end of the liquid inlet pipe penetrates through the tower body and extends inside the tower body, a spraying device communicated with the liquid inlet pipe is arranged inside the tower body, a gasdispersing mechanism is rotatably connected with the internal bottom of the tower body, the upper end of the gas dispersing mechanism is fixedly connected with the spraying device, the lower end of the tower body is fixedly connected with a rotating motor used for driving the gas dispersing mechanism, and a gas outlet is formed in the upper end of the demisting tank. According to the energy-saving and emission-reducing exhaust gas desulfurization tower, the structure is compact, the thorough mixing between exhaust gases and a desulfurization solution is improved, and thus, the desulfurizationeffect of the exhaust gases is improved; desulfurized waste liquid is further treated, so that the discharge of harmful liquid is avoided.

Owner:孙菊萍

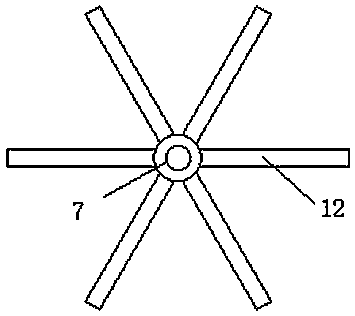

Method for removing fine particles and heavy metals in coal fume

ActiveCN102773162ALarge structure sizeLess investmentElectrostatic separationVortex flow apparatusSorbentPre-charge

The invention relates to a method for removing fine particles and heavy metals in coal fume. The method is an electric precipitator coupling charging absorbing agglomeration technology. The method comprises the steps of: pre-charging (positive charge) on an adsorbent by a charging spray gun, and spraying the adsorbent to an area between two adjacent electric fields of the electric precipitator; by a Coulomb agglomeration action between a positively charged absorbent particle and a fine particle which is negatively charged by last electric field and is not captured, and an absorption action of the charged absorbent, capturing a plurality of pollutants including fine particles, heavy metals and condensable substances, onto the absorbent to form larger particles; and efficiently capturing the larger particles by the electric field at the back of the electric precipitator, so as to achieve the purpose of synergistically removing a plurality of pollutants in smoke. Compared with prior art, the method of removing fine particles and heavy metals in coal fume has the advantages of high efficiency and low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV

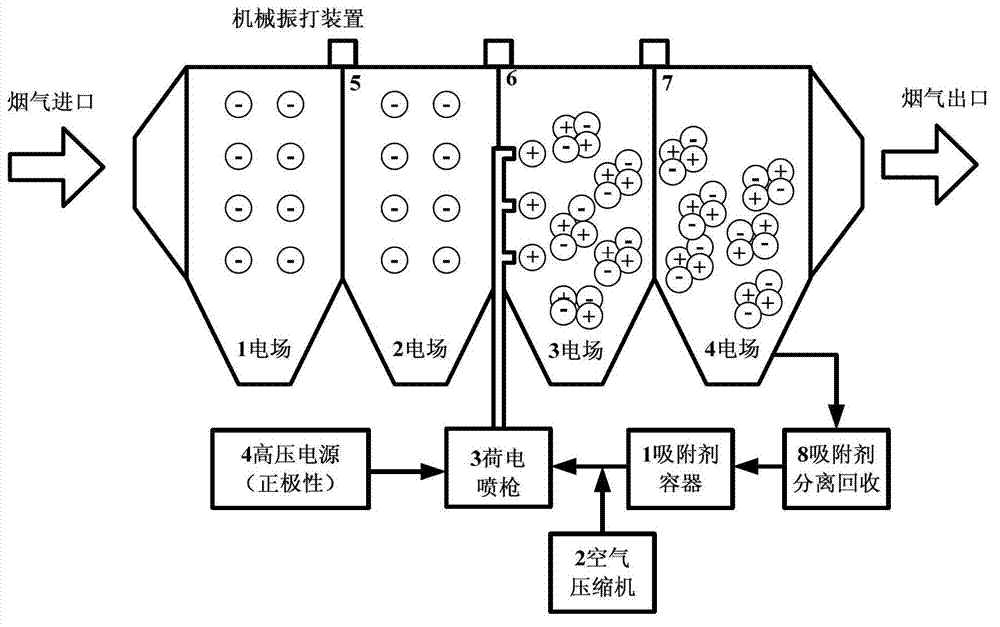

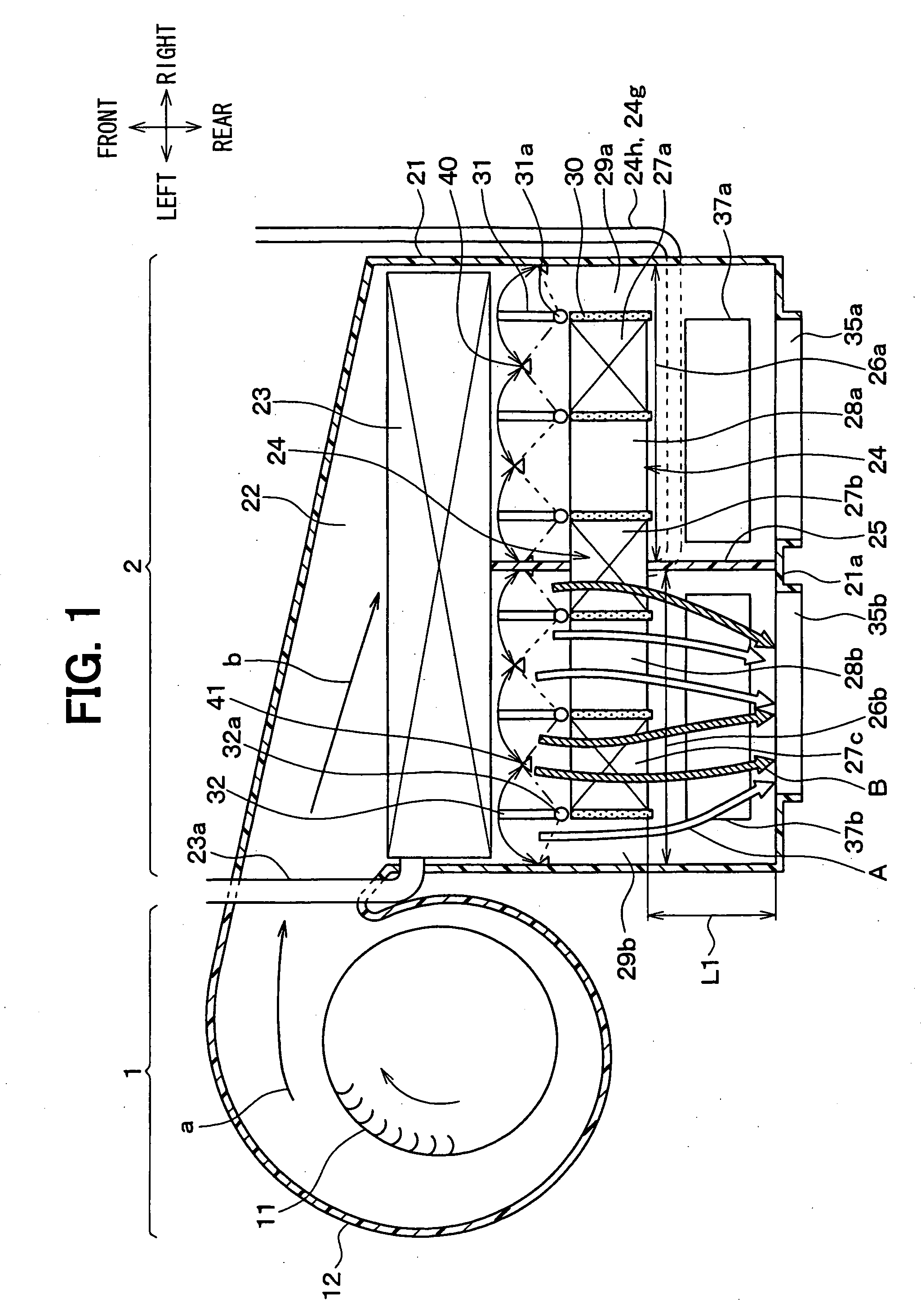

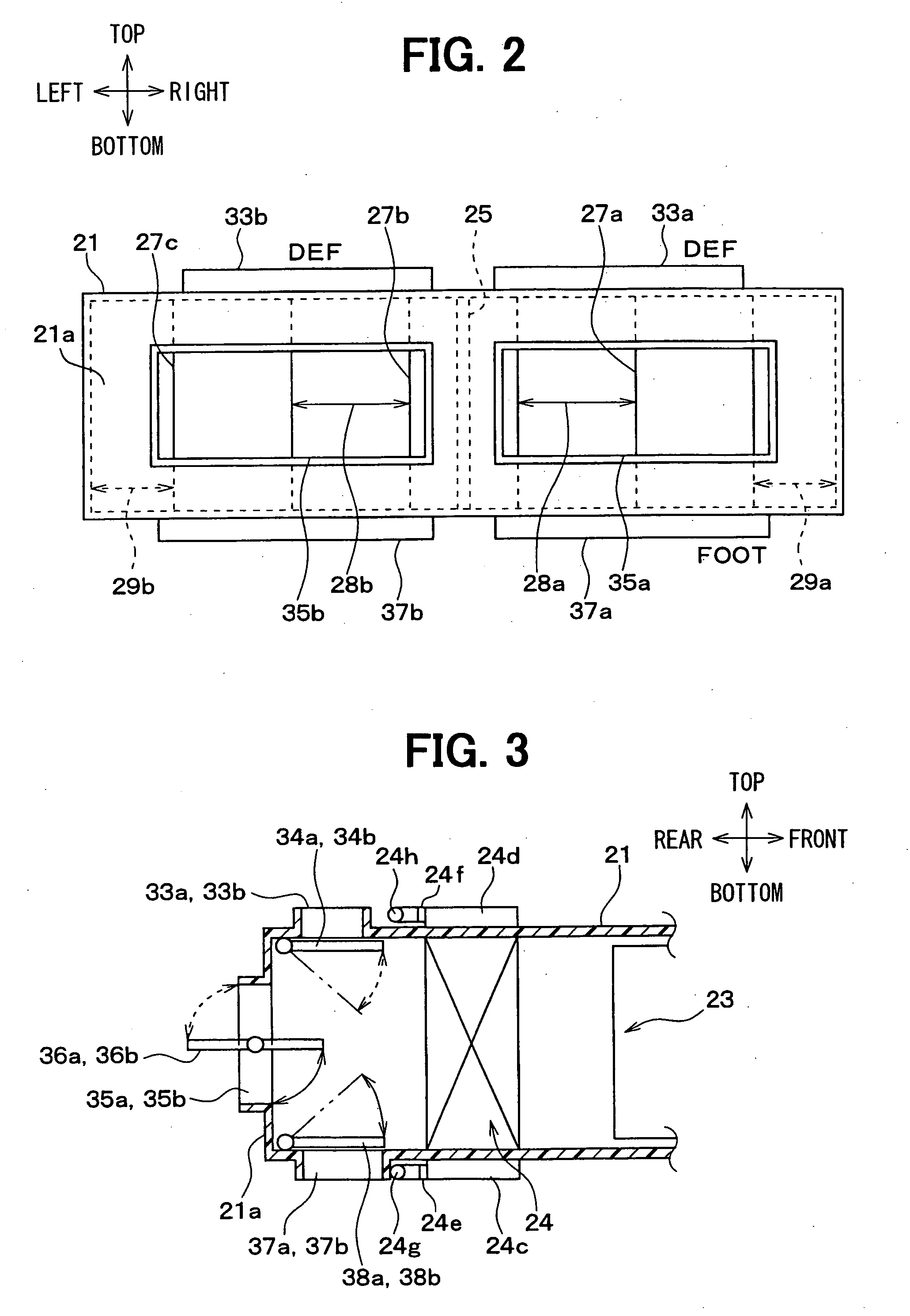

Heat exchanger and air conditioner

InactiveUS20070125521A1Reduce pressure lossIncrease the degree of mixingAir-treating devicesRailway heating/coolingEngineeringHeat exchanger

A heating heat exchanger includes plural tubes which are arranged in parallel and through which a thermal fluid for heating air flows, and plural fins which are joined to the tubes. The tubes and the fins are arranged to form plural heating parts equal to or more than three in which air is heated, and at least two bypass passages each of which is provided between adjacent heating parts, through which the air passes without exchanging heat with the thermal fluid. Furthermore, first and second tank parts for distributing the thermal fluid to and for collecting the thermal fluid from the tubes are arranged at two longitudinal ends of the tubes and extend to across an area where the bypass passages and the heating parts are provided. In addition, the bypass passages and the heating parts are arranged in an arrangement direction perpendicular to an air flow direction.

Owner:DENSO CORP

Lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities

InactiveCN106732040AAvoid pollutionAvoid non-conformitiesDispersed particle filtrationTransportation and packagingEngineeringScrew conveyor

The invention provides lithium battery cathode material mixing equipment capable of preventing dust flying and removing impurities. The equipment comprises a tank body and an upper cover, a mixing cavity is formed inside the tank body, an auxiliary feeding pipe and a filtering device are arranged on the upper cover, the filtering device is composed of an exhausting pipe and a filtering tank, and a feeding device is arranged on the side wall of the top of the tank body and composed of a feeding pipe, a feeding screw conveyor, a feeding motor and a material storing tank; a material guiding device, an impurity removing device and a stirring device, the material guiding device is composed of a material guiding motor, a rotating shaft and a material guiding disc, the impurity removing device is composed of multiple concentric electromagnetic rings, and the stirring device is composed of a stirring motor, a stirring shaft and stirring pieces. Raw material dust is prevented from directly causing dust pollution through the filtering device, and recycling of the raw material dust is facilitated, so that unqualified products caused by unbalanced proportion is prevented; mixing degree of raw materials is increased through the stirring device, so that the raw materials are mixed more uniformly.

Owner:SHENZHEN JUOCAN TECH CO LTD

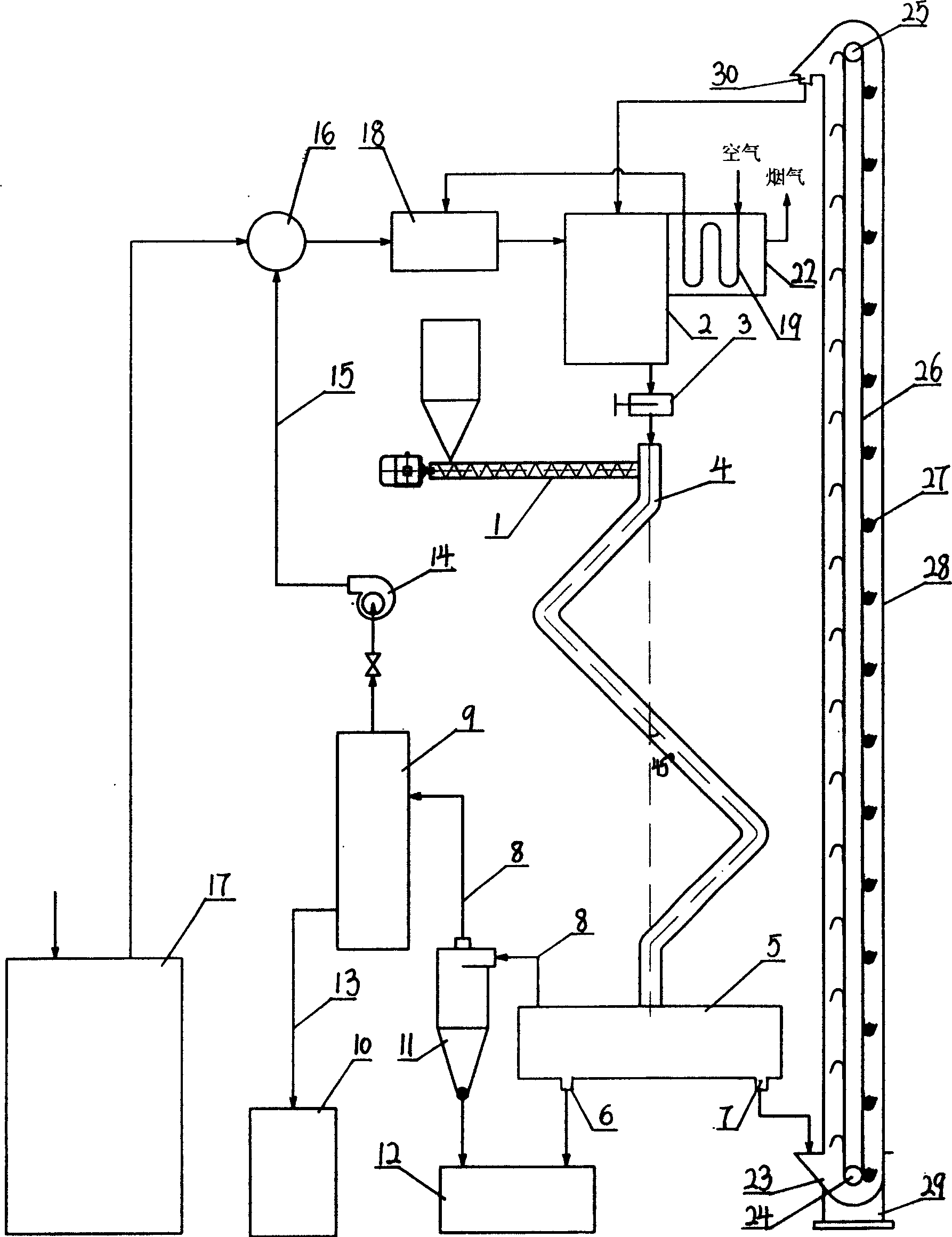

Biomass pyrolysis liquefying systems

InactiveCN1490380ALow costTake advantage ofLiquid hydrocarbon mixture productionHeat carrierResidual biomass

A biomass cracking and liquefying system is disclosed. The Z-shaped reaction pipe has a top end connected respectively with the feeder of biomass and the heat carrier outlet of the heat carrier heater, and a bottom end connected to the separator whose top end is connected to cooling unit and whose bottom end has residual biomass outlet and heat carrier outlet. The input of gas mixer is connected respectively to the gas outlet of biomass gasifier and the thermocomposed gas outlet of cooling unit, and its output is connected to gas burner communicated to the heater of heat carrier. It features that the combustible gas generated in gasifying and liquefying biomass is used as the energy source for thermodecomposing and liquefying, so having low cost.

Owner:SHANDONG UNIV OF TECH

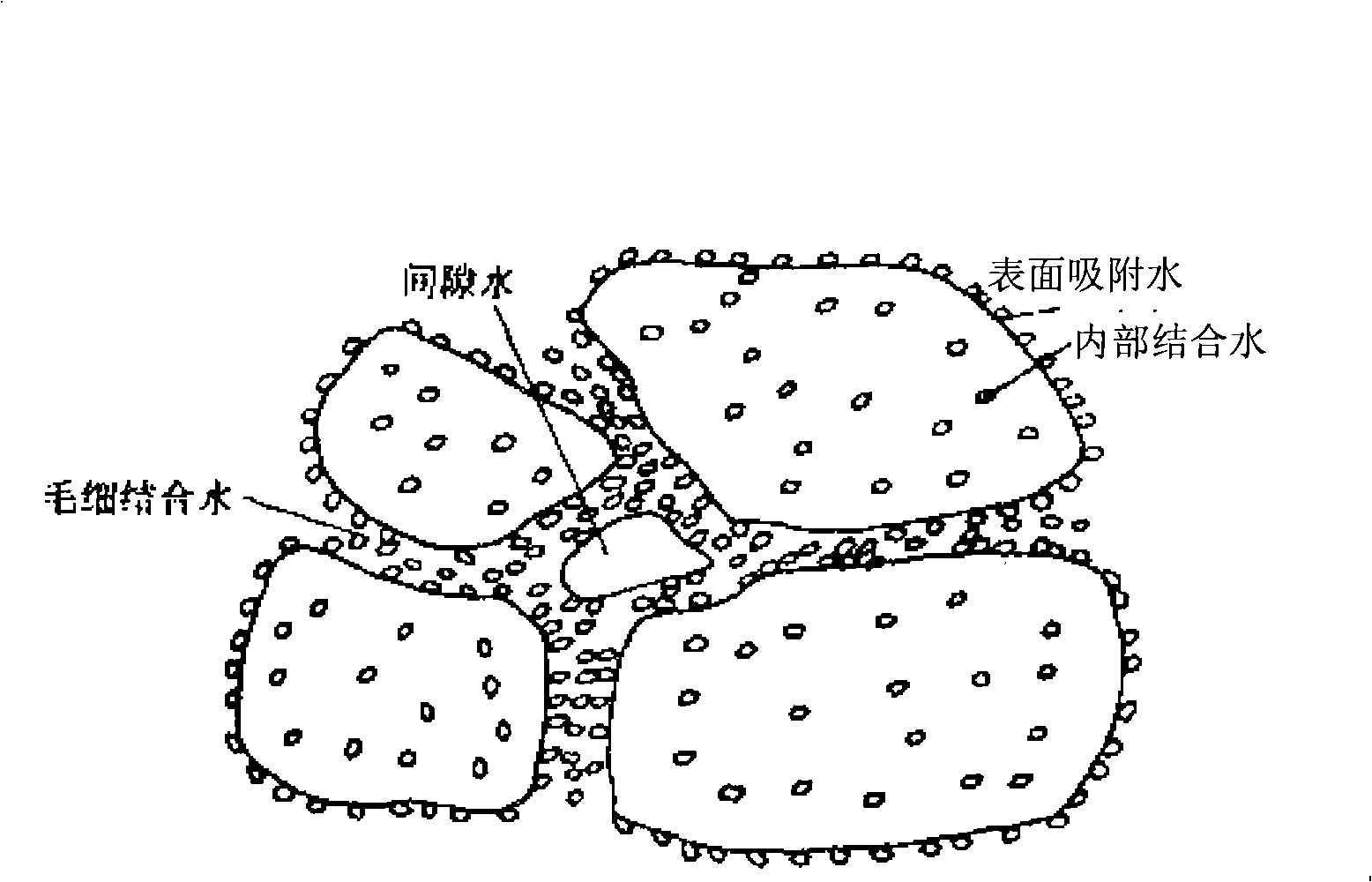

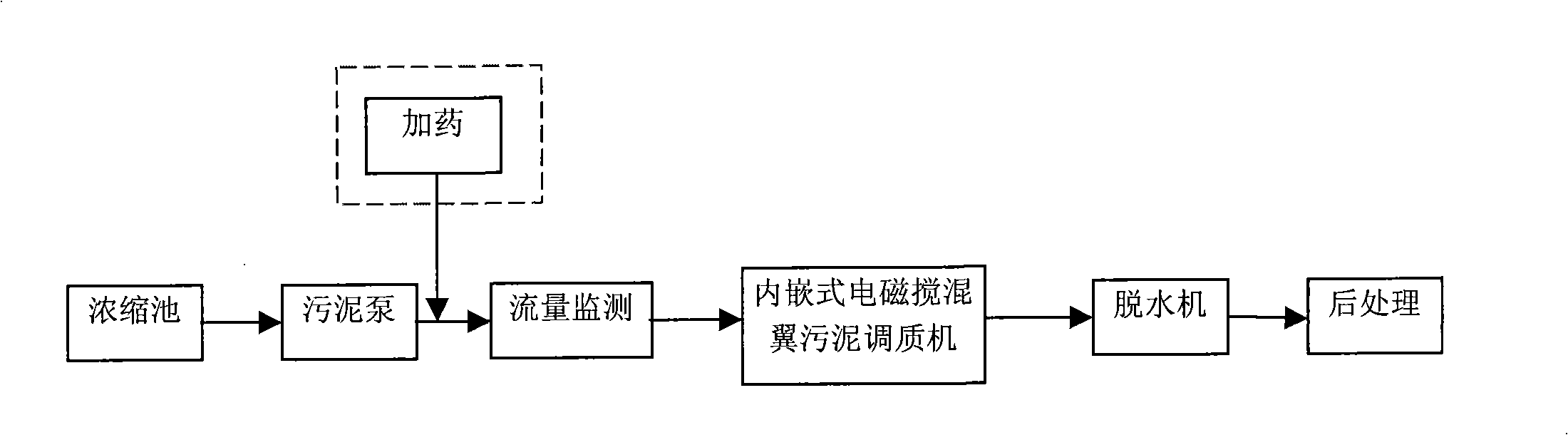

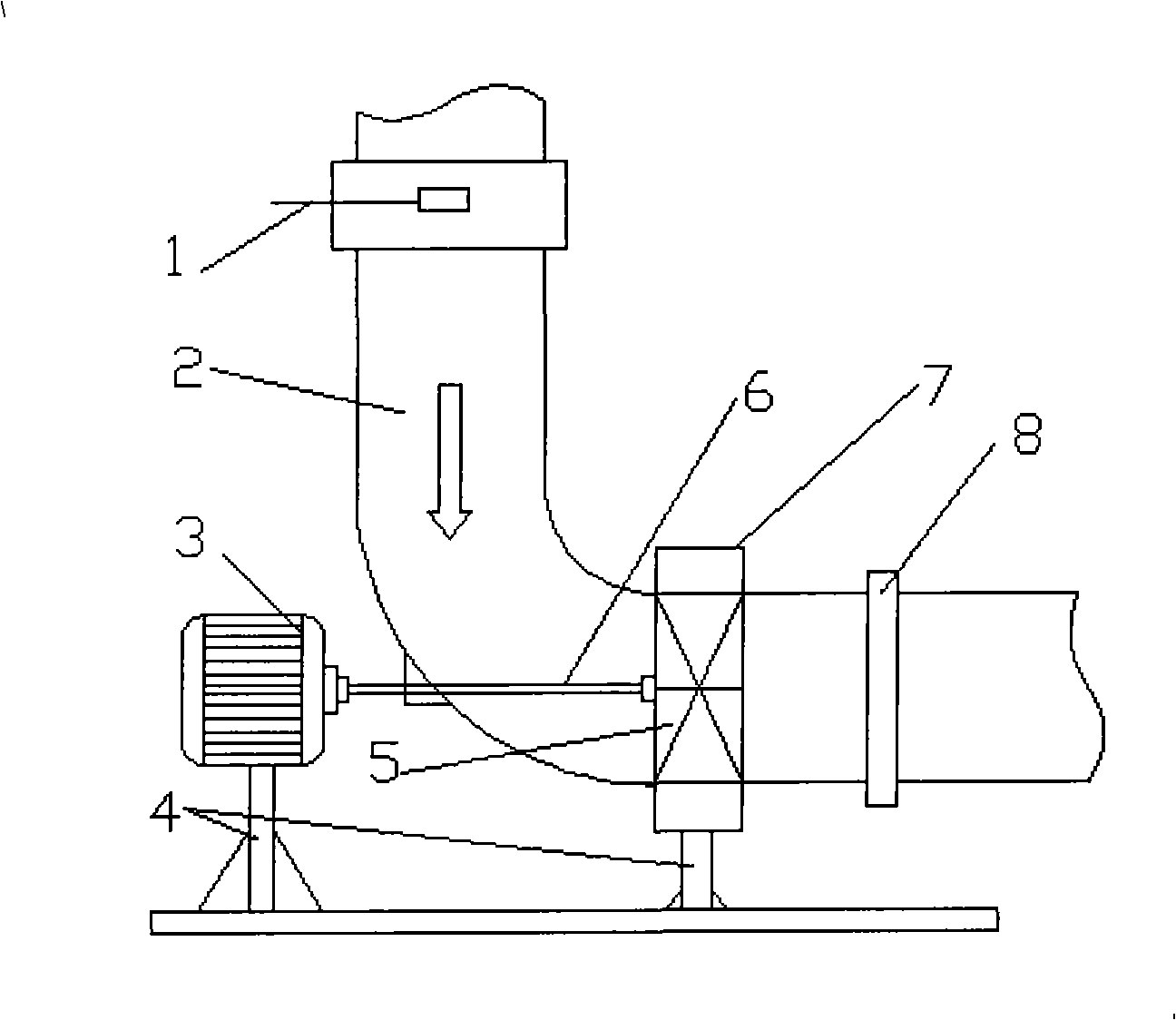

Method and apparatus for improving sludge dehydration

InactiveCN101328002APrecise temperingLower specific resistanceSludge treatment by de-watering/drying/thickeningEnergy expenditureDewatered sludge

The invention discloses a method for improving the dehydrating property of the sludge and equipment thereof. The method is to adopt an inner embedded type electromagnetic swirling wing sludge conditioner arranged in the sludge pipe or an external magnet-rotary sludge conditioner arranged on the sludge pipe to quench and temper the sludge, so as to achieve the purpose of sludge specific resistance reduction and sludge dehydrating property improvement. After the method and the equipment are implemented, the water content of the final dewatered sludge (mud cake) can reach 70-80% which reduces by 2-15% comparing to the technology without conditioner treatment. The work efficiency of the dewaterer is greatly improved, the energy consumption of the dewaterer is reduced by 5-40% and the reagent dosing is reduced by 5-100%. The method and equipment of the invention are not only suitable for the transformation of the old equipment in the prior sludge treatment, but also suitable for the establishment of the new equipment.

Owner:上海滨浦水处理设备有限公司

Preparation method of cyclohexanone from oxidation of cyclohexanol

ActiveCN102079694AImprove conversion rateHigh selectivityMolecular sieve catalystsCarbonyl compound preparation by oxidationCyclohexanoneMolecular sieve

A preparation method of cyclohexanone from catalytic oxidation of cyclohexanol is characterized by contacting reactants containing cyclohexanol and hydrogen peroxide with a catalyst at a temperature of 0-180 DEG C and under the pressure of 0.1-3.0MPa, wherein the molar ratio of cyclohexanol to hydrogen peroxide is 1:(0.1 to 10.0), the catalyst is a titanium silicalite molecular sieve based catalyst, and the mass ratio of cyclohexanol and the catalyst is (1-200):1. The method has no special requirements on equipment and the production process is simple, is easy to control and is beneficial to industrial production and application. The invention has the advantages of high cyclohexanol conversion rate, good selectivity, long time stable operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com