System for deep treatment of coking wastewater by means of catalytic ozonation-ceramic membrane filtration

A technology of ozone oxidation and advanced treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The composition of wastewater is complex and changeable, so as to avoid the sharp reduction of activity, save equipment, metal dissolution and small carbon deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

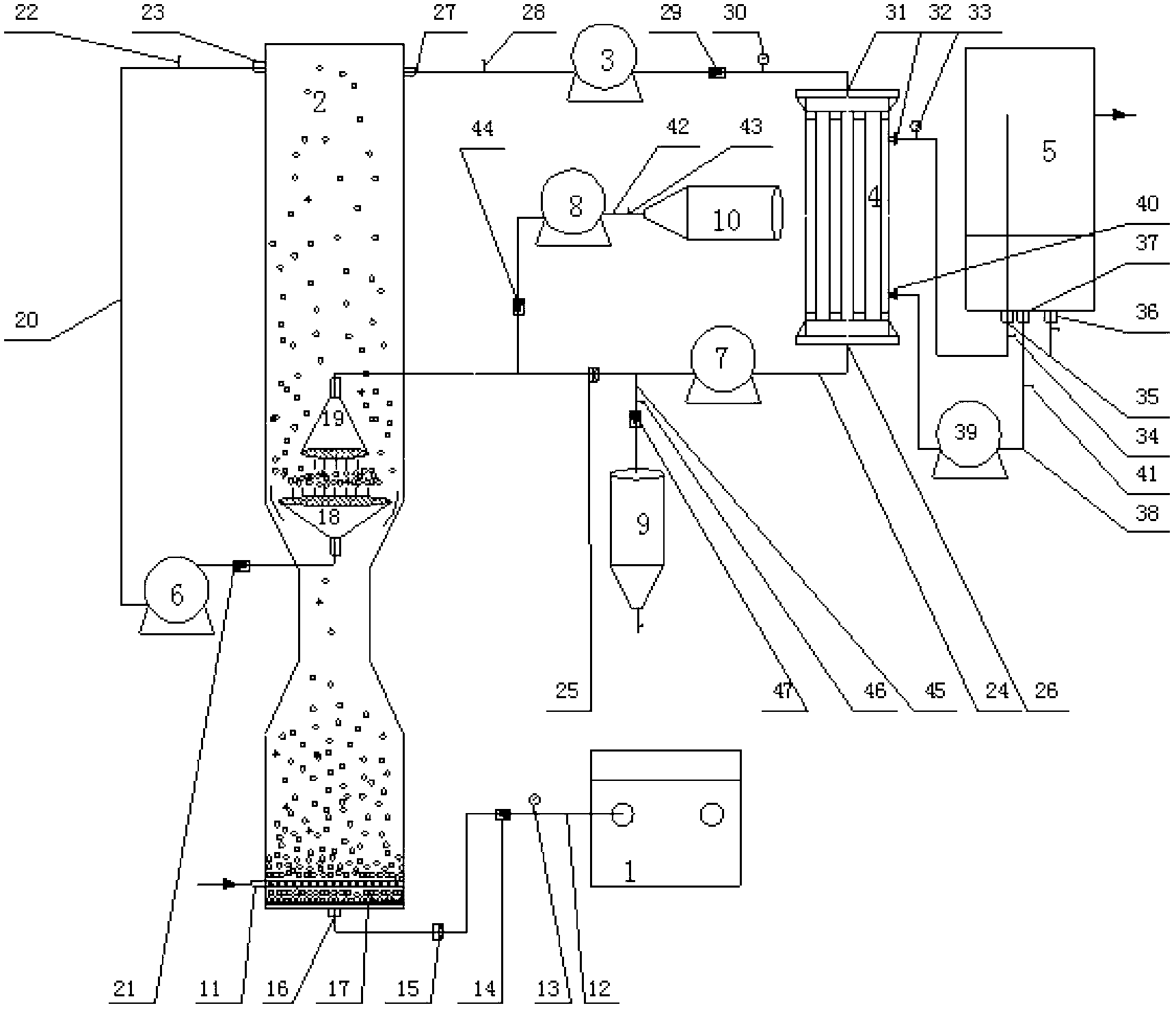

[0039] Such as figure 1 As shown, the system is mainly composed of an ozone generator 1, a catalytic ozonation reactor 2, a booster pump 3, a ceramic membrane module 4, a gas-liquid separator 5, a waste water return pump 6, a catalyst return pump 7, a catalyst addition pump 8, Catalyst outflow tank 9, catalyst adding tank 10 and corresponding pipe fittings, valves and instruments are composed.

[0040] The system of the present invention works like this: the coking wastewater enters the catalytic ozonation reactor 2 through the water inlet pipe 11, and the ozone and oxygen mixed gas that comes out from the ozone generator 1 passes through the inlet pipe 12, and flows through the pressure gauge 13 and the flow meter successively. 14. The one-way valve 15 enters the ozone oxidation reactor 2 from the air inlet 16, and after passing through the microporous aeration plate 17, a large number of tiny bubbles are formed in the ozone oxidation reactor 2. The smaller the bubbles, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com