Patents

Literature

70results about How to "Increase the ascending velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

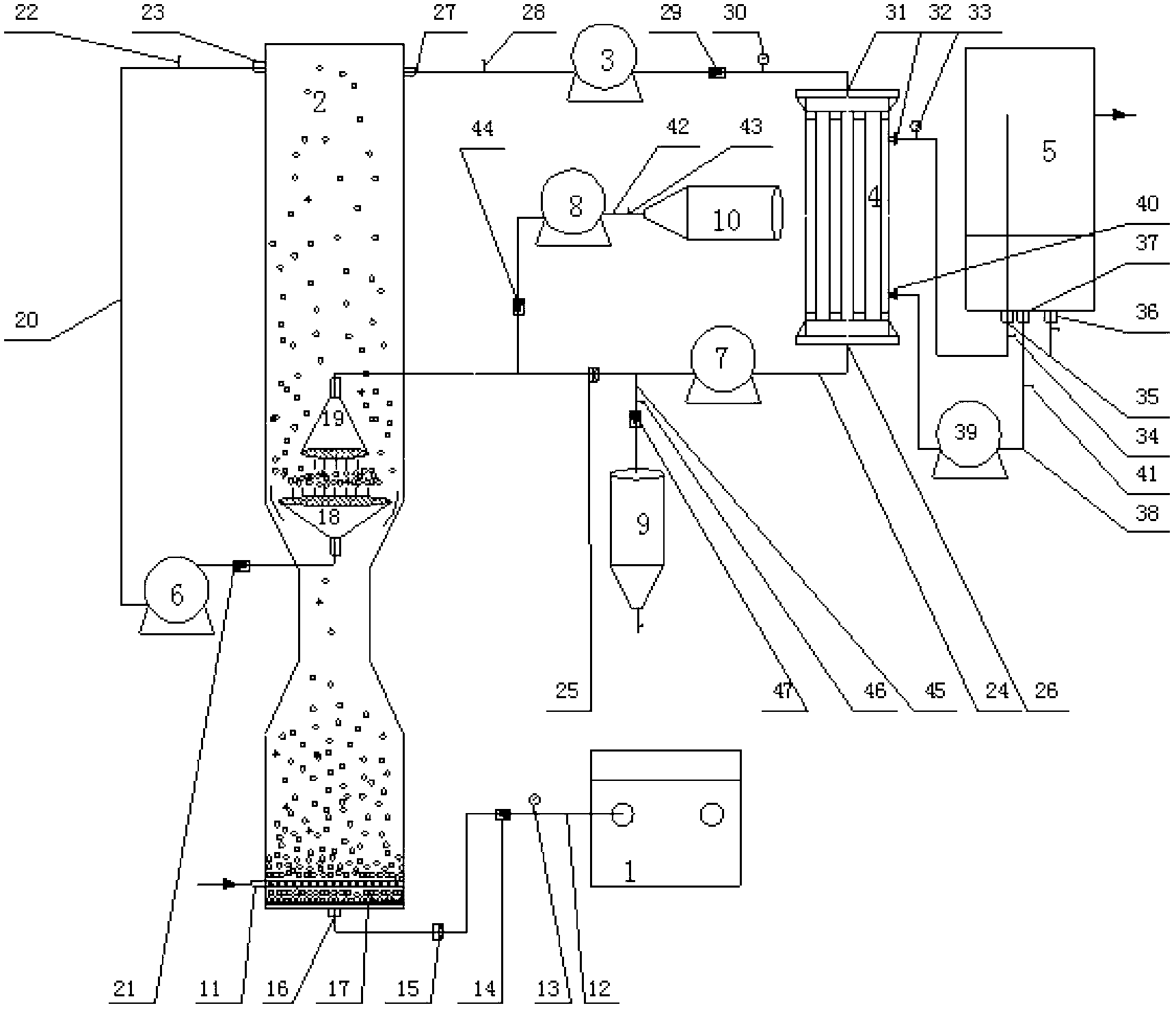

System for deep treatment of coking wastewater by means of catalytic ozonation-ceramic membrane filtration

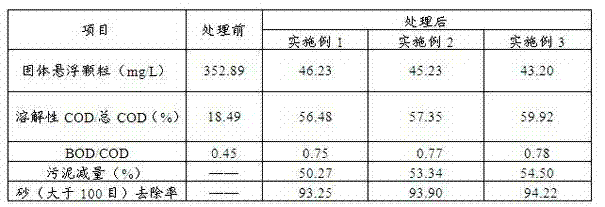

InactiveCN102849875AStrong upward impactInhibition falls intoMultistage water/sewage treatmentParticulatesChemical oxygen demand

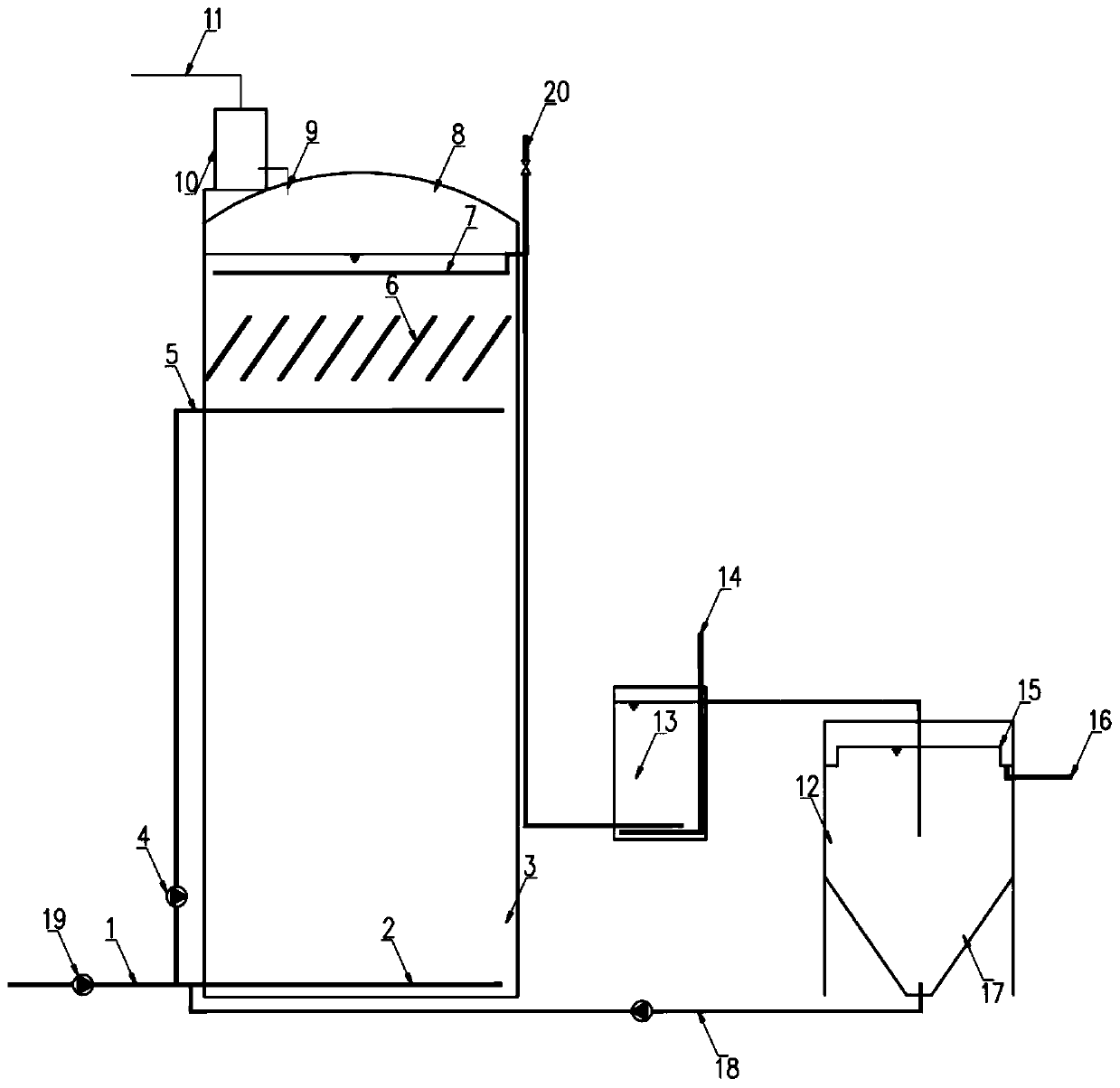

The invention discloses a system for deep treatment of coking wastewater by means of catalytic ozonation-ceramic membrane filtration, mainly consisting of an ozone generator, an ozone oxidation reactor, a booster pump, a ceramic membrane component, a gas-liquid separator, a tail gas absorbing device, a wastewater reflowing pump, a catalyst reflowing pump, a catalyst adding pump, a catalyst outflowing groove, a catalyst adding groove and corresponding pipe fittings, valves and instruments. According to the system, the application of a powder catalyst in a dynamic reactor can be realized due tothe combination of the catalytic ozonation and the ceramic membrane separation; the ozonation and the catalytic ozonation can be guaranteed to be carried out in a single reactor in a segmental way due to the convection current of the reflowing wastewater and the catalyst slurry and the impact of upcurrent; the mass transfer resistance when the ozonation and the catalytic ozonation are independently used can be reduced; the use ratio of hydroxyl free radical and the removal rate of organic matters can be improved; the aims, such as the COD (chemical oxygen demand), the chroma and the turbidityof the deeply-treated coking wastewater, can be achieved; and the problems that the activity is suddenly reduced when the powder catalyst is formed into particulates, the running needs to be suspended when the mass transfer resistance is increased due to the use of the particulate catalyst and the particulate catalyst is changed and the like can be solved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

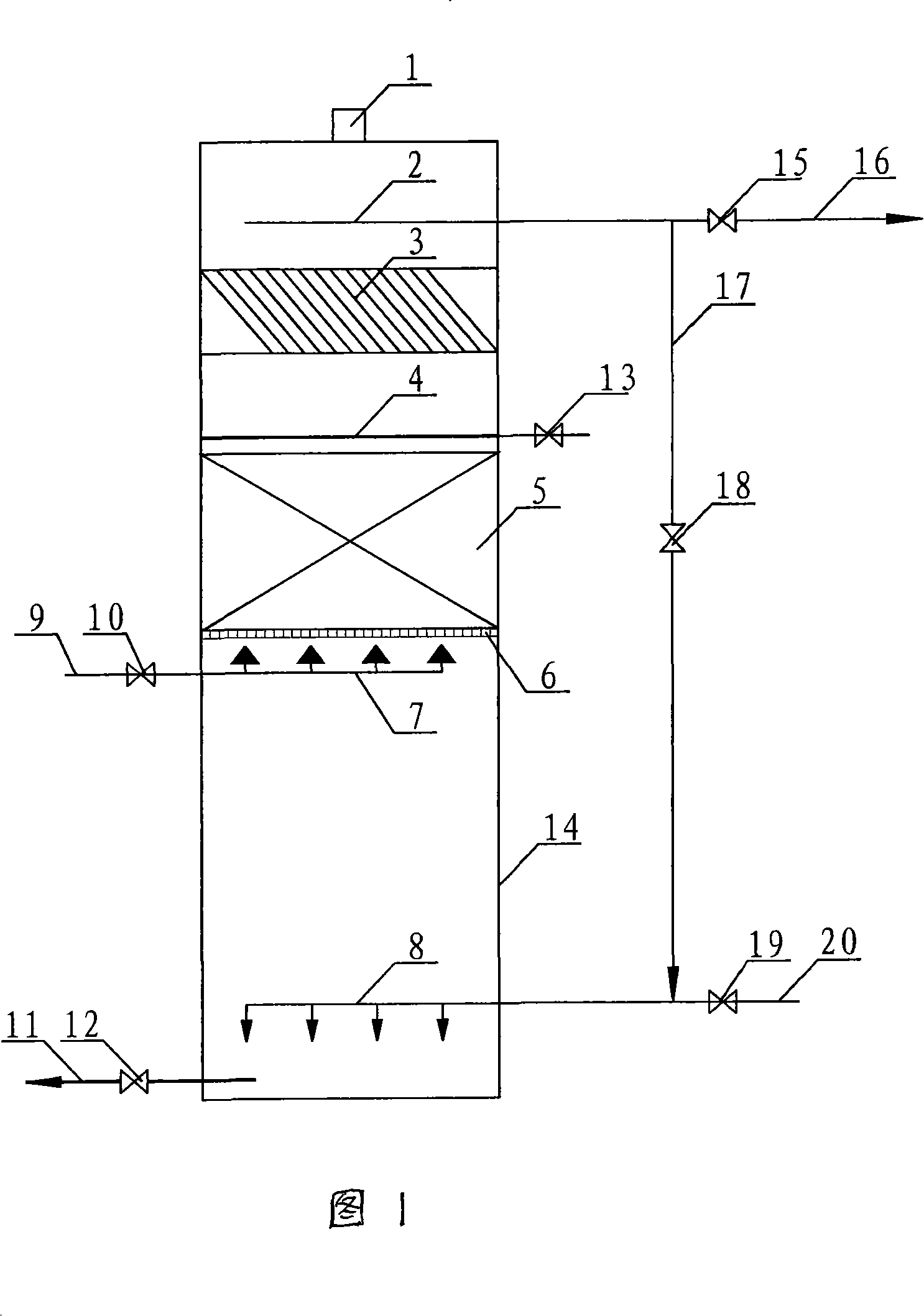

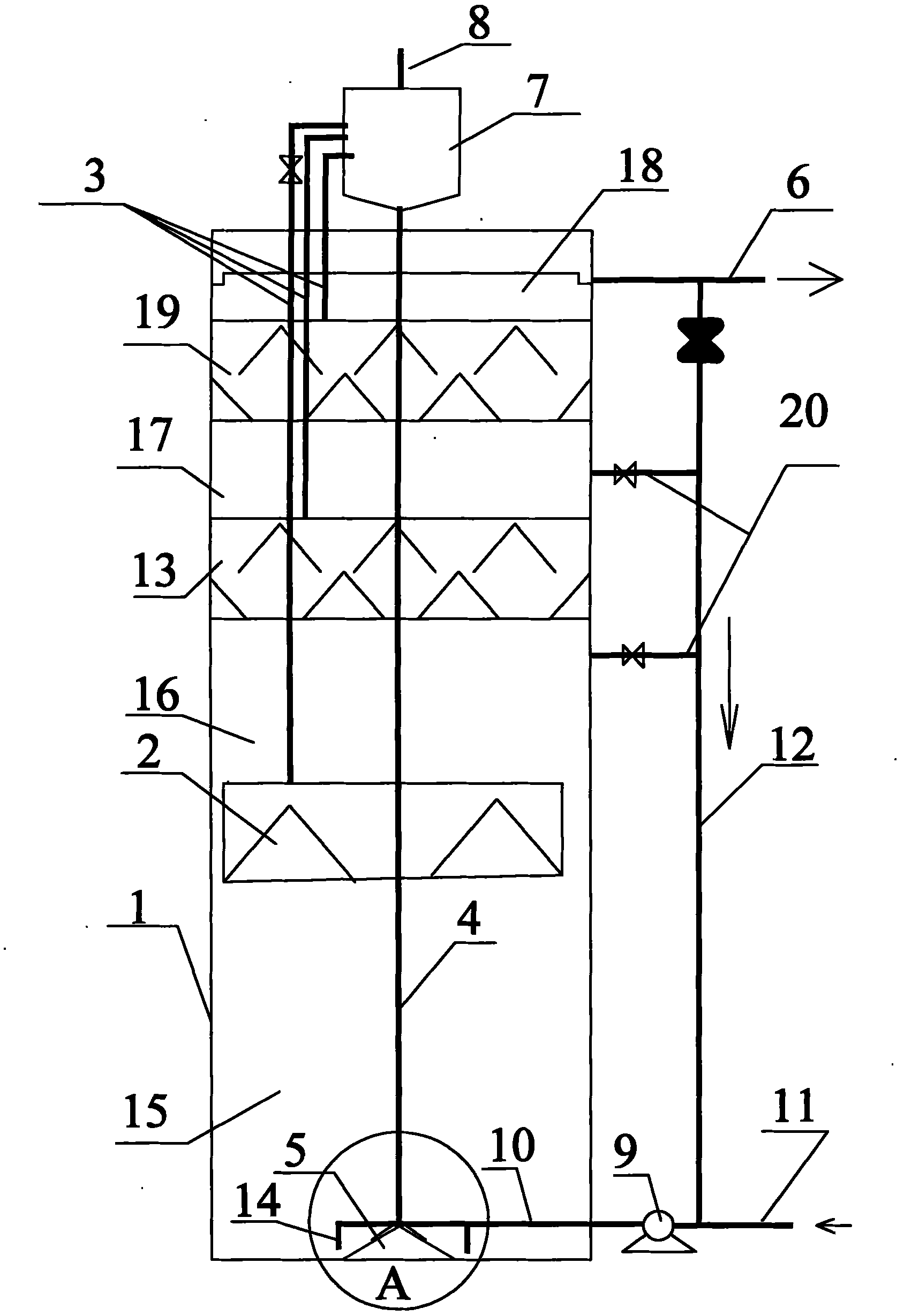

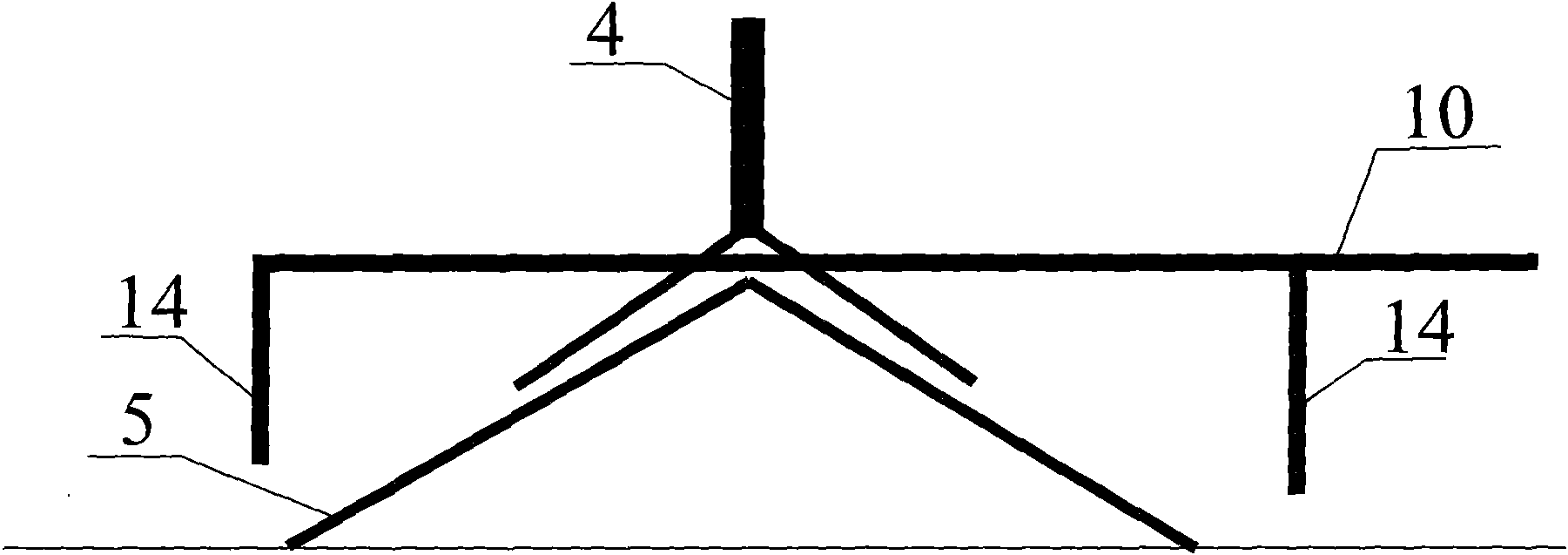

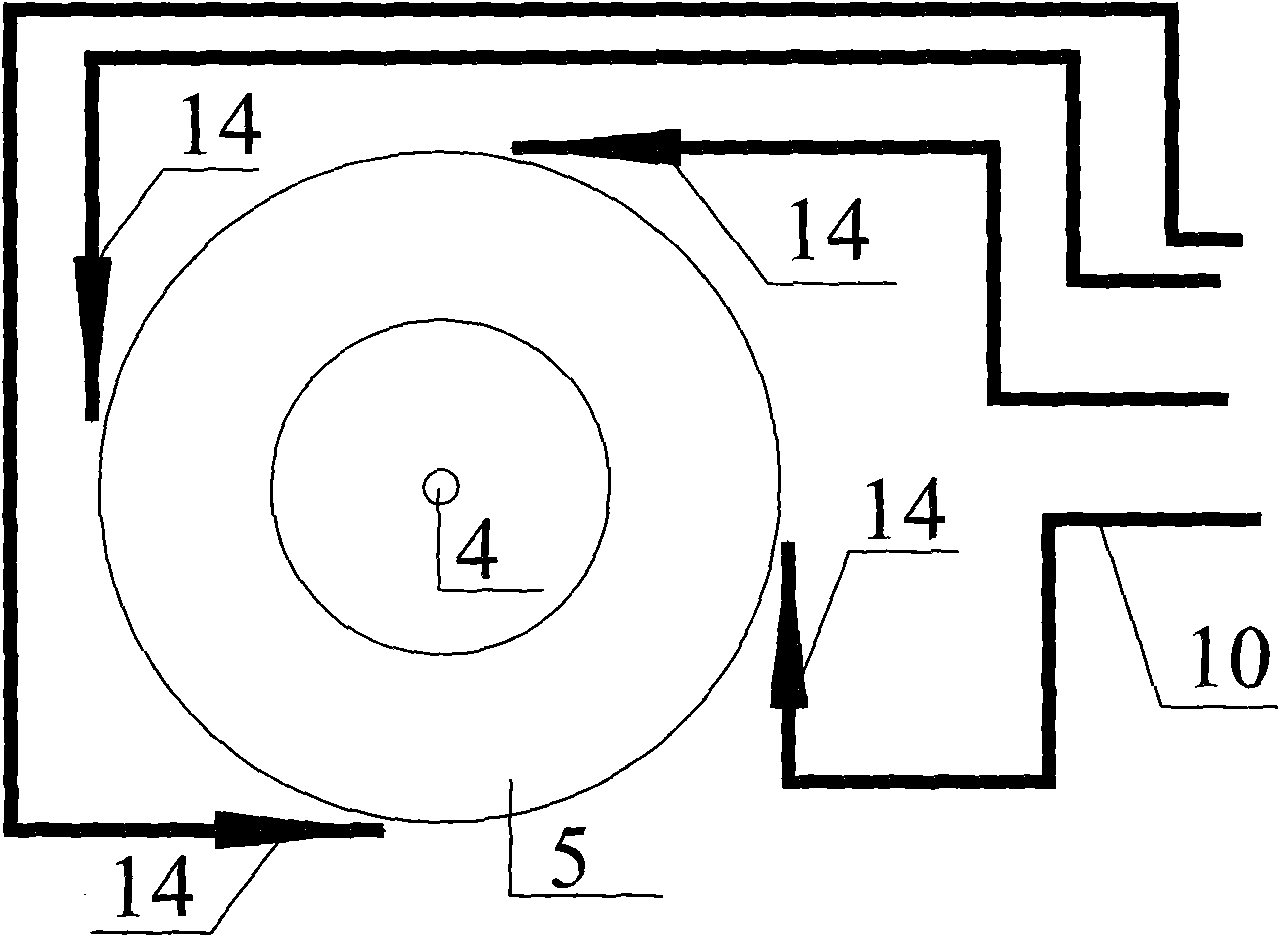

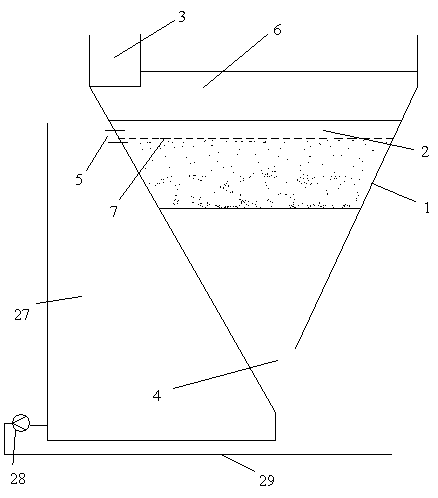

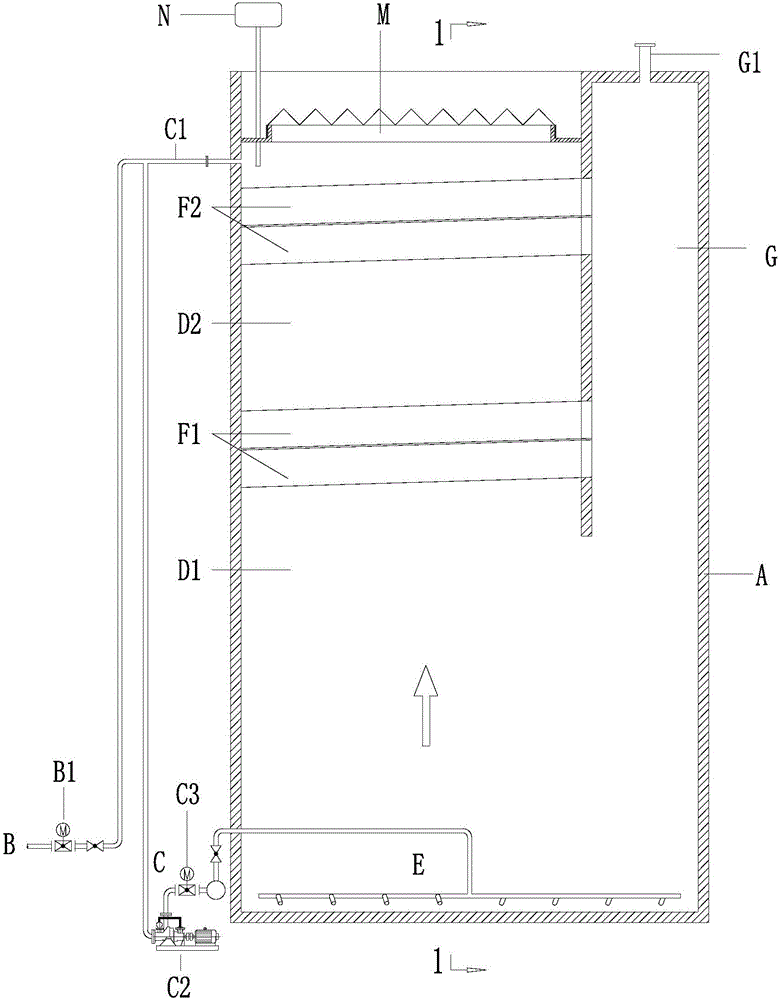

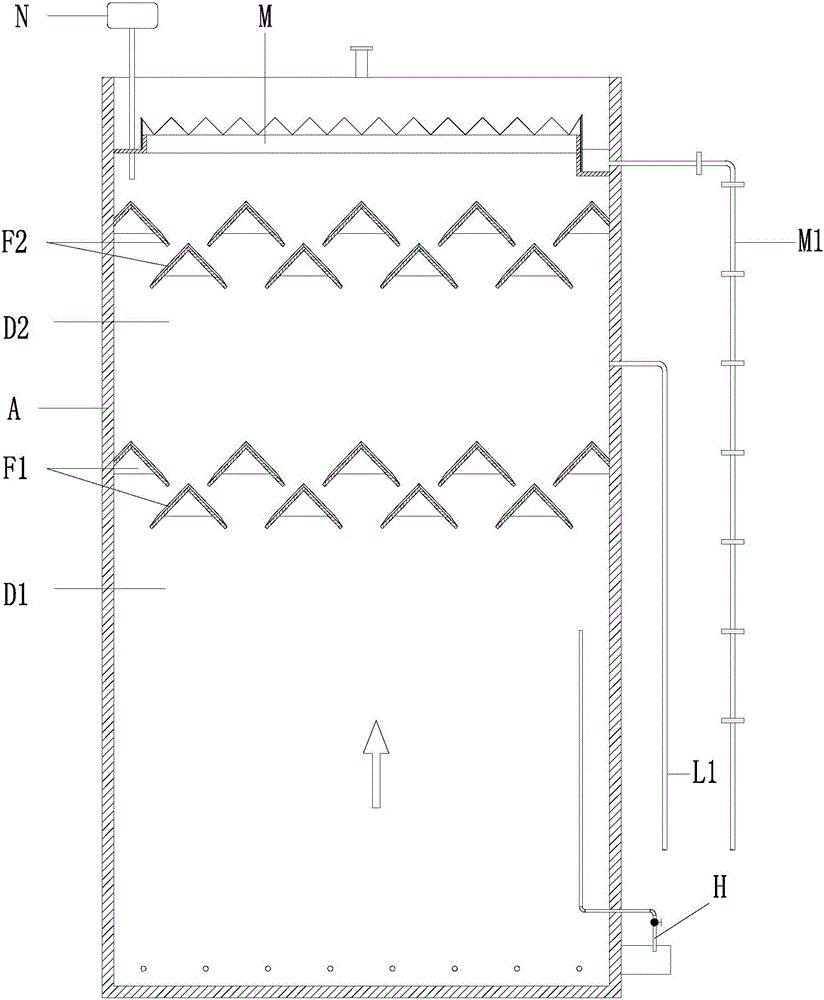

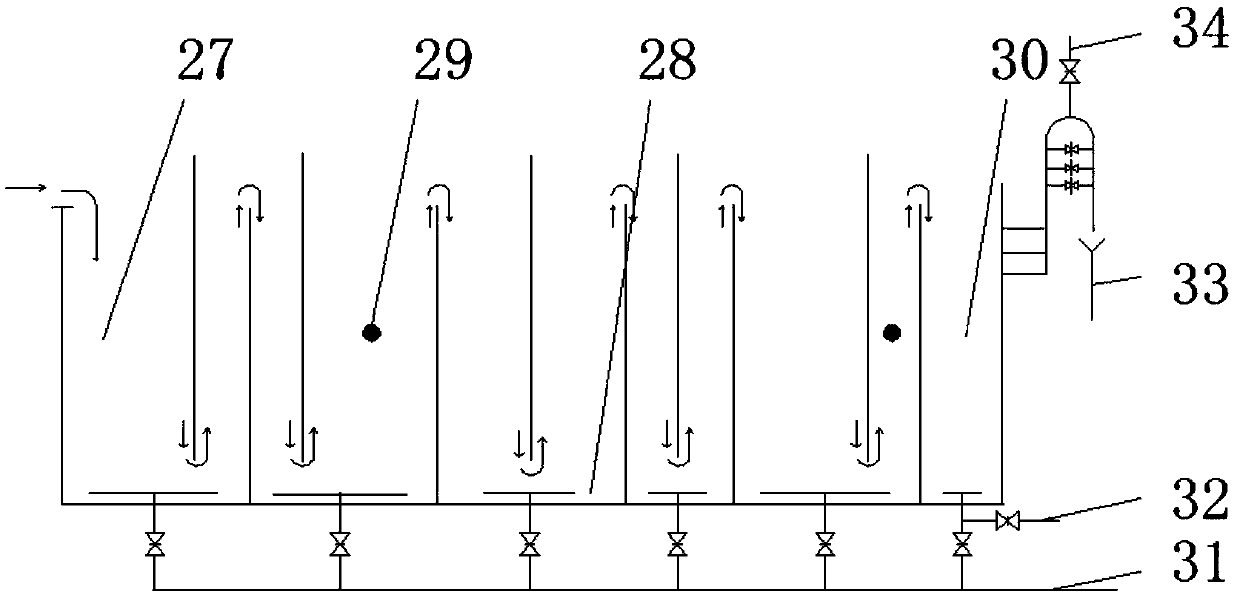

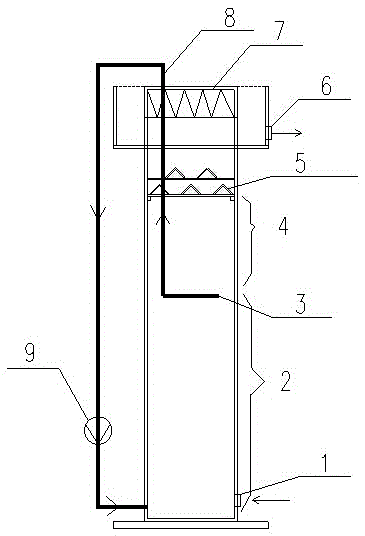

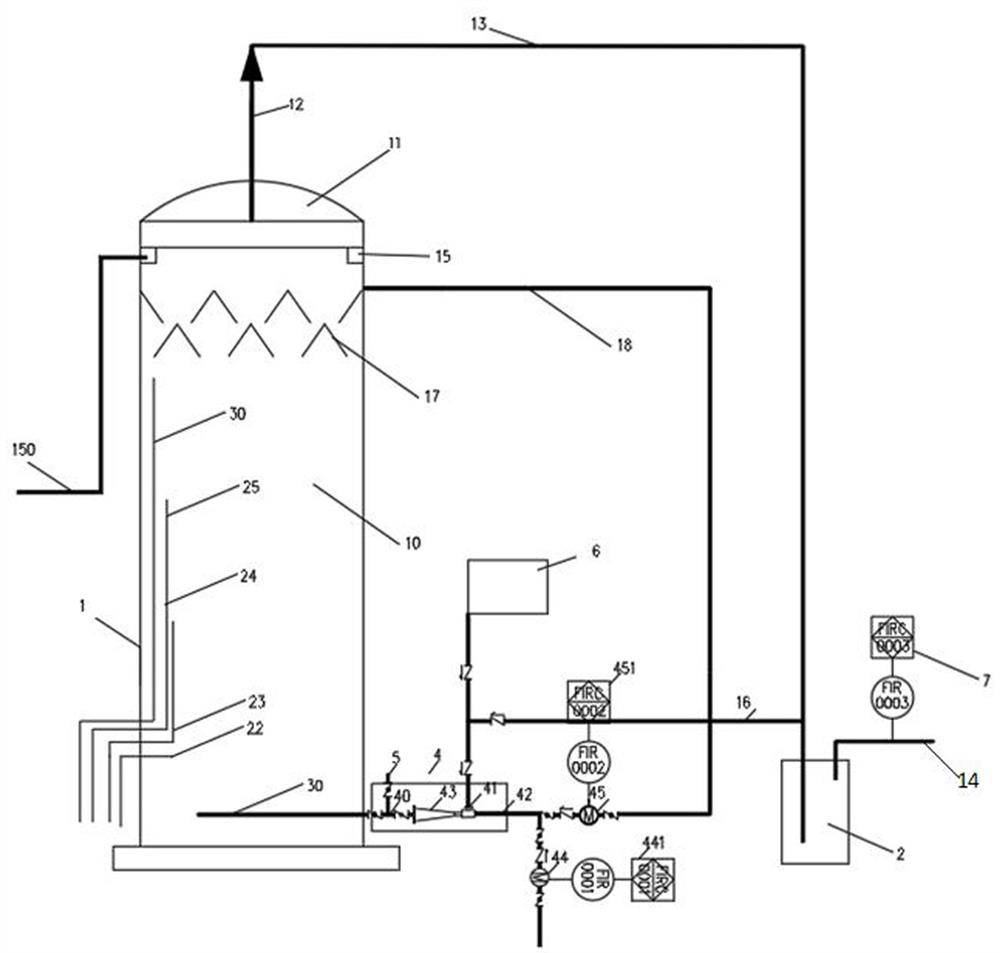

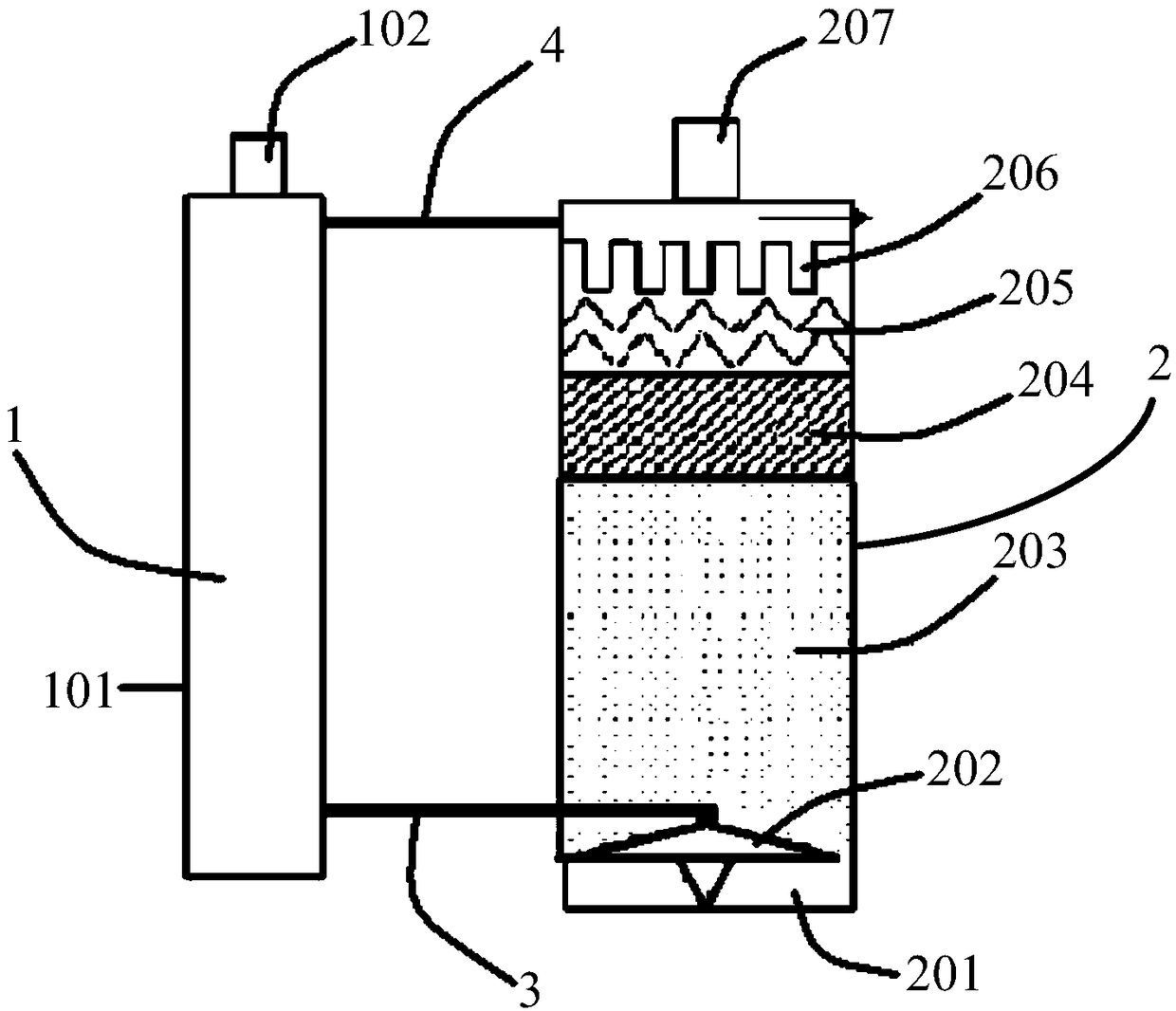

Sewage biochemical treatment equipment

InactiveCN101125706AIncrease the ascending velocityFully contactedSustainable biological treatmentWater/sewage treatment by flocculation/precipitationFiltrationDistributor

The invention provides a sewage biochemical processor, comprising a shell body, a water distributor, an aerator, filling materials, a supporting board and a mud-water-gas separating device that are arranged in the shell body, an inlet tube, an outlet tube and a mud discharging tube that are connected with the shell body and arranged outside the shell body, and gas gathering holes arranged at the top part of the shell body. The invention is characterized in that: the mud-water-gas separating device is formed by inclined boards or inclined tubes that are arranged on the upper part of the shell body in an inclined way and in parallel with each other, a drug feeder is arranged between the filling materials and the mud-water-gas separating device in the shell body and connected with a drug feeding tube arranged in a drug feeding device outside the shell body, and a return tube, the upper end and the lower end of which is communicated with the outlet tube and the inlet tube, is provided. The invention has reasonable and compact structure and compound filling materials that are in reasonable arrangement, thus, biochemical effects of biological oxidation, flocculation and absorption, etc. to the sewage and physical and chemical effects of filtration, micro-flocculation, sedimentation, etc. can be completed in the same tank body, thereby having the advantages of high treatment efficiency, rapid start, low cost, simple operation, easy maintenance and lower operating cost.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

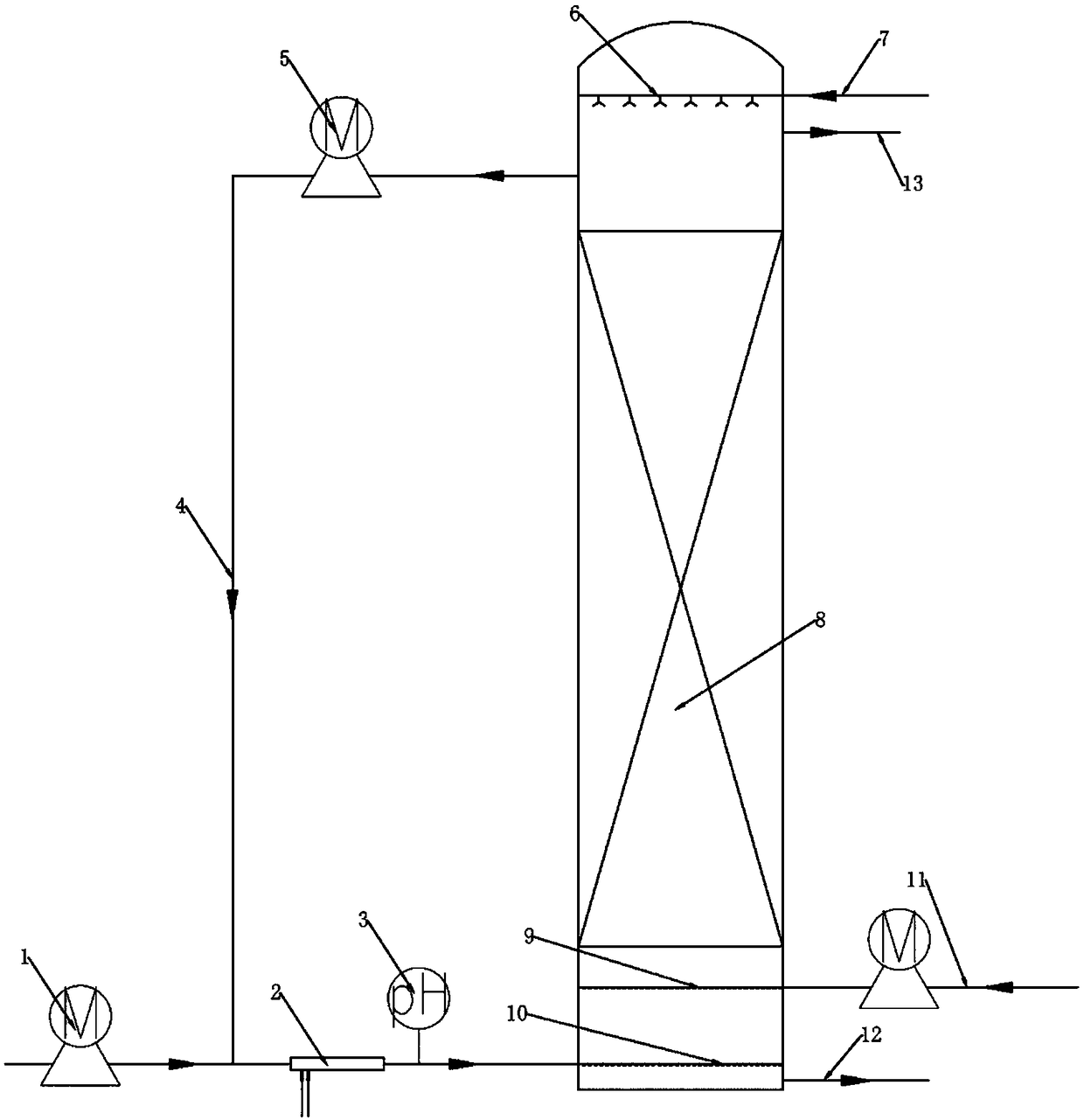

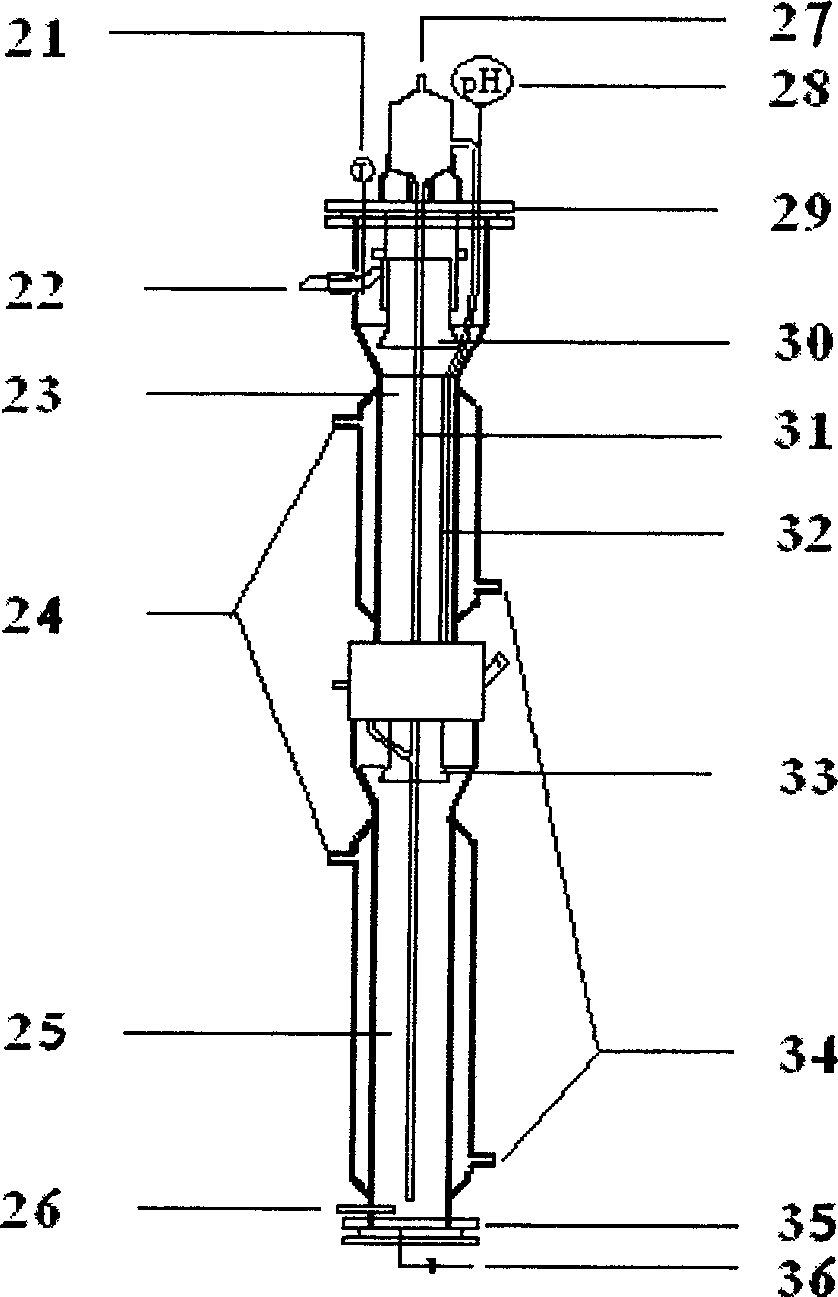

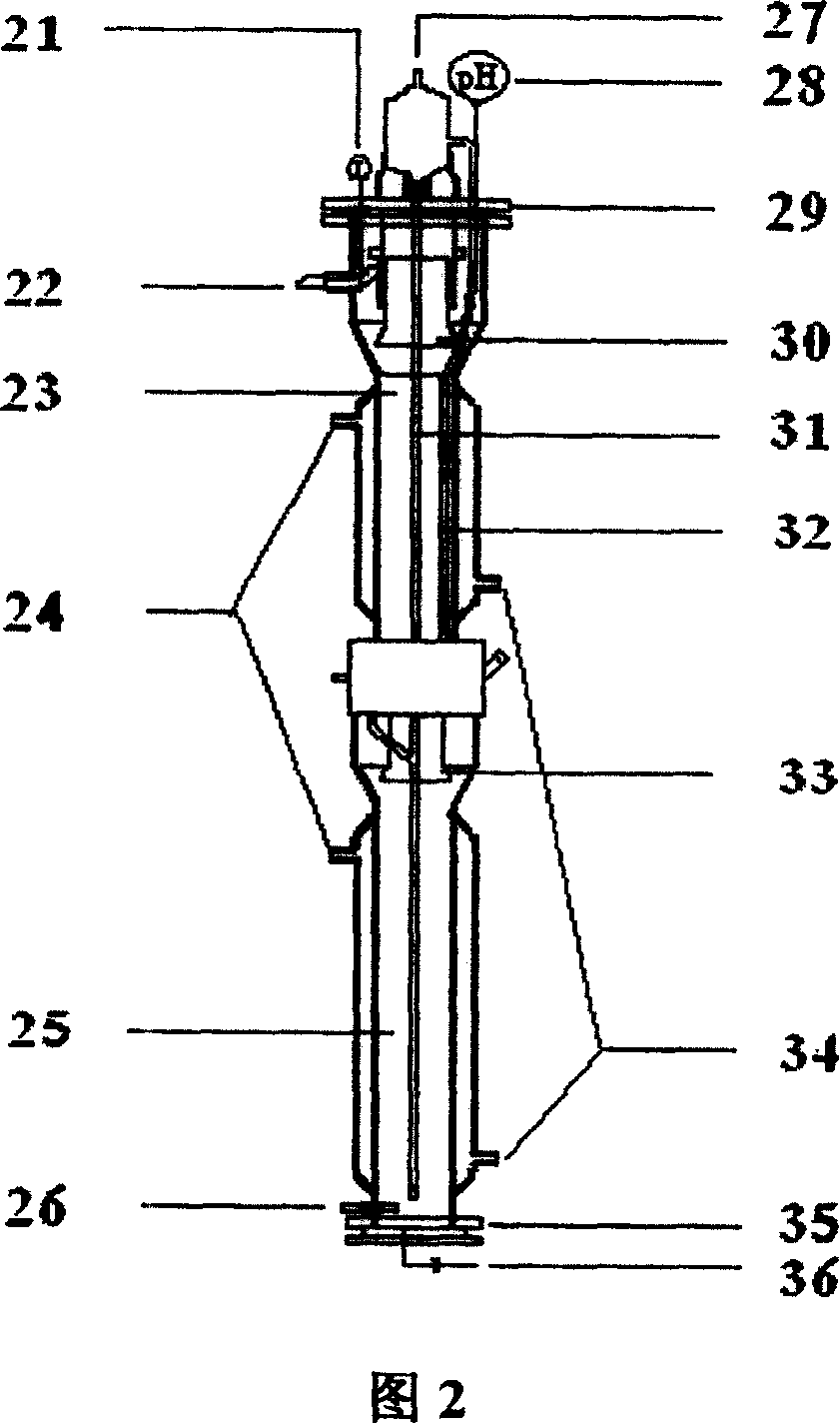

Fenton catalytic oxidation reactor and high-difficulty treatment method for industrial wastewater

InactiveCN108585164AHigh removal rateReduce outputWater treatment compoundsWater/sewage treatment by oxidationRefluxIndustrial effluent

The invention relates to a Fenton catalytic oxidation reactor and a high-difficulty treatment method for industrial wastewater. The Fenton catalytic oxidation reactor comprises a reactor main body; and the interior of the reactor main body is provided with a water inlet distributing pipe, an oxidant adding pipe, a solid phase catalyst layer and a spraying device in sequence from the bottom to thetop, wherein the water inlet distributing pipe is sequentially connected with an online pH meter, a pipeline mixer and a water inlet lifting pump through a wastewater inlet pipe, the oxidant adding pipe is connected with an oxidation medicine adding pump, the spraying device is connected with a flushing water inlet pipeline, a reactor water outlet pipe and a backflow pipeline are arranged from thetop to the bottom between the solid phase catalyst layer and the spraying device, and the backflow pipeline communicates with the wastewater inlet pipe through a reflux pump. The reactor disclosed bythe invention has a pollutant removing rate of the wastewater 30% or more higher than a Fenton fluidized bed under the same water-inlet conditions and the same medicine-adding conditions; and under the condition of a same removing rate, a medicine adding amount of the reactor disclosed by the invention is reduced by 25%-40% than that of a conventional Fenton reactor, and the chemical sludge yieldis reduced by 18% or more.

Owner:华夏碧水环保科技股份有限公司

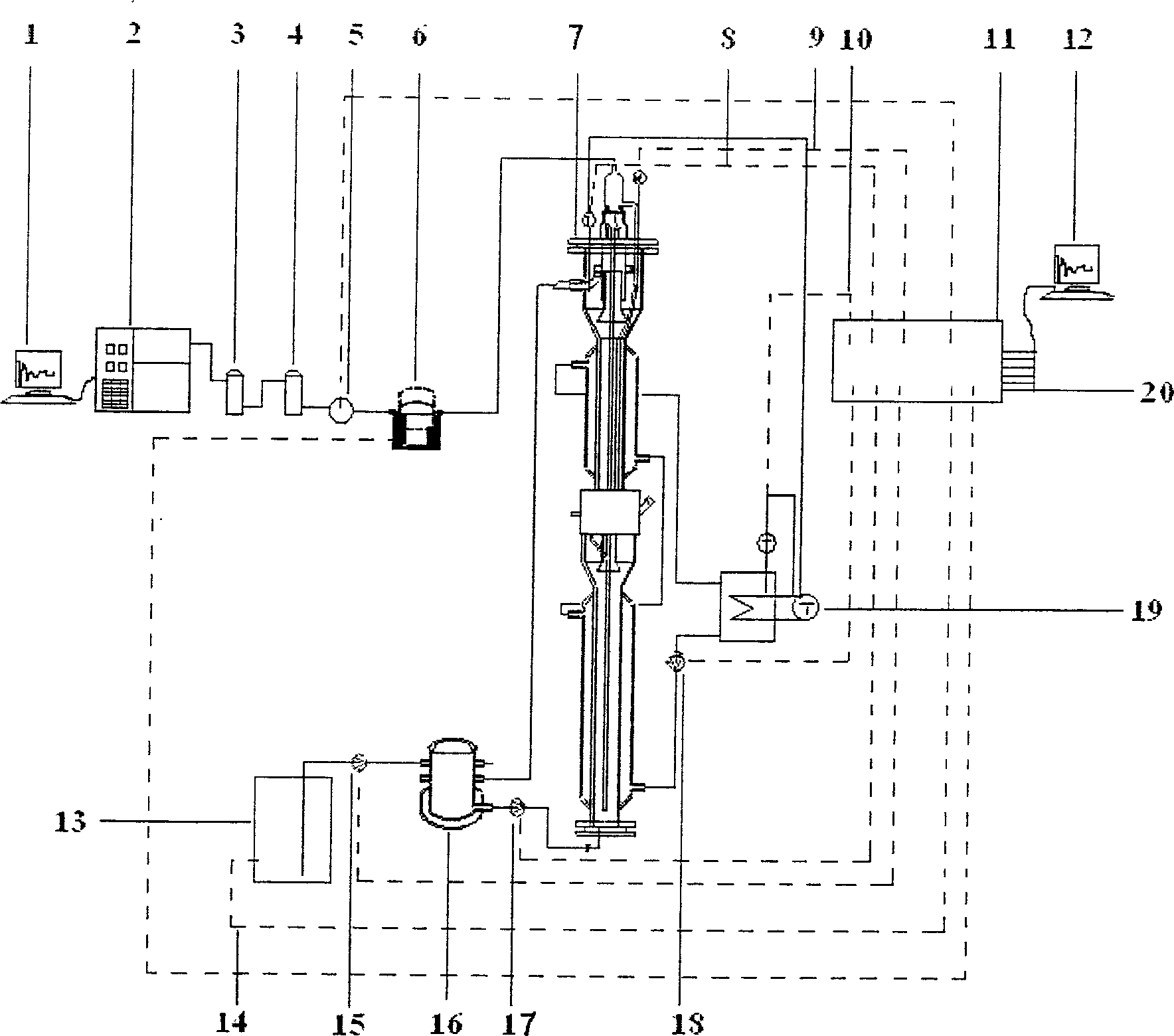

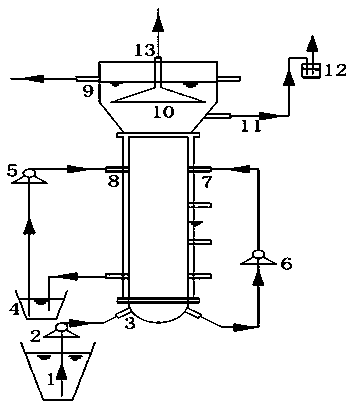

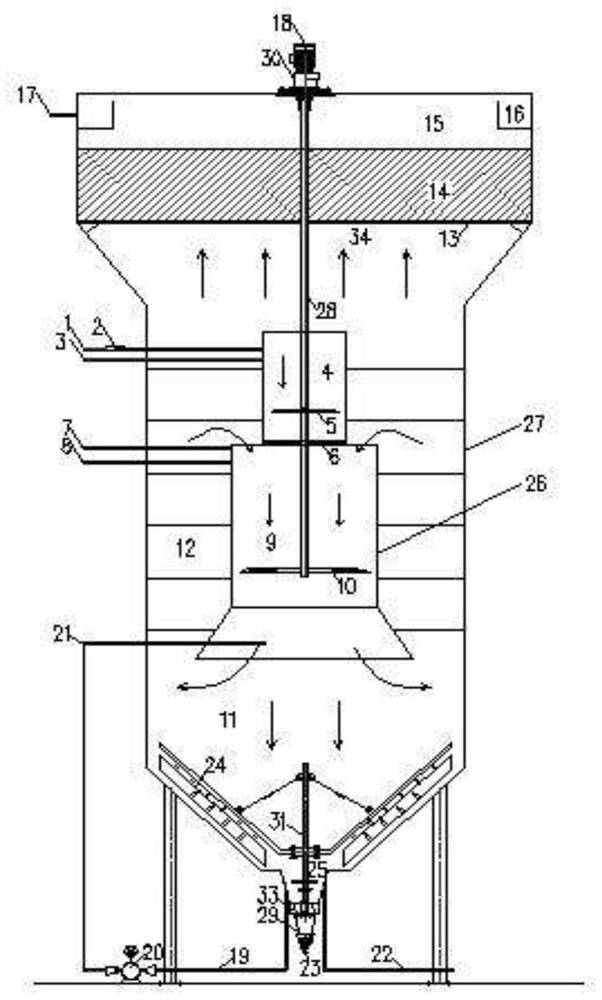

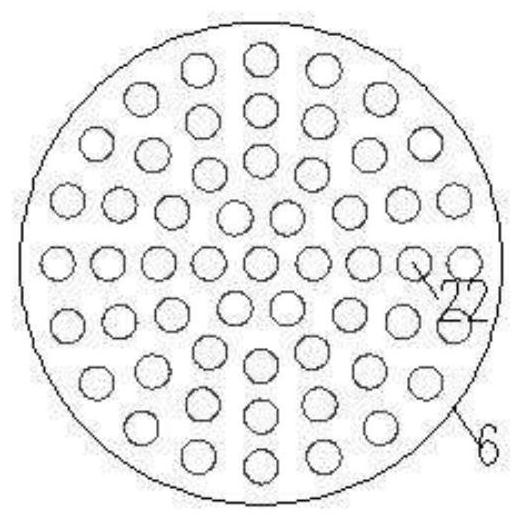

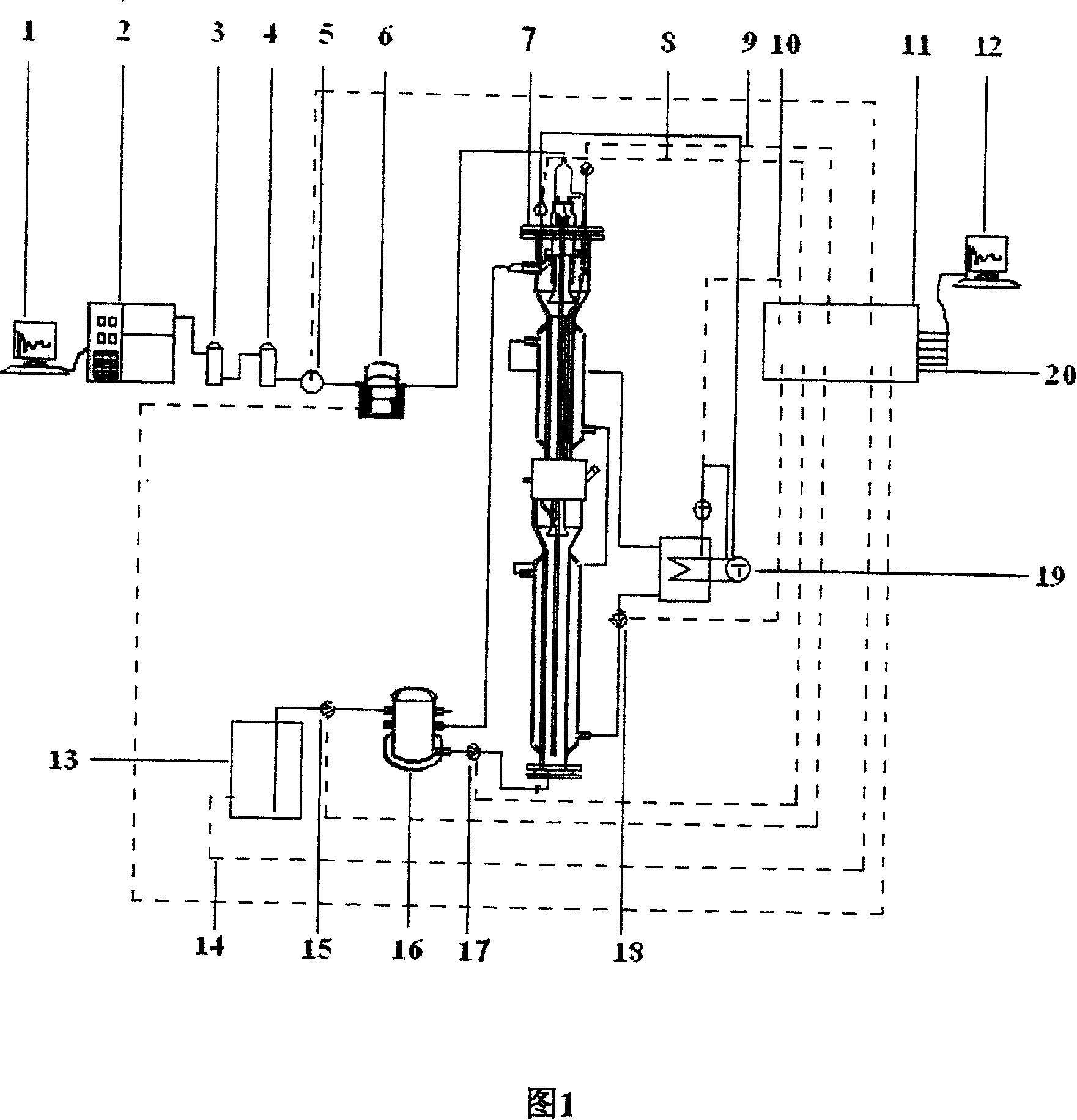

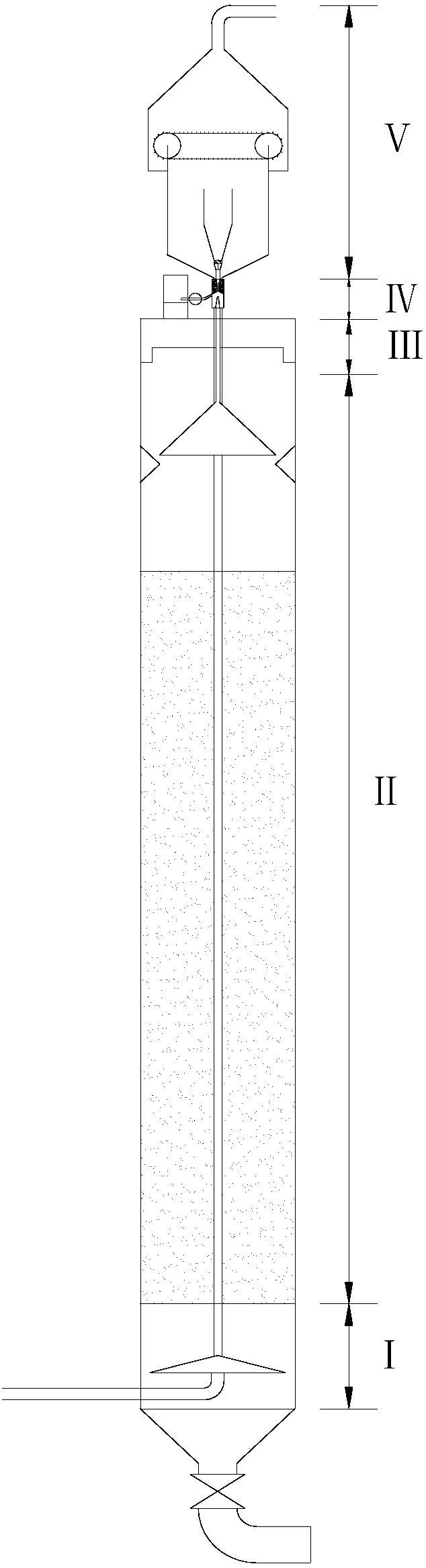

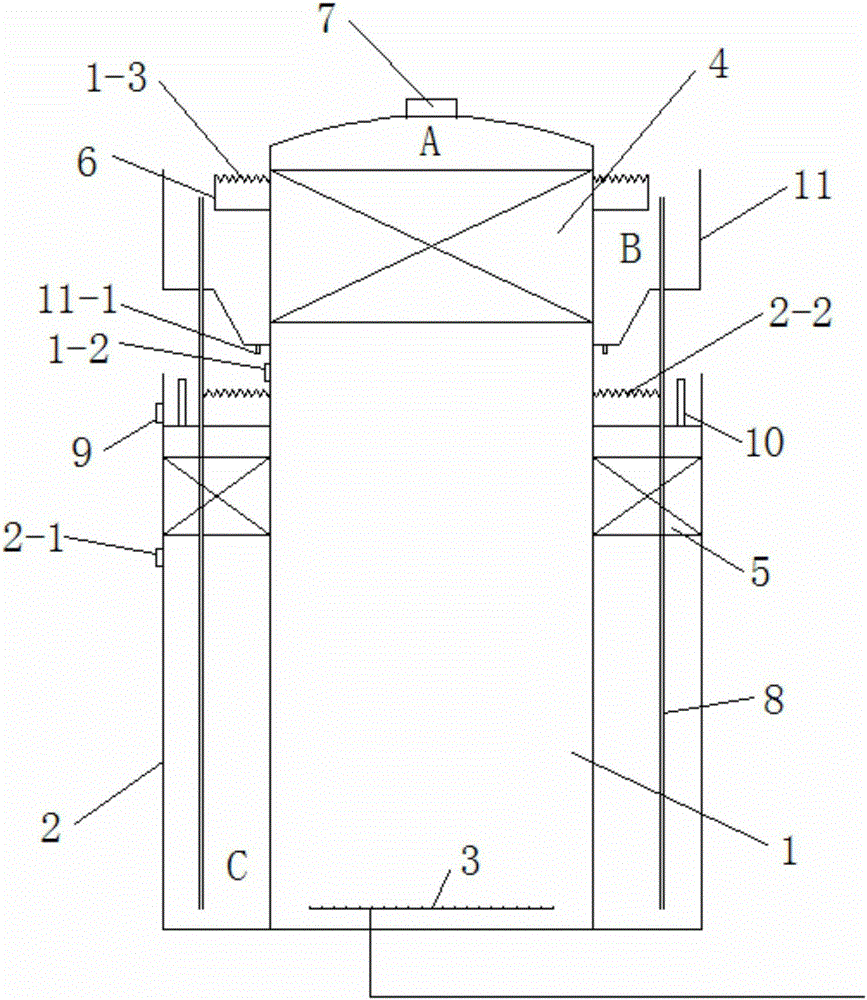

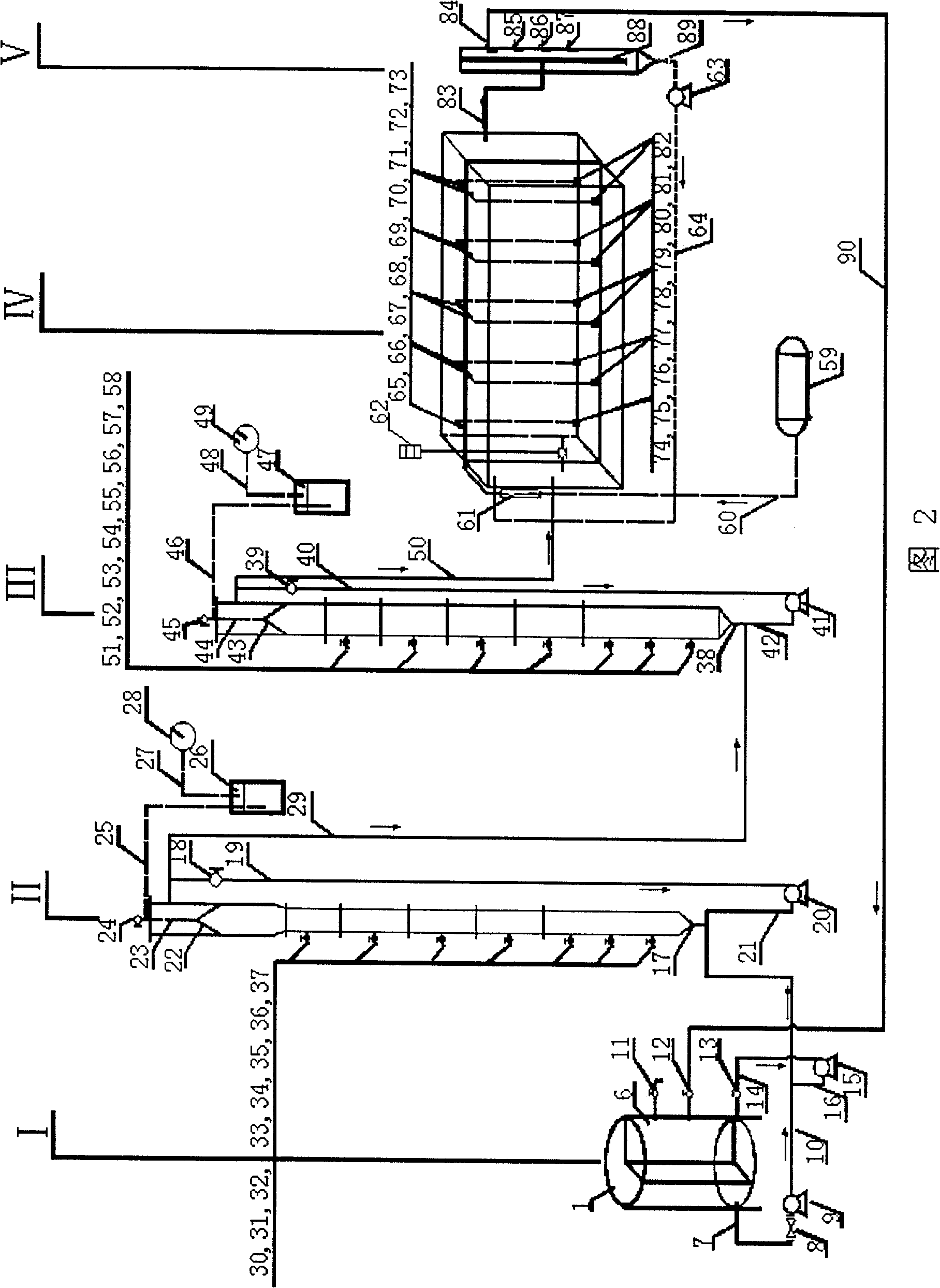

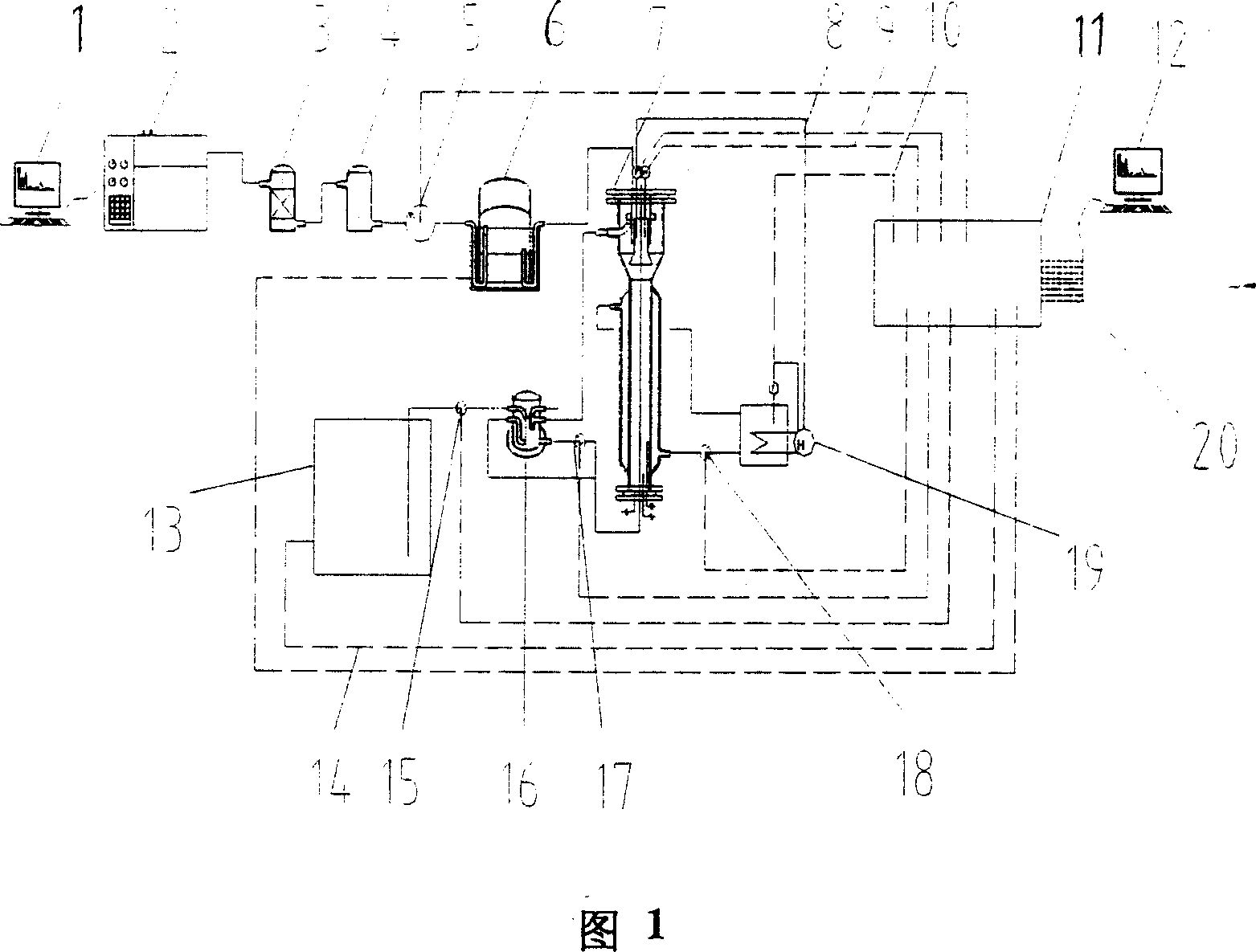

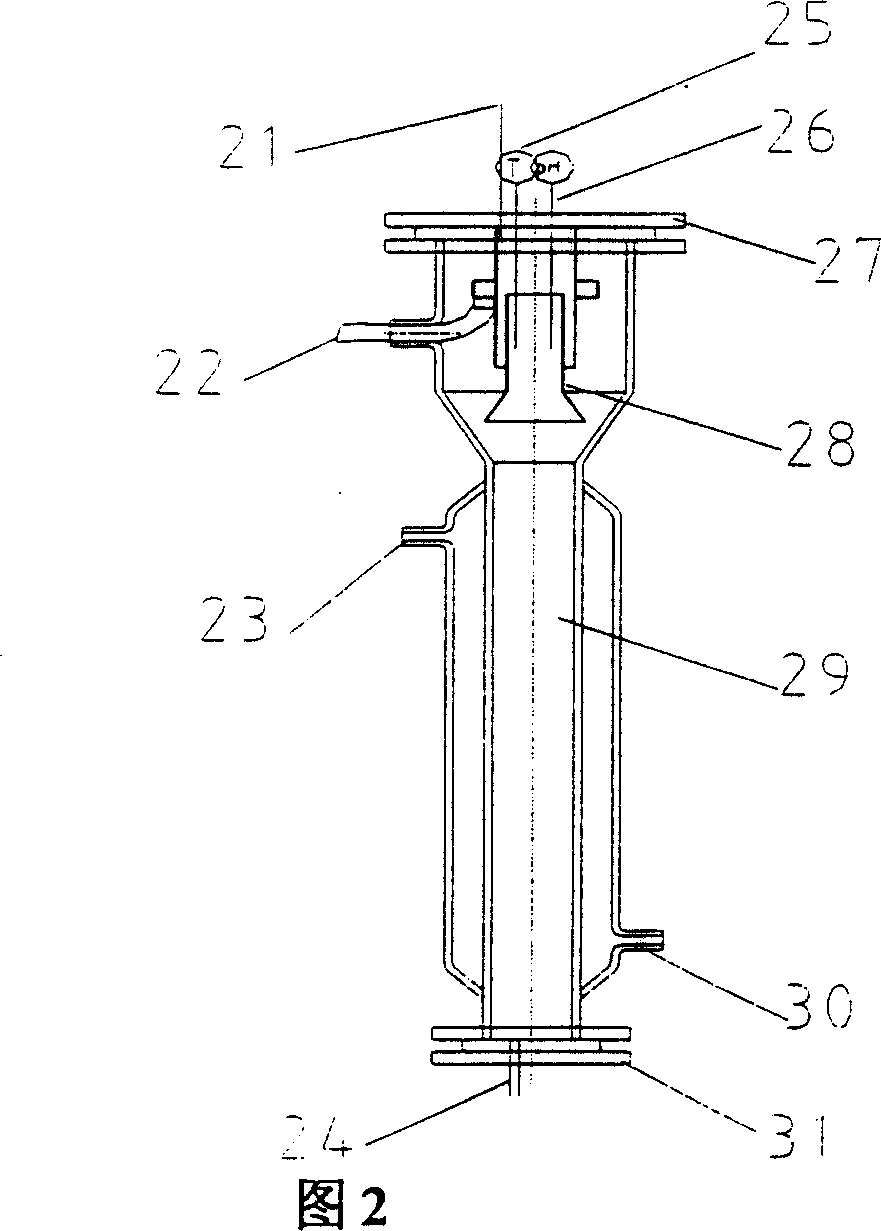

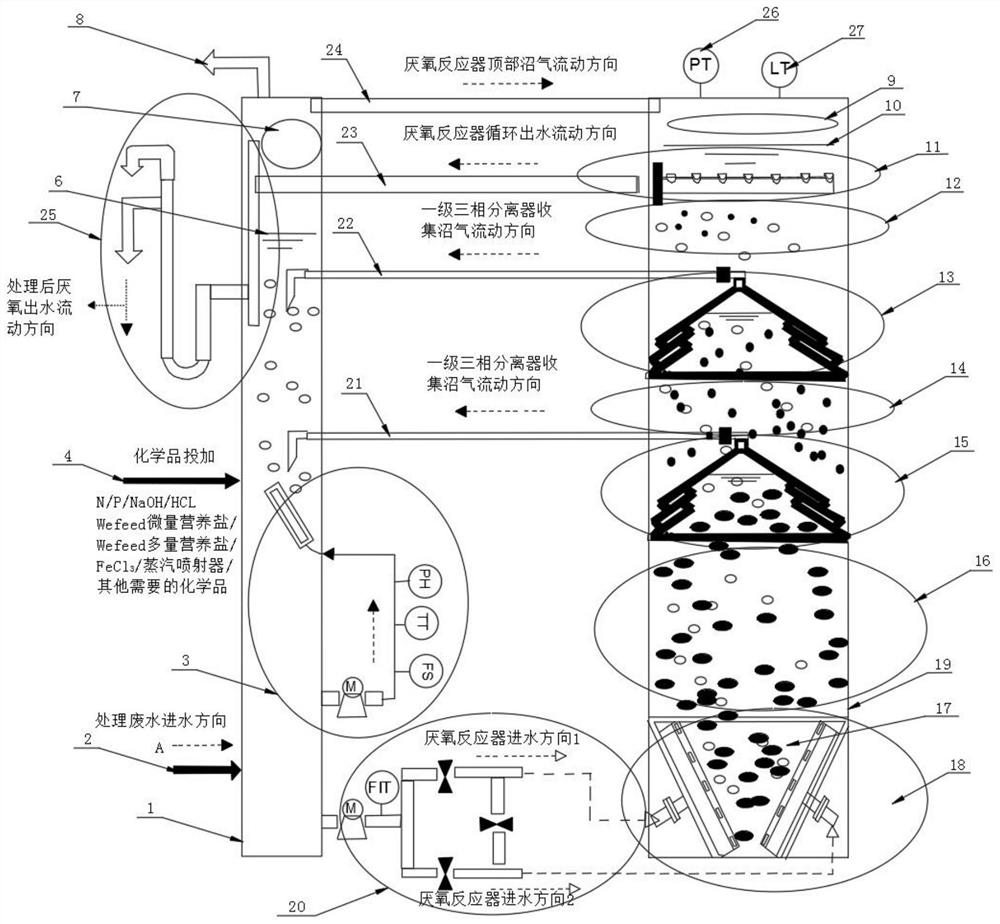

Waste water treatment apparatus for generating firedamp and self-circulating anaerobic reactor thereby

InactiveCN1907886AEasy to handleImprove efficiencyWaste based fuelTreatment with anaerobic digestion processesHigh concentrationLow load

This invention relates to a biogas production wastewater treatment device and a cycle anaerobic reactor used in the device, which is used for environmental engineering. The device invented consists of a new self-cycle anaerobic reactor and a computer control system. The core self-cycle anaerobic reactor comprises two overlapping anaerobic reaction zones in series, wherein the upper parts of the two reaction zone are established gas-solid-liquid three phase separators respectively. The lower reaction zone is at an extreme high load, while the upper reaction zone is at low load. The three-phase separator sludge can be separated and returned to the main separator by the separator and biogas is collected. Internal reactor is capable of forming self-circle liquid, and can strengthen mass transfer process of organism and granular sludge and improve handling capability. The floor place of the three phase separator is small, high concentration of organic wastewater can be treated and biogas as biological energy can be produced. The device can achieve the scale biogas technology and automated production, and is an ideal scale wastewater treatment and gas production equipment.

Owner:WUXI MASHENG ENVIRONMENT ENERGY TECH CO LTD

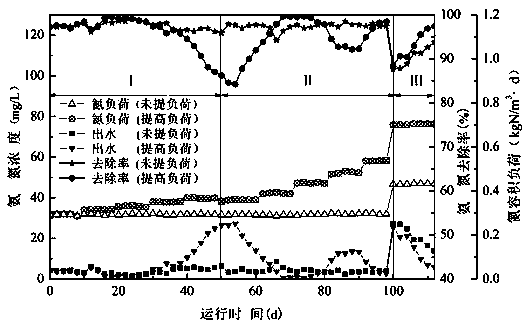

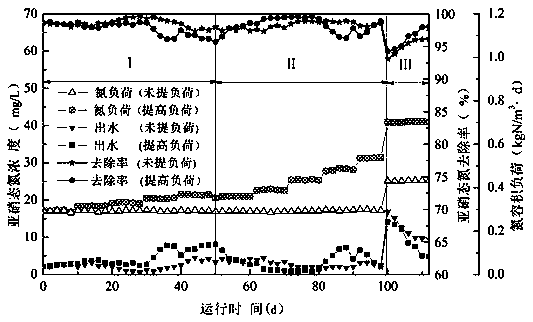

Method for increasing forming speed of anaerobic ammonia oxidation granule sludge

ActiveCN105502652AIncreased nitrogen loadingRapid enrichmentWater contaminantsTreatment with anaerobic digestion processesFecesSubstrate concentration

The invention relates to a method for increasing the forming speed of anaerobic ammonia oxidation granule sludge. The method comprises the steps that practical industrial wastewater with low C / N is taken as a culturing nutrient source of the anaerobic ammonia oxidation granule sludge, and the mass concentration ratio of NH4<+>-N to NO2<->-N of inflow water is controlled to be (1.05-1.42) to 1; a mixture of anaerobic sludge and livestock breeding faeces is taken as inoculated sludge, by means of the modes of changing the substrate concentration of the inflow water, shortening the hydraulic retention time, controlling the granule size, the granule sludge settling speed and MLVSS / MLSS of the anaerobic ammonia oxidation granule sludge and the like, a nitrogen load of anaerobic ammonia oxidation inflow water is changed, the retention and amplification problems of anaerobic ammonia oxidation bacteria can be effectively solved, and by means of granulation of anaerobic ammonia oxidation sludge, the influence of nitrogen removal efficiency dropping caused by environmental changes can be weakened to some extent.

Owner:上海生迈缘生物科技有限公司

Multistage recirculation reactor for anaerobic sludge

InactiveCN102139955AIncrease contact areaWell mixedTreatment with anaerobic digestion processesGuidance systemReflux

The invention relates to a sewage treatment device, in particular relates to a multistage recirculation reactor for anaerobic sludge. The whole reactor is divided into a precipitation zone, an upper reaction zone, a middle reaction zone and a lower reaction zone through an upper three-phase separator, a middle three-phase separator and a lower gas collector which are successively arranged inside the reactor from up to down; the bottom of a gas-liquid separation tank is connected with an inner reflux circulation pipe which stretches to the bottom inside the reactor; the bottom inside the reactor is provided with an inner reflux liquid guiedvane and a water distribution pipe, wherein the inner reflux liquid guiedvane is corresponding to the outlet of the inner reflux circulation pipe, the effluent direction is tangent to the inner reflux liquid guiedvane, and the water distribution pipe is connected with a water inlet pipe II; the lower parts of the upper reaction zone and the middle reaction zone are respectively provided with an external duct; and the outside of the reactor is provided with an outer reflux circulation pipe which is respectively connected with a water outlet pipe, a water inlet pipe I and the external duct. By using the reactor, the external flow of sludge can be effectively prevented, and the sludge can be effectively mixed by utilizing inner and outer double steam guidance systems and the water distribution device.

Owner:SHANDONG JIANZHU UNIV

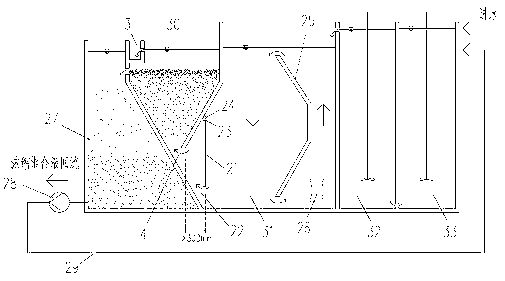

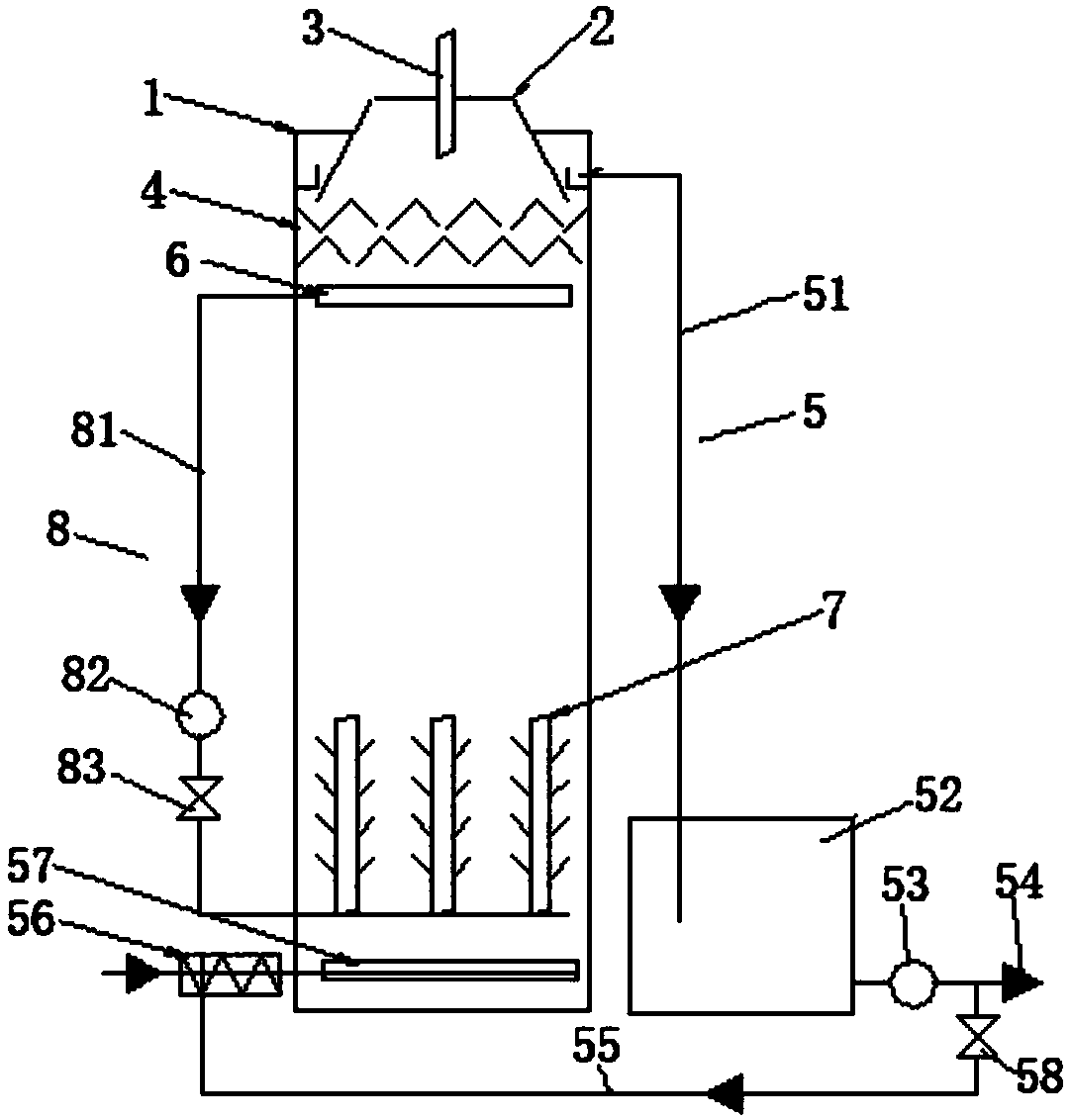

Integration device for sewage treatment bio-diatomite suspension filter bed

ActiveCN103058378AAvoid destructionAchieve separationTreatment with aerobic and anaerobic processesLoose filtering material filtersWater flowEngineering

The invention provides an integration device for a sewage treatment bio-diatomite suspension filter bed. The integration device comprises an anoxic section, an anaerobic section, an aerobic section, a solid-liquid suspension filter separation section and a forced balance section, wherein a gas-water separation section is arranged between the aerobic section and the solid-liquid suspension filter separation section; the aerobic section is provided with a forced stirring guide plate which comprises an upper section, a middle section and a lower section; and compared with the upper and lower sections, the middle section is narrower than one side surface of the aerobic section, so that the ascending velocity of water flow is accelerated. A concentration diffusion communicating groove is formed in the solid-liquid suspension filter separation section and is used for leading the concentrated solution of the bio-diatomite suspended solid from the suspension filter bed; and the bio-diatomite suspended solid layer is stabilized around the height of the concentration diffusion communicating groove. The forced balance zone is arranged at the rear end of the solid-liquid suspension filter separation section; the bio-diatomite suspended solid enters the forced balance section by the concentration diffusion communicating groove; and the bio-diatomite suspended solid is reflowed to the front at the bottom of the forced balance zone by a reflowing pipeline at the bottom of the forced balance section so as to be recycled.

Owner:TONGJI UNIV +1

Anaerobic reactor for treating waste water containing emulsified liquid

InactiveCN102229447AReduce water distribution areaEven distribution of waterTreatment with anaerobic digestion processesChemical oxygen demandWater quality

The invention relates to an anaerobic reactor for treating waste water containing emulsified liquid. The height-diameter ratio of a tank body is greater than 3; an inlet water distributor is arranged at the bottom part of the tank body; the anaerobic reactor is provided with a granular sludge region which is suspended at the lower part of the tank body and a floccus sludge region which is suspended at the upper part of the granular sludge region; the surface loading of a deposit chamber of a triphase separator is not higher than 0.5m<3> / m<2>.h; and an outer circulating system is adopted. Because of the coexistence of the granular sludge region and the floccus sludge region of the anaerobic reactor, the COD (chemical oxygen demand) removal rate of the waste water containing the emulsified liquid is improved to more than 60%, the subsequent waste water processing technology pressure is reduced, the total effluent quality of a whole waste water treating system can reach the standard, and the operation cost of the whole waste water treating system is lowered.

Owner:SHIYAN BISHUIYUAN ENVIRONMENTAL PROTECTION TECH CENT

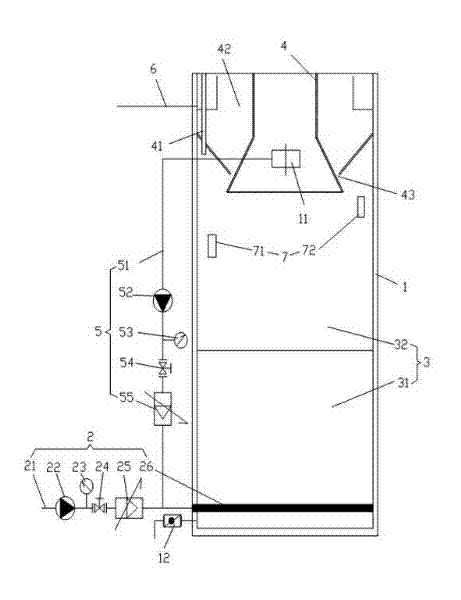

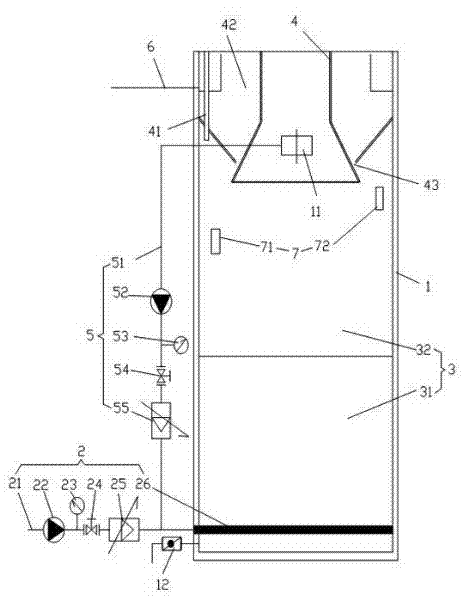

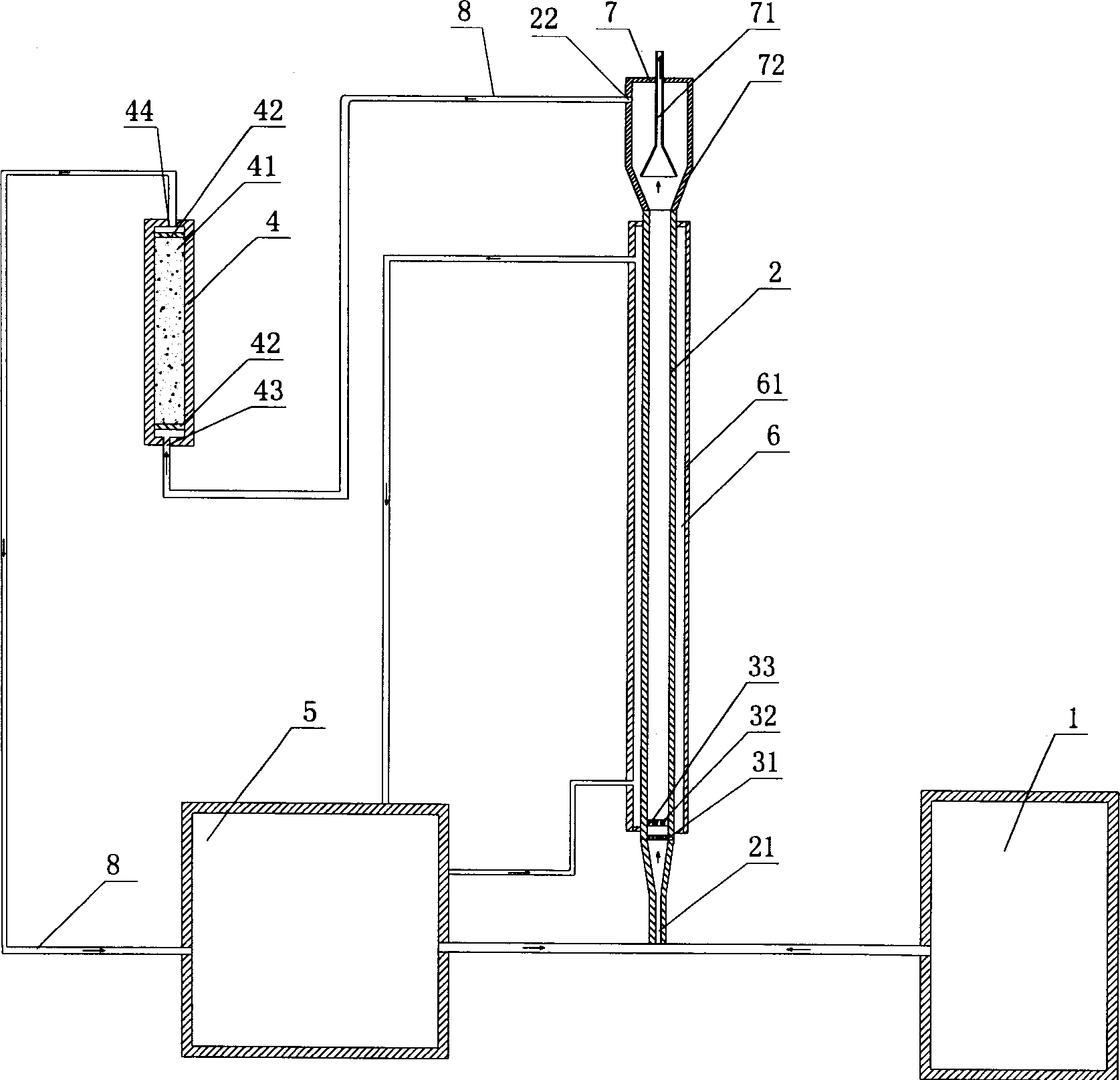

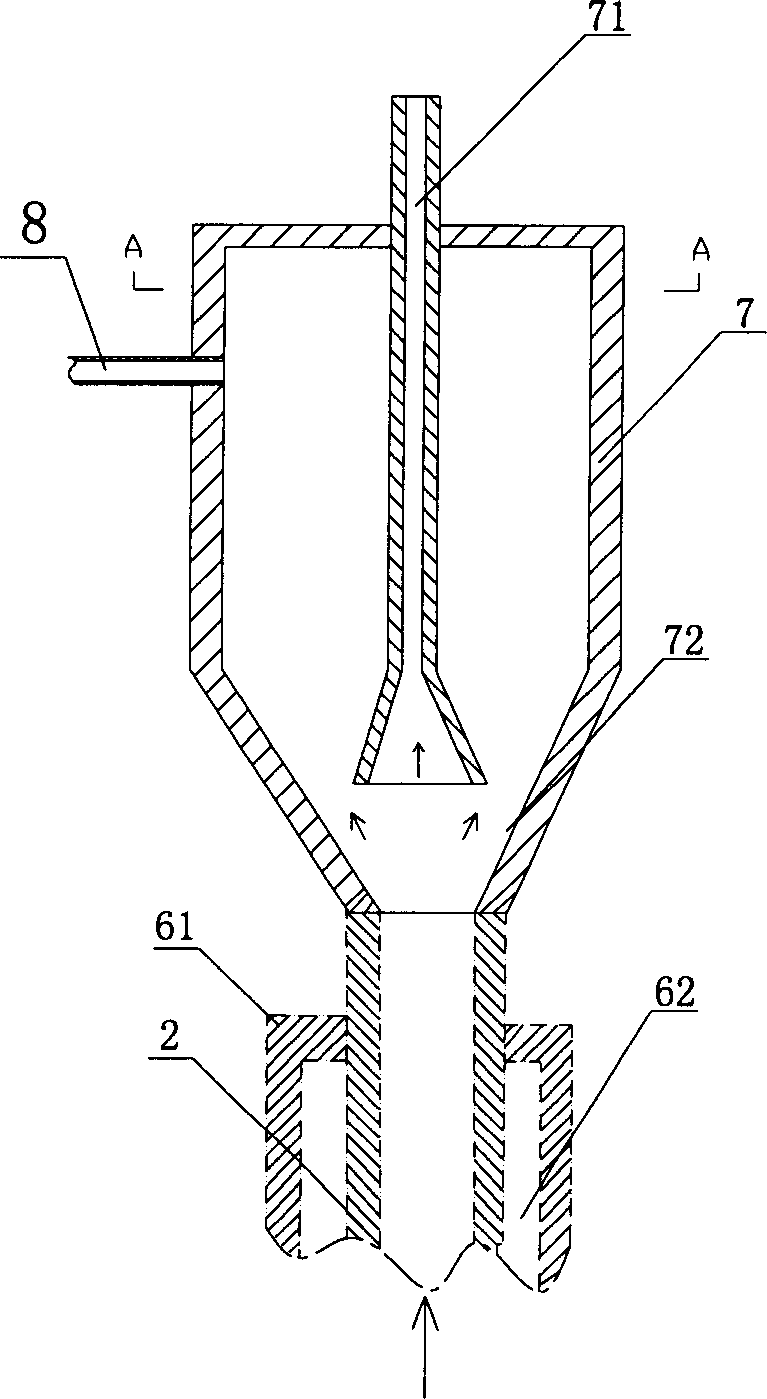

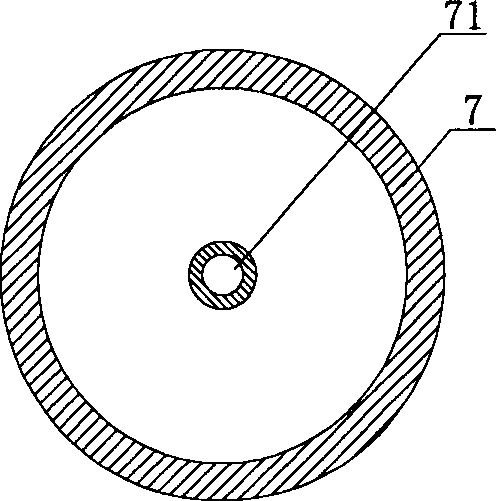

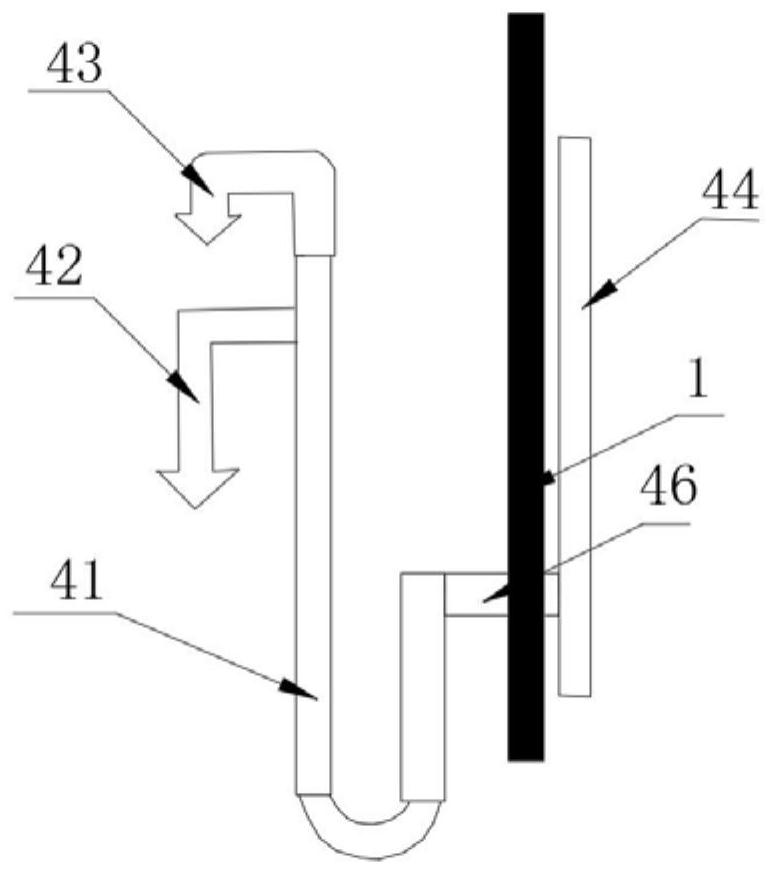

Novel anaerobic reactor based on UASB and treatment system

PendingCN109761449AIncrease the ascending velocityImprove mass transfer effectMultistage water/sewage treatmentSiphonControl system

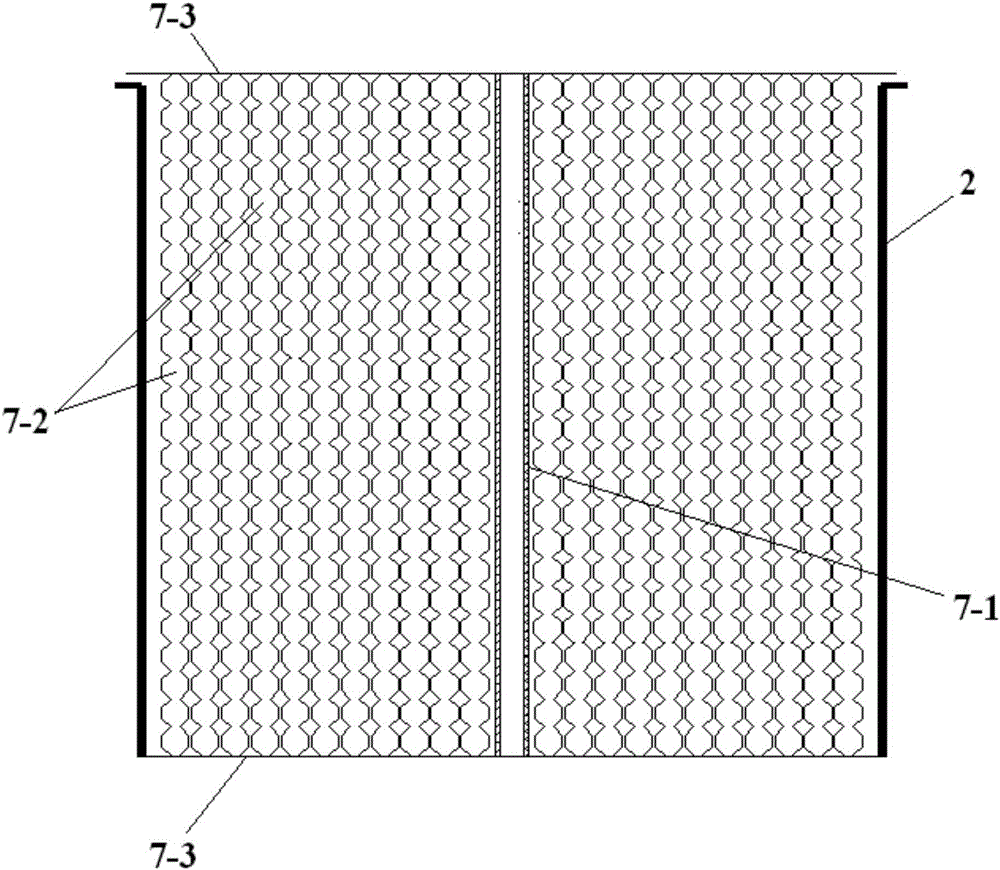

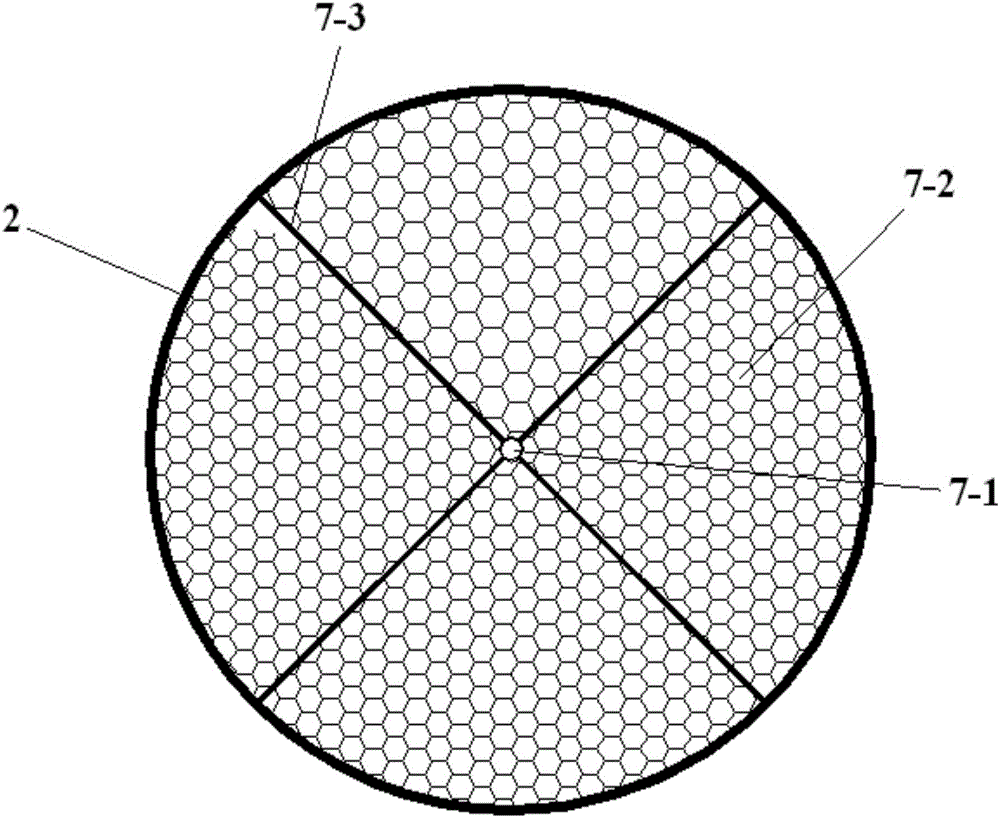

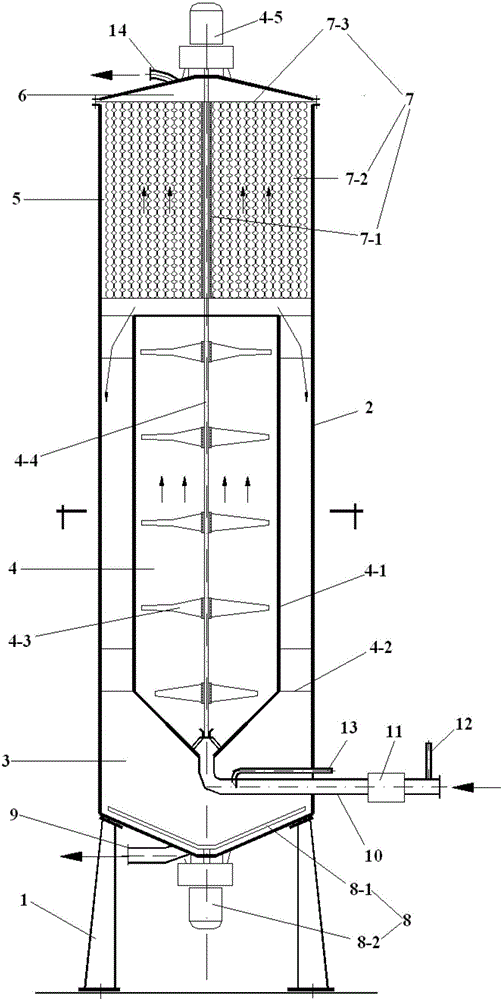

The invention discloses a novel anaerobic reactor based on UASB and a treatment system. The novel anaerobic reactor comprises a novel anaerobic reactor body, a degassing pool, a precipitation pool andan automatic monitoring system, wherein an anaerobic reactor control system realizes fully automatic control through information such as temperature and flow rate; the anaerobic reactor body and thedegassing precipitation pool consist of a water inlet pipe, water distribution pipes, a tank body, a circulation system, a corrugated board separator, an arch top air seal, a water sealing tank, a siphon water outlet system and a degassing precipitation pool. The bottom water distribution pipes are used for water distribution; the uniform water inlet at the bottom can be effectively ensured; the sludge deposition probability due to nonuniform water distribution is reduced; a low-region circulation system is added, so that the low-region high flow rate is realized; the mass transfer effect is effectively improved; contaminants and particle mud are in sufficient contact; the operation efficiency of the reactor is enhanced; a gas collection mode of a inclined plate and the arch top air seal is used, so that the investment cost is reduced; meanwhile, the marsh gas collection efficiency is improved; through the arrangement of the degassing precipitation pool, lost sludge in the anaerobic reactor can be supplemented, and the stable operation is ensured.

Owner:河南省绿韵环保科技有限公司

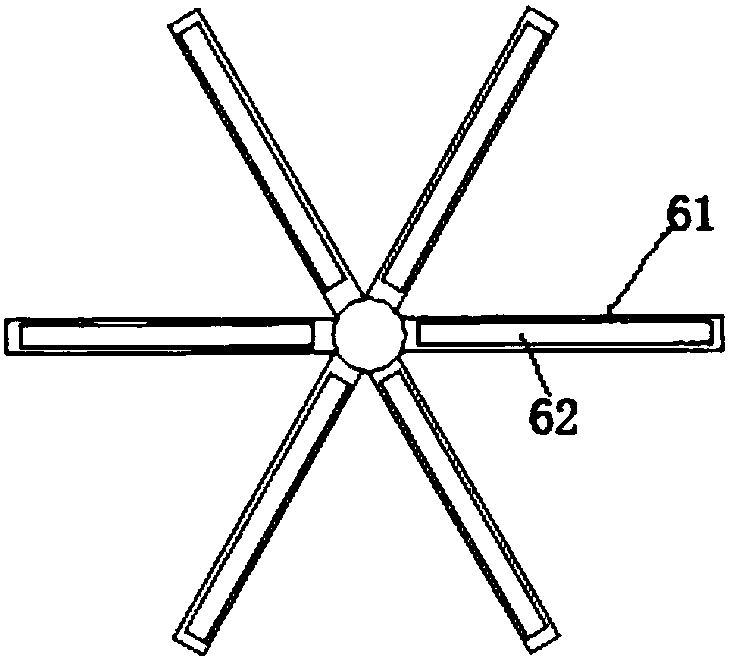

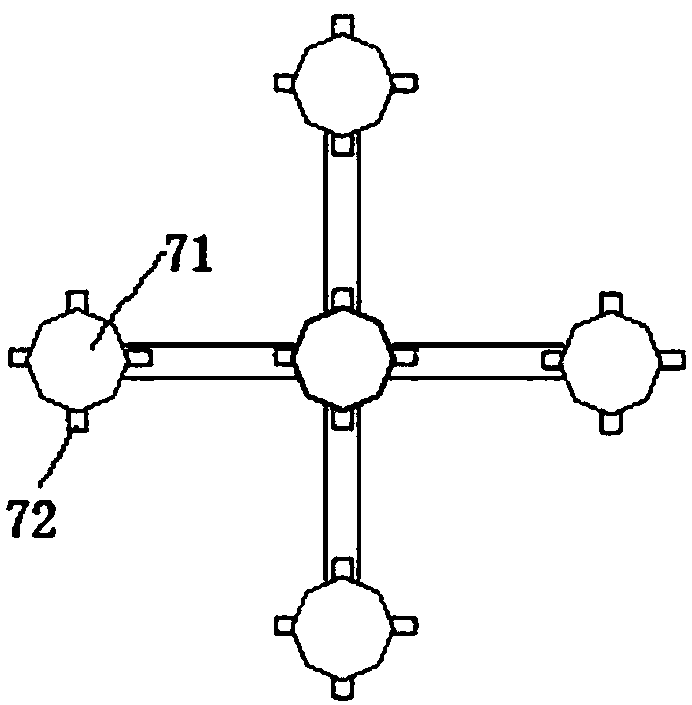

Vertical eddy current reinforced separation device and granulation fluidized bed for efficient solid-liquid separation

ActiveCN105858735AIncrease productivityWon't breakSludge treatment by de-watering/drying/thickeningTreatment involving filtrationFluidized bedEddy current

The invention provides a vertical eddy current reinforced separation device and a granulation fluidized bed for efficient solid-liquid separation. The vertical eddy current reinforced separation device is arranged in a separation area; and the vertical eddy current reinforced separation device comprises a stirring shaft sleeve arranged at the center, wherein multiple corrugated pipes vertically fixed together are arranged at the periphery of the stirring shaft sleeve, the two ends of each corrugated pipe are clamped between a pair of crisscross frames, the centers of the crisscross frames are arranged at the two ends of the stirring shaft sleeve, the end parts of the crisscross frames are fixed on the inner wall of a tank body in the separation area. The vertical eddy current reinforced separation device can produce vertical eddy current, and the vertical eddy current has secondary growth promoting effect on small particles entering the device, so that yield of large particles is improved, and separation efficiency is improved. The granulation fluidized bed provided by the invention also can improve the yield of the large particles and the separation efficiency due to adoption of the vertical eddy current reinforced separation device.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

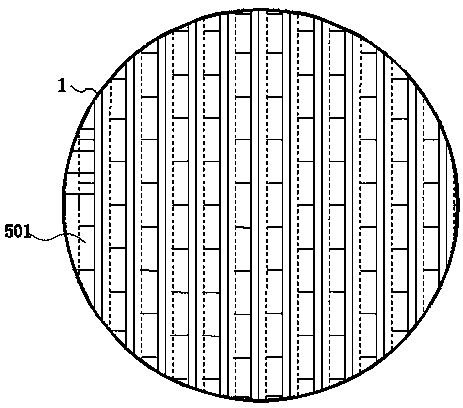

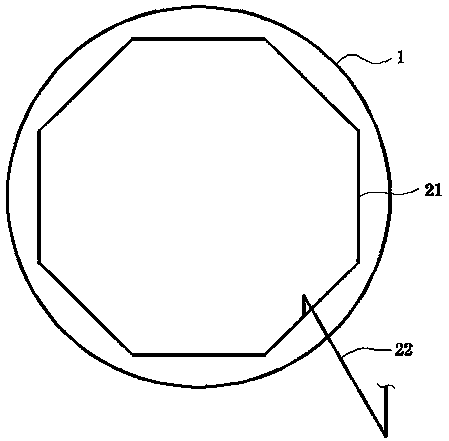

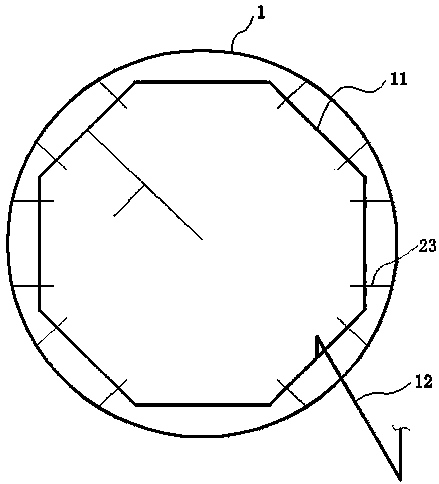

High-load crystal nucleus solid-liquid separation device and method

InactiveCN112062330ASolve the problem of not being able to growLarge particle sizeSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentFlocculationSludge

The invention discloses a high-load crystal nucleus solid-liquid separation device and method. The device comprises an inner shell and an outer shell, and a clear water area, a honeycomb filler, a separation area, a concentration area and a sludge collection area are sequentially arranged in the outer shell from top to bottom; the inner shell is arranged in the separation area and comprises a granulation area and a flocculation area which communicate with each other up and down, and the size of a top inlet of the flocculation area is larger than that of a bottom outlet of the granulation area;the granulation area is connected with a water inlet pipe and a seed crystal adding pipe; the flocculation area is connected with a coagulant adding pipe and a coagulant aid adding pipe; stirrers arerespectively arranged in the granulation area and the flocculation area; a sludge return pipe is connected between the bottoms of the sludge collection area and the flocculation area, and a sludge return pump is arranged on the sludge return pipe. Crystals are added to serve as a carrier, the particle size of flocs is increased, the purification effect of the crystals on softened water and turbidity-removed water is enhanced, meanwhile, the interception effect of colloidal and suspended pollutants is enhanced through mechanical friction and extrusion in the crystals and the adsorption bridging effect of PAM, and efficient purification of the softened water and the turbidity-removed water is achieved.

Owner:NANJING GUONENG ENVIRONMENTAL PROTECTION ENG

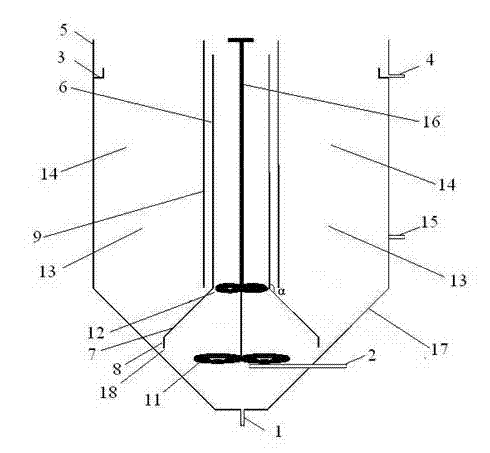

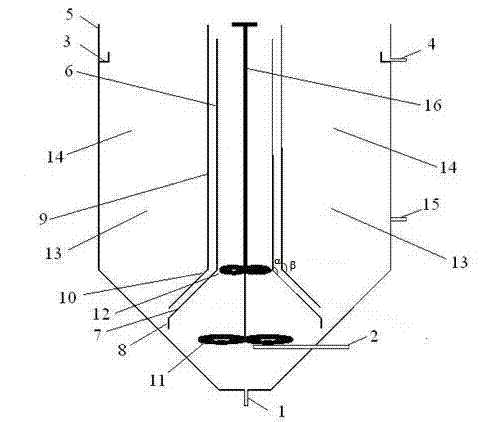

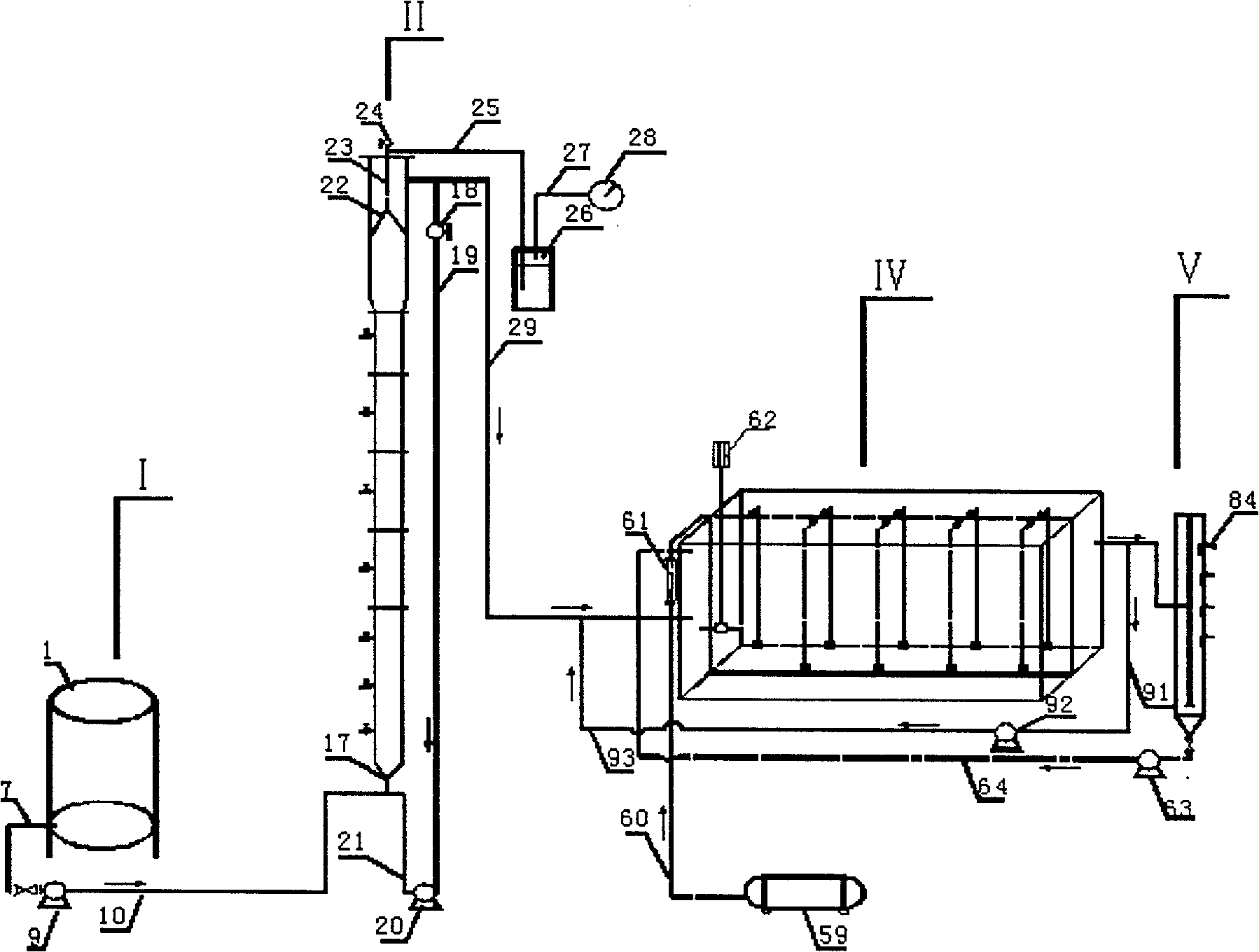

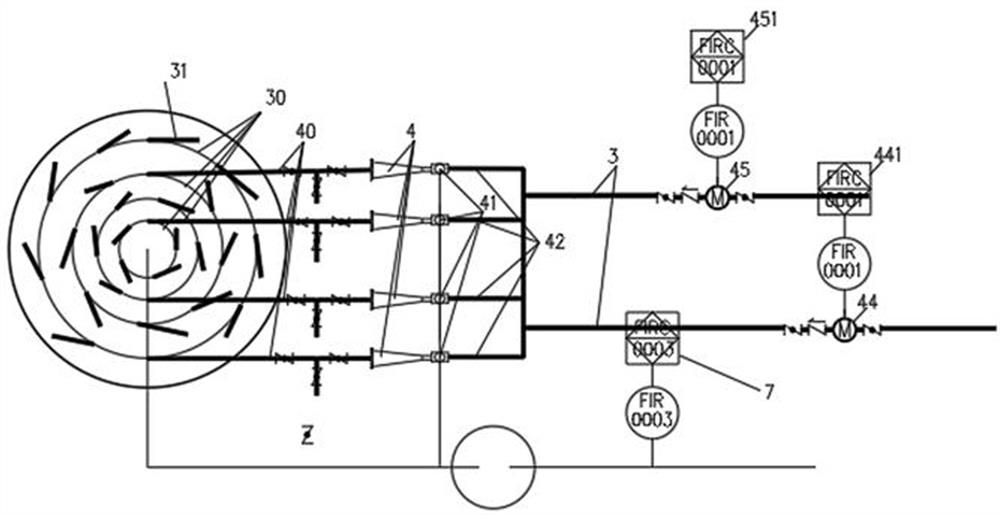

Internal circulation hydrolysis reactor and process thereof

ActiveCN102774962AImprove carbon source utilizationIncrease the ascending velocityTreatment with anaerobic digestion processesPre treatmentProcess engineering

The invention discloses an internal circulation hydrolysis reactor. The internal circulation hydrolysis reactor comprises a central barrel, a guide barrel and an outer barrel which are arranged from inside to outside, wherein a propeller is arranged in the central barrel and used for controlling the ascending velocity of wastewater in the central barrel to be 20-60m / h. The wastewater quickly penetrates through the central barrel and flows into the outer barrel through the guide barrel to form the ascending flow state, the wastewater and sludge are synchronously hydrolyzed, solid is separated from liquid, the sludge in a sludge hydrolysis region enters the central barrel through a backflow seam, and then, the sludge is uniformly mixed with water and is separated from sand. The reactor and a process of the reactor integrate the functions of carbon source development, sludge reduction, sand removal and the like, and are widely suitable for the preprocessing process of the low-concentration wastewater.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

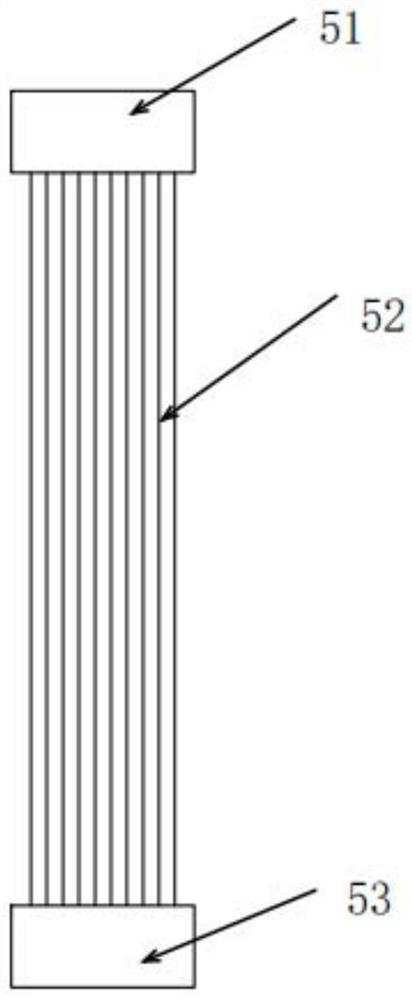

Method for electrochemically regenerating zeolite subjected to anerobic biochemical treatment and ammonia nitrogen adsorption

InactiveCN102190399AEasy loadingEasy to pourMultistage water/sewage treatmentCombustible gas purificationEnvironmental resistanceAmmoniacal nitrogen

The invention belongs to the technical field of environmental protection, and relates to a method for electrochemically regenerating zeolite subjected to anerobic biochemical treatment and ammonia nitrogen adsorption. The method comprises the following steps of: contacting pretreated town sewage with high-activity anaerobic sludge in a reactor, degrading organic pollutants in the sewage into final products such as CH4, CO2, H2O and the like by using various microbes in the anaerobic sludge, and performing electrochemical regeneration. By the method, the zeolite regeneration time is short; moreover, the ammonia nitrogen is oxidized into nitrogen and other substances in the electrochemical process, so the difficulty in treating used regenerated liquid is overcome to realize ammonia-nitrogen-free emission. Compared with bio-regeneration method and the like, the method has the advantages of small occupied area, simple operation and larger development space, and can fulfill the aims of recycling energy and saving energy.

Owner:FUDAN UNIV

Efficient anaerobic bioreactor for treating leachate of waste incineration plant

ActiveCN105668781AReduce load shockSpeed up the responseWaste based fuelTreatment with anaerobic digestion processesAutomatic controlDistribution system

The invention relates to an anaerobic bioreactor for treating leachate of a waste incineration plant.The anaerobic bioreactor mainly comprises an anaerobic tank, a water distribution system, a reaction system, a biogas collecting system and a water discharge system.The anaerobic bioreactor has the advantages that landfill leachate directly flows into a reflux pipe, and struvite crystal generation of a reflux system and the water distribution system is avoided; water inflow is diluted while the ascending flow speed of the reactor is increased by the aid of internal reflux, anaerobic sludge is in an expansion state in the vertical direction, anaerobic microorganisms sufficiently contact with matrix to reach a good mass transfer effect, the organic pollutants in the leachate of the waste incineration plant are removed efficiently, volume load can reach 8-10kgCOD / m<3>.d, and COD removing rate reaches up to 85-95%; the reactor is low in energy consumption, high in gas production rate, beneficial to energy recycling, capable of achieving automatic control, simple in operation, stable and durable, short in construction period, small in floor space and capable of saving land resources, and the floor space of the reactor is about 40% of that of other anaerobic systems.

Owner:深圳市南科大资产经营管理有限公司

Waste water treatment apparatus for generating firedamp and self-circulating anaerobic reactor thereby

InactiveCN100376492CEasy to handleImprove efficiencyWaste based fuelTreatment with anaerobic digestion processesHigh concentrationLow load

This invention relates to a biogas production wastewater treatment device and a cycle anaerobic reactor used in the device, which is used for environmental engineering. The device invented consists of a new self-cycle anaerobic reactor and a computer control system. The core self-cycle anaerobic reactor comprises two overlapping anaerobic reaction zones in series, wherein the upper parts of the two reaction zone are established gas-solid-liquid three phase separators respectively. The lower reaction zone is at an extreme high load, while the upper reaction zone is at low load. The three-phase separator sludge can be separated and returned to the main separator by the separator and biogas is collected. Internal reactor is capable of forming self-circle liquid, and can strengthen mass transfer process of organism and granular sludge and improve handling capability. The floor place of the three phase separator is small, high concentration of organic wastewater can be treated and biogas as biological energy can be produced. The device can achieve the scale biogas technology and automated production, and is an ideal scale wastewater treatment and gas production equipment.

Owner:WUXI MASHENG ENVIRONMENT ENERGY TECH CO LTD

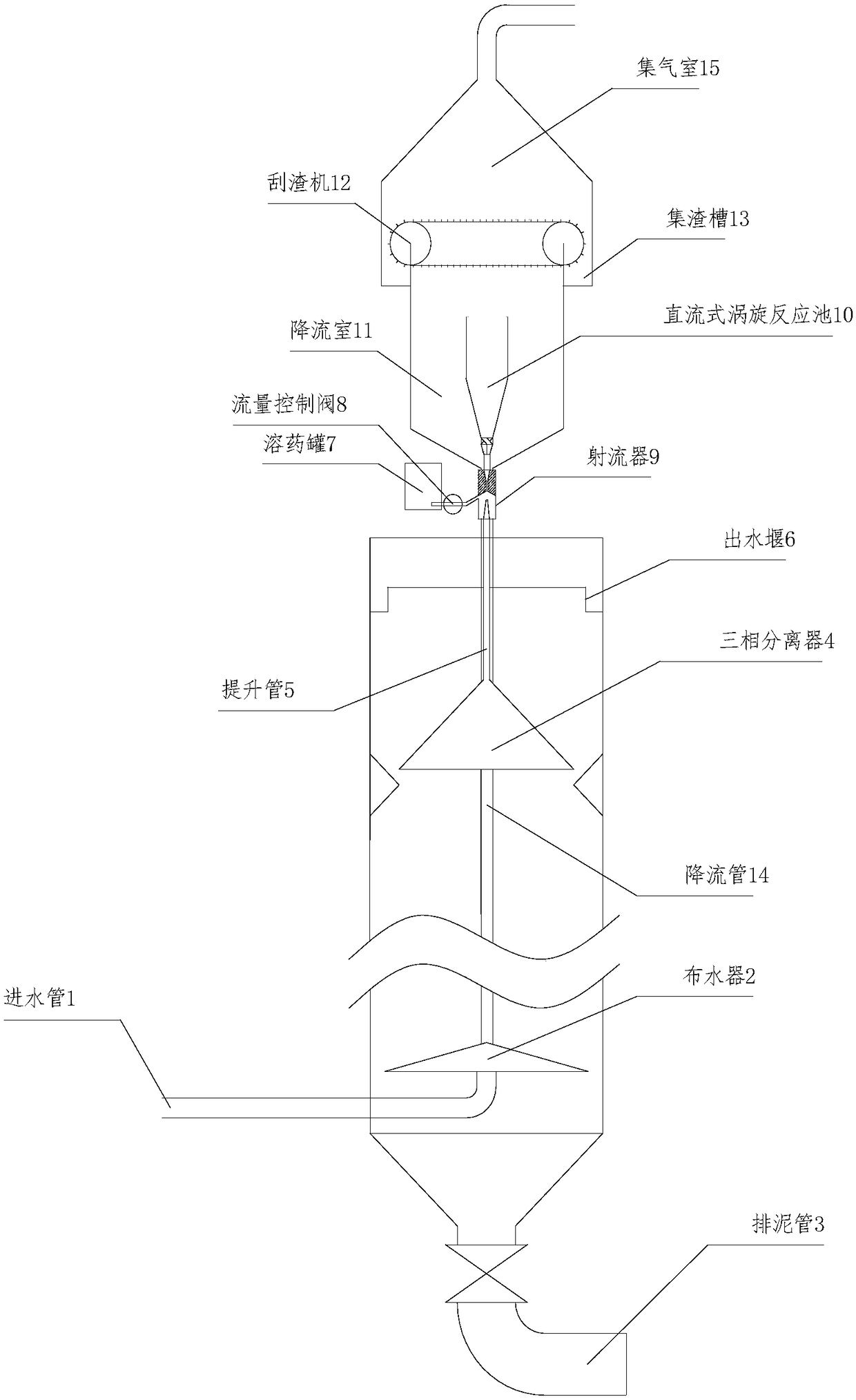

Co-flocculation air-floating anaerobic bioreactor and method thereof

ActiveCN108558128AGood removal effectSmall pressure dropSpecific water treatment objectivesMultistage water/sewage treatmentParticulatesSlag

The invention discloses a co-flocculation air-floating anaerobic bioreactor and a method thereof. The co-flocculation air-floating anaerobic bioreactor mainly comprises a biological reaction area, a dosing Mixed Zone and a flocculation air flotation area, wherein the biological reaction area is provided with a sludge discharge pipe, a three-phase separator and a lifting pipe; the dosing Mixed Zoneis provided with a dissolving tank, a flow control valve and a jet device; the flocculation air-floating zone is provided with a direct-current type vortex reaction tank, a flow-reducing chamber, a slag-scraping machine, a slag-collecting tank, a drop-down pipe and a current-collecting chamber. The co-flocculation air-floating anaerobic bioreactor combines the anaerobic biological reaction and the co-flocculation air flotation process, and uses the biogas generated by the anaerobic biological reaction for air-floating removal of the particulate matter, and meanwhile, generates the copolymerization adhesion effect. The method has the advantages of good water quality, high medicament saving, high efficiency and low energy consumption.

Owner:ZHEJIANG UNIV

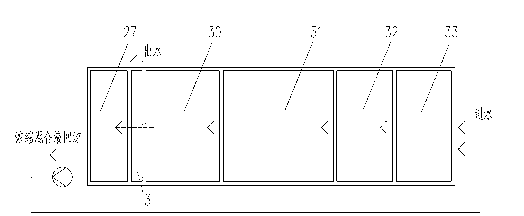

Novel efficient low-consumption UASB (upflow anaerobic sludge blanket) +ABR (anaerobic baffled reactor) granular sludge process based brewing industrial wastewater treatment method

InactiveCN107673469AIncrease contactIncrease reaction rateTreatment with anaerobic digestion processesIndustrial wastewater treatmentEngineering

The invention discloses a novel efficient low-consumption UASB (upflow anaerobic sludge blanket) +ABR (anaerobic baffled reactor) granular sludge process based brewing industrial wastewater treatmentmethod. A UASB+ABR reactor is adopted, a sewage speed-regulation constant-flow pump is mounted on the lower portion of the lateral side of the UASB+ABR reactor, a first liquid flow meter is arranged on the lateral side of the sewage speed-regulation constant-flow pump, and a backflow speed-regulation constant-flow pump, a second liquid flow meter and a sludge discharging pipeline are mounted on the lateral side of the UASB+ABR reactor. The inner bottom of the UASB+ABR reactor is provided with a first reaction chamber, and a three-phase separator is arranged above a second reaction chamber which is arranged above the first reaction chamber. The novel efficient low-consumption UASB+ABR granular sludge process based brewing industrial wastewater treatment method has advantages that by internal modification of the UASB+ABR reactor, a flow guide is additionally arranged below the three-phase separator, three reaction chambers are formed in the whole reactor, and accordingly an anaerobic sludge granulation process is quickly promoted by sludge floc to quickly degrade organics.

Owner:ANHUI GOLDEN SEED WINERY CO LTD

Urban sewage treatment of anaerobic biological-low voltage electric field oxidizing coupling system

InactiveCN1778712AImprove removal efficiencyIncrease the ascending velocityWater/sewage treatment by electrochemical methodsWater/sewage treatment by magnetic/electric fieldsLow voltageOutfall

An urban sewage treatment from anaerobic biological-low voltage electric field oxidation coupling system is carried out by taking coupling system with expanding anaerobic particle mud bed reactor and low-voltage electric field reactor, turning on low-voltage electric field reactor when outfall ammonia nitrogen of anaerobic reactor above discharge standard, ammonia nitrogen oxidizing by electrochemical method below discharge standard, turning off reactor of low-voltage electric field, treating sewage by anaerobic reactor and discharging directly. It can achieve national discharge standard.

Owner:FUDAN UNIV

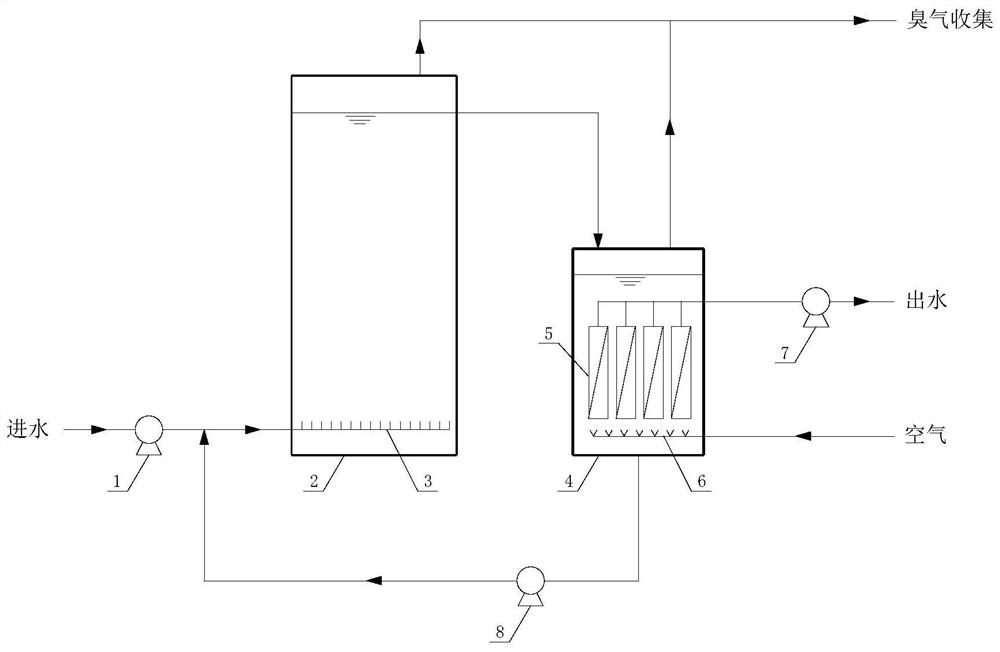

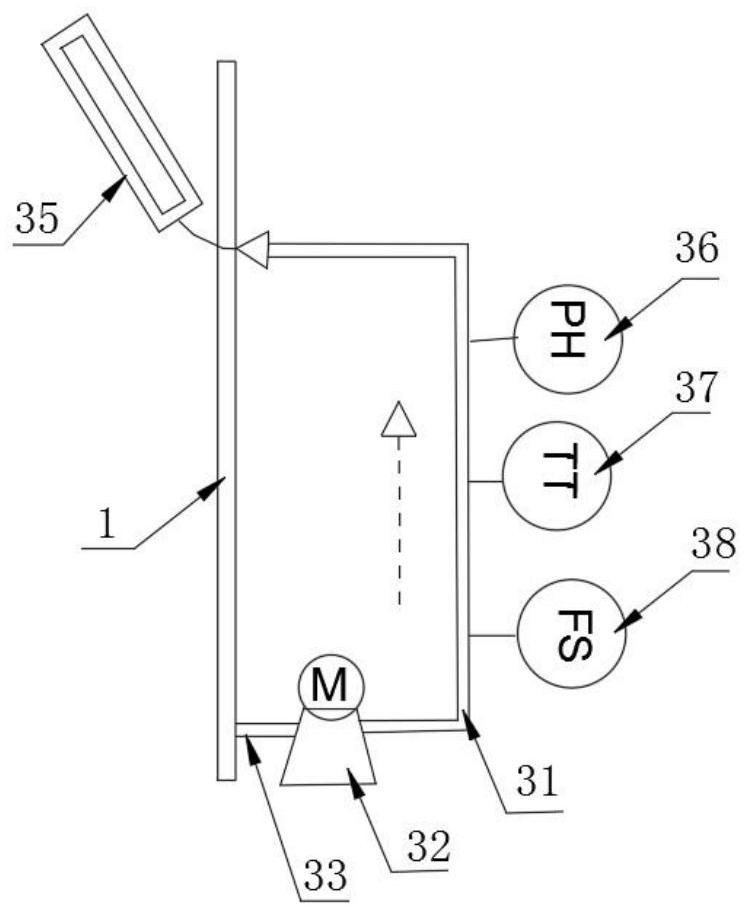

Developing solution wastewater treatment system

PendingCN113501621ALow toxicityReduce inhibitionWater contaminantsTreatment with anaerobic digestion processesSludgeTreatment system

The invention discloses a developing solution wastewater treatment system, the system mainly comprises a TMAH decomposition reaction tank and a membrane separation tank, a water distributor is arranged in the decomposition reaction tank, and the water distributor uniformly distributes reaction tank inlet water and membrane separation tank circulating reflux at the bottom of the tank; an immersed membrane component is mounted in the membrane separation tank, a perforated aeration pipe is arranged at the lower part of the membrane component, the aeration pipe is connected with an air pipeline outside the tank, membrane wires of the immersed membrane component are shaken through aeration, sludge is prevented from being deposited on the surfaces of the membrane wires, and the reaction tank and the membrane separation tank form a closed loop by the whole system through a connecting pipeline. The treatment system disclosed by the invention does not need to heat wastewater, and is simple to operate and relatively low in energy consumption; the treatment load of the reaction tank is improved, the effective volume of the reaction tank is reduced, and the occupied area of the system is saved; and moreover, the maximum concentration of TMAH (Tetramethyl Ammonium Hydroxide) tolerated by the whole system is 2000mg / L, and the removal rate of the TMAH can reach more than 80%.

Owner:上海东振环保工程技术有限公司

Integral treatment apparatus for urban sewage

InactiveCN1792878AEasy to cutAvoid affecting the adsorption effectTreatment with anaerobic digestion processesAmmoniacal nitrogenMunicipal sewage

A comprehensive treating system for city sewage is composed of an admission water tank, a reactor with water inlet on its bottom, water outlet on its top, screen plate at said water inlet and three-phase separator at its water outlet, an adsorptive column with zeolite as its filler and the screen plates at its water inlet and outlet, and a treating water tank. Its advantage is high effect to remove COD, ammoniacal nitrogen and P.

Owner:HUNAN UNIV

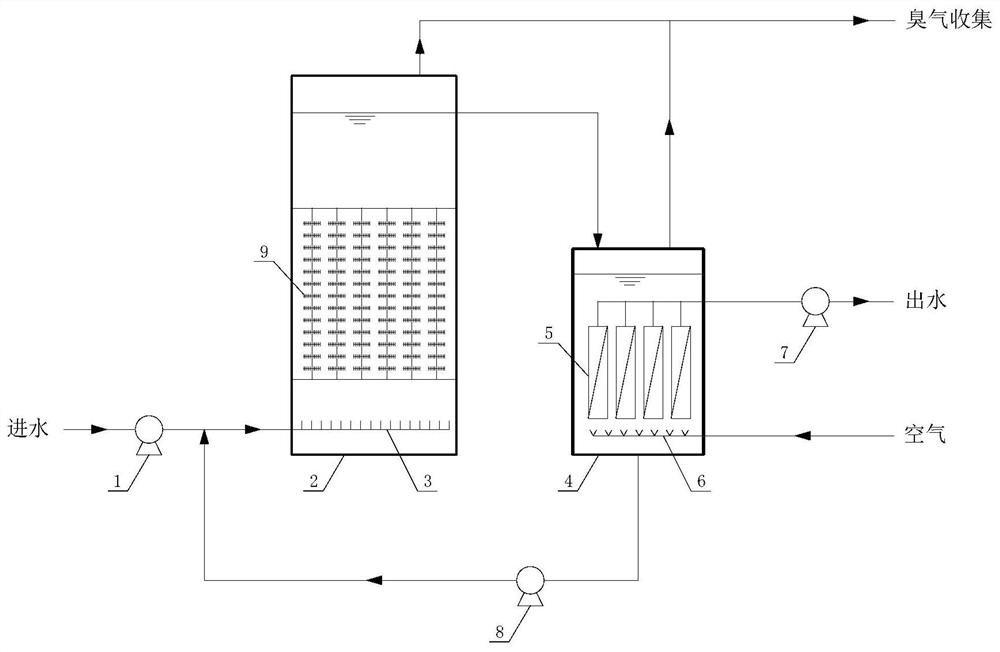

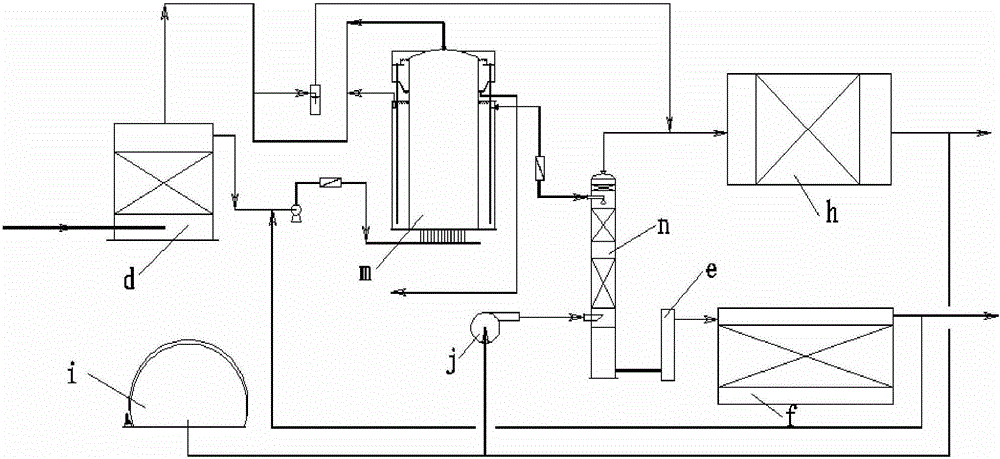

Culture sewage processing system based on EGSB anaerobic reactor

ActiveCN105417889AIncrease the ascending velocityRapid dilutionFatty/oily/floating substances removal devicesTreatment involving filtrationConstructed wetlandBiological filter

The invention discloses a culture sewage processing system based on EGSB anaerobic reactor. The processing system comprises a screen tank, a fine grain screening device, a PH adjusting tank, an oil insulation adjusting tank, a water volume adjusting tank, an EGSB anaerobic reactor, a tower-type biological filter, an oxidation pond and a subsurface flow constructed wetland which are in series connection in order. The EGSB anaerobic reactor comprises a water distributing device, a reaction region, a three-phase separator and a water collection region which are arranged from bottom to top in order, and also comprises a reaction region partition device. The reaction region partition device comprises an adjustable lifter pipe and a perforated pipe communicated with the lifter pipe vertically. The reaction is divided into a first sludge region above the perforated pipe and a second sludge region with the position of the perforated pipe as a boundary. The reaction region partition device also comprises a lifter driving device driving the lifter pipe to go up and down in the reaction region. The lifter pipe is connected with a sewage backflow circulating pipe. A circulating pump is arranged on the sewage backflow circulating pipe. Scale marks indicating the going-up-and-down distance of the adjustable lifter pipe are arranged on the adjustable lifter tube.

Owner:四川中喻环境治理有限公司

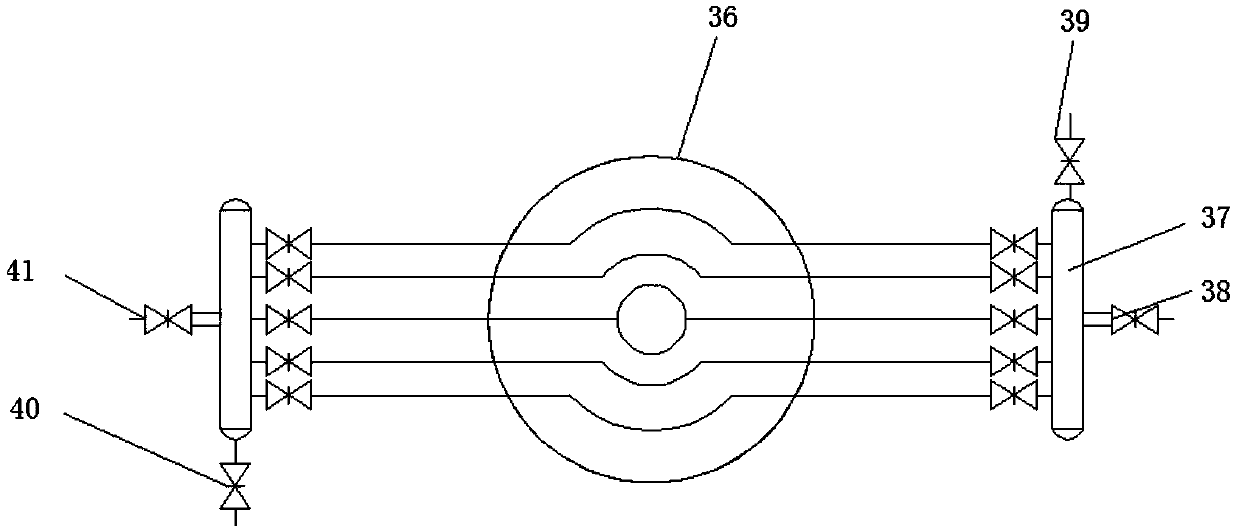

Sleeve type split-phase anaerobic reactor for organic wastewater treatment as well as regulating and controlling method for treating sulfur-containing and nitrogen-containing wastewater by using reactor

ActiveCN105198176APrevent outflowCompact layoutWater contaminantsMultistage water/sewage treatmentWater qualityMethane production

The invention relates to an anaerobic reactor for treating organic wastewater and an application method, particularly to a sleeve type split-phase anaerobic reactor for organic wastewater treatment as well as a regulating and controlling method for treating sulfur-containing and nitrogen-containing wastewater by using the reactor, and aims to solve problems that existing two-stage anaerobic reactor equipment occupies large areas and pipeline connection is complex. The sleeve type split-phase anaerobic reactor comprises an inner barrel, an outer barrel, a water distribution device and two three-phase separation devices, wherein the inner barrel and the outer barrel are arranged coaxially, the water distribution device is mounted at the bottom of the inner barrel, one three-phase separation device is arranged at the upper part of the inner barrel, a water outlet is formed in the wall of the inner barrel, a settling zone is defined by a cofferdam and the outer wall of the inner barrel, and multiple downcomers are fixed on a bottom plate of the cofferdam and extend to the bottom of the outer barrel. The sleeve type two-stage anaerobic reactor is closely arranged, occupies a small area and is simple to manage and control, the two-stage biochemical treatment process of hydrolytic acidification and anaerobic methane production of the wastewater is finished in one reactor, and the quality of effluent is improved.

Owner:HARBIN INST OF TECH +1

Apparatus and method of treating city domestic refuse percolation liquid by two-stage UASB+A/O technique

ActiveCN100422096CIncrease the ascending velocityPrevent compactionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater qualityOxygen

Owner:BEIJING UNIV OF TECH

Internal circulation anaerobic reaction system with denitrification function

InactiveCN112573653AControl flow rateIncrease disturbanceSpecific water treatment objectivesBiological treatment apparatusIndustrial waste waterReaction zone

The invention relates to the technical field of industrial wastewater, and discloses an internal circulation anaerobic reaction system, which comprises an anaerobic tank body, and is characterized inthat a reaction region is arranged in the anaerobic tank body; A biogas collection chamber is arranged at the top of the anaerobic tank body and connected with the water seal tank through a biogas collection pipe and a biogas main pipe, the water seal tank is connected with a biogas outlet pipe, and biogas is discharged through the biogas outlet pipe; An effluent weir is arranged at the inner topof the anaerobic tank body and is provided with a water outlet pipe; A three-phase separator is arranged at the inner top of the anaerobic tank body; A water distribution device is arranged at the bottom of the anaerobic tank body; A jet device is arranged at the outer bottom of the anaerobic tank body, a water outlet of the jet device is connected with the part, located outside the anaerobic tankbody, of the water distribution device, a gas guide port of the jet device is connected with a biogas main pipe through a biogas guide pipe, and a water inlet of the jet device is connected with a circulating water pipe arranged between the three-phase separator and the effluent weir. The reaction speed of wastewater and sludge can be increased, the sludge removal effect is improved, and sludge deposition is avoided.

Owner:华夏碧水环保科技股份有限公司

Efficient bicirculating anaerobic reactor

PendingCN107720956ASolve the phenomenon of water and mudIncrease the ascending velocityTreatment with anaerobic digestion processesReaction zoneAnaerobic reactor

The invention relates to an efficient bicirculating anaerobic reactor. The bicirculating anaerobic reactor comprises an anaerobic reactor body. A gas collector communicated with an inner cavity of theanaerobic reactor body is arranged at the top of the anaerobic reactor body, and is provided with a gas exhaust pipe. A separator is arranged in the anaerobic reactor body. A primary circulating system is connected to a position, located above the separator, on the anaerobic reactor body. A sludge collector is arranged at a position, located below the separator, in the anaerobic reactor body. A reaction region is arranged at the bottom of the anaerobic reactor body. A sludge distribution system is arranged in the reaction region, and is connected with the sludge collector through a secondarycirculating system. The primary circulating system of the anaerobic reactor can effectively improve anti-impact resistance of the anaerobic reactor and biochemistry of inlet water. The secondary circulating system cooperates with the sludge collector and the sludge distribution system, so that the phenomenon that outlet water of the anaerobic reactor carries sludge can be solved effectively, lifting speed of anaerobic sludge can be increased, and activity of the anaerobic sludge can be stimulated.

Owner:北京北控工业环境科技有限公司

Spiral-flow type reflux hydrolytic acidification reactor

ActiveCN109133342AReduce flow rateWell mixedWater distributersTreatment with anaerobic digestion processesNuclear engineeringSludge

The invention discloses a spiral-flow type reflux hydrolytic acidification reactor and belongs to the field of sewage treatment reactors. The spiral-flow type reflux hydrolytic acidification reactor comprises a reactor body and is characterized in that an effluent weir is connected to the top of the reactor body, a water outlet pipe is connected to the effluent weir, a retaining ring is connectedinto the upper end of the reactor body, a sludge discharge pipe is arranged at the bottom of the reactor body, a sludge outlet pipe is connected to the sludge discharge pipe, a PE baffle plate component is further arranged inside the upper end of the reactor body, the PE baffle plate component is located above the retaining ring, and a first PE water distribution pipe and a second water distribution pipe are arranged at the bottom of the reactor body. The spiral-flow type reflux hydrolytic acidification reactor has the advantages that sewage is sufficiently mixed with sludge in the reactor body, rotation-ascending spiral flow is formed, reaction efficiency is increased, sludge concentration in the reactor is guaranteed, the sewage is separated from treated sewage, and the sludge is retained in the efficient hydrolytic acidification reactor.

Owner:SUZHOU KEDA ENVIRONMENTAL PROTECTION ENG CO LTD

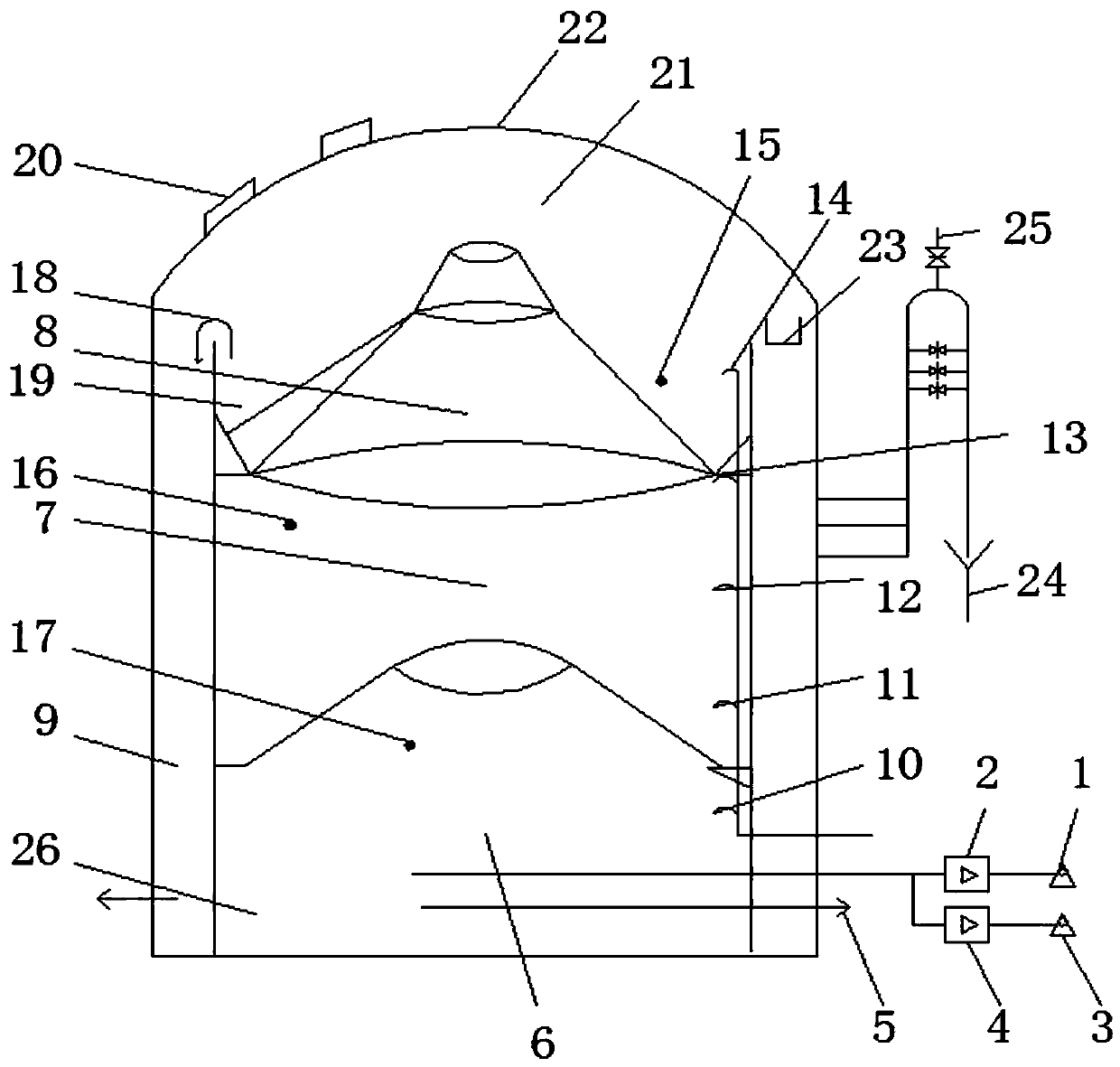

Combination type anaerobic digestion reactor

PendingCN108059236AImprovement and optimization of internal main structureSimple structureWater treatment parameter controlBiological treatment apparatusPh controlSewage

The invention discloses a combination type anaerobic digestion reactor. The combination type anaerobic digestion reactor comprises a return-flow tank, a reaction tank, a water inlet pipe and a return-flow pipe, the bottom part of the return-flow tank is communicated with the bottom part of the reaction tank through the water inlet pipe, a sludge discharge area, a jet type water distributor, a granule sludge bed, a biological packing area, a three-phase separator and a water outlet are sequentially arranged in a tank body of the reaction tank from bottom to top, one end of the return-flow pipeis communicated with the water outlet, the other end of the return-flow pipe is communicated with the top part of the return-flow tank, and a water inlet is formed in the bottom part of the return-flow pipe. The inner main structure of the traditional UBF (Upflow Blanket Filter) reactor is improved and optimized, the three-phase separator, a return-flow system comprising the return-flow pipe and the return-flow tank, an online pH control device and the jet type water distributor are added, and the combination type anaerobic digestion reactor improves the SS sewage treatment capability, the pollutant load impact resistance and the stability of the traditional anaerobic digestion reactor, and has the characteristics of simpleness in operation, safety, reliability, and high treatment efficiency.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +2

Highly effective methane-producing device for high concentration waste water treatment

InactiveCN100345776CIncrease the ascending velocityImprove efficiencyWaste based fuelTreatment with anaerobic digestion processesHigh concentrationComputer monitoring

The invention discloses a high concentration wastewater treatment device which produces methane highly effectively, belonging to the equipment device used for environmental engineering. The device which is full-automatic, with methane effectively produced, and with organic wastewater anaerobic treatment, comprises mainly of a novel expanded granular sludge bed (shortly called EGSB), a reactor, and a computer monitoring system. The device can effectively treat organic wastewater, and at the same time it can produce methane highly-effectively. And it provides a perfect environmental engineering equipment device for the effective treatment to organic wastewater and scope-production of methane.

Owner:JIANGNAN UNIV

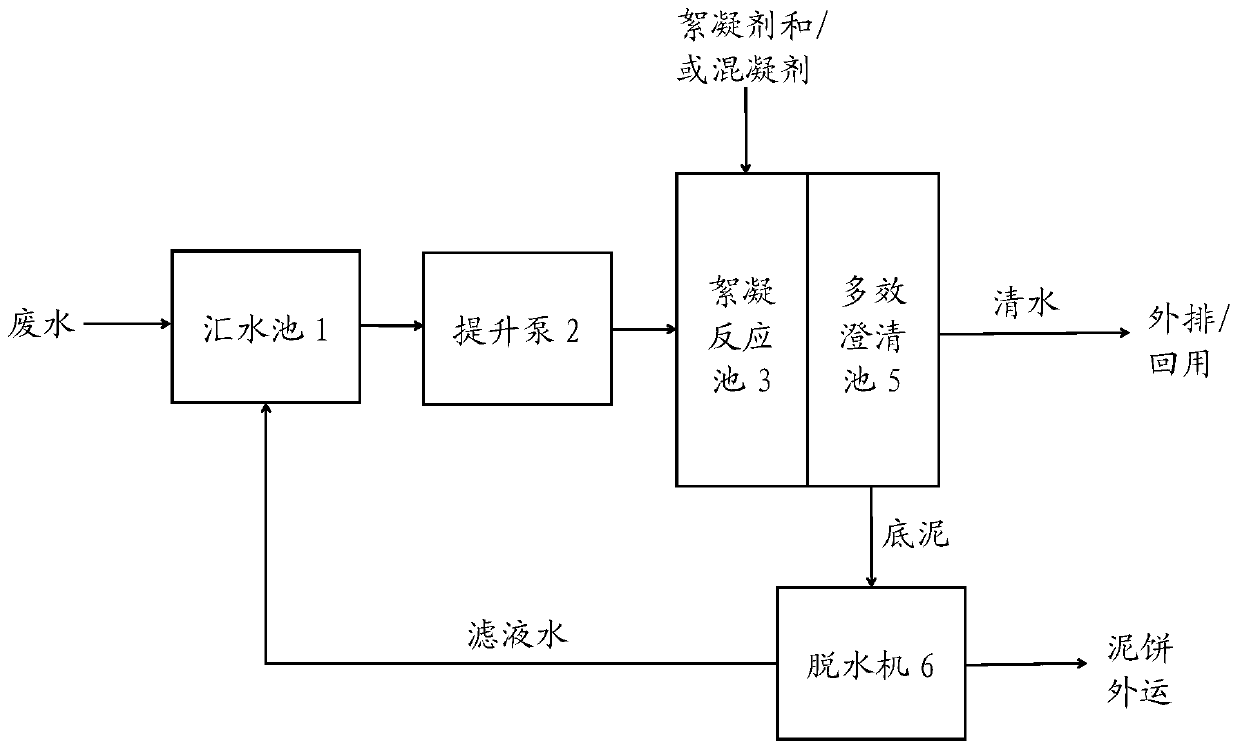

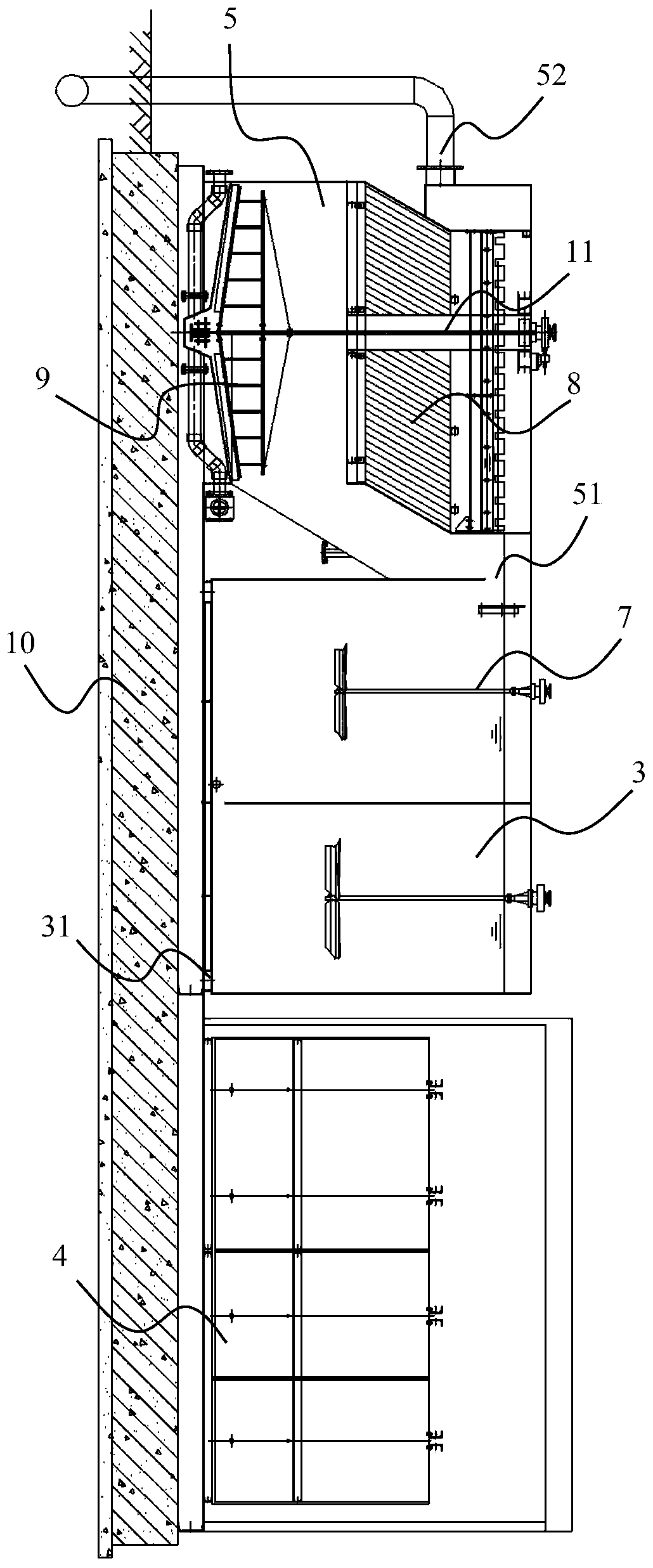

Integrated multi-effect clarification system and clarification method thereof

PendingCN110723842AHigh speed waterCompact outletWater/sewage treatment by centrifugal separationSpecific water treatment objectivesFlocculationWater discharge

The invention discloses an integrated multi-effect clarification system and a clarification method thereof. The integrated multi-effect clarification system is used for treating wastewater stored in awater collecting tank. The system comprises a lifting pump, a flocculation reaction tank, a flocculation dosing tank, a multi-effect clarification tank and a dehydrator. The clarification method comprises following steps: inputting wastewater in the water collecting tank into the flocculation reaction tank through a wastewater inlet by using the lifting pump, starting an axial flow stirrer, and adding a flocculating agent and / or a coagulant at the same time; starting a hydrocyclone and a mud scraper, so that precipitation water in the multi-effect clarification tank is discharged into the dehydrator and flows back to the water collecting tank after filtering in the dehydrator, and clear water filtered again through an inclined plate group at the top is discharged through a clear water discharge port. According to the system, various technologies beneficial to solid-liquid separation, such as chemical flocculation, mechanical stirring, loading precipitation and inclined tube separation, are highly integrated, high-speed and compact effluent of the multi-effect clarification system is kept, the effluent quality is good, and the multi-effect clarification system has the advantages ofhigh impact resistance and running cost saving, and the flexibility of operation and running is improved.

Owner:北京华德创业环保设备有限公司

External circulation granular sludge anaerobic reactor system with large height-diameter ratio

PendingCN112142201APromote innovationIncrease the ascending velocityBiological treatment apparatusTreatment with anaerobic digestion processesProcess engineeringReaction zone

The invention discloses an external circulation granular sludge anaerobic reactor system with a large height-diameter ratio, and relates to the technical field of wastewater anaerobic treatment. The system comprises a homogenizing regulation tank, an anaerobic reactor, an anaerobic reactor system effluent distribution pipe, a chemical adding pipeline, a jet mixing system, a first-stage DUO type full-coverage multichannel three-phase separator, a second-stage DUO type full-coverage multichannel three-phase separator, an anaerobic effluent collection pipe, a pot-shaped pulse water distribution system, a double-path pulse feeding system, a first anaerobic reaction zone, a second anaerobic reaction zone, a third anaerobic reaction zone and a fourth anaerobic reaction zone. According to the invention, the problem of blockage of the water distribution system in treatment of papermaking wastewater containing high-concentration calcium ions is avoided, strong rotational flow generated in the pot-shaped water distribution system can be avoided, and blockage of water distribution slits is prevented; compared with comparative analysis of an IC internal circulation anaerobic reactor, the invention has a more stable and efficient treatment effect and has a wide application prospect.

Owner:上海复森环境科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com