Sewage biochemical treatment equipment

A processor and biochemical technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. problems, to achieve the effect of improving the rising flow rate, small footprint, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

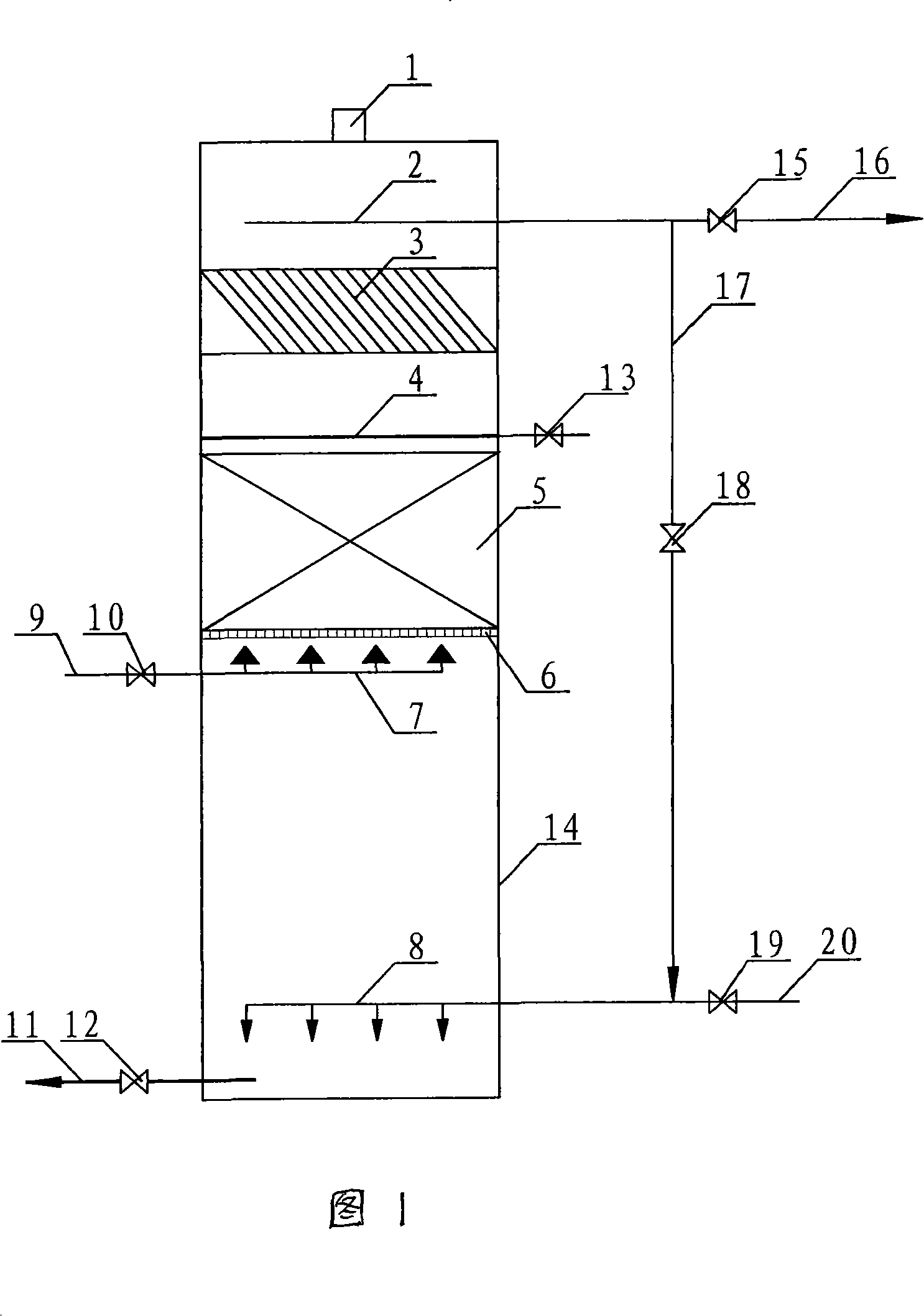

[0027] Referring to Fig. 1, a kind of embodiment of sewage biochemical processor, housing 14 is made circular cylinder by the steel plate (carbon steel plus FRP or stainless steel) of certain thickness, and the bottom is supported by base, and housing 14 top is provided with There are air collecting holes 1. The lower part of the housing 14 is provided with an inlet pipe 20 controlled by a water inlet valve 19, and the upper part is provided with an outlet pipe 16 controlled by an outlet valve 15. The outlet pipe 16 communicates with the inlet pipe 20 through a return pipe 17, and the return flow is controlled by a return valve 18. . The filler 5 in the housing 14 is a composite filler 5 with microorganisms on the surface, the composite filler 5 is supported by a support plate 6, and an aerator 7 is arranged below to connect with an air intake pipe 9 . A dosing device 4 is arranged above the combined packing 5 to connect with the dosing pipe and is controlled by a dosing valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com