Combination type anaerobic digestion reactor

An anaerobic digestion and reactor technology, used in anaerobic digestion treatment, chemical instruments and methods, water treatment parameter control, etc. problems, to achieve the effect of improving effluent quality, reducing pressure, and improving the ability to resist the impact of pollutant loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

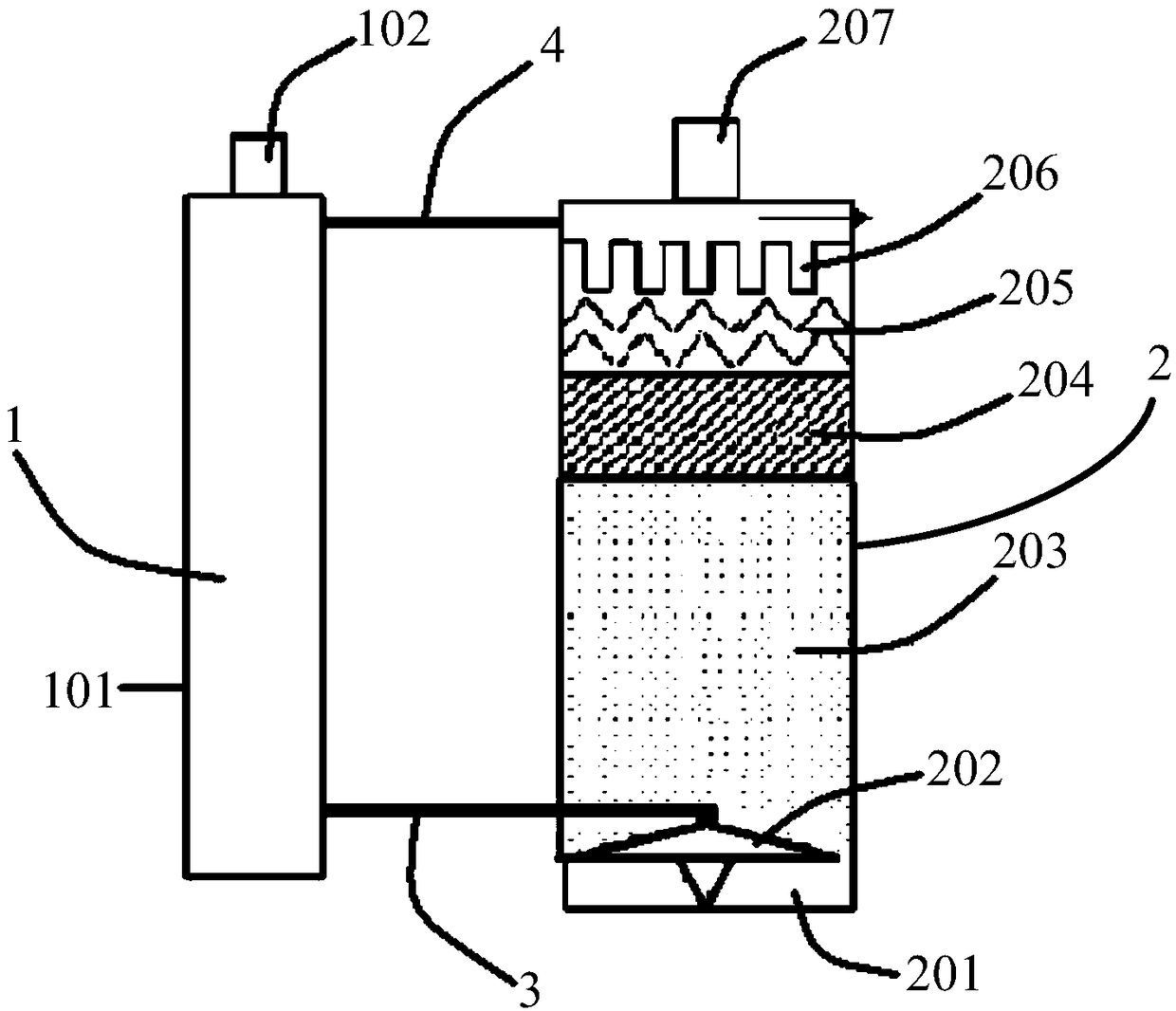

[0022] see figure 1 , the present invention provides a kind of composite anaerobic digestion reactor, comprises reflux tank 1, reaction tank 2, water inlet pipe 3 and reflux pipe 4, the bottom of reflux tank 1 is connected with the bottom of reaction tank 2 through water inlet pipe 3; Reaction In the tank body of the tank 2, a sludge discharge area 201, a jet-type water distributor 202, a granular sludge bed 203, a biological filler area 204, a three-phase separator 205 and a water outlet 206 are sequentially arranged from bottom to top, and one end of the return pipe 4 is connected to the The water outlet 206 is connected, and the other end is connected with the top of the return tank 1; the return pipe 4 is provided with a flow regulating device 5, which is used to adjust the flow of sewage entering the return pipe 4 after being separated by the three-phase separator 205. The bottom of the reflux tank 1 is provided with a water inlet 101 .

[0023] Such as figure 1 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com