Highly effective methane-producing device for high concentration waste water treatment

A technology for wastewater treatment and biogas production, applied in anaerobic digestion treatment, waste fuel, etc., can solve the problem that the reactor cannot meet the requirements well, achieve the effect of improving volume utilization, simplifying the process, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

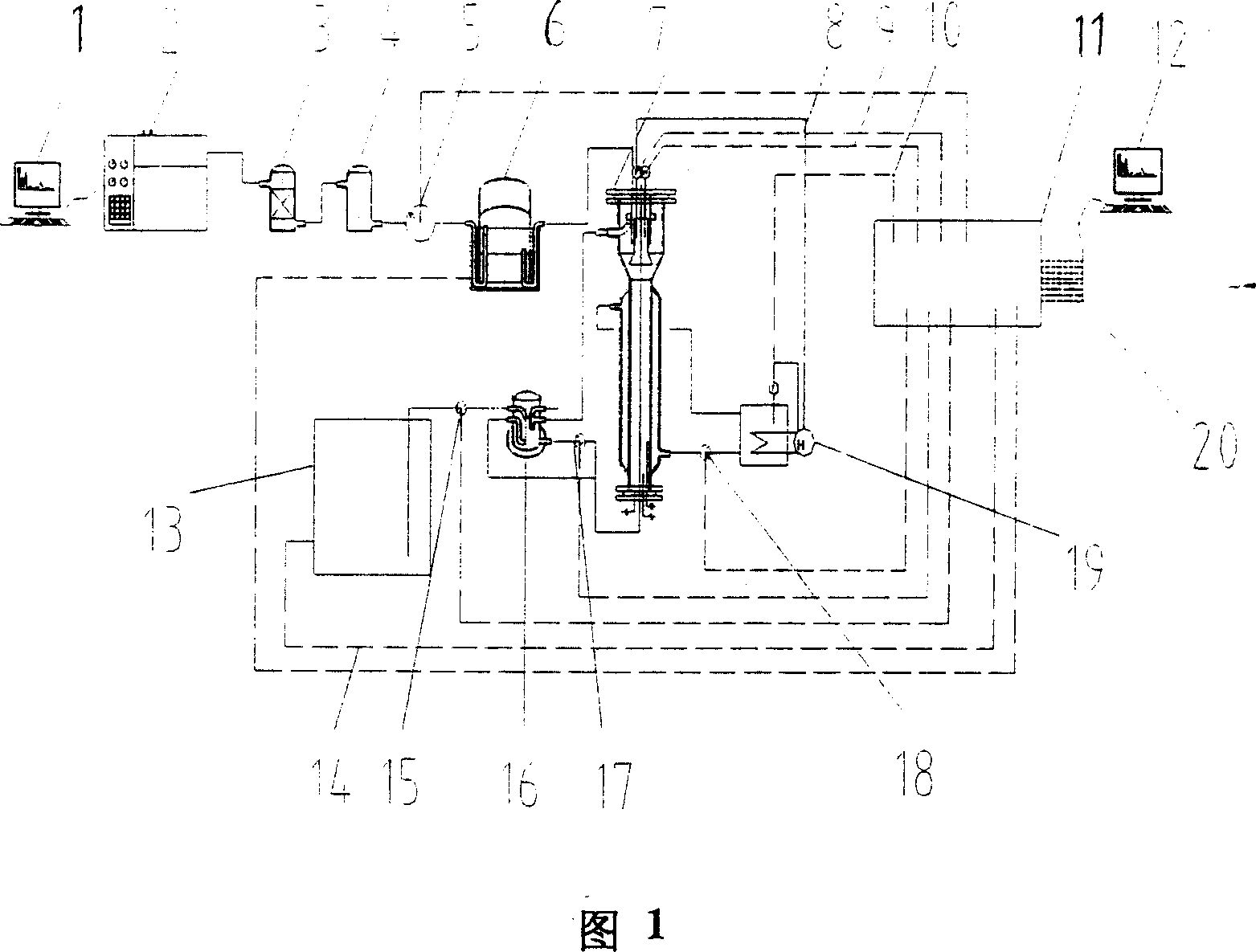

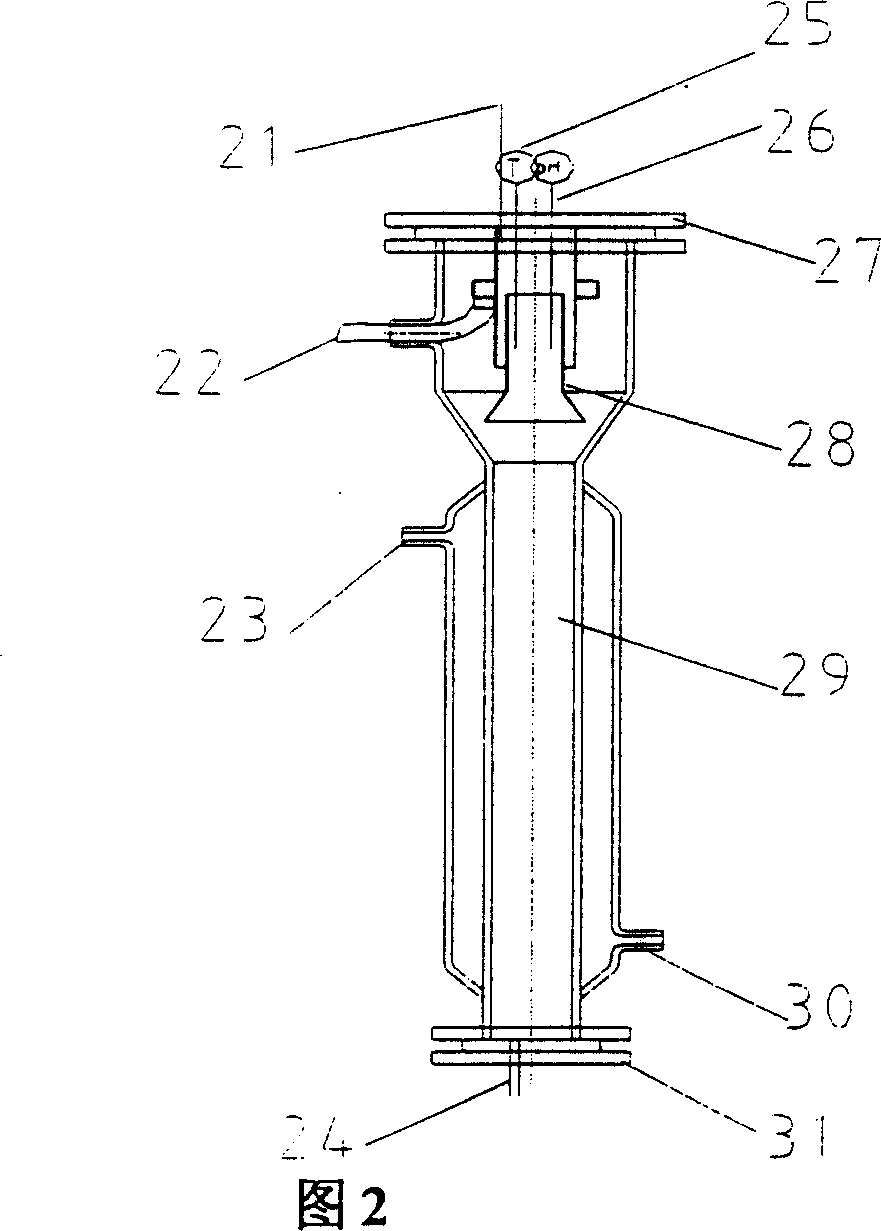

[0019] A wastewater treatment device for high-efficiency biogas production is a fully automatic and efficient biogas-producing device for anaerobic treatment of organic wastewater composed of an expanded granular sludge bed reactor and a computer monitoring system. The device is composed of a data processor 1 and an online biogas detection 2, desulfurization tank 3, scrubber tank 4, gas flow meter 5, floating gas tank 6, EGSB reactor 7, temperature panel display 8, pH panel display 9, temperature overheating control 10, control data cabinet 11, terminal controller 12. Feed tank 13, low liquid level alarm 14, feed pump 15, buffer tank 16, circulation pump 17, heat pump 18, heater 19, computer data line 20, feed tank 13 is connected to feed pump 15, The feed pump 15 is connected to the buffer tank 16, and the buffer tank 16 is connected to the EGSB reactor 7. Wastewater comes out of the buffer tank 16 and enters the wastewater inlet 24 at the bottom of the reactor through the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com