Efficient bicirculating anaerobic reactor

An anaerobic reactor and double-circulation technology, applied in the field of water treatment, can solve the problems of hindering the mass transfer efficiency of anaerobic reactor sludge, reducing the reactor treatment efficiency, and slowing down the metabolism of anaerobic microorganisms, so as to solve the problem of water discharge zone Mud phenomenon, improve the biochemical properties of influent, promote the effect of granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

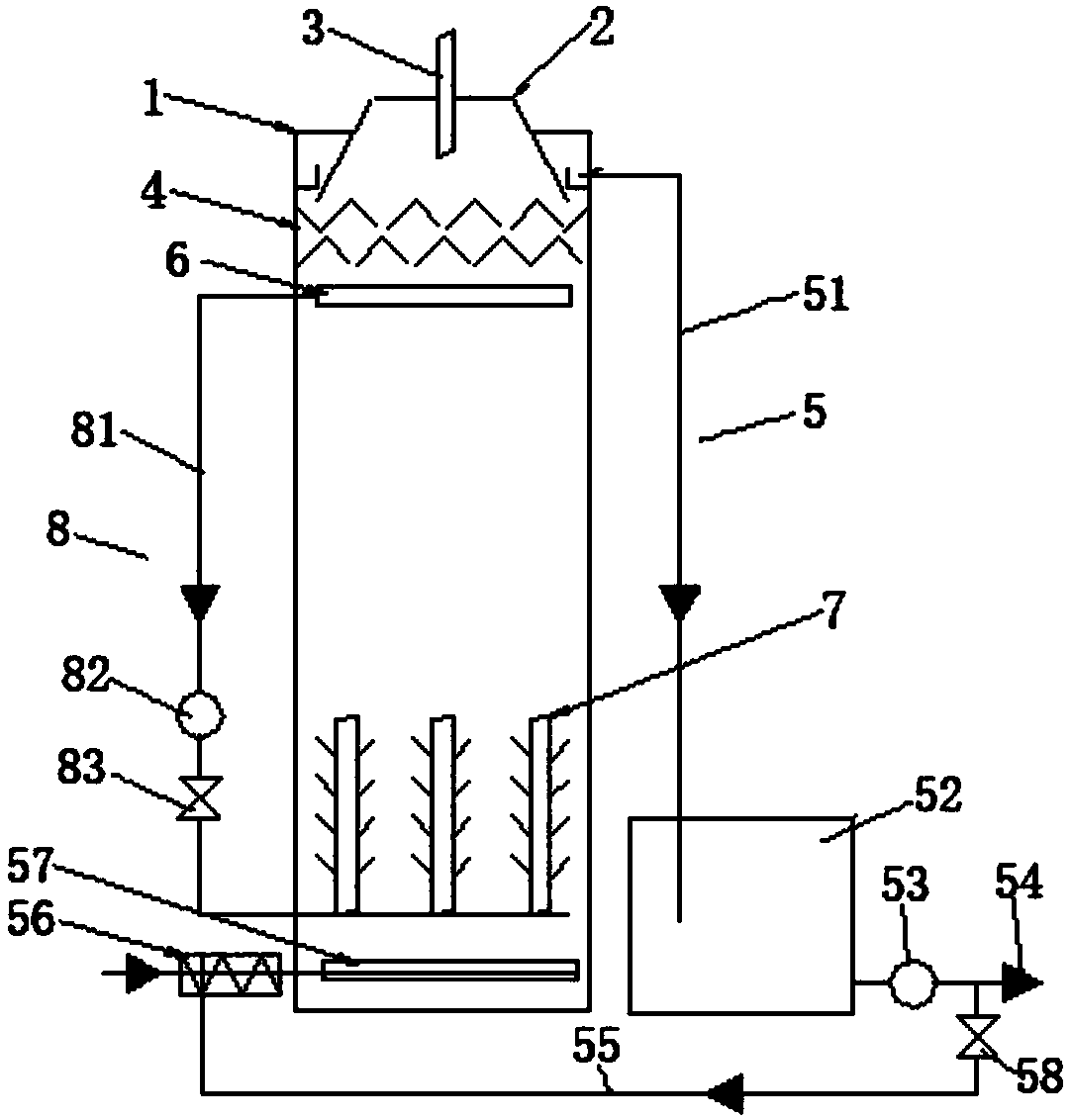

[0028] refer to figure 1 As shown, the application of the high-efficiency double-cycle anaerobic reactor in this embodiment in the treatment of coal chemical industry wastewater is carried out as follows: 1. Through the water inlet pump, the coal chemical industry wastewater is pumped into the reactor 1 through the water inlet, and pumped into the reactor 1. Add hydrolytic acidifying bacteria, acid-producing bacteria, and hydrogen-producing methanogenic bacteria within 1 hour, the COD of the influent is 2500-3500 mg / L, and the B / C ratio is below 0.1. Control the temperature of the influent water at 30-37°C, the pH of the influent water at 7.5-8.5, and the residence time at 20h.

[0029] 2. The water outlet from the primary circulation system 5 at the top of the reactor 1 enters the buffer tank 52 of the primary circulation system through the pipeline 51, and the water outlet passes through the primary circulation pump 53, wherein the treated water flows back to the water inlet...

Embodiment 2

[0034] The difference between this embodiment and method 1 is that the strains added to the reactor are cultured with sludge from the anaerobic section of wastewater treatment in other chemical industries, the influent COD is 3500-4000 mg / L, and the B / C ratio is below 0.1. The temperature of the influent water is 27-35°C, the pH of the influent water is controlled at 7.0-7.5, and the residence time is 30 hours. Other conditions and processing procedures are the same as in Case 1.

[0035]Compared with the existing reactor, through two independent circulation systems, the anaerobic reactor can improve the treatment capacity of the industrial wastewater which is difficult to biochemically treat. Among them, the first-stage circulation system 5 can not only increase the rising flow rate in the reactor, but also adjust the biodegradability of the influent, and improve the load shock resistance of the anaerobic reactor. The secondary circulation system 8 is not affected by the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com