Integrated multi-effect clarification system and clarification method thereof

A clarification tank and clear water technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, special treatment targets, etc., can solve problems such as irremovable, achieve good effluent quality, excellent effluent quality, and increase flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

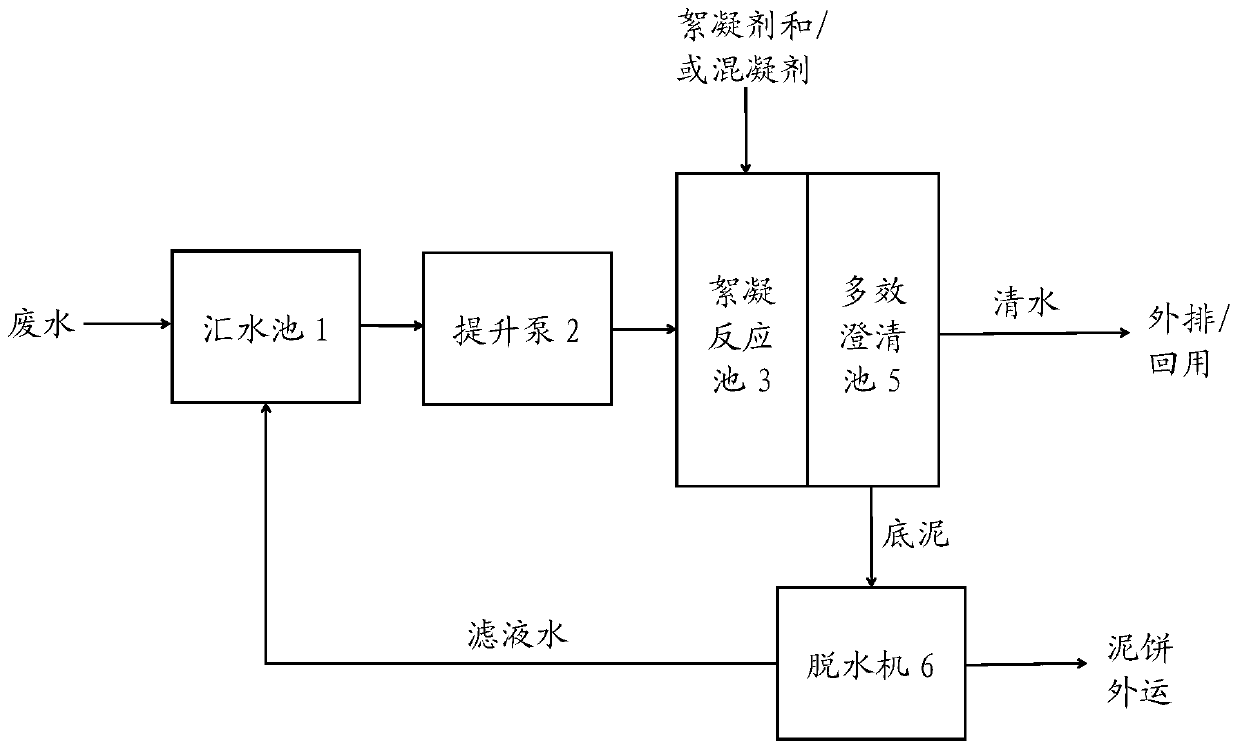

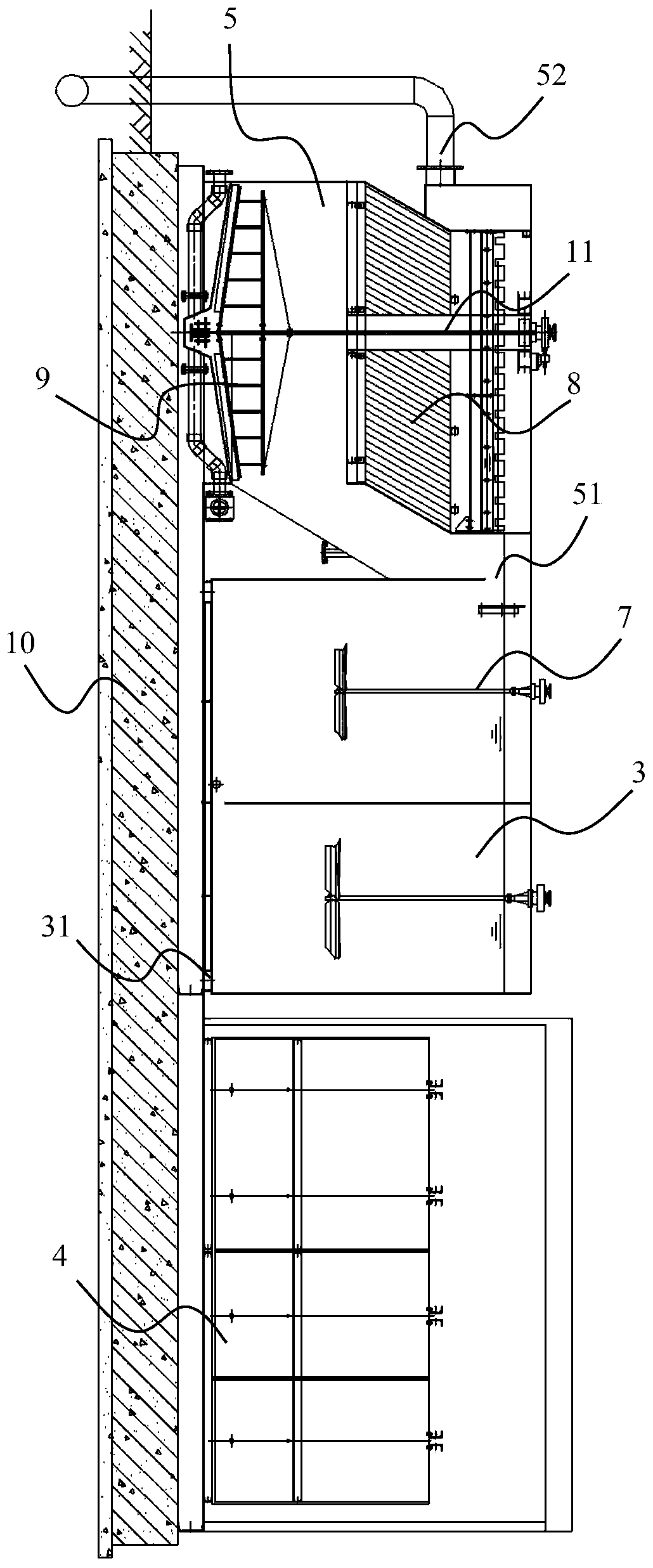

[0053] See attached figure 1 And attached figure 2 , the embodiment of the present invention discloses an integrated multi-effect clarification system for treating wastewater stored in a sump 1; including: a lifting pump 2, a flocculation reaction tank 3, a flocculation dosing tank 4, and a multi-effect clarification tank 5 and dehydrator 6;

[0054] One end of the lift pump 2 communicates with the sump 1;

[0055] The waste water outlet of the flocculation reaction tank 3 is located at the bottom thereof, and communicates with the other end of the lift pump 2; the top of the flocculation reaction tank 3 is equipped with an axial flow mixer 7 inserted into it;

[0056] The flocculation dosing tank 4 communicates with the flocculation reaction tank 3 through a pipeline, and is used to add flocculant and / or coagulant to the flocculation reaction tank 3;

[0057] The side wall of the multi-effect clarifier 5 is fixed to the side wall of the flocculation reaction tank 3, and t...

Embodiment 2

[0067] See attached figure 1 and figure 2 , this embodiment discloses an integrated multi-effect clarification method, comprising the following steps:

[0068] S1. The waste water in the sump 1 is input into the flocculation reaction tank 3 through the waste water outlet 31 through the lifting pump 2, and the axial flow mixer 7 is turned on, and flocculants and / or coagulants are added at the same time;

[0069] S2. Turn on the hydrocyclone 11 and the mud scraper 9, so that the sedimentation water entering the multi-effect clarifier 5 is discharged into the dehydrator 6, and the filtrate of the dehydrator 6 is returned to the sump 1, and the top passes through the inclined plate group 8 The clear water filtered again is discharged through the clear water outlet 52 .

[0070] In order to further optimize the above-mentioned technical solution, in S1, fine sand and / or magnetic powder-based dense media carriers are added.

[0071] The concrete principle of this embodiment is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com