Treatment method of sintering flue gas desulphurization wastewater

A technology for desulfurization wastewater and sintering flue gas is applied in the field of iron and steel smelting and processing, and can solve the problems of secondary pollution, high cost of wastewater treatment, and no report on the treatment process of sintering flue gas desulfurization wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

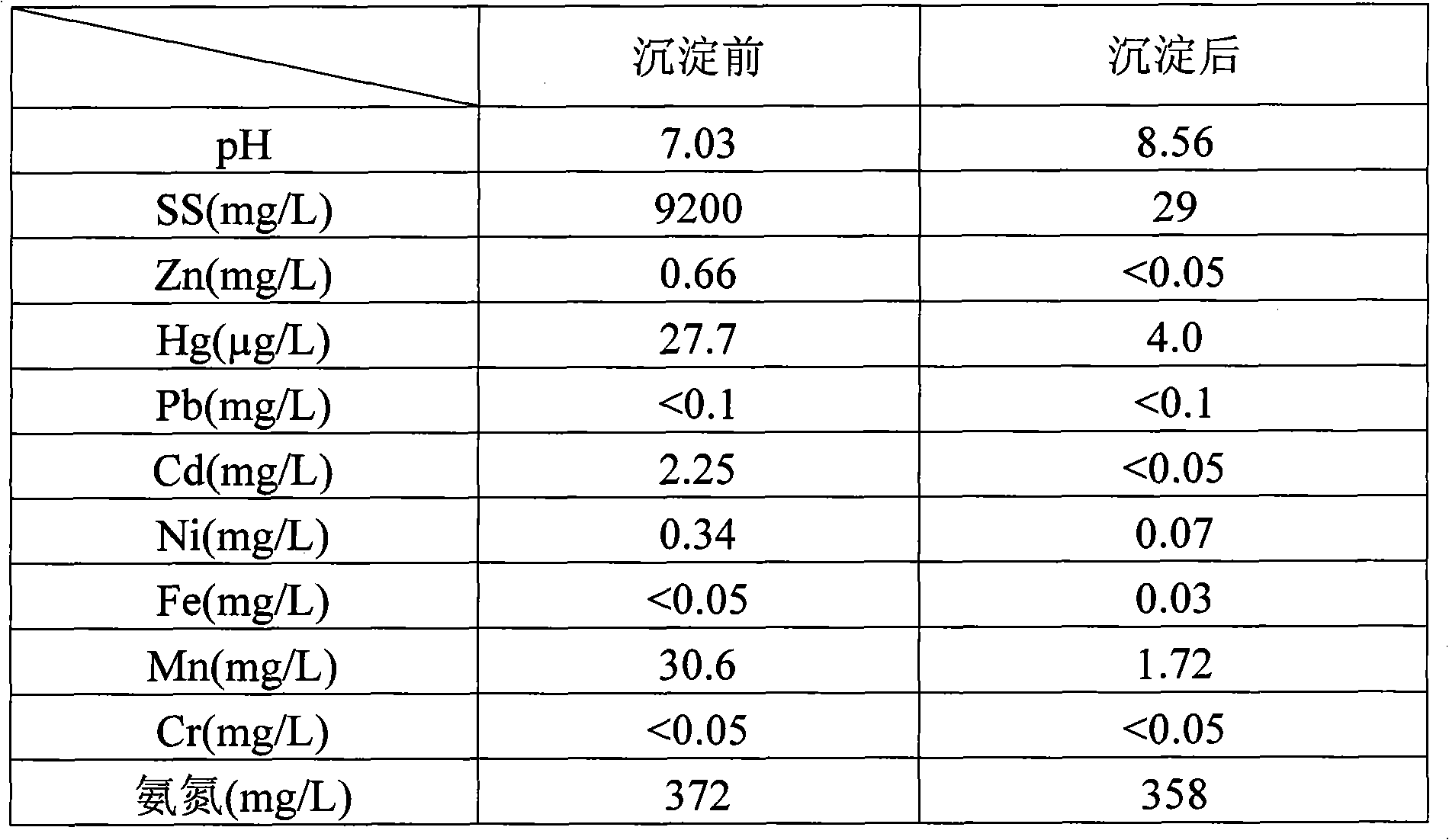

[0034] Sintering flue gas desulfurization wastewater contains a large amount of suspended solids and trace amounts of heavy metal ions, and needs to be neutralized, coagulated, and precipitated before entering the biochemical treatment system of coking wastewater. The reaction conditions are: adding calcium hydroxide solution to adjust the pH of desulfurization wastewater to 8.5, adding 10ppm polyacrylamide, and reacting for 30 minutes to precipitate. The water quality of sintering flue gas desulfurization wastewater before and after treatment is shown in Table 1. It can be seen that after neutralization, coagulation, and precipitation treatment, all heavy metal ions have reached the national first-level emission standard, and the removal rate of ammonia nitrogen is very low, only 3.8%.

[0035] Table 1 Neutralization and precipitation effects of sintering flue gas desulfurization wastewater

[0036]

Embodiment 2

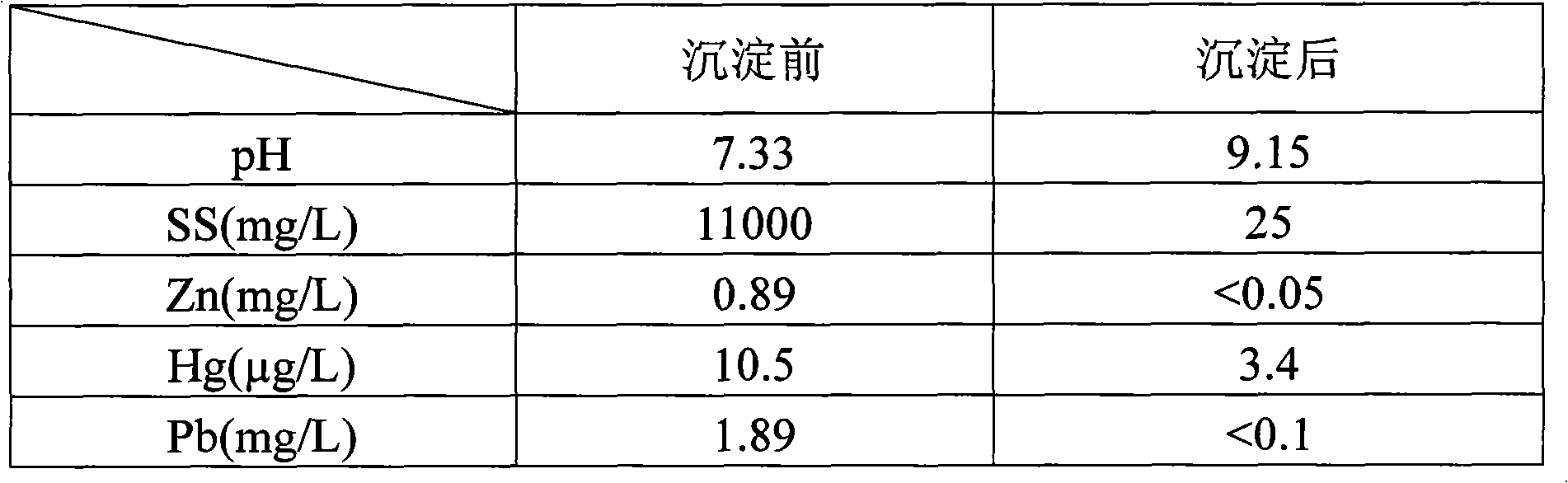

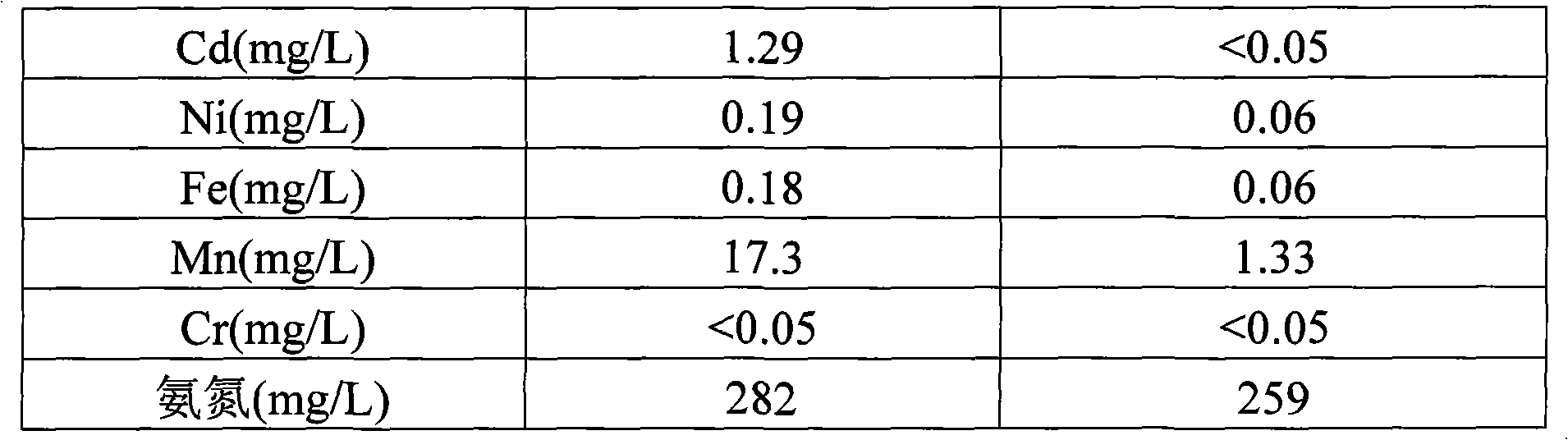

[0038]The reaction conditions for neutralization, coagulation, and precipitation are: add calcium hydroxide solution to adjust the pH of desulfurization wastewater to 9, add 30ppm polyferric sulfate and 1ppm polyacrylamide at the same time, react for 30min and then precipitate. The water quality of sintering flue gas desulfurization wastewater is shown in Table 2. It can be seen that after neutralization, coagulation, and precipitation treatment, all heavy metal ions have reached the national first-level emission standard, and the removal rate of ammonia nitrogen is 8.2%.

[0039] Table 2 Neutralization and precipitation effects of sintering flue gas desulfurization wastewater

[0040]

[0041]

Embodiment 3

[0043] The reaction conditions for neutralization, coagulation, and precipitation are: add calcium hydroxide solution to adjust the pH of desulfurization wastewater to 9.5, and add 200ppm of polyferric sulfate at the same time, and precipitate after 30 minutes of reaction. The water quality of sintering flue gas desulfurization wastewater before and after treatment as shown in Table 3. It can be seen that after neutralization, coagulation, and precipitation treatment, all heavy metal ions have reached the national first-level emission standard, and the removal rate of ammonia nitrogen has reached 16%. Table 3 Neutralization and precipitation effects of sintering flue gas desulfurization wastewater

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com