Patents

Literature

140results about How to "Act as a diluent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

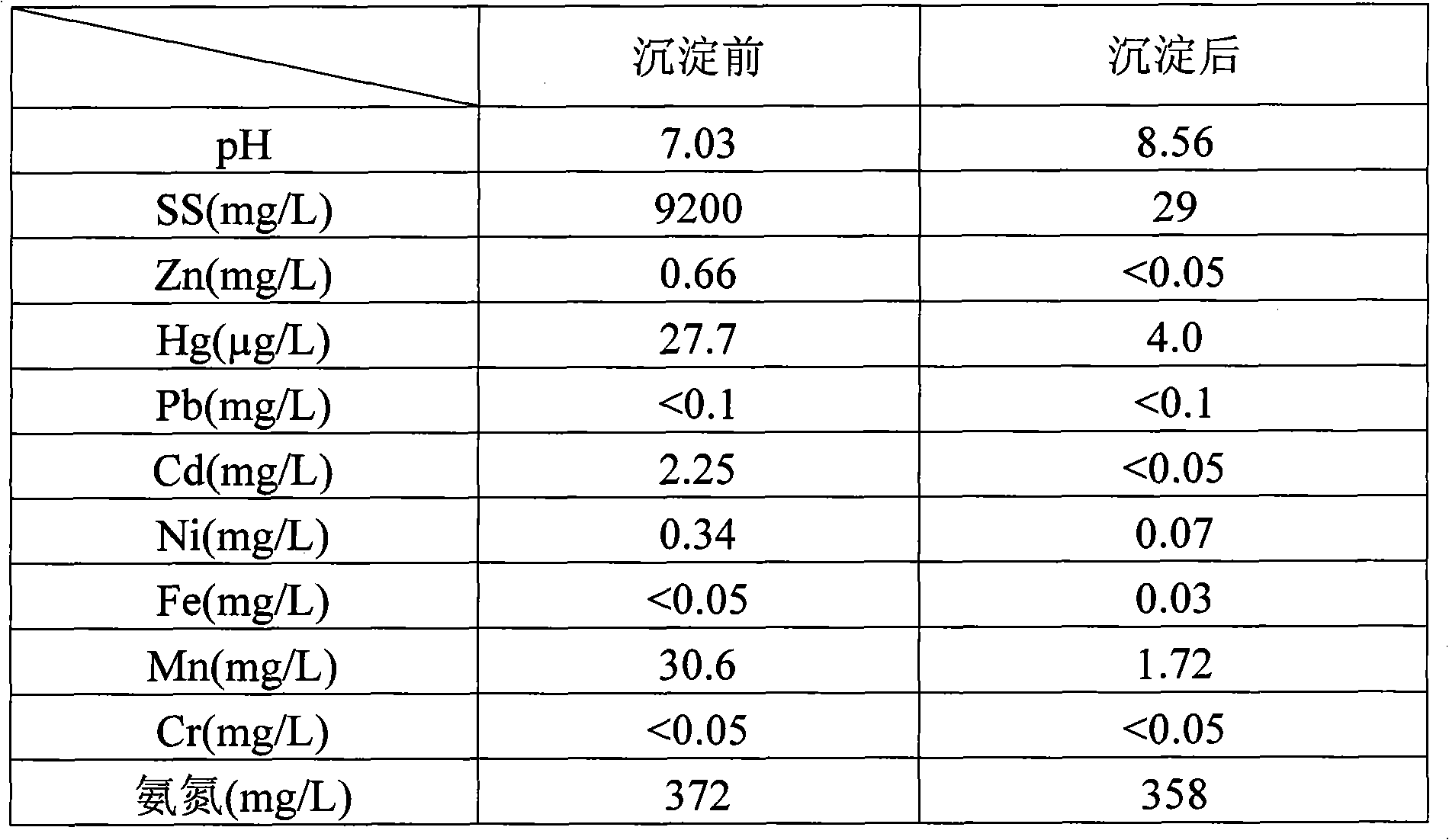

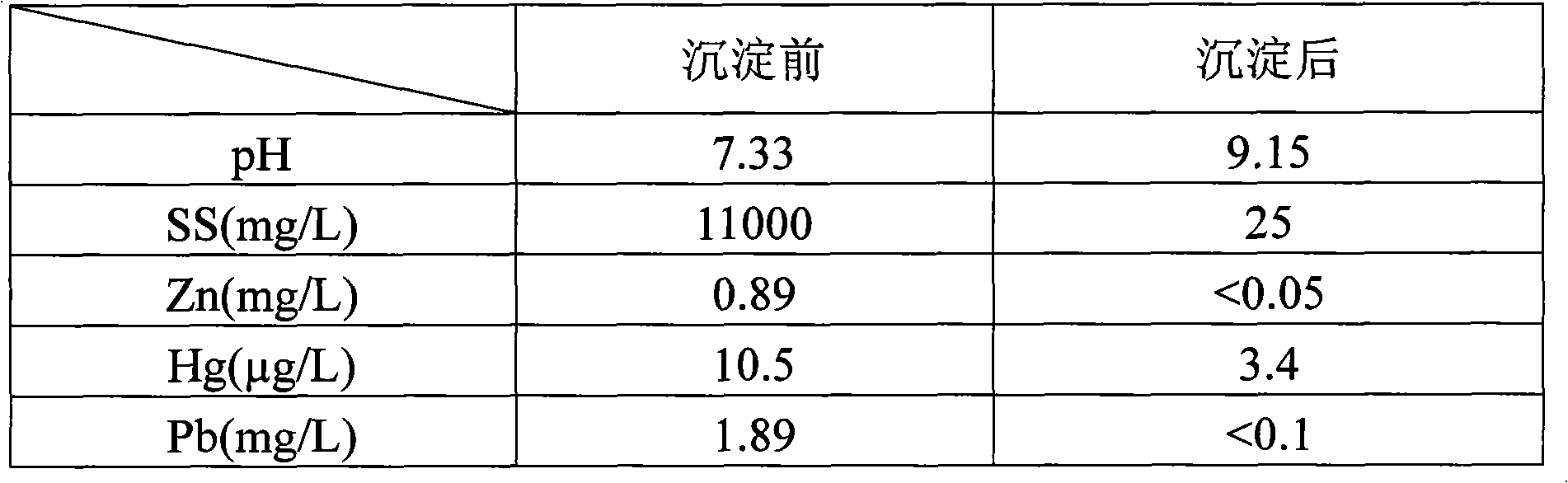

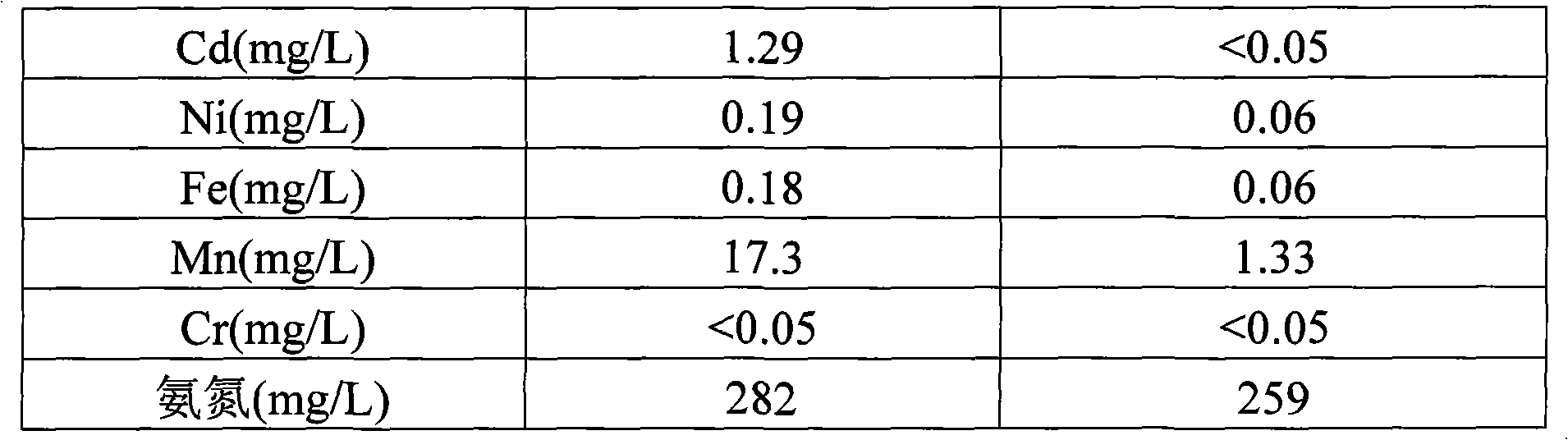

Treatment method of sintering flue gas desulphurization wastewater

ActiveCN101993169AReduce processing costsReduce the amount of waterTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationFlue gas

The invention discloses a treatment method of sintering flue gas desulphurization wastewater, which completes the treatment on the sintering flue gas desulphurization wastewater through the following five steps of: 1. neutralization and coagulation: regulating the pH value of the sintering flue gas desulphurization wastewater to 8.5 to 9.5 by lye, and adding 0 to 200ppm of coagulating agents; 2. flocculation: adding 0 to 10ppm of coagulant aids for forming flocs; 3. precipitation and filter liquor separation; 4. biochemical treatment on filter liquor; and 5. deep treatment. The treatment method can be used for reducing the treatment cost of the desulphurization wastewater without generating influence on other treatment systems, thereby having good application and popularization prospects.

Owner:BAOSHAN IRON & STEEL CO LTD

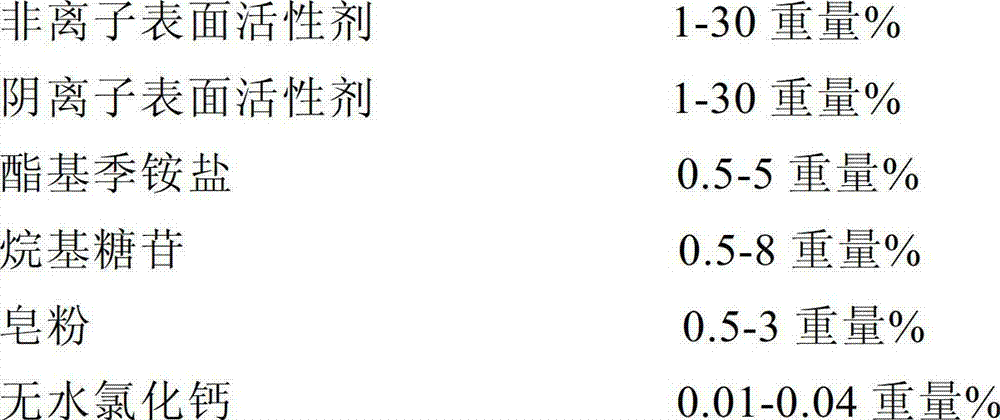

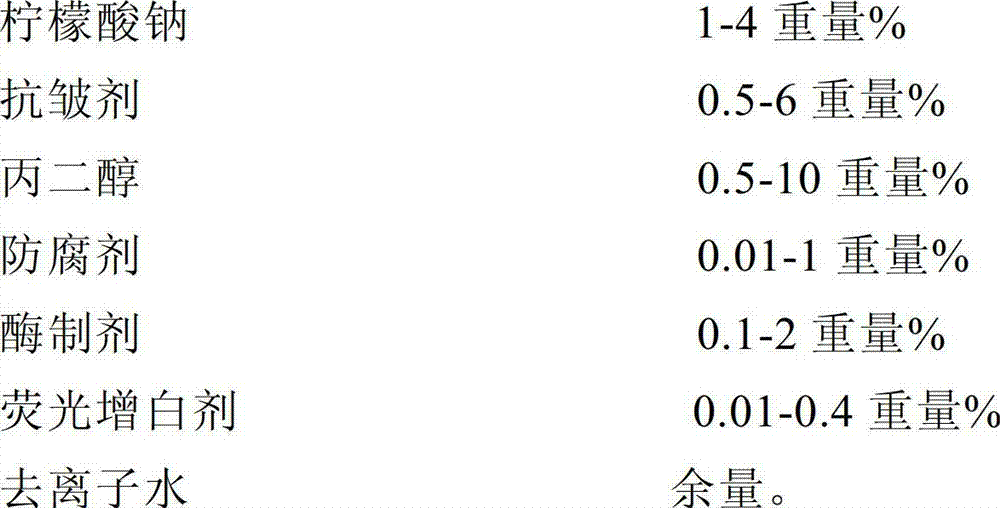

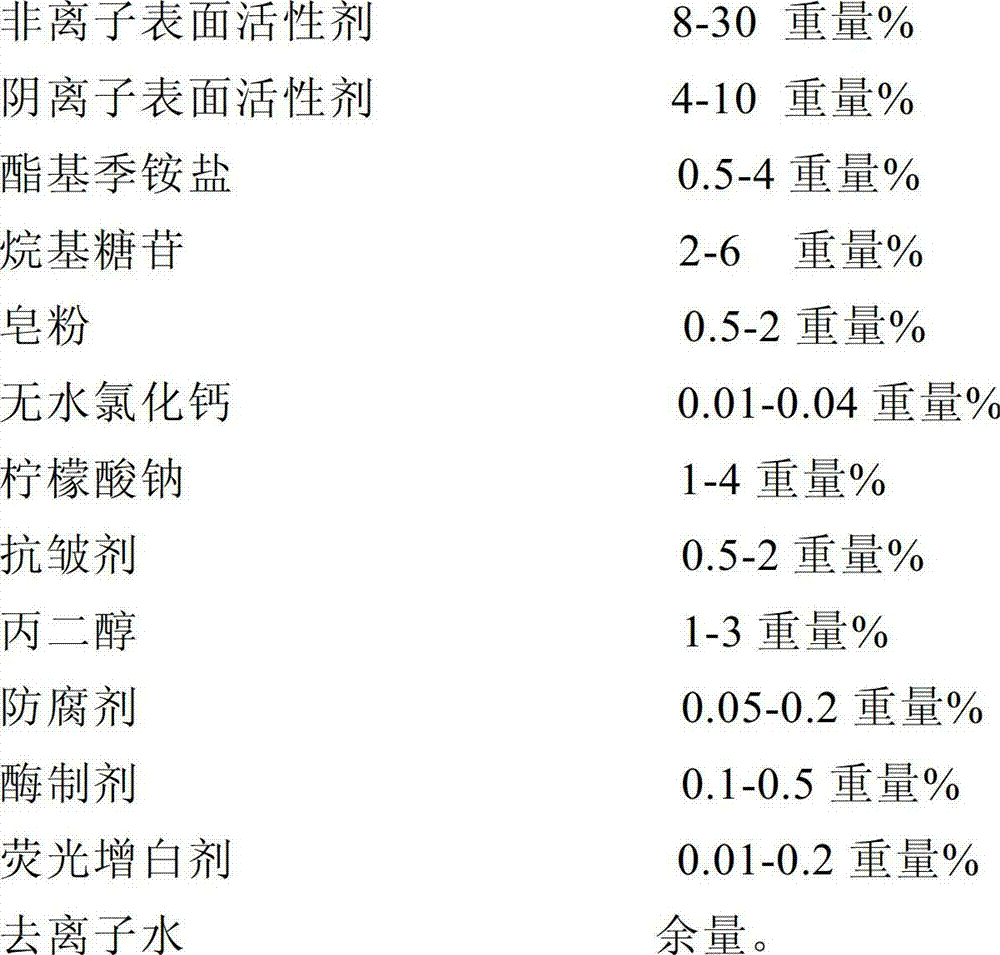

Low-foaming anti-crease soft laundry detergent and preparation method thereof

ActiveCN102965222AGood flexibilityImprove antistatic performanceSurface-active non-soap compounds and soap mixture detergentsSurface-active agentsLaundry detergent

The invention relates to a low-foaming anti-crease soft laundry detergent and a preparation method thereof. The low-foaming anti-crease soft laundry detergent comprises the following components according to proportions: 1-30 percent by weight of nonionic surface active agent, 1-30 percent by weight of anionic surface active agent, 0.5-5 percent by weight of ester quaternary ammonium salt, 0.5-8 percent by weight of alkyl-glycoside, 0.5-3 percent by weight of soap powder, 0.01-0.04 percent by weight of anhydrous calcium chloride, 1-4 percent by weight of sodium citrate, 0.18-1.8 percent by weight of anti-crease agent, 0.5-10 percent by weight of propylene glycol, 0.01-1 percent by weight of preservative, 0.1-2 percent by weight of enzymic preparation, 0.01-0.4 percent by weight of fluorescent whitening agent and the balance of deionized water. The laundry detergent has the advantages of softness, crease resistance, low foaming, stable system, high enzymatic activity and strong detergency.

Owner:NEW ERA HEALTH IND GRP +1

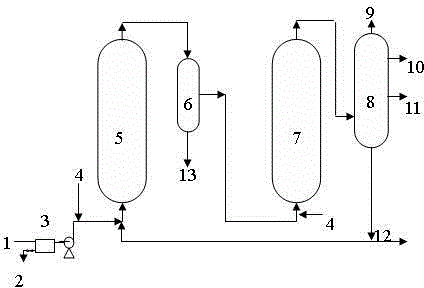

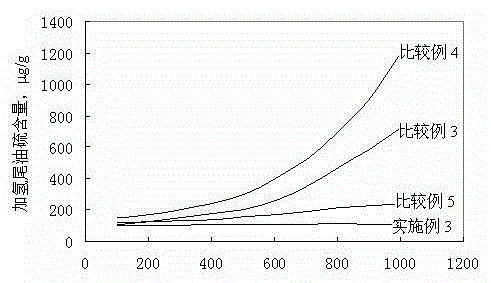

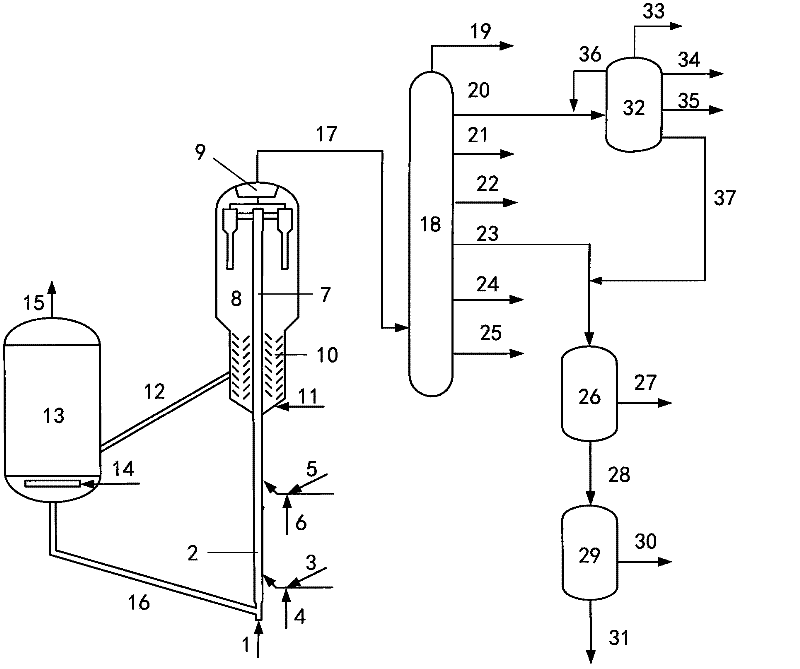

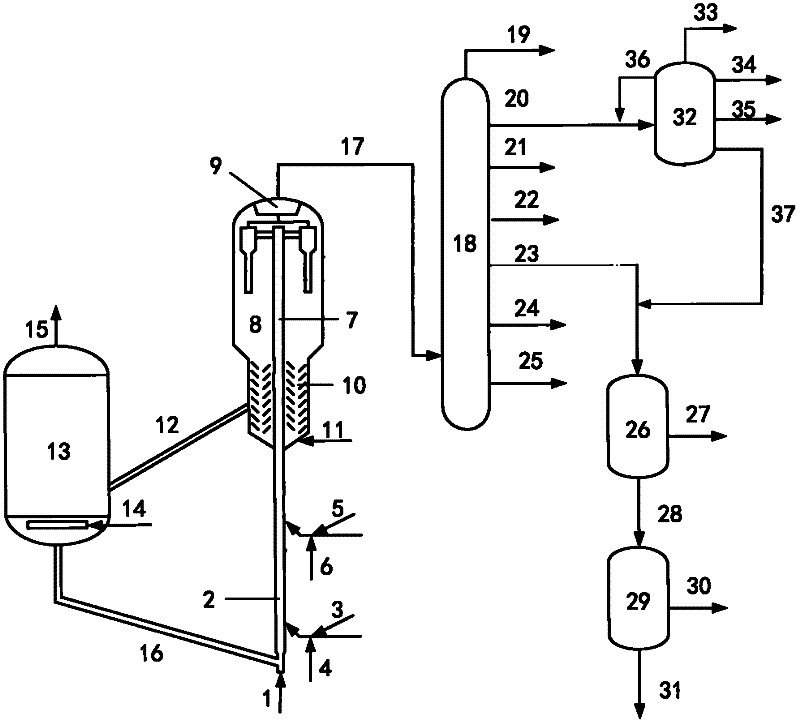

Method for hydrogenation of coal tar via fluidized bed

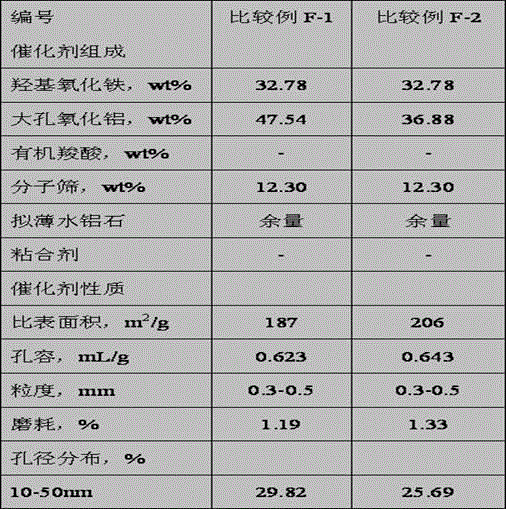

ActiveCN104593060AConsistent activityEasy to removeTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a method for hydrogenation of coal tar via a fluidized bed. The method comprises the following steps: subjecting a coal tar raw material to hydro-upgrading; carrying out separation to remove water; and then carrying out hydrorefining and fractionation so as to obtain a gasoline fraction, a diesel fraction and hydrogenation tail oil. A hydro-upgrading catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina, a molecular sieve and pseudo-boehmite; and a hydrofining catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina and a binder. The method provided by the invention adopts cheap iron oxyhydroxide as an active metal component, the hydro-upgrading catalyst and the hydro-refining catalyst are graded, so cost is low. According to the invention, moderate cracking of coal tar is carried out before refining of coal tar, so impurities in coal tar are effectively removed, product distribution and product quality are adjusted, and the running period of a device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

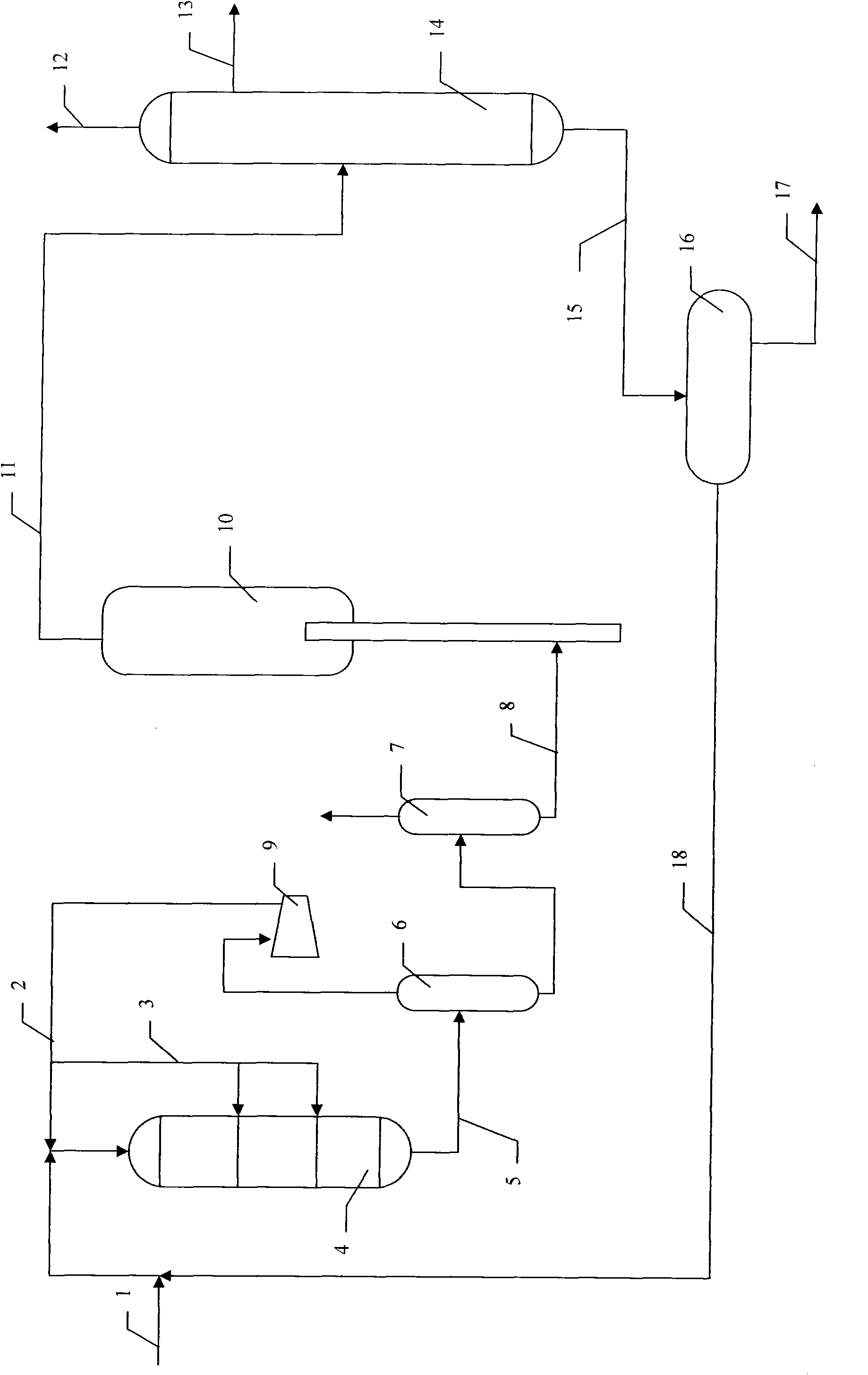

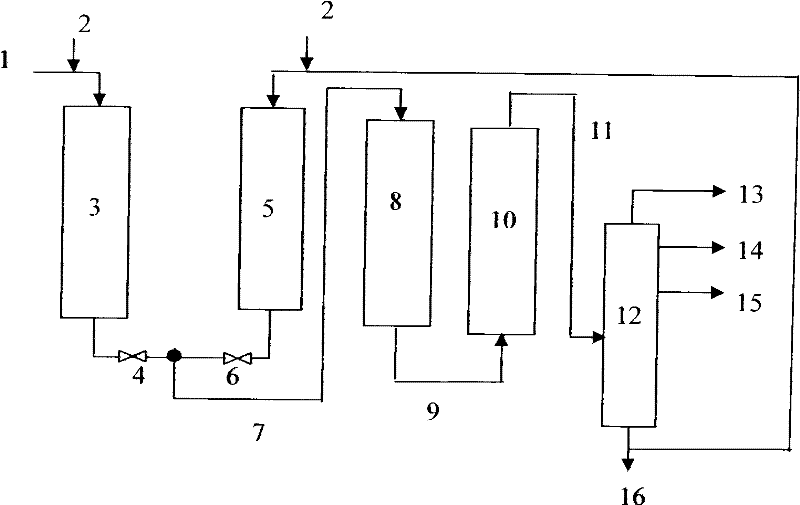

Wax oil hydrogenated treatment and catalytic cracking combined method

ActiveCN101875856AGuarantee normal productionSolve the problem that it is difficult to separate the catalyst solid powderTreatment with hydrotreatment processesGas phaseCombined method

The invention discloses a wax oil hydrogenated treatment and catalytic cracking combined method, which comprises the following steps of: performing hydrogenated reaction on hydrogenated treatment raw materials in the presence of hydrogen and hydrogenated treatment catalyst, performing gas-liquid separation on the hydrogenated reaction effluent, circulating the gas phase for the hydrogenated reaction, directly feeding the liquid phase into a catalytic cracking device without fractionation, and mixing dry gas and liquefied gas separated from the catalytic cracking reaction effluent, catalytic cracking heavy fraction formed by catalytically cracking gasoline and the hydrogenated treatment raw materials to perform hydrogenated reaction. Compared with the prior art, the method can produce maximum gasoline, meanwhile saves equipment investment, makes full use of reaction heat energy and reduces the production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

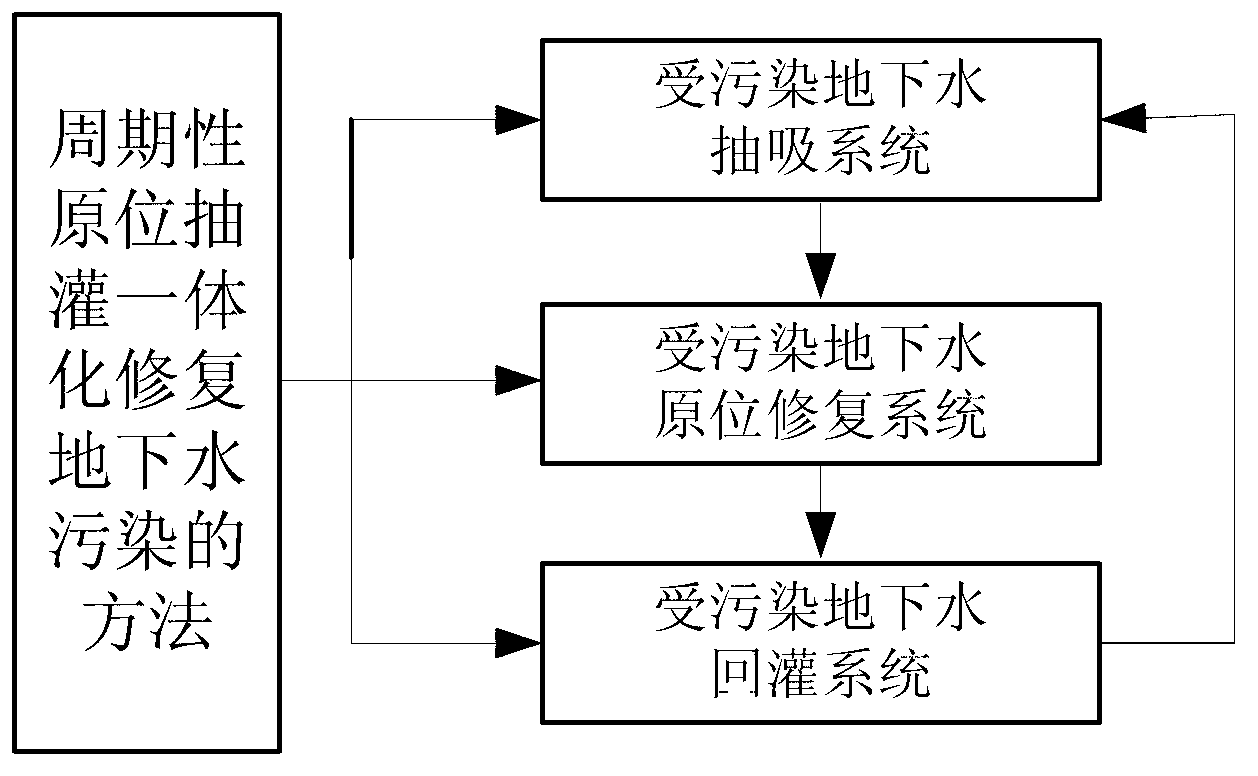

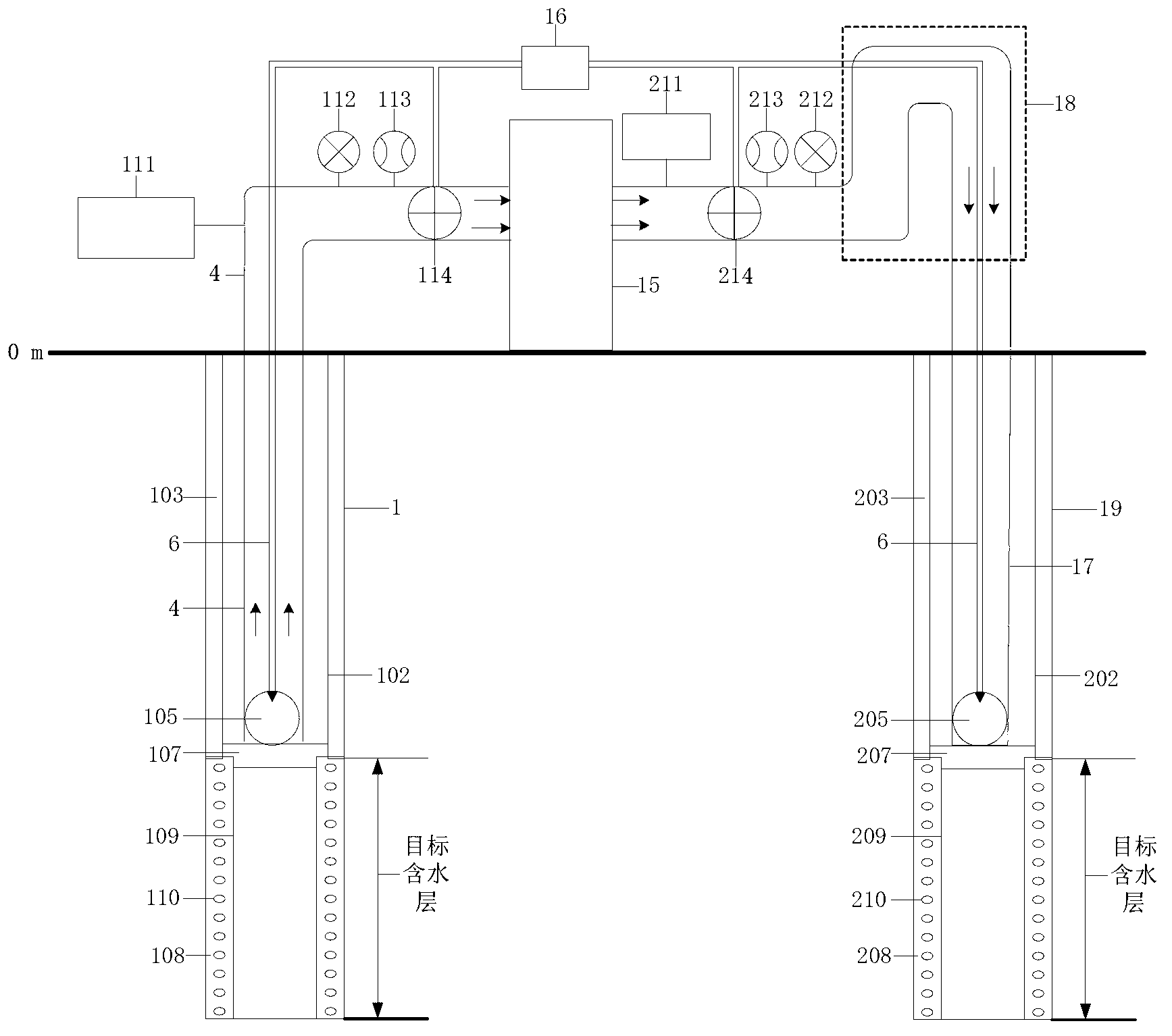

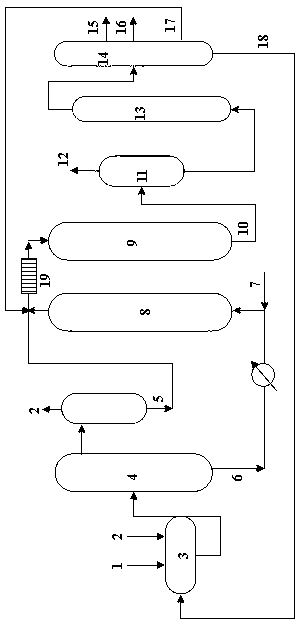

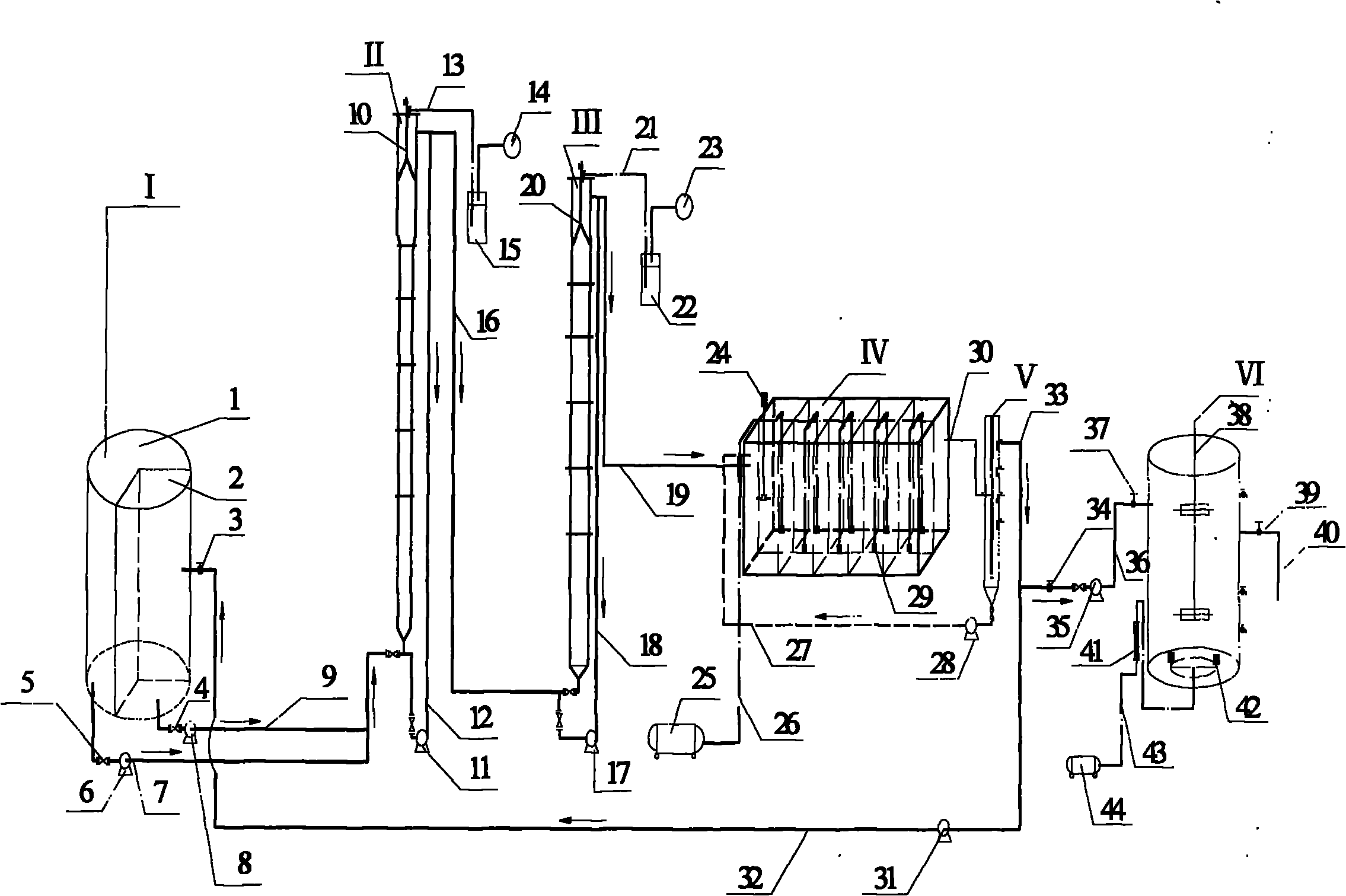

Device and method for periodic in-situ pumping based integrated repairing of groundwater pollution

ActiveCN103303986AAct as a diluentReduce concentrationContaminated soil reclamationFluid removalEnvironmental engineeringEngineering geology

The invention belongs to the technical field of in-situ preparing of polluted underground water, and particularly relates to a device and method for periodic in-situ pumping based integrated repairing of groundwater pollution. The device comprises a polluted underground water pumping system, an in-situ repairing system and a recharge system, wherein the pumping system is composed of a pumping well and a pumping pipeline; the pumping system is connected with the in-situ repairing system; the in-situ repairing system is connected with the recharge system; and the recharge system comprises a recharge pipeline and a recharge well. The pumping well and the recharge well are subjected to a pumping test and a recharge test before the periodic in-situ pumping based integrated repairing of the underground water pollution is carried out. By adopting the method, the processed underground water is recharged to the original polluted water layer to dilute the original polluted water layer, so that the concentration of pollutants in a target aquifer is reduced, convenience is provided for subsequent treatment, and the pollution manage cost is reduced. The processed polluted underground water is timely recharged; and the poor hydrogeololgy and engineering geology can be effectively avoided.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

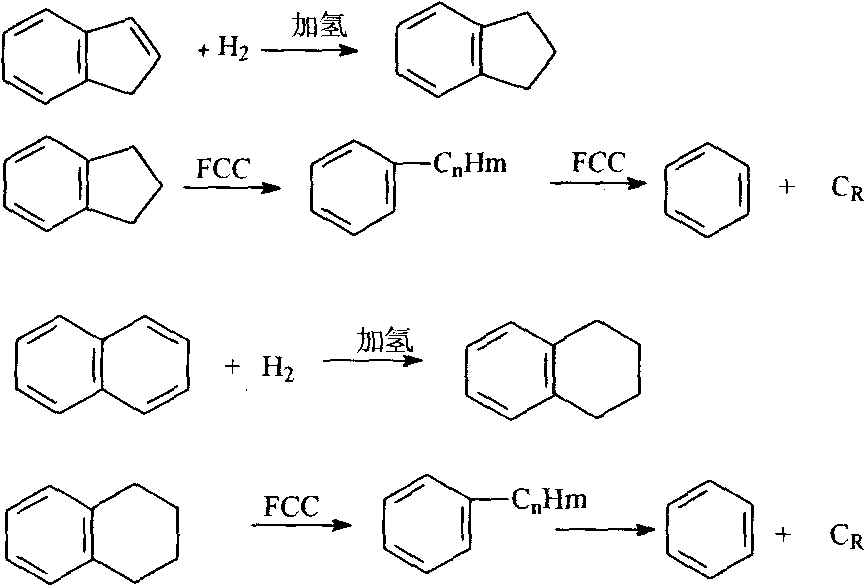

Catalytic conversion method for petroleum hydrocarbon

ActiveCN102344832AHigh yieldHigh selectivityTreatment with hydrotreatment processesExtraction purification/separationGasolineReaction temperature

The invention relates to a catalytic conversion method for petroleum hydrocarbon. According to the method, raw oil contacts a catalyst in a reactor to carry out a reaction, wherein the catalyst is rich in mesoporous zeolite; a cracking reaction is performed under the following conditions: a reaction temperature is 500-750 DEG C, weight hourly space velocity is 100-800 h<-1>, reaction pressure is 0.10-1.0 MPa, a weight ratio of the catalyst to the raw oil is 1:100, a weight ratio of water vapour to the raw oil is 0.05:1.0; the spent catalyst and the reaction oil gas are separated; the spent catalyst is subjected to regeneration, and returns to the reactor, the reaction oil gas is separated to obtain a product, wherein the product comprises ethylene, propylene, propane, butane and arene-rich catalytic gasoline; the catalytic gasoline is subjected to selective hydrogenation, and enters an arene extraction apparatus to separate to obtain the target product of light arene; the raffinate oil, the propane and the butane are subjected to steam cracking to further produce ethylene and propylene. With the method provided by the present invention, the yields of the ethylene and the propylene are respectively 20.31 wt% and 31.67 wt%, the yield of BTX is 24.39 wt%.

Owner:CHINA PETROLEUM & CHEM CORP +1

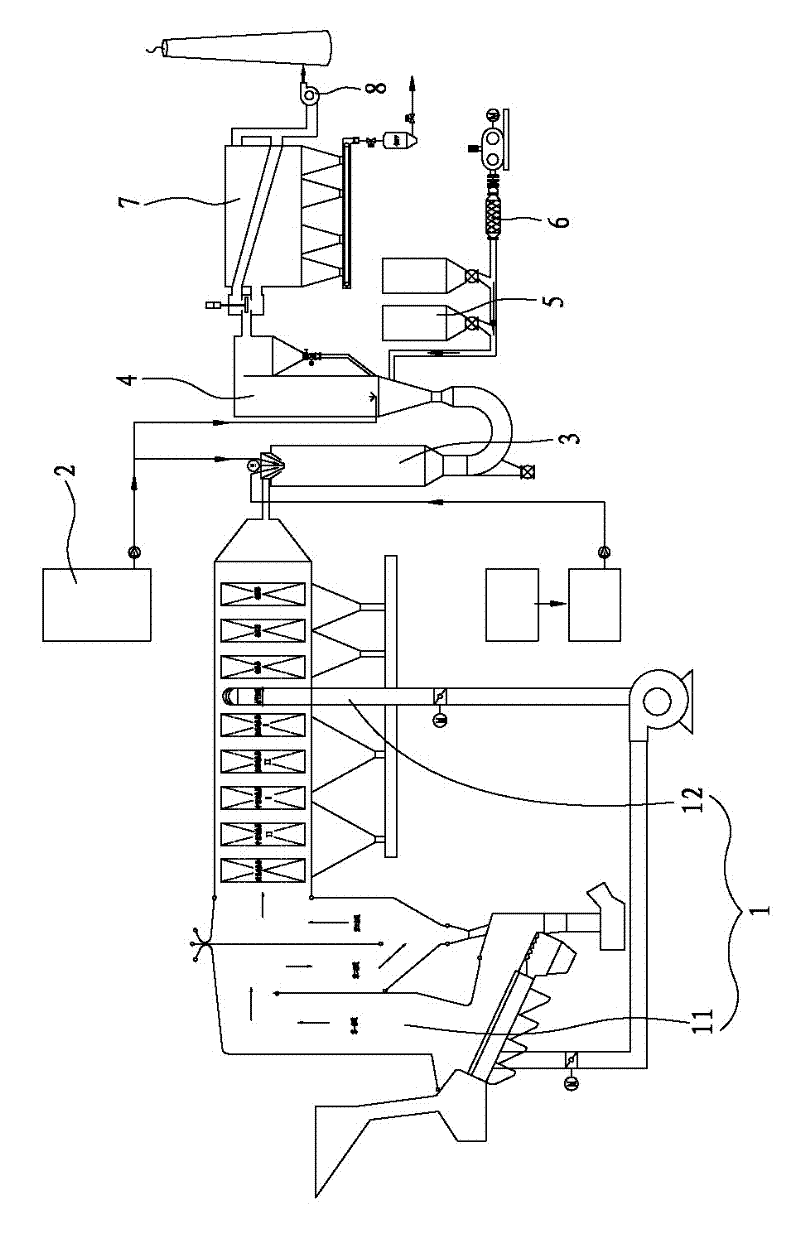

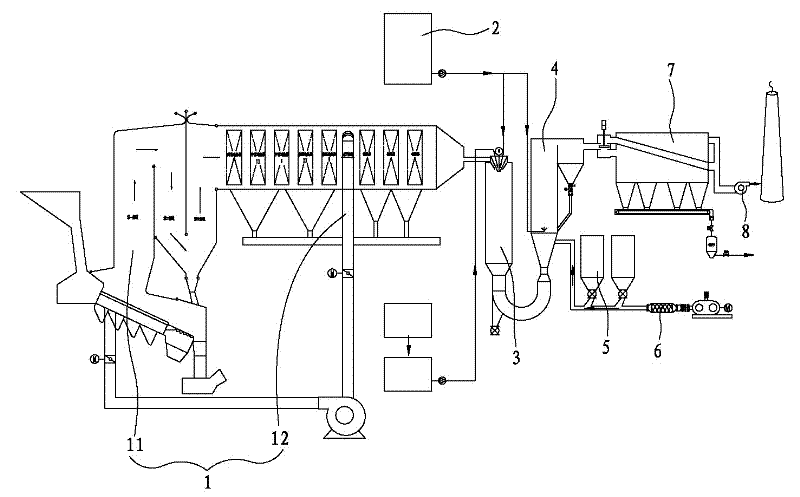

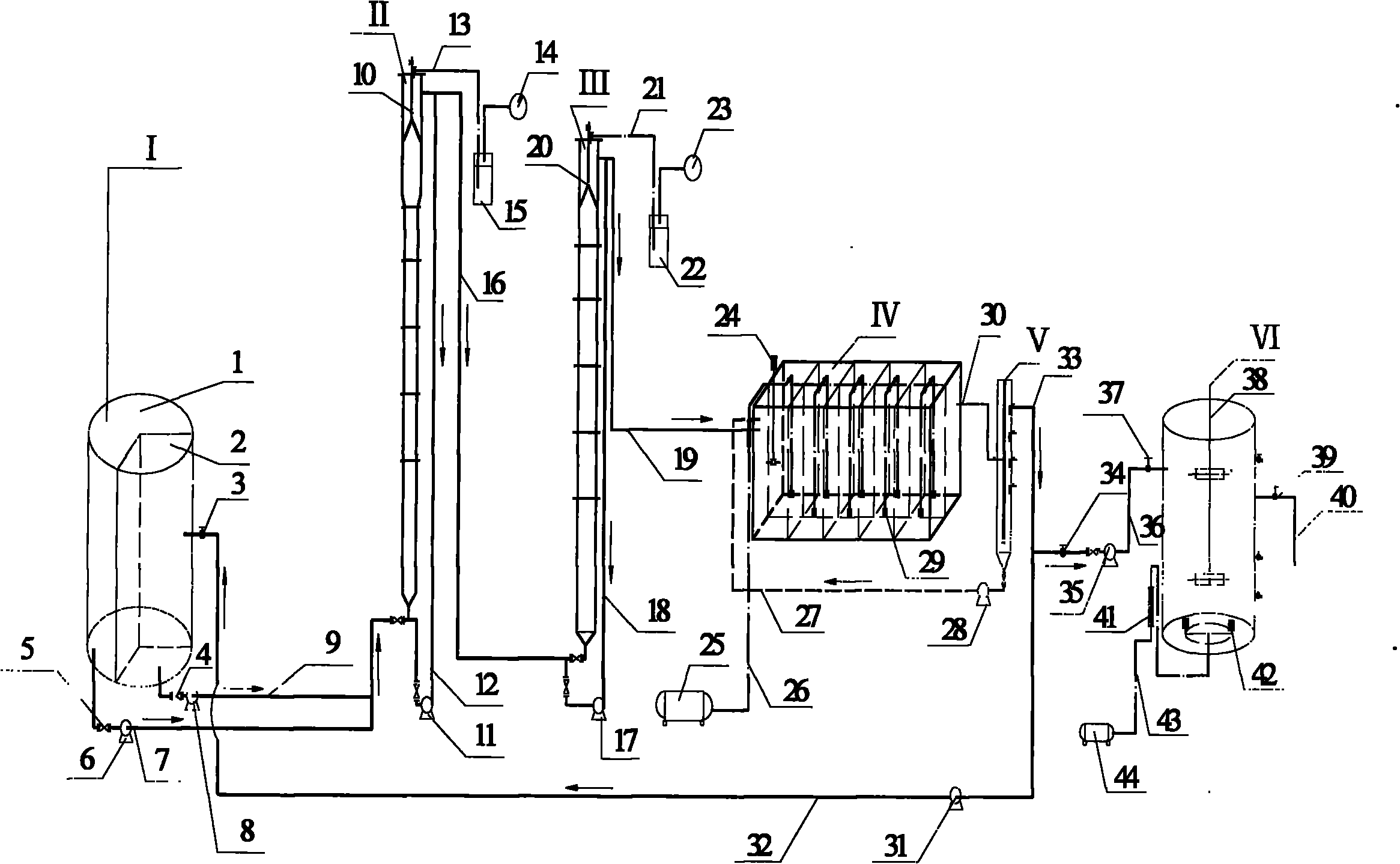

Waste burning smoke purification process and purification system

InactiveCN102233230AEmission reductionSuppress generationLighting and heating apparatusDispersed particle separationEnvironmental engineeringSpray dried

The invention discloses a waste burning smoke purification process. The process comprises a denitration step and an acid removal step. The denitration step comprises a combination step of a smoke recycling process and a selective non-catalytic reduction (SNCR) denitration process; the acid removal step comprises a primary acid removal step and a secondary acid removal step; and a spray drying method is used for removing acid in the primary acid removal step, and a suspension boiling method is used for removing acid in the secondary acid removal step. The generation of NOx is inhibited by the smoke recycling process, acidic gases in the smoke are removed by the secondary acid removal process, and the burned smoke is efficiently purified with relatively low operating cost. The deep purification effect of the smoke is achieved by organically combining several processes.

Owner:瀚蓝(厦门)固废处理有限公司 +3

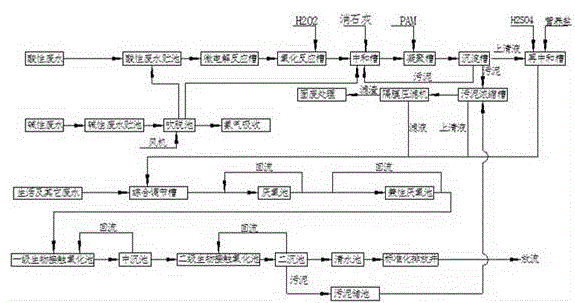

High-concentration fluorine chemical wastewater treatment technology

ActiveCN104961304AReduce dosageAvoid unstable water quality parametersWater contaminantsMultistage water/sewage treatmentMicroorganismSludge

The invention provides a high-concentration fluorine chemical wastewater treatment technology which comprises the following sequential treatment on the chemical wastewater: (1) classified collection, oil isolation and settling; (2) microelectrolysis decomposition; (3) Fenton oxidation; (4) neutralization and coagulation; (5) flocculation; (6) precipitation and sludge backflow; (7) re-neutralization; and (8) biochemical treatment. Through separate treatment on the acid-alkaline wastewater, refractory precipitate or complex generated when two kinds of wastewater are mixed can be avoided; before the wastewater enters a microelectrolysis reaction tank, alkaline wastewater is properly used as a pH regulator, and thus the addition of the pH regulator in the whole system is reduced; in the technology, part of the precipitated sludge flows back into a pH neutralizing tank, and thus the fluorine removal effect is improved; by mixing domestic wastewater with the production wastewater after physicochemical treatment, readily biodegradable organic nutrients can be introduced, and the salt concentration in water is further reduced so as to protect the microorganisms; and by adopting the technology, the problems of large investment and high operation cost in chemical wastewater treatment are solved.

Owner:DALIAN SHIDATE ENVIRONMENTAL SCI & TECH CO LTD

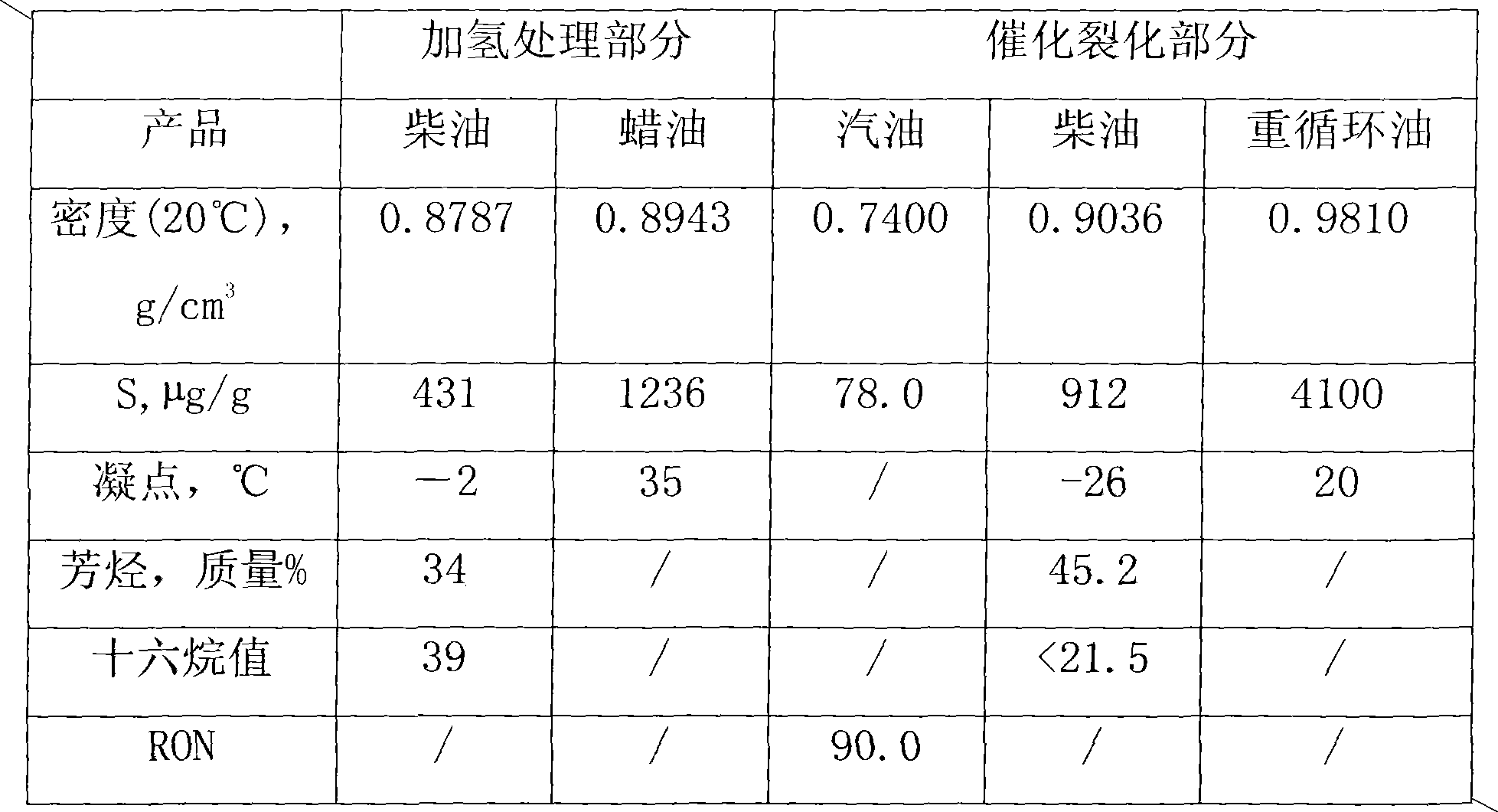

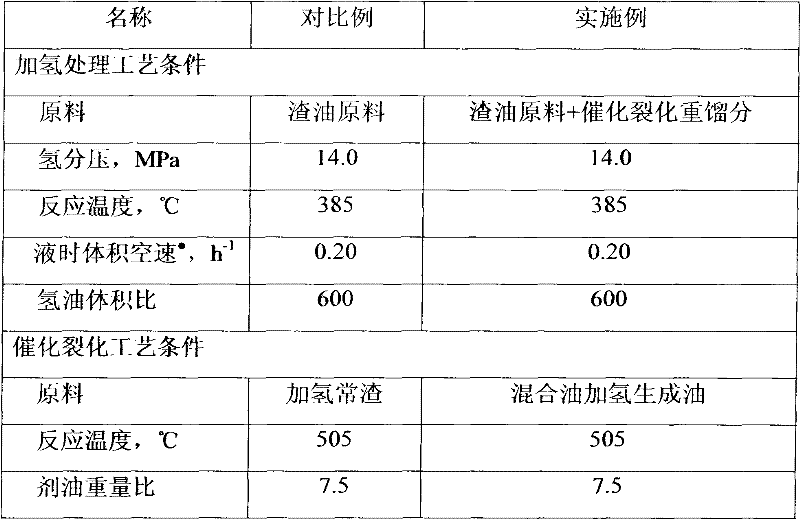

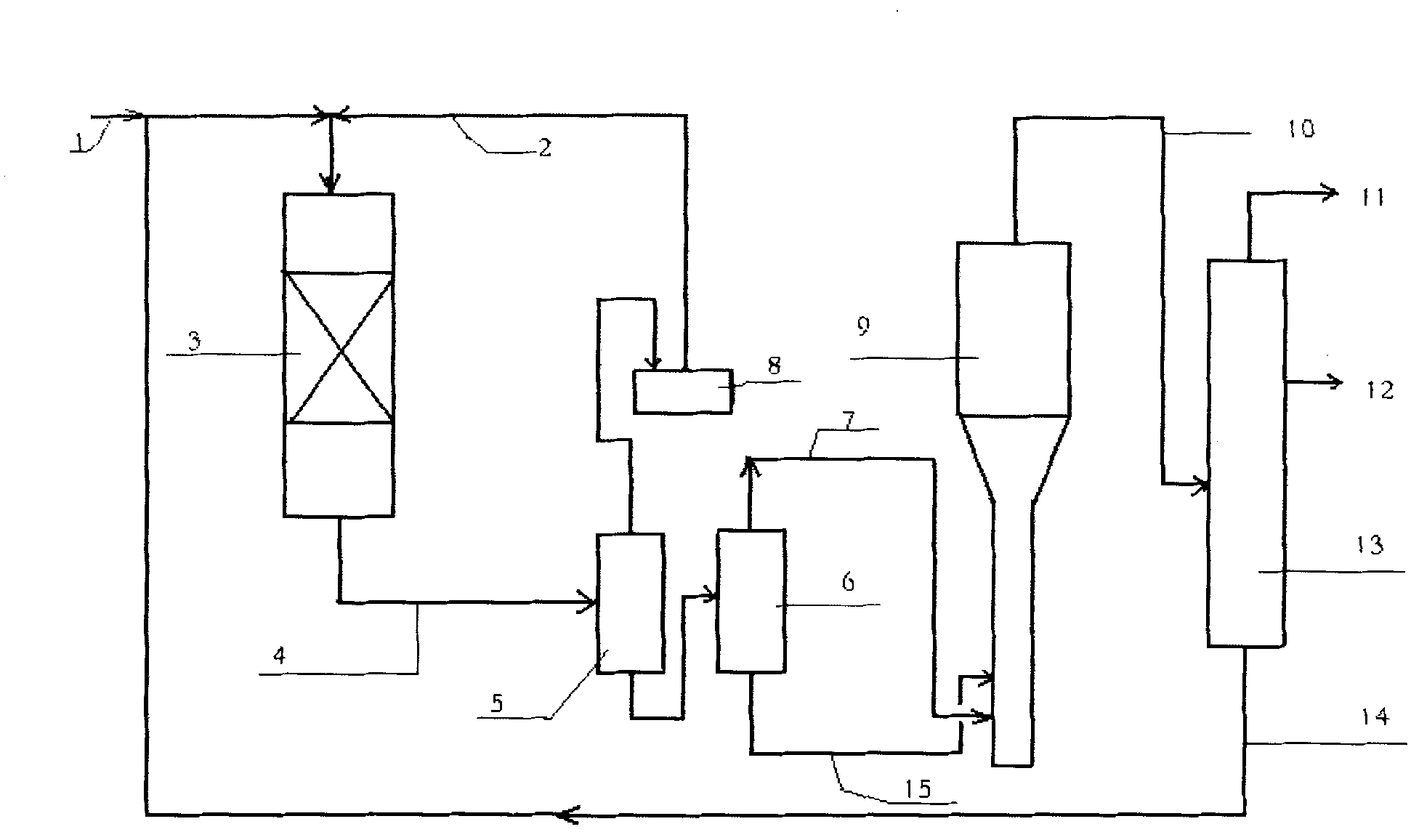

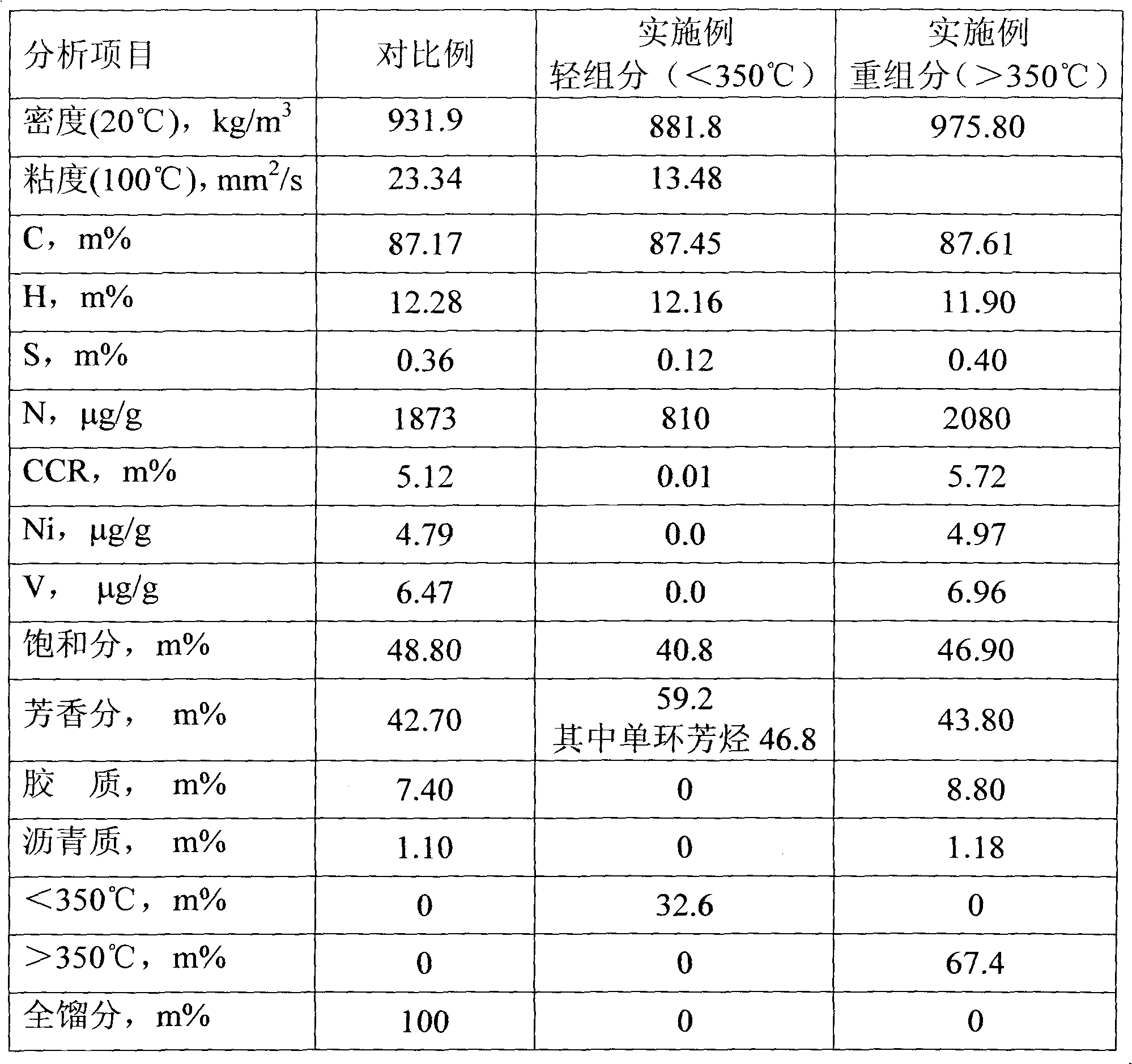

Hydrotreatment and catalytic cracking combined method for residuum

InactiveCN102732314AHigh aromatic contentHigh content of impurities such as sulfurTreatment with hydrotreatment processesPtru catalystGasoline

The invention discloses a hydrotreatment and catalytic cracking combined method for residuum. The hydrotreatment and catalytic cracking combined method for residuum comprises the following steps that a residuum raw material and at least part of a catalytically cracked diesel fraction undergo a hydrotreatment reaction in the presence of hydrogen and a hydrotreatment catalyst in a hydrotreatment device; a hydrotreatment reaction effluent is subjected to gas-liquid separation; a gas phase is circularly used for a hydrotreatment reaction and a liquid phase directly enters into a catalytic cracking device without passing through a fractionation device and then undergoes a catalytic cracking reaction; a catalytic cracking reaction effluent is treated by the fractionation device so that dry gas, liquefied gas, a catalytically cracked gasoline fraction, a catalytically cracked diesel fraction, catalytically cracked recycle oil and catalytically cracked slurry are separated out; a part or all of the catalytically cracked diesel fraction is fed back to the hydrotreatment device and then undergoes a hydrotreatment reaction; and the catalytically cracked recycle oil is fed back to the catalytic cracking device and then undergoes a catalytic cracking reaction. Compared with the prior art, the hydrotreatment and catalytic cracking combined method for residuum can realize maximum-yield production of gasoline, save an equipment investment, fully utilize reaction heat and reduce production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined process for in-depth conversion of residual oil

ActiveCN103102980ARealize comprehensive utilizationImprove the effect of hydrotreating reactionTreatment with hydrotreatment processesPtru catalystFluidized bed

The invention discloses a combined process for in-depth conversion of residual oil. The combined process comprises the following steps: (1) mixing a residual oil raw material with at least part of oil slurry of a catalytic cracking unit and allowing an obtained mixture to enter into a solvent deasphalting unit so as to obtain deasphalted oil and de-oiled asphalt; (2) allowing the de-oiled asphalt obtained in step (1) to enter into a fluidized bed hydrotreatment unit and carrying out fluidized bed hydrotreatment in the presence of hydrogen and a fluidized bed hydrotreatment catalyst; and (3) mixing an effluent of fluidized bed hydrotreatment obtained in the step (2) with the deasphalted oil, adding at least a part of recycle oil of the catalytic cracking unit at the same time and allowing an obtained mixture to enter into a fixed bed hydrotreatment unit, wherein generated oil of an effluent of fixed bed hydrotreatment is used as a raw material for the catalytic cracking unit. Compared with the prior art, the combined process provided by the invention has the advantages of wide sources of the raw materials, low equipment investment, stable operation, a long operation period and a good synergistic and coordination effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

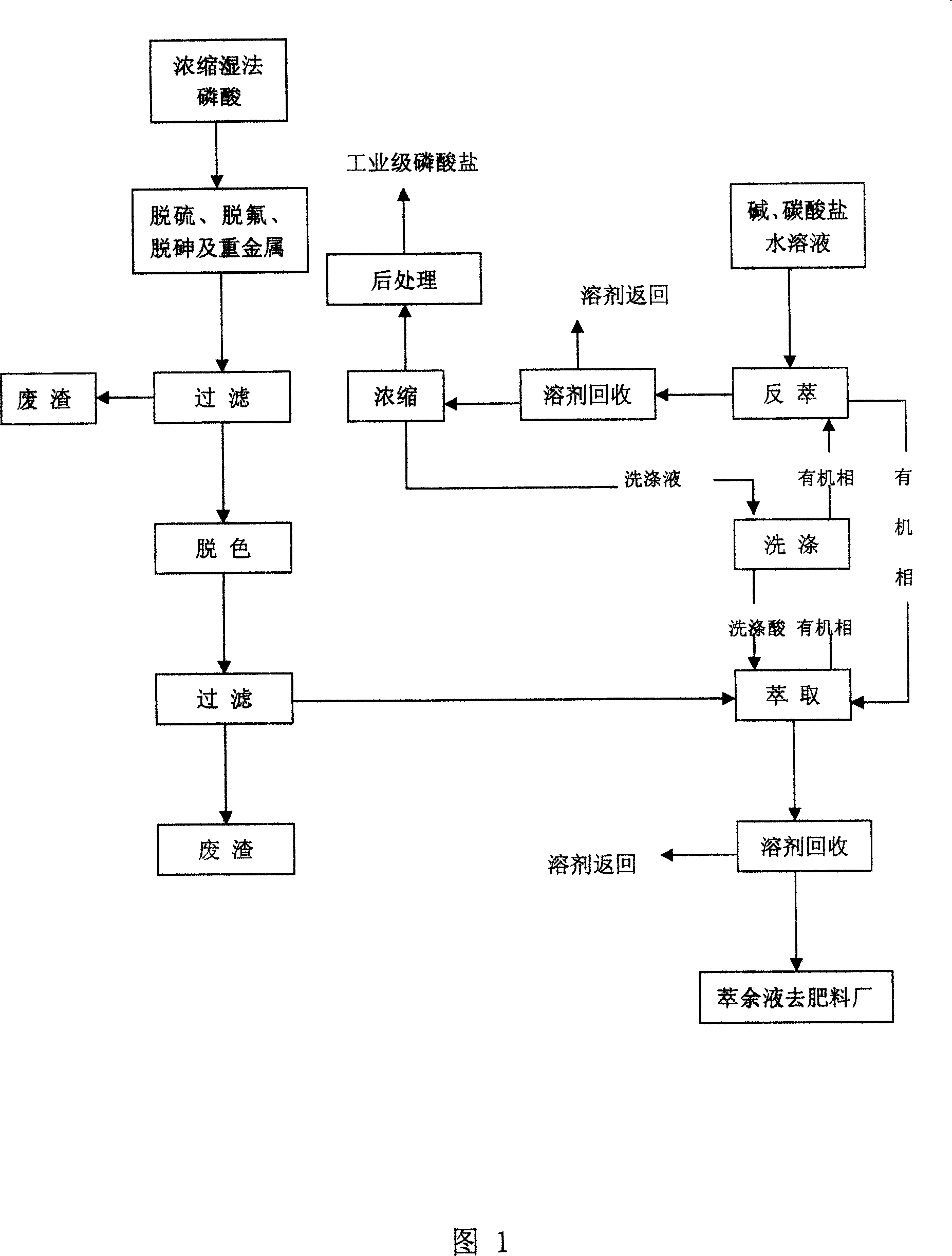

Method for preparing technical grade phosphate using wet method phosphoric acid as raw material

InactiveCN1994871ATake full advantage of the combined utilityReduce lossesPhosphatesCompound organicAlkaline earth metal

The invention discloses a making method of industry-grade phosphate based on wet process phosphoric acid as raw material, which comprises the following steps: desulfurizing; defluorinating; stripping arsenic; removing heavy metal; decoloring; extracting predisposed wet process phosphoric acid through compound organic solvent of ketone and phosphate ester; washing; reextracting; condensing; post-processing to obtain the product; adopting alkali solution of potassium carbonate, sodium carbonate or alkaline-earth metal as extractor.

Owner:YUNNAN CHEM RES INST

Auxiliary enhancement chemical agent for oil extraction with heat

ActiveCN102643636AMitigate negative impactWide range of heat injectionDrilling compositionPetroleumAmmonium carbonate

The invention discloses an auxiliary enhancement chemical agent for oil extraction with heat. The chemical agent comprises component A, component B and component C; the component A is petroleum surfactant solution; petroleum surfactant solution is obtained by the reaction of crude oil and deacidification agent; the component B comprises at least three ingredients of ammonium acid carbonate, ammonium carbonate, sodium hydrogen carbonate, ammonium chloride and sodium nitrite; and the component C is organic metal salt or ionic liquid. The auxiliary enhancement chemical agent for the oil extraction with heat has the following beneficial effects that three components of the auxiliary enhancement chemical agent for the oil extraction with heat are cheap and easy to get, single action of the three components is supplemental with one another and coordinated to make enhancement, self-growing surfactants, gases and catalysts of an oil layer in an adjacent well area can play roles in stages of thickened oil heat injection, well stewing and oil extraction, so that the viscosity is reduced by emulsifying, gas driving and catalyzed modifying of thickened oil, self-growing surfactants and gases generated in a far well area play leading roles, and the viscosity is reduced by dissolved gas expansion of thickened oil or by promoting low-temperature emulsification of thickened oil through generated gases of the oil layer.

Owner:CHINA NAT OFFSHORE OIL CORP +1

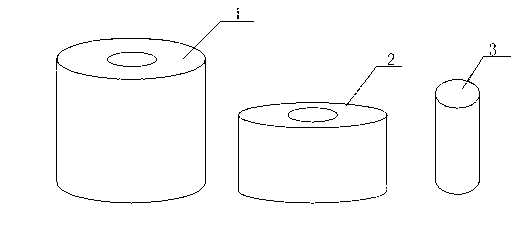

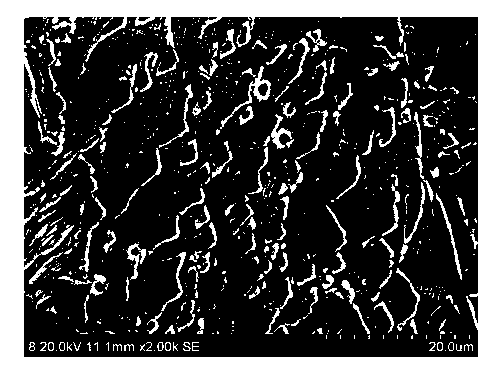

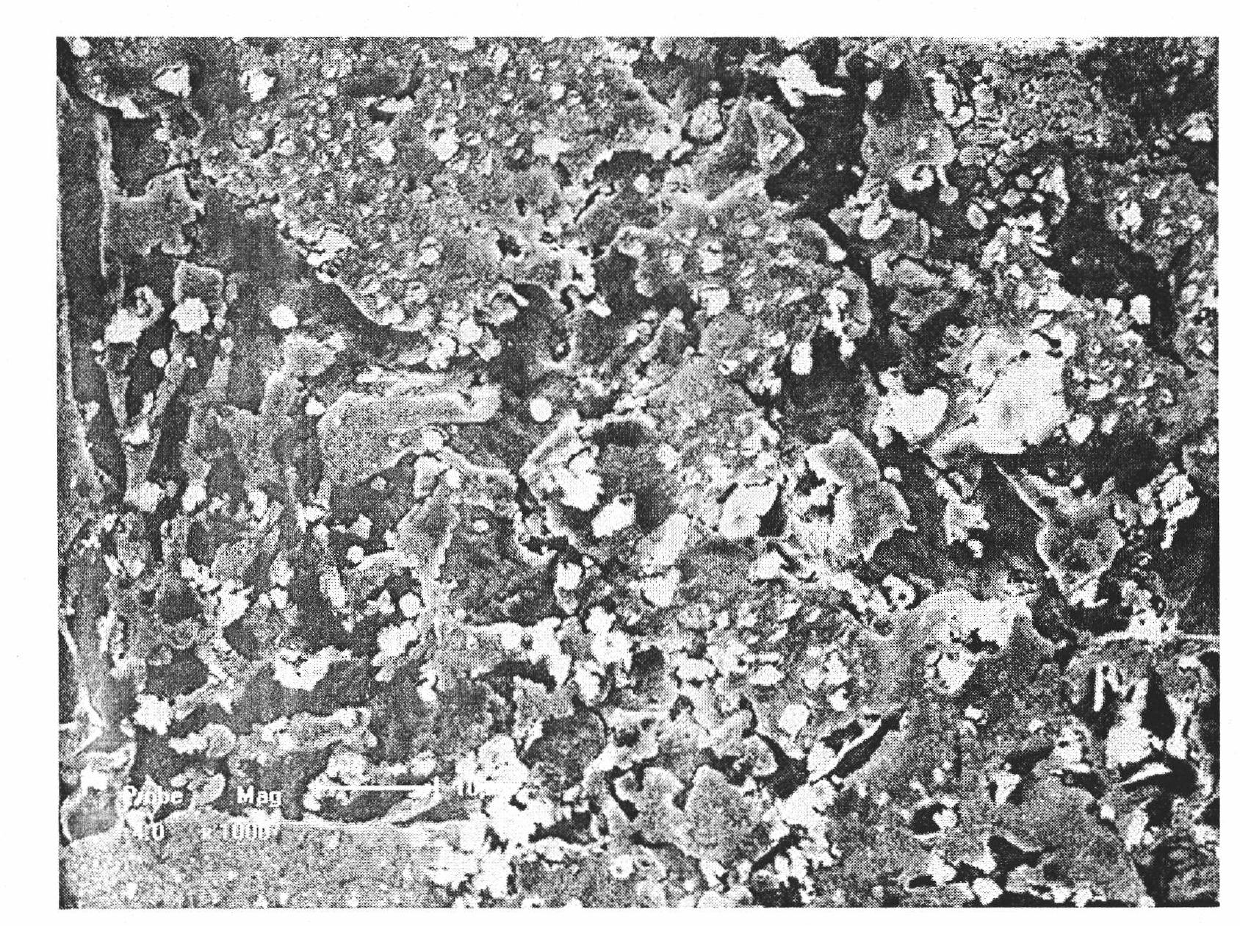

Laser sintering synthesis method of ceramic-particle-reinforced nickel-aluminum-based composite

InactiveCN102876926AEasy to control speedPlay a role in strengthening the matrixNumerical controlPhase formation

The invention belongs to the technical field of material processing and particularly relates to a laser sintering synthesis method of a ceramic-particle-reinforced nickel-aluminum-based composite. The technical scheme includes that the laser sintering synthesis method includes the steps: mixing nickel powder with aluminum powder according to the atomic ratio of Ni to Al of 3:1, adding tungsten concentrate powder accounting for 0.5-2wt% of the total weight of nickel-aluminum mixed powder, performing ball milling to obtain uniformly-mixed mixed powder, compacting the mixed powder to a cylindrical compact, placing the compact on a numerically-controlled machine tool, starting a CO2 laser machine with the laser powder of 900-1200W for laser radiation for 10-20s, and lighting the surface of the compact to enable the compact to generate self-propagating reaction, so that the ceramic-particle-reinforced nickel-aluminum-based composite by laser sintering synthesis is obtained. According to the laser sintering synthesis method, matrix reaction, reinforced phase formation and metal-based composite preparation are combined together, and the reinforced ceramic phase subjected to in-situ synthesis enables high-temperature mechanical properties of a nickel-aluminum intermetallic compound to be obviously improved and enhanced.

Owner:LIAONING TECHNICAL UNIVERSITY

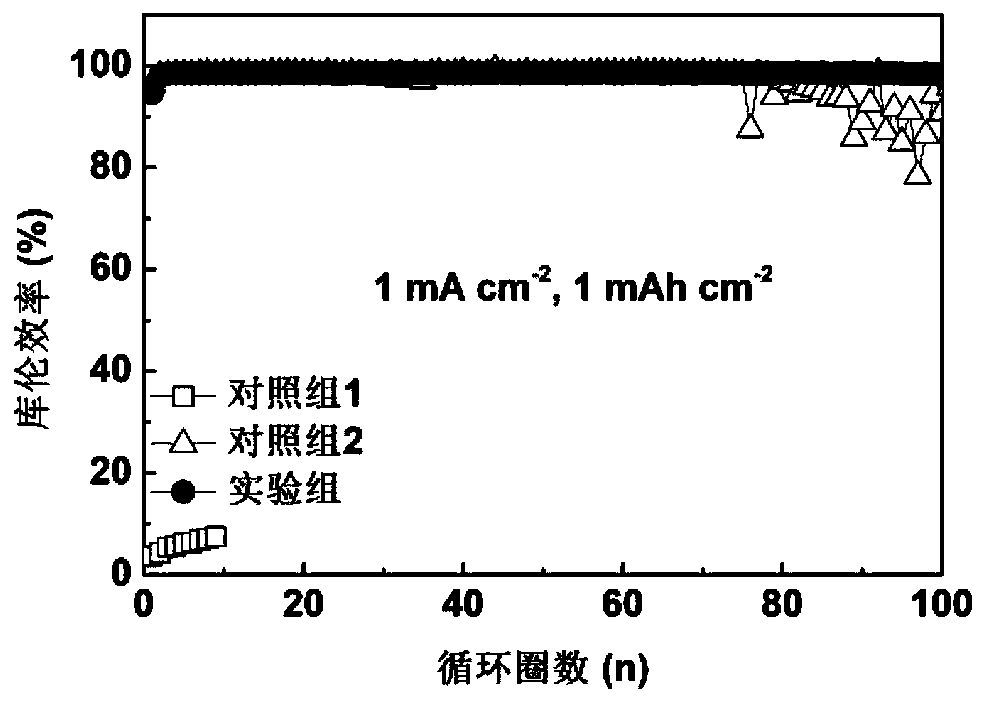

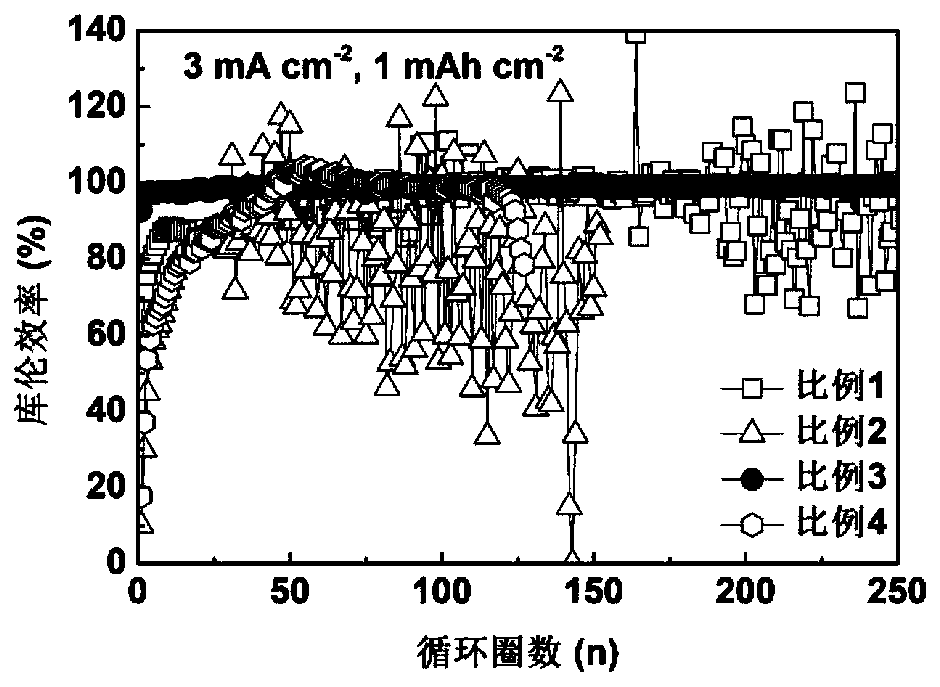

Lithium metal battery electrolyte accommodating aromatic compound as diluent

ActiveCN110890592AAltered solvationReduce conductivityLi-accumulatorsOrganic electrolytesElectrolytic agentPhysical chemistry

The invention relates to a lithium metal battery electrolyte accommodating aromatic compounds as diluents, and belongs to the technical field of lithium metal batteries. The electrolyte contains a lithium salt, a solvent for dissolving the lithium salt and a diluent, wherein the diluent is an aromatic compound; wherein the diluent is used for inhibiting lithium dendrites generated by uneven deposition of a lithium metal negative electrode in the lithium metal battery in the circulation process, and is used for inhibiting the lithium metal negative electrode in the lithium metal battery from reacting with an electrolyte. According to the invention, the aromatic diluent is added to dilute the high-concentration lithium salt electrolyte. Therefore, the solvation structure of the lithium saltin the electrolyte is improved to accelerate lithium ion transmission; according to the electrolyte, the degree of uneven local current density on the surface of lithium metal is reduced, lithium metal deposition is homogenized, so that growth of dendrites on the surface of the lithium metal is inhibited, the electrolyte has high conductivity, low viscosity and good wettability, the coulombic efficiency of the lithium metal battery can be effectively improved, and the cycle life of the lithium metal battery is greatly prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for treating rubbish percolates of different times for deep denitrification by using bipolar USAB+A/O+SBR process

InactiveCN101805096ATake advantage ofHigh denitrification efficiencyTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentHigh concentrationTotal nitrogen

The invention discloses a method for treating rubbish percolates of different times for deep denitrification by using a bipolar USAB+A / O+SBR process, which belongs to the technical field of biological denitrification and is suitable for performing advanced treatment on the rubbish percolates. In the method, water output by an A / O reactor passes through a secondary sedimentation tank, then part of the water flows back into a first-stage UASB reactor to perform denitrification, so the method fully uses sufficient carbon sources of raw water, realizes an efficient denitrification efficiency, and fully uses the characteristic that the rubbish percolates contain high-concentration organic substances. Dissolved oxygen (DO), an oxidation-reduction potential (ORP) and a pH value sensor are used for monitoring the degradation and the short-range nitrification / denitrification processes of the organic substances in the reactor, and the short-range nitrification / denitrification processes can be well controlled according to monitored pH values and ORP values. The average ammonia nitrogen concentration of final yielding water is 2 mg / L, the total nitrogen concentration is lower than 40 mg / L, and the ammonia nitrogen removal rate and the total nitrogen removal rate are above 98 percent. The method completely depends on biological treatments, reduces the cost and simplifies the process. The method performs denitrification on the rubbish percolates, not only realizes complete nitrification but also realizes short-range nitrification, and realizes the deep removal of the nitrogen in the rubbish percolates.

Owner:LANZHOU SHUISEN ELECTRONICS TECH

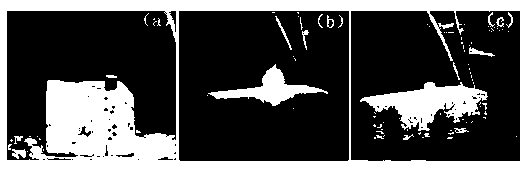

Method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion

InactiveCN101906572AIncrease profitImprove performanceSelf-propagating high-temperature synthesisIron powder

The invention discloses a method for synthesizing in-situ formed ceramic particle reinforced iron-aluminum-based composites by laser combustion, belonging to the technical field of materials. The in-situ formed ceramic particle reinforced iron-aluminum-based composites are prepared by the following steps of: putting tungsten ore powder, iron powder, aluminum powder and carbon powder in a ball mill for milling to obtain a mixed powder material; and compressing the mixed powder material into a pressed compact, transmitting a high-energy laser beam by employing a CO2 laser processing machine to ignite the surface of the pressed compact and trigger self-propagating high temperature synthesis of the pressed compact. By the invention, two ceramic particle reinforced phases are simultaneously formed on one substrate, which shortens the preparation process of the composites, lowers material manufacture cost and facilitates large-scale production and application.

Owner:LIAONING TECHNICAL UNIVERSITY

Hydrotreatment and catalytic cracking deeply-combined method for residuum

InactiveCN102732315AQuality improvementIncrease productionTreatment with hydrotreatment processesPtru catalystGasoline

The invention discloses a hydrotreatment and catalytic cracking deeply-combined method for residuum. The hydrotreatment and catalytic cracking deeply-combined method for residuum comprises the following steps that a residuum raw material, at least part of catalytically cracked heavy recycle oil and at least part of catalytically cracked slurry undergo a hydrotreatment reaction in the presence of hydrogen and a hydrotreatment catalyst in a hydrotreatment device; a hydrotreatment reaction effluent is subjected to gas-liquid separation; a liquid phase directly enters into a catalytic cracking device without passing through a fractionation device and then undergoes a catalytic cracking reaction; a catalytic cracking reaction effluent is treated by the fractionation device so that dry gas, liquefied gas, a catalytically cracked gasoline fraction, a catalytically cracked diesel fraction, catalytically cracked heavy recycle oil and catalytically cracked slurry are separated out; and a part or all of the catalytically cracked heavy recycle oil and the catalytically cracked slurry are fed back to the hydrotreatment device and then undergo a hydrotreatment reaction. Compared with the prior art, the hydrotreatment and catalytic cracking deeply-combined method for residuum can realize maximum-yield production of gasoline, save an equipment investment, fully utilize reaction heat and reduce production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

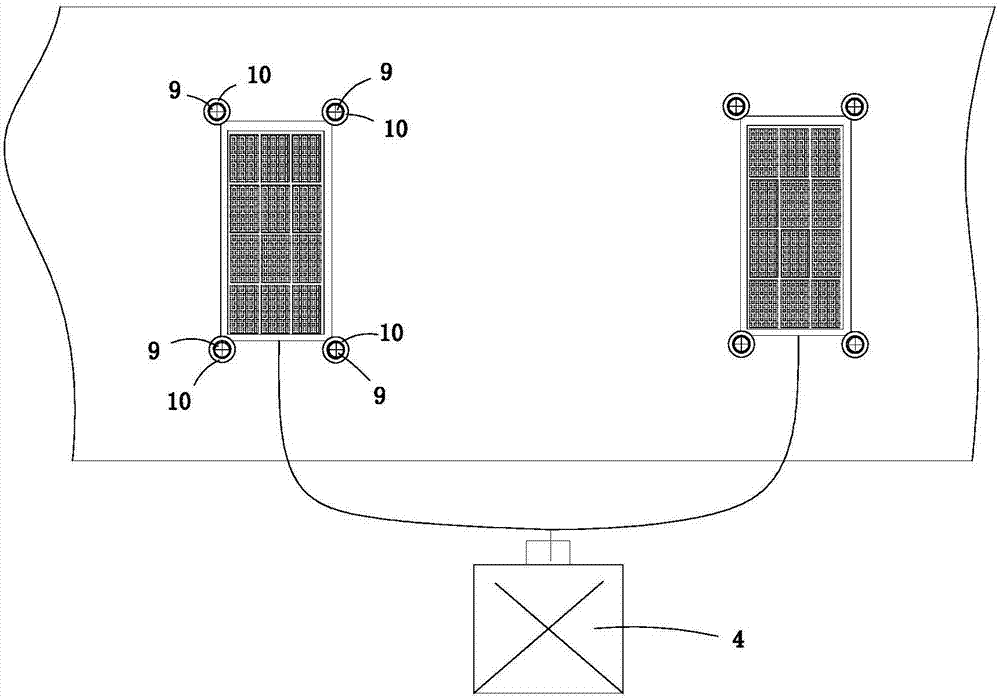

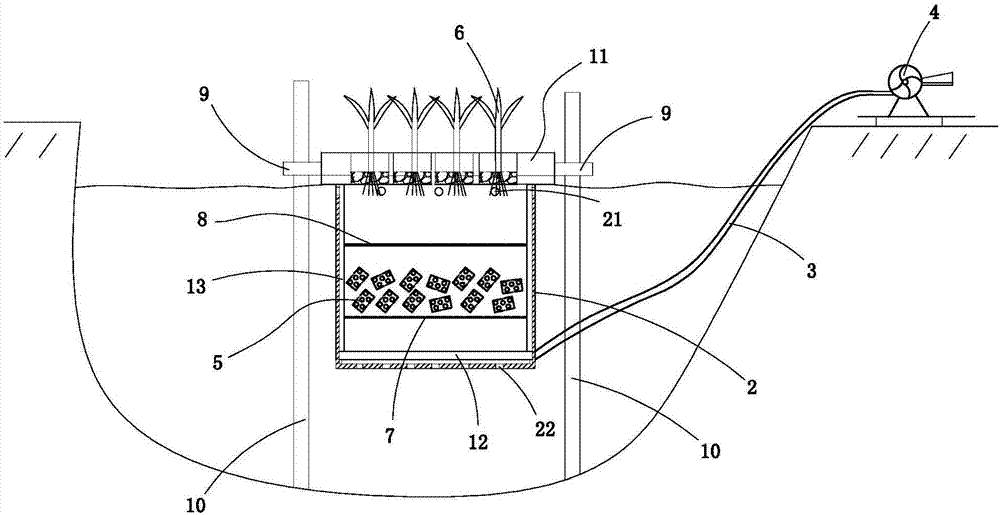

Method for treating closed water pollution

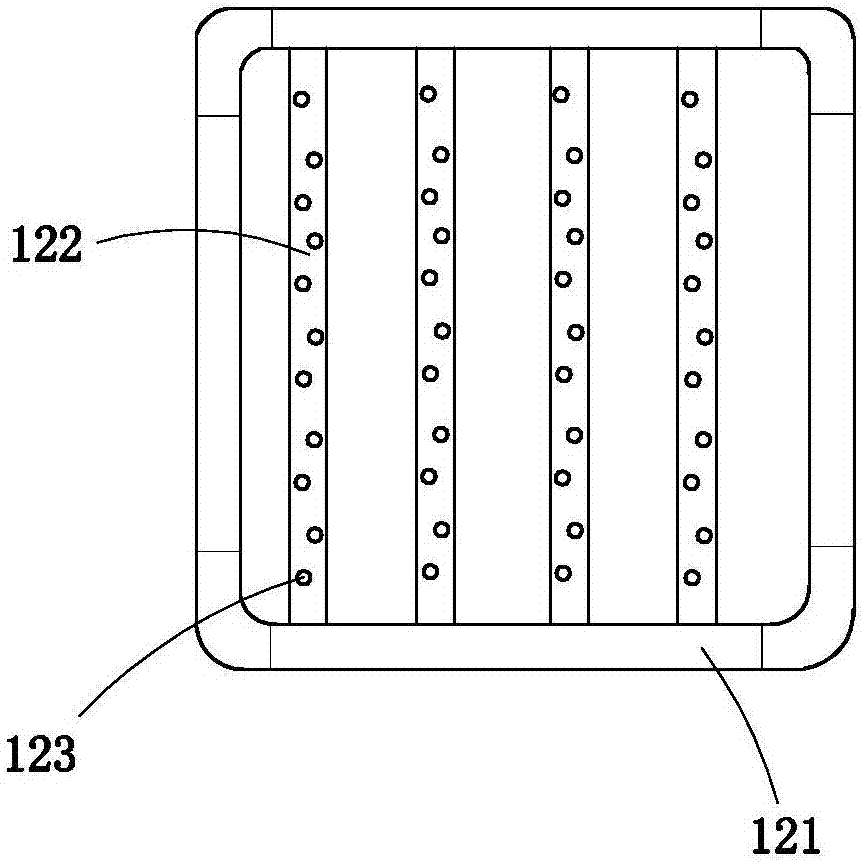

PendingCN107500420ASimple structureLow costBiological treatment apparatusSustainable biological treatmentEngineeringAeration

The invention discloses a method for treating closed water pollution. The method is realized in the manner of mounting at least one floater in a closed river and a fan on river bank. Each floater comprises an upper frame, a lower frame and a support frame; a plant floating island is arranged in the upper frame; flexible sheets are arranged on the outer lateral part of the support frame and the bottom of the lower frame; a plurality of water inlets are formed in the flexible sheet at the bottom; a water outlet is formed in the top of the flexible sheet on the lateral part; a hollow main pipe and a hollow branch are arranged on the lower frame; the hollow branch is connected with the hollow main pipe; the hollow main pipe is connected with the fan through a hose; an aeration hole is formed in the hollow branch; an upper restraining net and a lower restraining net are arranged at an interval along the vertical direction in a channel between the upper frame and the lower frame; a space between the upper restraining net and the lower restraining net is filled with a filling block. One or multiple parallel floaters can be arranged according to the size of the closed water. According to the invention, the purifying effect for the polluted water can be effectively promoted and the self-cleaning function for recovering water can be finally realized.

Owner:陈学群

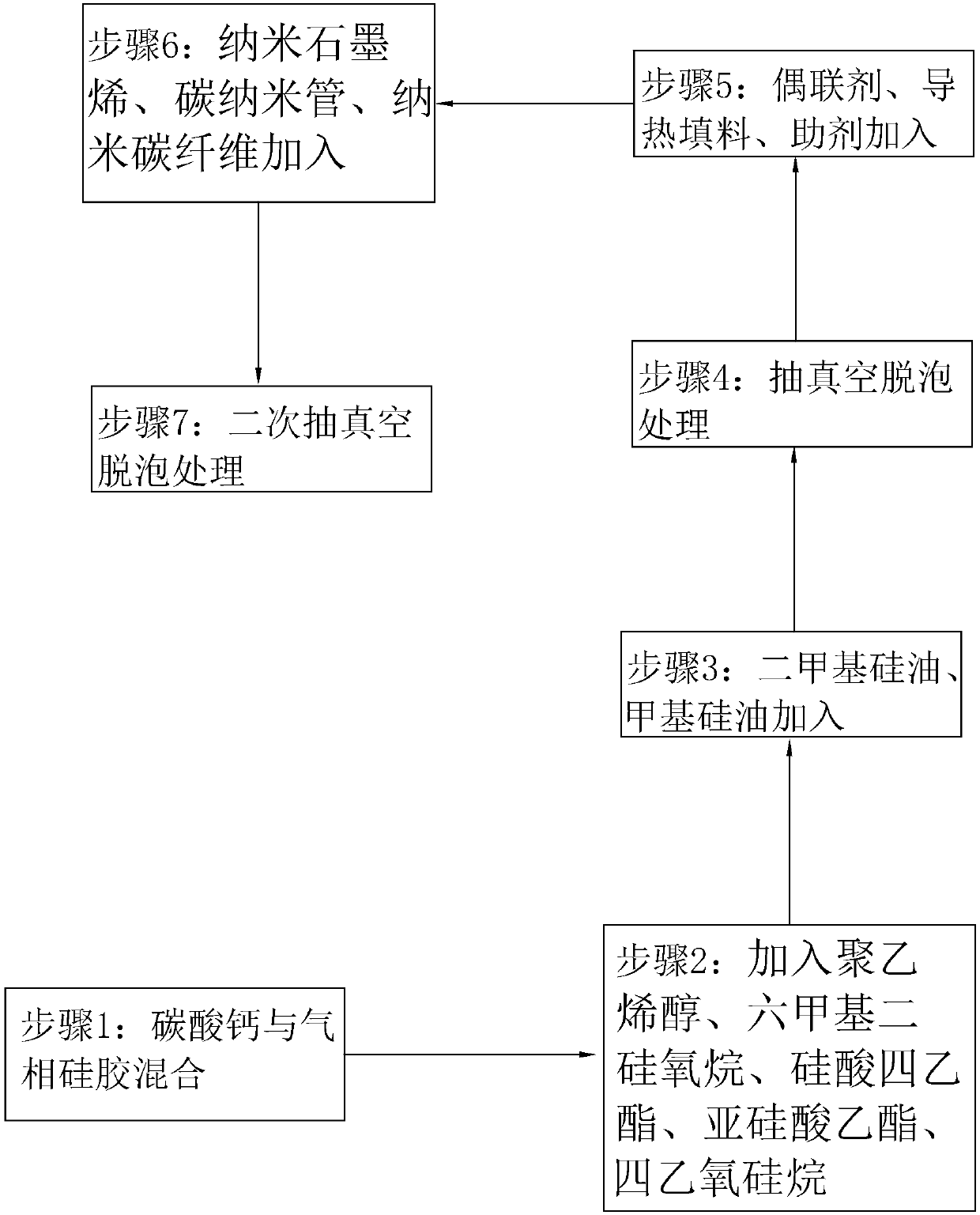

Heat conduction silicone grease as well as processing method and application thereof

InactiveCN107739513AImprove thermal conductivityEasy to useHeat-exchange elementsFilling materialsGas phase

The invention relates to heat conduction silicone grease as well as a processing method and application thereof. The heat conduction silicone grease is prepared from substances of simethicone, heat conduction filling materials, coupling agents, auxiliary agents, methylsilicone oil, gas phase silicone and the like. In the prior art, when the heat conduction silicone grease with high viscosity is used, a surface coating method is generally used, i.e., a thick layer of heat conduction silicone grease coats on the surface of an electronic device; then, a heat radiation fin is adhered onto the heatconduction silicone grease. By using the operation mode, the consumption of the heat conduction silicone grease is great; in addition, pores can be easily generated between the heat radiation fin andthe heat conduction silicone grease. When the heat conduction silicone grease provided by the scheme is used, the heat conduction silicone grease can be dripped into the electronic device; then, theheat radiation sheet can be adhered onto the heat conduction silicon grease by force; the viscosity of the heat conduction silicone grease is low, and the flowability is good, so that during the adhesion on the heat radiation fin by force, the heat conduction silicone grease completely fits the shape of the two opposite sides of the heat radiation fin and the electronic device; the heat radiationeffect reduction due to pore remaining between the heat radiation fin and the electronic device can be avoided.

Owner:苏州柯仕达电子材料有限公司

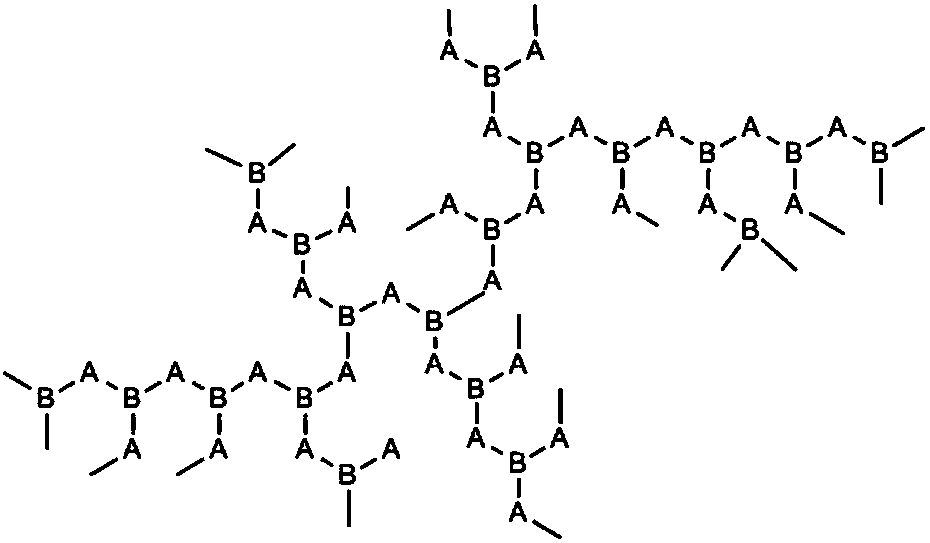

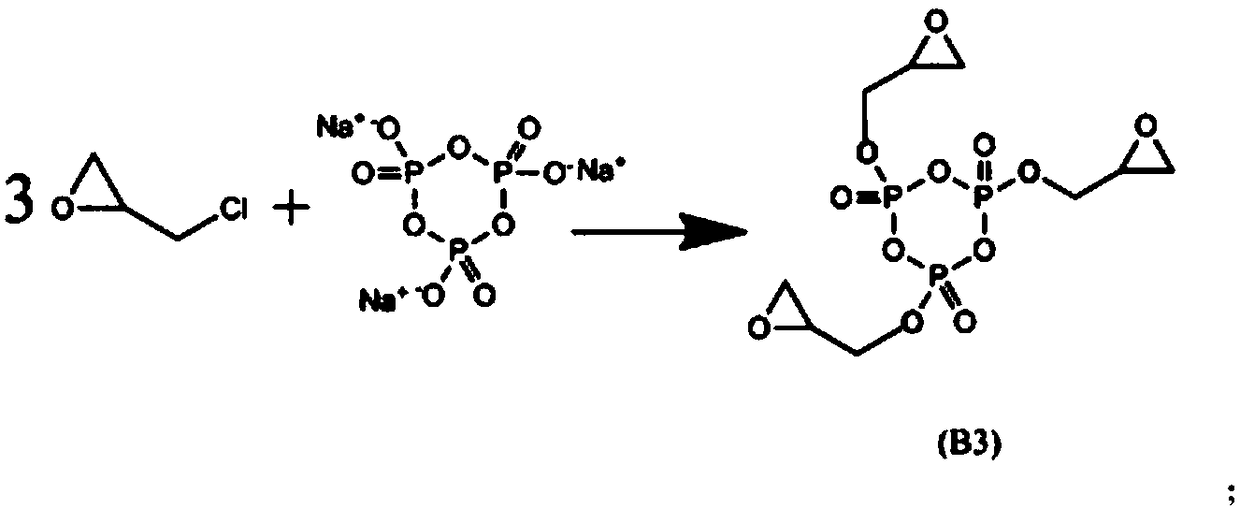

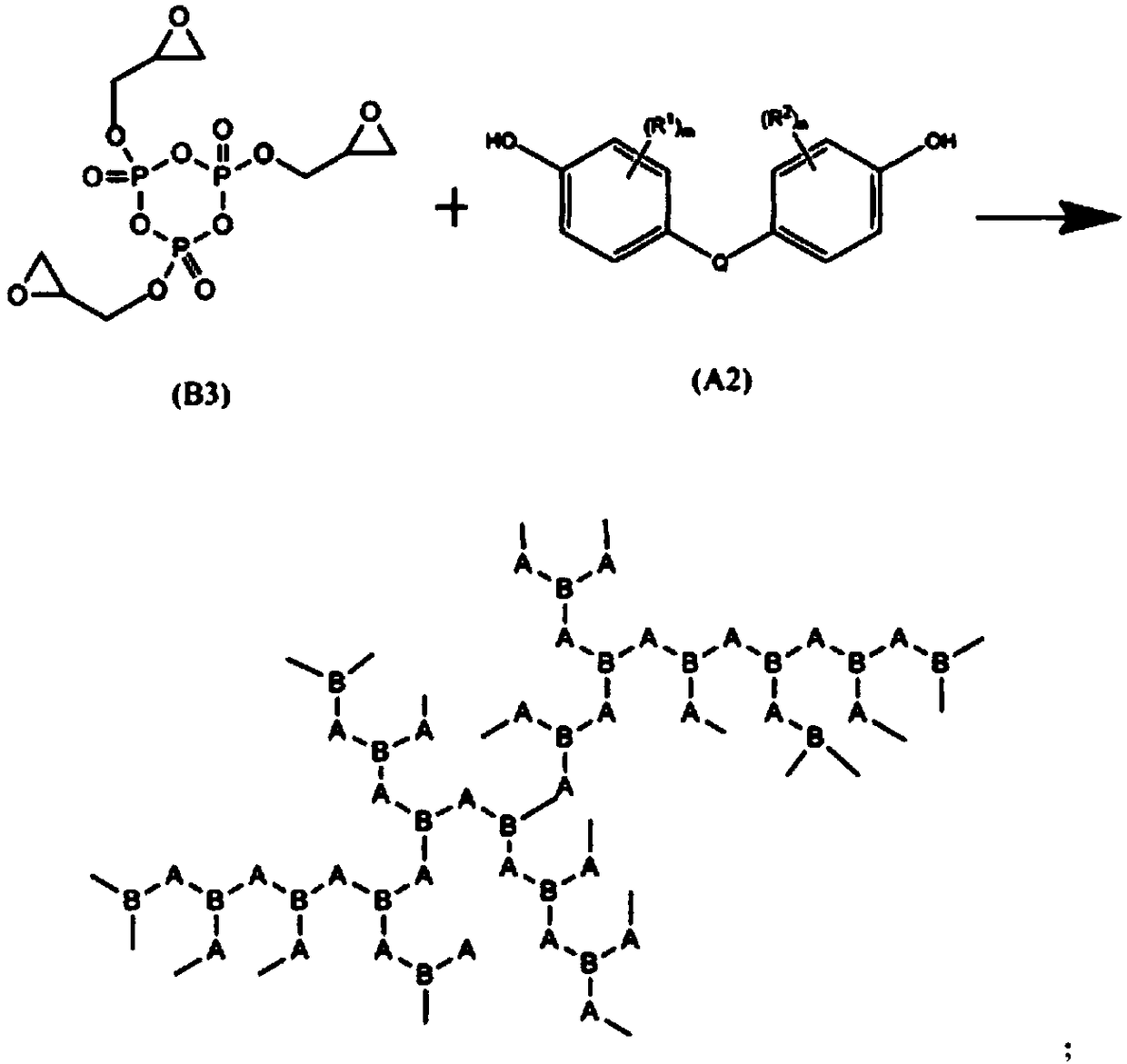

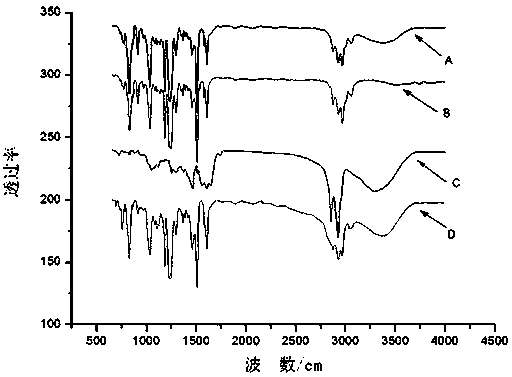

Epoxy-terminated hyperbranched polyphosphate and preparation method thereof

The invention relates to epoxy-terminated hyperbranched polyphosphate and a preparation method thereof, aiming at solving the technical problems that in the prior art, epoxy resin is lower in relativemolecular mass, poorer in corrosion resistance, higher in viscosity and troublesome in construction, the toxicity of curing agent varieties for the epoxy resin is larger, and the epoxy resin is moreaffected by the environment. The epoxy-terminated hyperbranched polyphosphate provided by the invention is prepared adding a branching agent into tri-epichloropropyl trimetaphosphate (B3), and enabling the tri-epichloropropyl trimetaphosphate (B3) and the branching agent to be subjected to an epoxide ring-opening reaction so as to obtain the epoxy-terminated hyperbranched polyphosphate. Furthermore, the invention also provides the preparation method of the epoxy-terminated hyperbranched polyphosphate. The epoxy-terminated hyperbranched polyphosphate and the preparation method thereof can be widely applied to the technical field of organic synthesis.

Owner:SHANDONG RUNKE CHEM +1

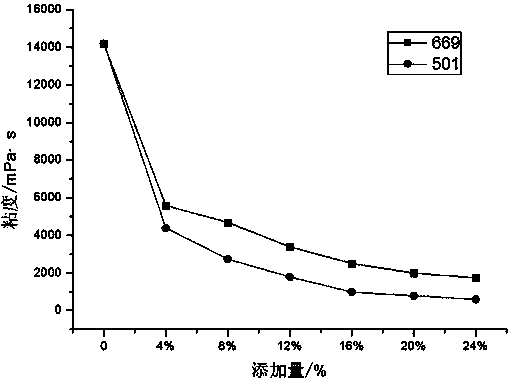

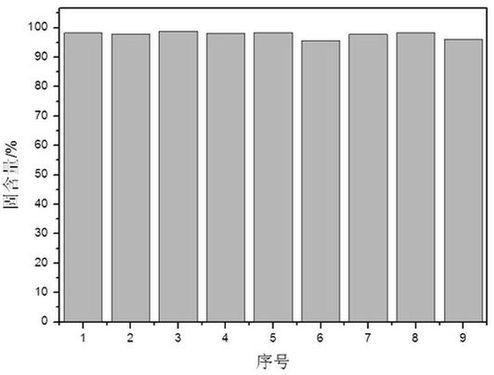

Solvent-free epoxy heavy-duty anticorrosive coating and preparation method thereof

InactiveCN110157293AReduce pollutionExcellent chemical stabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyOrganic solvent

The invention relates to the field of anticorrosive coatings, in particular to a solvent-free epoxy heavy-duty anticorrosive coating and a preparation method thereof. The solvent-free epoxy heavy-dutyanticorrosive coating comprises a component A and a component B; the component A comprises 100 parts of a solvent-free epoxy resin, 8-16 parts of a active diluent, 70-115 parts of a pigment and filler, 1.5-2.6 parts of a coupling agent, 1.5-2.6 parts of a dispersing agent, and 0.8-1.3 parts of a thixotropic agent; and the component B is a curing agent, and the mass ratio of the component B to theliquid epoxy resin in the component A is (1.5:1)-(3.5:1). The solid content of the heavy-duty anticorrosive coating is 98% or more, and the coating is an environment-friendly coating; the coating contains only a very small amount of a volatile organic solvent, so that only a small amount of shrinkage cavities and pinholes are formed after the coating is cured, and the compactness of the coating effectively increases the barrier properties and permeability resistance of an anticorrosive coating layer.

Owner:HENAN UNIV OF URBAN CONSTR

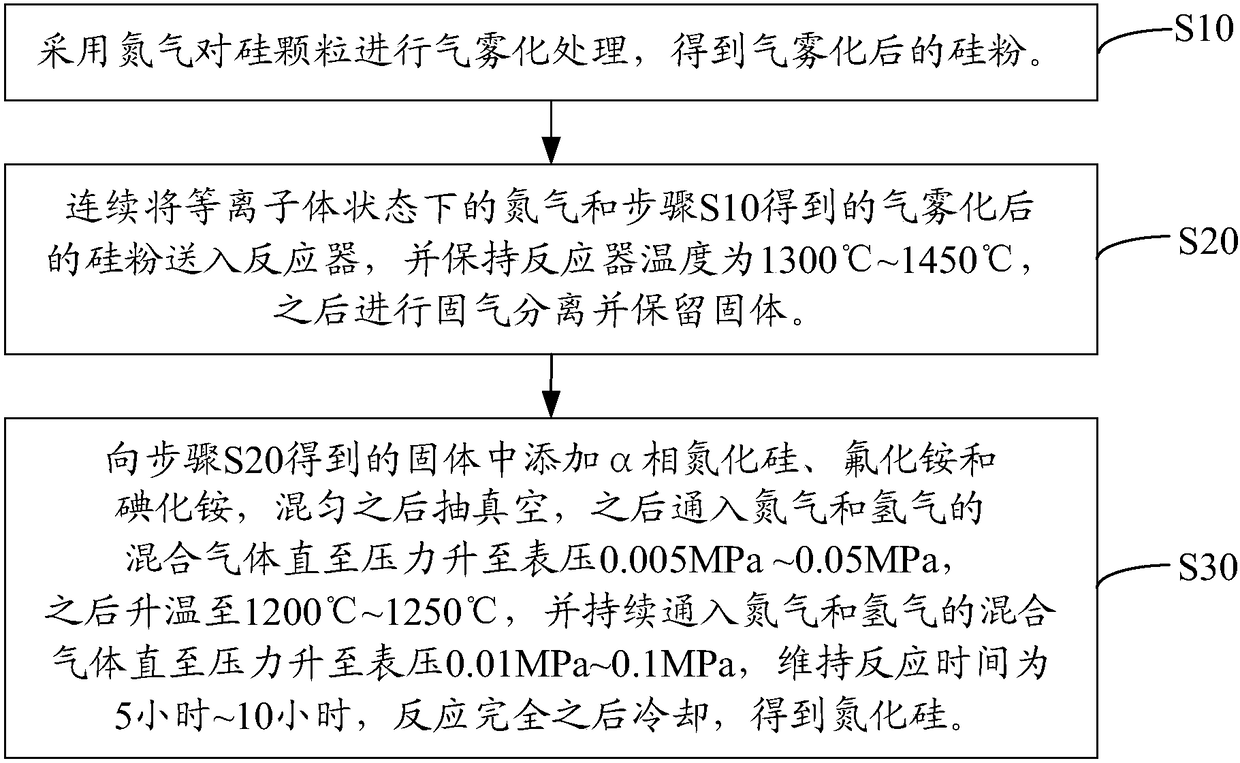

Silicon nitride and preparation method thereof

ActiveCN108529576AAvoid violent reactionsAct as a diluentNitrogen compoundsHydrogenSynthesis methods

The invention relates to silicon nitride and a preparation method thereof. The preparation method of the silicon nitride comprises the following steps: performing gas atomization treatment on siliconparticles by using nitrogen to obtain silicon powder subjected to gas atomization; continuously nitrogen under the plasma state and the silicon powder subjected to gas atomization into a reactor, maintaining the temperature of the reactor to 1300 to 1450 DEG C, performing solid and gas separation and retaining solid; and adding alpha-phase silicon nitride, ammonium fluoride and ammonium iodide into the solid, mixing uniformly, vacuumizing, introducing mixed gas of nitrogen and hydrogen until the pressure is increased to the gauge pressure of 0.005 to 0.05 MPa, heating to 1200 to 1250 DEG C, continuously introducing the mixed gas of nitrogen and hydrogen until the pressure is increased to the gauge pressure of 0.01 to 0.1 MPa, maintaining the reaction time for 5 to 10 hours, and cooling after complete reaction to obtain the silicon nitride. The preparation method of the silicon nitride is a composite synthesis method. By the preparation method of the silicon nitride, high alpha-phase silicon nitride can be obtained.

Owner:SUZHOU GCL ENERGY TECH DEV CO LTD

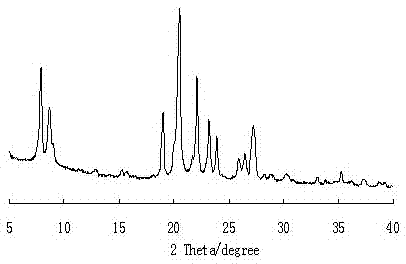

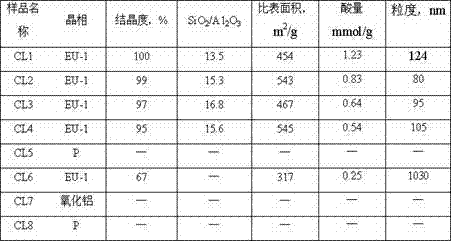

EU-1 molecular sieve and synthesis method thereof

ActiveCN106946267AHigh crystallinityHigh acid densityCrystalline aluminosilicate zeolitesMolecular sieveSynthesis methods

The invention discloses an EU-1 molecular sieve and a synthesis method thereof, wherein the crystal structure of the EU-1 molecular sieve is a typical EUO structure. The synthesis method comprises: mixing an inorganic alkali, an aluminum source, a silicon source, a templating agent and water, stirring to obtain a silicon-aluminum gel, and crystallizing for a certain time; and adding water, a second templating agent and alumina, uniformly stirring, and carrying out hydrothermal crystallization to obtain the EU-1 molecular sieve. According to the present invention, the EU-1 composite molecular sieve synthesized by the method is the low silica-alumina ratio zeolite, and has the high crystallinity; and with the synthesis method, the generation of the impurity crystal can be avoided, and the operation is simple and easy to perform.

Owner:CHINA PETROLEUM & CHEM CORP +1

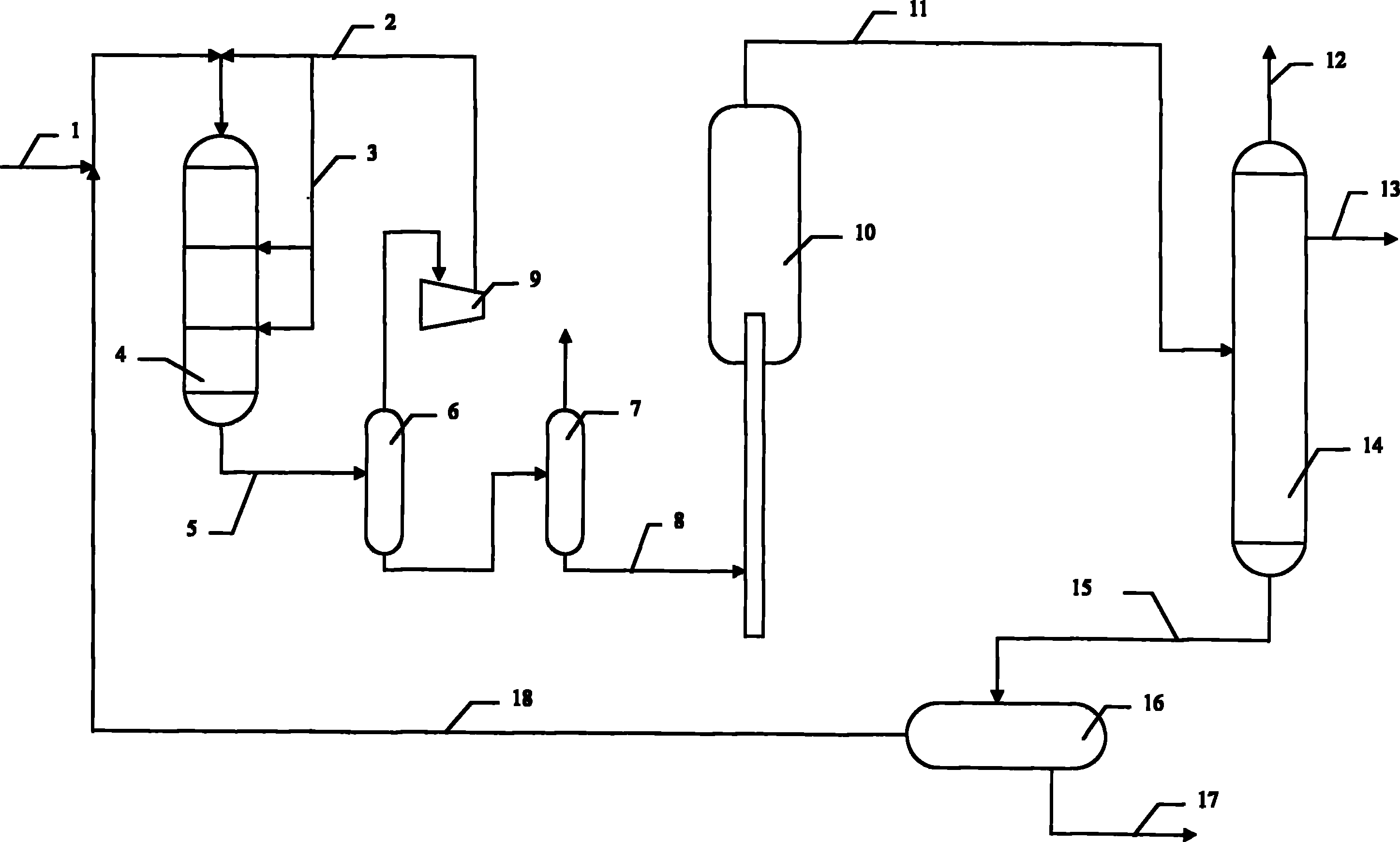

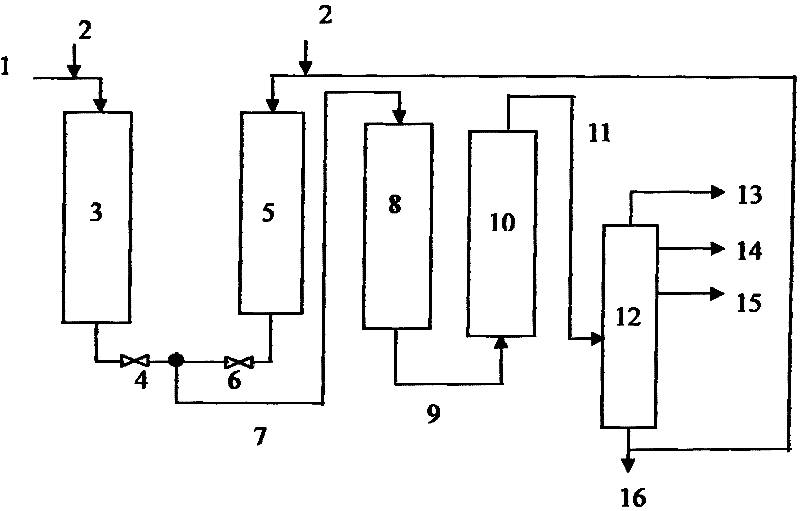

Residual oil hydrogenation treatment and catalytic cracking combination method

ActiveCN102453544AHigh aromatic contentLow cetane numberTreatment with hydrotreatment processesGas phaseFractionation

The present invention discloses a residual oil hydrogenation treatment and catalytic cracking combination method. According to the method, the residual oil hydrogenation treatment process comprises two hydrogenation protection reactors, wherein the two hydrogenation protection reactors are arranged in parallel connection, the feed material of the first hydrogenation protection reactor is the residual oil raw material, and the feed material of the second hydrogenation protection reactor is the catalytic cracking heavy fraction; the effluents of the two reactors are mixed, and the resulting mixture enters a hydrogenation treatment reaction zone to carry out a hydrogenation reaction; the effluent of the hydrogenation reaction is subjected to gas-liquid separation, wherein the resulting gas phase is circularly adopted for the hydrogenation reaction, and the liquid phase directly enters a catalytic cracking apparatus without fractionation; the effluent of the catalytic cracking reaction is separated to obtain dry gas, liquefied gas, catalytic cracking gasoline, and catalytic cracking heavy fraction after catalytic cracking of the gasoline, wherein the catalytic cracking heavy fraction is adopted as the feed material of the second hydrogenation protection reactor. With the method, the operating period of the residual oil hydrogenation apparatus can be prolonged, the maximum amount of the catalytic cracking gasoline can be produced, and the equipment investment can be saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

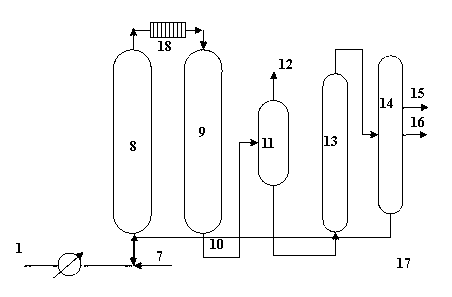

Residual oil hydrogenation treatment and catalytic cracking combined processing method

ActiveCN102311798AIncrease processing costReduce investmentTreatment with hydrotreatment processesFiltrationGas phase

The invention discloses a residual oil hydrogenation treatment and catalytic cracking combined processing method, which comprises: performing the hydrogenation reaction of a residual oil raw material in the presence of hydrogen and a hydrogenation treatment catalyst, and performing gas-liquid separation of efflux of hydrogenation reaction, wherein a gas phase is circularly used in a hydrogenation reaction, and a liquid phase is fractioned to form a light component and a heavy component; allowing a light component to enter a reactor from the bottom of a catalytic cracking riser reactor, allowing a heavy component to enter the reactor as secondary feed of the catalytic cracking riser reactor and performing a catalytic cracking reaction; and separating a dry gas, a liquefied gas and a gasoline fraction from efflux of a catalytic cracking reaction, wherein the fractions of diesel are not separated and enter a residual oil hydrogenation device after filtration. Compared with the prior art, the method can produce high-octane number gasoline and high-added-value liquefied gas to a maximum degree; meanwhile, the method can fully utilizes reaction heat and reduces production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreatment and catalytic cracking combined method for residuum

InactiveCN102732311AQuality improvementIncrease productionTreatment with hydrotreatment processesPtru catalystGasoline

The invention discloses a hydrotreatment and catalytic cracking combined method for residuum. The hydrotreatment and catalytic cracking combined method for residuum comprises the following steps that a residuum raw material and at least part of catalytically cracked heavy recycle oil undergo a hydrotreatment reaction in the presence of hydrogen and a hydrotreatment catalyst in a hydrotreatment device; a hydrotreatment reaction effluent is subjected to gas-liquid separation; a gas phase is circularly used for a hydrotreatment reaction and a liquid phase directly enters into a catalytic cracking device without passing through a fractionation device and then undergoes a catalytic cracking reaction; a catalytic cracking reaction effluent is treated by the fractionation device so that dry gas, liquefied gas, a catalytically cracked gasoline fraction, a catalytically cracked diesel fraction, catalytically cracked heavy recycle oil and catalytically cracked slurry are separated out; and a part or all of the catalytically cracked heavy recycle oil is fed back to the hydrotreatment device and then undergoes a hydrotreatment reaction. Compared with the prior art, the hydrotreatment and catalytic cracking combined method for residuum can realize maximum-yield production of gasoline, save an equipment investment, fully utilize reaction heat and reduce production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined process of hydrotreatment and catalytic cracking for residual oil

ActiveCN103102985AImprove responseLess investmentTreatment with hydrotreatment processesFluidized bedFixed bed

The invention discloses a combined process of hydrotreatment and catalytic cracking for residual oil. The combined process comprises the following steps: (1) mixing a residual oil raw material and heavy distillate oil of a catalytic cracking unit and allowing an obtained mixture to enter into a fluidized bed hydrotreatment unit for fluidized bed hydrotreatment; (2) allowing an effluent of fluidized bed hydrotreatment obtained in the step (1) to enter into a fixed bed hydrotreatment unit for fixed bed hydrotreatment, wherein generated oil of an effluent of fixed bed hydrotreatment is used as a raw material for the catalytic cracking unit; and (3) mixing the residual oil raw material with a catalytic heavy fraction obtained after dry gas, liquefied gas and catalytic gasoline are separated from an effluent of a catalytic cracking reaction and subjecting an obtained mixture to fluidized bed hydrotreatment. Compared with the prior art, the combined process provided by the invention has the advantages of wide sources of the raw materials, low equipment investment, stable operation, a long operation period and a good synergistic and coordination effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Slag ball content control method for preparation of mineral wool from silicon-manganese slag

The invention provides a slag ball content control method for preparation of mineral wool from silicon-manganese slag and relates to improvement of a technological method for preparing mineral wool from metallurgical slag, particularly from the silicon-manganese slag. The method is characterized in that a flux is added to hot melt slag of a silicon-manganese alloy in the preparation process, wherein the flux contains calcium fluoride and magnesium oxide, adding amount of calcium fluoride is 5%-8% by weight of the hot melt slag of the silicon-manganese alloy, and the adding amount of magnesiumoxide is 3%-5% by weight of the hot melt slag of the silicon-manganese alloy. According to the method, the slag is diluted by adding the flux to the hot melt slag of the silicon-manganese alloy, flowability of the hot melt slag is enhanced, fibers can become thinner due to wool forming in a high-speed centrifugation state, content of slag balls in the mineral wool is reduced, tensile strength of the mineral wool is improved, cost is lower, and operation is facilitated; glass state of high-temperature melt of the prepared mineral wool is good, fiber forming rate is high, fiber forming quality is excellent, slag ball content is lower than 8%, heat conductivity coefficient is low, tensile strength is high, and diversified market demands can be met.

Owner:NINGXIA JIYUAN JUNTAI NEW MATERIAL TECH CO LTD

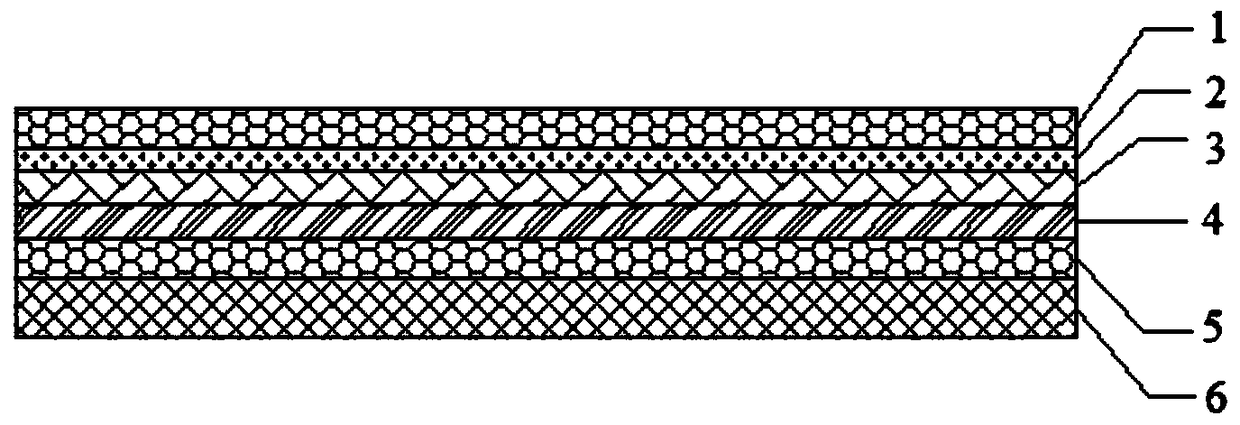

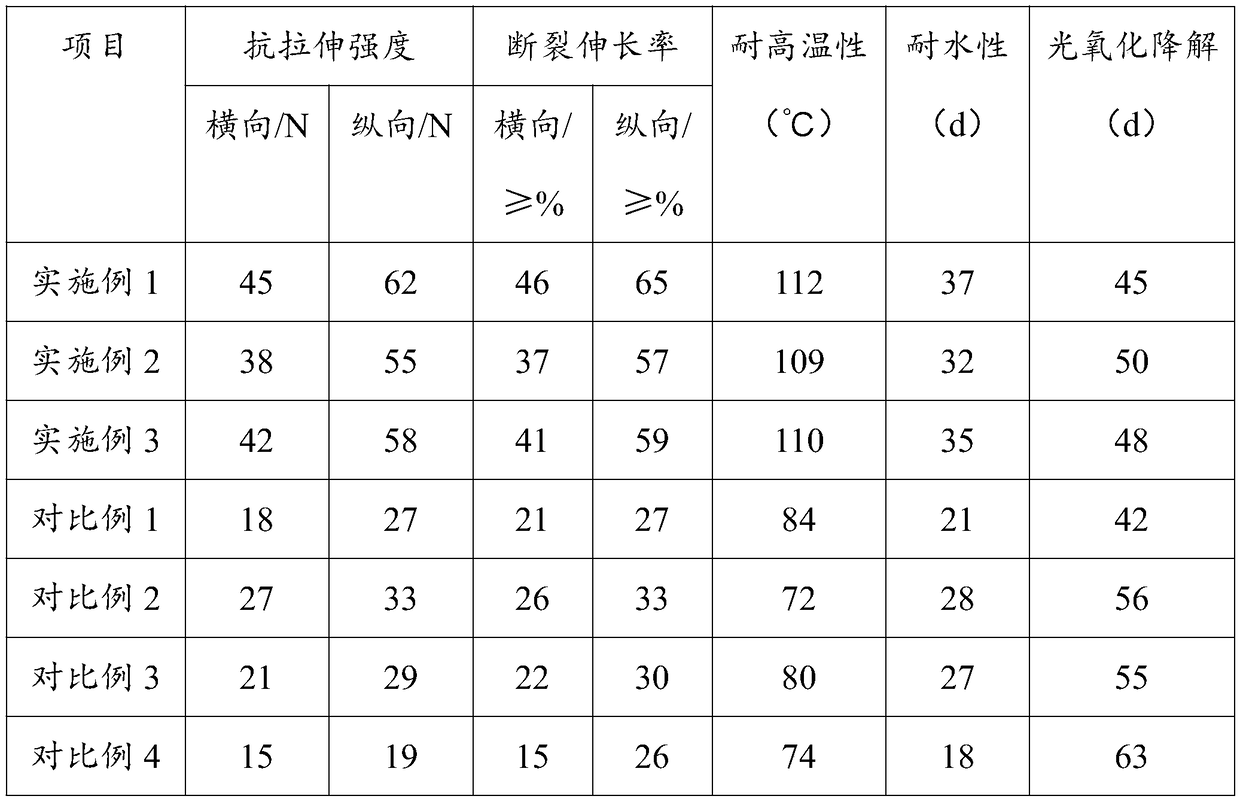

Environment-friendly degradable composite film for packaging and preparation method thereof

The invention discloses an environment-friendly degradable composite film for packaging and a preparation method thereof. The degradable composite film is of a composite structure comprising a first modified polyvinyl alcohol layer, an insulating layer, a titanium dioxide fireproof layer, a polyvinyl alcohol composite layer, a second modified polyvinyl alcohol layer and a PET release film layer. The modified polyvinyl alcohol layer is prepared from the following raw materials in parts by weight: 45-76 parts of modified polyvinyl alcohol, 6-12 parts of bamboo carbon fibers, 3-8 parts of a medical stone powder, 2-5 parts of a nano calcium carbonate powder, 1-4 parts of lignocellulose, 3-6 parts of polyethylene glycol 400 and 2-5 parts of acetyl tributyl citrate. The composite film formed byhot-pressing stretching has excellent tensile strength, elongation at break, water resistance and high-temperature resistance. The used raw materials are non-toxic and environment-friendly and high indegradation rate, and can be substantially degraded if being photo-oxidized for 45 days. The environment-friendly degradable composite film is suitable for serving as a composite film for packaging food, chemical products and pesticides.

Owner:江西中聚宏新材料科技有限公司

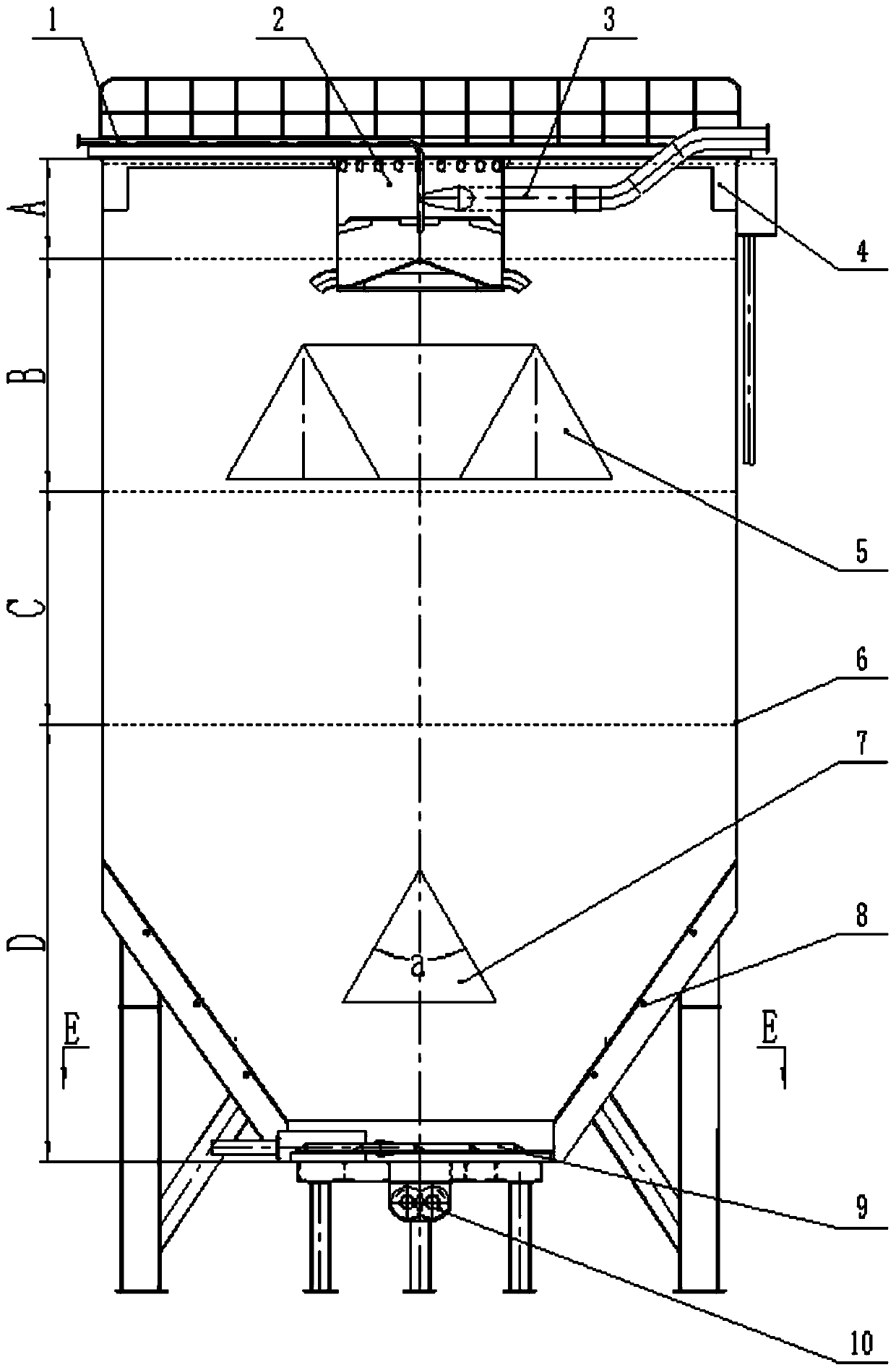

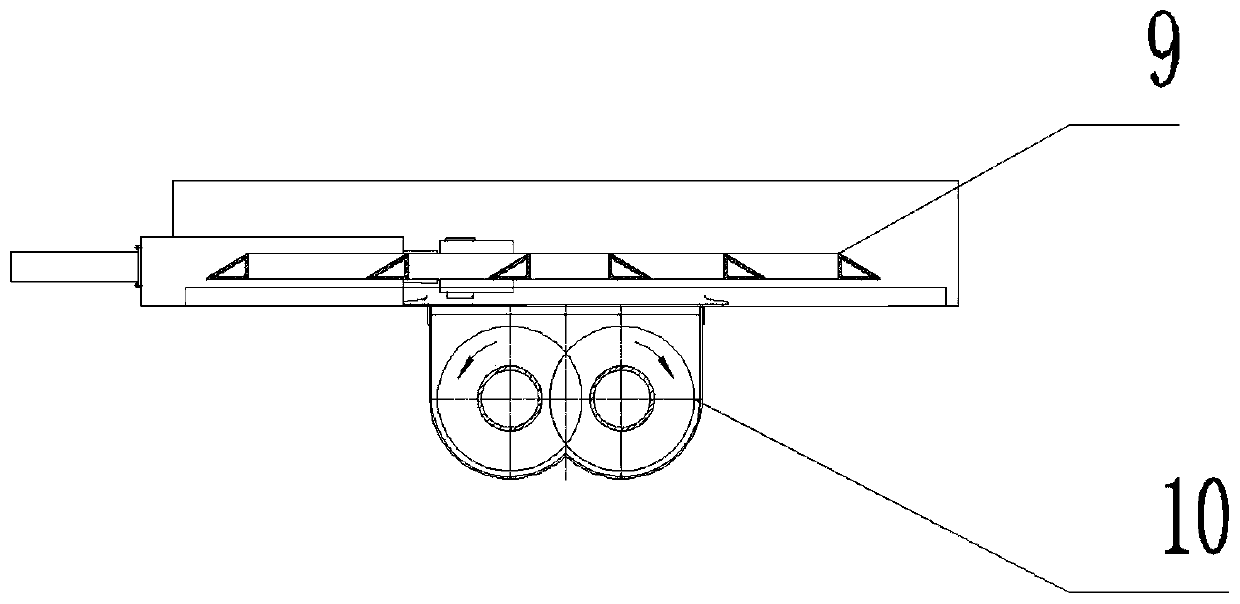

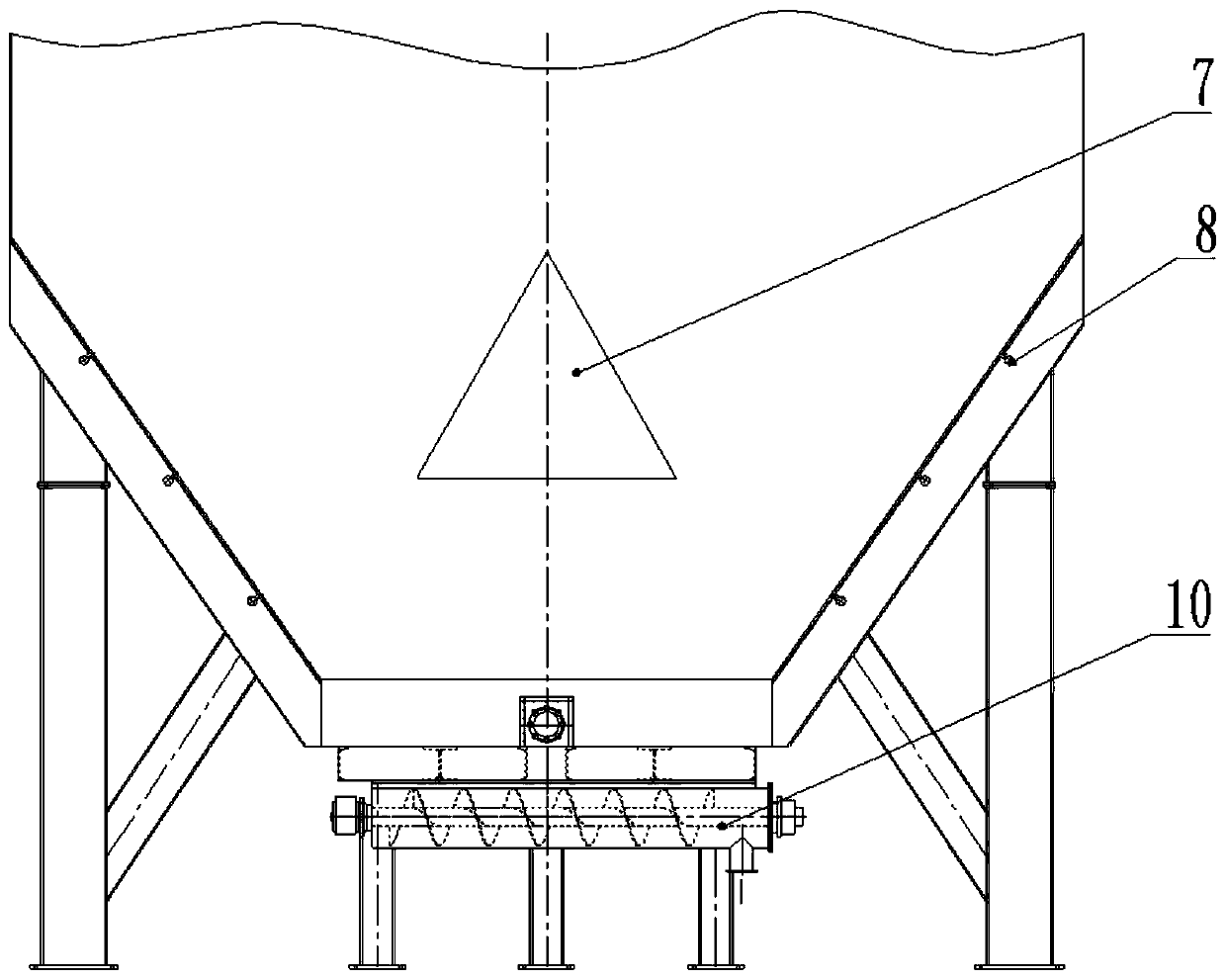

Rake-free separation tailing thickening sand bin

PendingCN110152359ACan't play the role of deliverySmooth dischargeSettling tanks feed/dischargeCentrifugal force sediment separationFlocculationHigh concentration

The invention relates to a rake-free separation tailing thickening sand bin, and aims to solve the problems that tailing concentration equipment in the prior art is complex in structure, low in sand discharging concentration and unsmooth in discharging. The rake-free separation tailing thickening sand bin comprises a sand bin body, a flocculation feeding tube, a center feeding barrel with a middleseparation plate, a tailing feeding tube, an overflow groove, an annular sedimentation cone, a sliding frame fluidization device and a double-screw discharging device. Through design of the structure, flow field variation of a material flow in the sand bin is changed, and the flocculation agglomeration speed of fine particle tailings is accelerated; and meanwhile, a mechanical sliding frame fluidization sand-discharging technology is adopted, so that smooth sand discharging under a condition of highest underflow concentration is realized. The rake-free separation tailing thickening sand bin has the outstanding advantages of small size, simple structure, low manufacturing cost, high concentration efficiency, high underflow concentration and the like.

Owner:北京金诚信矿山技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com