Patents

Literature

93results about How to "Avoid violent reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

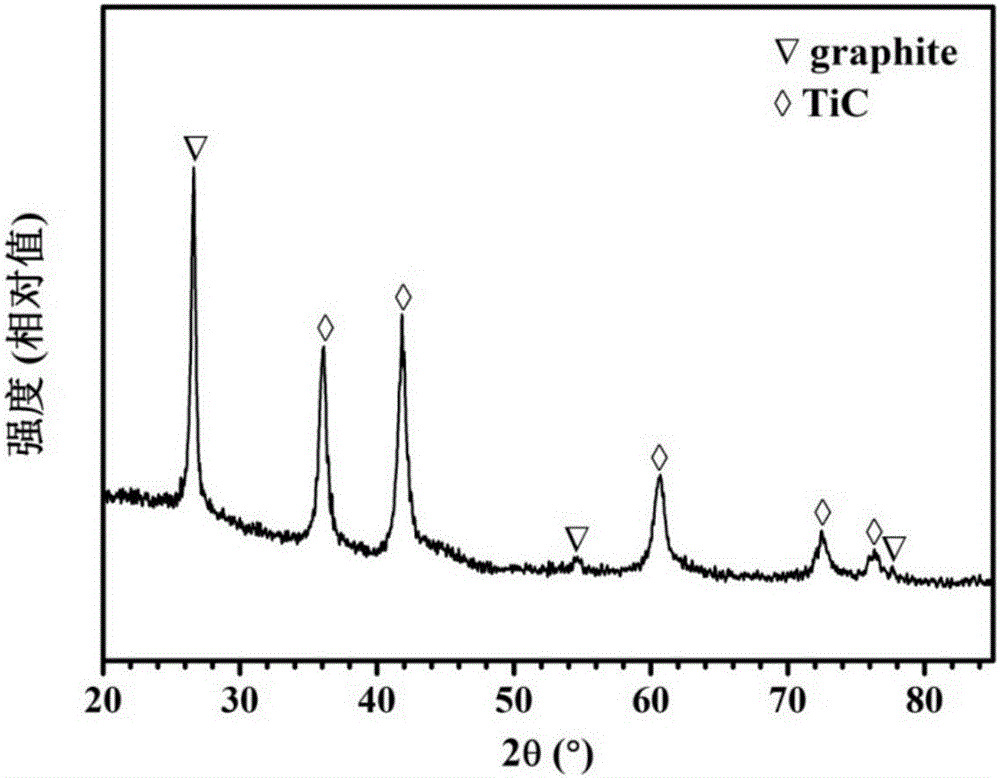

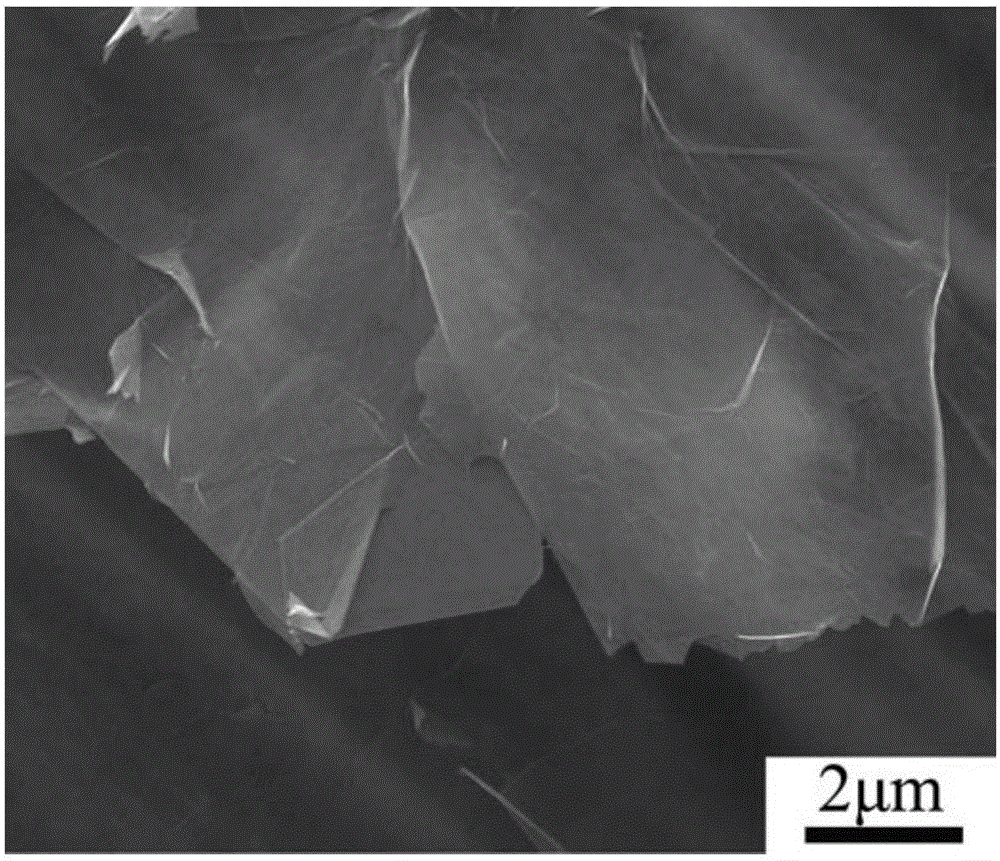

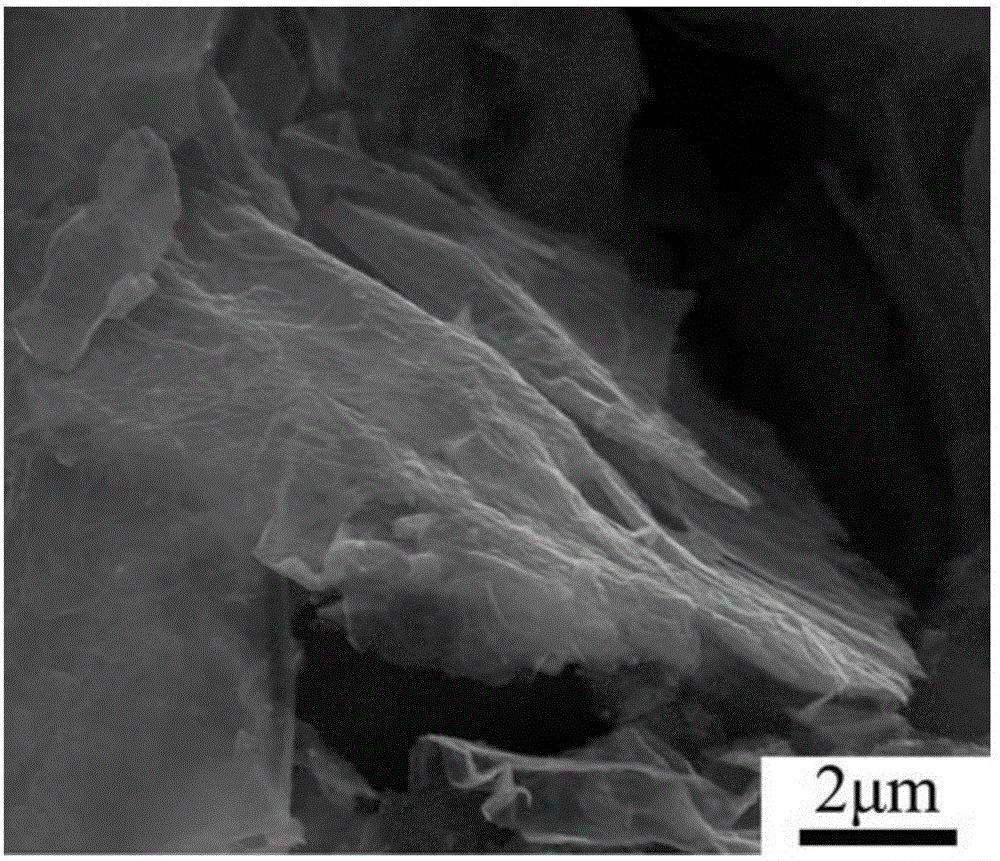

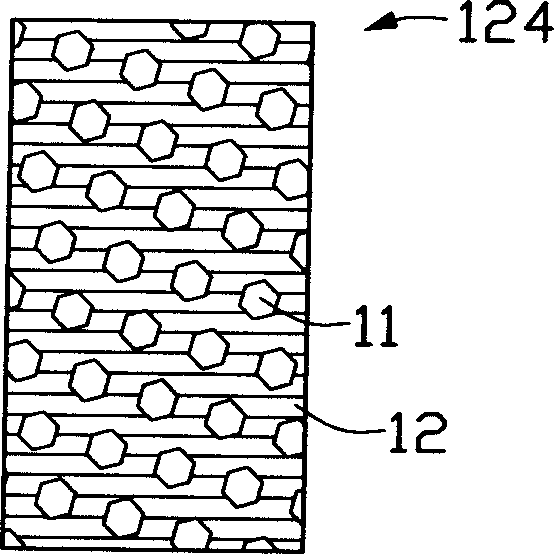

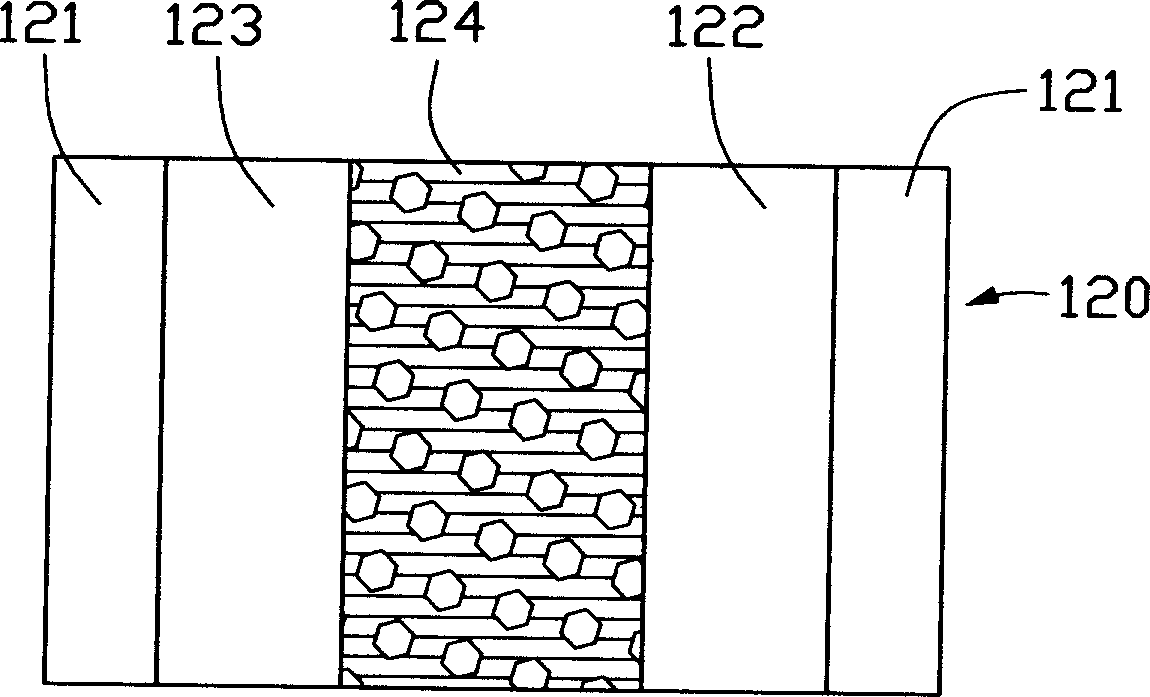

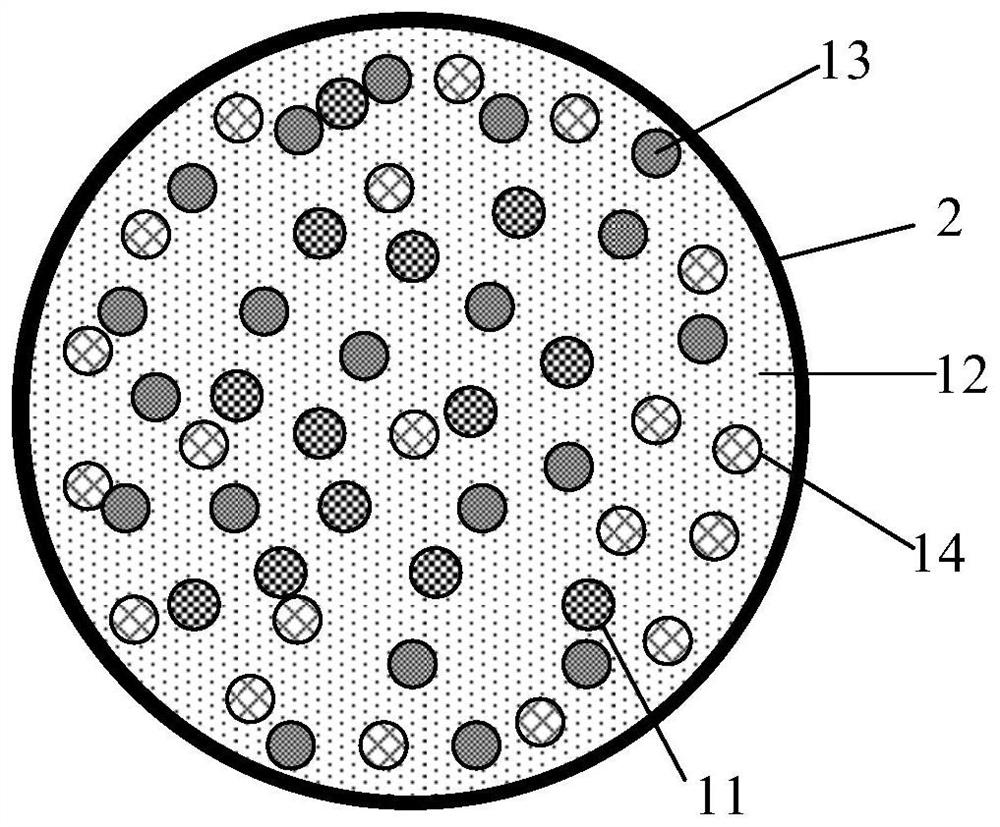

Metal-matrix composite material and preparation method thereof

InactiveCN105861866AImprove interfacial bond strengthModulation of interfacial binding strengthCvd grapheneBlock layer

The invention provides a metal matrix composite material, which uses metal as a matrix and uses graphene modified on the surface of carbide as a reinforcement. Due to the surface modification of the carbide, the interface bonding strength between the metal matrix and the graphene can be adjusted. For example, when the chemical affinity between graphene and the metal matrix is too strong and an excessive reaction occurs, resulting in an excessively strong interface bond, the carbide can be used as a diffusion barrier to avoid the overreaction and weaken the interface bond; When the interfacial affinity is weak, the carbide can be used as a transition layer to promote interfacial wetting and improve interfacial bonding force.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

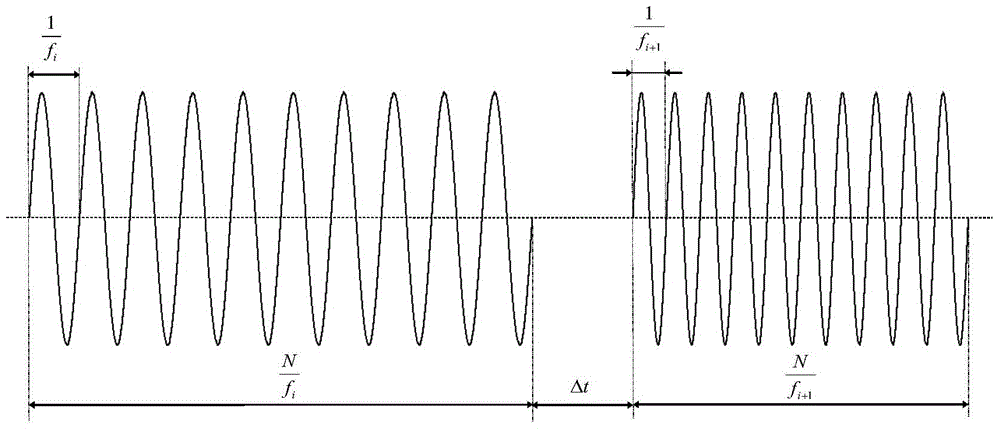

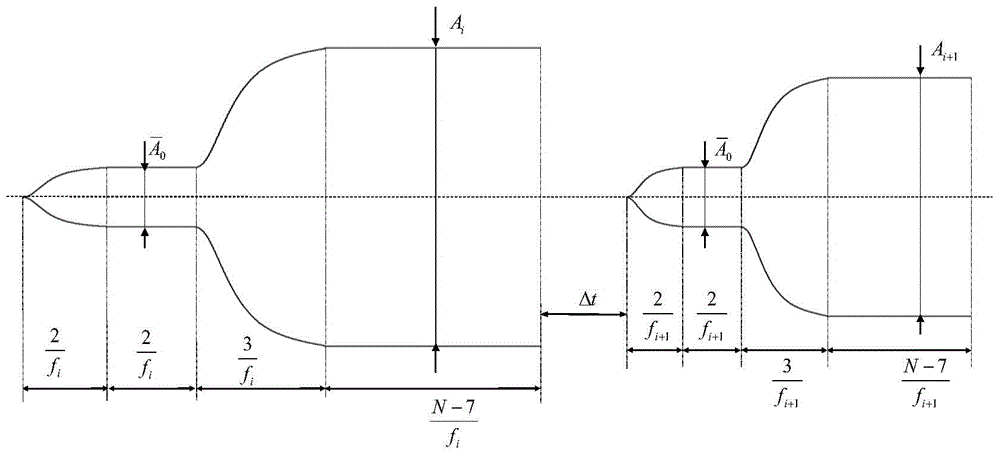

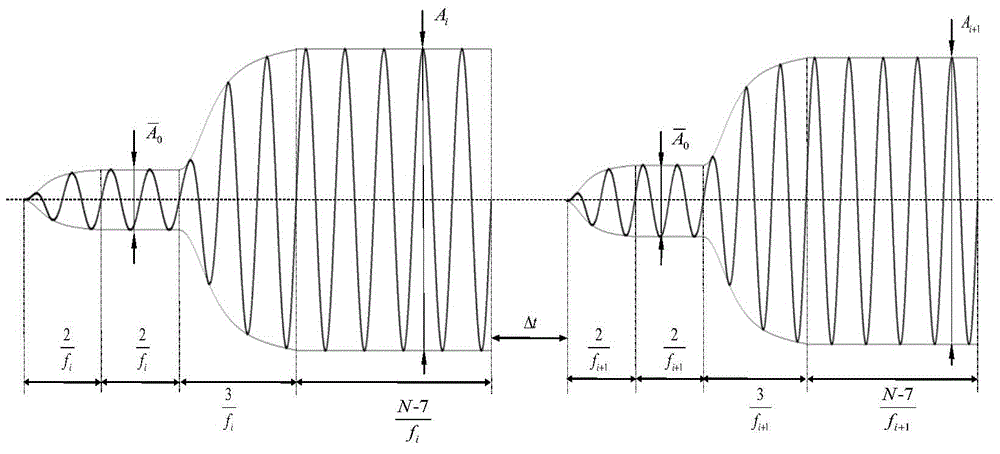

Automatic amplitude modulation frequency scanning method for airplane servo elasticity frequency response test

ActiveCN103558843AAvoid violent reactionsImprove the signal-to-noise ratio of the loop response signalElectric testing/monitoringAdaptive controlAeroelasticitySignal-to-noise ratio (imaging)

The invention belongs to the field of airplane aeroelasticity tests, and relates to an airplane ground test scope, in particular to an automatic amplitude modulation frequency scanning method for an airplane servo elasticity frequency response test. Control plane overloads are fed back to automatically adjust a frequency scanning amplitude value, on the premise that safety of a control pane structure is guaranteed, control plane deflection exciting force of all frequency scanning points is kept maximum so that sufficiently large airplane structure response can be excited, the signal to noise ratio of a response signal of an airplane-flight control combined circuit is improved, test errors are reduced, and reliability of a test result is improved. Meanwhile, the adjusting process of an excitation signal amplitude value is controlled through construction of a hyperbolic tangent-exponent function, violent response of a control plane caused by sudden changes of the excitation signal amplitude value is prevented from happening in the process of frequency scanning, and safety of the control plane structure is ensured. In addition, the advantages of a real-time simulation system of a computer are brought into full play, in the process of the test, people only need to slightly click a mouse, so that parameters such as control limit overloads and excitation signal cycles can be adjusted, and the automatic amplitude modulation frequency scanning method is high in practicability.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

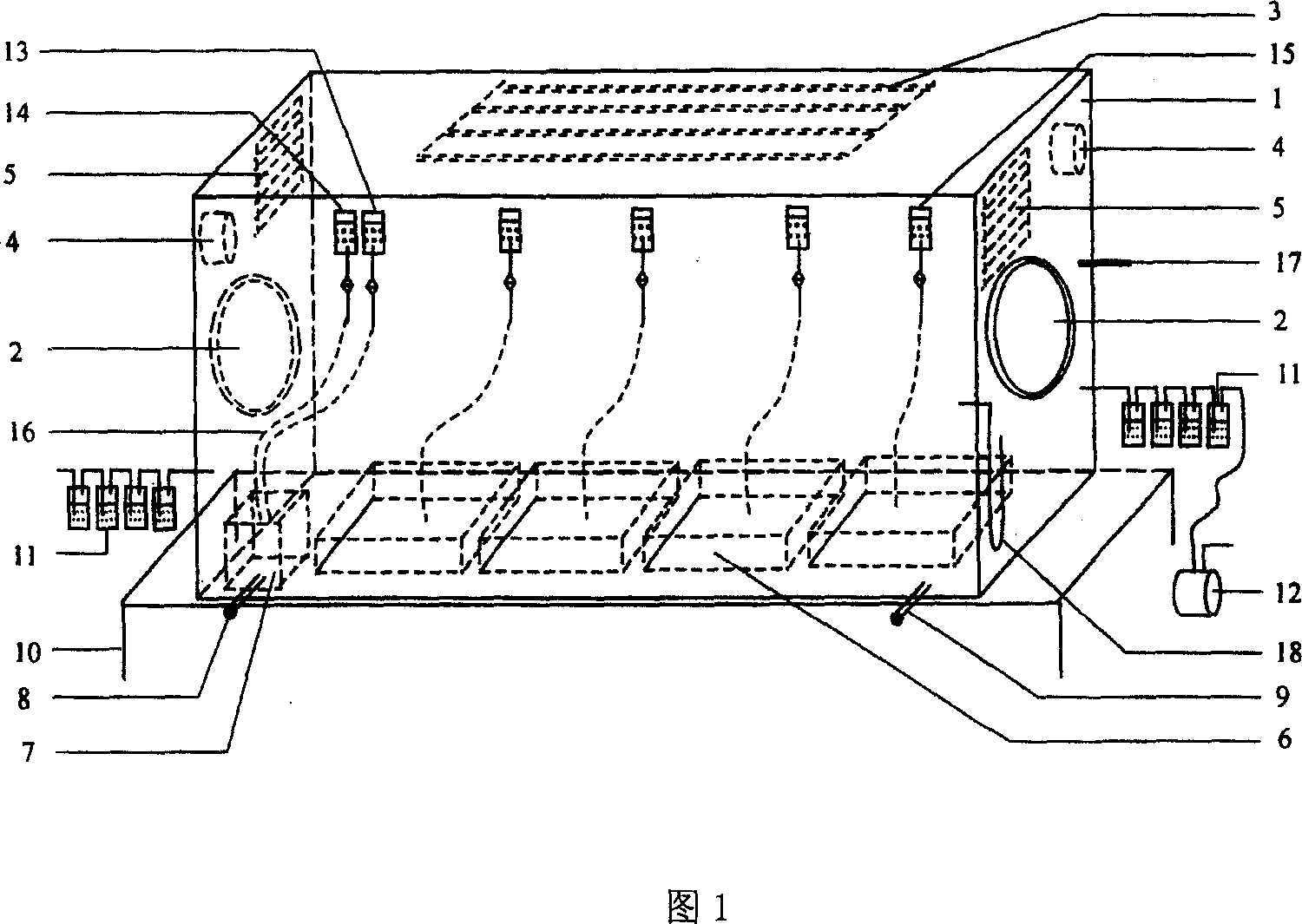

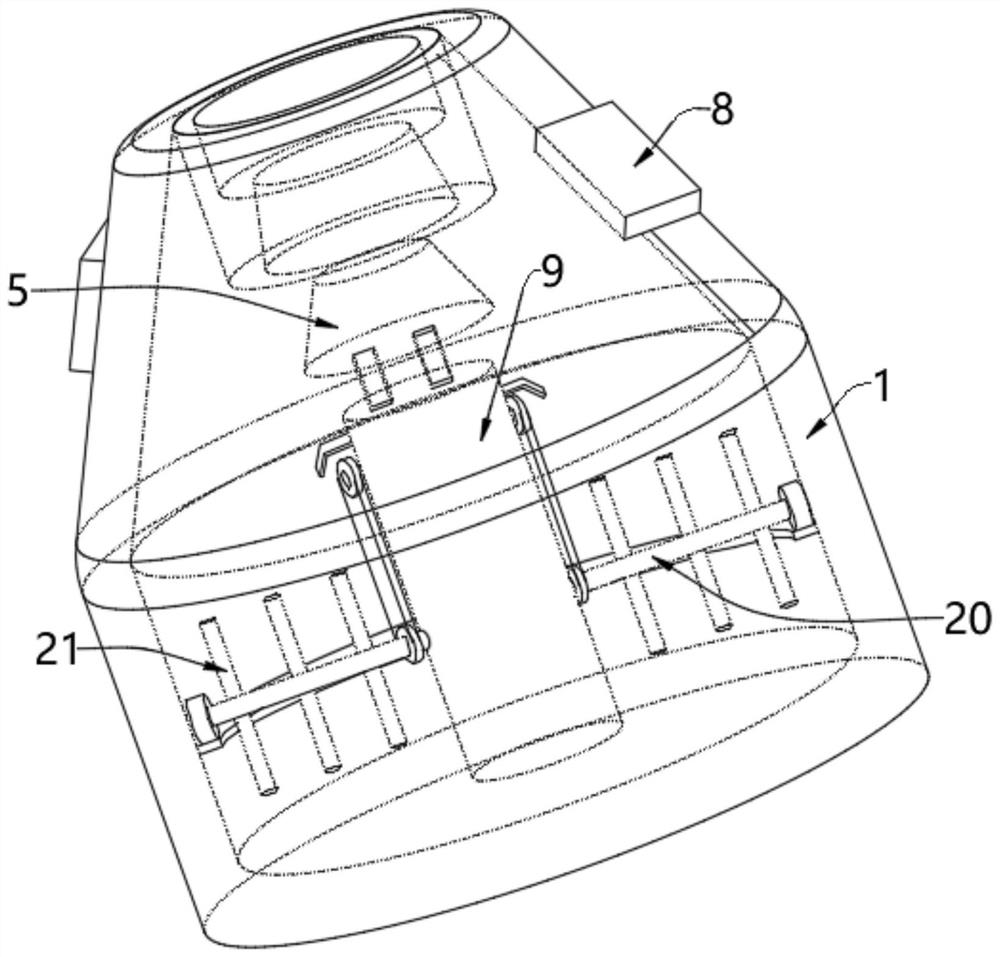

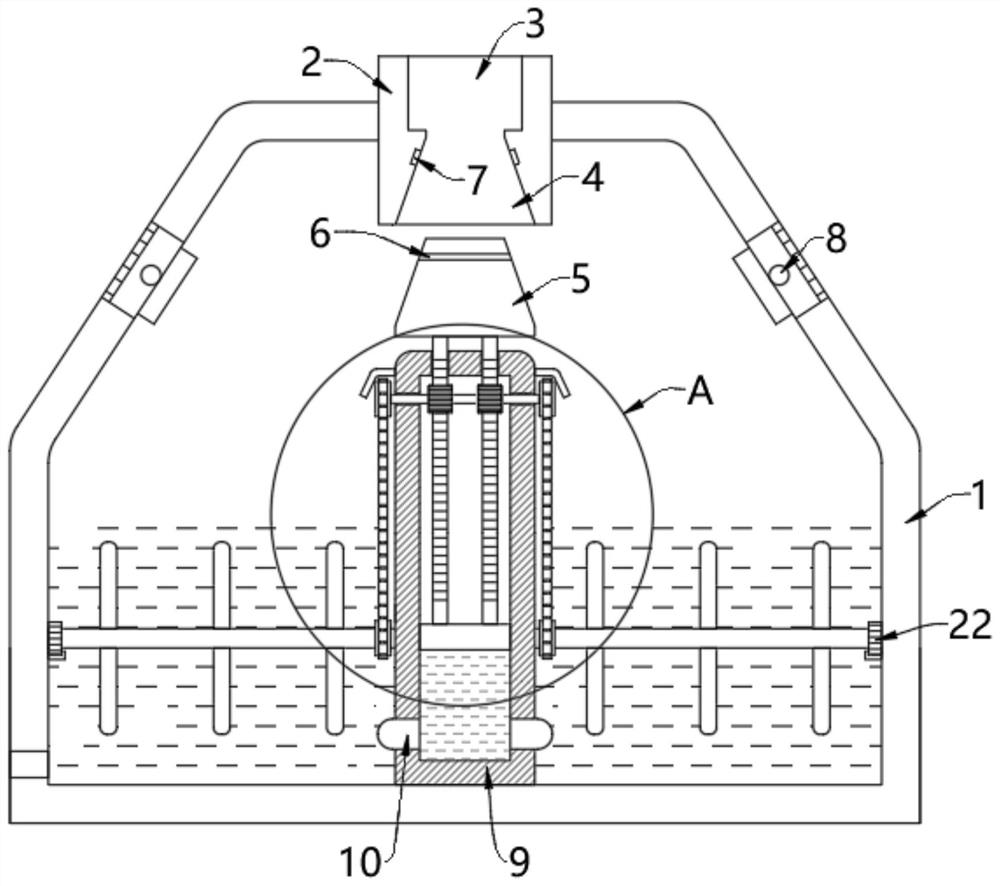

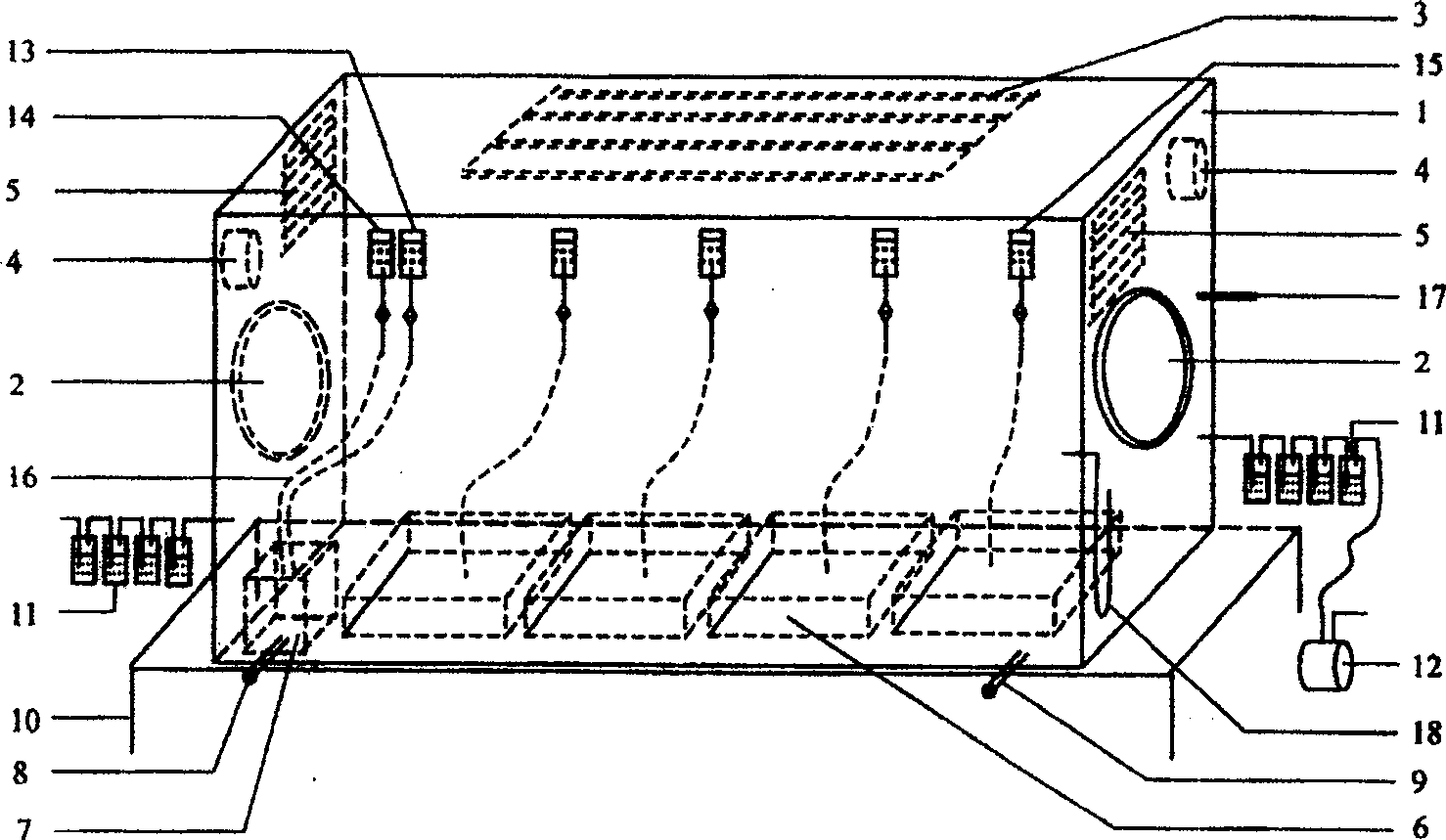

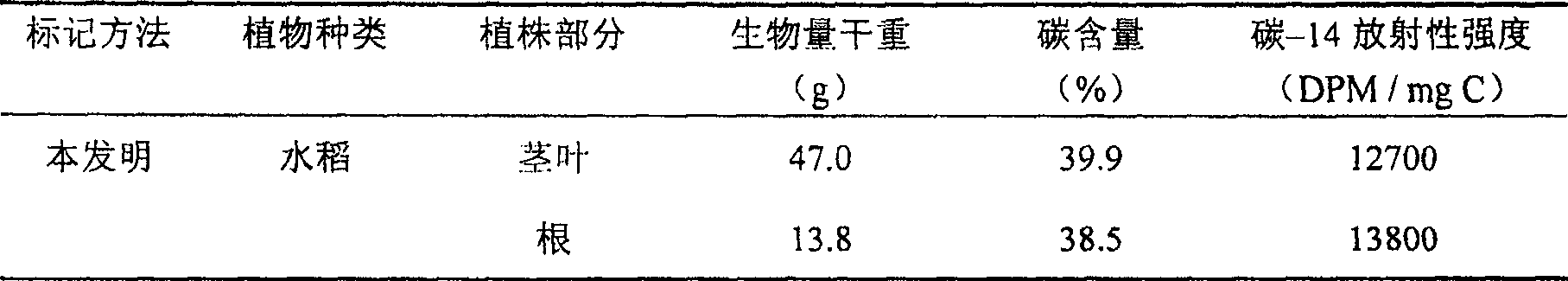

Method and device for plants carbon isotope labelling

InactiveCN101015248ANo escape lossAvoid violent reactionsSamplingEducational modelsFluid infusionDaylight

The invention discloses a method and device for marking plant carbon isotopes. The method comprises following steps: sowing seed in the cultivating disk which located in the soil; putting cultivating disk into air- tight box; adding sodium carbonate marked with carbon-14 or carbon- 13 under air- tight condition, carrying out reaction with hydrochloric acid in reaction tank to generate carbon dioxide for plant photosynthesis. The carbon dioxide in box is mixed with electrical fan, and light is replenished with daylight lamp, the temperature and humidity are reduced by using cooling tube, and water is added into cultivating disk with fluid infusion bottle. The plant marked with carbon- 13 or carbon- 14 is got after cultivation. The invention is characterized by simple and safe operation, prevention of carbon marked with carbon isotopes escape, increased utilization coefficient of carbon isotopes, suitability for carbon isotopes mark for various plants, especially for woody plant.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

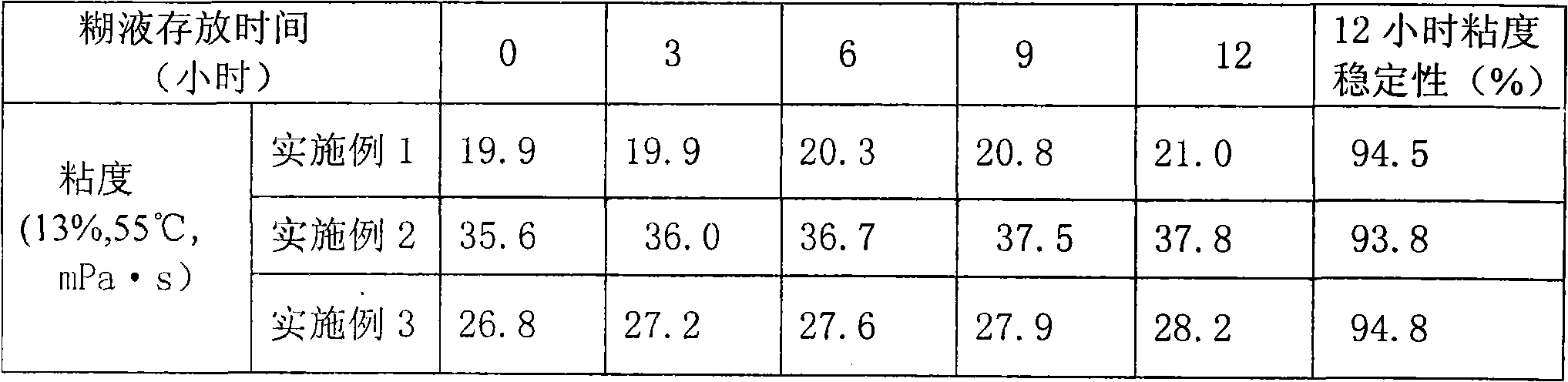

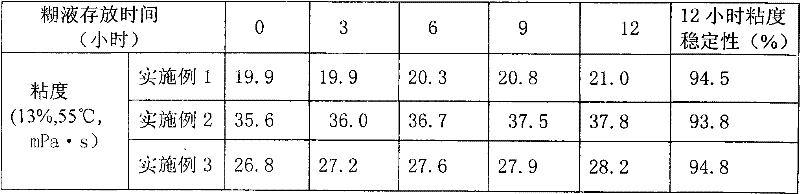

Preparation method of low-viscosity cation starch

InactiveCN102161708AStrong positive chargeLow viscosityWater-repelling agents additionPapermakingSurface strength

The invention relates to a preparation method of low-viscosity cation starch, comprising the following steps: 1) preparing native starch into a 35-40% starch suspension by clear water, successively adding an inhibitor, an activated viscosity breaking agent and a metal ion catalyst under the state of stirring, heating to 42DEG C, adding a cation etherifying agent activated by an alkaline activator, keeping the temperature of 42-52DEG C, and reacting for 0.5-3 hours; 2) continuously adding an oxidant A in a flowing mode, and reacting for 2-5 hours; 3) cooling to 30-35DEG C, adjusting pH to 8.5 by hydrochloric acid, continuously adding an oxidant B in a flowing mode, adjusting the pH of the starch suspension to 8.5-9.5 by a base catalyst, keeping the temperature of 30-38DEG C, and reacting for 0.5-1.5 hours; and 4) adjusting the pH of the suspension to 6.5 by the hydrochloric acid, adding a stabilizer, washing after 20 minutes, dewatering and drying to obtain the product. The starch particle has strong positive charge, paste has the characteristics of low viscosity, good rheological property and high adhesive strength and is used for high-density surface sizing for papermaking, and the surface strength and the printability of paper can be obviously improved.

Owner:广西农垦明阳生化有限公司

Preparation method of metal resin complex and metal resin complex prepared thereby

The invention provides a preparation method of an aluminum alloy resin complex and the aluminum alloy resin complex prepared thereby. The preparation method of the aluminum alloy resin complex comprises the following steps: S1, anodic oxidation: a metal substrate with a surface comprising an anodic oxidation film layer is obtained by anodic oxidation of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, treatment with an etching liquid: the metal substrate containing the anodic oxidation film layer and obtained by the step S1 is immersed in the etching liquid for treatment to obtain a surface treated metal substrate; S3, injection: the surface of the surface treated metal substrate is injected with a resin composition, and then the metal resin complex is obtained after molding; and the etching liquid contains HCl and a soluble halogen acid salt, or contains H3PO4 and a soluble phosphate. In the metal resin complex, the binding force between aluminum alloy and resin is strong, and the process is simple, and is easy for large-scale production.

Owner:BYD CO LTD

Preparation method of metal resin complex and metal resin complex prepared thereby

ActiveCN103451704AReduce reaction exothermImprove bindingSurface reaction electrolytic coatingAlloy substratePhosphoric acid

The invention provides a preparation method of a metal resin complex and the metal resin complex prepared thereby. The preparation method of the metal resin complex comprises the following steps: S1, anodic oxidation: a metal substrate with a surface comprising an anodic oxidation film layer is obtained by anodic oxidation of a pretreated metal substrate, and the metal substrate is an aluminum alloy substrate or aluminum substrate; S2, treatment with phosphoric acid: the metal substrate containing the anodic oxidation film layer and obtained by the step S1 is immersed in a phosphoric acid solution for treatment to obtain a surface treated metal substrate; and S3, injection: the surface of the surface treated metal substrate is injected with a resin composition, and then the metal resin complex is obtained after molding. In the metal resin complex, the binding force between metal and resin is strong, and the process is simple, is easy for large-scale production, and has no pollution.

Owner:BYD CO LTD

Gas phase SO3 film-scrapping sulfonating technology

InactiveCN101445418ALess investmentReduce energy consumptionLiquid-gas reaction of thin-film typeSulfo/sulfonyldioxy group formation/introductionGas phaseProduct gas

The invention relates to a gas phase SO3 film-scraping sulfonating technology which belongs to the technical field of production technology which prepares anionic surfactant by using gas phase SO3 film-scraping sulfonating liquid organic materials. The invention is carried out according to the following steps: A: liquid SO3 is vaporized to gas phase SO3, the gas phase SO3 is sucked in a mixer shaft through a turbo-blower, the gas phase SO3 is mixed with inert gases recycled in a sulfonating reactor to reaction gas with the volume concentration being 0.1 to 10 percent, and then the reaction gas goes into a reaction cylinder body through reaction gas distribution holes on the upper part of the scraping plate shaft; B: the organic materials go into the sulfonating reactor and downwards flow along the inner wall of the reaction cylinder body, a scraping plate is rotated along with the mixer shaft under the action of a transmission system, the organic materials are continuously suffered with film scaping-spread coating-film scaping in the inner wall of the reaction cylinder body, the organic material are alternately updated and uniformly coated on the inner wall of the reaction cylinder body, and the organic materials are completely contacted and reacted with the reaction gas which goes from the reaction gas distribution holes to form reaction products. The design of the technology is reasonable, and the invention can be suitable for sulfonating or sulphating materials with various viscosities.

Owner:ZANYU TECH GRP CO LTD

Aluminum alloy for hydrogen production and preparation method of aluminum alloy

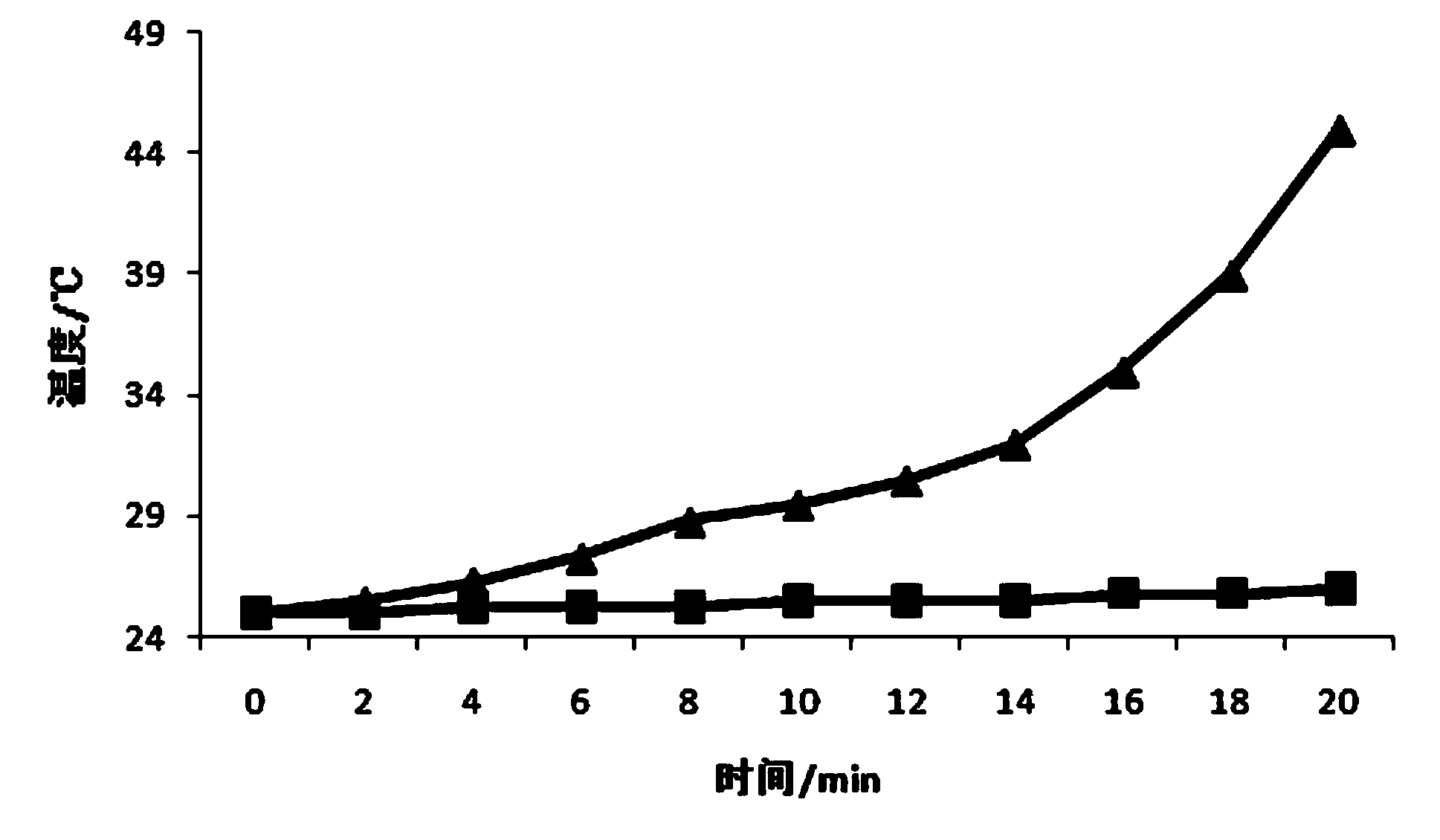

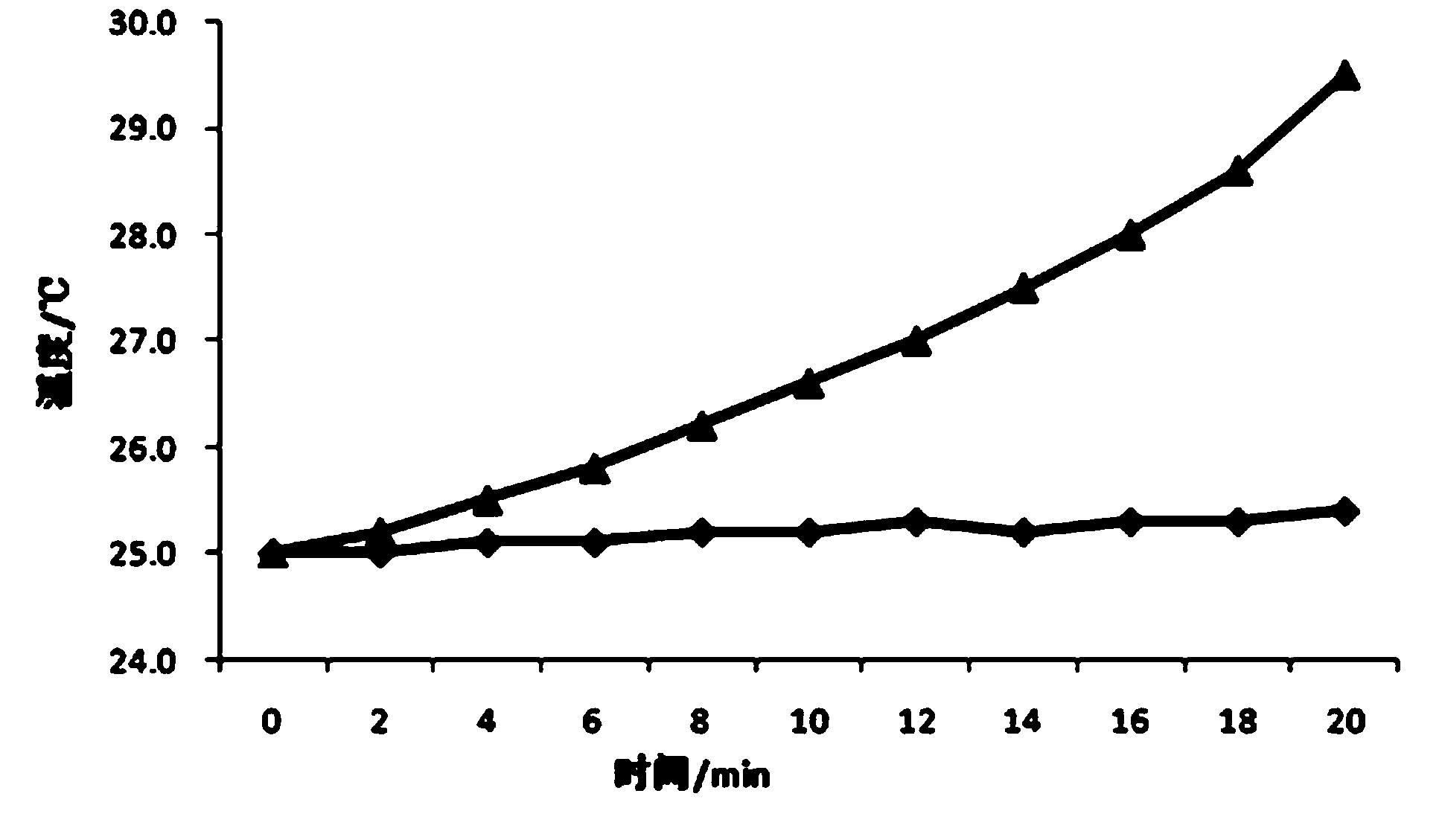

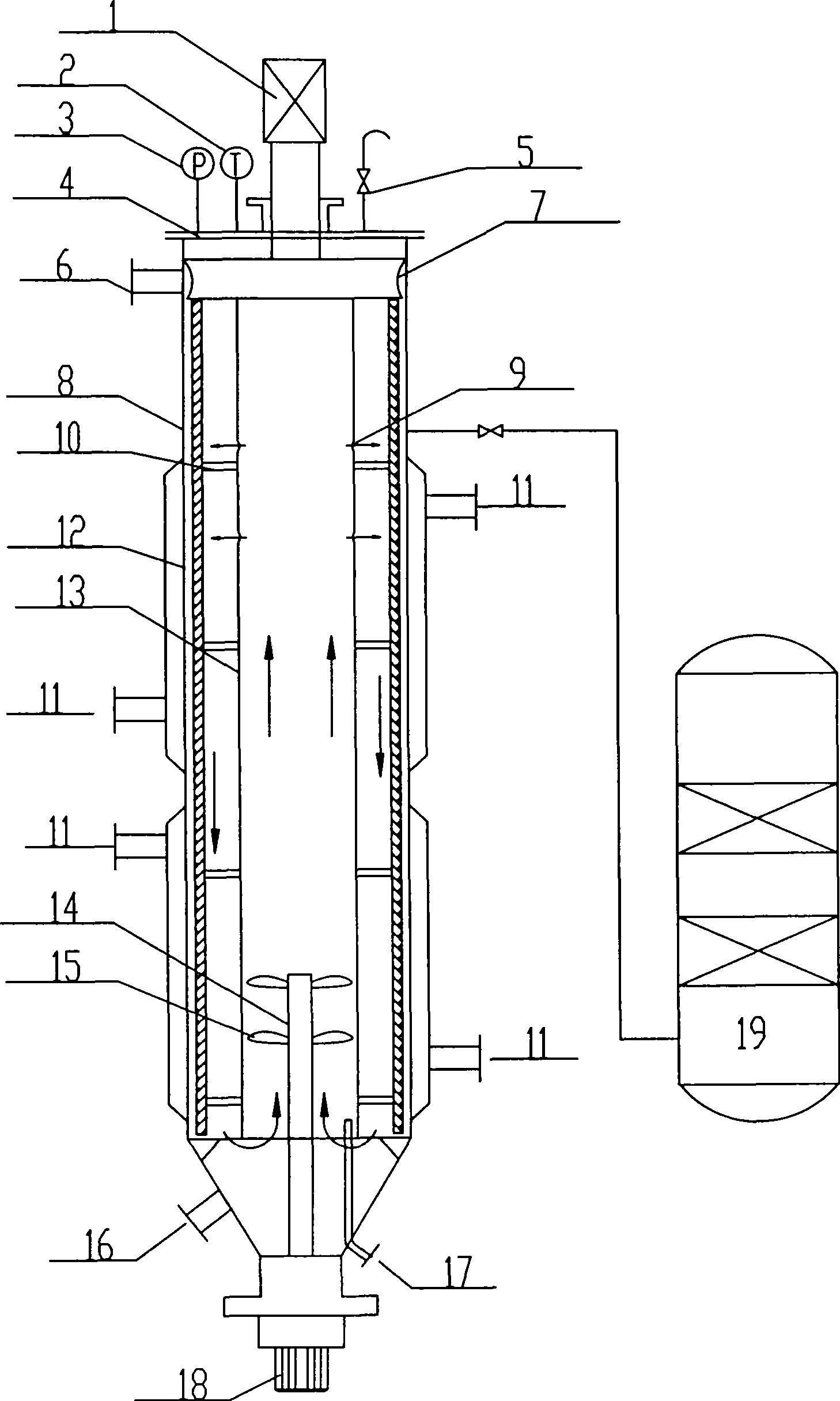

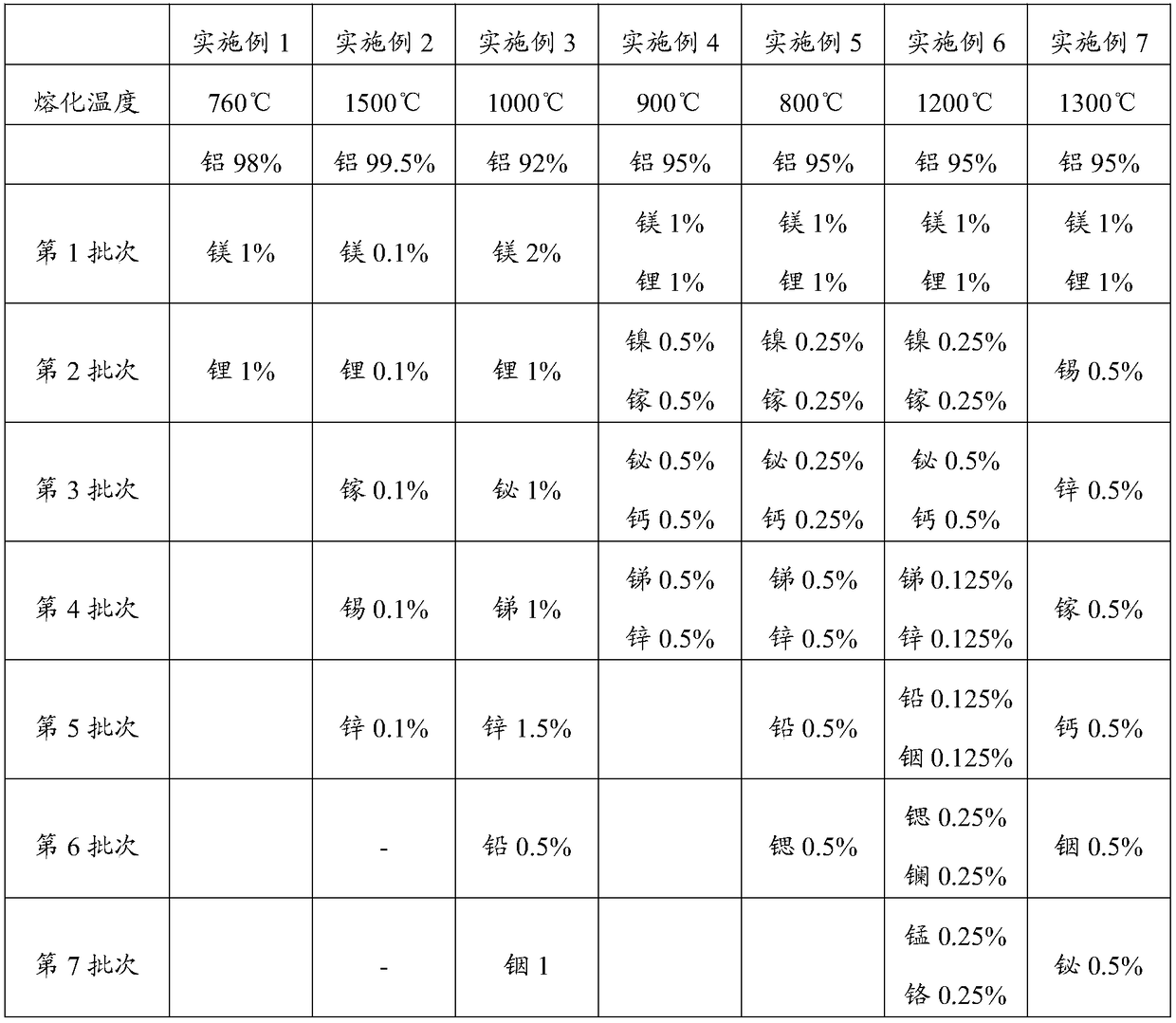

The invention provides an aluminum alloy for hydrogen production and a preparation method of the aluminum alloy, and belongs to the technical field of hydrogen production materials. The aluminum alloycomprises the following ingredients by weight percentage: 90-99.9% of aluminum and 0.1-10% of other metals, wherein the other metals comprise one or more of lanthanum, lithium, gallium, molybdenum, lead, tin, zinc, antimony, titanium, indium, bismuth, manganese, nickel, cadmium, strontium, magnesium and calcium. The activity of an aluminum metal is improved, and a too sharp reaction can be prevented by adding the other metals, and the aluminum alloy can react with water mildly at ordinary temperature to generate hydrogen.

Owner:江苏迅易新能源科技有限公司

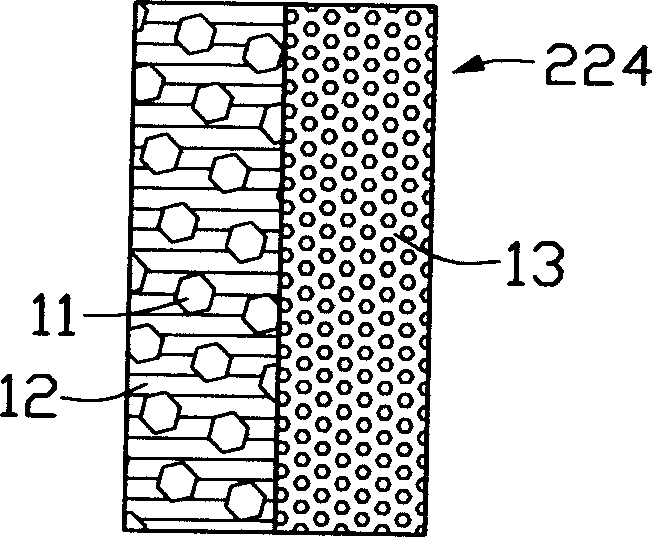

A lithium secondary battery isolating film and lithium secondary battery using the same

InactiveCN1567614ALow cost of preparationExtended service lifeSecondary cellsCell component detailsMolecular sieveCell isolation

The invention relates to a lithium secondary cell isolation film, at least including a strong water absorption material-high molecular composite layer, where the preferred strong water absorption material is molecular sieve. The strong water absorption material can completely absorb the residual and infiltration water in manufacturing process of the lithium secondary cell so as to prevent the poisoning of the lithium secondary cell or the reaction of lithium metal with the water, thus prolonging the service life. In addition, the proper combination of the strong water absorption material with the high-molecular composite can increase the mechanical strength of the isolation film and reduce the electrode penetration and thus it improves the safety of the lithium secondary cell. The invention also relates to a lithium secondary cell using this isolation film.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

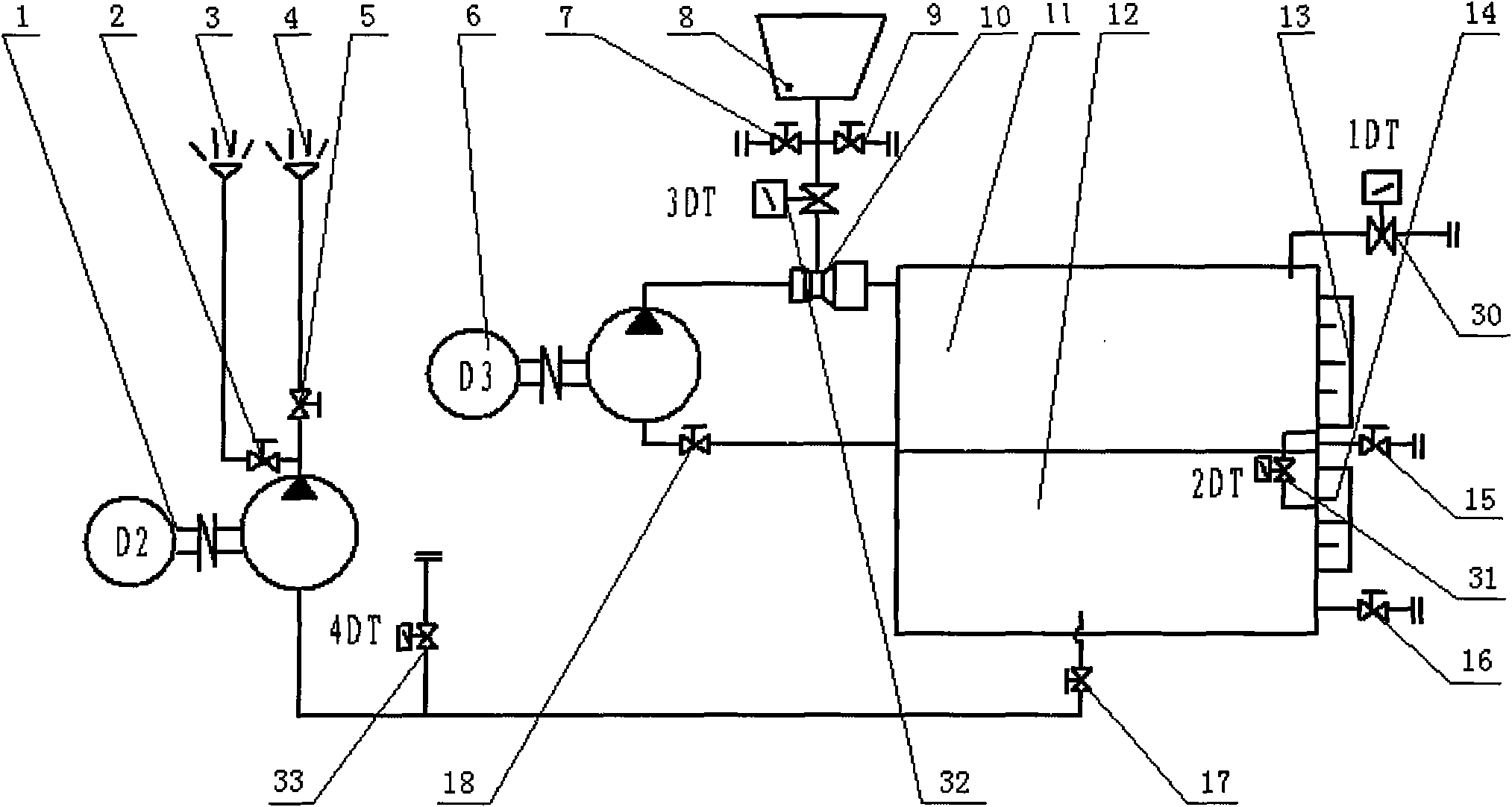

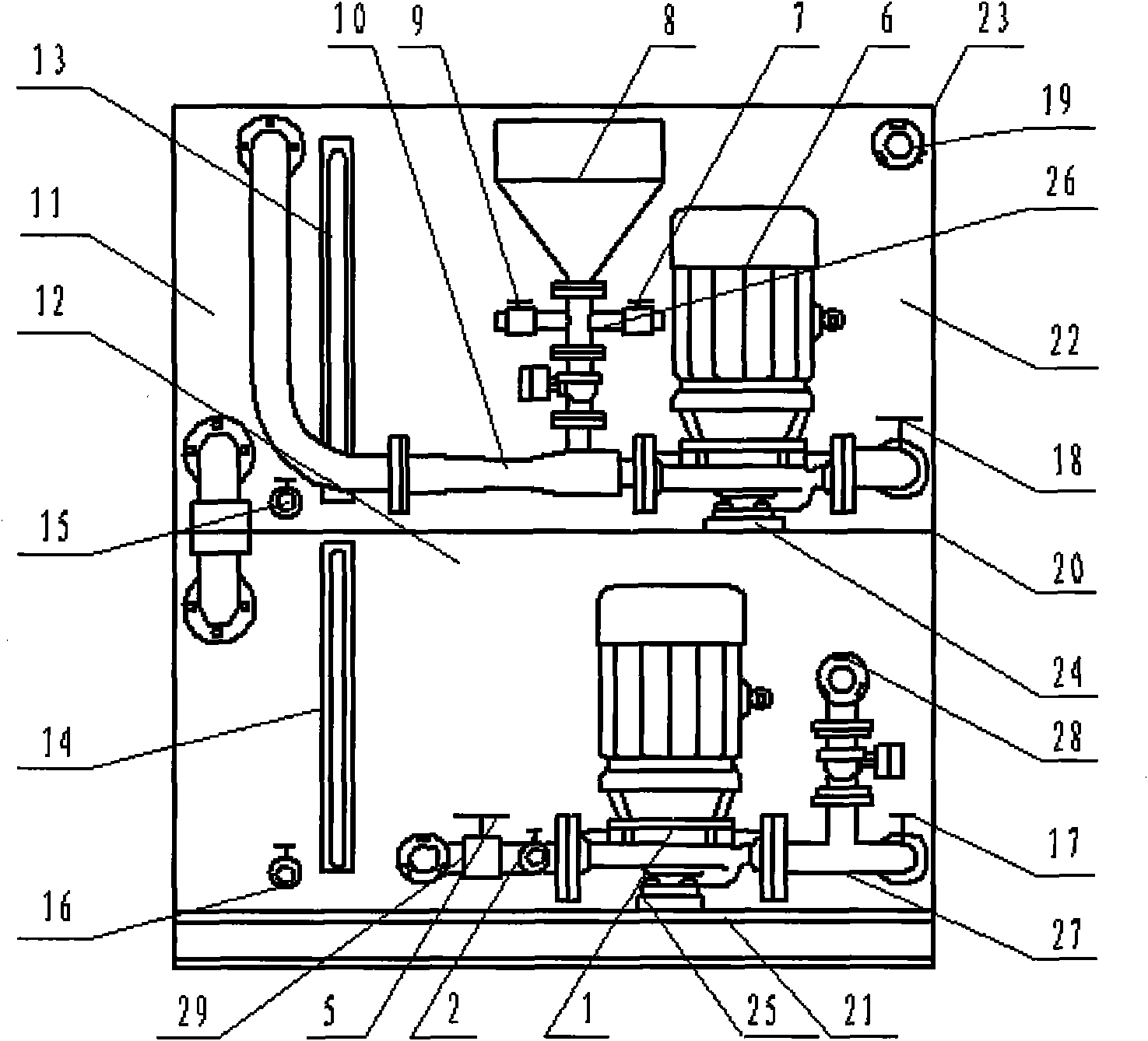

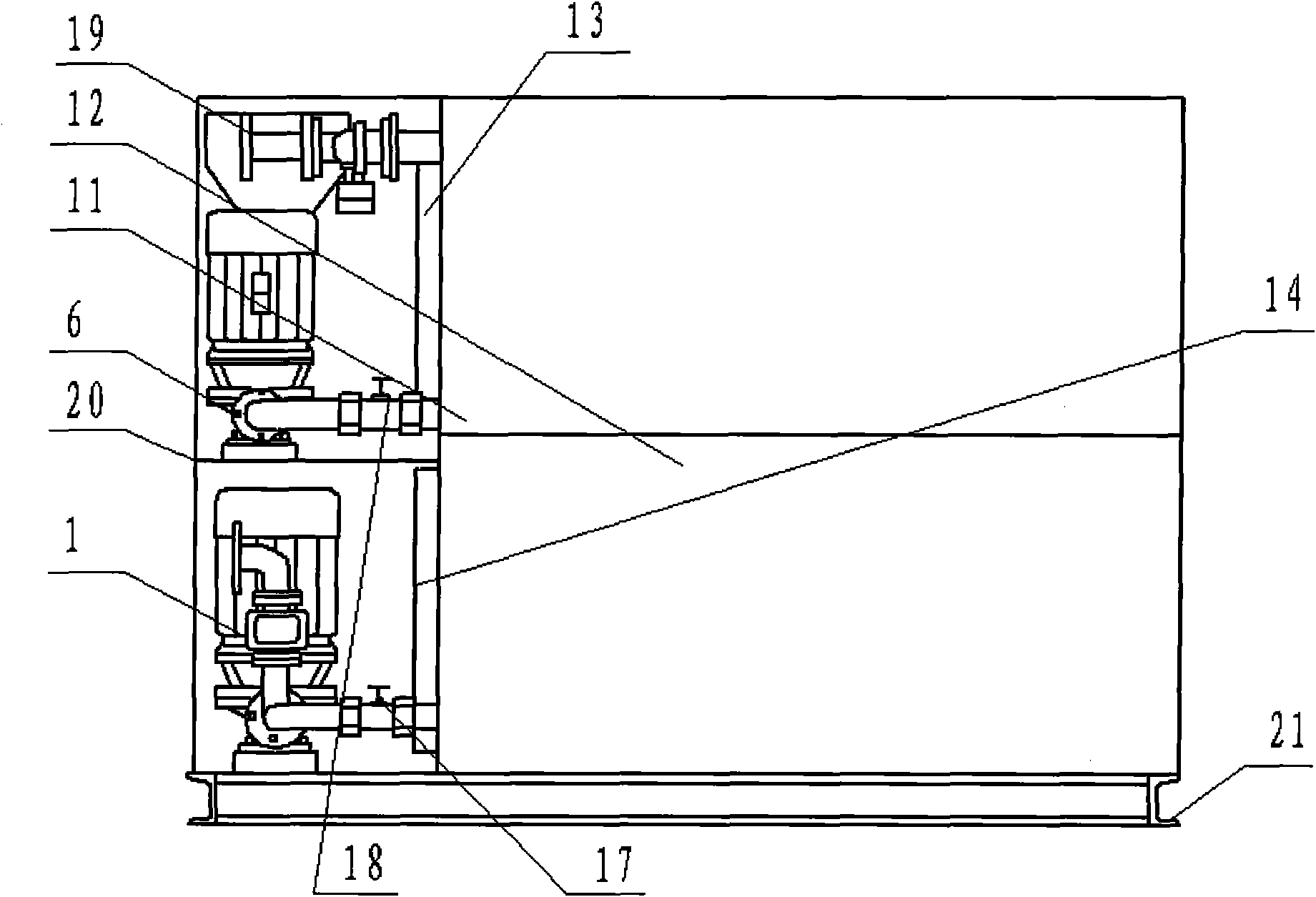

Emergency treatment device for dangerous chemical leakage

InactiveCN101898016ASpeed up the flowAvoid violent reactionsChemical protectionEmergency treatmentLiquid tank

The invention discloses an emergency treatment device for dangerous chemical leakage. A partition plate is arranged in the middle of a liquid tank to form a structure taking upper and lower stirring chambers and a liquid storage chamber as a main body; the bottom of the liquid tank and the extending outer edge of the middle partition plate are provided with a steel plate framework with an upper layer and a lower layer; a stirring pump is fixed on the middle extending partition plate; an ejector inlet is communicated with the stirring pump, while an outlet is communicated with the stirring chambers; an electric ball valve is arranged at an ejector negative pressure port and communicated with a four-way pipe; a hopper is arranged on the upper part of the four-way pipe; and a spray pump is fixed on a lower extending steel plate, a liquid inlet of the spray pump is communicated with a liquid outlet of the liquid storage chamber, a liquid outlet of the spray pump is communicated with a three-way pipe II, and the other two ports of the three-way pipe II are connected with a hydrant I and a control valve I respectively. The device is suitable for emergency treatment of accidents in production, storage, transportation, selling, use and waste treatment of dangerous chemicals, and avoids heavy casualties, property loss and environmental pollution.

Owner:TAIYUAN UNIV OF TECH

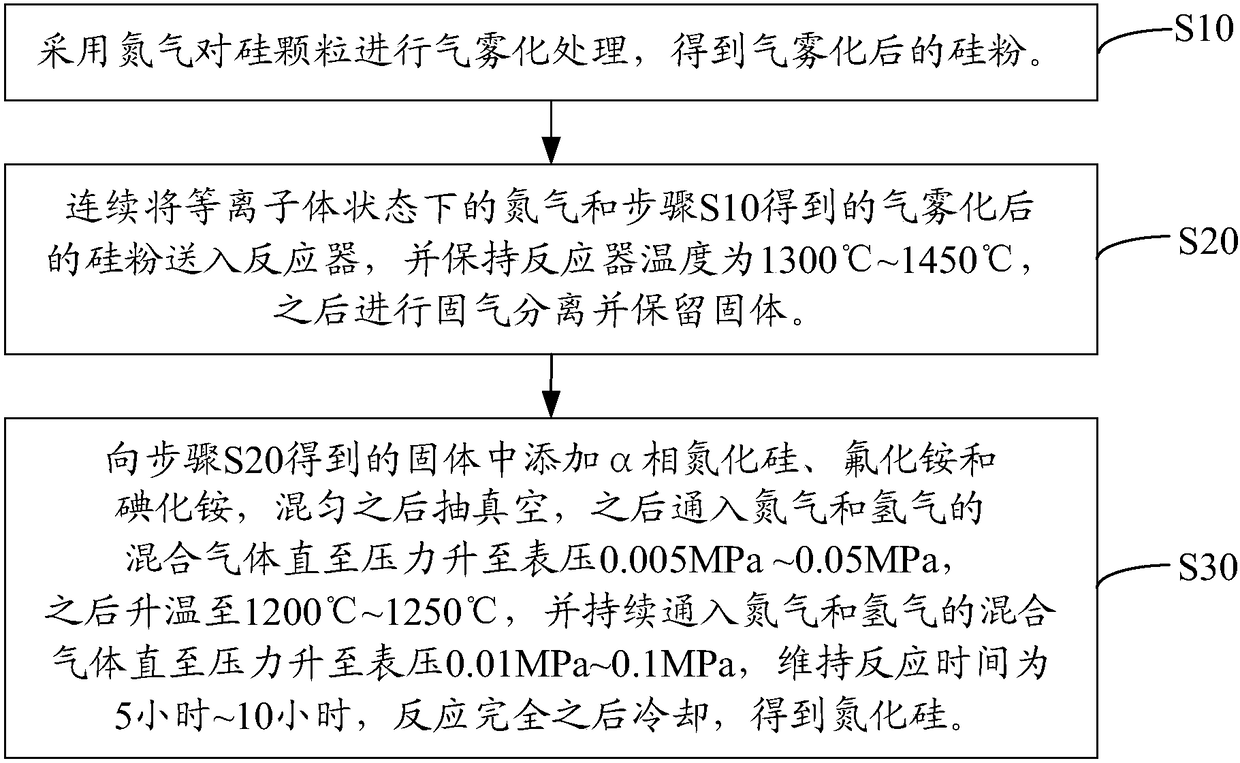

Silicon nitride and preparation method thereof

ActiveCN108529576AAvoid violent reactionsAct as a diluentNitrogen compoundsHydrogenSynthesis methods

The invention relates to silicon nitride and a preparation method thereof. The preparation method of the silicon nitride comprises the following steps: performing gas atomization treatment on siliconparticles by using nitrogen to obtain silicon powder subjected to gas atomization; continuously nitrogen under the plasma state and the silicon powder subjected to gas atomization into a reactor, maintaining the temperature of the reactor to 1300 to 1450 DEG C, performing solid and gas separation and retaining solid; and adding alpha-phase silicon nitride, ammonium fluoride and ammonium iodide into the solid, mixing uniformly, vacuumizing, introducing mixed gas of nitrogen and hydrogen until the pressure is increased to the gauge pressure of 0.005 to 0.05 MPa, heating to 1200 to 1250 DEG C, continuously introducing the mixed gas of nitrogen and hydrogen until the pressure is increased to the gauge pressure of 0.01 to 0.1 MPa, maintaining the reaction time for 5 to 10 hours, and cooling after complete reaction to obtain the silicon nitride. The preparation method of the silicon nitride is a composite synthesis method. By the preparation method of the silicon nitride, high alpha-phase silicon nitride can be obtained.

Owner:SUZHOU GCL ENERGY TECH DEV CO LTD

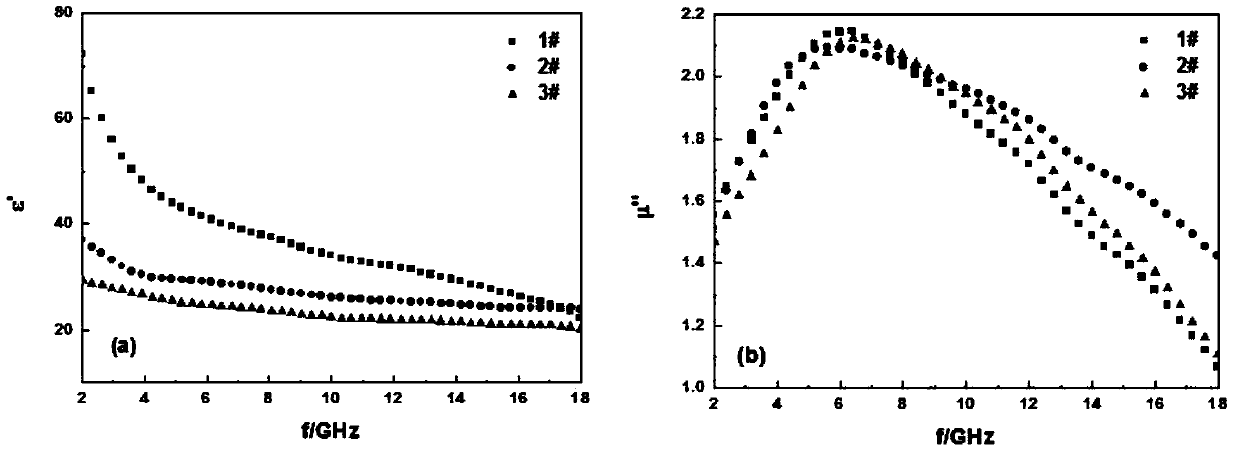

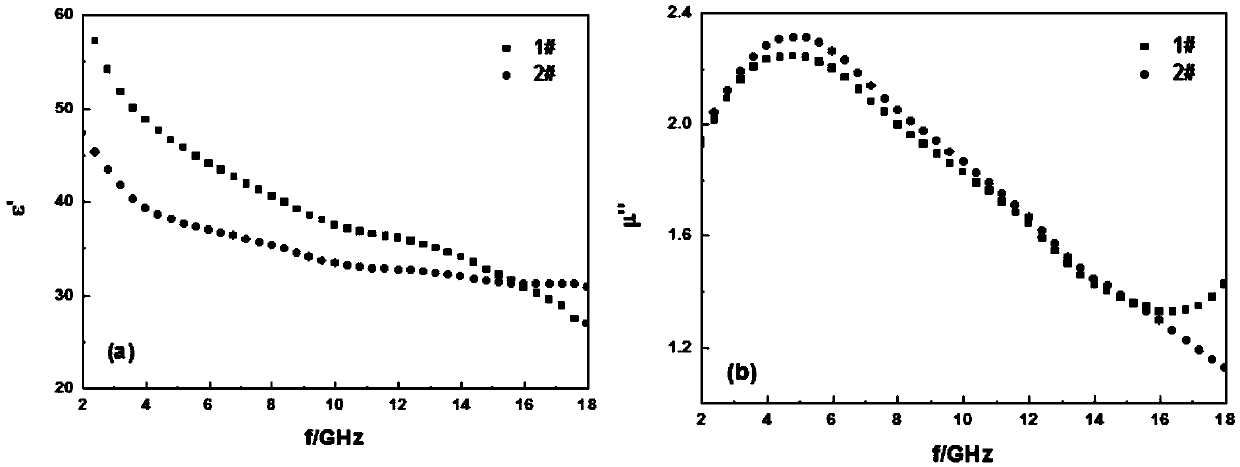

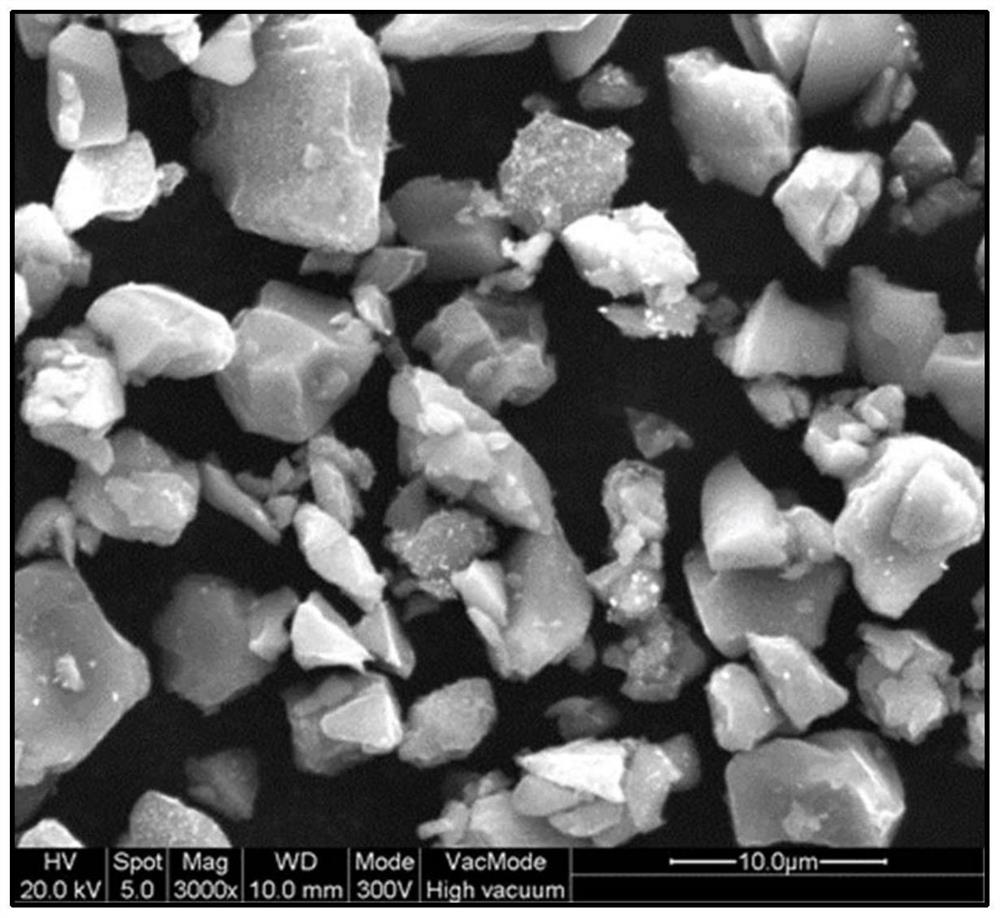

Modification method for electromagnetic parameters of carbonyl iron powder

InactiveCN105502517AHigh dielectric constantLow dielectric constantIron carbonylsDielectricNon destructive

The invention relates to a modification method for electromagnetic parameters of carbonyl iron powder and belongs to the field of absorbent preparation. The technical problem that the dielectric constant and the magnetic parameter of a carbonyl iron powder absorbent prepared through an existing preparation method are mismatched at a high mixing amount is solved. The preparation method includes the steps that firstly, the untreated carbonyl iron powder is treated according to a ball milling method through metal pots and ball milling balls so that the purposes of increasing the specific surface area, changing the micro-shape and then adjusting the electromagnetic parameters can be achieved; then, a passive film is generated on the surface of the carbonyl iron powder through a metal passivation chemical technology so that the dielectric constant of the carbonyl iron powder can be effectively reduced; finally, relatively-uniform phosphatized micron-size carbonyl iron powder particles are obtained by grinding the dried carbonyl iron powder in a non-destructive mode. By testing the electromagnetic parameters of the carbonyl iron powder, it is found that the real part of the dielectric constant of the treated carbonyl iron powder is significantly reduced, and the magnetic loss is kept unchanged basically, so that the purposes of parameter matching and parameter modification are achieved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

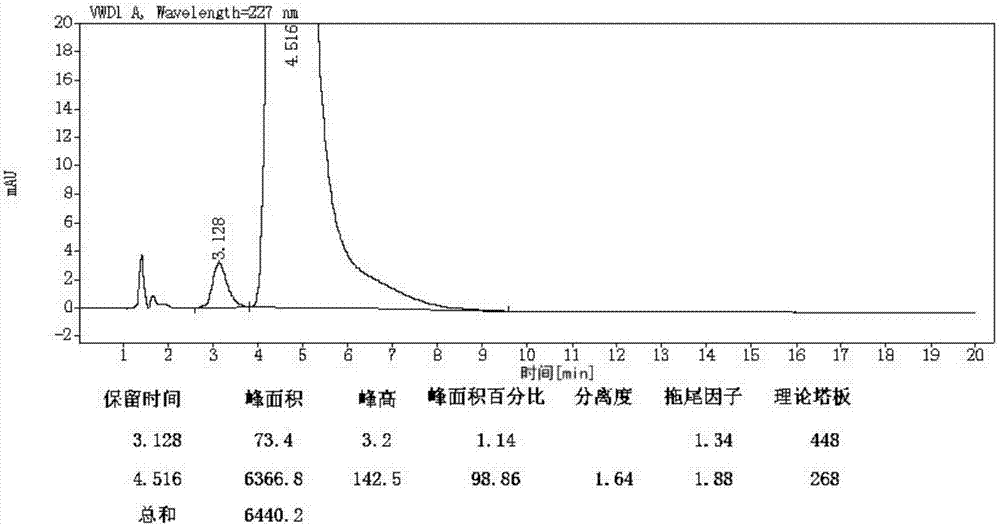

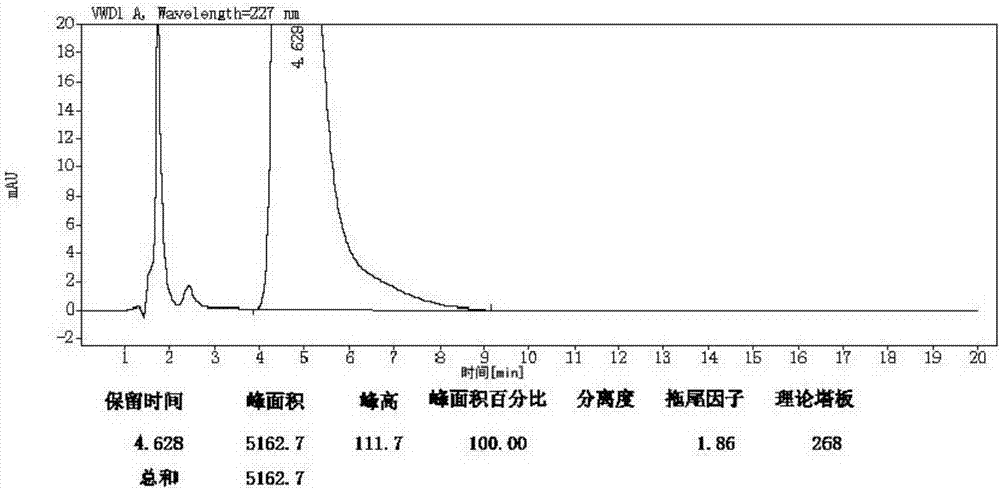

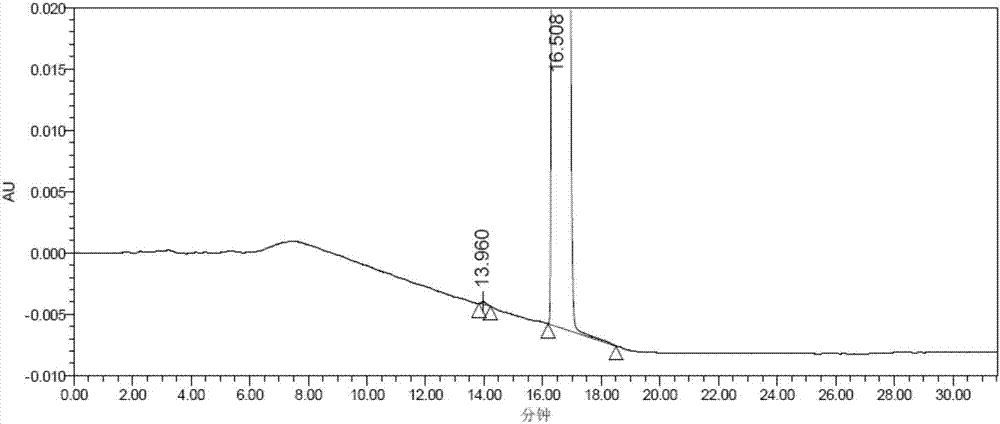

Preparation and purification method of valsartan

InactiveCN107056720AAvoid residueAvoid violent reactionsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPurification methodsValsartan

The invention relates to the field of medicinal chemistry and discloses a preparation and purification method of valsartan. The method comprises the steps of (S1) adding L-valine and alcohol to a reaction kettle, slowly dropwise adding thionyl chloride, carrying out heating reflux reaction, adding isopropyl acetate for pulping, carrying out suction filtration to obtain an intermediate 1; (S2) carrying out nucleophilic reaction on the intermediate 1 and a starting material 2 in a solvent under an alkaline condition to obtain an intermediate 2; (S3) carrying out nucleophilic reaction on the intermediate 2 and valeryl chloride in the solvent under the alkaline condition to obtain an intermediate 3; and (S4) carrying out cyclization reaction on the intermediate 3, sodium azide and a catalyst ((-)-sparteine-Cu (II) complex) in the solvent, washing, crystallizing and drying to obtain the valsartan. The sodium azide and the catalyst ((-)-sparteine-Cu (II) complex) are used in the cyclization reaction, and the cyclization yield can reach 90%. According to the purification method, the purity of the raw materials of the valsartan is greater than 99.99%, the content of a solvent residue (ethyl acetate) is smaller than 0.5%, the content of a specific impurity is smaller than 0.1%, other unknown individual impurities are avoided and an enantiomer impurity is not detected.

Owner:湖南千金湘江药业股份有限公司

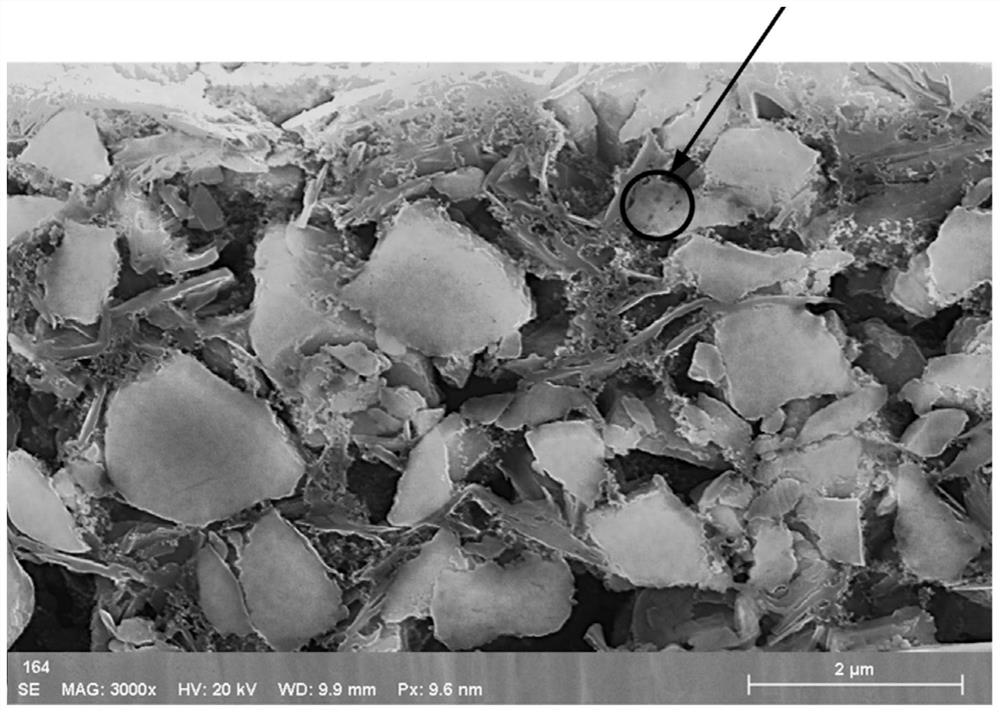

Secondary doped silicon-based negative electrode material and preparation method thereof

ActiveCN112751011AImprove the first Coulombic efficiencyReduce consumptionNegative electrodesSecondary cellsCarbon coatingPhysical chemistry

The invention provides a secondary doped silicon-based negative electrode material and a preparation method thereof, the secondary doped silicon-based negative electrode material comprises an inner core and a carbon coating layer; the inner core comprises silicon, a silicon oxide, silicate of a first metal element and silicate of a second metal element, the general formula of the silicon oxide is SiOx, x is greater than 0 and less than 2; the activity of the first metal element is lower than that of the second metal element; and the carbon coating layer is coated on the surface of the inner core. According to the secondary doped silicon-based negative electrode material and the preparation method of the secondary doped silicon-based negative electrode material, the first coulombic efficiency and the capacity retention ratio of a secondary battery can be improved.

Owner:SHANGHAI SHANSHAN TECH CO LTD

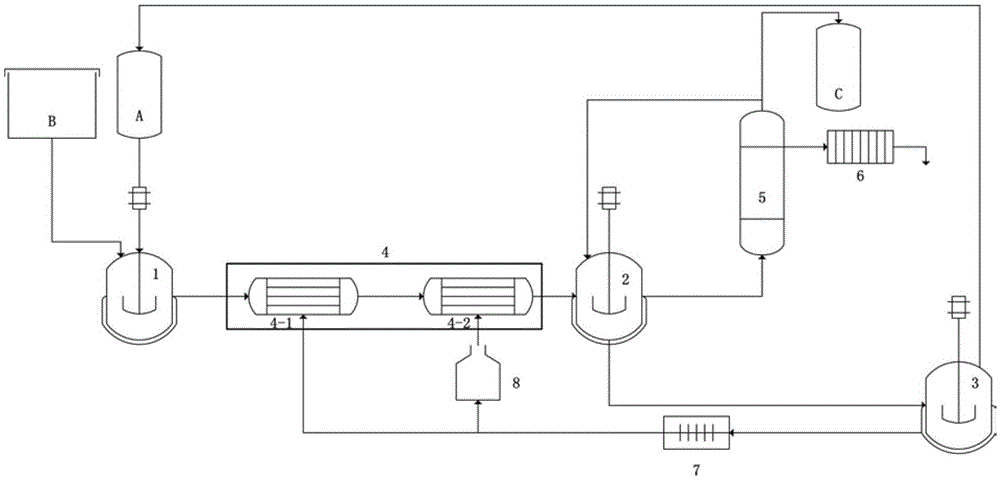

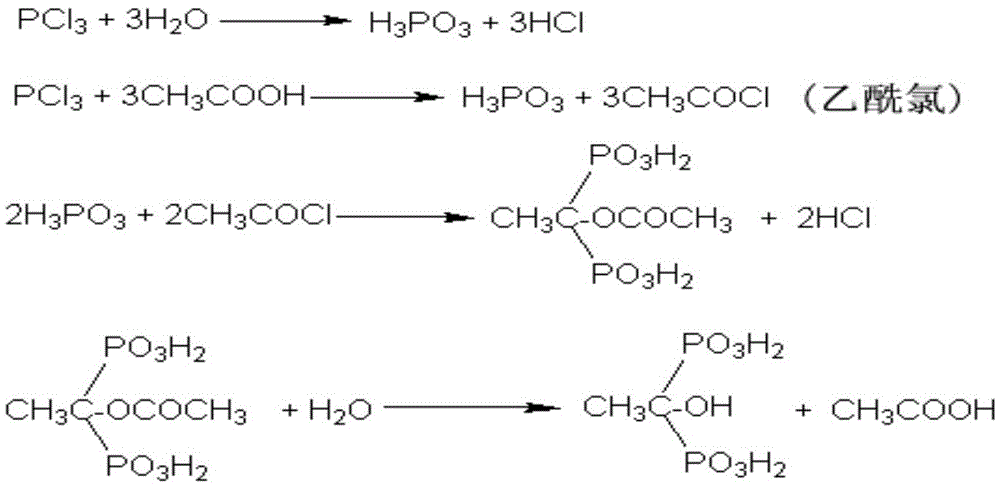

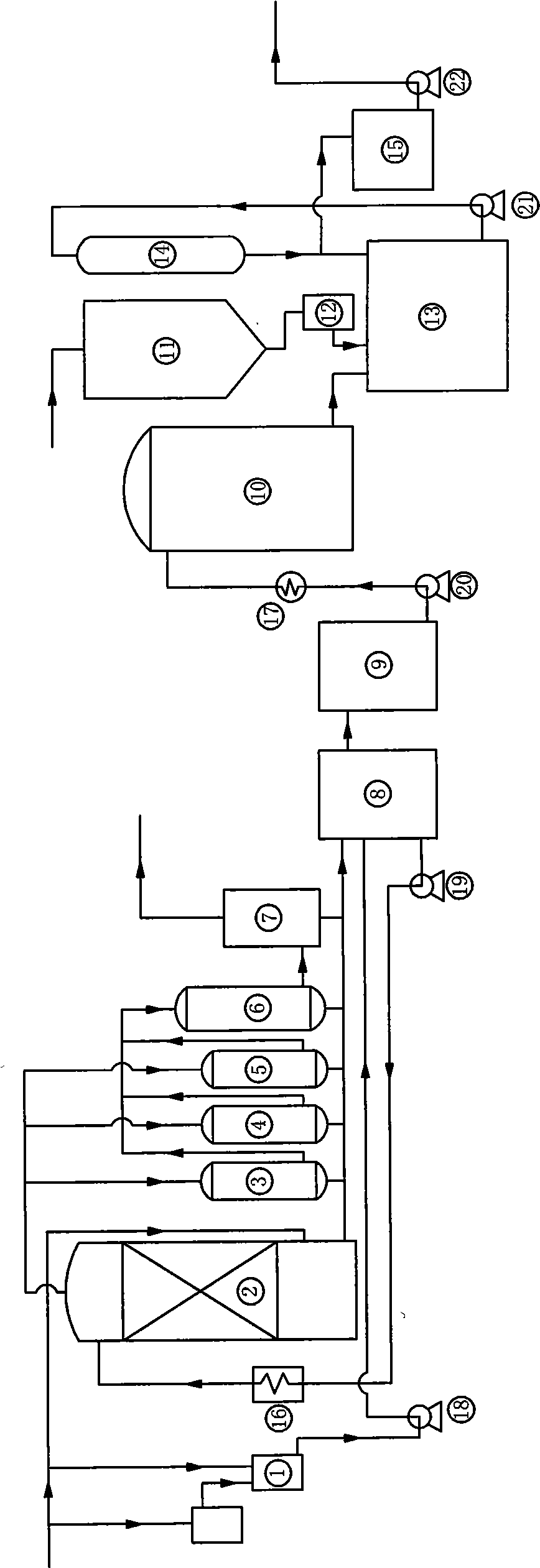

Production method and system for co-production of acetyl chloride by 1-hydroxyethylidene-1,1-diphosphonicacid

InactiveCN105622667ADoes not affect reaction efficiencyRapid hydrolysis reactionOrganic compound preparationGroup 5/15 element organic compoundsMixed materialsPhosphorus trichloride

The invention provides a production method for co-production of acetyl chloride by 1-hydroxyethylidene-1,1-diphosphonicacid. The method comprises the following steps: starting a reaction still for stirring, pumping a certain amount of acetic acid or acetic acid aqueous solution in, and meanwhile dripping a certain amount of phosphorus trichloride into the reaction still for mixing; after mixing, leading into a heat exchanger for preheating; preheating a mixed material, leading into a synthesis reactor for an esterification reaction, enabling generated acetyl chloride to enter into a rectifying tower to be separated to obtain high-purity acetyl chloride or back drop into the synthesis reactor, enabling hydrochloric acid and uncondensed acetyl chloride to enter a multi-stage exhaust absorption apparatus; enabling generated acetic ester to enter a hydrolysis kettle for hydrolyzation, promoting acetic ester to evaporate out by negative pressure operation to be reused, replenishing deionized water to promote the hydrolyzation to obtain HEDP, and reusing excess heat through a steam recycling machine on the heat exchanger. The production method has the following beneficial effects: the production efficiency is promoted; the operative difficulty and labor intensity are reduced; the technical parameter requirements on the synthesis reactor can be lowered; the reaction efficiency can be greatly improved; product overstocking caused by acetyl chloride encountering poor sales is avoided; the production cost is saved; the exhaust emission is reduced.

Owner:天津科维津宏环保科技有限公司 +3

Device for producing sodium hypochlorite by using waste chlorine water and production method thereof

InactiveCN101531341ARealize "0" emissionSolve external pollutionHypochloriteSocial benefitsSodium hypochlorite

The invention discloses a device for producing sodium hypochlorite by using waste chlorine water and a production method thereof. The device comprises a chlor-alkali producing device, a waste chlorine collecting device and a reaction device, and a waste chlorine collecting pipeline is arranged between the chlor-alkali producing device and the waste chlorine collecting device. The production method comprises that: firstly, all chlorine water generated by the chlor-alkali producing device in the normal producing process enters the waste chlorine collecting device through the waste chlorine collecting pipeline; and then the chlorine water is added with alkali liquor through the reaction device for reaction to generate the sodium hypochlorite. The production method solves the problem of pollution by draining the chlorine water, realizes zero emission of the waste chlorine water, and improves the environmental protection and social benefits.

Owner:SHANDONG XINLONG GROUP CO LTD

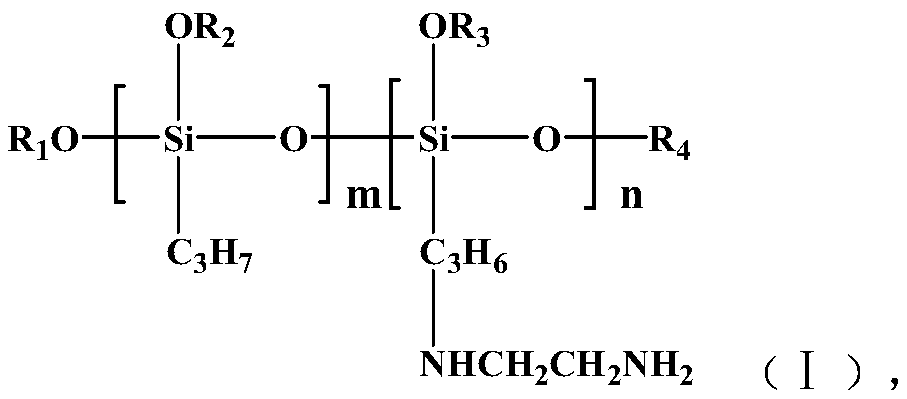

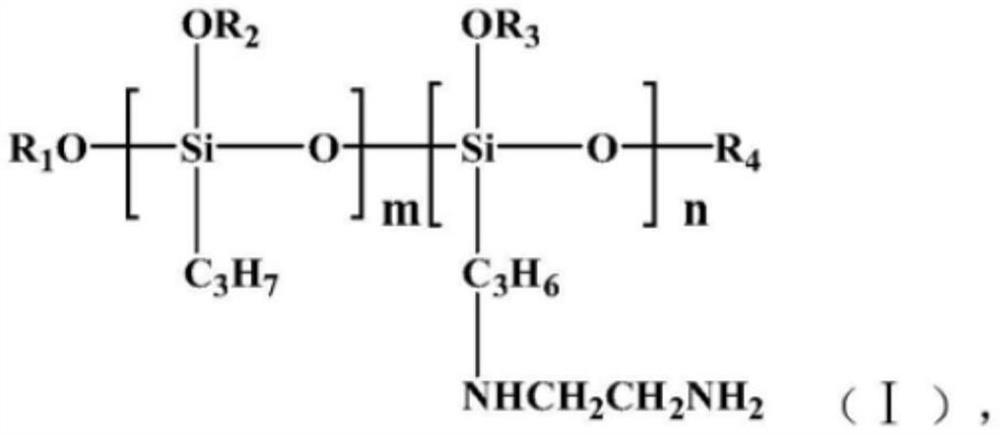

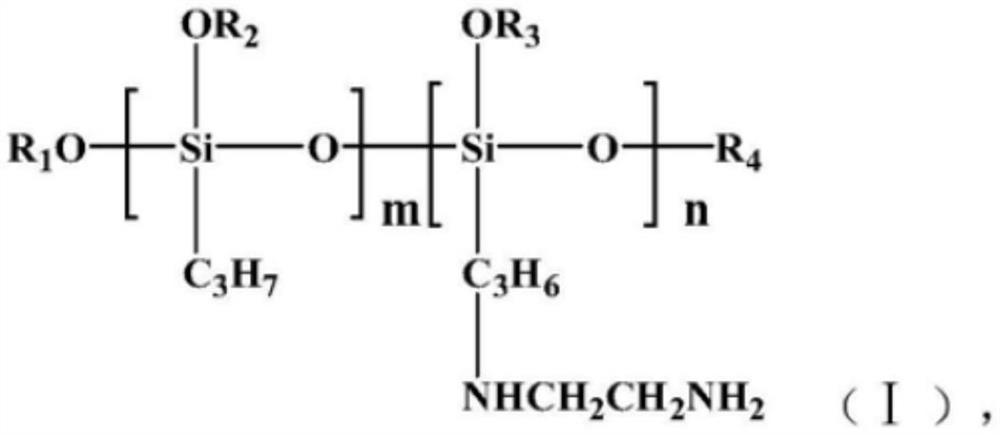

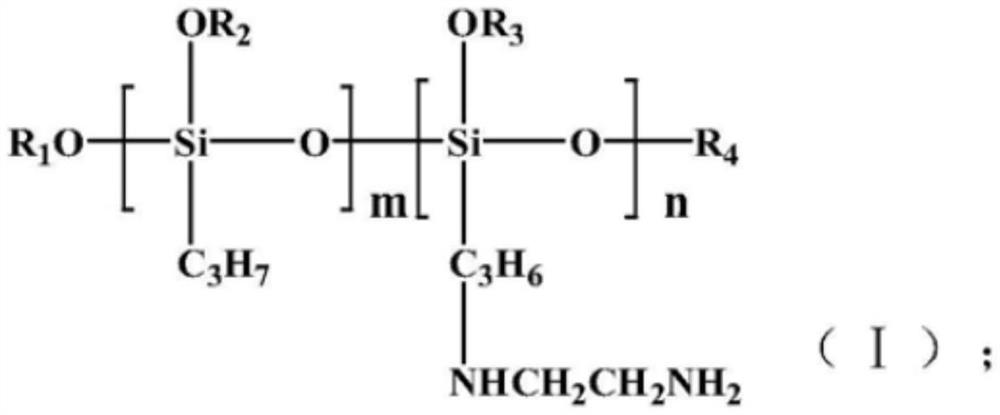

Asphalt polyurethane waterproof coating suitable for cement base layer and preparation method and application of asphalt polyurethane waterproof coating

ActiveCN110760264AEasy to controlGood adhesionRoofingProtective foundationPolymer scienceBituminous waterproofing

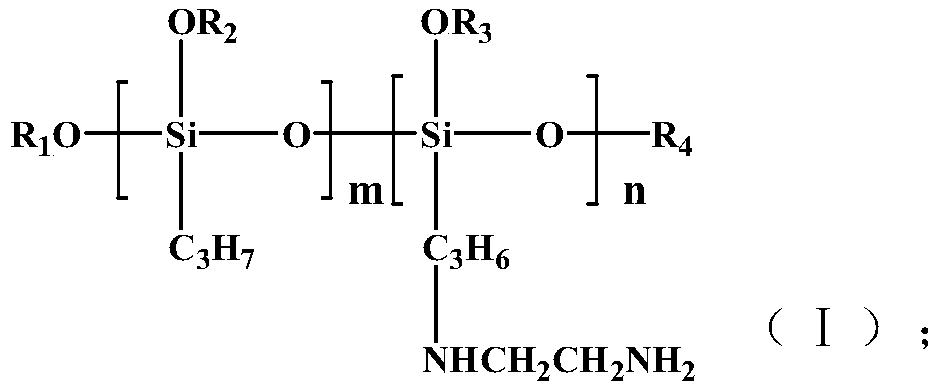

The invention discloses an asphalt polyurethane waterproof coating suitable for a cement base layer and a preparation method and application of the asphalt polyurethane waterproof coating. Raw materials of the asphalt polyurethane waterproof coating comprise asphalt, a compatilizer, a water removal agent, a catalyst, filler and a terminated polyurethane prepolymer, wherein the terminated polyurethane prepolymer is prepared through a reaction of a compound which is shown in a formula (I) and a polyurethane prepolymer, and the terminated polyurethane prepolymer contains no isocyanate-terminatedgroups; and the preparation method comprises the following steps: preparing the terminated polyurethane prepolymer firstly, and then mixing the terminated polyurethane prepolymer with the remaining raw materials so as to obtain the coating. The invention further discloses application of the waterproof coating in construction of an asphalt waterproof coiled material on the cement base layer. The waterproof coating has a safe preparation process, the coating can be coated directly on the cement base layer with high content of water when the coating is in use, and a reaction is performed betweenthe hydrolyzed coating with silicate in the cement, so that the bonding force on the wet base layer is improved; and excellent bonding strength can be formed between the coating and the asphalt waterproof coiled material, particularly a short time of surface drying and hard drying and moderate viscosity are achieved, the heating step before construction can be avoided basically, and on-site construction is facilitated.

Owner:JIANGSU CANLON BUILDING MATERIALS

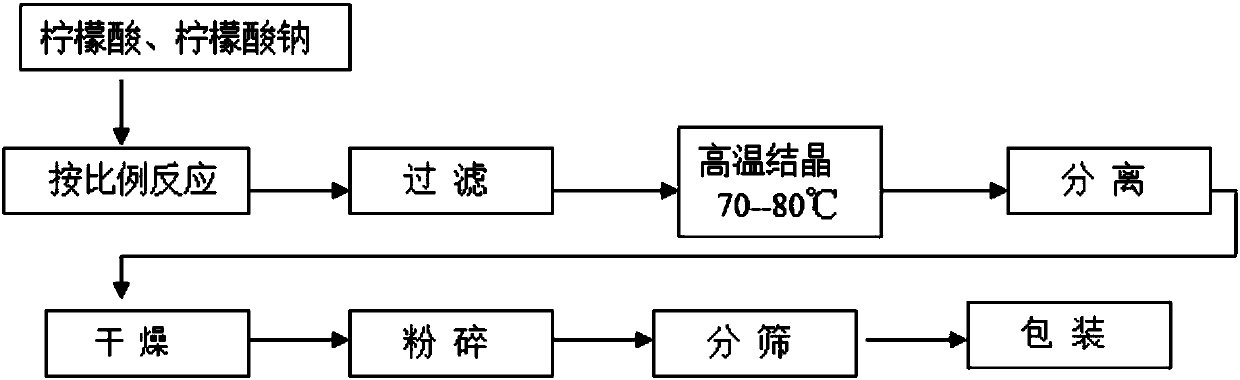

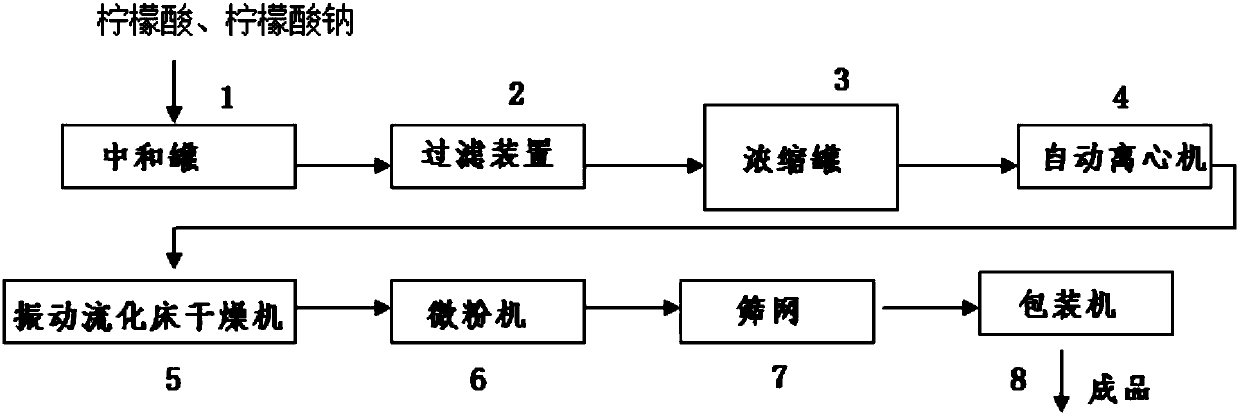

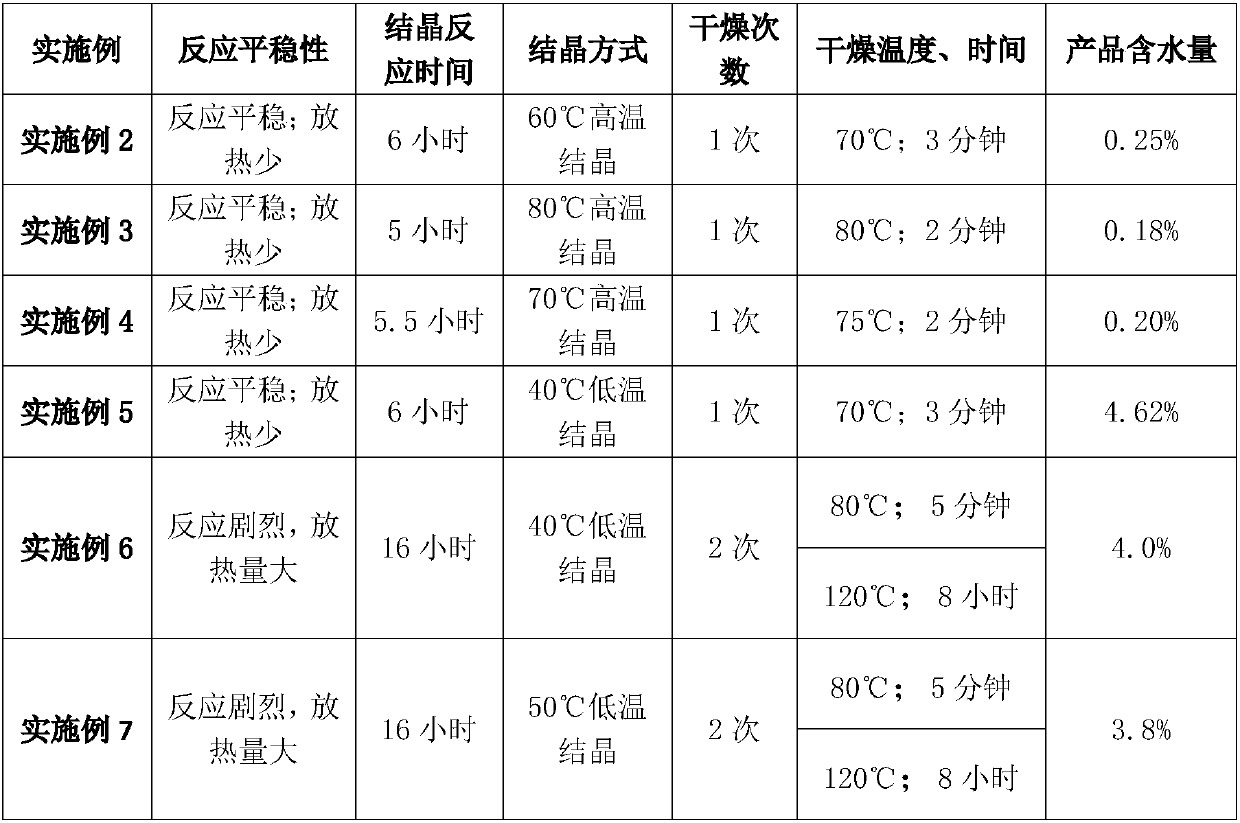

Preparation method and preparation system for sodium dihydrogen citrate

ActiveCN107935838AShorten time and drying timeReduce manufacturing costOrganic compound preparationCarboxylic acid salt preparationCitrate sodiumPulverizer

The invention provides a preparation method and a preparation system for sodium dihydrogen citrate. The preparation method comprises the following steps: taking sodium citrate and citric acid as reaction raw materials, successively passing the raw materials through a neutralization tank for a neutral reaction, adjusting a pH value to 2.6 to 2.8 and filtering; enabling filtrate to enter a concentrating tank, keeping the temperature of the concentrating tank at 60 to 80 DEG C and carrying out crystallization reaction for 5 to 6 hours; after the crystallization reaction ends, carrying out solid-liquid separation by using an automatic centrifuge; enabling a crystal to directly enter a vibrating fluidized bed drier, drying at the temperature of 70 to 80 DEG C for 2 to 3 minutes, and removing surface water to directly obtain the sodium dihydrogen citrate; then crushing with a pulverizer and sieving through a 60-mesh sieve, thus obtaining a finished product. The invention further provides thepreparation system for the sodium dihydrogen citrate prepared according to the preparation method. According to the preparation method and the preparation system for the sodium dihydrogen citrate, disclosed by the invention, the sodium citrate and the citric acid are taken as the reaction raw materials, stable reaction and low heat release are realized; crystallization reaction time and drying time can be shortened, production cost can be reduced and production efficiency is improved.

Owner:NINGXIANG XINYANG CHEM

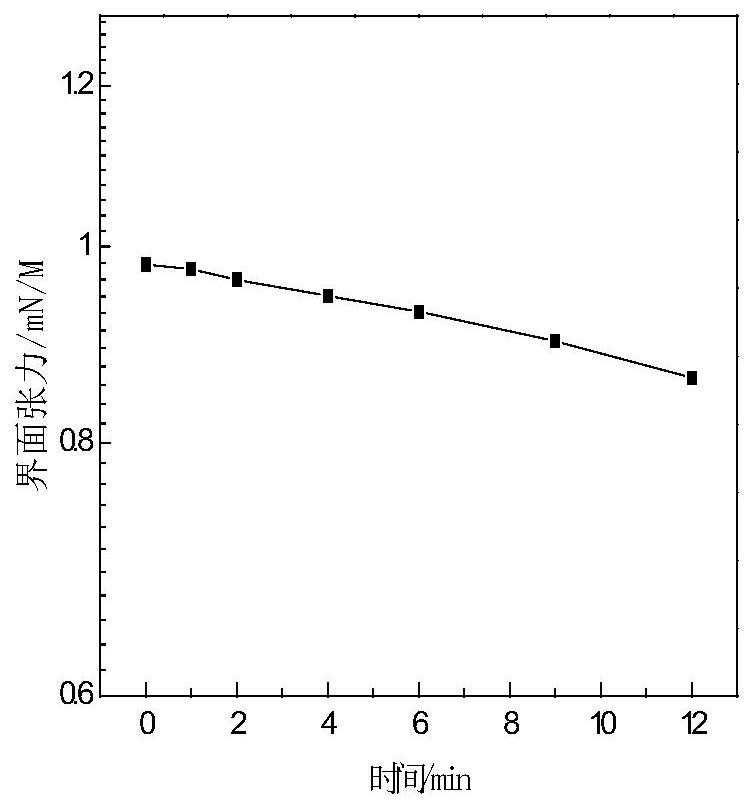

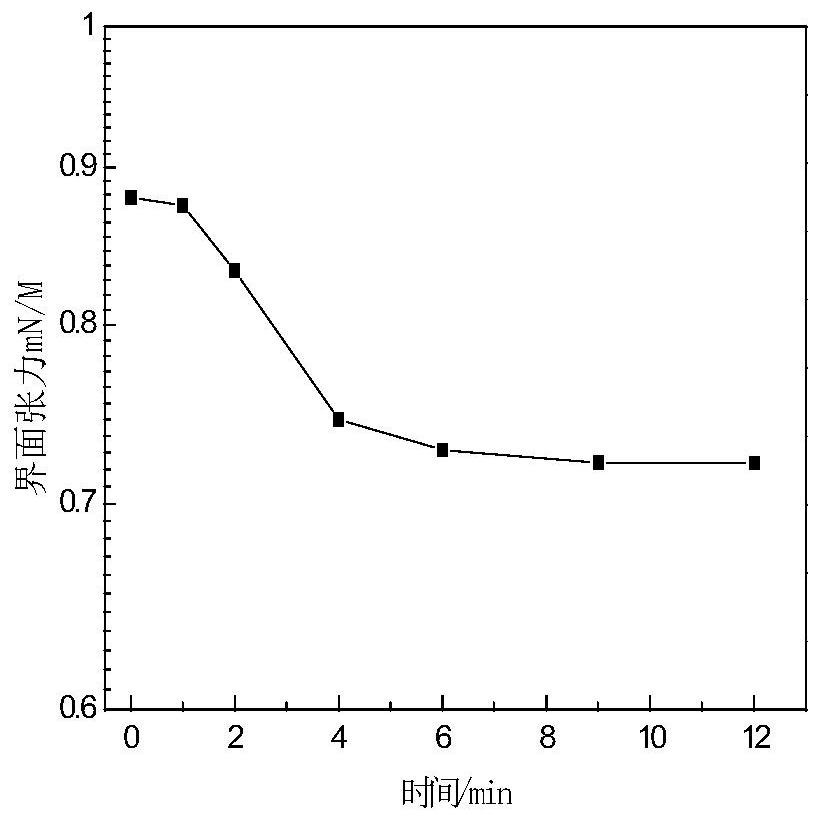

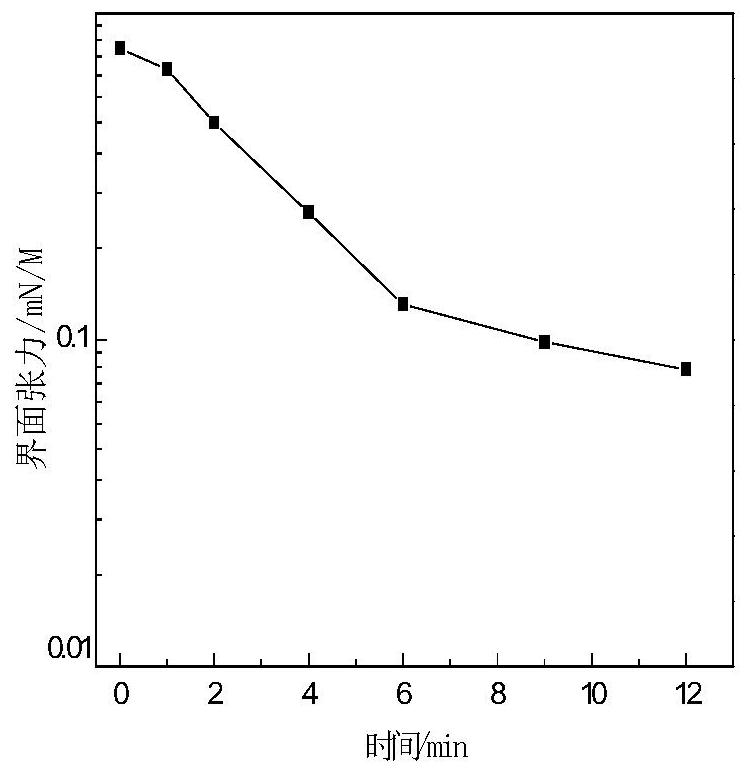

Salt-tolerant polymer microsphere blocking agent and preparation method thereof

The invention discloses a salt-resistant polymer microsphere plugging agent and a preparation method thereof. The polymer microsphere plugging agent is prepared from the following raw materials: white oil, fumed silica, an acrylamide monomer, acrylic acid, sorbitan fatty acid ester, N,N-methylene bisacrylamide, ammonium persulfate, sodium hydrogen sulfite, a hydrophilic group surfactant, water and the like. The salt-tolerant polymer microspheres with ultralow interfacial tension are synthesized by adopting an inverse emulsion polymerization method, a prepared polymer microsphere plugging agent is novel polymer microspheres with ultralow interfacial tension, the interfacial tension can reach 4.3*10 <-3> mN / m, the salt tolerance can reach 50000 mg / L of mineralization degree, and the problems that existing polymer microspheres are low in interfacial tension and poor in salt tolerance are solved.

Owner:SHAANXI UNIV OF SCI & TECH

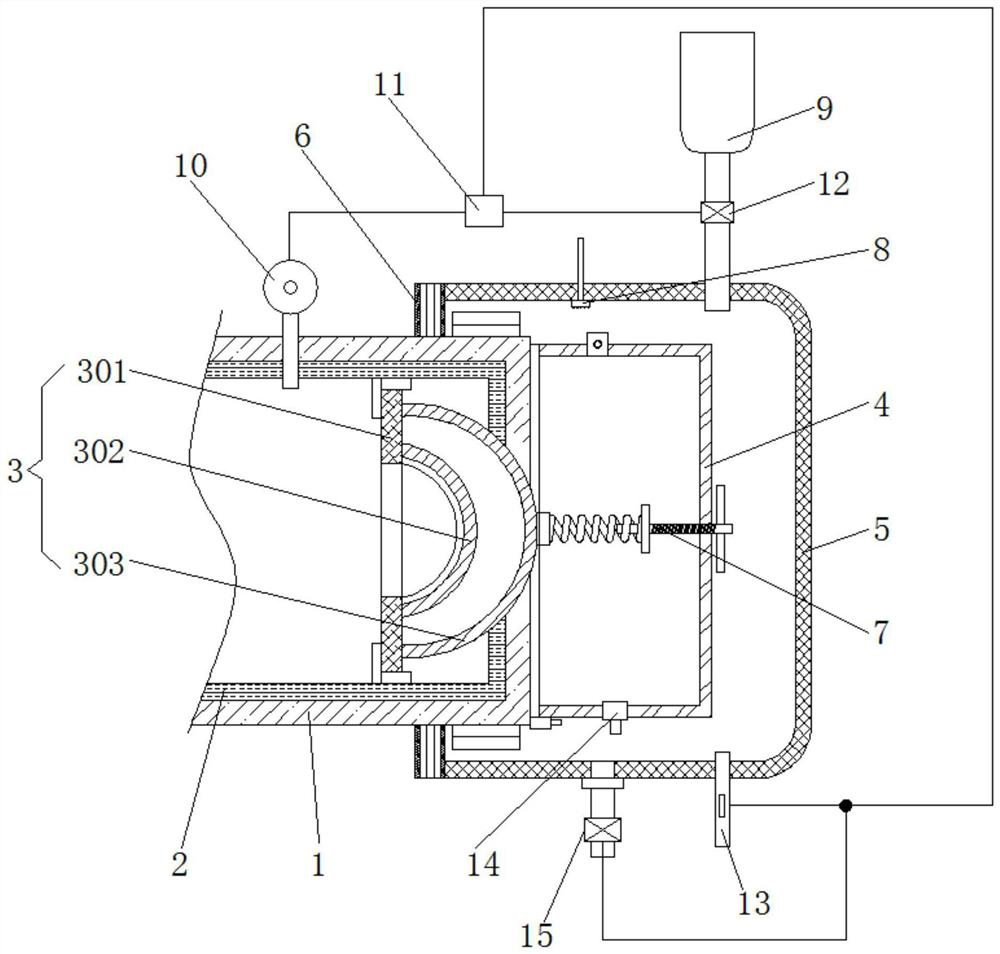

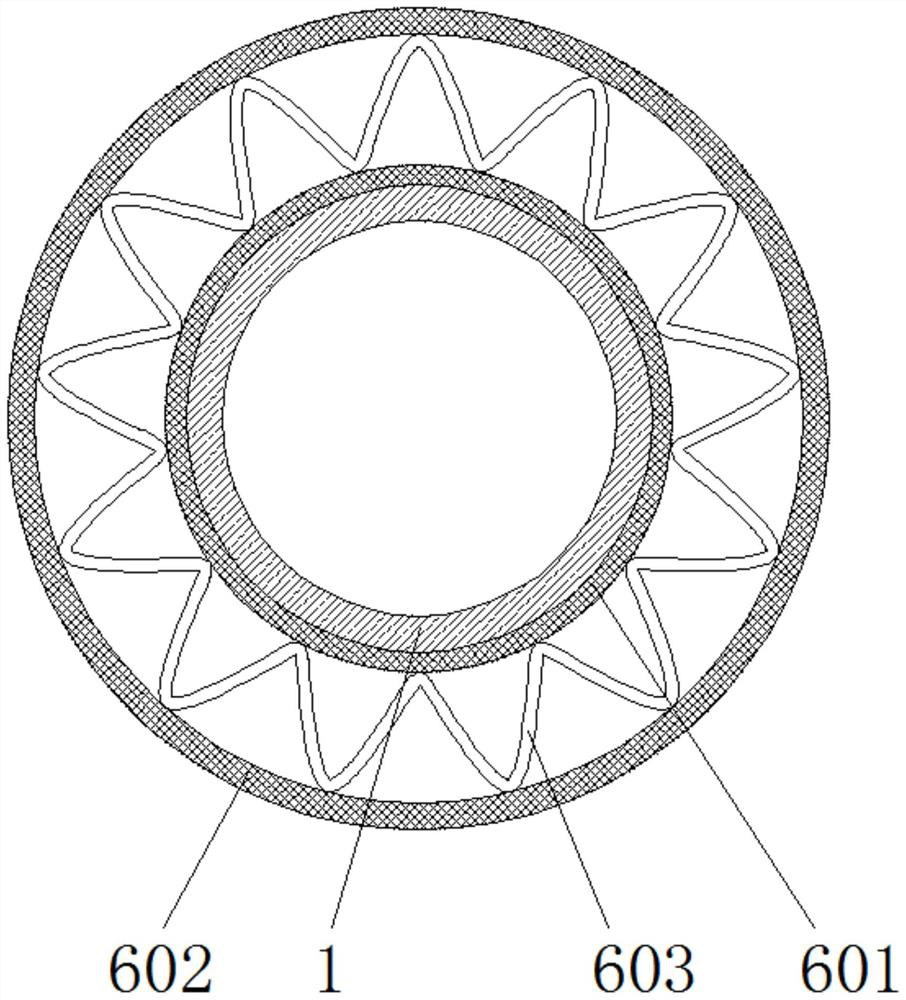

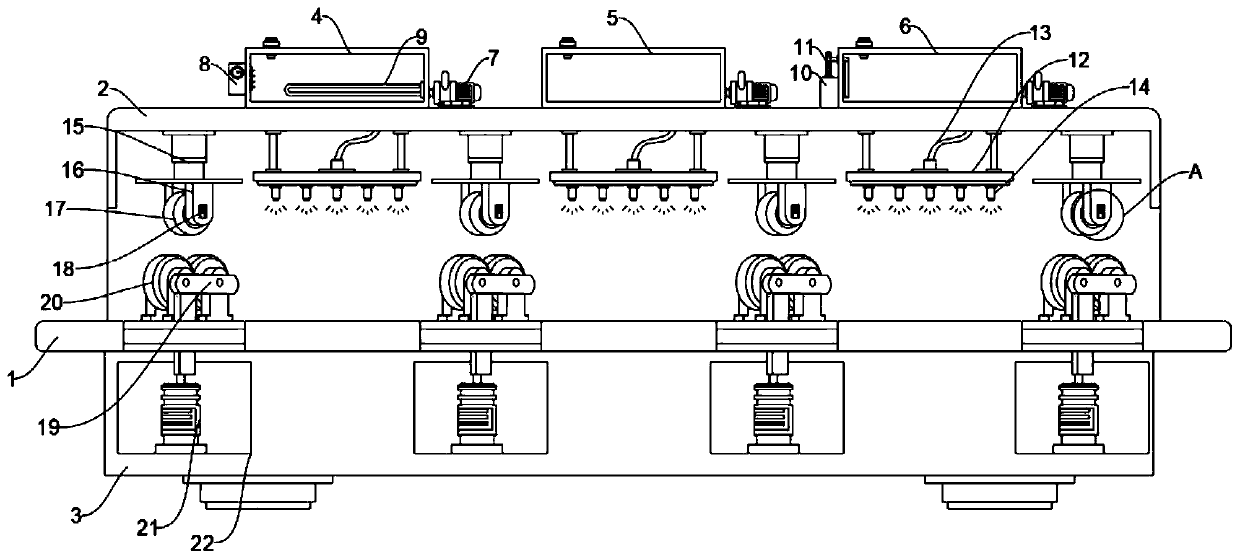

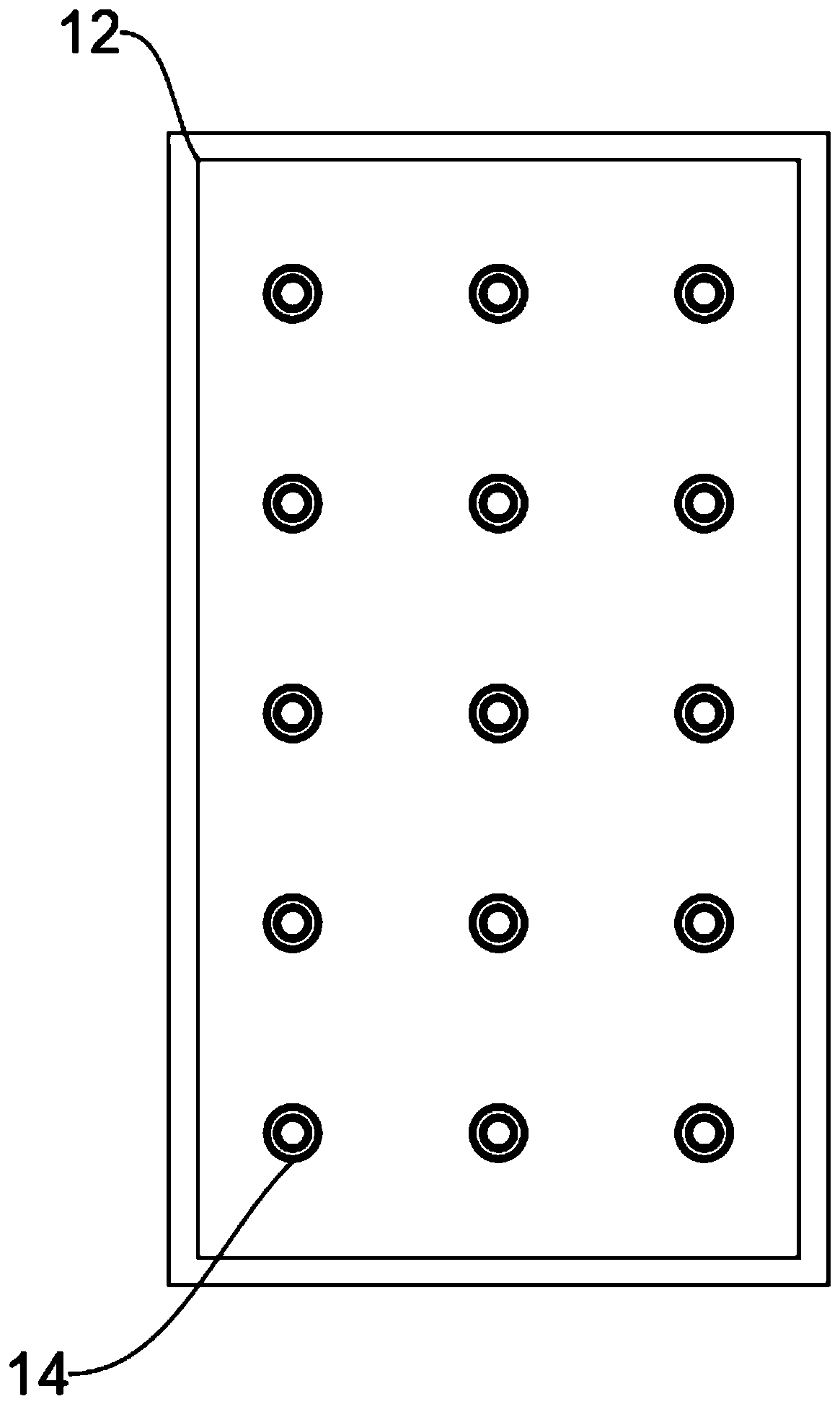

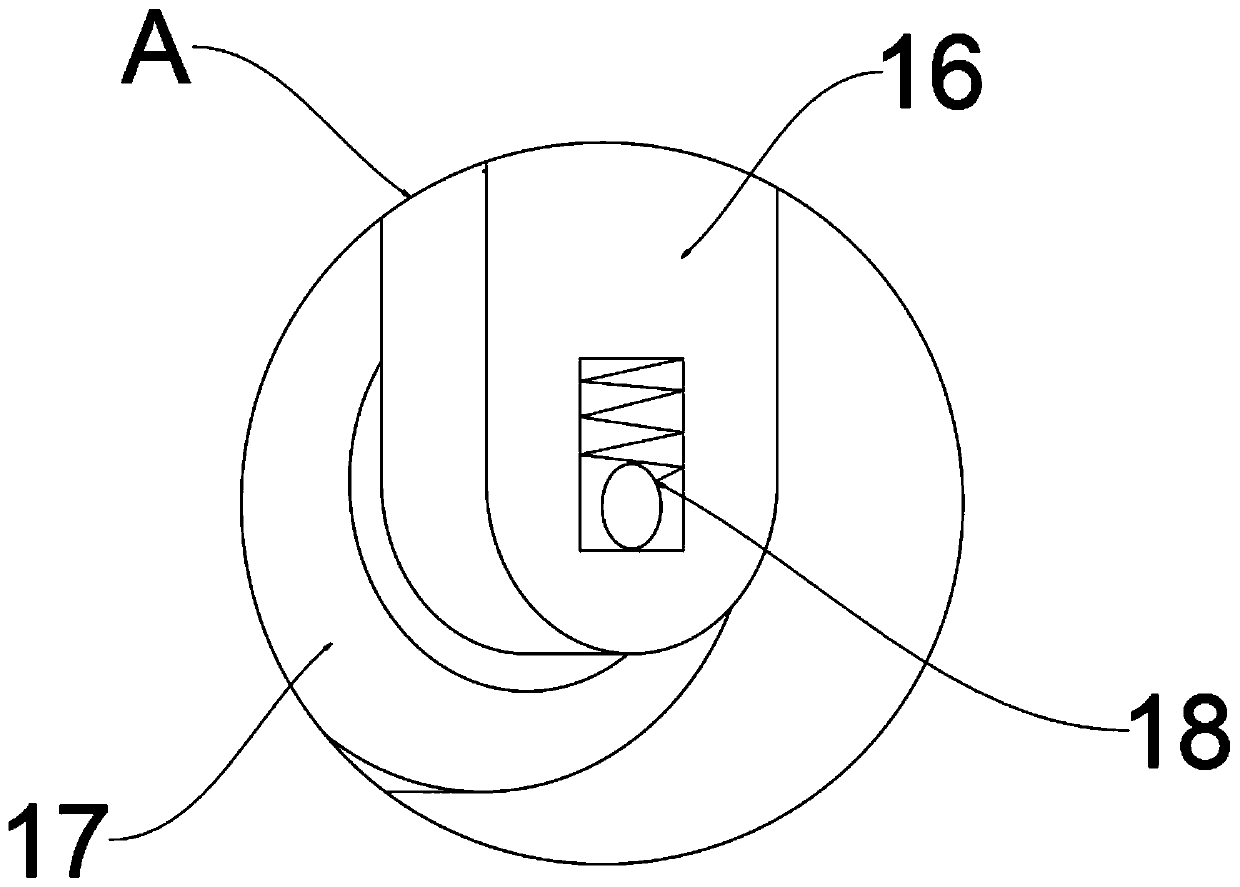

Laboratory waste liquid treatment equipment

InactiveCN113307346ASafe handlingReduce inflowWater/sewage treatment by neutralisationMechanical engineeringMechanics

The invention relates to the technical field of laboratory waste liquid treatment, and discloses laboratory waste liquid treatment equipment which comprises a shell, a liquid injection cylinder is fixedly mounted on the inner top wall of the shell, a liquid injection groove is formed in the upper half portion of the interior of the liquid injection cylinder, and a flow limiting groove is formed in the lower half portion of the interior of the liquid injection cylinder; and a flow limiting plug moves up and down in the flow limiting groove to adjust the size of a liquid injection channel of the flow limiting groove. The waste liquid and a waste liquid treatment reagent are subjected to a neutralization reaction in the shell to release heat, so that the temperature of the mixed liquid is increased, the heat is transferred into mercury through the heat conducting rod, the mercury is heated and rapidly evaporated, the air pressure above the mercury is increased, and the air pressure above the mercury is increased to push a sealing sliding plug to move upwards; and the sealing sliding plug moves upwards to drive the flow limiting plug to move upwards through the connecting rod, the flow limiting plug moves upwards to stretch into the flow limiting groove, the size of a liquid injection channel of the flow limiting groove is adjusted, and then the inflow amount of the waste liquid treatment reagent is reduced.

Owner:XIAN UNVERSITY OF ARTS & SCI

Method and device for plants carbon isotope labelling

InactiveCN100482065CNo escape lossAvoid violent reactionsSamplingEducational modelsIsotopic labelingWoody plant

The invention discloses a method and device for marking plant carbon isotopes. The method comprises following steps: sowing seed in the cultivating disk which located in the soil; putting cultivating disk into air- tight box; adding sodium carbonate marked with carbon-14 or carbon- 13 under air- tight condition, carrying out reaction with hydrochloric acid in reaction tank to generate carbon dioxide for plant photosynthesis. The carbon dioxide in box is mixed with electrical fan, and light is replenished with daylight lamp, the temperature and humidity are reduced by using cooling tube, and water is added into cultivating disk with fluid infusion bottle. The plant marked with carbon- 13 or carbon- 14 is got after cultivation. The invention is characterized by simple and safe operation, prevention of carbon marked with carbon isotopes escape, increased utilization coefficient of carbon isotopes, suitability for carbon isotopes mark for various plants, especially for woody plant.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

Diffusion furnace for photovoltaic cell manufacturing

PendingCN112210831APlay a sealing rolePrevent leakageFinal product manufactureDiffusion/dopingThermodynamicsCell fabrication

The invention relates to the technical field of photovoltaic cell manufacturing, and discloses a diffusion furnace for photovoltaic cell manufacturing. The diffusion furnace comprises a furnace body,a quartz tube is arranged in the furnace body, an inner sealing piece is arranged on the inner wall of the quartz tube, the outer wall of the furnace body is rotatably connected with a furnace door, and the side wall of the furnace body is sleeved with an outer cover. A hoop ring is fixedly connected to the end, connected with the furnace body, of the outer cover, an extrusion piece is arranged between the inner sealing piece and the furnace door, and a one-way air valve is installed on the outer wall of the furnace door. The inner sealing piece plays a role in sealing the tube opening of thequartz tube, gas in the quartz tube is prevented from leaking outwards, heat loss caused by air convection is reduced under the action of the vacuum cavity in the inner sealing piece, and therefore the temperature difference between the tube opening of the quartz tube and the inner cavity of the quartz tube is reduced, and the uniformity of sheet resistance of silicon wafers in the quartz tube isimproved; and the deformation of the inner arc plate at high temperature improves the extrusion force on the inner wall of the quartz tube so that the connecting gap is reduced, and the sealing performance is further improved.

Owner:阳忠海

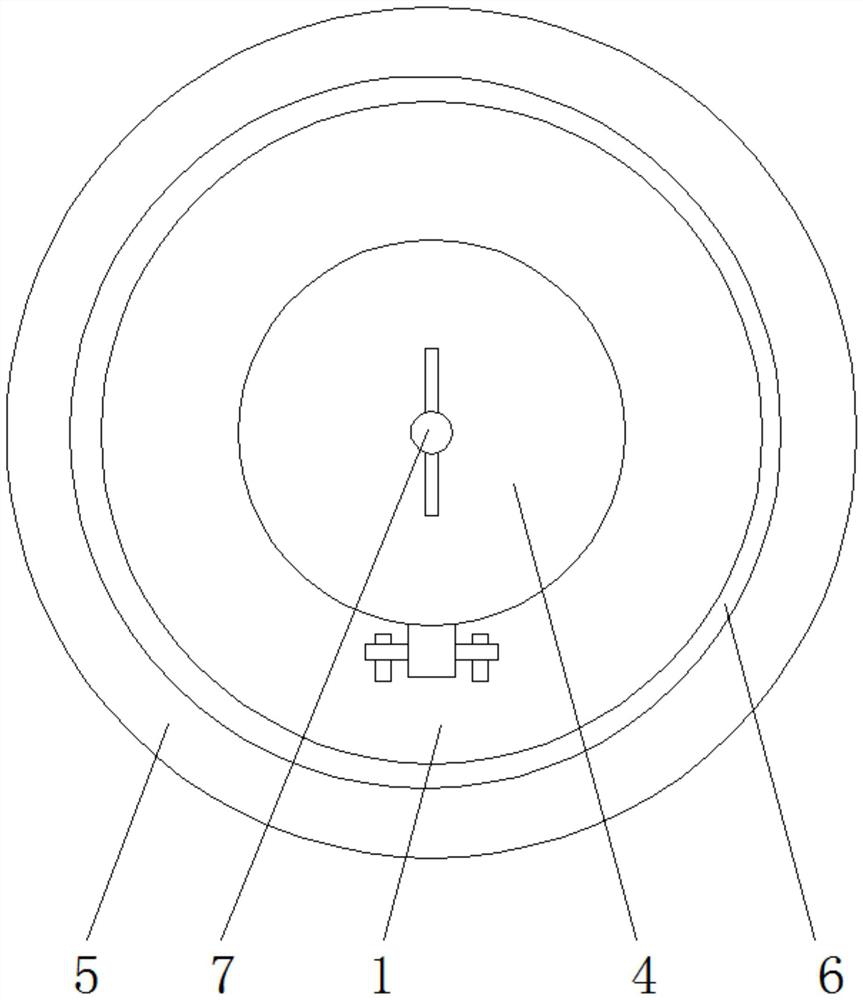

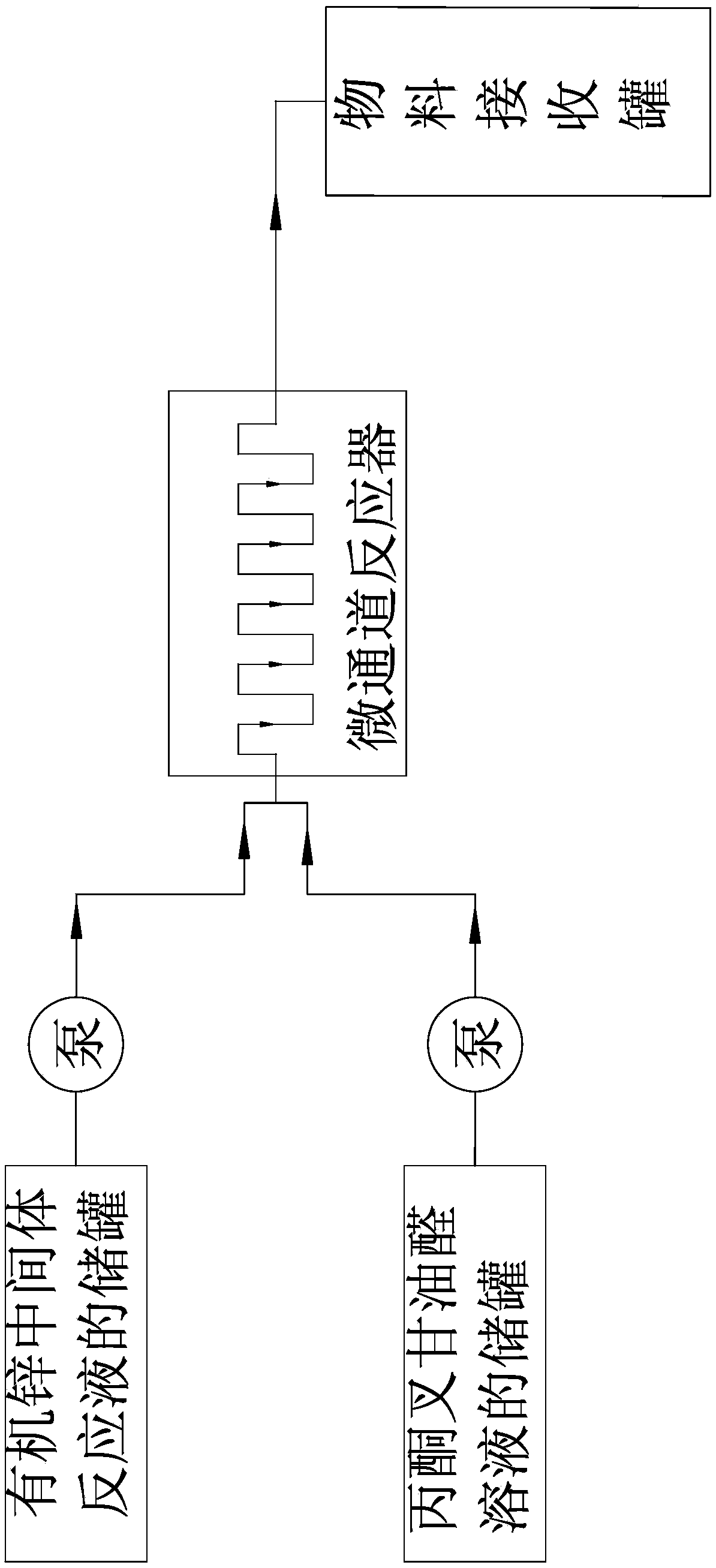

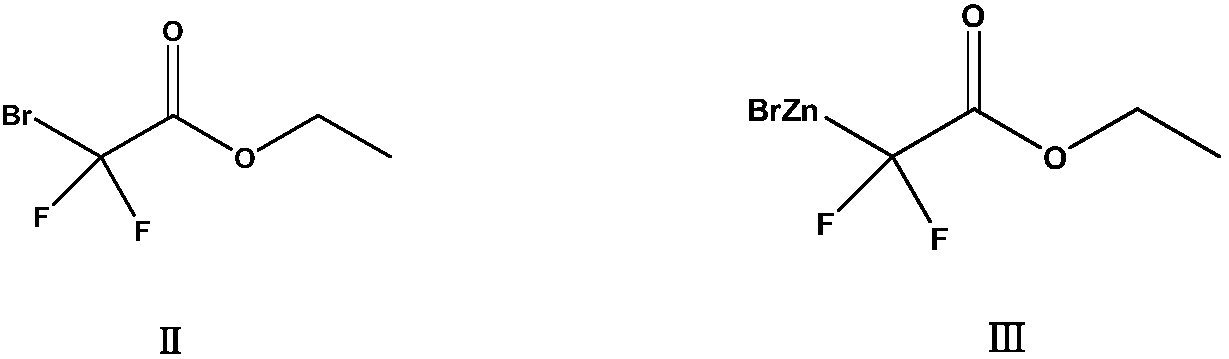

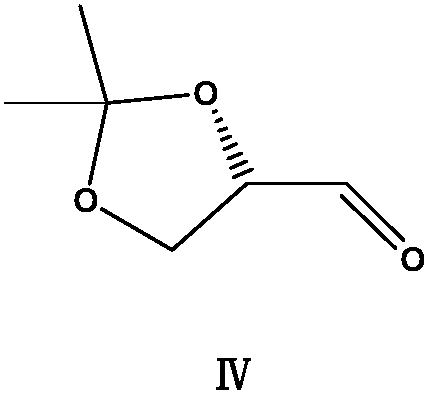

Preparing method of gemcitabine intermediate

The invention relates to a preparing method of a gemcitabine intermediate, and belongs to the technical field of medicine intermediate synthesis. In order to solve the problems that an existing methodis violent in reaction and not stable in yield, the preparing method of the gemcitabine intermediate is provided. The method includes the steps of adding iodine powder to an organic zinc intermediate-state reaction solution obtained through the reaction of ethyl bromodifluoroacetate and activated zinc powder in a first solvent, adding acetonylidene glyceraldehyde to a second solvent to obtain a corresponding acetonylidene glyceraldehyde solution, synchronous pumping the organic zinc intermediate-state reaction solution and the acetonylidene glyceraldehyde solution into a micro-channel reactorfor a condensation reaction to obtain outflow liquid, and conducting acidification to obtain the corresponding product (gemcitabine intermediate). The problem of the violent reaction can be effectively overcome, and the effects of mild reaction and high product yield are achieved.

Owner:江苏八巨药业有限公司

Preparation method of asphalt polyurethane waterproof coating suitable for cement base layer

The invention discloses a preparation method of an asphalt polyurethane waterproof coating suitable for a cement base layer. The preparation method comprises the following steps: firstly preparing an end-capped polyurethane prepolymer, and then mixing the end-capped polyurethane prepolymer with residual raw materials to prepare the asphalt polyurethane waterproof coating, wherein the end-capped polyurethane prepolymer is prepared by reacting a compound as shown in a formula (I) with a polyurethane prepolymer, and the end-capped polyurethane prepolymer does not contain an isocyanate-terminated group; the waterproof coating comprises the following raw materials: asphalt, a compatilizer, a moisture scavenger, a catalyst, a filler and an end-capped polyurethane prepolymer. According to the method, the preparation process is safe, wherein the prepared waterproof coating can be directly coated on a cement base layer containing a large amount of water during use and reacts with silicate in cement after hydrolysis, so that the bonding force on a wet base layer is improved; besides, the excellent bonding strength between the waterproof coating and an asphalt waterproof roll can be achieved, and particularly the surface drying and hard drying time is short and the viscosity is moderate (the step of temperature rise before construction can be basically avoided), so that on-site construction is facilitated.

Owner:JIANGSU CANLON BUILDING MATERIALS

Preparation method of low-viscosity cation starch

InactiveCN102161708BStrong positive chargeLow viscosityWater-repelling agents additionPapermakingSurface strength

The invention relates to a preparation method of low-viscosity cation starch, comprising the following steps: 1) preparing native starch into a 35-40% starch suspension by clear water, successively adding an inhibitor, an activated viscosity breaking agent and a metal ion catalyst under the state of stirring, heating to 42DEG C, adding a cation etherifying agent activated by an alkaline activator, keeping the temperature of 42-52DEG C, and reacting for 0.5-3 hours; 2) continuously adding an oxidant A in a flowing mode, and reacting for 2-5 hours; 3) cooling to 30-35DEG C, adjusting pH to 8.5 by hydrochloric acid, continuously adding an oxidant B in a flowing mode, adjusting the pH of the starch suspension to 8.5-9.5 by a base catalyst, keeping the temperature of 30-38DEG C, and reacting for 0.5-1.5 hours; and 4) adjusting the pH of the suspension to 6.5 by the hydrochloric acid, adding a stabilizer, washing after 20 minutes, dewatering and drying to obtain the product. The starch particle has strong positive charge, paste has the characteristics of low viscosity, good rheological property and high adhesive strength and is used for high-density surface sizing for papermaking, and the surface strength and the printability of paper can be obviously improved.

Owner:广西农垦明阳生化有限公司

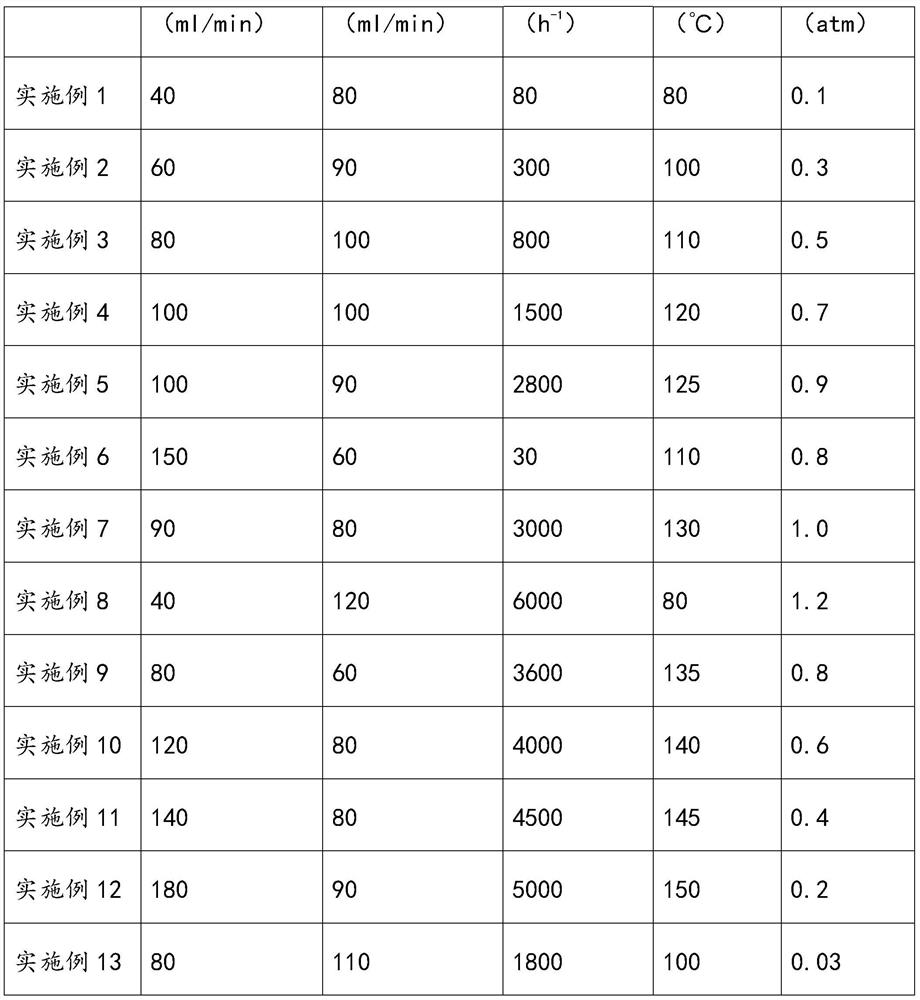

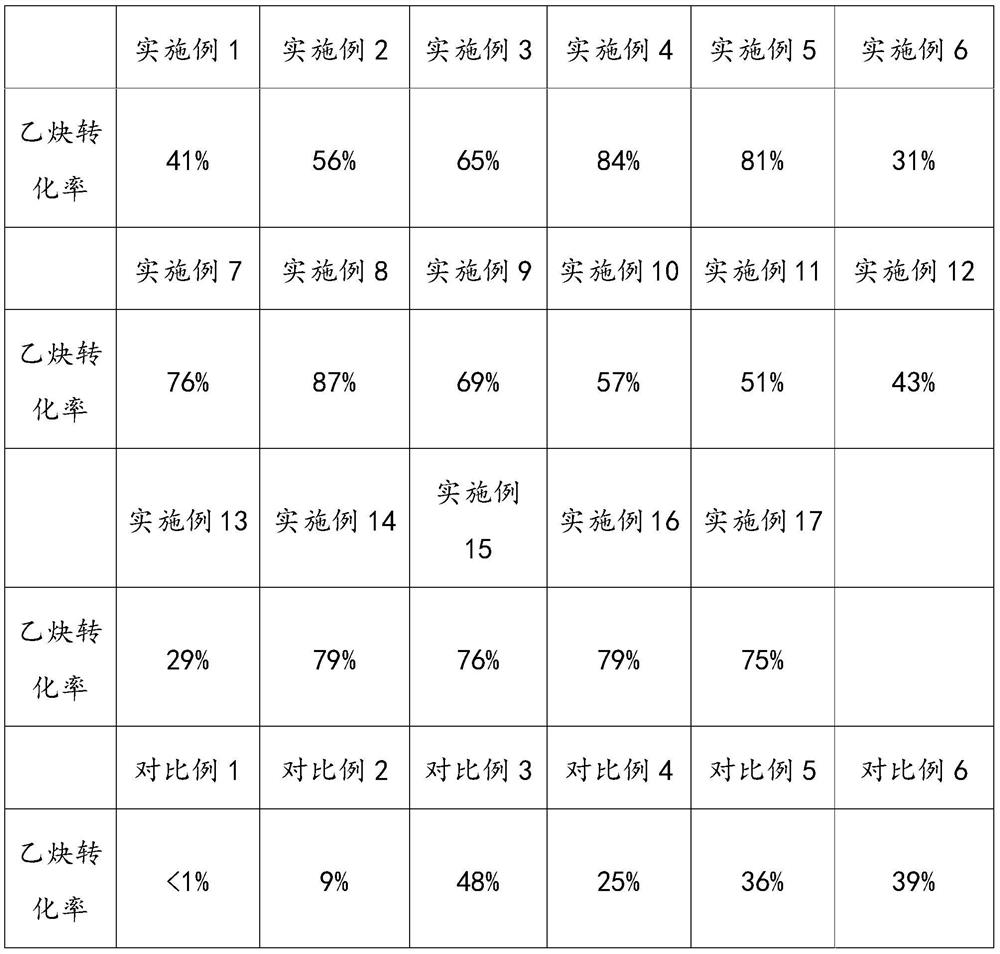

A kind of production technology of trans-1,2-dichloroethylene

ActiveCN110054546BWide variety of sourcesCheap sourcePhysical/chemical process catalystsPreparation by halogen additionAlkaline earth metalPtru catalyst

The invention relates to the field of preparation of trans-1,2-dichloroethylene, in particular to a production process of trans-1,2-dichloroethylene, which comprises the following steps: catalytic reaction of acetylene and chlorine under oxygen-free conditions, and the catalyst It is an alkaline earth metal chloride, and the reaction temperature is 80-150°C. The production process of trans-1,2-dichloroethylene provided by the present invention generates 1,2-dichloroethylene by selecting acetylene and chlorine to react under the action of an alkaline earth metal catalyst, the reaction is simple, and the source is wide and cheap, and the production cost It is relatively low, and there is no three-waste discharge at the same time, and it is safe to operate. It is a clean production process. Since the raw materials used are acetylene and chlorine, the atom economy is also high.

Owner:ZHEJIANG NORMAL UNIVERSITY +1

High-temperature stability nickel cobalt lithium manganate composite electrode as well as preparation method and application thereof

InactiveCN107768627AIncrease compaction densityReduce volumeCell electrodesSecondary cellsTernary complexComposite electrode

The invention discloses a high-temperature stability nickel cobalt lithium manganate composite electrode as well as a preparation method and application thereof. The preparation method disclosed by the invention comprises the following steps: mixing lithium acetate, nickel sulfate, cobalt sulfate and manganese sulfate according to a molar ratio of 1:0.47:0.2:0.33 to obtain a mixture, adding 20-30weight parts of the mixture into 100 weight parts of water, and dissolving to obtain an aqueous phase; adding ammonia gas into an oil phase, stabilizing the oil-water phase by an emulsifier, preparinga precursor by an inverse emulsion method, and pre-sintering to obtain a ternary complex; coating the ternary complex by aluminum hydroxide, calcining at the temperature of 980-1050 DEG C under inertgas shielding for 4-8 hours, finally furnace cooling, thereby obtaining the composite electrode material. According to the method disclosed by the invention, the problems that the conventional nickelcobalt lithium manganate electrode material is poor in high stability and the compaction density is not high enough are solved.

Owner:长沙仲善新能源科技有限公司

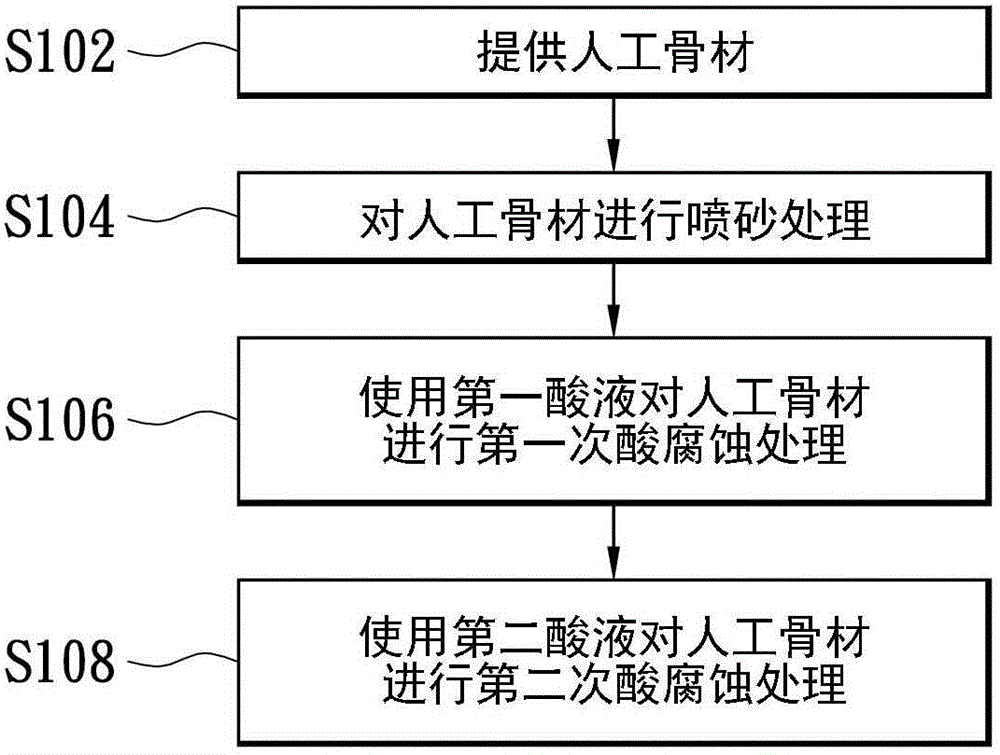

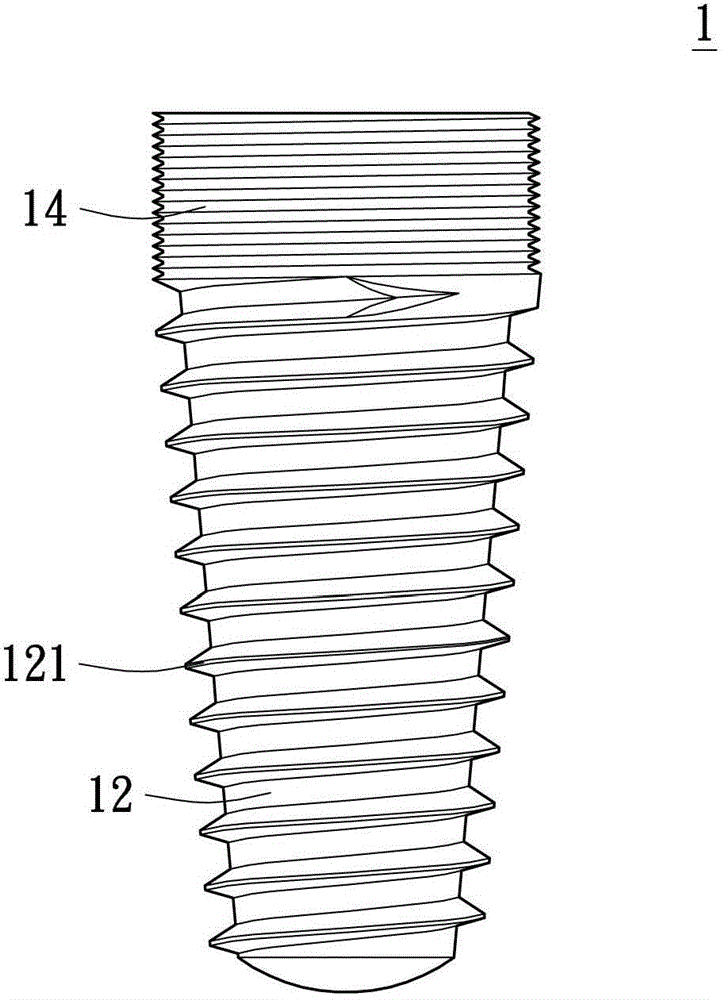

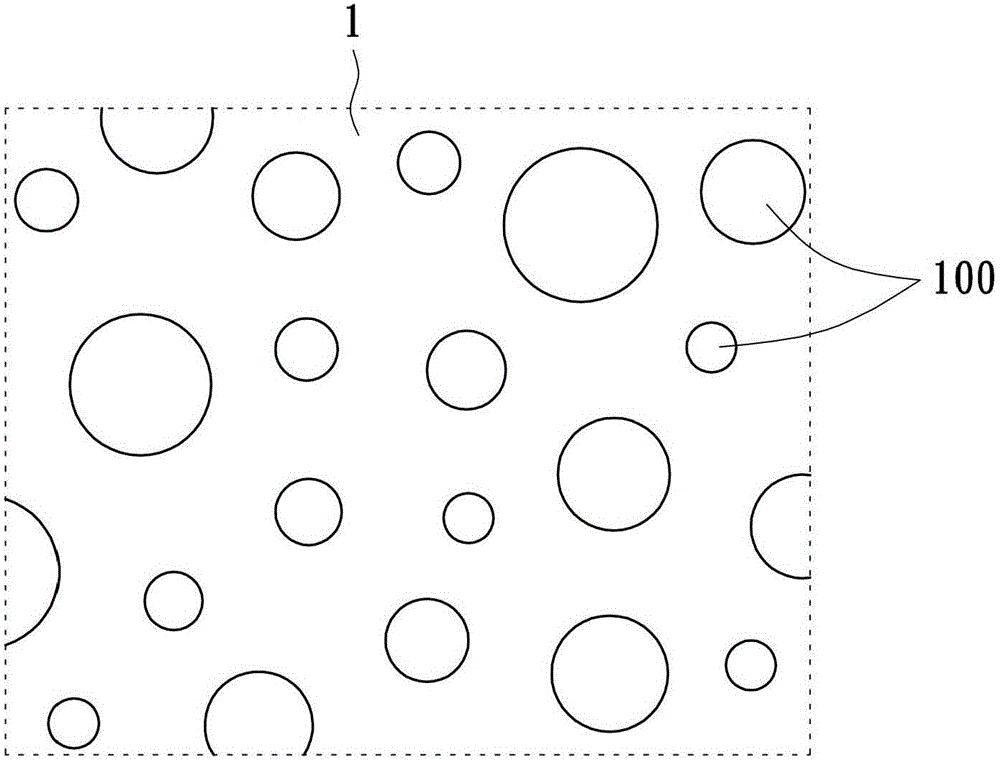

Surface treated artificial bone material and its surface treatment method

InactiveCN104027176AShorten speedReduced stabilityDental implantsArtificial teethAcid corrosionArtificial bone

The invention provides a surface treatment method of an artificial bone material. The method comprises the following steps: 1, providing the artificial bone material; and 2, sandblasting the artificial bone material, carrying out first acid corrosion treatment on the artificial bone material by using a first acid solution, and carrying out second acid corrosion treatment on the artificial bone material by using a second acid solution, wherein the first acid solution and the second acid solution are two acidic solutions in order to form a plurality of micro-pores on the surface of the artificial bone material. The invention also provides a surface treated artificial bone material.

Owner:长庚医疗科技(厦门)有限公司 +1

Cooling device for seamless steel tube production

InactiveCN111036696AHigh affinityAvoid violent reactionsWork cooling devicesMetal rolling arrangementsAir pumpHeater Rod

The invention discloses a cooling device for seamless steel tube production, relates to the technical field of seamless steel tube machining, and aims at solving the problem that an existing cooling device is poor in cooling effect. A shell is arranged over a workbench. A heating water tank is arranged at one side of the upper portion of the shell. A heating rod is mounted in the heating water tank; a temperature sensor is mounted at one end of the heating water tank; a normal-temperature water tank is arranged on one side of the heating water tank; a condensed water tank is arranged on one side of the normal-temperature water tank; an air pump is mounted at one end of the condensed water tank; pressure pumps are mounted at the other sides of the heating water tank, the normal-temperaturewater tank and the condensate water tank; and water collecting discs are arranged under the heating water tank, the normal-temperature water tank and the condensate water tank correspondingly; a transmission mechanism is installed at the upper end of the workbench; a conveying wheel is installed on one side of the transmission mechanism; an electric push rod is installed above the conveying wheel,and a limiting wheel is installed in the installation base.

Owner:江苏冰溶管业有限公司

Core material of magnesium-calcium-aluminum-iron alloy core-spun yarns and application thereof

The invention discloses a core material of magnesium-calcium-aluminum-iron alloy core-spun yarns and application thereof. The core material of the magnesium-calcium-aluminum alloy core-spun yarns is characterized by being composed of, by weight, 6-25% of magnesium, 5-24% of calcium, 5-35% of aluminum and the balance iron and inevitable impurities, wherein the mass ratio of the magnesium to the calcium ranges from 6 to 11 to 18 to 11. In the refining process of molten steel, the core material of the magnesium-calcium-aluminum alloy core-spun yarns is made into the core-spun yarns and added into the molten steel to modify sulfides in sulfur-bearing steel. In the refining process, the core material of the magnesium-calcium-aluminum alloy core-spun yarns is fed to make the core-spun yarns, and therefore the morphology of the sulfides can be effectively adjusted and controlled, and the machinability and the comprehensive property of steel can be improved.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com