A kind of production technology of trans-1,2-dichloroethylene

A production process, the technology of dichloroethylene, applied in organic chemistry, physical/chemical process catalyst, halogen addition preparation, etc., can solve the problem of high production cost, achieve low production cost, high atom economy, and no three wastes discharge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

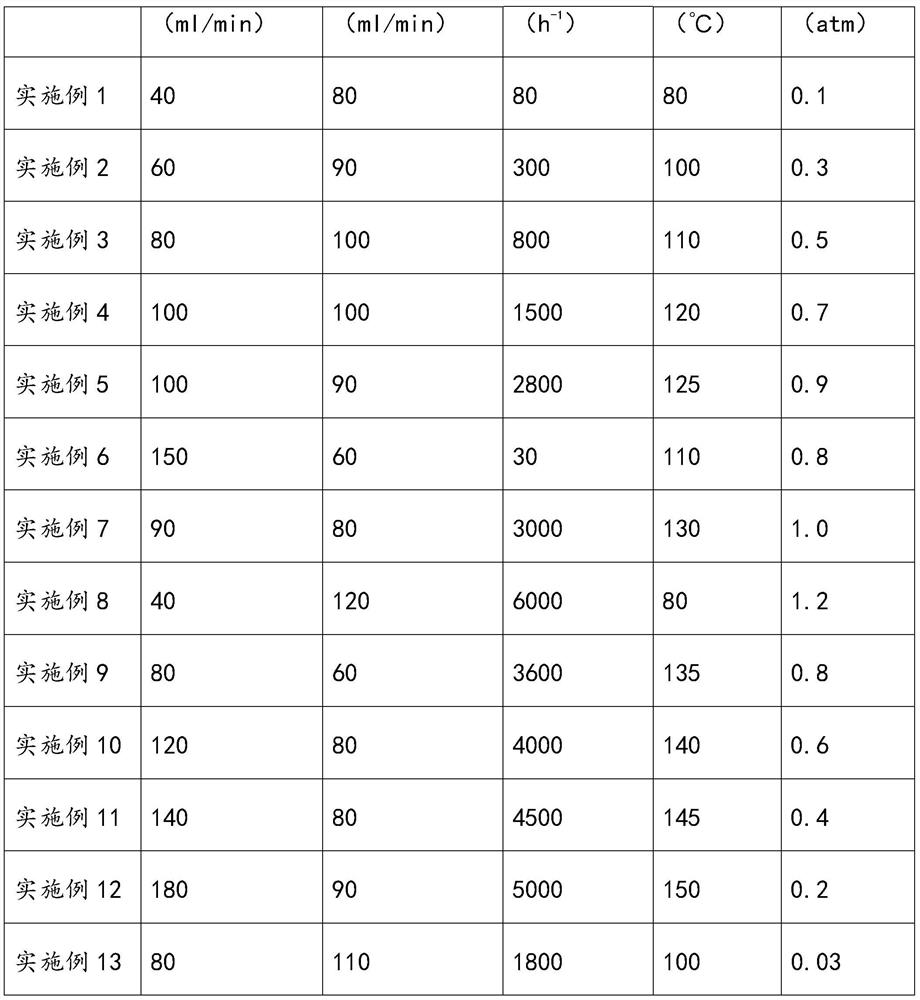

Examples

Embodiment 1-10

[0029] Embodiment 1-10 relates to a production process of trans-1,2-dichloroethylene, specifically comprising the following steps:

[0030] S1: add barium chloride catalyst into 100ml tetrachloroethane solvent;

[0031] S2: heating the reaction system;

[0032] S3: Under the condition of condensing and refluxing, acetylene and chlorine gas are continuously passed into the solvent for 2 hours. See Table 1 for the feeding speed, catalyst consumption, reaction temperature and reaction pressure of each implemented acetylene and chlorine.

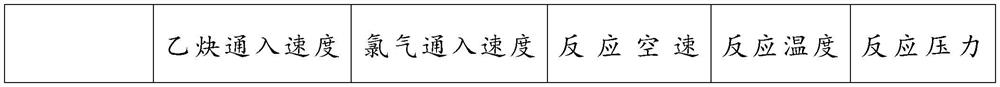

[0033] Table 1. The process operating conditions of each embodiment

[0034]

[0035]

Embodiment 14-15

[0037] Examples 14-15 relate to a production process of trans-1,2-dichloroethylene. The difference between Examples 14-15 and Example 4 is that the types of catalysts are different. The catalysts of each example are shown in Table 2.

[0038] Table 2. Catalyst types of each embodiment

[0039] Catalyst type Example 14 magnesium chloride Example 15 calcium chloride

Embodiment 16-17

[0041] Examples 16-17 relate to a production process of trans-1,2-dichloroethylene. The difference between Examples 16-17 and Example 4 lies in the types of organic solvents. See Table 3 for the organic solvents in each example.

[0042] Table 3. The organic solvent of each embodiment

[0043] Types of organic solvents Example 16 Pentachloroethane Example 17 Hexachloroethane

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com