Patents

Literature

563results about How to "Cheap source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

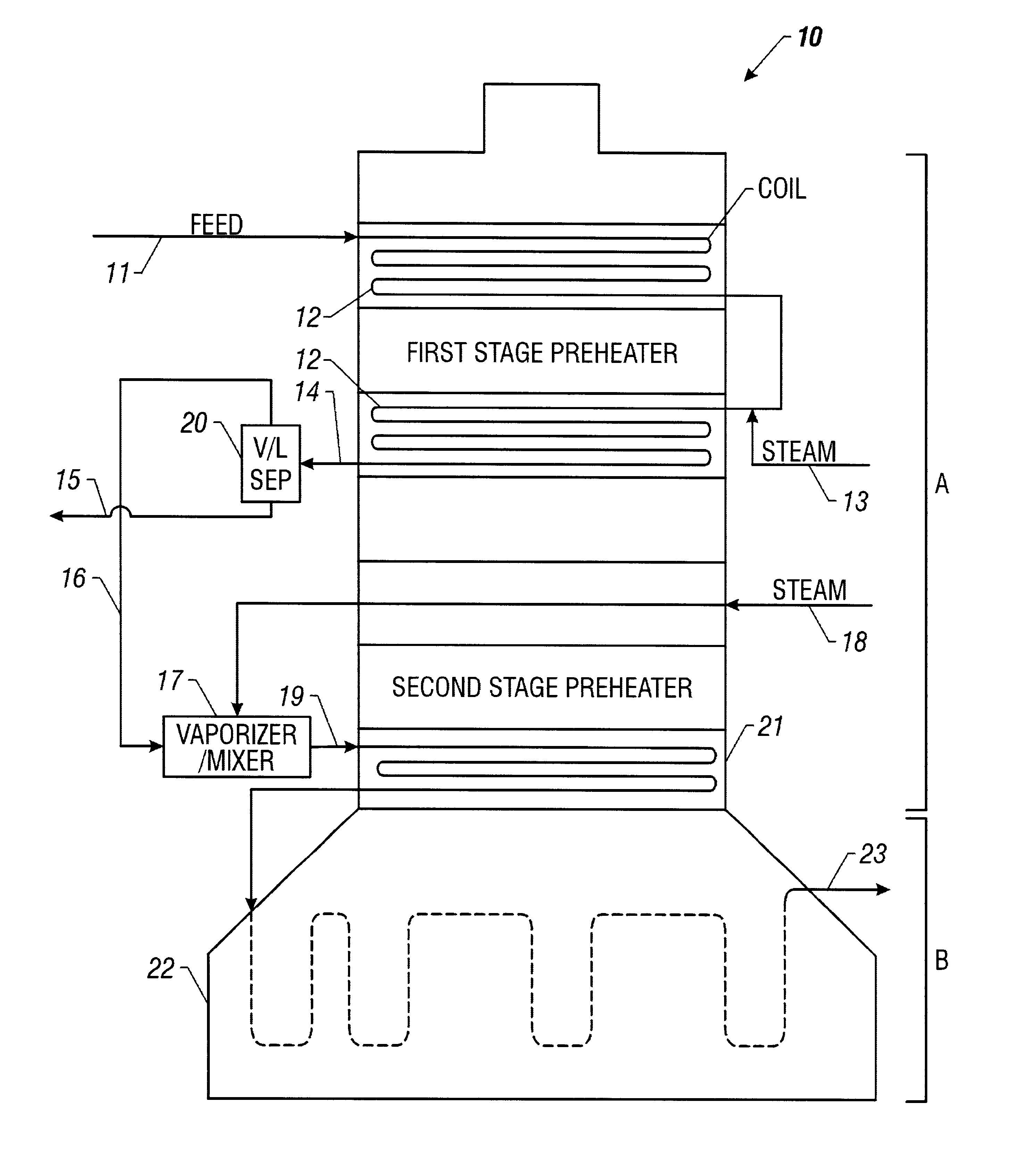

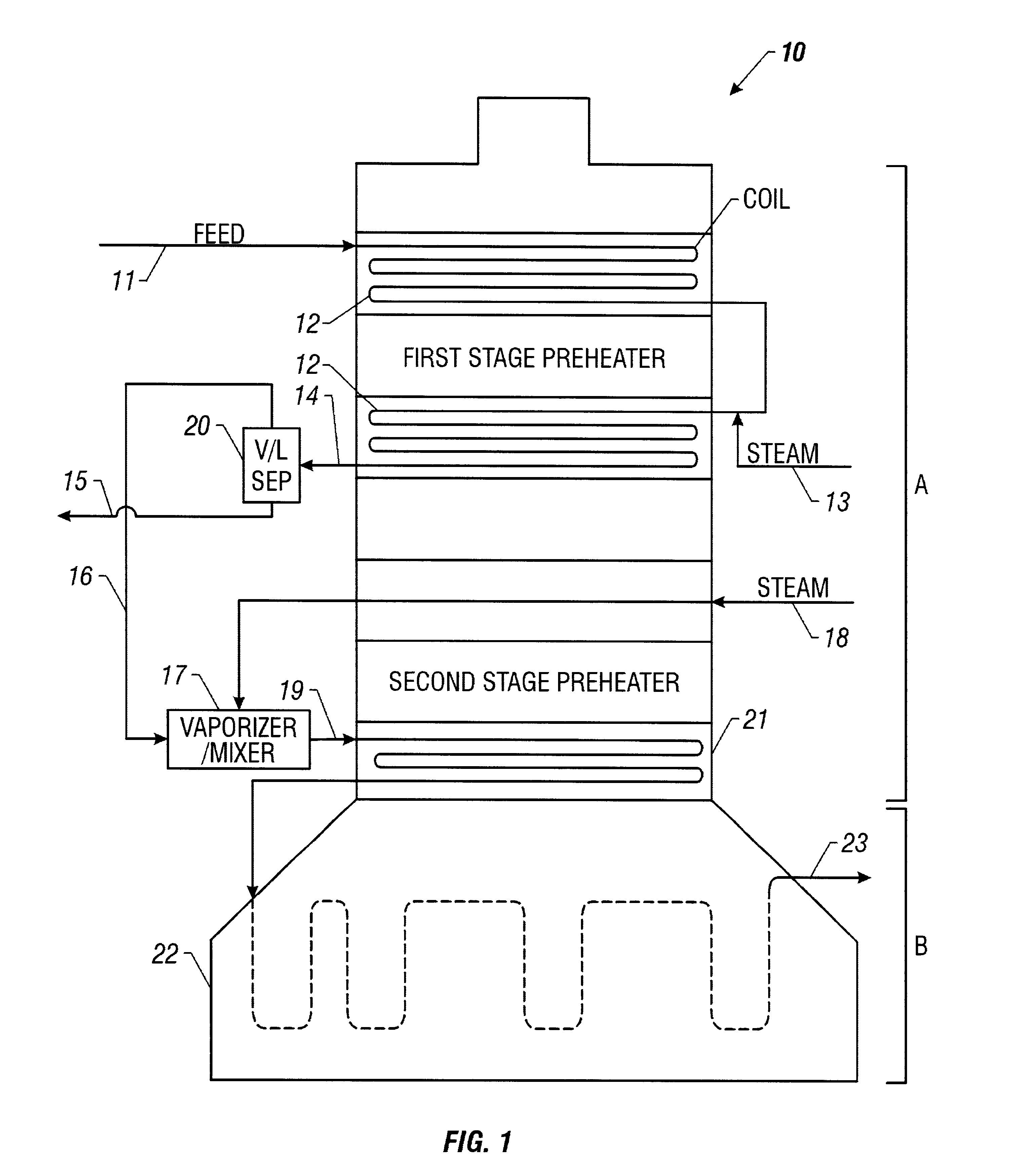

Thermal cracking of crude oil and crude oil fractions containing pitch in an ethylene furnace

InactiveUS6632351B1Cheap sourceMinimizing coke formationThermal non-catalytic crackingHydrocarbonsEthyleneChemistry

Owner:SHELL OIL CO

Thermoplastic cellulosic fiber blends as lost circulation materials

ActiveUS9453156B2Reduce circulation lossHigh densitySolid waste managementFlushingThermoplasticThermosetting polymer

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

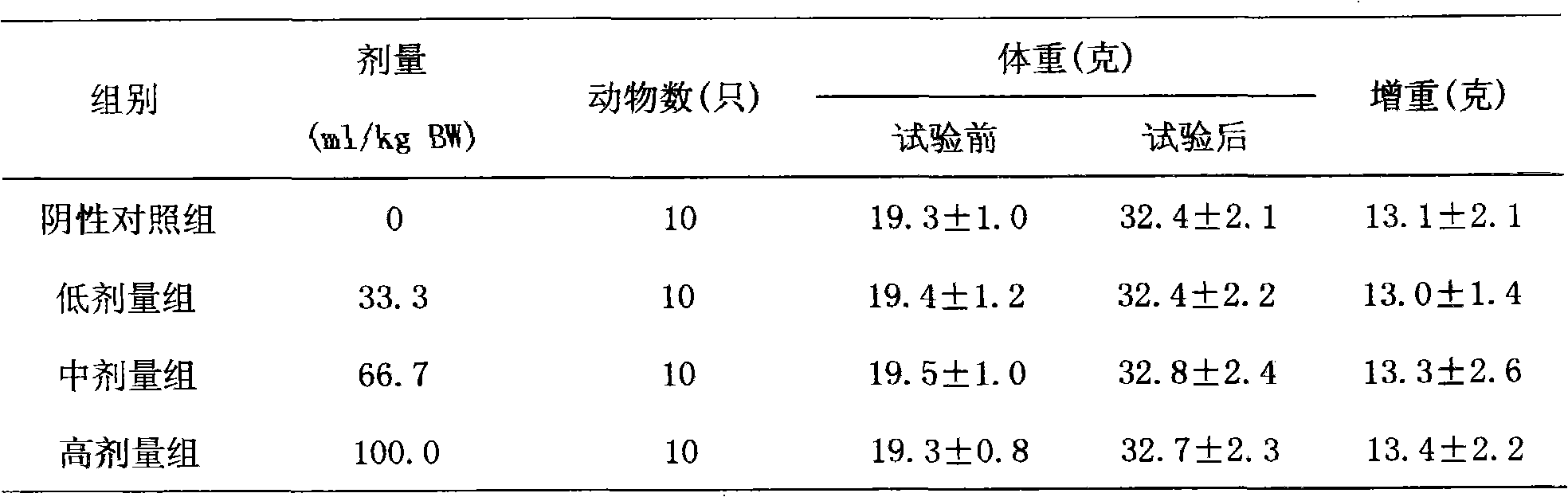

Health food for reinforcing immune function of human body and preparation technique thereof

ActiveCN101292742ACheap sourceStable sourceImmunological disordersFood preparationPharmacyCordycepin

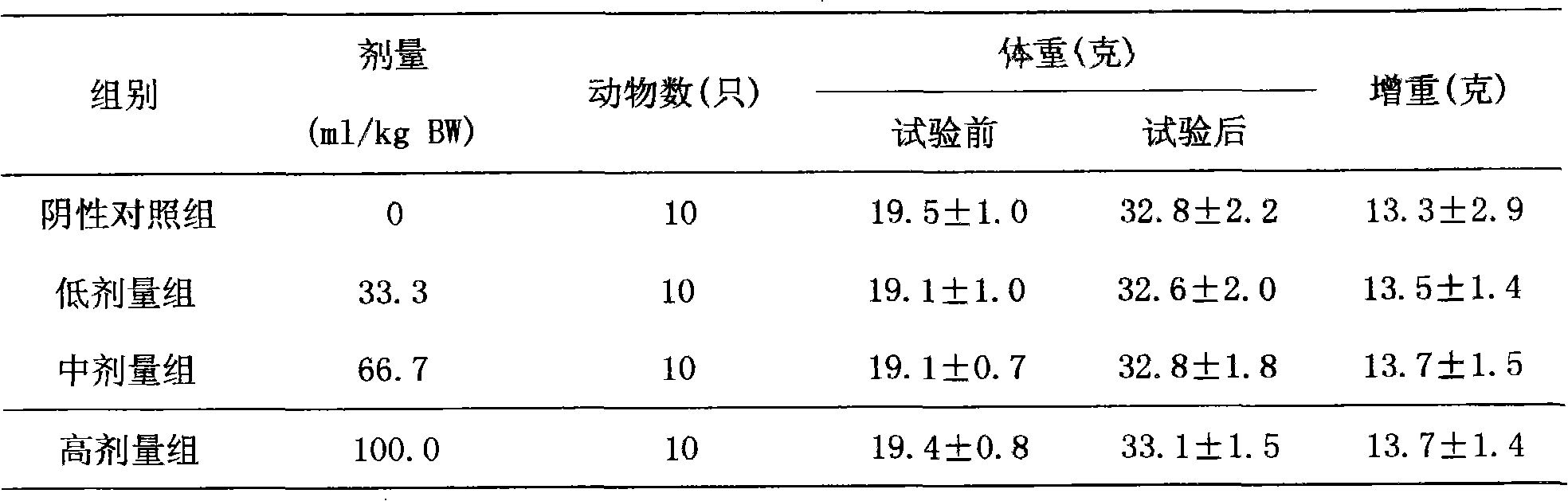

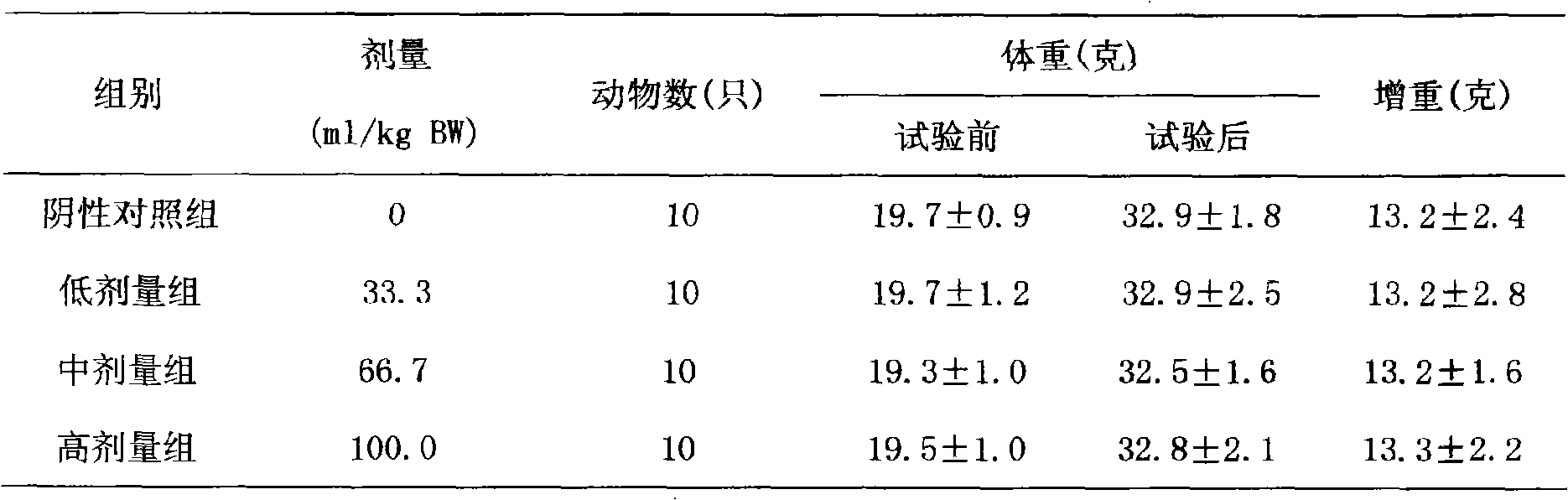

The invention aims at providing a health-care food enhancing immune function of human body and provides a preparation technique thereof. The health-care food, according to weight proportion, is produced by raw materials comprising 10-50 portions of gen-seng, 10-50 portions of glossy ganoderma and 10-50 portions of zymotic cordycepin powder; the raw materials comprising the gen-seng, the glossy ganoderma and the zymotic cordycepin powder are positioned in a hop-pocket; the processed raw materials are carried out heating and decoction for 1-3 times (each time is for 1-2 hours) after being added with water for soaking for one hour; extraction solution is mixed, filtered and concentrated to defined amount; after being cooled, concentrated solution is carried out high-speed centrifugal impurity removal; the obtained concentrated solution is produced into required preparation independently or by adding with accessories acceptable in medical science with the conventional processes of pharmacy.

Owner:JIANGZHONG PHARMA

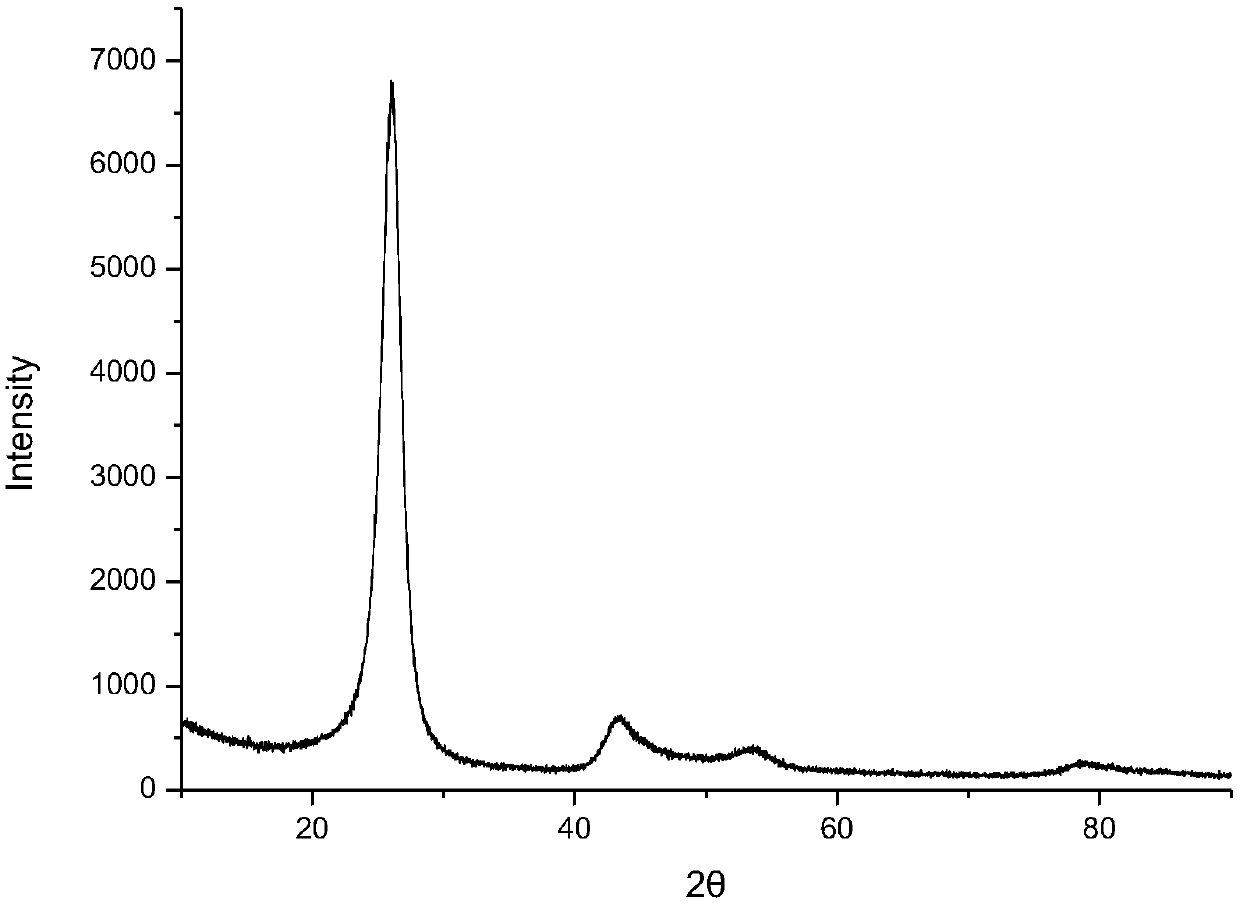

Silicon dioxide aerogel and preparation method thereof

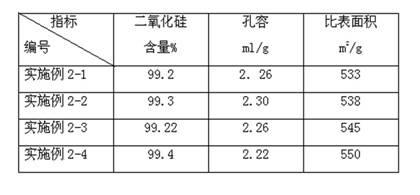

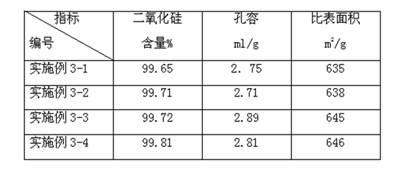

The invention discloses silicon dioxide aerogel and a preparation method thereof. The silicon dioxide aerogel of a three-dimensional network structure is prepared by the step of subjecting alkaline silicate and inorganic acid to neutralization reaction, washing, rapidly dehydrating for drying, and crushing; the aerogel is internally filled with pores of about 20nm and has the silica content (dry basis) of more than 99.0%, the BET (Brunauer, Emmett and Teller) specific surface area of 300-800m<2> / g, the pore space volume of 1.6-3.0, the average granularity of 3-20 mum and the pore volume of 1.7-3.6ml / g. In the invention, the alkaline silicate is used as a silicon source and is subjected to neutralization reaction with the inorganic acid, the raw materials are readily available, cheap and innoxious, and the process flow is short and is easy for industrialization.

Owner:广州凌玮科技股份有限公司

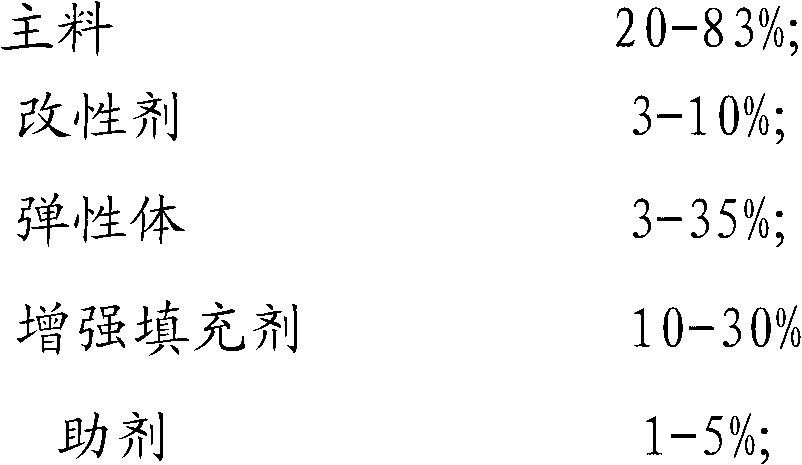

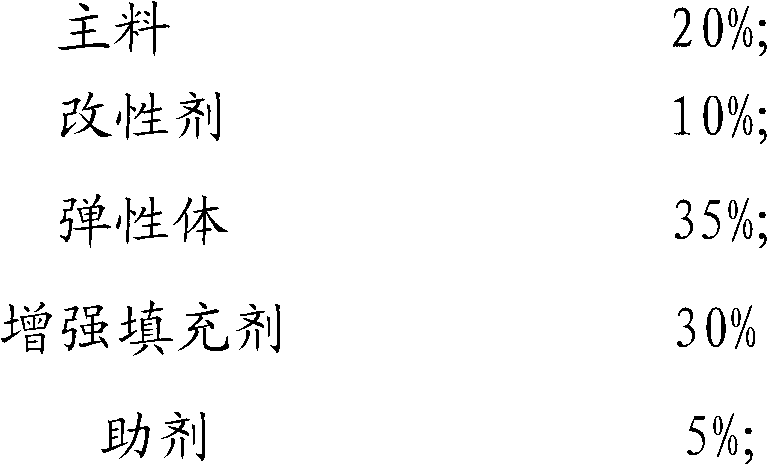

Composite material special for blow molding of reinforced nylon air inlet pipe and preparation method thereof

The invention provides a composite material special for blow molding of a reinforced nylon air inlet pipe. The composite material comprises the following components in percentage by mass: 20-83 percent of main material, 3-10 percent of modifier, 3-35 percent of elastomer, 10-30 percent of enhancing filler and 1-5 percent of auxiliary agent. The composite material special for blow molding of the reinforced nylon air inlet pipe can be used in blow molded products of air inlet pipelines, oil paths or cooling system pipelines at the peripheries of automobile engines. The composite material contains the reinforcing filler; the strength and the high temperature resistance performance of the composite material are improved; and the composite material is rich and cheap in raw materials and is suitable for promotion and application.

Owner:辰东意普万新材料(广东)有限公司

Direction reduction and electric furnace smelting-separation preparation process of vanadium-titanium magnetite cold bound pellet

The cooled agglomerated carbon-contained pellet prepared with vanadium titano magnetite concentrate and opposite direct reduction with former pellet comprises: mixing the concentrate, reducer and bonding agent, drying, grinding, and pelletizing to obtain the cooled agglomerated carbon-contained pellet drying and sieving into the reduction furnace with reducer for reduction atmosphere; loading the reduced pellet into electric furnace to melt and separate the iron liquid, V, Ti and Cr. This invention is fit to the pellet on wide application temperature and low energy consumption, has well efficiency and low running cost, and can also extract V, Ti Fe and Cr from electric furnace with high yield and obvious environmental protection.

Owner:鲜帆 +2

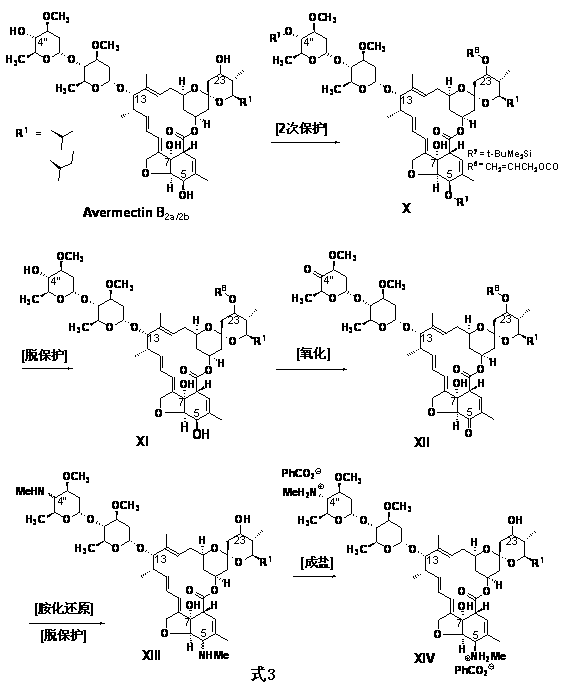

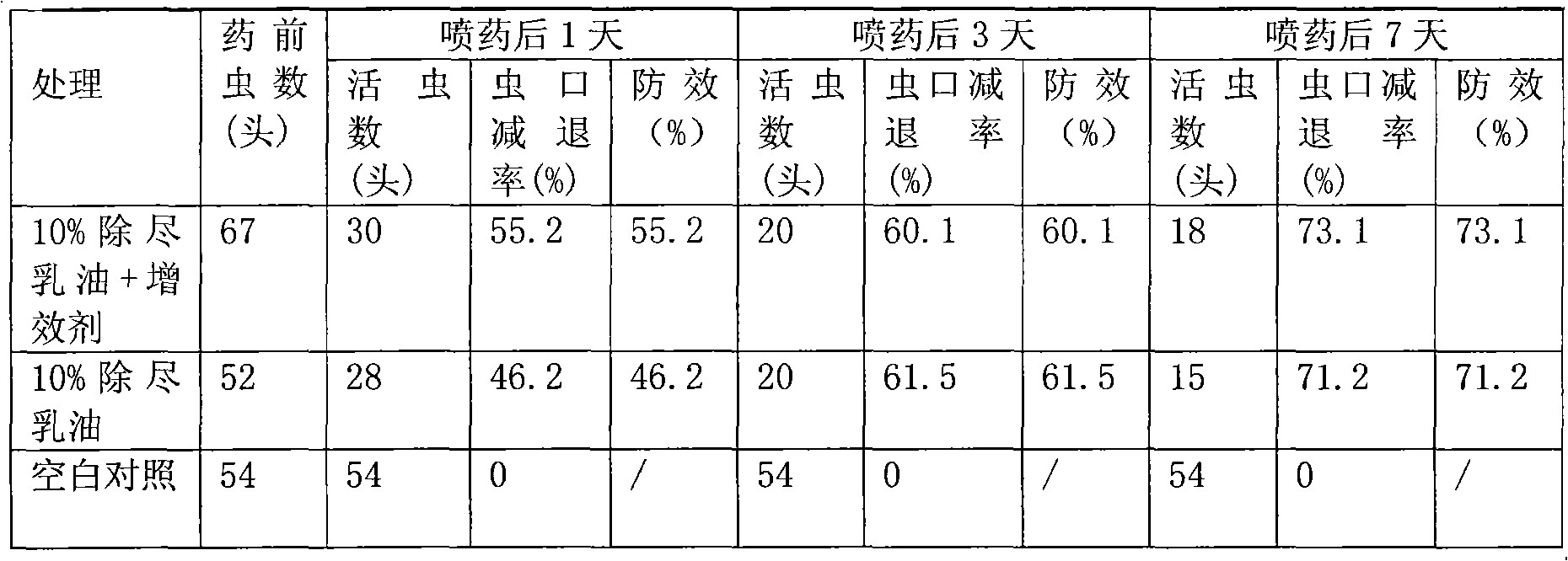

Avermectin B2a/2b amine derivatives, derivative salts thereof, and preparation method and application of avermectin B2a/2b amine derivative salt

ActiveCN103214532AImprove insecticidal effectImprove biological activitySugar derivativesSugar derivatives preparationKetoneOrganic acid

The invention relates to avermectin B2a / 2b amine derivatives and derivative salts thereof, and a preparation method and an application of the avermectin B2a / 2b amine derivative salts. The avermectin B2a / 2b amine derivatives comprise six types of compounds. The avermectin B2a / 2b amine derivative salts are salts formed by reactions of the six types of avermectin B2a / 2b amine derivatives and organic acid and inorganic acid. The preparation method of the avermectin B2a / 2b amine derivative salts comprises the steps that: (1) avermectin B2a / 2b is subjected to a protective reaction with tert-butyl dimethyl chlorosilane or allyl chloroformate; (2) protected B2a / 2b is subjected to a reaction with an oxidant, such that an avermectin B2a / 2b ketone compound is obtained; (3) the ketone compound is subjected to an amination reaction, such that protected amine derivative is obtained; and (4) the protective agent is removed, such that B2a / 2b amine derivative is obtained; the derivative is subjected to a reaction with organic or inorganic acid, such that avermectin B2a / 2b amine derivative salt is obtained. According to the invention, avermectin B2 is adopted as a matrix for synthesizing avermectin B2a / 2b amine derivative and avermectin B2a / 2b amine derivative salt, such that avermectin B2 applciation range is widened.

Owner:HEBEI VEYONG BIO CHEM

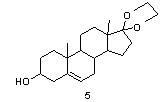

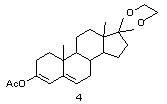

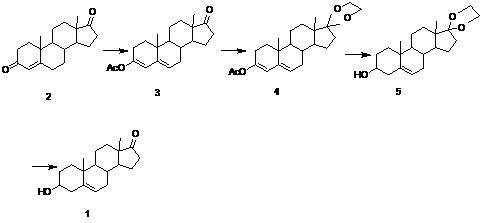

Preparation method of dehydroisoandrosterone

ActiveCN102603841AWide variety of sourcesCheap sourceSteroidsChemical synthesisEsterification reaction

The invention relates to a preparation method of dehydroisoandrosterone. According to the preparation method, a compound 1 is prepared by a compound 2 through esterification reaction, ketalation reaction, reduction reaction and hydrolysis reaction. When the dehydroisoandrosterone is prepared by the chemical synthetic method, the defects of difficulty in control, cumbersome post treatment, high risk, pollution of the environment, and the like in traditional production method are avoided. Compared with the traditional production method, the reaction conditions of the preparation method are easyto control, the post treatment process is simple, and the yield is higher can be up to 80.79% after refining. Raw materials of the preparation method can be prepared by sterol through microbial fermentation, the raw materials are wide in sources, are cheap and relatively environmentally friendly and can be purchased from Hunan Nuokai Biological Pharmaceutical Co., Ltd, and the structural formulasof the compound 1 and the compound 2 are as follows.

Owner:湖南成大生物科技有限公司

Thermoplastic Cellulosic Fiber Blends as Lost Circulation Materials

ActiveUS20120108472A1Reduce circulation lossImproved and effective and economical compositionSolid waste managementFlushingThermoplasticThermosetting polymer

A method is disclosed for reducing lost circulation in drilling wells, employing composite materials as lost circulation materials. The composites comprise a thermoplastic polymer and cellulosic fibers. Optionally the composites may include other components such as calcium carbonate, clay, oil and other blending agents.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

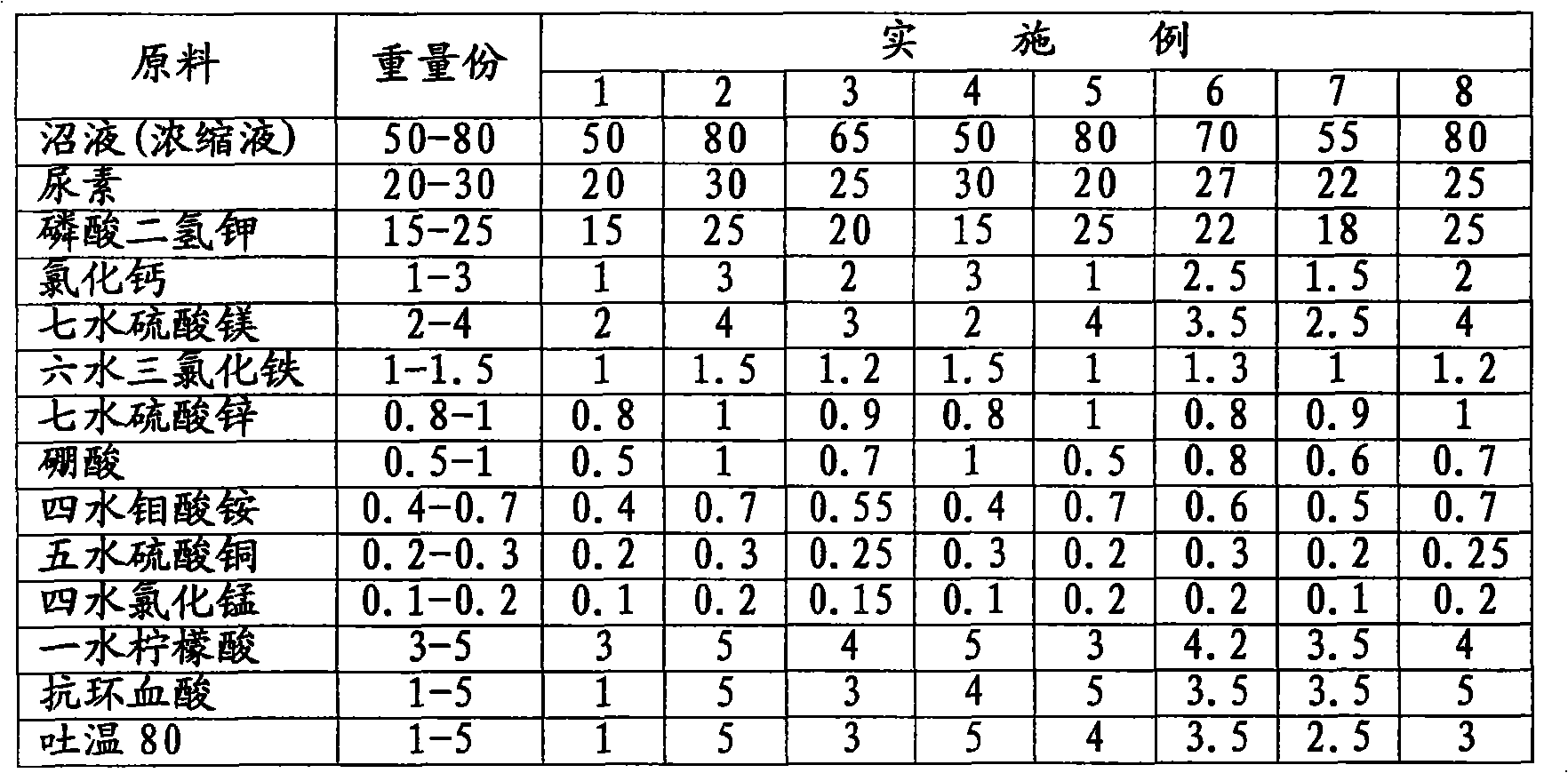

A liquid fertilizer containing biogas slurry

InactiveCN101550039AFertilizer efficiency is stableRich in nutrientsClimate change adaptationBioloigcal waste fertilisersNutrientChemistry

A liquid fertilizer containing biogas slurry is composed of 50-80 weight parts (the same as below) of biogas slurry concentrated solution, 20-30 parts of urea, 15-25 parts of potassium dihydrogen phosphate, 1-3 parts of calcium chloride, 2 -4 parts of magnesium sulfate heptahydrate, 1-1.5 parts of ferric chloride hexahydrate, 0.8-1 parts of zinc sulfate heptahydrate, 0.5-1 parts of boric acid, 0.4-0.7 parts of ammonium molybdate tetrahydrate, 0.2-0.3 parts of cupric sulfate pentahydrate, 0.1-0.2 parts of manganese chloride tetrahydrate, 3-5 parts of citric acid monohydrate, 1-5 parts of ascorbic acid, 1-5 parts of tween 80, whose pH value is 7-8.5, the use of liquid fertilizer is diluted 500-2000 times with water, the pH value is adjusted to 6-7 by acid, the liquid fertilizer can be used as soilless culture and / or foliage fertilizer to spray, has advantages of stable fertilizer, rich and perfect nutrient ingredients, abundant sources of material, low cost, environmental protection, large usable floor area due to convenient transportation.

Owner:ZHEJIANG FORESTRY UNIVERSITY

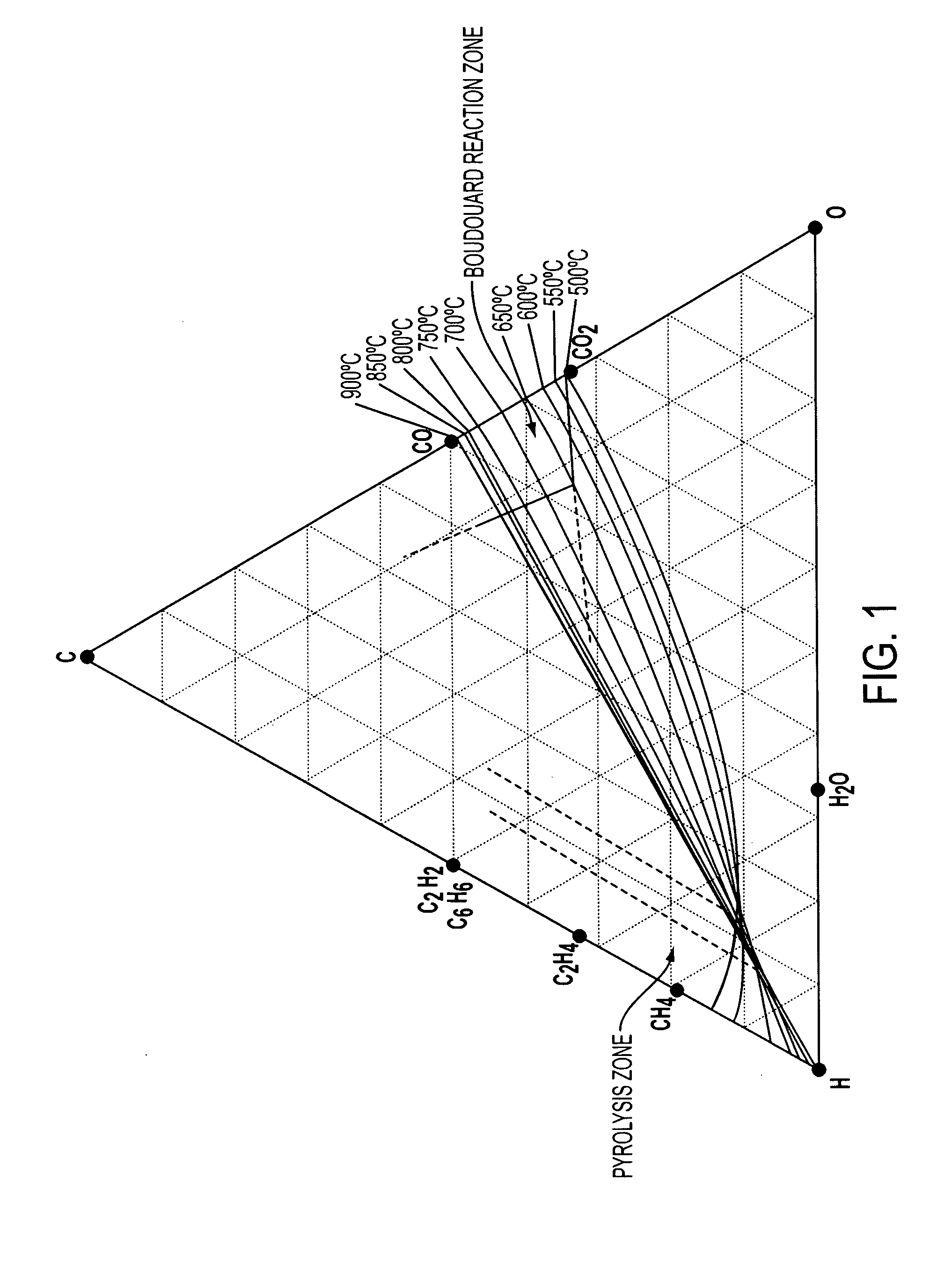

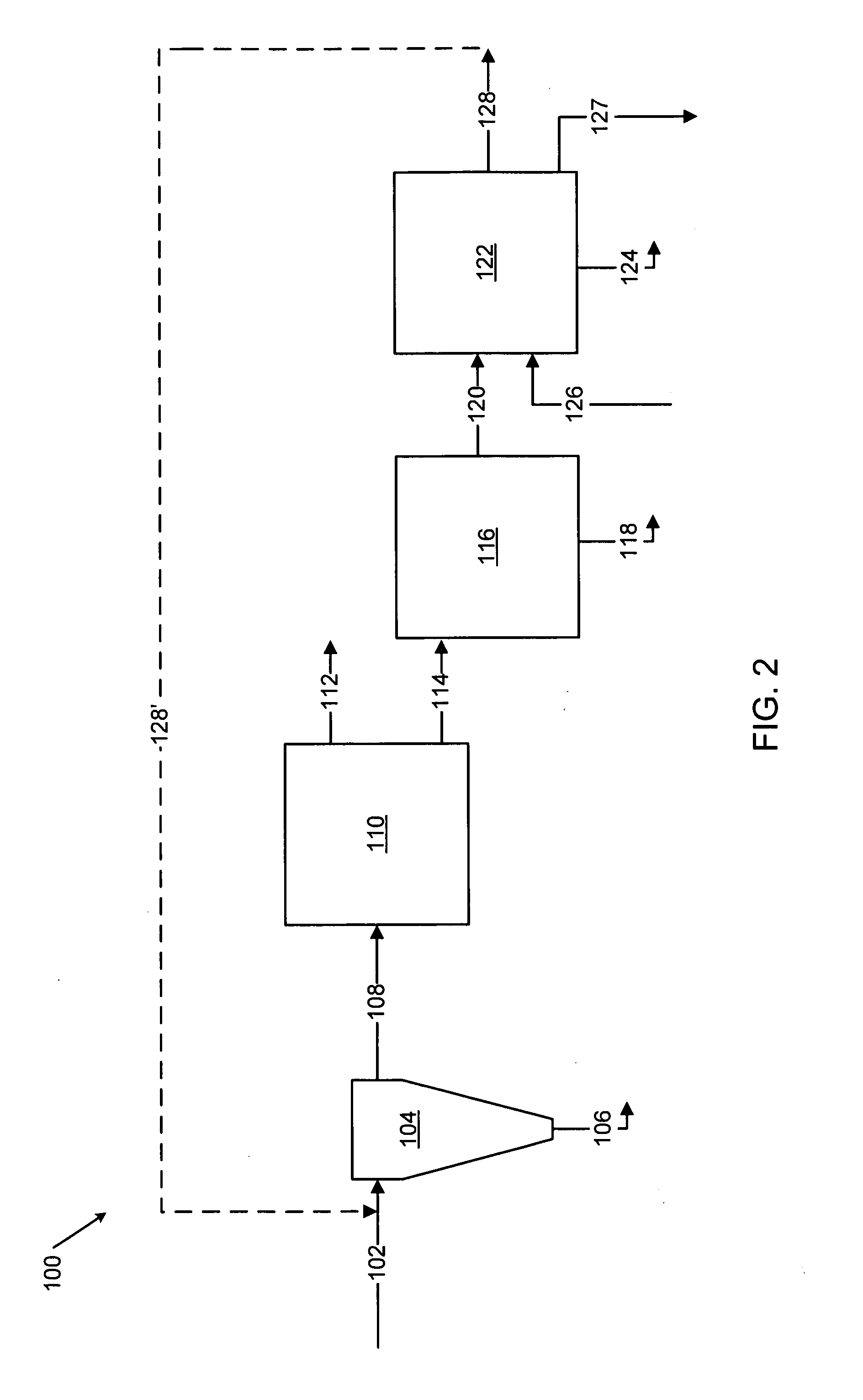

Methods for treating an offgas containing carbon oxides

ActiveUS20150059527A1Cheap sourceIncrease valueMaterial nanotechnologyPigmenting treatmentParticulatesSolid carbon

A method of treating an offgas includes purifying the offgas to remove particulate matter, water, undesirable gaseous components and inert gases to produce a dried carbon oxide gas feedstock, and converting at least a portion of carbon oxides in the dried carbon oxide gas feedstock into solid carbon. In other embodiments, a method includes passing a dried carbon oxide gas feedstock through a multi-stage catalytic converter. A first stage is configured to catalyze methane-reforming reactions to convert methane into carbon dioxide, carbon monoxide and hydrogen with residual methane. A second stage is configured to catalyze the Bosch reaction and convert carbon oxides and hydrogen to solid carbon and water.

Owner:SEERSTONE

Method for preparing high-specific-surface-area activated carbon from tobacco stalks

InactiveCN103121682AImprove qualityWide variety of sourcesCarbon compoundsSolid waste disposalActivated carbonSlag

The invention discloses a method for preparing high-specific-surface-area activated carbon from tobacco stalks, which comprises the following steps: pulverizing tobacco stalks into granules, mixing the granules and an activating agent according to a mass ratio of (1:8)-(2:1), adding the obtained mixture into water, evenly stirring, and impregnating for 10-14 hours; after impregnation is finished, filtering, drying the filter residue, placing into an electric furnace having a nitrogen protective atmosphere, and carbonizing at 450-750 DEG C for 1-2 hours; and after carbonization is finished, cooling in a nitrogen atmosphere, washing the obtained furnace slag, and drying. According to the method, high-quality activated carbon can be simply and quickly prepared from wastes in the tobacco industry. Thus, the method changes wastes into valuable substances, fully utilizes resources, avoids environmental pollution, has good economic benefits and is beneficial to industrial production.

Owner:CENT SOUTH UNIV

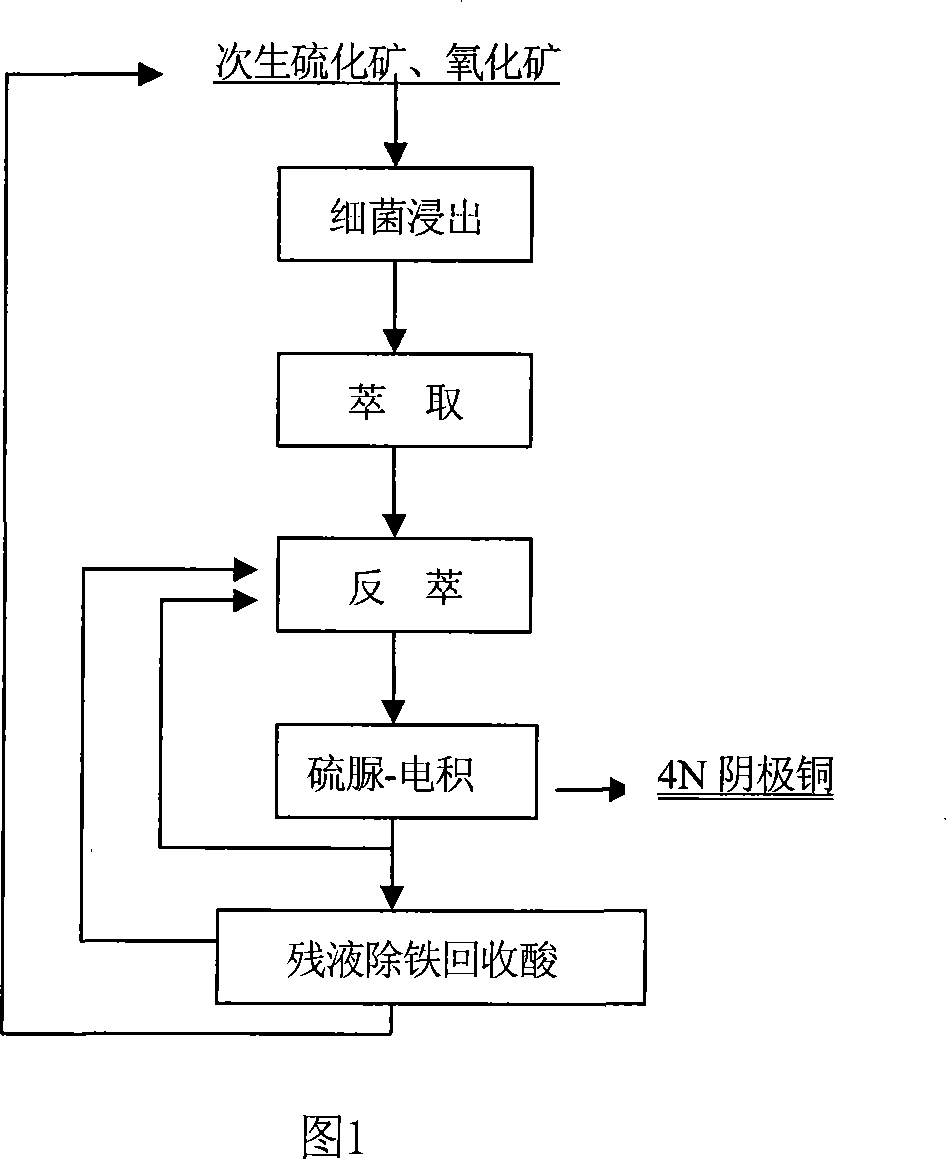

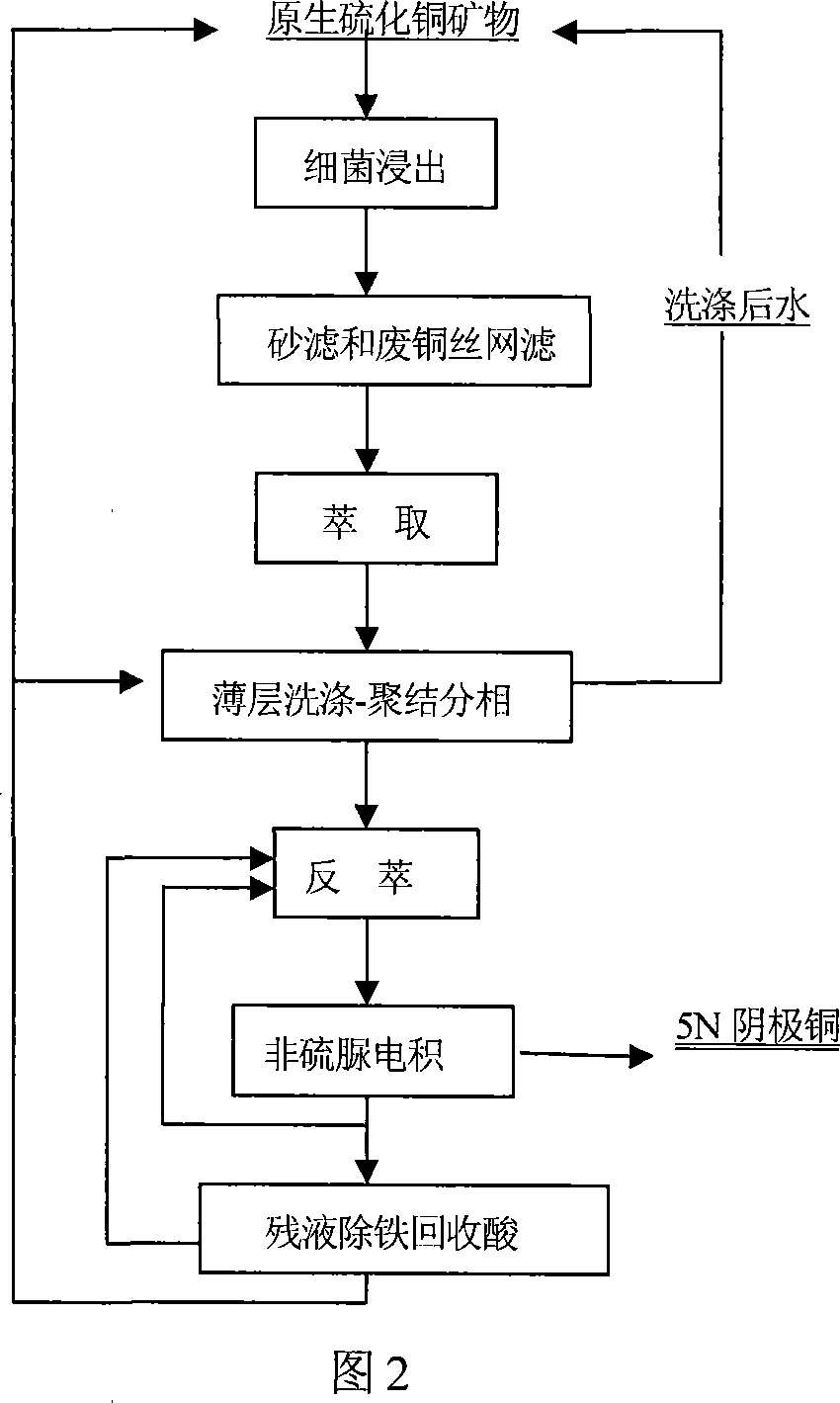

Method of preparing high purity copper by bacteria leaching primary sulfide ore

InactiveCN101033508AEnhanced synergistic leachingIncrease leaching ratePhotography auxillary processesProcess efficiency improvementSulfurThin layer

The invention relates to a method of preparing high pure copper from the leachate of primary sulfide ore bacteria, including: it leaches the primary sulfide ores and its mixture by using the mixture of middle and mesophilic bacterias. It filters and extracts the bacterial leaching solution, and conducts thin-layer wash-condensate, coalescence phase, and back-extraction electrowinning for the organic phase load. The invention uses hybrid strains of bacteria and sub-culture techniques to enhance the synergy of the bacterial leaching role and the minerals leaching rate, uses gelatin and other additives without sulfur element to reduce the sulfur impurities.

Owner:CENT SOUTH UNIV

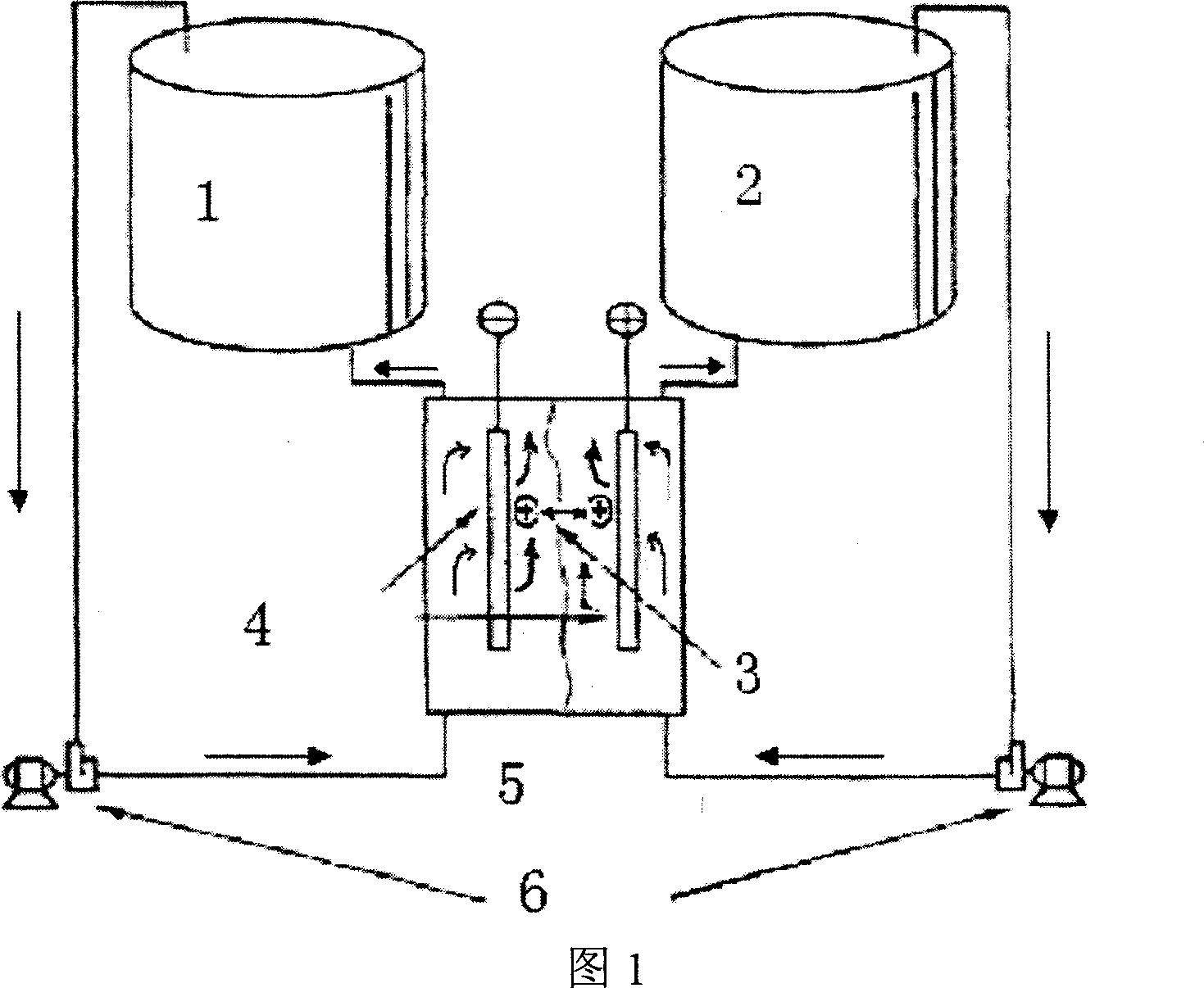

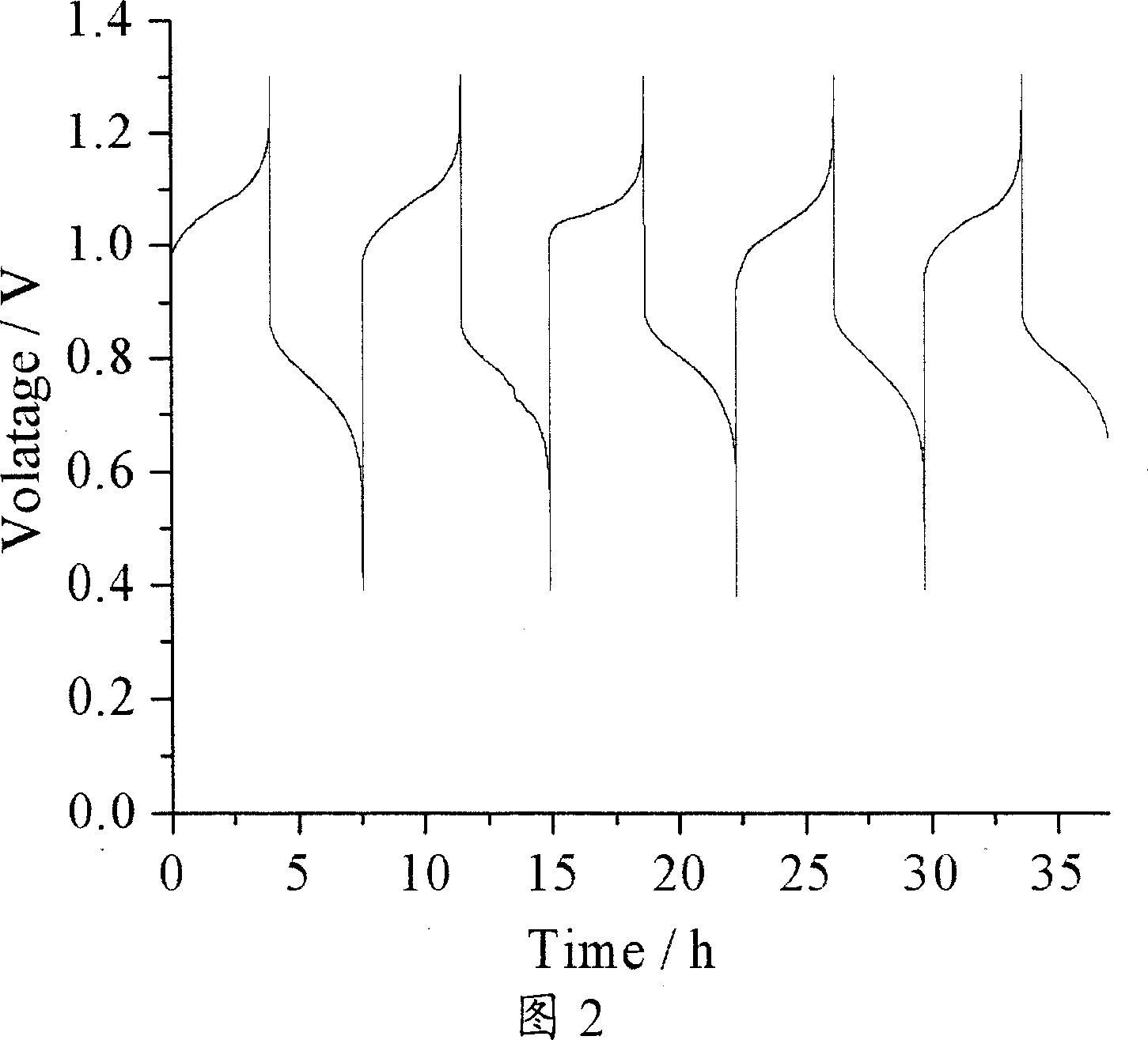

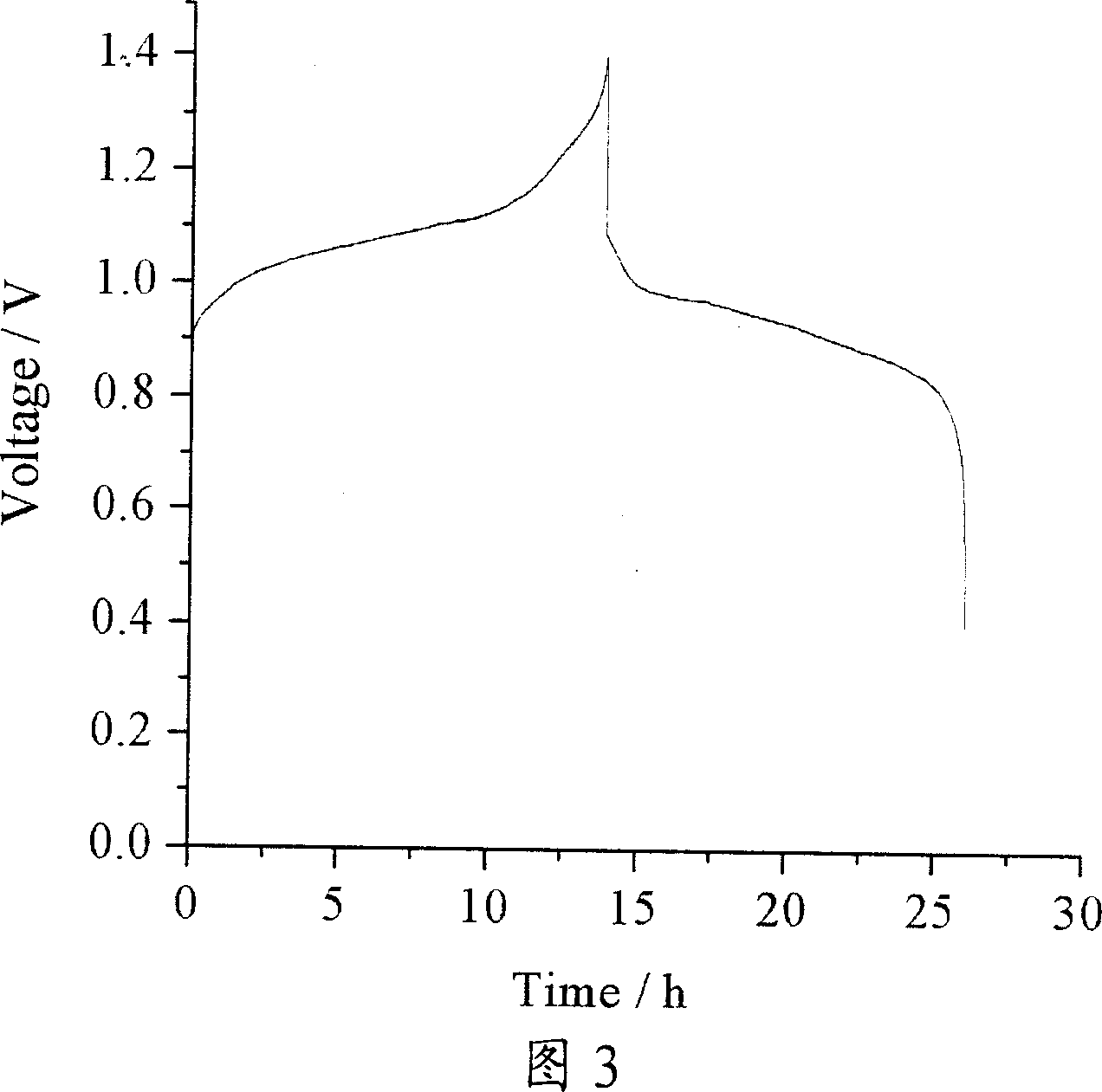

Iron composite/halogen electrochemical system for flow electric storage

InactiveCN101047261AReduce capacityImprove energy conversion efficiencyElectrolyte moving arrangementsCell electrodesElectricityHalogen

A Fe-matched matter-halogen electrochemical system used on liquid flow energy storage is prepared as separating positive / negative electrode electrolyte by positive ion exchange film and storing said electrolyte in external container, generating charge / discharge process by making oxidation / reduction reaction on inert carbon felt electrode through pump stream via battery, applying soluble Fe(III) / Fe(II) -matched matter oxidation / reduction electric pair as negative electrode and applying halogen oxidation / reduction electric pair as positive electrode.

Owner:DALIAN RONGKE POWER

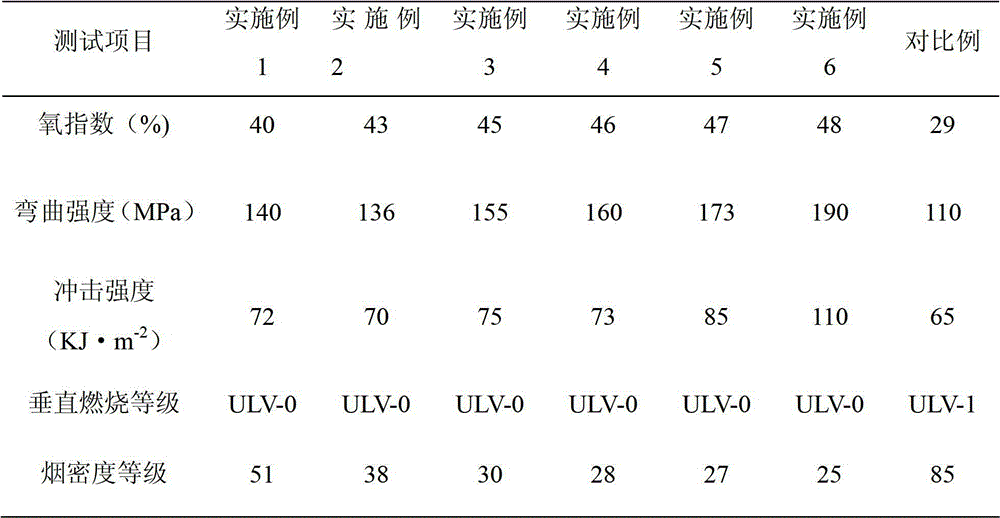

Low smoke halogen-free environment-protection fire-retardation type sheet molding compound and preparation method thereof

InactiveCN102942761AImprove flame retardant performanceReduce combustion smoke densityCoatingsOrganosiliconPhenol formaldehyde resin

The present invention discloses a low smoke halogen-free environment-protection fire-retardation type sheet molding compound, which comprises, by weight, 60-80 parts of an unsaturated polyester resin mixture, 20-60 parts of a thermoplastic high molecule polymer slurry, 1-3 parts of an initiator, 2-4 parts of a thickener, 0.02-0.5 part of a polymerization inhibitor, 5-15 parts of a mold release agent, 90-140 parts of a filler, 80-150 parts of aluminum hydroxide powder, 1-10 parts of an organosilicon synergist, 1-8 parts of a smoke suppressant, 5-25 parts of a liner phenol formaldehyde resin, and 80-200 parts of reinforcing fibers. Compared with the conventional fire retardation agent, the low smoke halogen-free environment-protection fire-retardation type sheet molding compound has the following advantages that: a fire retardation performance of the composite material is increased, smoke density during burning is reduced, excellent mechanical properties of the material is maintained, and disadvantages of large smoke density during burning and low comprehensive mechanical performance of the existing fire-retardation sheet molding compound are solved.

Owner:CHANGZHOU UNIV

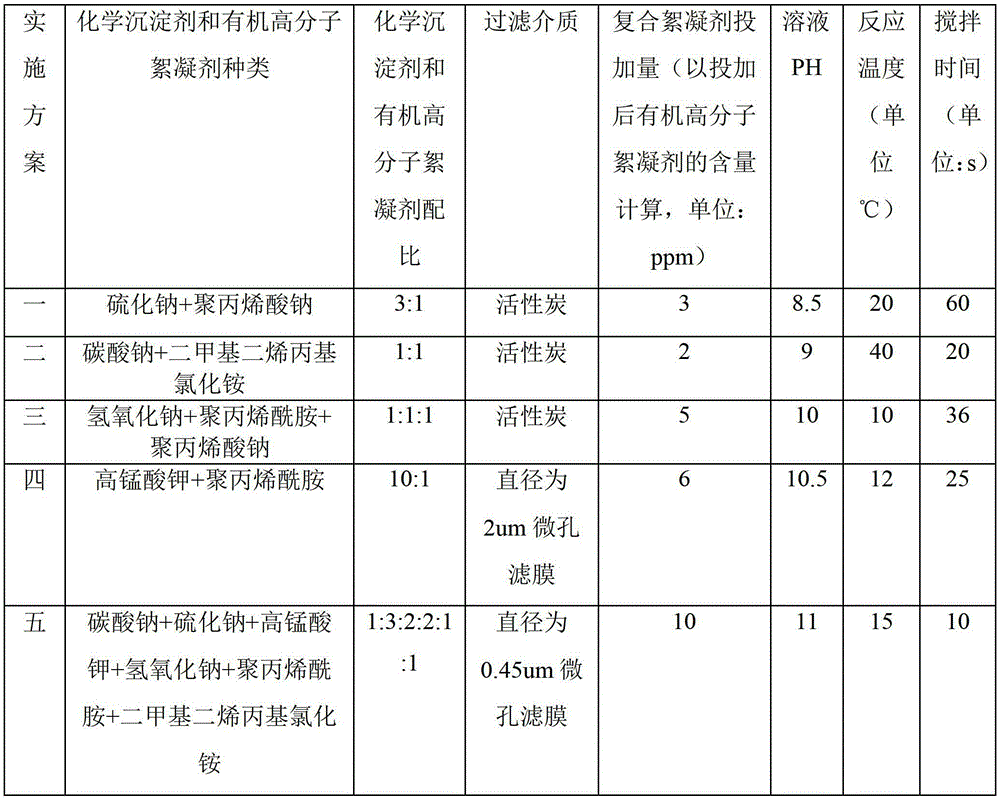

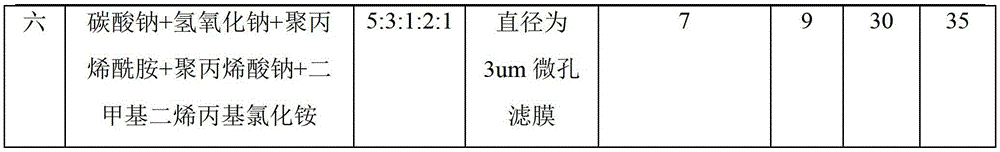

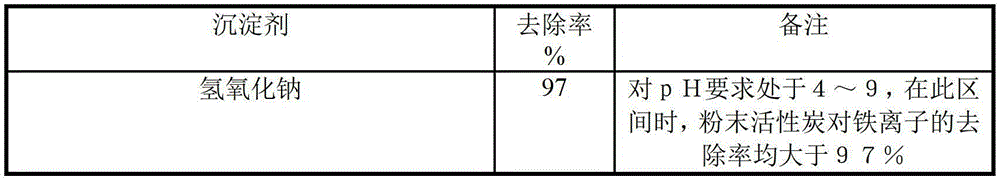

Composite flocculating agent for processing radioactive elements iron, cobalt, manganese and silver in nuclear waste water and processing method

InactiveCN103151088AGood removal effectQuick and effective removalRadioactive contaminantsWater/sewage treatment by flocculation/precipitationSludgeManganese

The invention discloses a composite flocculating agent for processing radioactive elements iron, cobalt, manganese and silver in nuclear waste water and a processing method, which belongs to the technical field of the nuclear waste water treatment. The composite flocculating agent consists of a chemical precipitator and an organic polymer flocculating agent, wherein the chemical precipitator is one or combination of more than one of potassium permanganate, sodium sulfide, sodium carbonate and sodium hydroxide; the organic polymer flocculating agent is polyacrylamide, sodium polyacrylate and / or dimethyl diallyl ammonium chloride; and the processing method comprises the following steps of configuring the composite flocculating agent, charging the composite flocculating agent, regulating a pH value of the solution, mixing, flocculating and filtering. Due to the adoption of the composite flocculating agent and the processing method, multiple radioactive element ions of ultralow trace concentration in the nuclear waste water can be efficiently removed, and advantages such as rapidness and high efficiency in reaction process, charging in one step and little dangerous chemical sludge can be realized.

Owner:NANJING UNIV YIXING ENVIRONMENTAL PROTECTION RES INST

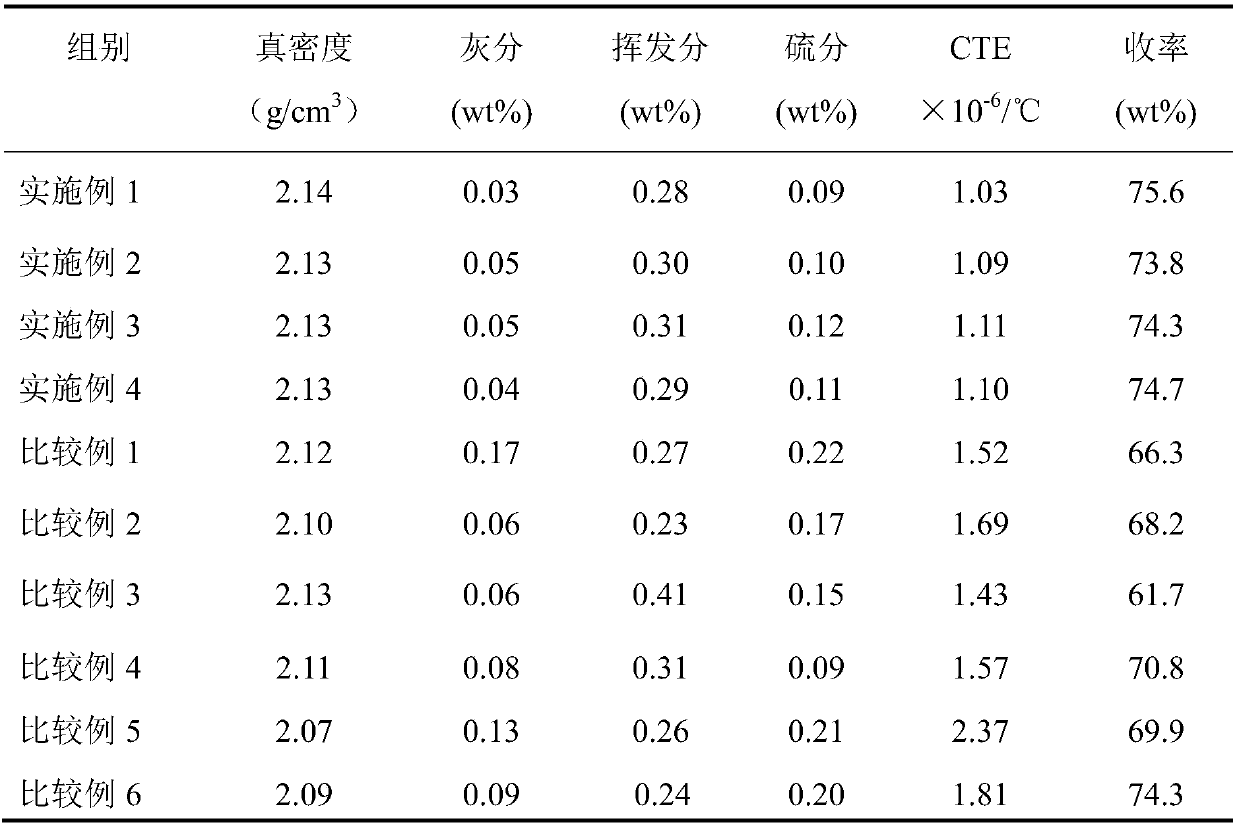

Technology for producing coal-series needle coke by taking middle-temperature and low-temperature coal tar asphalt as raw material

ActiveCN107694552AGood qualityHigh yieldWorking-up pitch/asphalt/bitumen by selective extractionPhysical/chemical process catalystsPre treatmentWide area

The invention relates to a technology for producing coal-series needle coke by taking middle-temperature and low-temperature coal tar asphalt as a raw material. The technology mainly comprises the following steps: carrying out decompression and distillation, and extraction and removal on middle-temperature and low-temperature coal tar; combining hydrogenation treatment, thermal polymerization andcalcining technologies under the action of a non-metal homogeneous mild-hydrogenation catalyst to prepare the coal-series needle coke with good performance and relatively high yield. The non-metal homogeneous mild-hydrogenation catalyst is mainly prepared from the following raw materials in percentage by mass: 55 weight percent to 79 weight percent of semi-coke, 20 weight percent to 40 weight percent of coke and 1 weight percent to 5 weight percent of graphene. According to the technology provided by the invention, after the raw material is subjected to combined pre-treatment, a refined asphalt raw material is reasonable in constitution and has a few of impurities; the catalyst has excellent modification performance and does not need to be separated subsequently; the graphene component also can be used for promoting a middle phase in a thermal polymerization process to form a wide-area and ordered fibrous structure and a high-performance needle coke product is easy to form.

Owner:NORTHWEST UNIV +1

Photocatalytic rutile titanium dioxide

InactiveUS7521039B2High activityCheap sourceMaterial nanotechnologyPigmenting treatmentPhysical chemistryLighting spectrum

The present invention is directed to photocatalytically active rutile titanium dioxide. The photocatalytically active rutile titanium dioxide of the present invention demonstrates enhanced activity in the visible light spectrum. It may be produced by neutralizing rutile seed to a higher pH than that at which it has traditionally been neutralized prior to washing and thermally treating the seed.

Owner:TRONOX LLC

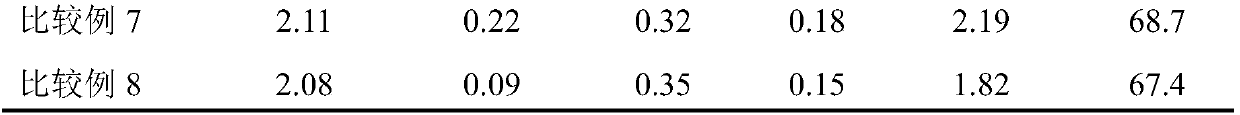

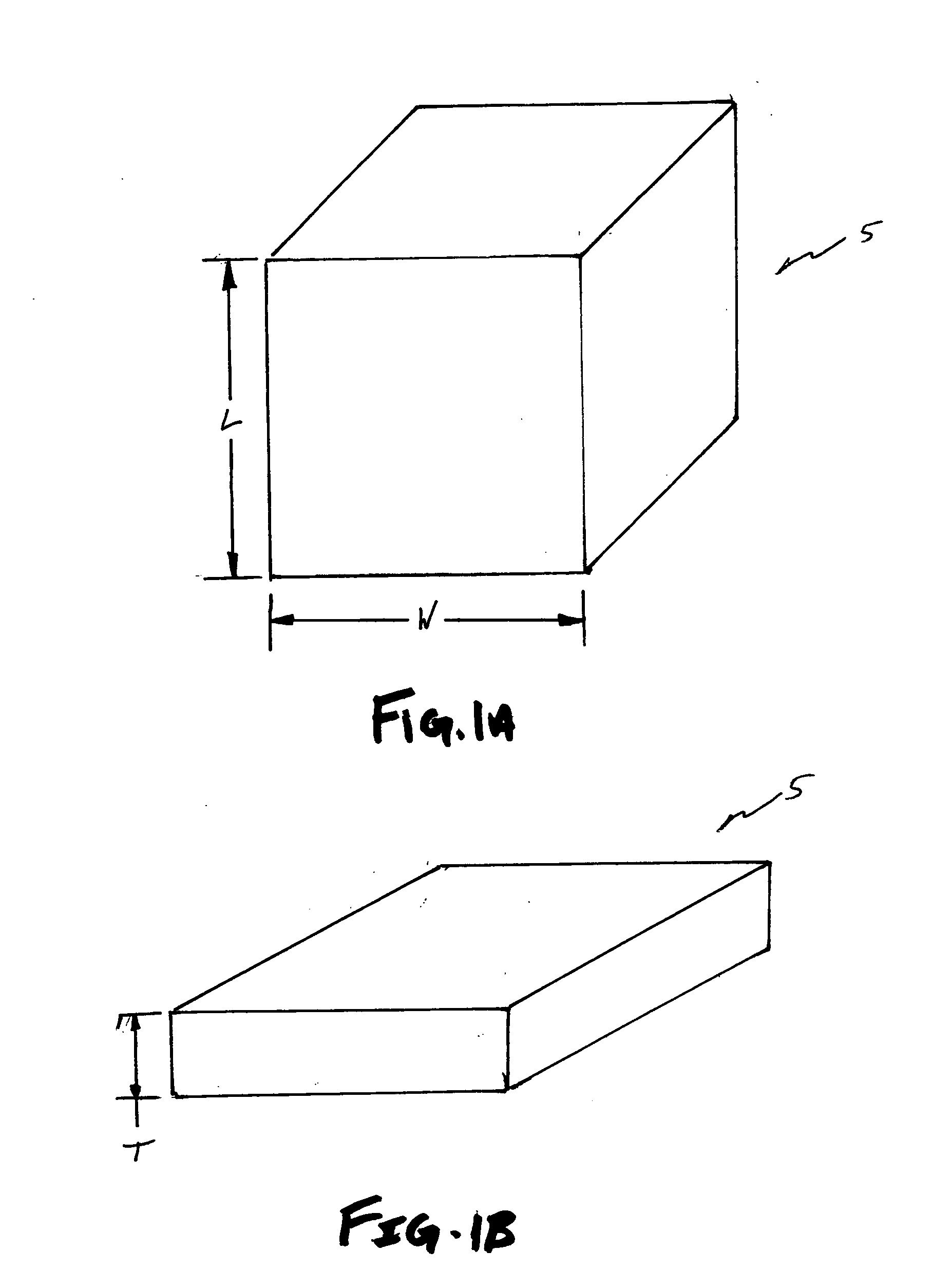

Rubberized concrete composition and method of making the same

The present invention provides a concrete composition that utilizes rubber aggregate with a distinct geometric shape. Preferably, the source of the rubber constituting the aggregate is used rubber tires cut by special saws or high pressure water jets to provide a smooth finished edge. Moreover, additional materials such as superplasticizers, fly ash, carbon fiber, fiberglass, and steel may also be mixed with the concrete compositions to vary the finish product's material properties.

Owner:PETR VILEM +1

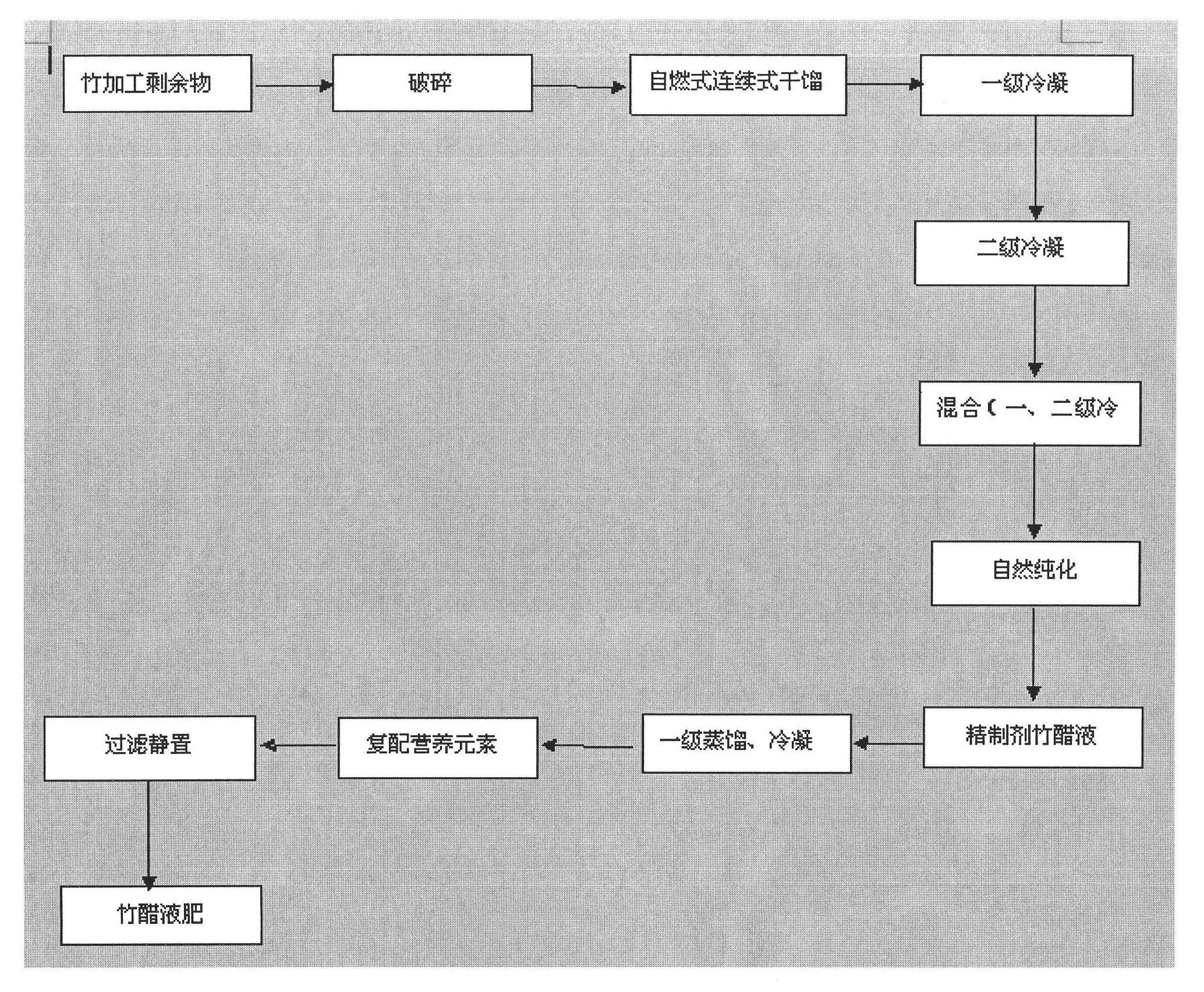

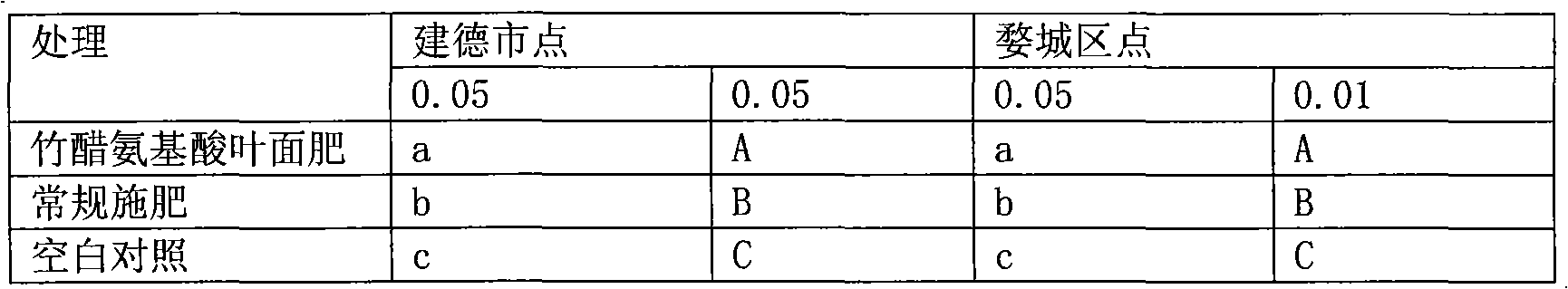

Process for preparing bamboo vinegar liquid fertilizer

The invention provides a process for preparing bamboo vinegar liquid fertilizer. The process comprises the following steps of: collecting various uncontaminated bamboo processing residues, and after crushing bamboo wood into bamboo chips, allowing the bamboo chips to enter a carbonization furnace to perform spontaneously-combustible and continuous carbonization at the temperature of between 200 and 500 DEG C; performing two-stage condensation, mixing bamboo vinegar liquid obtained through the two-stage condensation in a mixing tank, and standing and purifying for 180 days to obtain refined bamboo vinegar liquid; performing one-stage distillation on the refined bamboo vinegar liquid to obtain flavescent bamboo vinegar distillate; and finally, compounding a certain amount of organic materials selected from one or more of amino acid and chitosan and a proper amount of trace elements to prepare the bamboo vinegar liquid fertilizer.

Owner:岳永德 +3

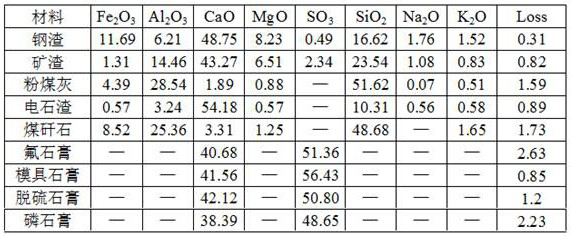

Industrial waste residue soil stabilizer and preparation method and construction method thereof

The invention discloses an industrial waste residue soil stabilizer. The industrial waste residue soil stabilizer is prepared from 5-50% of raw material steel slag powder, 20-40% of slag powder, 5-30%of fly ash, 8-25% of waste gypsum, 0-17% of coal gangue and 10-30% of carbide slag through the following method: firstly, raw materials including fly ash, coal gangue powder, waste gypsum, steel slagpowder and slag powder are sequentially added into a coulter type stirrer and are uniformly mixed at a high speed of 1500-2000 r / min for 20-30 min, finally, the carbide slag is added, stirring continues to be conducted for 10-20 min, and an obtained curing agent finished product is bagged, sealed and stored. The industrial waste residue soil stabilizer prepared by the invention can replace cementand lime to be applied to roadbed improvement and treatment, has the outstanding advantages of no calcination, energy conservation, environmental protection and the like, has obvious price advantagecompared with cement and lime, plays a positive role in promoting the resource utilization of industrial wastes such as fly ash, carbide slag, steel slag and the like, and has wide and far-reaching significance.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

Suspension emulsion gel loaded with fat-soluble vitamins and preparation method thereof

InactiveCN109288065ACheap sourceSource securityLipidic food ingredientsFood ingredient functionsVegetable oilAdditive ingredient

The present invention relates to a suspension emulsion gel loaded with fat-soluble vitamins and a preparation method thereof, and belongs to the technical field of food processing. The suspension emulsion gel comprises the following components in parts by weight: 1-10 parts of fat-soluble vitamins, 1-10 parts of vegetable proteins, 0.5-3 parts of polysaccharides and 30-60 parts of vegetable oil rich in unsaturated fatty acids. The preparation raw materials are cheap in source, safe, good in biocompatibility, fast in biodegradation and easy for modification. The prepared suspension emulsion gelhas good stability, is simple in technology, low in cots, safe, environmentally protective, good in product stability and high in bioavailability, can be used in various foods to enhance sensory value, edible value and nutritional value, and can also be used for preparing healthy functional foods or healthy accessory ingredients.

Owner:GUANGZHOU HANFANG PHARMA

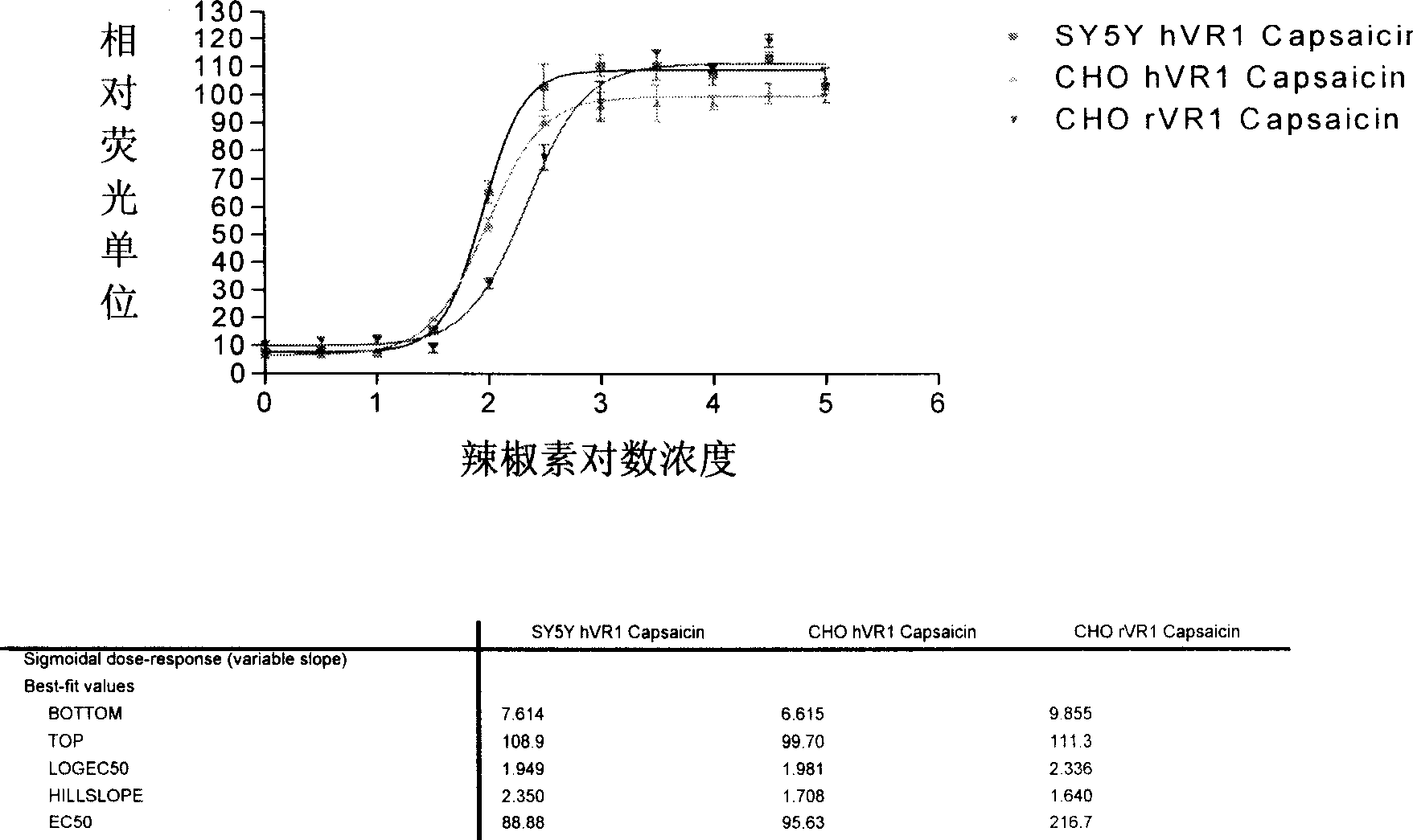

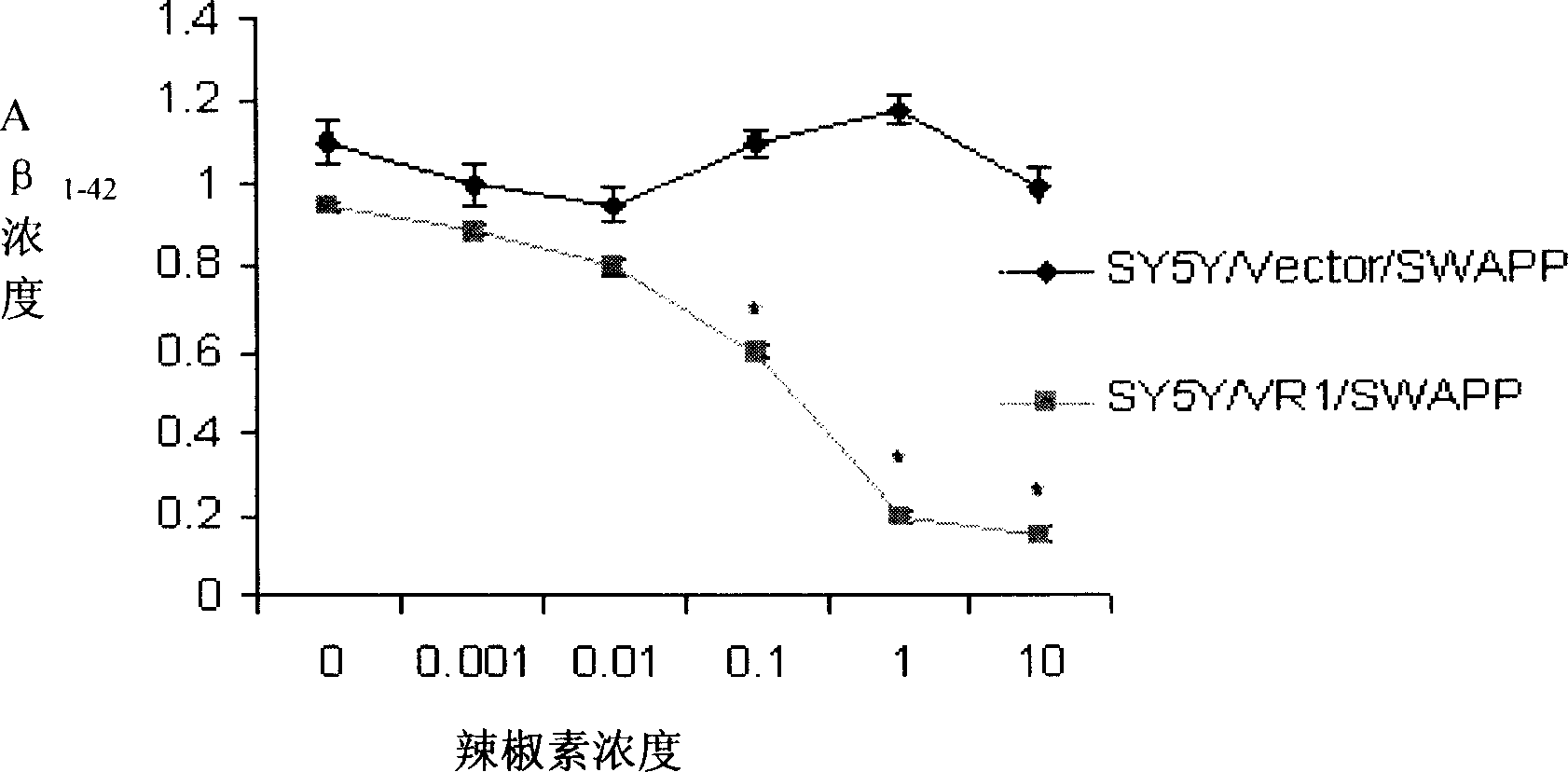

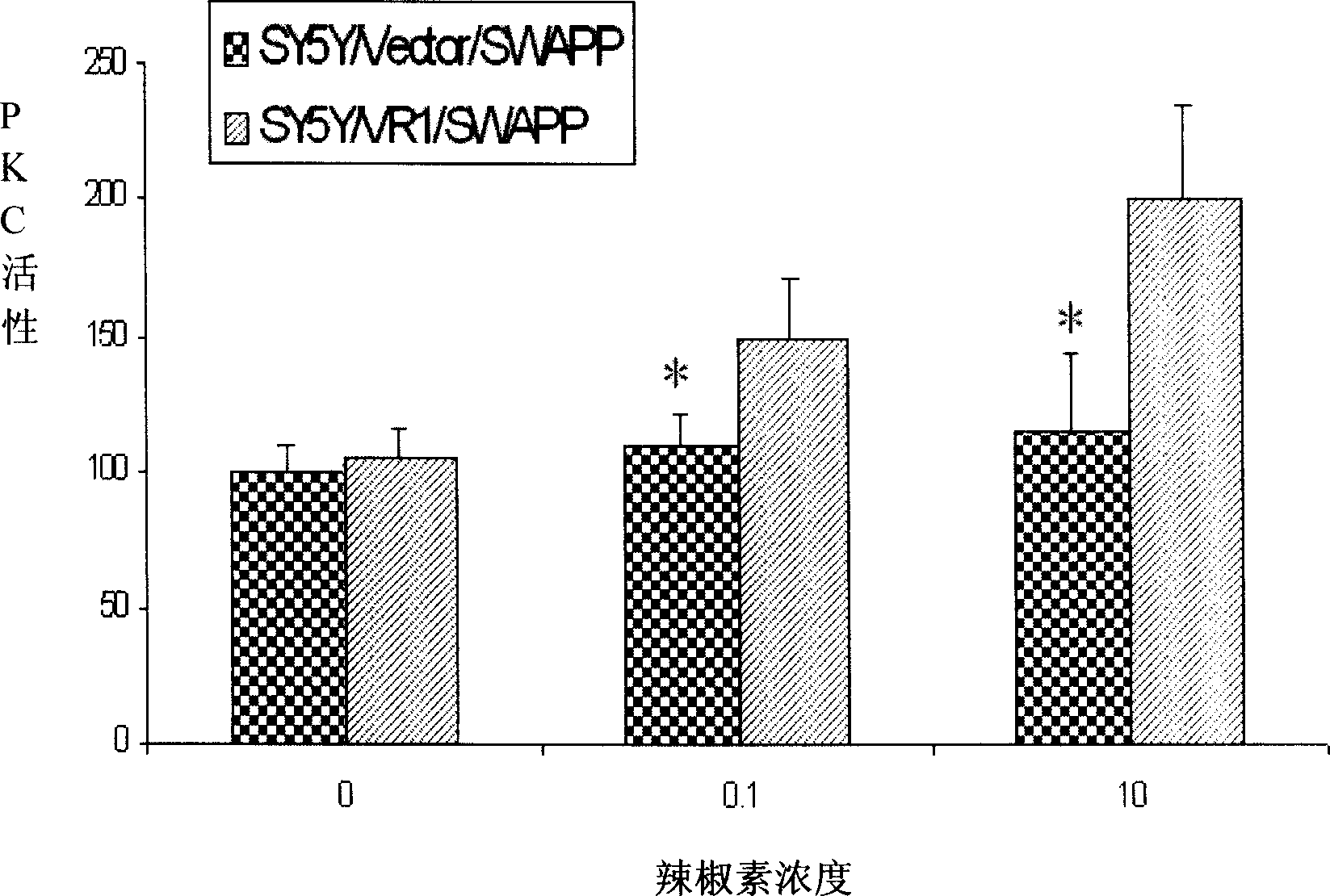

Use of vanillin receptor agonist in preparation of product for resisting Alzheimer disease

InactiveCN1736485ATechnical expertiseEnhance pharmacological effectsNervous disorderHeterocyclic compound active ingredientsCapsaicinAlzheimer's disease

Owner:SHANGHAI MEDICILON INC

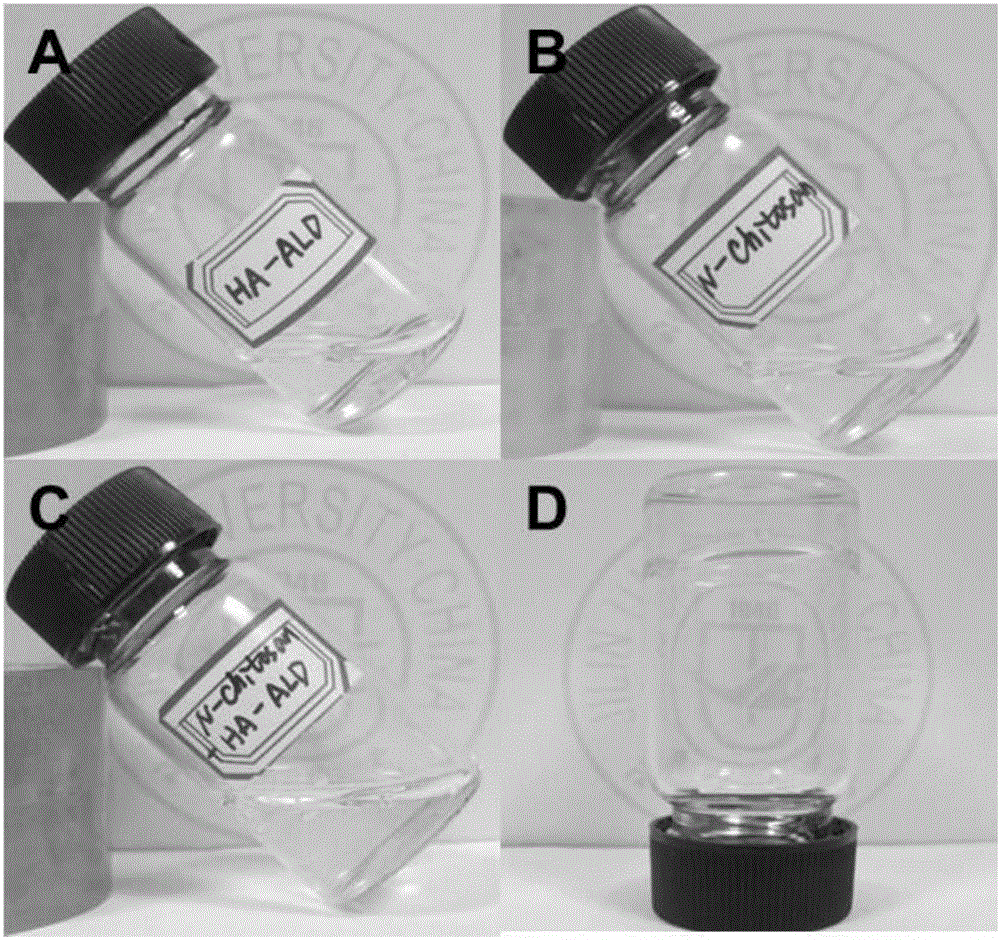

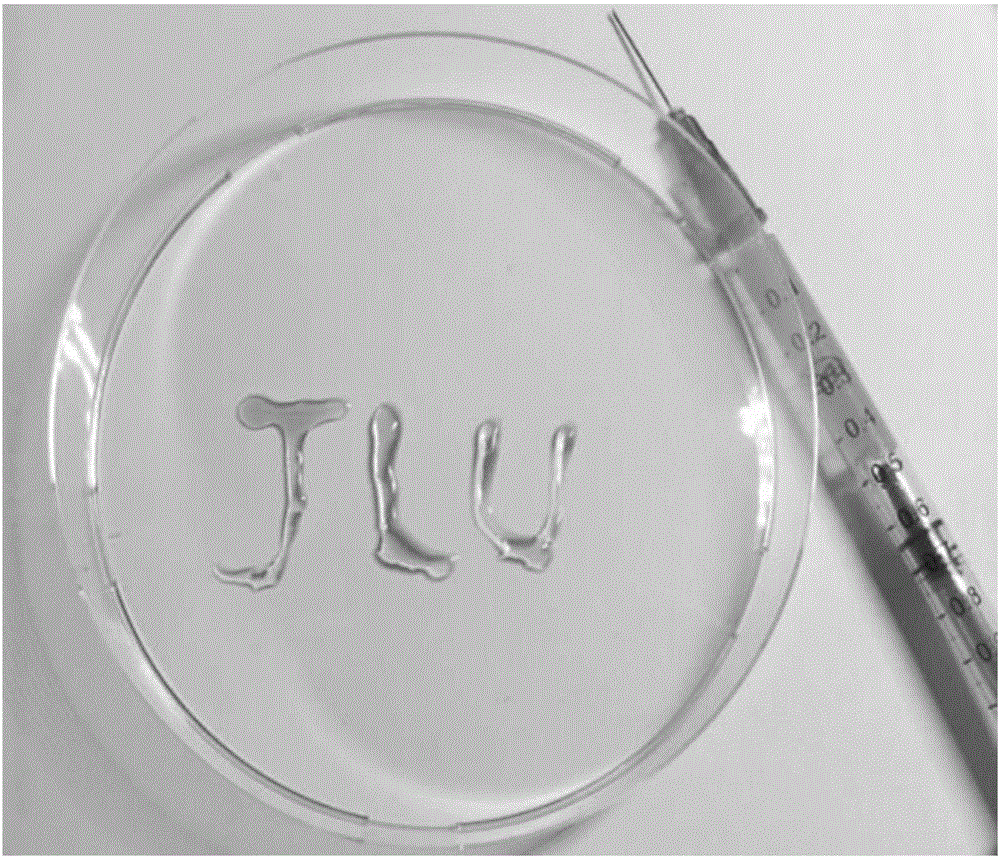

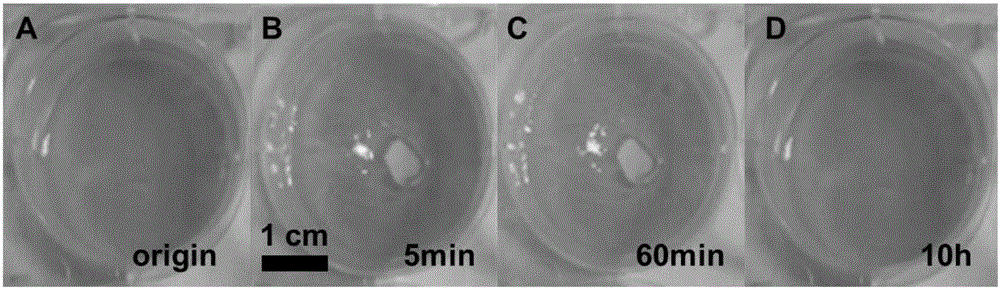

Injectable self-repairing hydrogel based on polysaccharides, preparation method and application of hydrogel to biological tissue engineering

The invention discloses injectable self-repairing hydrogel based on polysaccharides, a preparation method and application of the hydrogel to biological tissue engineering, and belongs to the technical field of high polymer materials. The method includes the steps of modifying natural high polymer chitosan so that the defect that the chitosan can only be dissolved in acid solutions can be overcome and the dissolubility of the chitosan in water can be improved; conducting mixing reaction on the chitosan and a modified sodium hyaluronate derivative solution, delaying the reaction time or raising the temperature so that sol can be converted into gel and hydrogel can be endowed with the injection characteristic and the self-repairing characteristic. It is shown through cell co-culture experiments that the intelligent hydrogel has the advantage of high biocompatibility, degradability and the like. The injectable self-repairing hydrogel as a novel medical high polymer carrier material has potential biological and medical application value when used for the co-culture together with cells, protein, DNA, antigens and other active substances, and even the delivery, release and other aspects of medicine and other in-vitro substances.

Owner:深圳智凝高分子材料科技有限公司

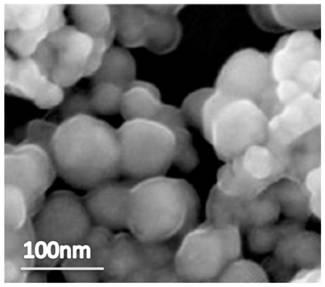

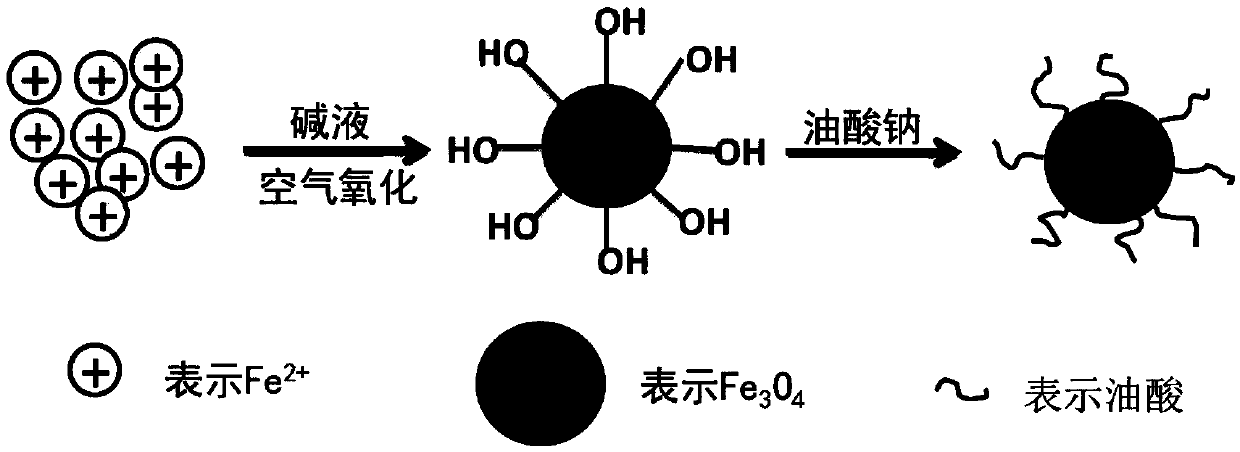

Nano magnetofluid fracturing fluid imbibition oil-increasing method for tight reservoir and modified nano magnetic particles

ActiveCN110454132AStrong lipophilic and hydrophobic propertiesSimple preparation processFluid removalDrilling compositionWater productionMagnetite Nanoparticles

The invention relates to a nano magnetofluid fracturing fluid imbibition oil-increasing method for a tight reservoir and modified nano magnetic particles. The nano magnetofluid fracturing fluid imbibition oil-increasing method comprises the steps that magnetic fracturing prepad fluid is pumped into a formation, a crack is formed in the formation, a magnetic field is applied to the well bottom, andthe modified nano magnetic particles in the magnetic fracturing prepad fluid are delivered to a target oil reservoir; a fracturing fluid base fluid and a propping agent for fracturing are mixed to form sand-carrying fluid to be pumped into the crack formed in the formation, so as to support the geometrical shape of the crack; and after fracturing construction, the magnetic field is applied to thewell bottom, thus the nano magnetic particles adsorbing crude oil flow back into a wellbore and then recovered out of the ground, and the magnetic particles are recovered through the magnetic force effect. The nano magnetofluid fracturing fluid imbibition oil-increasing method for the tight reservoir and the modified nano magnetic particles are suitable for an oilfield with the high water content, the modified nano magnetic particles have high lipophilicity and hydrophobicity, thus the magnetic particles adsorb the crude oil in the target oil reservoir and flow back to the wellbore through the pressure difference at the well bottom and the effect of the externally applied magnetic field, the crude oil output can be well increased, water production is reduced, the magnetic nanoparticles are recovered out of the ground in the oil recovery process, and the magnetic particles can be recovered through magnetic force to be reused, so that the production cost is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Synthesis method of [3aS, 6aR]-1,3-dibenzyl-tetrahydro-4H-fruo [3,4-d]-imidazolyl-2,4 [1H]-diketone [I]

The present invention provides the synthesis process of (3aS, 6aR)-1, 3-dibenzyl-tetrahydro-4H-furo[3, 4-d]-imidazolyl-2, 4(1H)-dione. Compound 1, 3-dibenzyl imidazolidine-2-one-2H-furo[3, 4-d]-imidazolyl-2, 4, 6-trione is made to produce enantiotropic selective ring-opening reaction with fatty alcohol and arylkyl alcohol under the catalysis of chiral amine to produce (4S, 5R)-1, 3-dibenzyl-5-alkoxycarbonyl-2-oxyimidazolidine-4-carboxylic acid, which is then reduced with borohydride and ring-closed under Lewis acid catalysis inside organic solvent to produce (3aS, 6aR)-1, 3-dibenzyl-tetrahydro-4H-furo[3, 4-d]-imidazolyl-2, 4(1H)-dione in the total yield over 88 %. The said process uses easy-to-obtain material, has mild reaction condition and is suitable for industrial production.

Owner:FUDAN UNIV

Method for easily and fast preparing rice hull-based porous carbon/silicon dioxide composite material

The invention relates to a method for easily and fast preparing a rice hull-based porous carbon / silicon dioxide composite material. The method particularly comprises the following steps of: (1) cleaning rice hulls, then crushing into power with a particle size of 20-80 meshes and preparing a phosphoric acid solution; (2) mixing the crushed rice hulls with the phosphoric acid solution; (3) treating the mixture at 400-600 DEG C for 20-90 minutes, and then cooling to obtain a crude product; (4) washing the crude product to neutral by using 40-100 DEG C water, wherein hot water used for washing every time needs to be poured out in time after the hot water is mixed with the crude product; and drying obtained filter residues to obtain the rice hull-based porous carbon / silicon dioxide composite material. The method disclosed by the invention overcomes the defects that the traditional technological operation is complex, has high requirement on raw materials and the like, and is capable of preparing the rice hull-based porous carbon / silicon dioxide composite material through a simple and fast one-step method by utilizing rice hull which is a low-cost renewable resource, thereby sufficiently utilizing the rice hulls and obtaining the material with high additional value; and the material with high additional value can be used in the fields of high-molecular addition, adsorption and separation, capacitors and the like.

Owner:JIANGNAN UNIV

Rolled tungsten-copper alloy material and preparation method thereof

InactiveCN101386948AImprove conductivityImprove thermal conductivityVolumetric Mass DensityElectronic packaging

The invention relates to a rolled tungsten-copper alloy material and a preparation method thereof, and relates to a tungsten-copper alloy material and a preparation method thereof. The invention solves the problems of poor compatibility between phases, less than 99 percent of density, high cost of manufacture equipment, complex technological process, large energy consumption and low production efficiency in the prior tungsten-copper alloy material. The rolled tungsten-copper alloy material is prepared by tungsten powder and copper powder. The preparation method comprises the following steps: firstly, preparation of mixed powder; secondly, preparation of a blank; thirdly, vacuum degassing of the blank; fourthly, preparation of an extruded tungsten-copper alloy material; and fifthly, acquisition of the rolled tungsten-copper alloy material after heating and pressurizing of the extruded tungsten-copper alloy material. The rolled tungsten-copper alloy material has good compatibility between the phases, and increases the density by 0.2 to 0.5 percent. The preparation method is simple, and has low equipment cost required, simple technology, low energy consumption and high production efficiency. The rolled tungsten-copper alloy material and the preparation method are suitable to be used in the fields of preparation, application and so on of electric spark machining electrodes, resistance welding electrodes and electronic packaging and heat sinking materials.

Owner:HARBIN INST OF TECH AT WEIHAI

Preparation method for conjugated oil, conjugated oil and application thereof

InactiveCN103074161AImprove conversion rateReduce dosageFatty acid chemical modificationFertilizer mixturesOil and greasePtru catalyst

The invention relates to the technical fields of oil deep processing and oil comprehensive utilization, and particularly discloses a preparation method for conjugated oil and application of the conjugated oil. The preparation method comprises the following steps: adding iodine into oil, reacting at the temperature of between 80 and 200DEG C for 0.5 to 5 hours under stirring in the nitrogen environment, and removing the iodine to obtain the conjugated oil. The preparation method is simple, the using amount of a catalyst is small, the conversion rate is high and solvents are not required to be added. Illegal cooking oil also can be taken as a raw material which is low in cost. The conjugated oil prepared can serve as a raw material for preparing fine chemicals, slow release fertilizers or controlled-release fertilizers.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Low molecular potassium alginate and its application

A low-molecular potassium alginate is prepared from edible seaweed, kelp, seatent, etc through extracting in hot water for 1-5 hr, separating, vacuum concentrating to obtain alginic acid, adding potassium salt to obtain potassium alginate, and degradating by enzyme. It can be used to prepare the medicines for lowering blood pressure and decreasing blood fat, blood sguar and cholesterine.

Owner:赵波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com