Silicon dioxide aerogel and preparation method thereof

A silicon dioxide and airgel technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of expensive raw materials, toxicity, complex process, etc., and achieve the effect of low price, non-toxicity, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: a total of four parallel samples

[0017] Take 50g of sodium silicate containing 25% silicon dioxide for each, add 75g of ethylene glycol aqueous solution with a concentration of 1% by weight, and prepare a sodium silicate solution with a silicon dioxide content of 10%, add 20% sulfuric acid solution 31.25g, react at 20°C for 3 hours, adjust the pH value to 2-3 with mineral acid, filter and wash with water until the sodium ion content is below 0.1%. Spray drying and crushing with a pulverizer to an average particle size of 3-5 microns; to obtain silica airgel. Its experimental data are as follows.

Embodiment 1 2

[0018] Embodiment 1 silica airgel physical and chemical properties table

[0019]

Embodiment 2

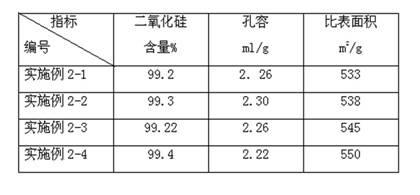

[0020] Embodiment 2: a total of four parallel samples

[0021] Take 50g of sodium silicate containing 25% silicon dioxide for each, add 33.3g of tap water containing 10% ethylene glycol, and prepare a sodium silicate solution with a silicon dioxide content of 15%, and prepare a sulfuric acid solution with a content of 5%. 125g, react at 40°C, react for 5 hours, adjust the pH value to 2-3, then filter, wash with water, spray dry and pulverize to obtain silica airgel with an average particle size of 5-10 microns. Its experimental data are as follows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com