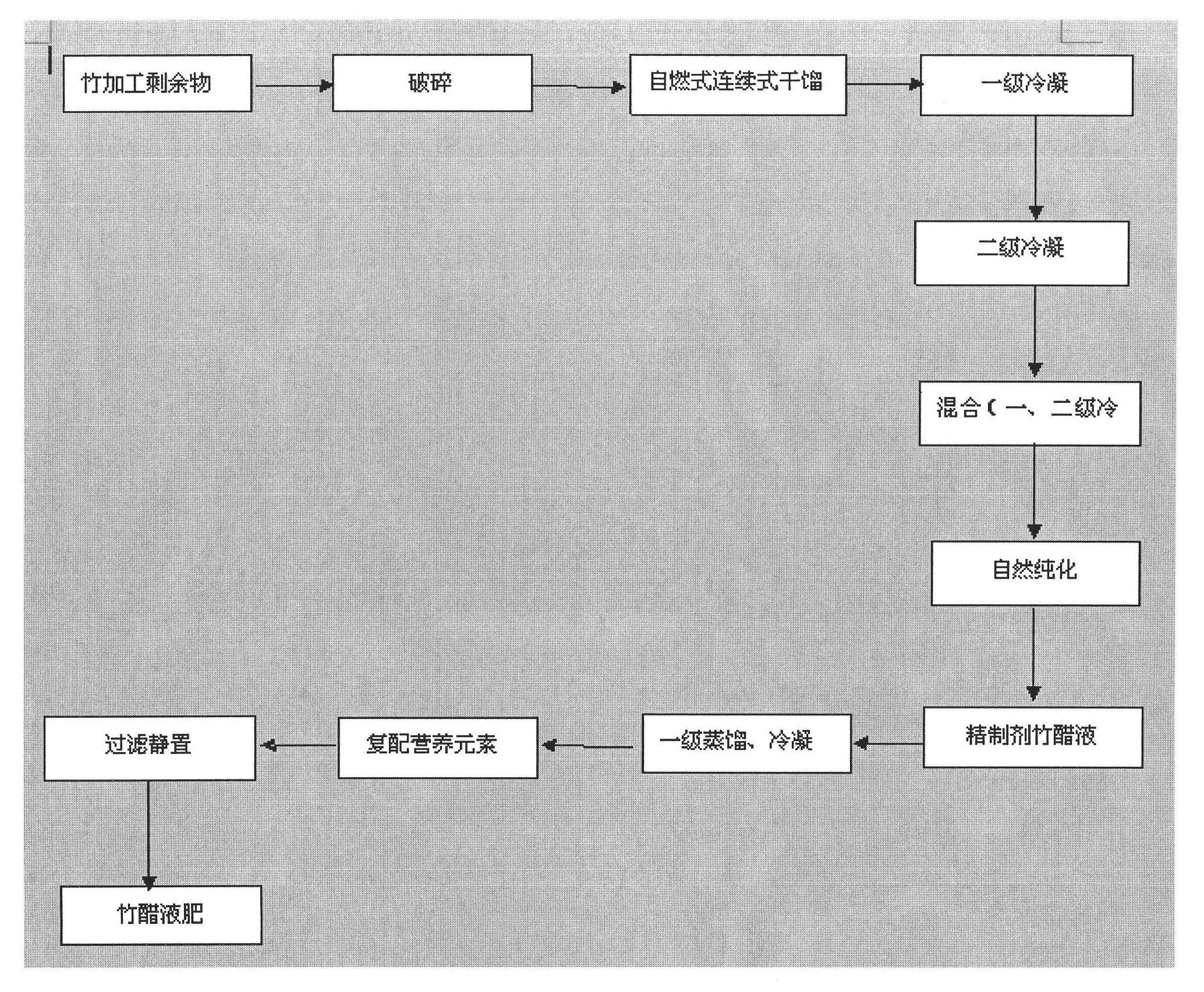

Process for preparing bamboo vinegar liquid fertilizer

A preparation process, bamboo vinegar liquid technology, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of inconsistency and no synergistic effect, and achieve the effect of fast absorption, simple and easy application method, and enhanced photosynthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] After collecting unpolluted bamboo processing residues, use disc-type bamboo shredders (extruding and cutting) to slice them. The size of the bamboo slices is 4-6cm×4-6cm, and then put them into Korean Juyu wood In the vinegar industry (2005-10 type) bamboo and wood vinegar extraction and purification equipment, the temperature is controlled in the range of 200°C-500°C, and the self-ignition continuous dry distillation is used for primary and secondary condensation, and the temperature is controlled at 80°C-120°C respectively. The bamboo vinegar liquid is obtained in the range of ℃ and the temperature is controlled in the range of 100°C-120°C to obtain the bamboo vinegar liquid, and the primary and secondary condensate are mixed in the mixing tank under normal temperature and pressure, and purified in a natural state for 180 One day, the refined bamboo vinegar solution was obtained.

[0040] Refined bamboo vinegar → one-stage distillation, condensation (distill the bamb...

Embodiment 2

[0043] After collecting unpolluted bamboo processing residues, use disc-type bamboo shredders (extruding and cutting) to slice them. The size of the bamboo slices is 4-6cm×4-6cm, and then put them into Korean Juyu wood In the vinegar industry (2005-10 type) bamboo and wood vinegar extraction and purification equipment, the temperature is controlled in the range of 200°C-500°C, and the self-ignition continuous dry distillation is used for primary and secondary condensation, and the temperature is controlled at 80°C-120°C respectively. The bamboo vinegar liquid is obtained in the range of ℃ and the temperature is controlled in the range of 100°C-120°C to obtain the bamboo vinegar liquid, and the primary and secondary condensate are mixed in the mixing tank under normal temperature and pressure, and purified in a natural state for 180 One day, the refined bamboo vinegar solution was obtained.

[0044] Refined bamboo vinegar → one-stage distillation, condensation (distill the bamb...

Embodiment 3

[0047] After collecting unpolluted bamboo processing residues, use disc-type bamboo shredders (extruding and cutting) to slice them. The size of the bamboo slices is 4-6cm×4-6cm, and then put them into Korean Juyu wood In the vinegar industry (2005-10 type) bamboo and wood vinegar extraction and purification equipment, the temperature is controlled in the range of 200°C-500°C, and the self-ignition continuous dry distillation is used for primary and secondary condensation, and the temperature is controlled at 80°C-120°C respectively. The bamboo vinegar liquid is obtained in the range of ℃ and the temperature is controlled in the range of 100°C-120°C to obtain the bamboo vinegar liquid, and the primary and secondary condensate are mixed in the mixing tank under normal temperature and pressure, and purified in a natural state for 180 One day, the refined bamboo vinegar solution was obtained.

[0048] Refined bamboo vinegar → one-stage distillation, condensation (distill the bamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com