Composite flocculating agent for processing radioactive elements iron, cobalt, manganese and silver in nuclear waste water and processing method

A technology of radioactive elements and composite flocculants, which is applied in the direction of radioactive purification, radioactive pollutants, chemical instruments and methods, etc., can solve the problems of long reaction time, operating cost, and large secondary pollution, and achieve rapid and effective removal, cheap raw material sources, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method for treating radioactive elements iron, cobalt, manganese and silver in nuclear power wastewater, the content of main nuclides in the wastewater to be treated is shown in Table 1.

[0038] Table 1 The average concentration levels of major nuclides in wastewater from a nuclear power plant

[0039] Major nuclides

Concentration (in ppt)

silver

7.74×10 -5

4.78×10 -4

iron

3.95×10 -4

1.52×10 -4

1.13×10 -4

8.54×10 -4

[0040] Its processing steps are:

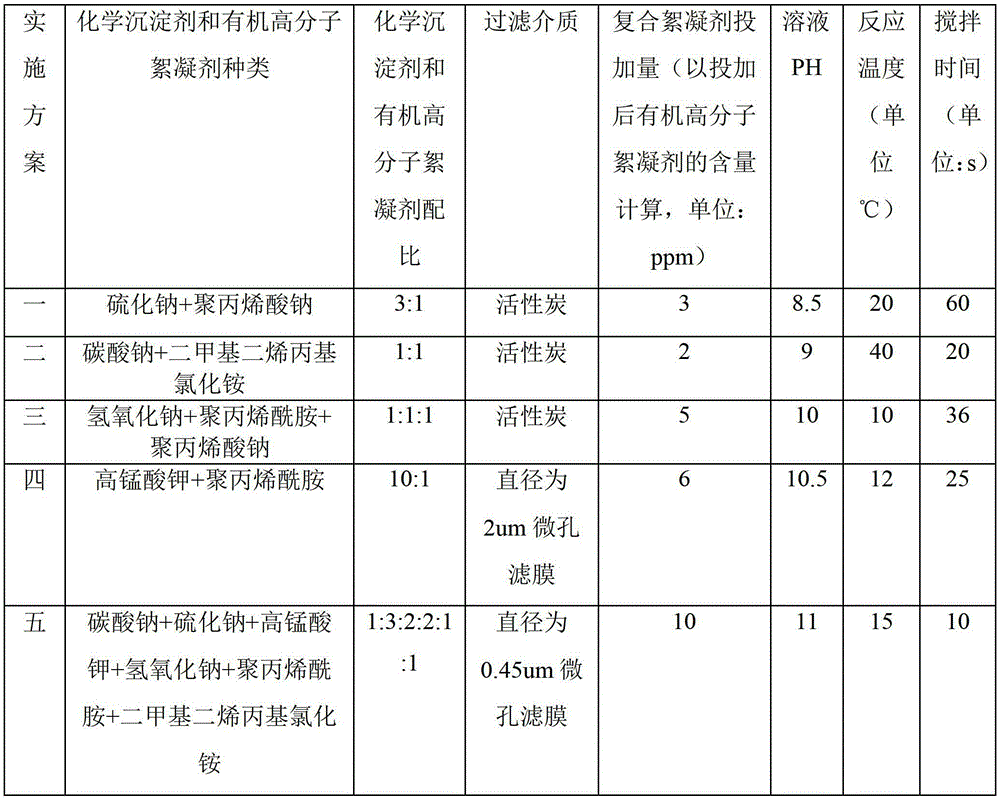

[0041] A) Use chemical precipitant and organic polymer flocculant to configure composite flocculant, chemical precipitant is one of potassium permanganate, sodium sulfide, sodium carbonate and sodium hydroxide or a combination of any of them; organic polymer The flocculant is polyacrylamide (PAM) and / or sodium polyacrylate and / or dimethyl diallyl ammonium chloride (DADMAC); the weight ratio of ch...

Embodiment 2

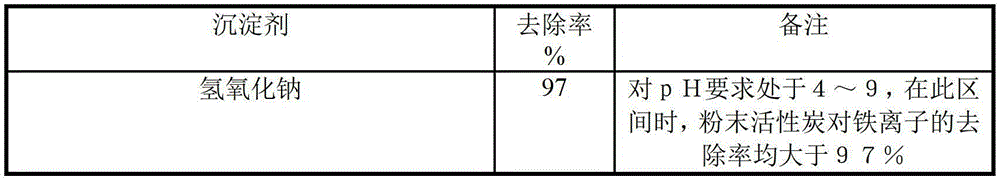

[0052] Different precipitants will have different effects. The removal effect of the present invention to iron ions is shown in Table 3. The removal effects of different precipitants of the present invention on manganese ions are shown in Table 4. The removal effects of different precipitants of the present invention on silver ions are shown in Table 5. The removal effects of different precipitants of the present invention on cobalt ions are shown in Table 6.

[0053] Table 3 The present invention is to the removal effect of iron ion

[0054]

[0055] Table 4 The present invention is to the removal effect of manganese ion

[0056]

[0057] Table 5 The present invention is to the removal effect of silver ion

[0058]

[0059] Table 6 The present invention is to the removal effect of cobalt ion

[0060]

Embodiment 3

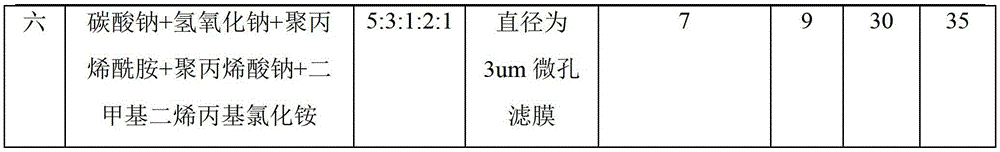

[0062] When the present invention is actually used, different combinations of precipitating agents can produce different effects, and the corresponding effects of the parameters are shown in Figures 7, 8, 9, 10 and 11.

[0063] Table 7 The present invention is to the removal effect of iron ion

[0064]

[0065] Table 8 The present invention is to the removal effect of manganese ion

[0066]

[0067]

[0068] Table 9 The present invention is to the removal effect of silver ion

[0069]

[0070] Table 10 The present invention is to the removal effect of cobalt ion

[0071]

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com