Technology for producing coal-series needle coke by taking middle-temperature and low-temperature coal tar asphalt as raw material

A low-temperature coal tar, needle coke technology, applied in the processing of tar pitch/petroleum pitch/natural pitch, tar processing by distillation, chemical processing of tar pitch/petroleum pitch/natural pitch, etc. The quality of coke products needs to be improved, the performance and quality of needle coke products are affected, and the pretreatment burden and difficulty are difficult to achieve the effect of narrow molecular weight distribution, excellent performance and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

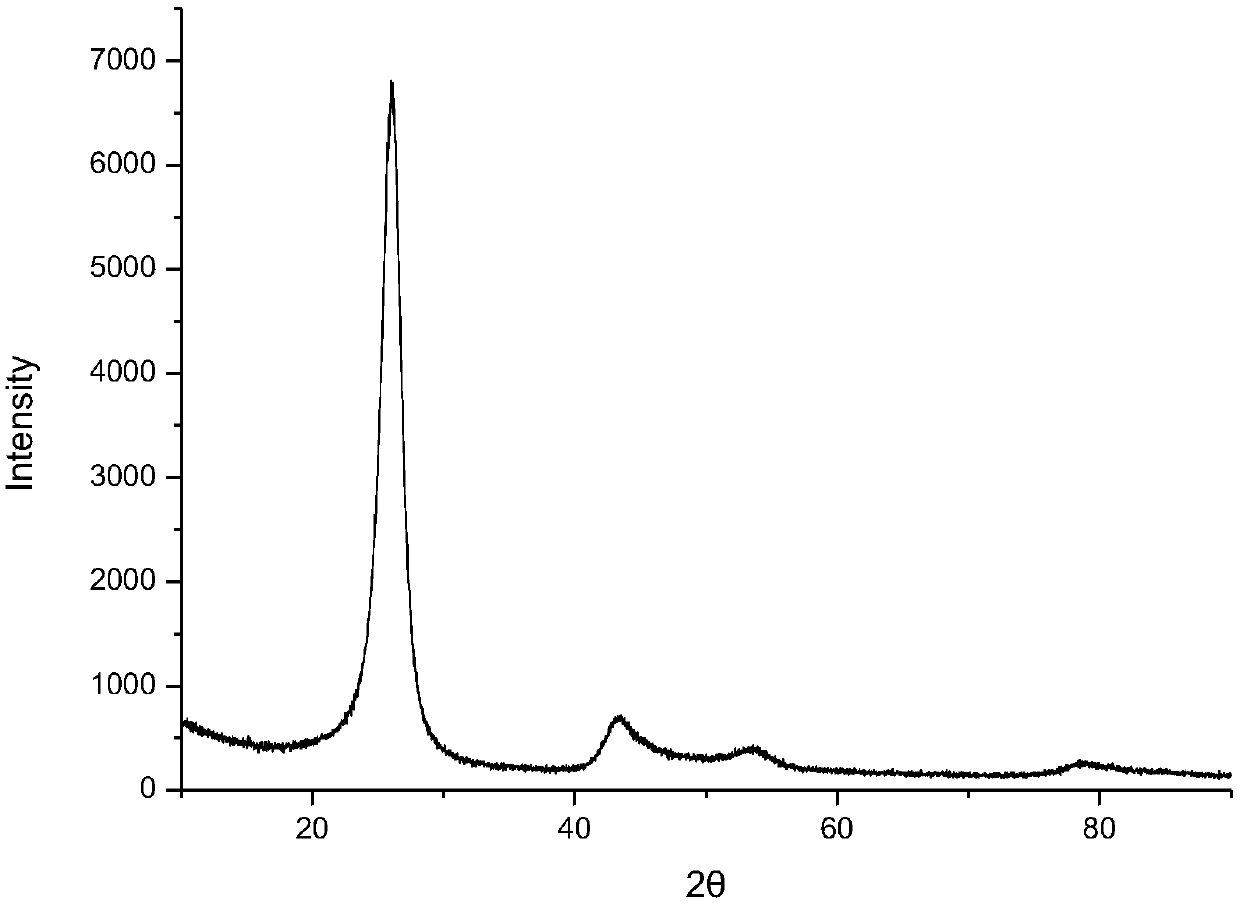

Image

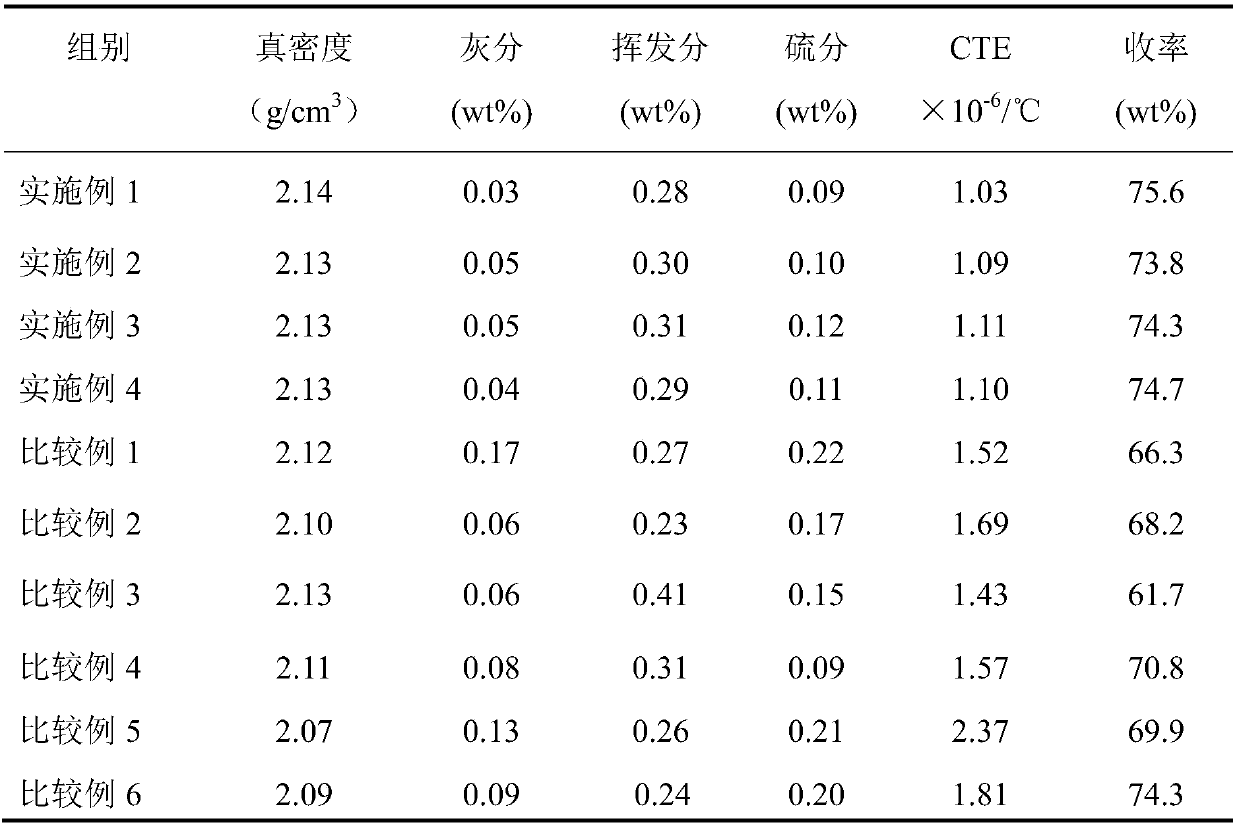

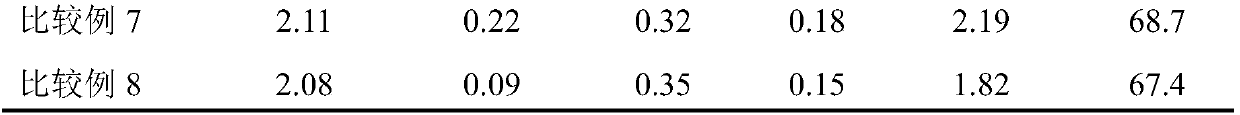

Examples

Embodiment 1

[0035] The above-mentioned non-metallic homogeneous mild hydrogenation catalyst is used in the process of producing coal-based needle coke with medium and low temperature coal tar pitch as raw material. The specific process steps are:

[0036] (1) Put 1 kg of medium-low temperature coal tar in a 2L high-temperature and high-pressure reaction kettle, and cut it through vacuum distillation to obtain 486.4 g of medium-low temperature coal tar pitch with a fraction of 350°C to 450°C.

[0037] (2) 700g of toluene and 300g of n-heptane are mixed and prepared as an extractant, and the medium and low temperature coal tar pitch fraction of step (1) is extracted for 12 hours at 85°C to remove the quinoline contained in the medium and low temperature coal tar pitch Insoluble matter, the content of quinoline insoluble matter (QI) was 0.084wt%.

[0038] (3) The medium and low temperature coal tar pitch after the extraction treatment is sent into the reactor, and then 30g of the above-menti...

Embodiment 2

[0044] The above-mentioned non-metallic homogeneous mild hydrogenation catalyst is used in the process of producing coal-based needle coke with medium and low temperature coal tar pitch as raw material. The specific process steps are:

[0045] (1) Put 1 kg of medium-low temperature coal tar in a 2L high-temperature and high-pressure reaction kettle, and cut it through vacuum distillation to obtain 479.8 g of medium-low temperature coal tar pitch of 350°C-450°C fraction.

[0046] (2) 600g of toluene and 400g of n-heptane are mixed and prepared as an extractant, and the medium and low temperature coal tar pitch fraction of step (1) is extracted for 12 hours at 70°C to remove the quinoline contained in the medium and low temperature coal tar pitch Insoluble matter, the content of quinoline insoluble matter (QI) is 0.097wt%.

[0047] (3) The medium and low temperature coal tar pitch after the extraction treatment is sent into the reactor, and then 15g of the above-mentioned non-me...

Embodiment 3

[0052] The above-mentioned non-metallic homogeneous mild hydrogenation catalyst is used in the process of producing coal-based needle coke with medium and low temperature coal tar pitch as raw material. The specific process steps are:

[0053] (1) Put 1 kg of medium-low temperature coal tar in a 2L high-temperature and high-pressure reaction kettle, and cut it through vacuum distillation to obtain 482.3 g of medium-low temperature coal tar pitch of 350°C-450°C fraction.

[0054] (2) 500g xylene and 500g hexanaphthene are mixed and prepared as an extractant, and the medium and low temperature coal tar pitch fraction of step (1) is extracted for 15 hours at 65°C to remove the quinone contained in the medium and low temperature coal tar pitch Phenyl insolubles, so that quinoline insolubles (QI) content is 0.093wt%.

[0055] (3) The medium and low temperature coal tar pitch after the extraction treatment is sent into the reactor, and then 20g of the above-mentioned non-metallic ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com