Aerial high-voltage live cable insulation sheath stripping machine

A technology of cable insulation and high-voltage electrification, which is applied in the direction of dismantling/armoring cable equipment, etc., can solve the problems of low work efficiency, and achieve the effect of convenient operation, simple structure and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

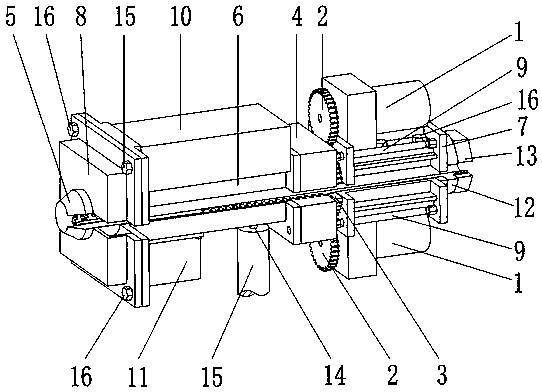

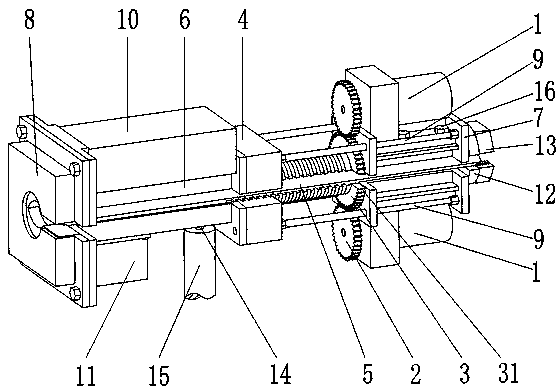

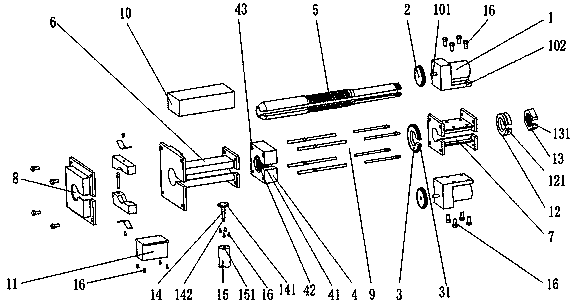

[0032] see Figure 1 to Figure 13 As shown, this embodiment is composed of two micro-motors 1, two gears 2, a C-shaped gear 3, a C-shaped transmission nut 4, a C-shaped rotating assembly 5, a C-shaped first sleeve 6, and a C-shaped second sleeve. Barrel 7, clamping device 8, four telescopic components 9, rechargeable battery 10, control device 11, C-type thrust bearing 12, C-type connecting nut 13, connector 14, insulating rod 15, several first bolts 16 and remote control device composition,

[0033] The micro-motor 1 is provided with an output shaft 101 and a bottom plate 102 with four bolt holes, the C-row gear 3 is provided with an axial groove 31, and the C-shaped transmission nut 4 is provided with an axial groove 41 and four bolt holes 42;

[0034] The C-shaped rotating assembly 5 is composed of a milling assembly 51 and a C-shaped rotating member 52. The milling assembly 51 is composed of two multi-edged milling cutters 511, a first knife rest 512, a second knife rest ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com