Patents

Literature

81results about How to "Fast peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

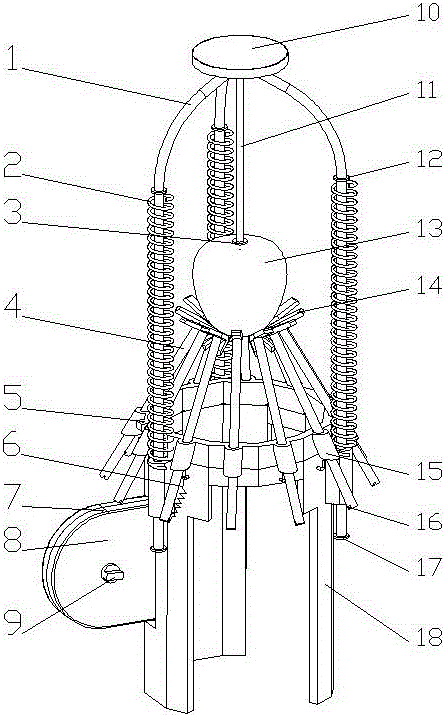

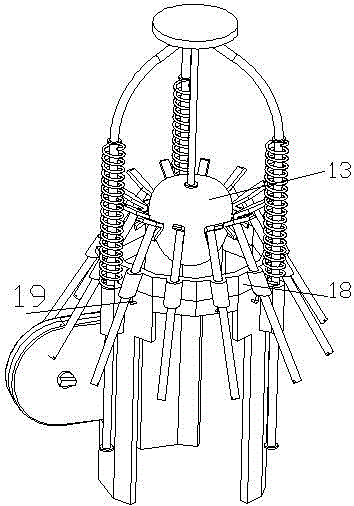

Aerial high-voltage live cable insulation sheath stripping machine

InactiveCN104184077AFast peelingGood qualityApparatus for removing/armouring cablesMicro motorEngineering

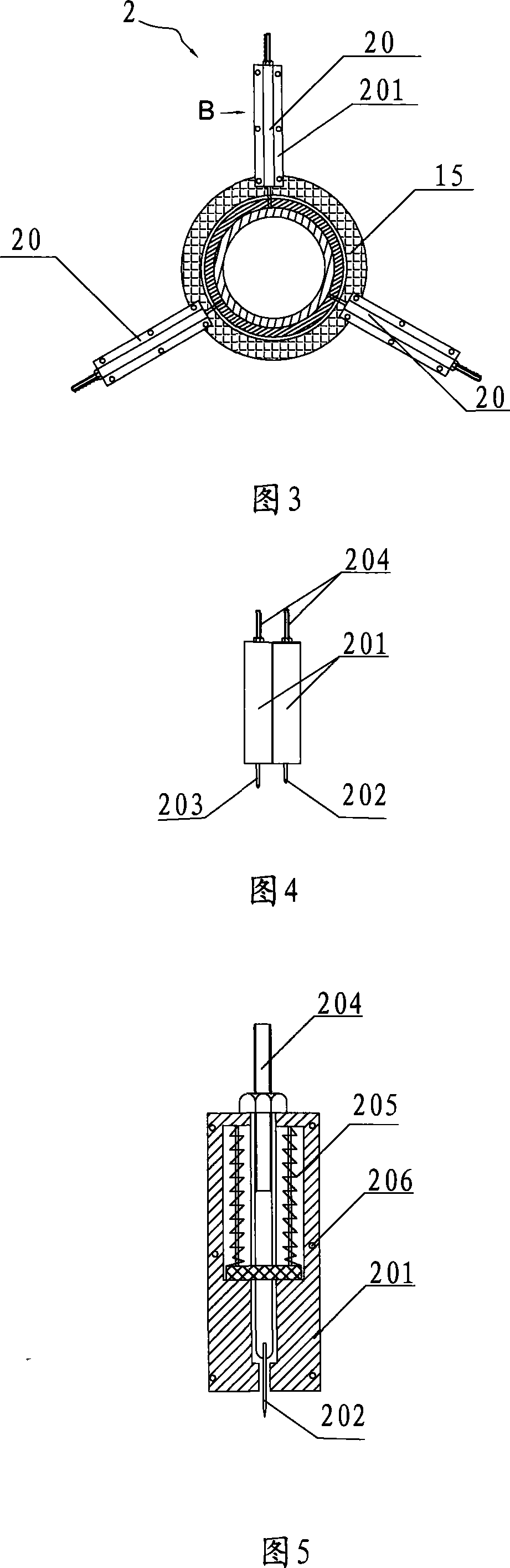

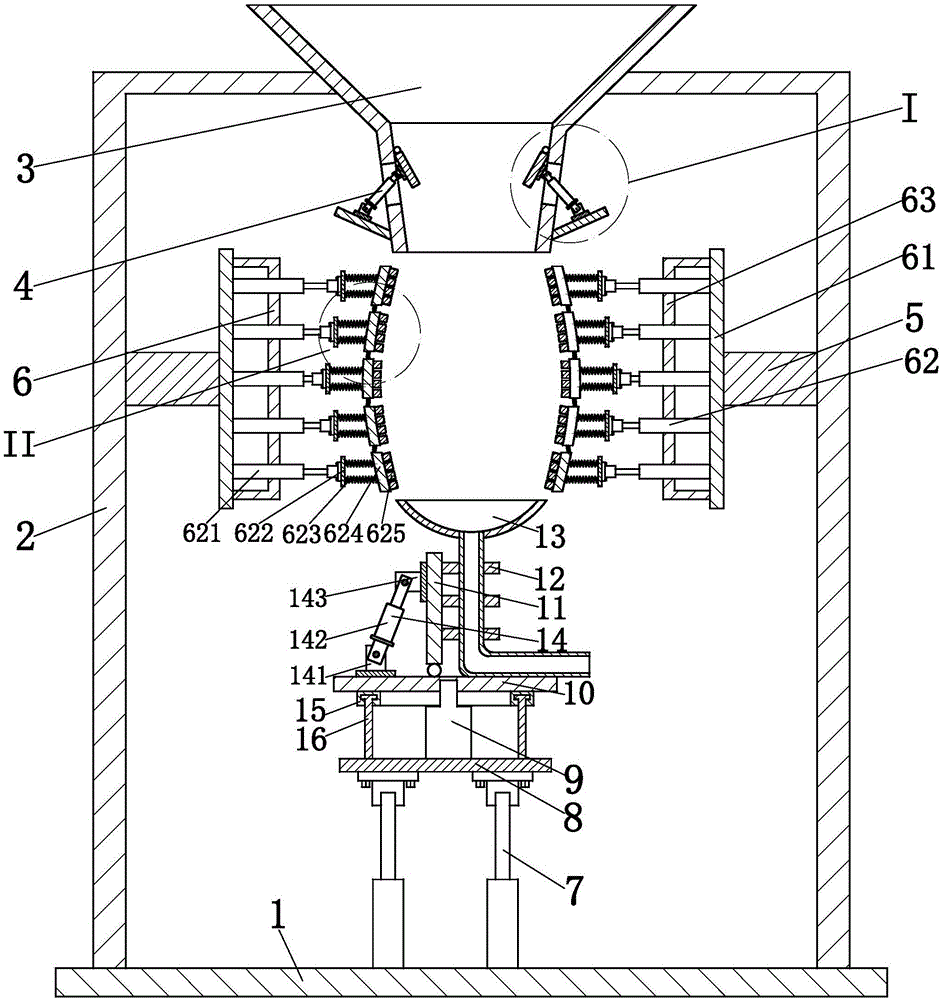

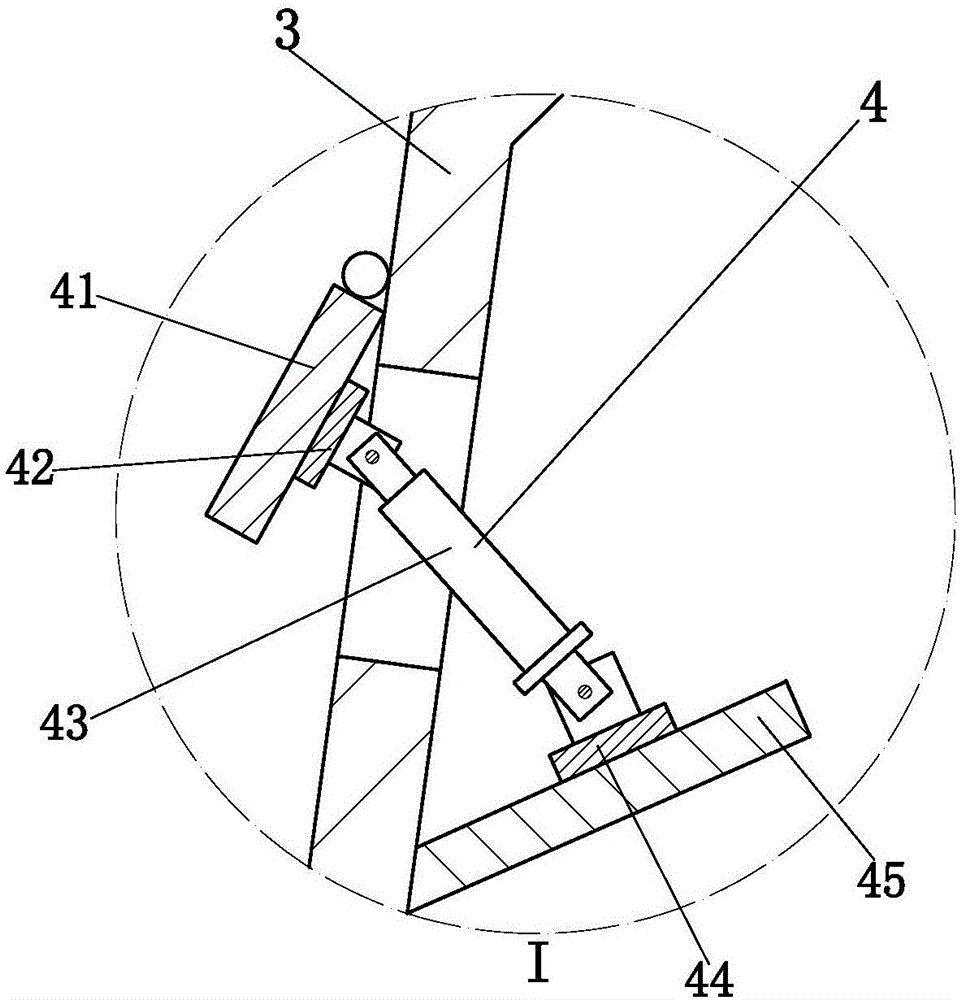

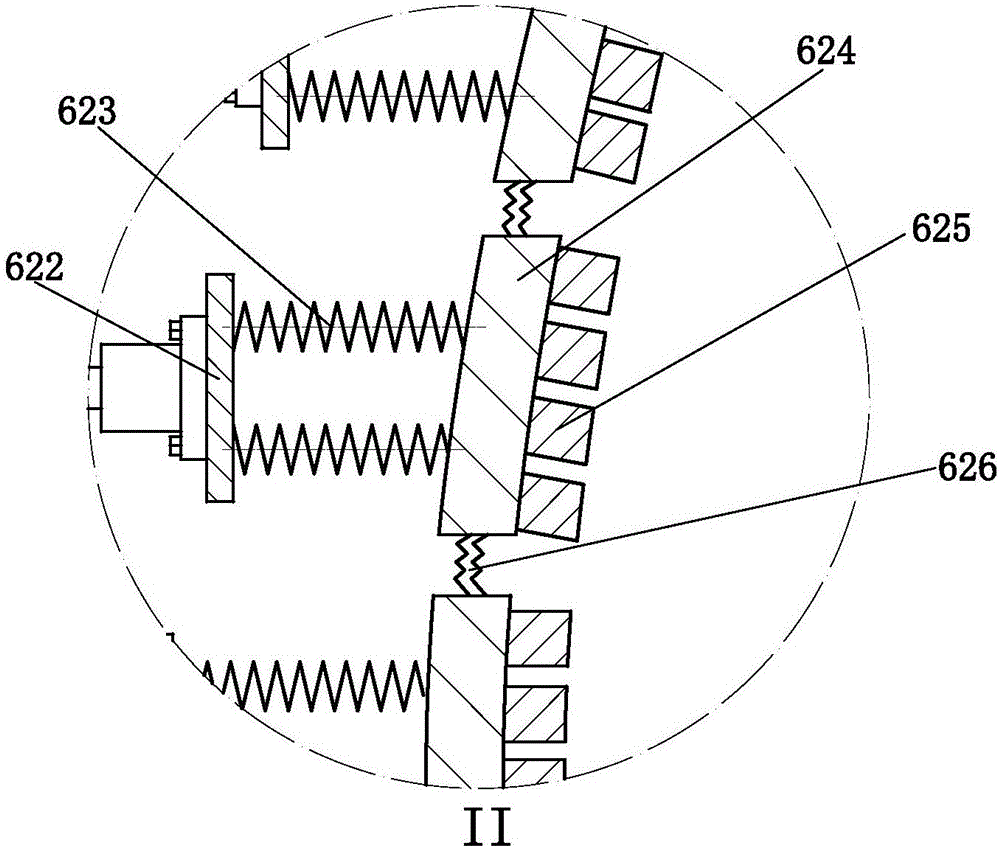

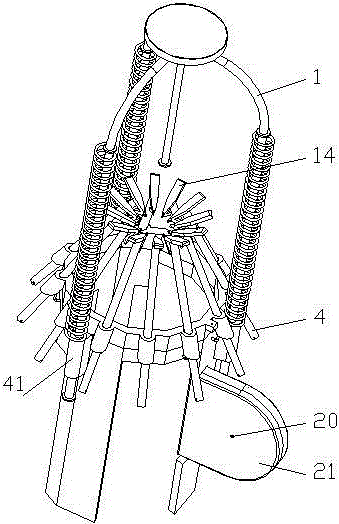

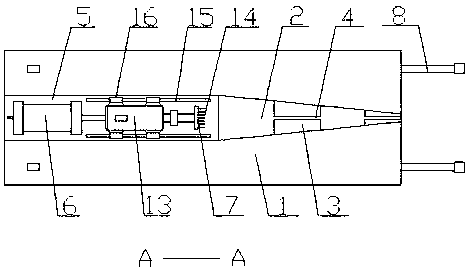

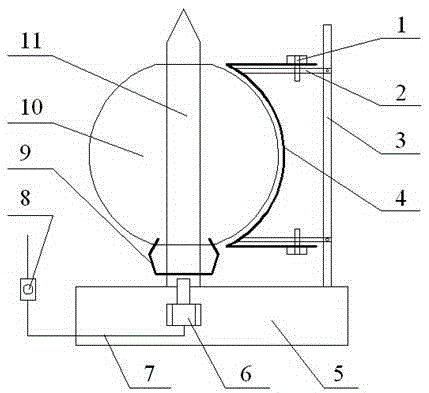

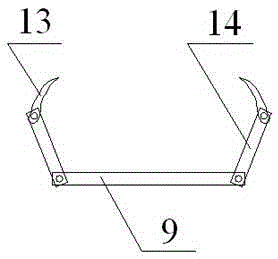

The invention discloses an aerial high-voltage live cable insulation sheath stripping machine. The aerial high-voltage live cable insulation sheath stripping machine is composed of two micro motors, two gears, a C-shaped gear, a C-shaped transmission nut, a C-shaped rotating assembly, a first C-shaped sleeve, a second C-shaped sleeve, a clamping device, four telescopic assemblies, a rechargeable battery, a control device, a C-shaped thrust bearing, a C-shaped connecting nut, a connecting piece, an insulation rod, multiple first bolts and a remote controller. According to the aerial high-voltage live cable insulation sheath stripping machine, the two driving gears are adopted to be meshed with the C-shaped incomplete gear, so that continuous uniform rotation of the C-shaped rotating assembly which is fixedly connected with the C-shaped incomplete gear is achieved; two moving tool rests of the aerial high-voltage live cable insulation sheath stripping machine maintain a symmetric structure all the time under the effect of a V-shaped steel leaf spring, so that two multi-blade milling tools fixedly connected to the two moving tool rests achieve synchronous milling on an insulation sheath, the stripping speed is high, and the stripping quality is good; the aerial high-voltage live cable insulation sheath stripping machine is simple in structure, convenient to operate and applicable to earth potential operation by the adoption of the insulation rod, and air humidity and other weather conditions have little impact on operation.

Owner:KUNMING UNIV

Quick skinning method for Acaudina molpadioides Semper

ActiveCN103027321AFast peelingGuaranteed nutritionFood preparationAdditive ingredientAquatic product

The invention relates to an aquatic product processing method, in particular to a quick skinning method for Acaudina molpadioides Semper. The invention discloses the quick skinning method for the Acaudina molpadioides Semper. The method comprises the following steps of: setting the shape of a fresh Acaudina molpadioides Semper, mechanically grinding skin, cleaning and removing stain, skinning in an enzymolysis way, cleaning and removing stain, repeatedly carrying out enzymolysis and the like. When the skin is mechanically ground, more than a half of the silt-containing skin of the Acaudina molpadioides Semper can be removed, and the skin of the Acaudina molpadioides Semper can be completely removed within a short time by means of skinning in an enzymolysis way, so that the Acaudina molpadioides Semper body can be changed to be clean and translucent, an edible part of a wall of the inner layer body of the Acaudina molpadioides Semper can not be influenced, and the nutritional ingredients of the Acaudina molpadioides Semper can be furthest remained. The skin of an Acaudina molpadioides Semper product prepared by means of cleaning and packing is free from silt, and the heavy metal content reaches the standard, so that the Acaudina molpadioides Semper product can be used for dipping and processing or can be used as the raw material for deep processing.

Owner:WENZHOU VOCATIONAL COLLEGE OF SCI & TECH

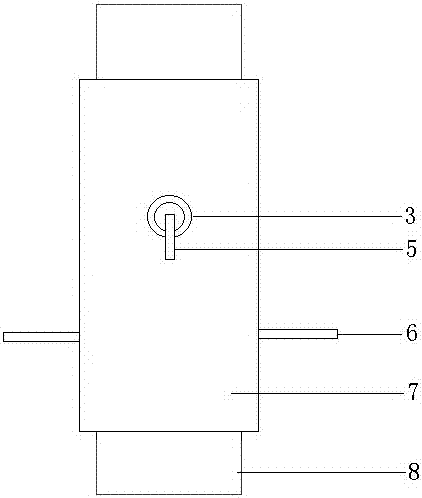

A cable peeling device

ActiveCN101188153APlay a fixed roleAvoid offsetBasic electric elementsApparatus for removing/armouring cablesKnife bladesElectrical and Electronics engineering

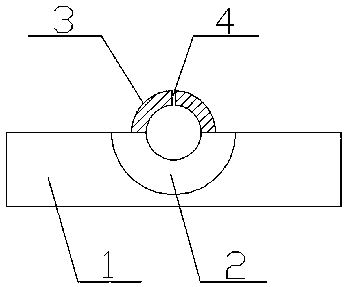

The invention relates to a cable flaying device, which comprises a fixing device and a flaying knife, wherein, the flaying knife is arranged on the fixing device; the fixing device comprises a fixing seat, and the upper part of the fixing seat is provided with a cable hole. The flaying knife comprises a plurality of cutting parts; each cutting part comprises at least a knife blade, and the knife edge of the knife blade is arranged toward the center of the cable hole. The speed of processing cables of the cable flaying device is fast, and the security is good.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

Potato full-automatic annular peeling device

ActiveCN106579478ASolution rangeAddress operational complexityVegetable peelingEngineeringLarge applications

Owner:凤阳小果食品加工有限公司

Equipment for rapid processing of dried persimmons based on rotation removal principle

InactiveCN108056482AEasy peeling workGuaranteed tasteVegetable peelingFood treatmentRapid processingEngineering

The invention provides equipment for rapid processing of dried persimmons based on a rotation removal principle. The equipment comprises a base plate, a first bearing is embedded in the middle of theupper side of the base plate, and a first rotating rod is fixedly connected to an inner ring of the first bearing and provided with a rotating device; a first extrusion rubber pad is fixedly connectedto the top of the first rotating rod, and a fruit peel bearing device is also fixedly connected to the side wall of the first rotating rod; two up-down moving devices are symmetrically and fixedly connected to the two ends of the base plate. The equipment has the advantages that the up-down moving devices drive a supporting plate to descend, the supporting plate drives a second rotating rod to descend, a positioning body arranged at the bottom of the second rotating rod penetrates into a persimmon, and then the first extrusion rubber pad and a second extrusion rubber pad are used for extruding the persimmon so that a driving device can drive the persimmon to rotate through the first rotating rod to provide convenience for peeling work.

Owner:徐中春

Processing method for green-bark salix integra woven artware

InactiveCN106182246AAvoid damageImprove toughnessWood treatment detailsCane mechanical workingCuticleLacquer

The invention discloses a processing method for green-bark salix integra woven artware. The processing method comprises the steps of material selecting, preliminary sterilizing and softening, bark peeling, secondary softening, setting, mould preventing and softening treatment, weaving and paint brushing. Compared with the prior art, the processing method for the green-bark salix integra woven artware has the following advantages that green-bark salix integra meeting specification requirements is selected and treated with treating fluid A, the effects of softening, preliminary sterilizing and surface bulking are achieved, peeling is accelerated, and damage to the salix integra by machines during peeling is reduced; the salix integra is softened again with hot steam, and then the bent salix integra is pressed to be straight, so that uniform weaving is facilitated; the salix integra is treated with treating fluid B, the tenacity of the green-bark salix integra can be improved, and the antisepsis function and the mould preventing function of the green-bark salix integra are enhanced; and after weaving and setting are completed, a product is brushed with finish paint. The finish paint has excellent pollution resistance, a film can be fast formed on the surface of the product, the finish paint is free of aftertack after being dried, sun cracking and warping do not occur after long-term use of the finish paint, and the surface of the product is maintained bright and attractive.

Owner:阜南佳利工艺品股份有限公司

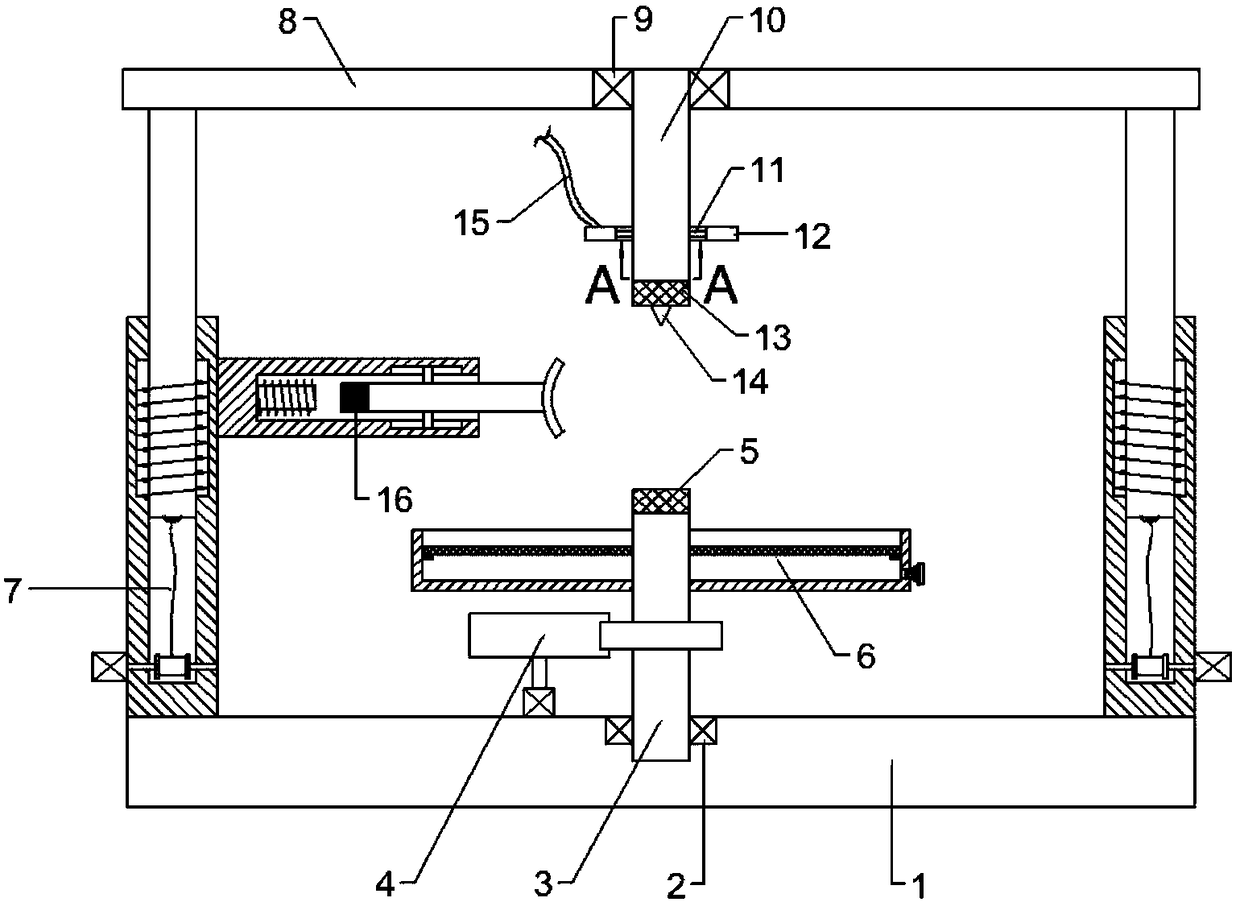

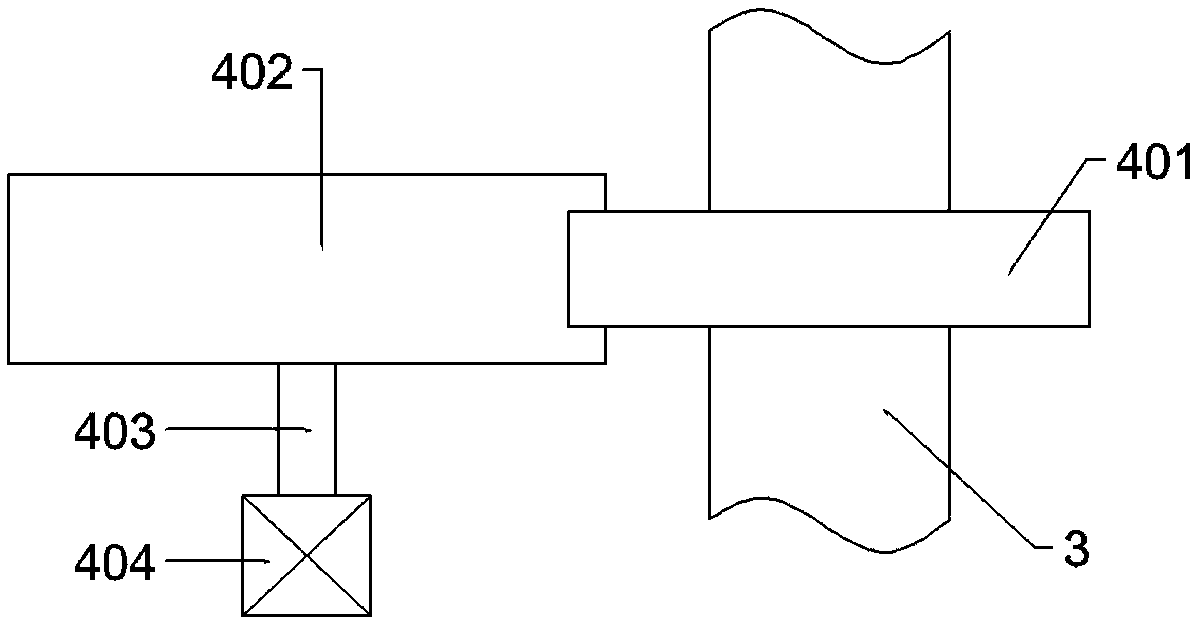

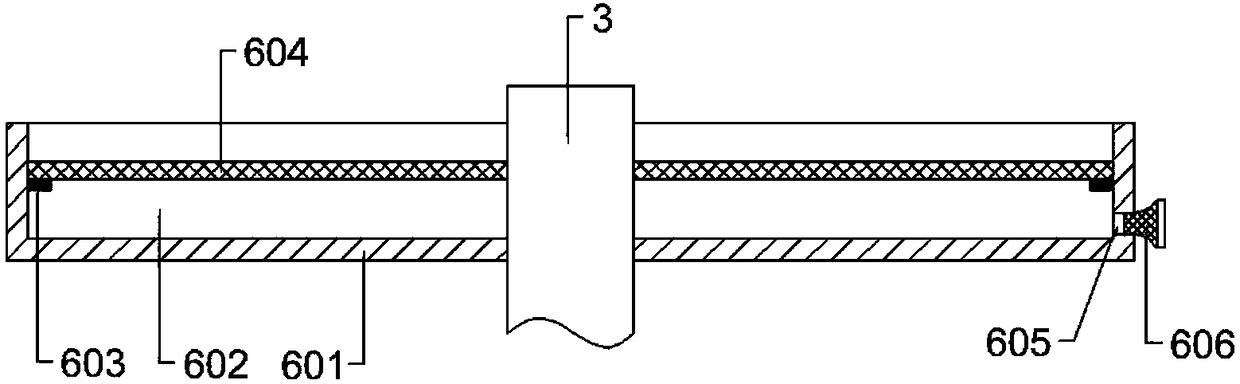

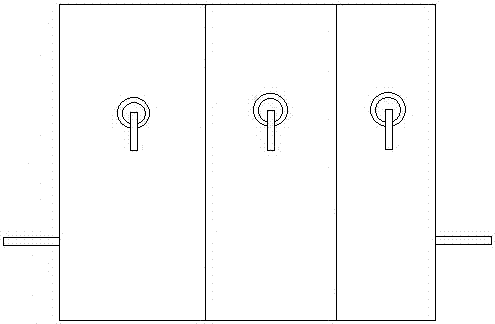

Cable fast peeling device for electronic communication

InactiveCN106340832AFast peelingThoroughly peeledApparatus for removing/armouring cablesElectronic communicationMaterial resources

The invention relates to a cable fast peeling device, and particularly relates to a cable fast peeling device for electronic communication. The technical problem to be solved is to provide a cable fast peeling device for electronic communication, and the device has the advantages of fast peeling speed, thorough peeling and a simple peeling process. In order to provide the cable fast peeling device for electronic communication, the device comprises a box body, an electric push rod I, a guide sleeve I, an electric push rod II, a peeling device, a collection groove, a baffle plate, a rotation shaft, a motor, a sliding rail, a spring I, a slide block, a pull wire, and an electric reel. The middle of the left wall of the box body is provided with a straight hole. The electric push rod I is arranged under the left wall in the box body. The upper end of the electric rod I is connected to the guide sleeve I. The bottom in the box body is provided with the collection groove and the slide rail which is at the left side of the collection groove. The slide rail is provided with the slide block. According to the device, the effects of the fast peeling speed, thorough peeling, and the simple peeling process are achieved, and a lot of manpower and material resources are saved.

Owner:湖北喵喵智能物联网科技有限公司

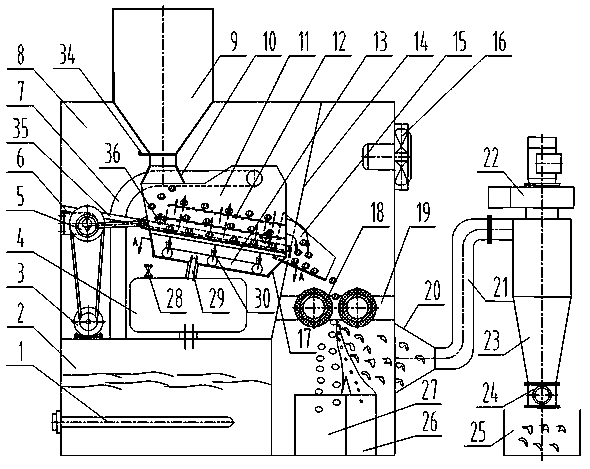

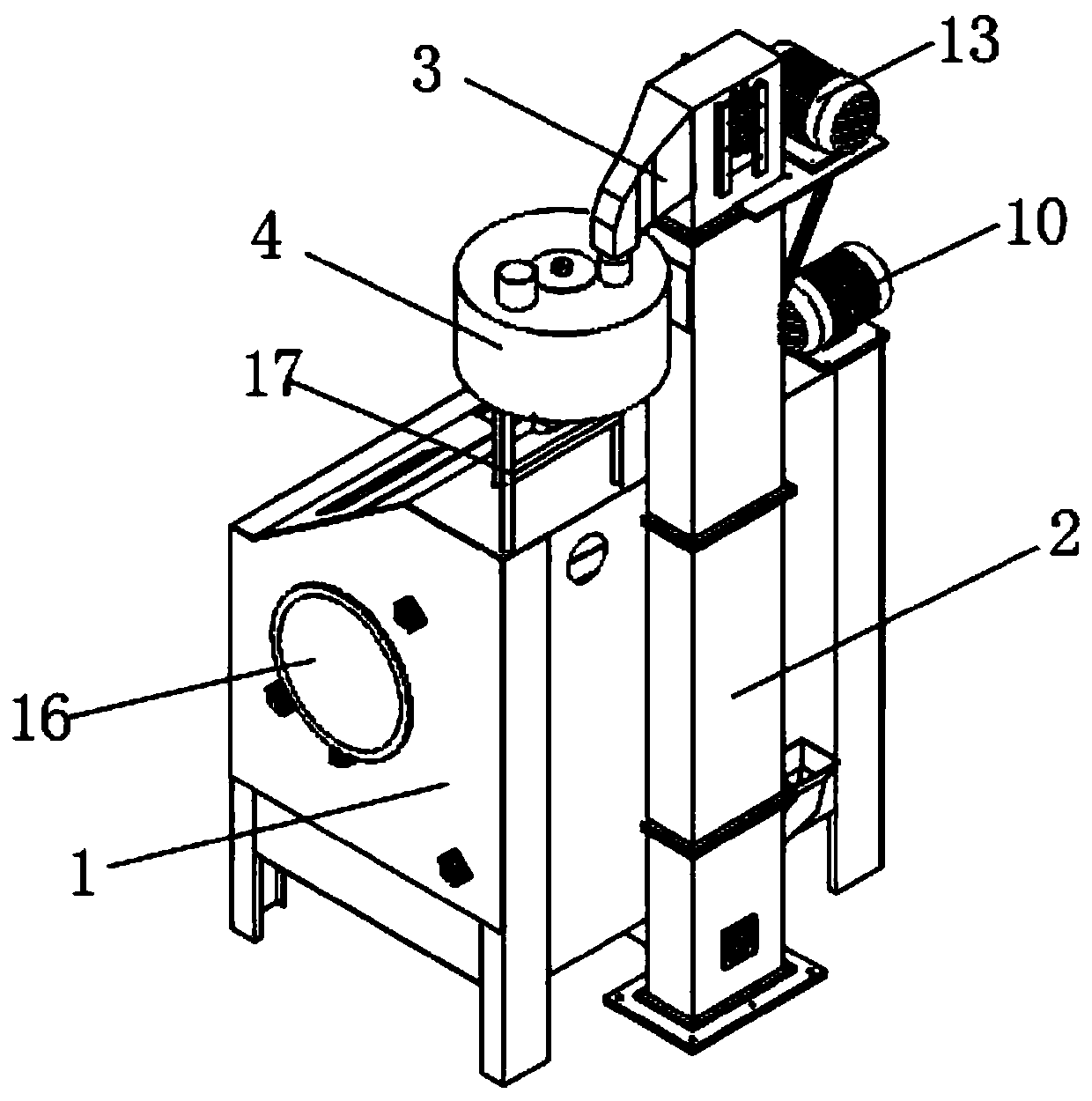

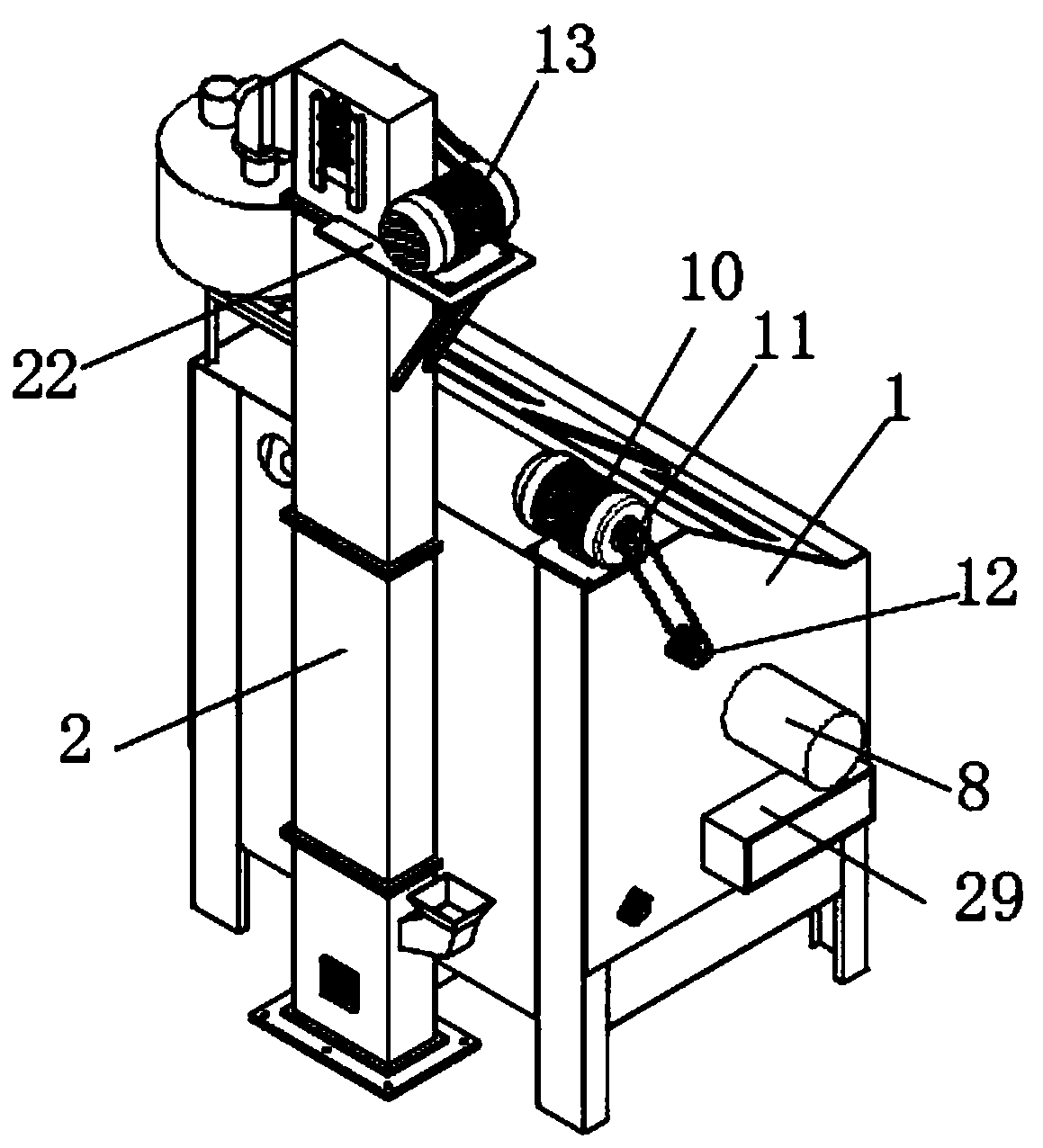

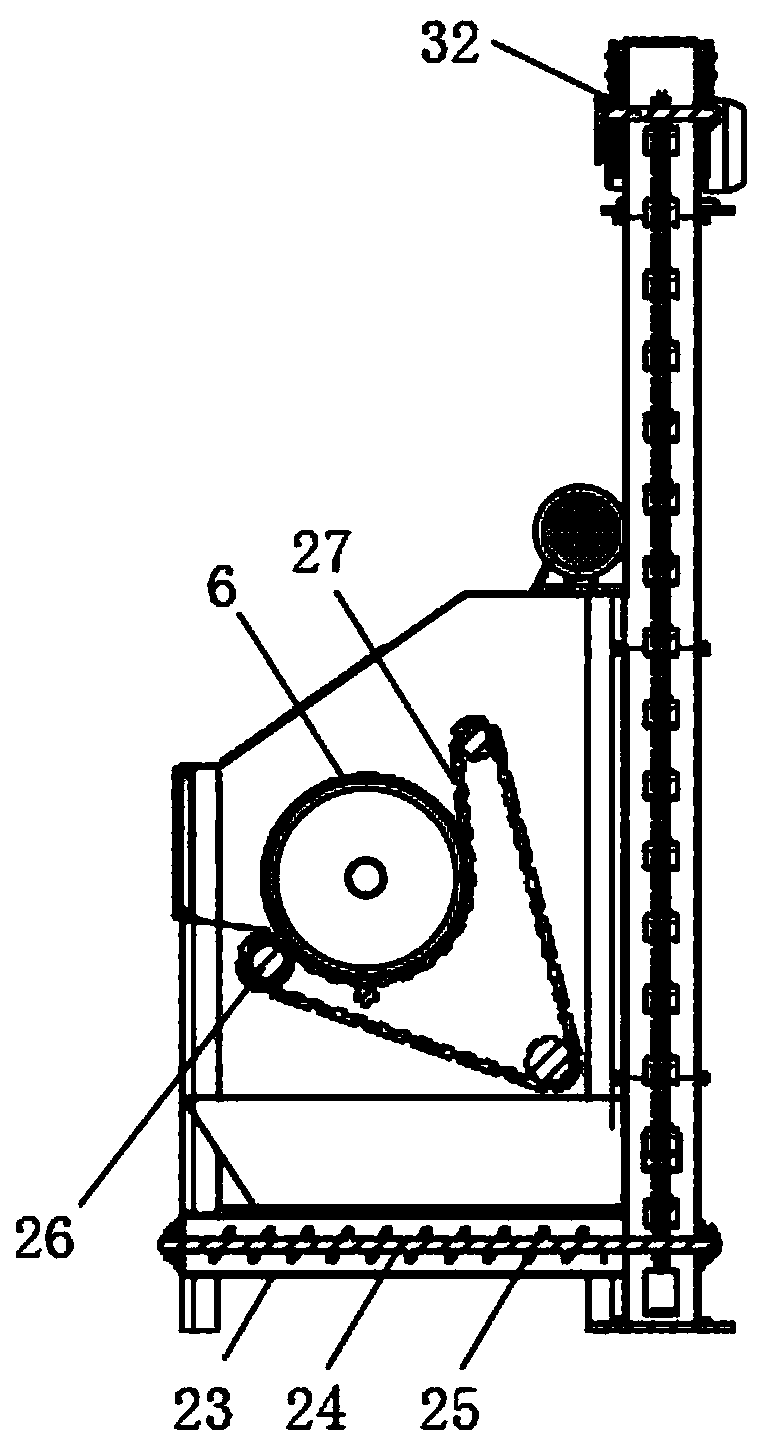

Irregular fruit fast peeling machine

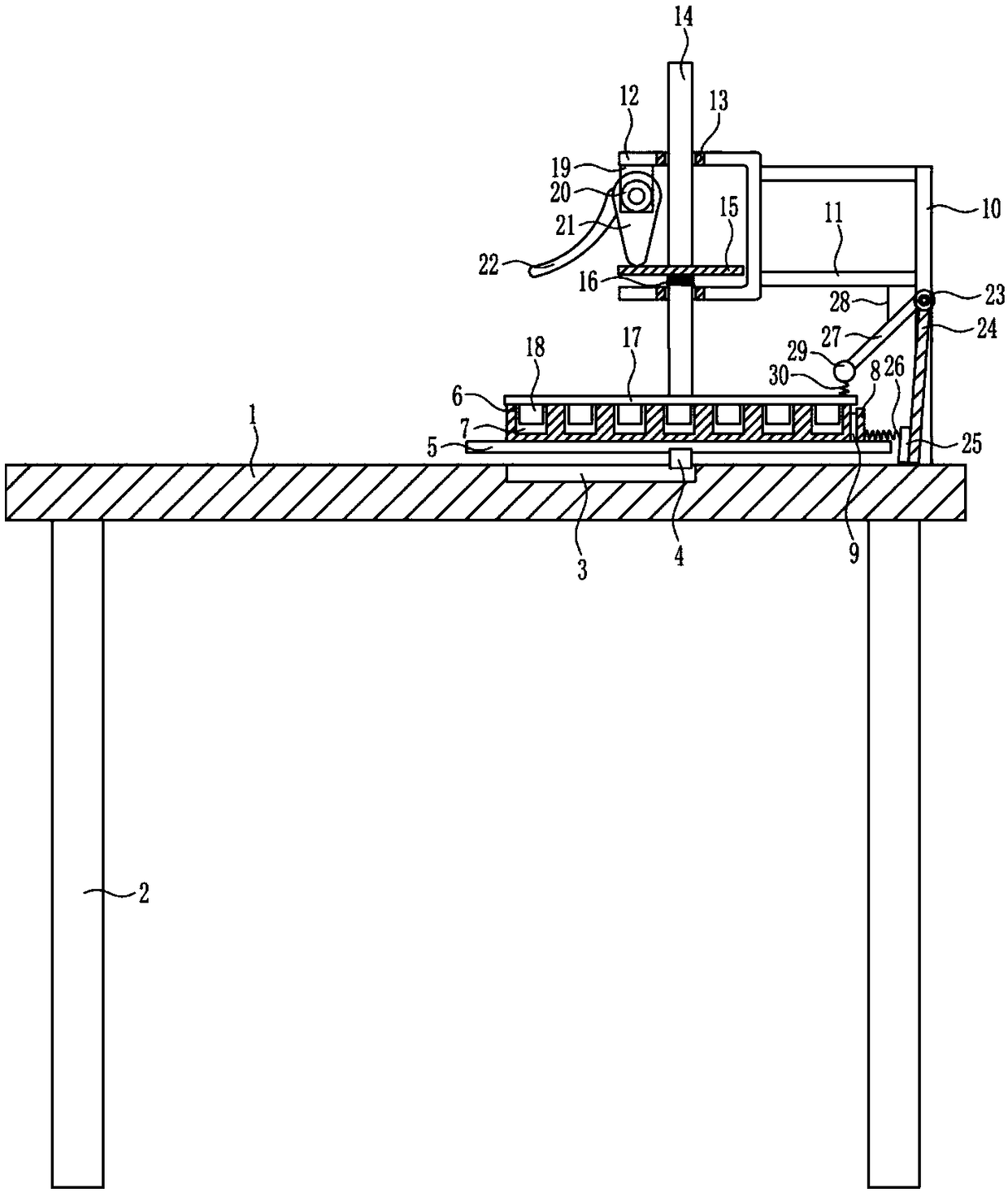

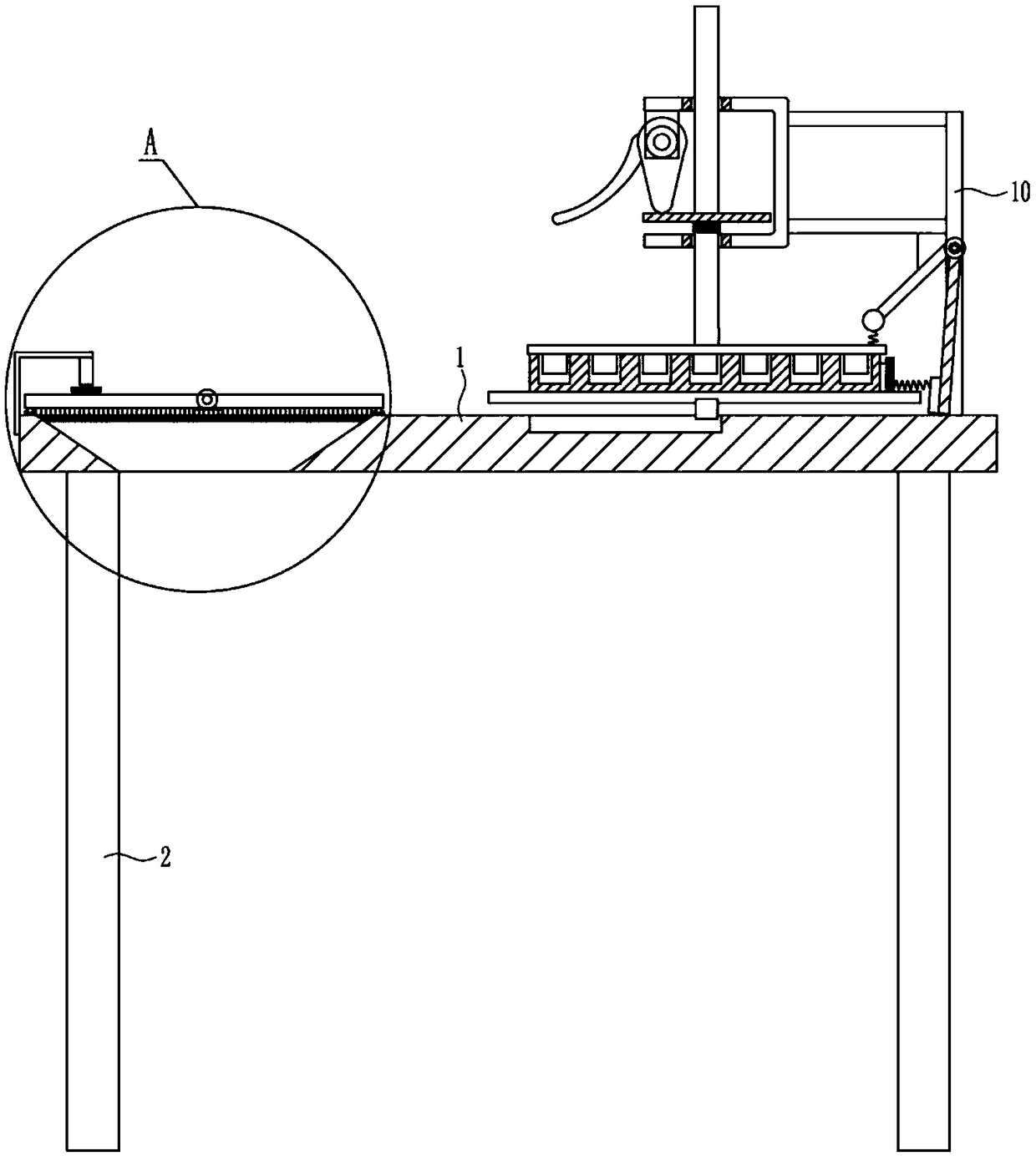

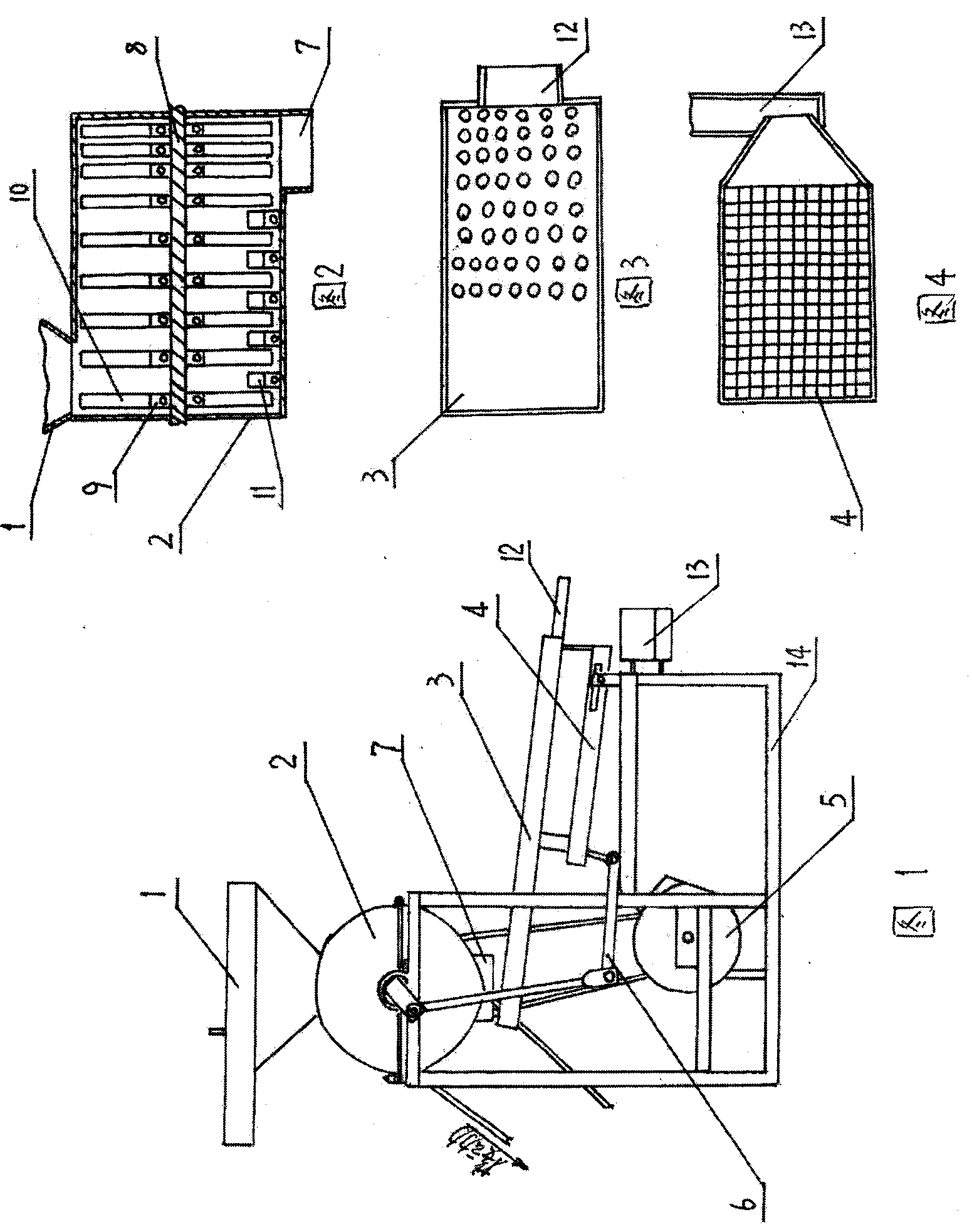

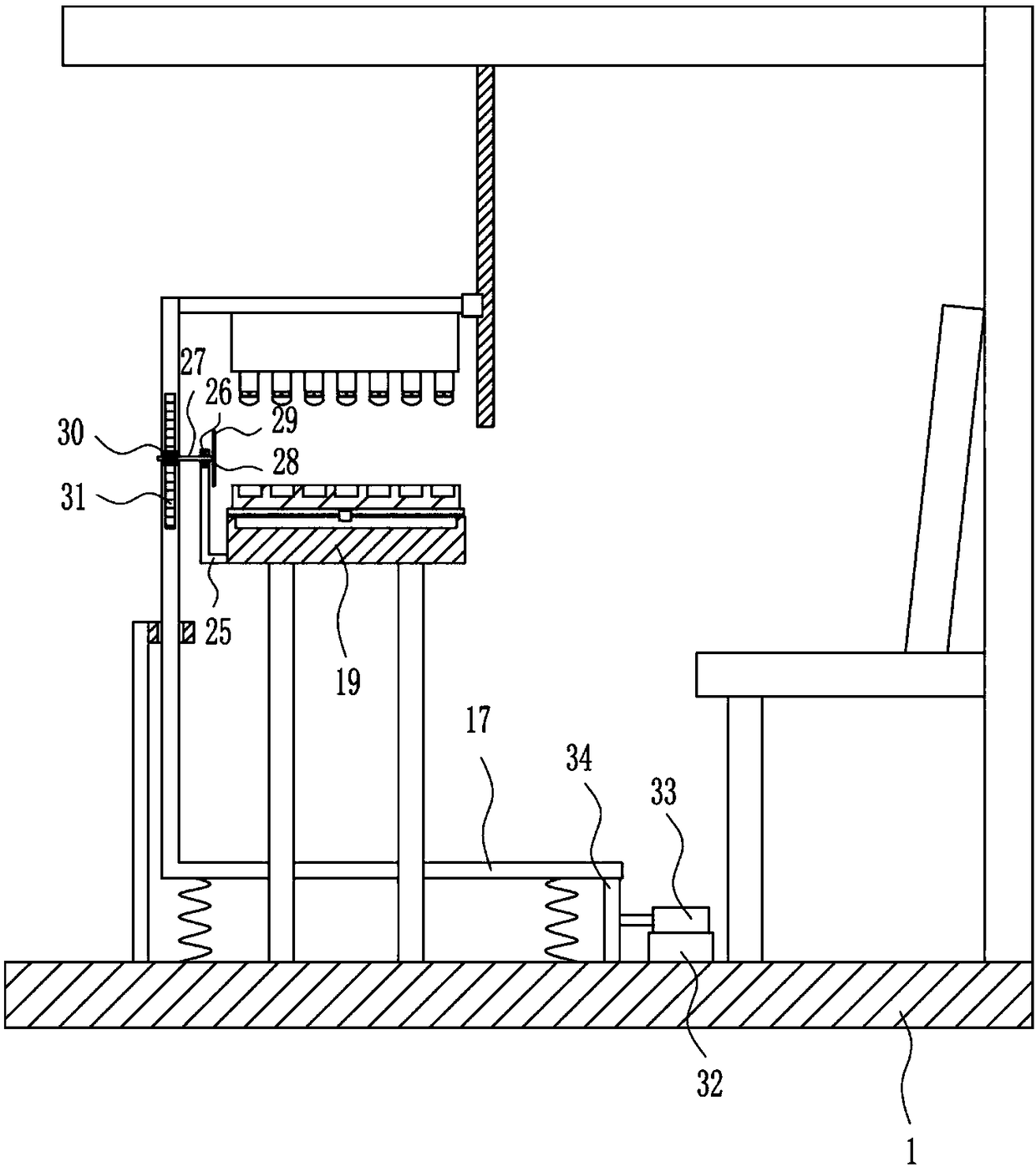

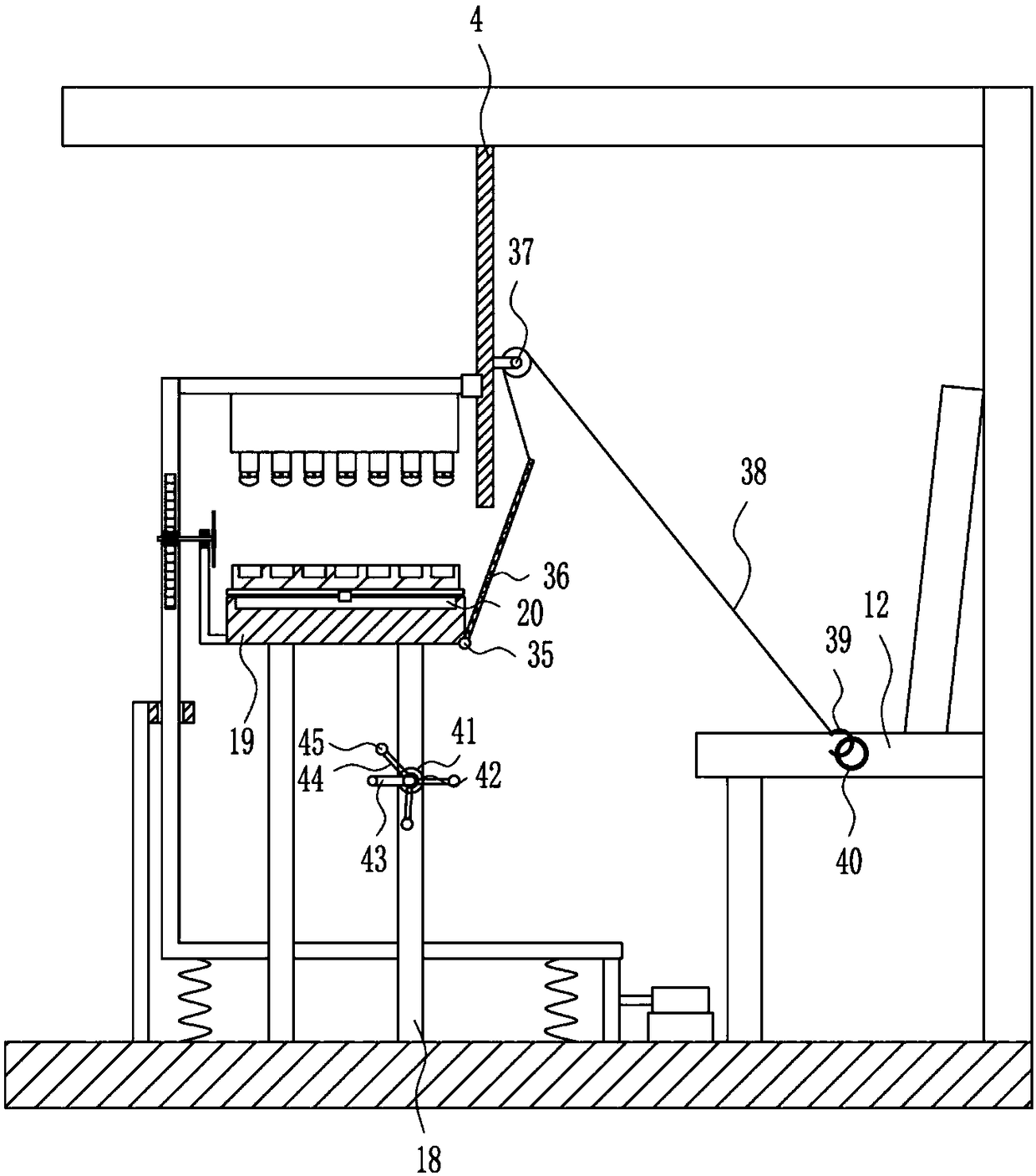

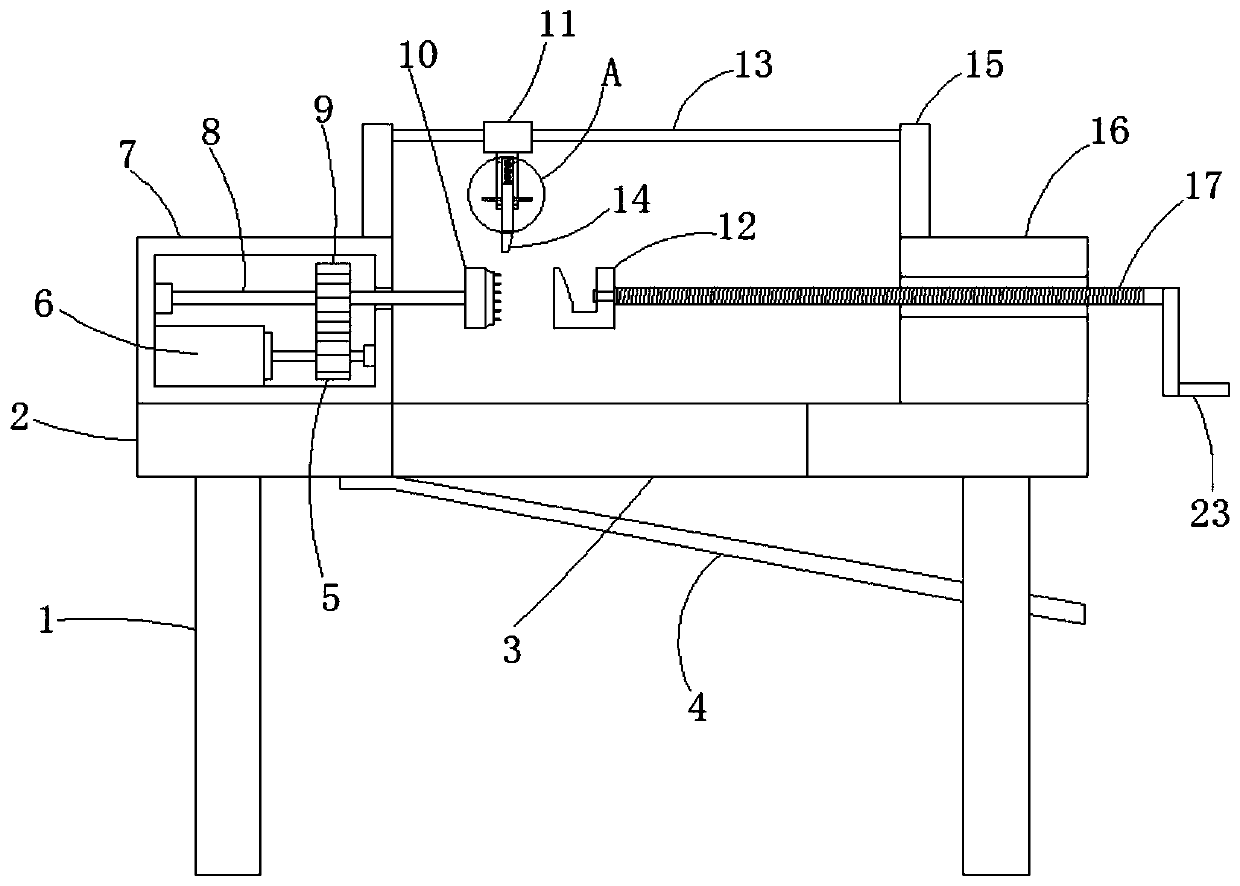

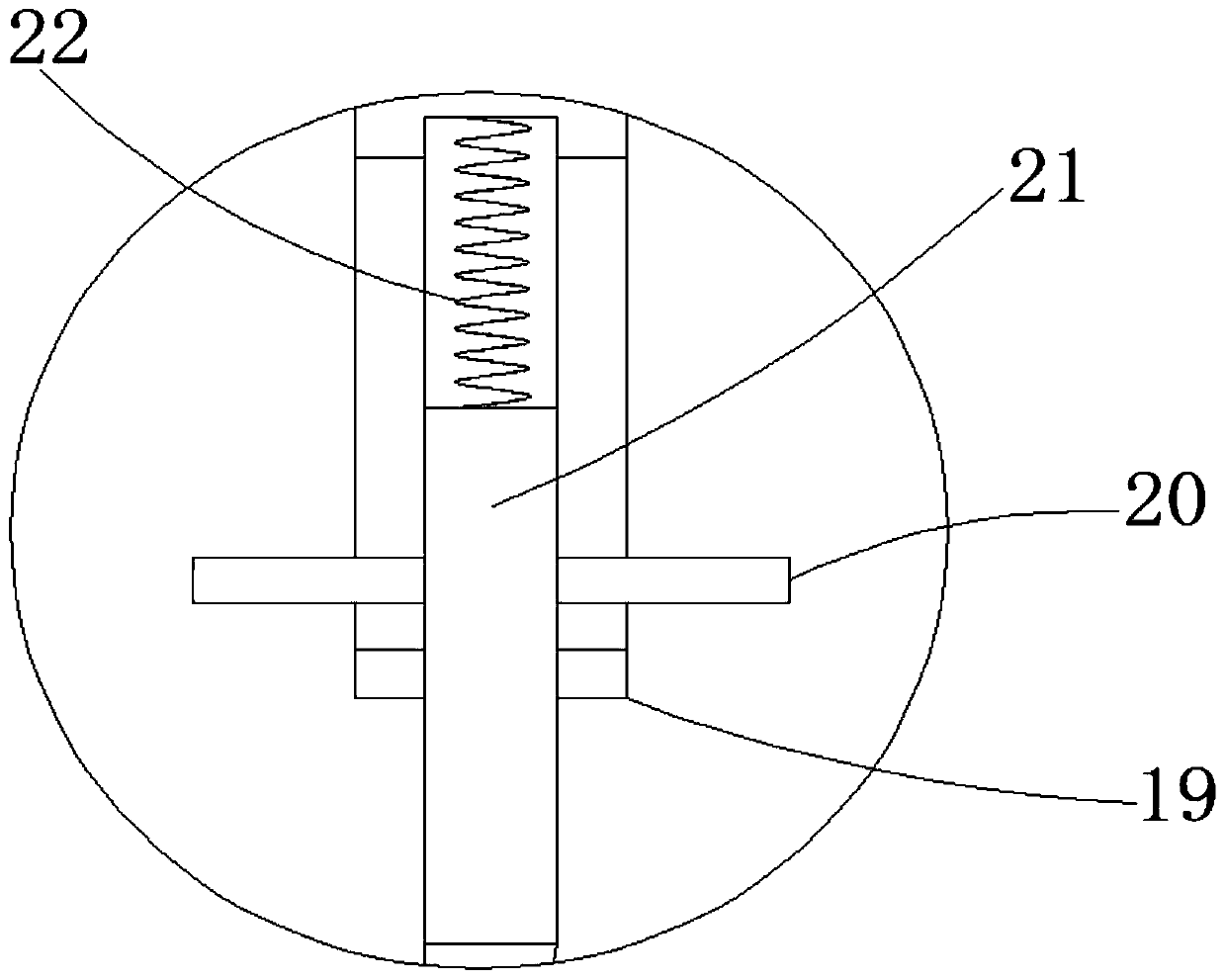

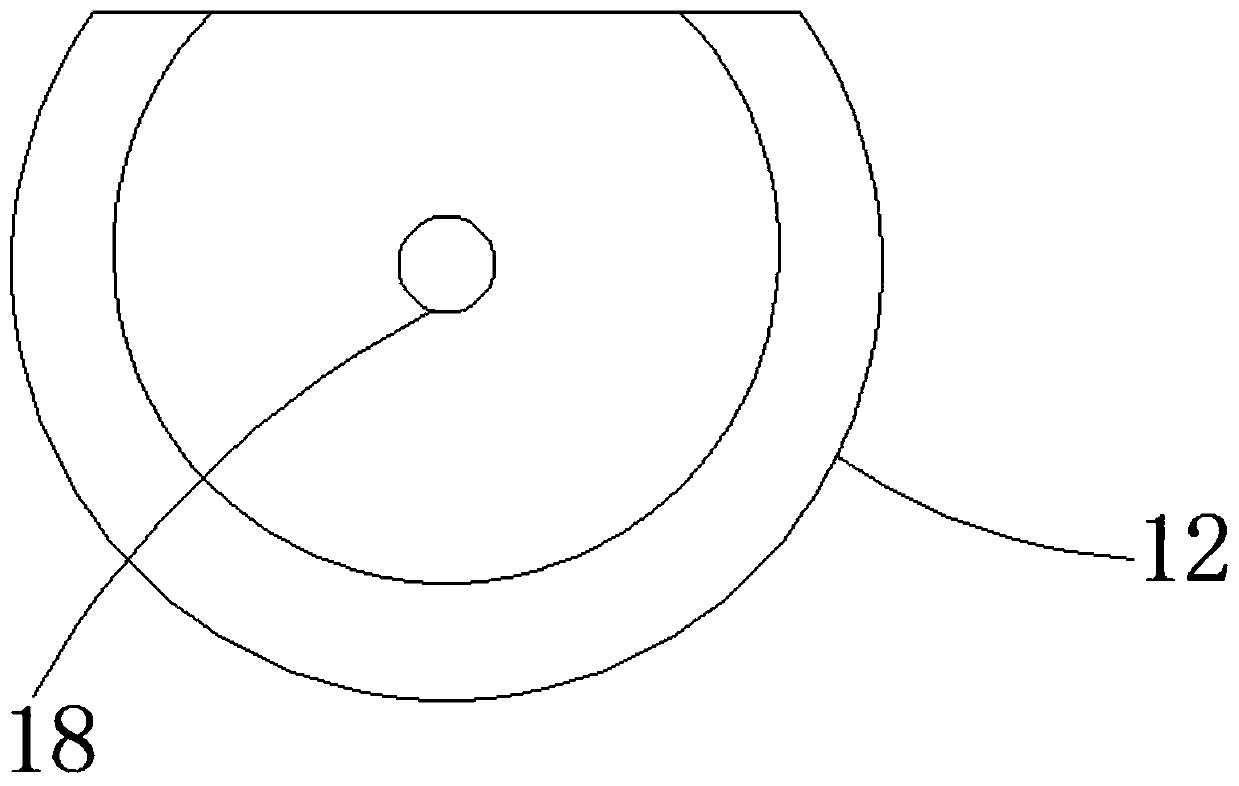

The invention relates to semi-automatic equipment, in particular to an irregular fruit fast peeling machine which mainly comprises a rack (18), a pressing mechanism (10), guide rods (4), blades (22) and an elastic adjusting box (8). Appropriate elastic force is selected through the elastic adjusting box (8), and cooperates with the pressing mechanism (10), the guide rods (4), the blades (22) and steel wires (27), so that food in irregular shapes is peeled. By adoption of the irregular fruit fast peeling machine, the irregular food such as apples and pears can be fast and conveniently peeled, the structure is ingenious, operation is simple, accidental injuries caused by utilization of a fruit knife can be effectively avoided, the peeling speed is greatly increased, and the machine has high market popularization value.

Owner:GUIZHOU NORMAL UNIVERSITY

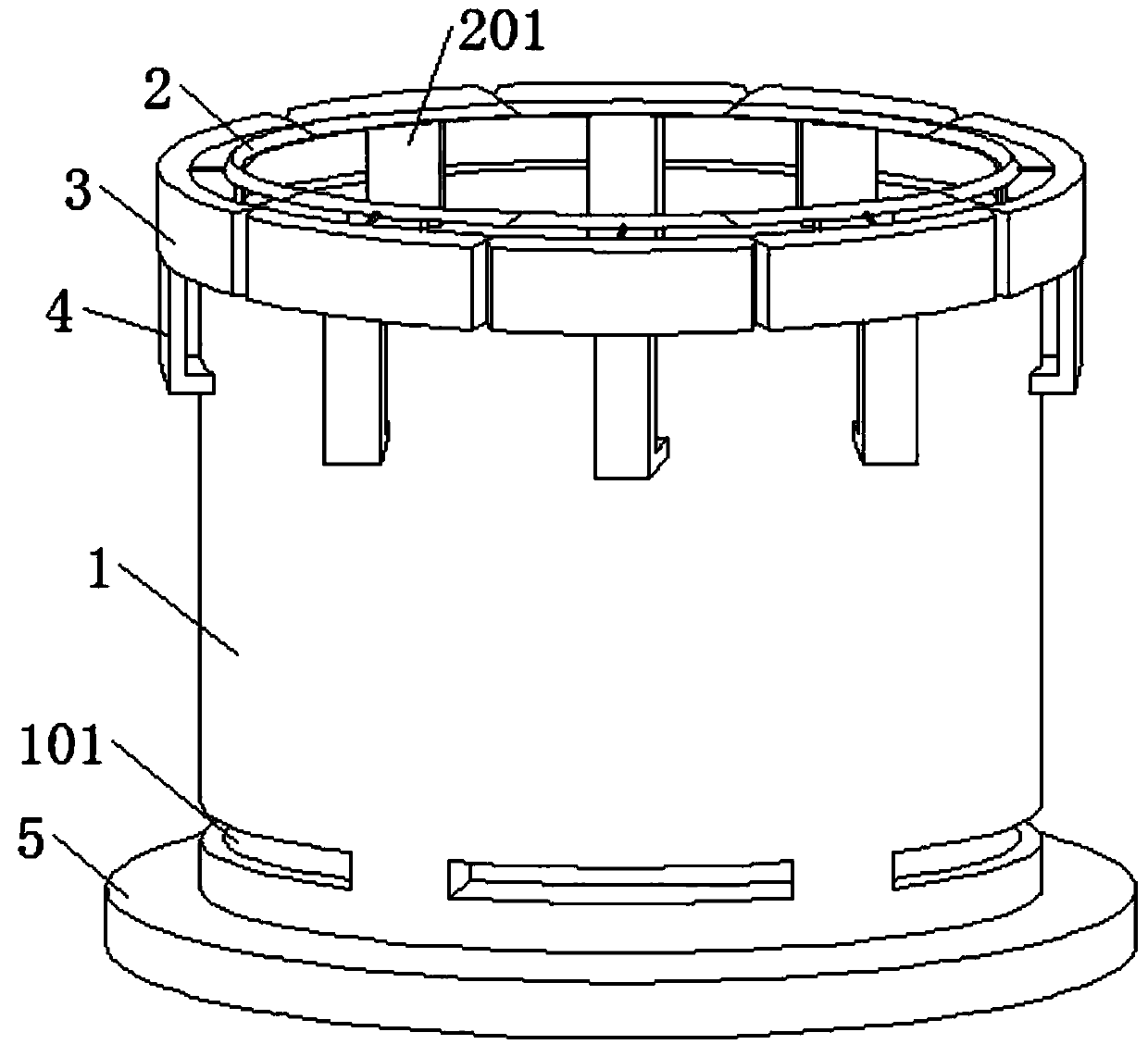

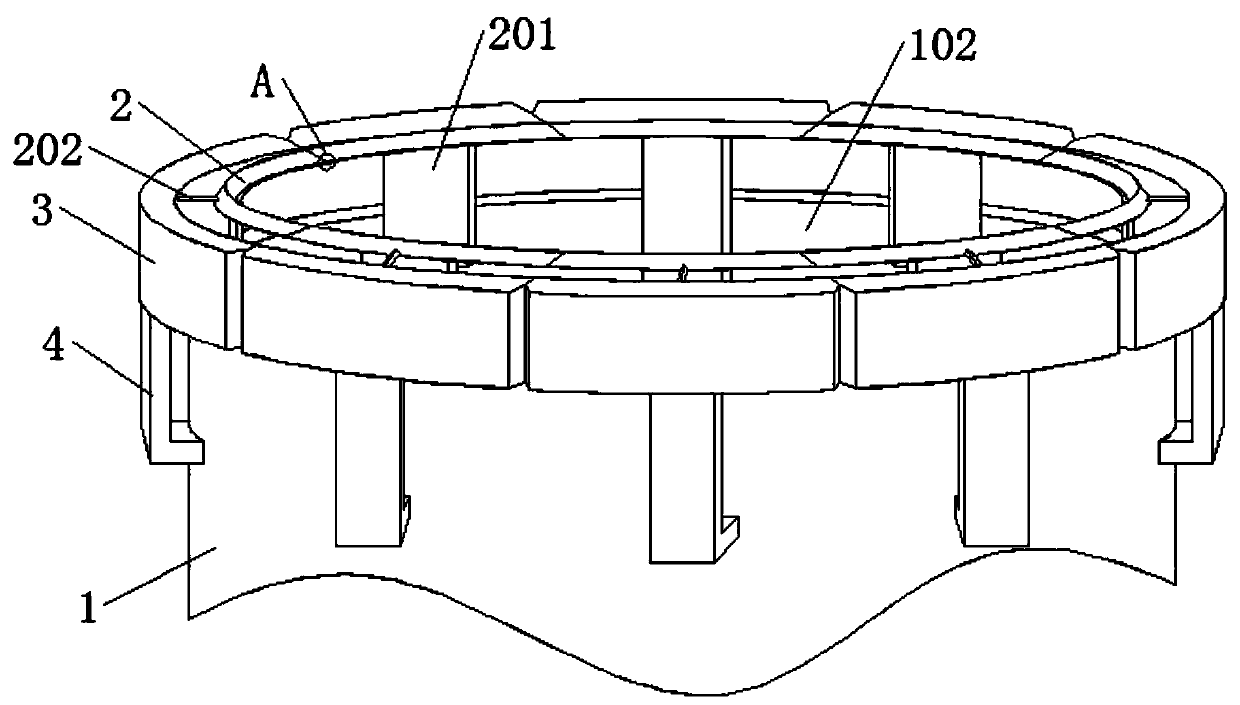

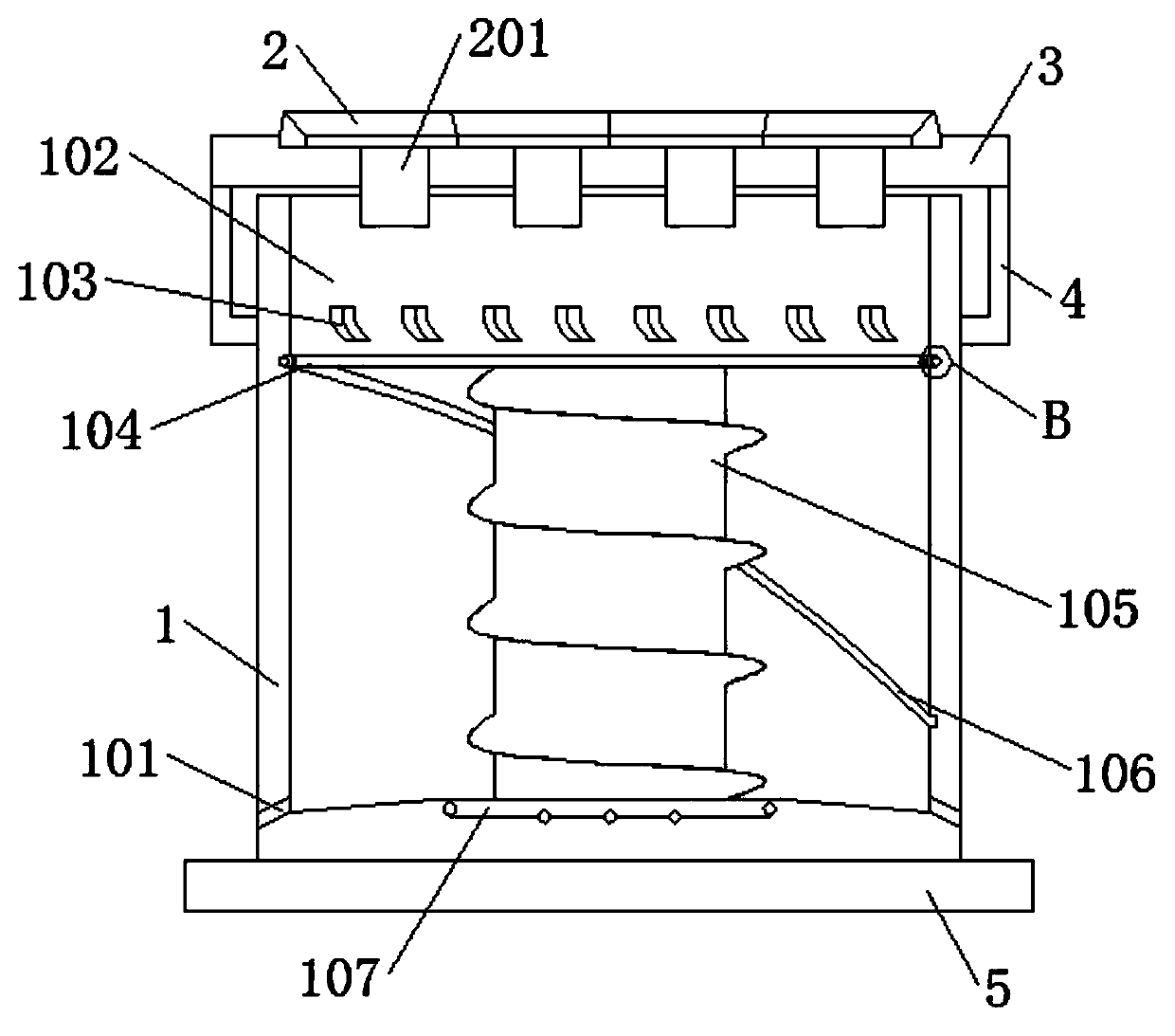

Water chestnut peeling equipment

ActiveCN112205639AFast peelingImprove efficiencyClimate change adaptationVegetable peelingAgricultural engineeringAgricultural science

The invention relates to the technical field of agricultural machinery processing, in particular to water chestnut peeling equipment. The equipment comprises a base and further comprises a controller,a peeling mechanism and a rotating mechanism, wherein the peeling mechanism is arranged at the top of the base and used for removing water chestnut peels; the peeling mechanism comprises a top plate,a scraper, a driving assembly and a sliding assembly; the rotating mechanism is located below the peeling mechanism and comprises an inserting rod, a locking assembly and two supporting plates; the two supporting plates are symmetrically arranged at the top of the base; the inserting rod is rotatably arranged at the top of one supporting plate; the locking assembly is rotatably arranged at the top of the other supporting plate; the locking assembly is in driving connection with the driving assembly; and the driving assembly is electrically connected with the controller. According to the waterchestnut peeling equipment, the peeling speed is high, the working efficiency is high, the peeling effect is better, and meanwhile, the removed peels can be collected, so that environmental pollutionis prevented, and potential safety hazards are relatively small.

Owner:胡少宇

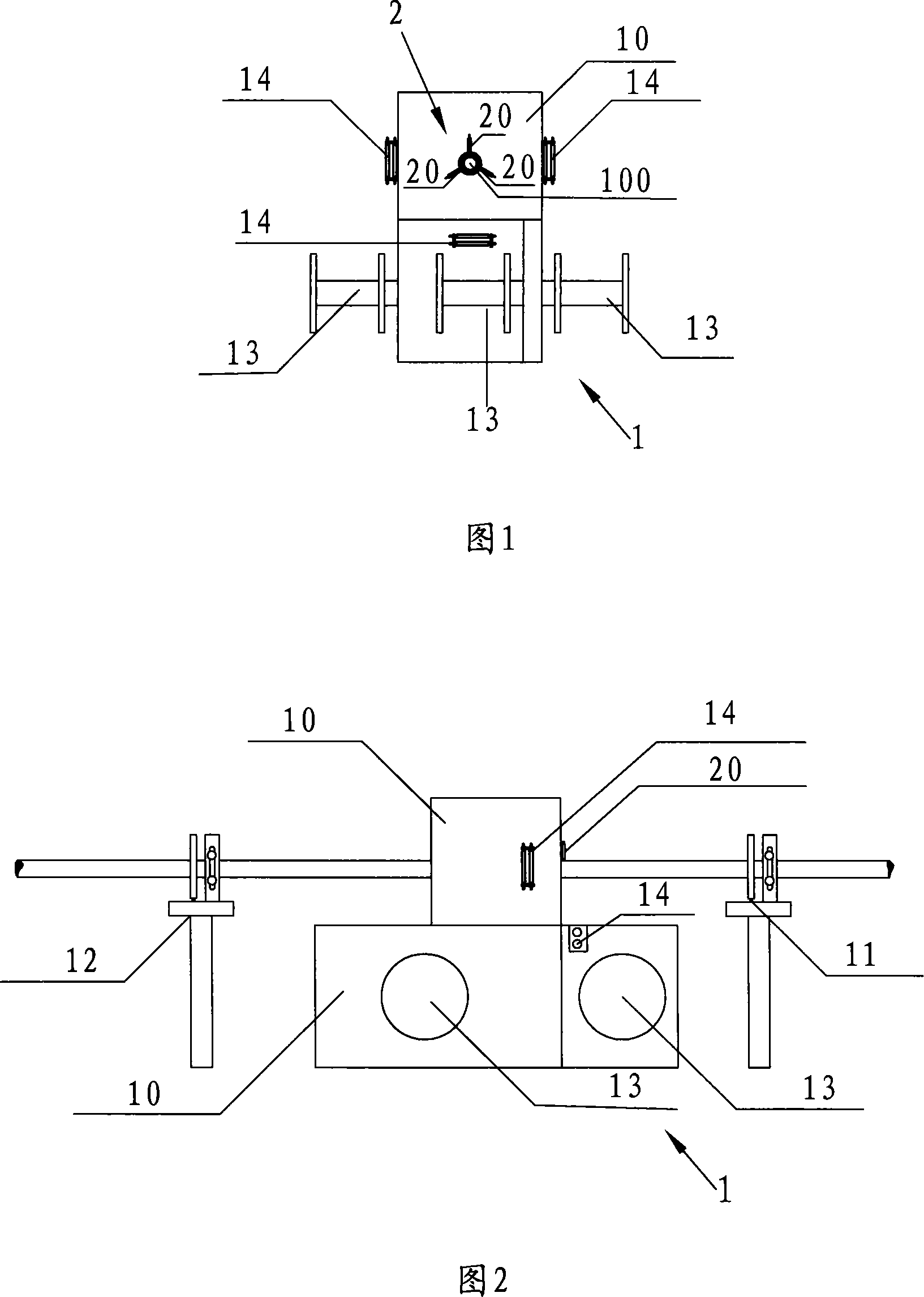

Cable stripper

InactiveCN107394687AImprove strip qualityAvoid injuryApparatus for removing/armouring cablesPower equipmentEngineering

The invention relates to a tool for electric equipment, in particular to a cable stripper for peeling cables during construction and maintenance. hole, the outer wall of the guide tube is provided with a fixed nut coaxial with the through hole through the bracket, a knife rod connected with the fixed nut is provided in the through hole, a knife is provided at the front end of the knife rod, and an adjusting handle is provided at the rear end of the knife rod. The cutter is in the form of an isosceles triangle, the bottom edge of the cutter is connected with the cutter bar, the waist of the cutter is respectively provided with a blade, and the inner wall of the guide tube corresponding to the blade is provided with an arc-shaped boss. The present invention adopts the above structure, and has the advantages of precise control of stripping It has the advantages of increasing the stripping speed and improving the work efficiency; it has the advantages of avoiding the scratching of the staff by the electrician's knife and ensuring the safety of the staff.

Owner:WEIHAI WENDENG POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

Simple auxiliary shelling device for bamboo shoots

The invention discloses a simple auxiliary shelling device for bamboo shoots. The simple auxiliary shelling device comprises a worktable, wherein the front end of the surface of the worktable is provided with a semi-circular truncated cone shaped groove, a circular-arc shaped stop block group is arranged above the semi-circular truncated cone shaped groove and is composed of two oppositely arranged 1 / 4 circular-arc shaped stop blocks, a gap is reserved between the two circular-arc shaped stop blocks and is a knife operating groove, the back of the semi-circular truncated cone shaped groove isan installing groove, an air cylinder is arranged in the installing groove, the head end of an ejection rod of the air cylinder is provided with a top plate, two ends of the worktable are provided with upward supports, a slant guiding rod is connected between the supports, the slant guiding rod and the semi-circular truncated cone shaped groove are symmetrically arranged, the slant guiding rod ismovably sleeved with a sliding block, the bottom of the sliding block is connected with a cutting knife through an installing rod, and the cutting knife faces the knife operating groove under the cutting knife. The simple auxiliary shelling device for bamboo shoots is simple in structure, very convenient to operate, capable of assisting a user to quickly strip bamboo shells, low in price and widein application range.

Owner:ZHENGAN COUNTY DINGQING SQUARE BAMBOO SHOOT

Sunflower seed shell peeling equipment for foods

The invention relates to shell peeling equipment for foods, in particular to sunflower seed shell peeling equipment for foods, and aims to provide the sunflower seed shell peeling equipment for foods,which is high in shell peeling speed and can perform shell peeling in batch, and through which body health can be protected. The sunflower seed shell peeling equipment for foods comprises a horizontal plate, supporting legs, a first sliding rail, a first sliding block, a moving plate, a first placing plate, a fixing block, a rubber cushion, a vertical plate, supporting plates, a frame body, a guiding sleeve, a guiding rod and the like, wherein the supporting legs are respectively connected to the left side and the right side of the bottom of the horizontal plate; the first sliding rail is mounted on the right side of the top of the horizontal plate in an embedding manner; the first sliding block is arranged on the first sliding rail; and the moving plate is connected to the top of the first sliding block. According to the sunflower seed shell peeling equipment disclosed by the invention, rubber blocks move downwards, and each rubber block cooperates with a corresponding groove, so that sunflower seeds can be subjected to shell peeling, and shell peeling in batches at one time can be performed; the shell peeling speed is high, so that cracking the sunflower seeds with teeth by labor is not needed, and body health can be protected; and a brush moves forwards, so that kernels and shells of the sunflower seeds can be separated.

Owner:宁夏伊瓶香粮油产业发展有限公司

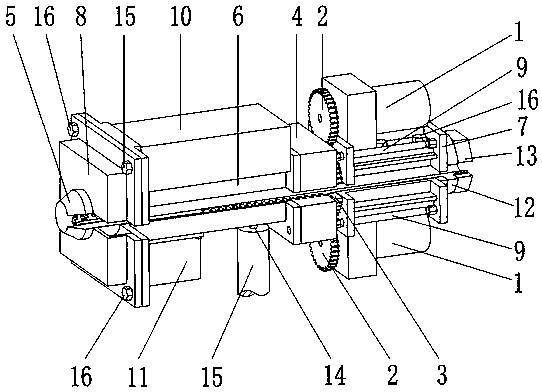

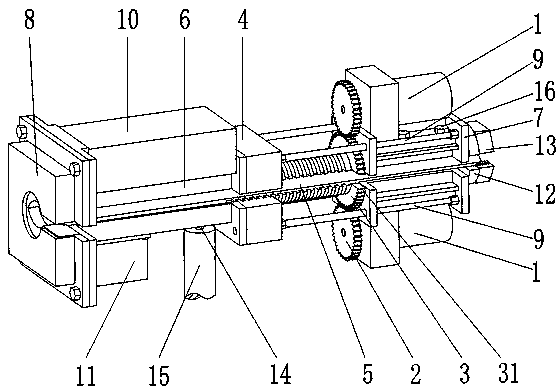

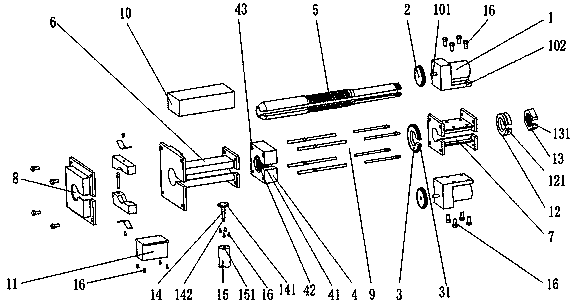

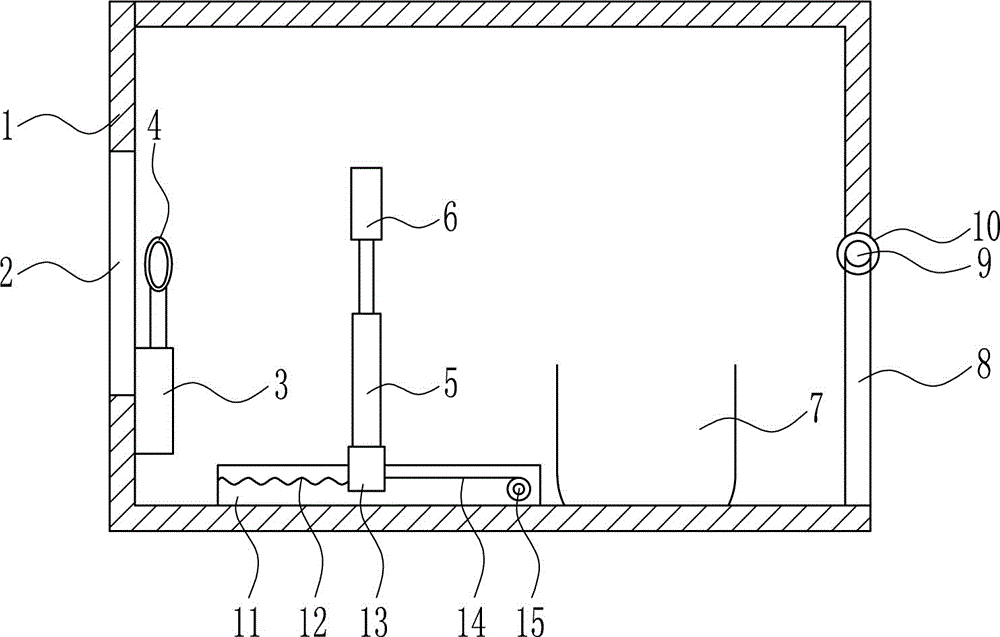

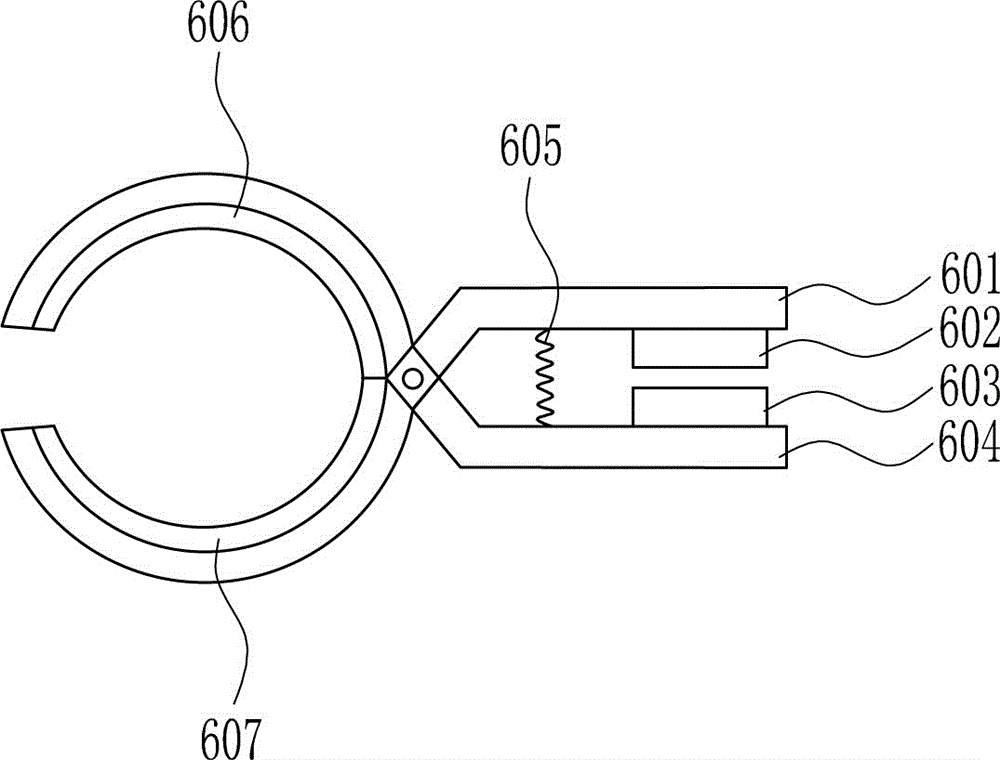

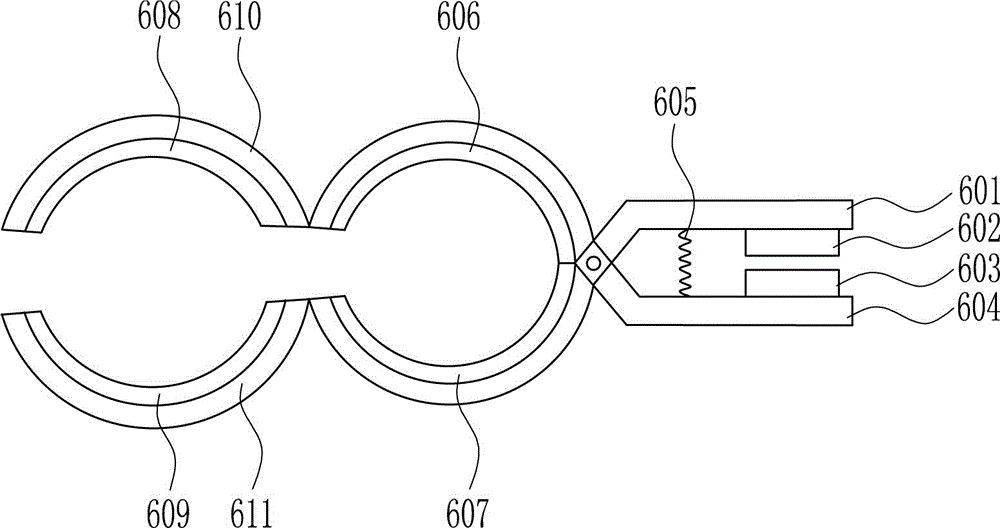

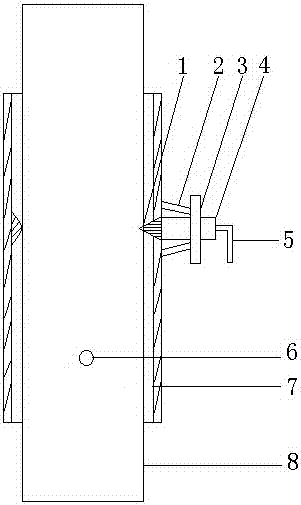

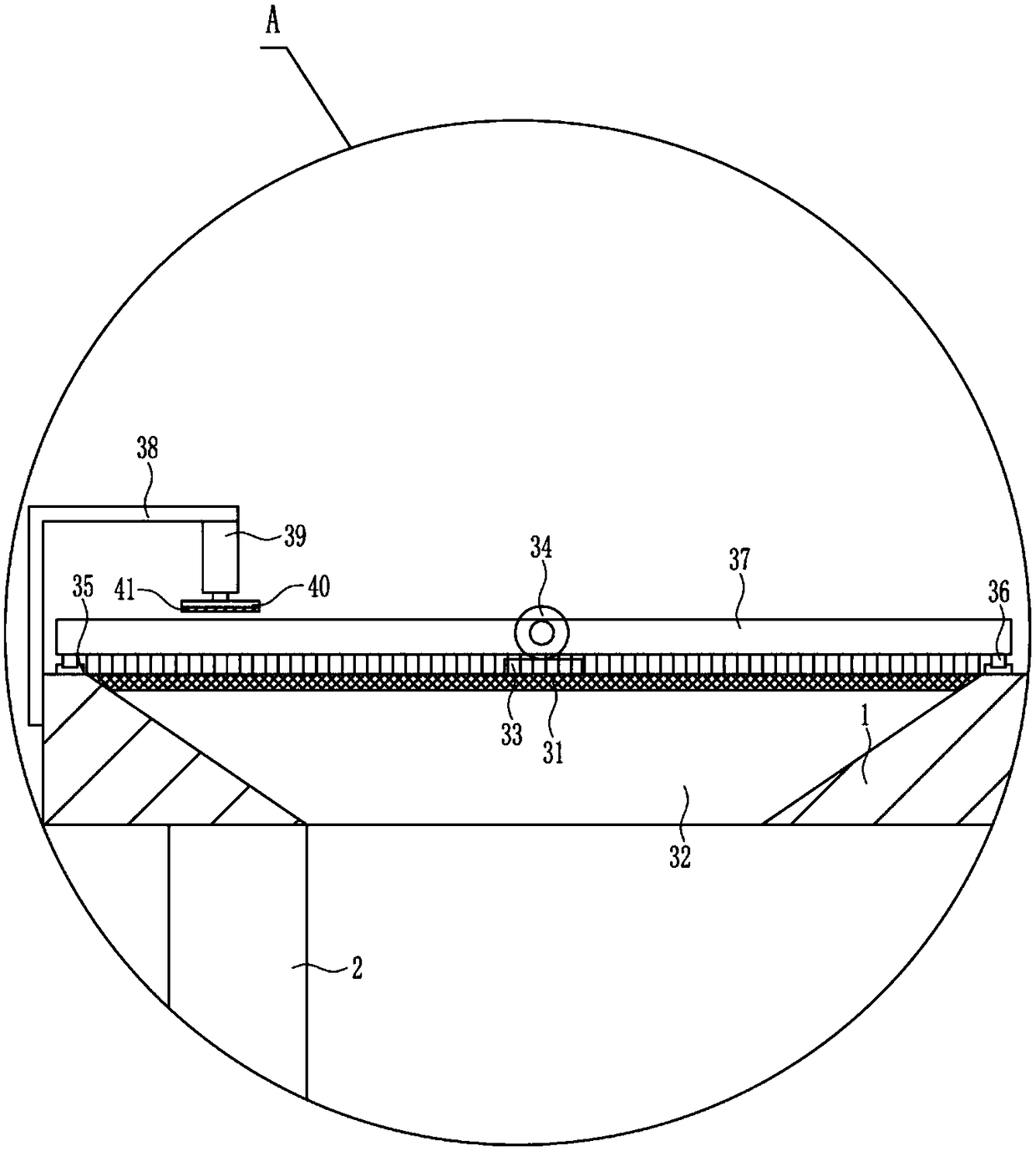

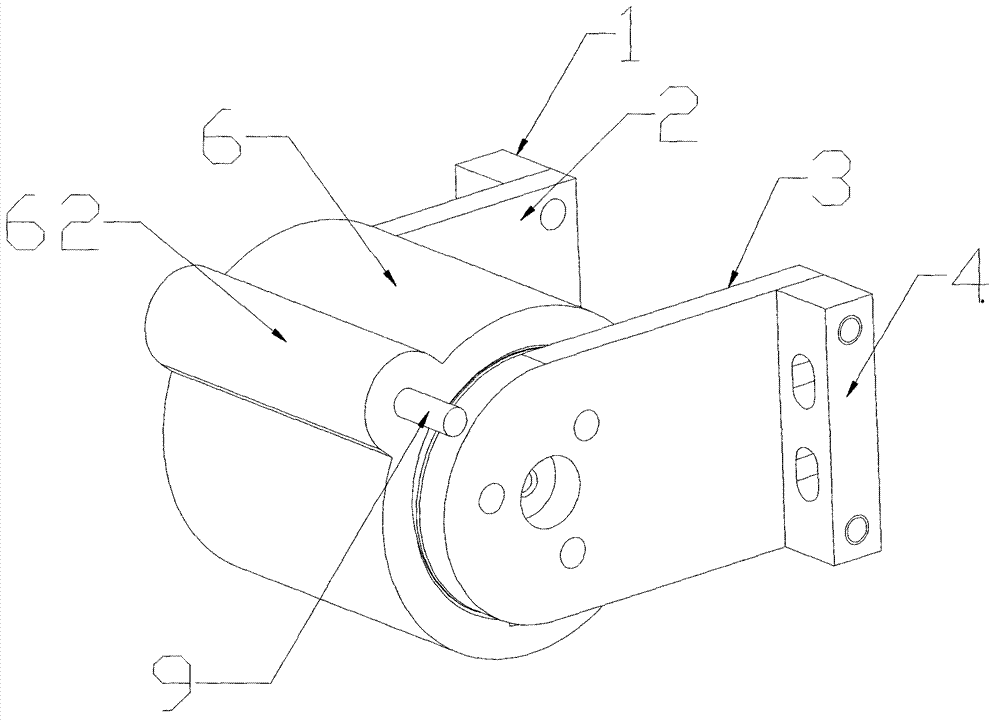

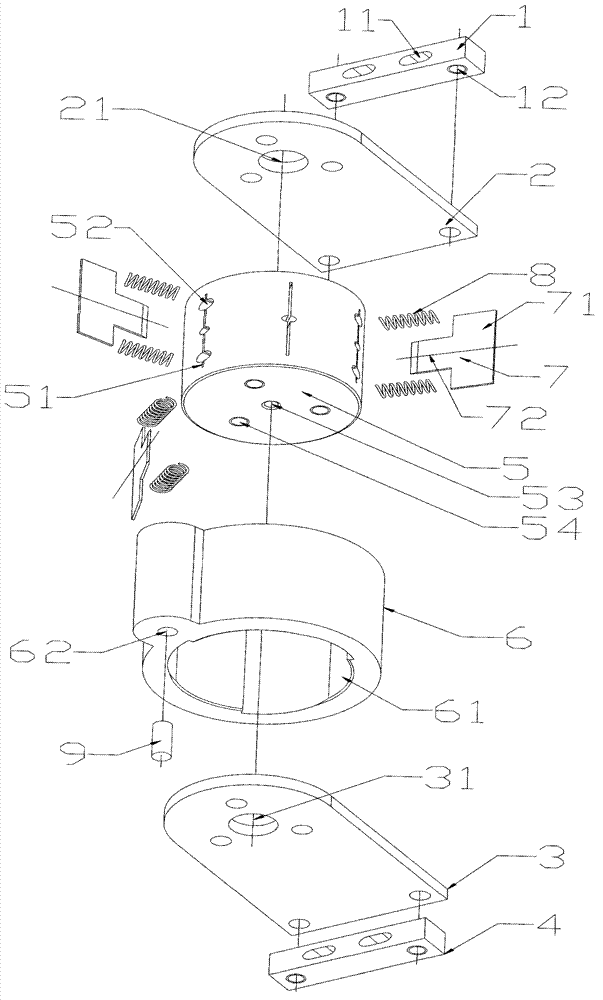

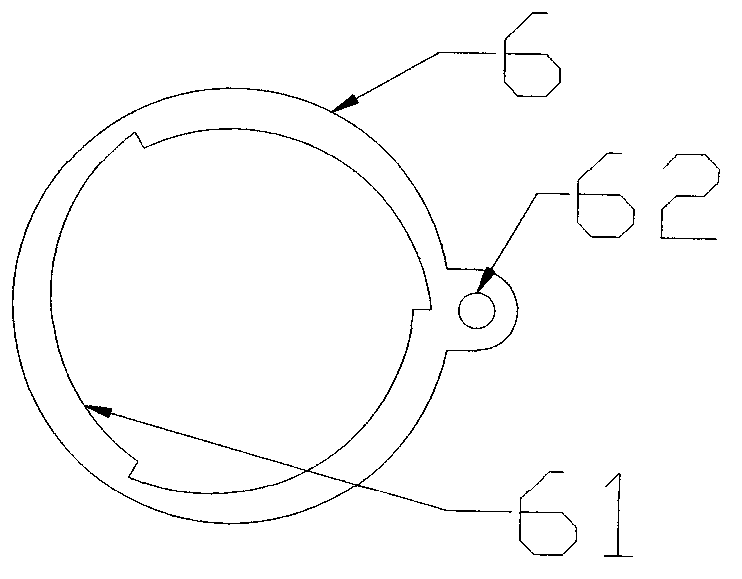

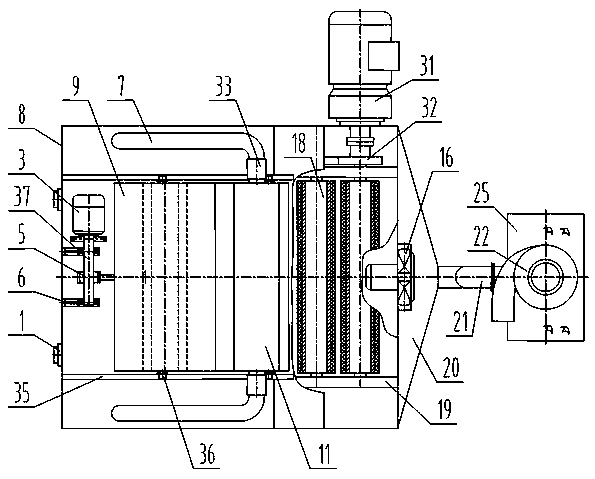

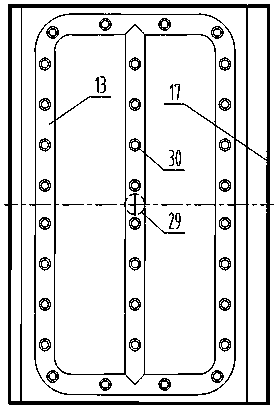

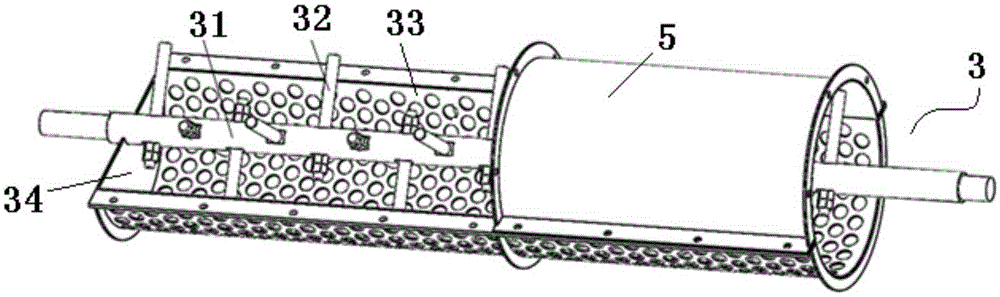

Straight knife edge wire cutting mechanism applied to peeling-wire machine

InactiveCN102761081AAccurate travelAdjustable strokeApparatus for removing/armouring cablesFixed frameWire cutting

The invention discloses a straight knife edge wire cutting mechanism applied to a peeling-wire machine, which consists of a driving device and a knife rest, wherein the driving device is provided with a cylinder, a cylinder fixing frame and a mounting fixing frame; and the driving device mainly uses the cylinder fixed on the panel of the peeling-wire machine as a power source. The knife rest is provided with a stator, a rotor, a knife blade set, a spring set and a fixing frame; the knife blade set is arranged in the stator, the knife edge of the knife blade keeps off from a wire hole III inside the stator under the action of the reaction force of the spring set, and the knife blade moves towards the wire hole III under the action of the rotary pushing action force of the rotor so as to achieve the wire cutting effect. The straight knife edge wire cutting mechanism applied to a peeling-wire machine has the advantages of accurate travel range, adjustable travel range, large driving force, high peeling speed, no damage to a cable core, stable performance, long service life, simple structure and low cost.

Owner:ZHONGSHAN YATAI MACHINERY

High temperature steam seed huller

InactiveCN110026263AHigh peeling rateAvoid damageGrain huskingGrain polishingEngineeringBreakage rate

The invention discloses a high temperature steam seed huller and is intended to provide the high temperature steam seed huller, high in hulling rate, low in exterior damage rate, low in breakage rate,low in cost and high in efficiency. The high temperature steam seed huller comprises a housing, a hulling device, a vibratory feeding device, a steam system, a winnowing system, a partition, an exhaust fan, a germ box, and a kernel box. The partition is arranged inside the housing and divides the housing into a vibratory feeding chamber on the left and a hulling chamber on the right; the vibratory feeding device and the steam system are arranged inside the vibratory feeding chamber; the steam system is positioned below the vibratory feeding device; the hulling device is arranged in the hulling chamber; the kernel box and the germ box are arranged below a lower outlet of the hulling device sequentially from left to right. The winnowing system is arranged on the outer side of a sidewall plate of the hulling chamber and is communicated with an air suction port. The high temperature steam seed huller is suitable for hulling for corn, soybean, peanut and other seeds.

Owner:张金伟

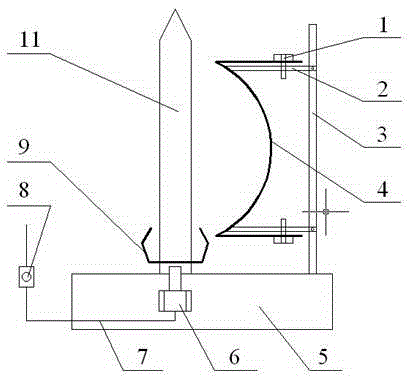

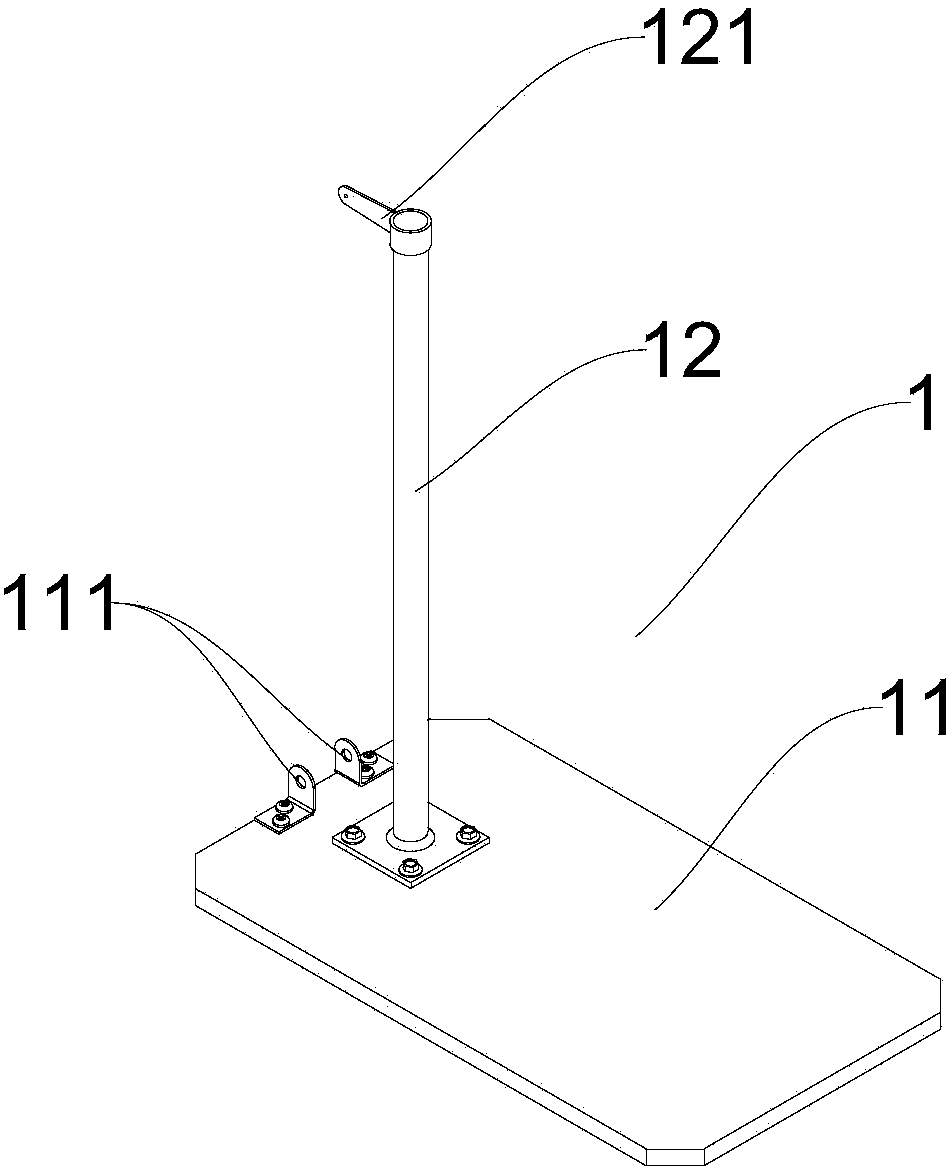

An automatic peeling machine with a fruit surface profiling function

The invention belongs to the mechanical field of articles of daily use and particularly relates to an automatic peeling machine with a fruit surface profiling function. The automatic peeling machine comprises a pedestal; a fruit fork and a vertical rod are arranged on the pedestal; a motor is arranged in the pedestal; the fruit fork is fixedly connected with a fixing device; a fruit is placed on the fruit fork; the bottom of the fruit fork is connected with a motor shaft; the motor is connected with a power wire and a switch; the vertical rod is fixedly connected with cross rods; the cross rods are provided with bolts and are connected with a profiling blade. The peeling machine is simple in structure and easy to operate; the fixing device can fix fruits of various shapes and sizes and prevent the fruits from rotating relative to the fruit fork and the freely-bendable profiling blade can simulate the profiles of fruits of various shapes and sizes, so that the peeling work for fruits can be completed rapidly at a time.

Owner:西安丰登农业科技有限公司

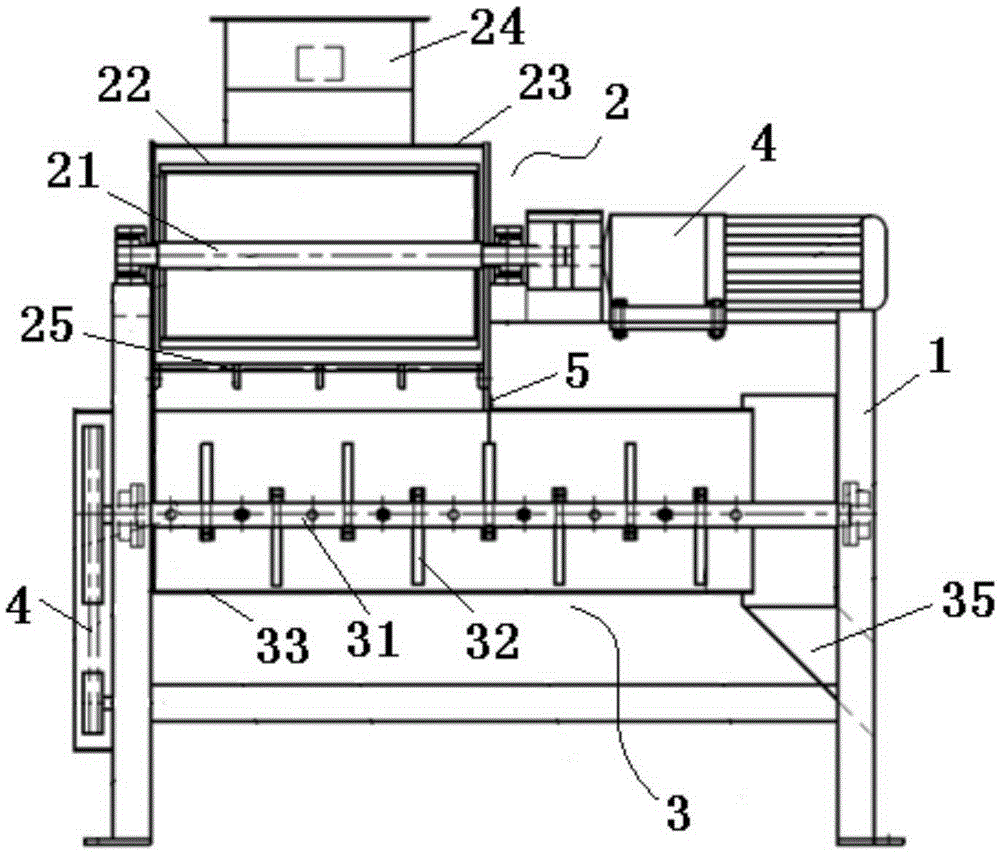

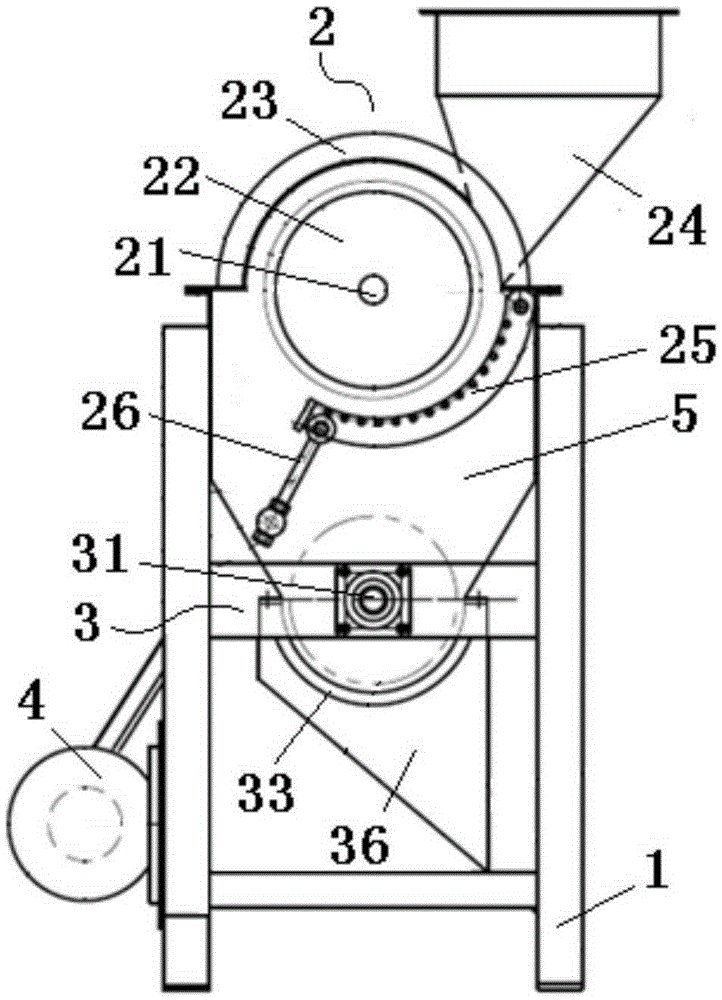

Clapping type Chinese chestnut peeling machine

The invention discloses a clapping type Chinese chestnut peeling machine which is characterized in that beating sheets fixed to a shaft (8) are arranged in a peeling cavity and a discharging cavity of a peeling device (2), the beating sheets are rubber boards (10) clamped in clamping machines (9), and a short beating sheet (11) is arranged between every two adjacent beating sheets in the peeling cavity and is fixed to the bottom edge of the peeling cavity. Compared with a traditional rubbing and extruding peeling device, the clapping type Chinese chestnut peeling machine has the advantages of being high in peeling speed, higher in operation efficiency, low in nut damage rate, good in fruit, shell and residue separation effect, high in fruit cleaning rate, simple in structure, low in cost and suitable for peeling Chinese chestnuts, tung nuts and the like.

Owner:刘金生

Sunflower seed unhusking equipment for food

The invention relates to sunflower seed unhusking equipment, and particularly relates to sunflower seed unhusking equipment for food. The technical problem of the invention is to provide the sunflowerseed unhusking equipment for the food which is high in unhusking speed and can be unhusked in batch. The sunflower seed unhusking equipment is characterized in that the sunflower seed unhusking equipment comprises a first mounting plate, a first support plate, a second support plate, a first sliding rail, a first sliding block, a first movable rod and the like; the right side of the top part of the first mounting plate is connected with the first support plate; the upper part of the left side surface of the first support plate is connected with the second support plate; the middle part of thebottom part of the second support plate is connected with the first sliding rail; the first sliding block is arranged on the first sliding rail. According to the sunflower seed unhusking equipment disclosed by the invention, a rubber block of the equipment is moved downwards and is matched with a groove so as to unhusk sunflower seeds; unhusking can be carried out in batch at a time, and the unhusking speed is high; wind power can be generated through positive and negative alternate rotation of the leaf blades, so that a layer of film, close to the lower part of a peel, of the sunflower seedsis blown away; due to arrangement of a mesh plate, the phenomenon that the layer of film, close to the lower part of the peel, of the sunflower seeds is blown away can be prevented.

Owner:XINCHANG LINYU MACHINERY TECH CO LTD

Electric fruit peeling machine

InactiveCN110013157ASolve the speed problemAddress insecurityPeelersDrive shaftAgricultural engineering

The invention discloses an electric fruit peeling machine, and relates to the field of fruit processing. The electric fruit peeling machine aims to solve the problems that in the prior art, fruits arepeeled slowly by hand and hand peeling is not safe. The electric fruit peeling machine comprises a top plate, support legs are welded on the bottom of the top plate, one side of the top part of the top plate is fixedly provided with a transmission box, a transmission shaft is connected to the inside of the transmission box in a rotating mode, and a fixing block is welded on one end of the transmission shaft; the top plate is provided with an installation block, a screw rod is connected to the installation block, a fixing pin is welded on an end close to the fixing block of the screw rod, andthe outer side of the fixing pin is in rotating connection with a clamping block; and connecting blocks are welded on top parts of the transmission box and the installation block, a sliding rod is welded between the two connecting blocks, a sliding block is sleeved on the outer side of the sliding rod in a sliding mode, a sleeve is welded on the bottom of the sliding block, an adjusting rod is connected to the inside of the sleeve in a sliding mode, and a blade is fixed on the bottom end of the adjusting rod. The electric fruit peeling machine has the advantages of being convenient for peelingfruits of different sizes, quick in peeling speed, convenient to use, high in safety, reasonable in structure design and strong in practicability.

Owner:福建优田生态农业有限公司

Peeling device for peeling garlic by utilizing thermal expansion and cold contraction

InactiveCN112401272AGuaranteed separation effectAvoid enteringFood treatmentThermodynamicsEngineering

The invention discloses a peeling device for peeling garlic by utilizing thermal expansion and cold contraction. The peeling device comprises an external control mechanism for starting an external driving device, a steam heating mechanism for heating steam, an adsorption peeling mechanism for peeling by airflow adsorption, and a magnetic peeling mechanism for peeling by magnetic vibration, whereina shell is arranged in the external control mechanism, the external control mechanism is fixedly connected with the steam heating mechanism through the left side of the shell, the inner wall of the shell is fixedly connected with a bearing A, the inner wall of the shell is fixedly connected with the adsorption peeling mechanism through the bearing A, and the inner wall of the adsorption peeling mechanism is fixedly connected with the magnetic peeling mechanism. Rapid refrigeration is carried out after heating, separation is carried out according to different shrinkage degrees of garlic seedsand garlic peels, and a bent arc plate is arranged in a channel to guide middle steam to be sprayed outwards, so that the steam is prevented from entering the shell, and the effect of thermal expansion and cold contraction is not affected.

Owner:高增光

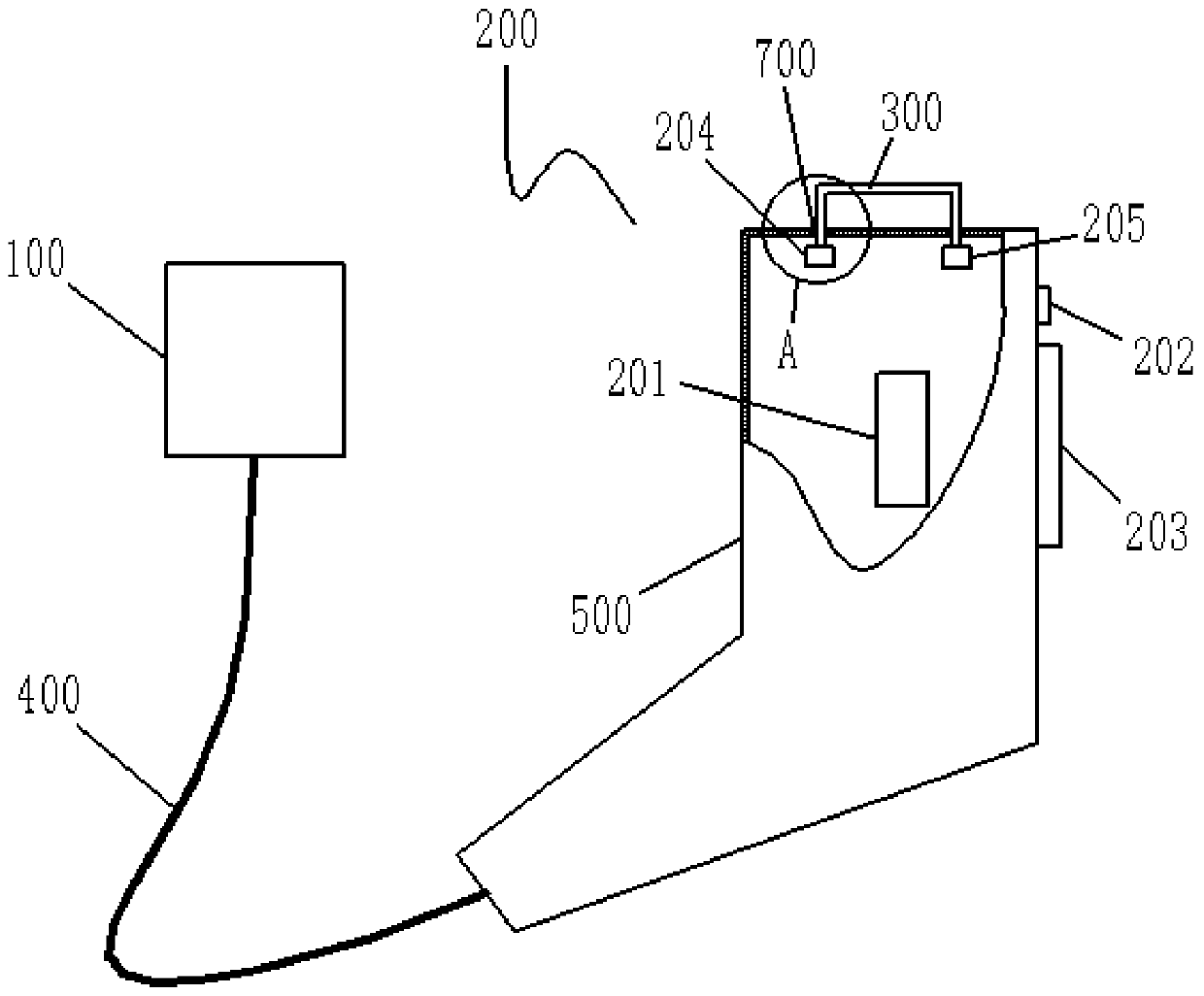

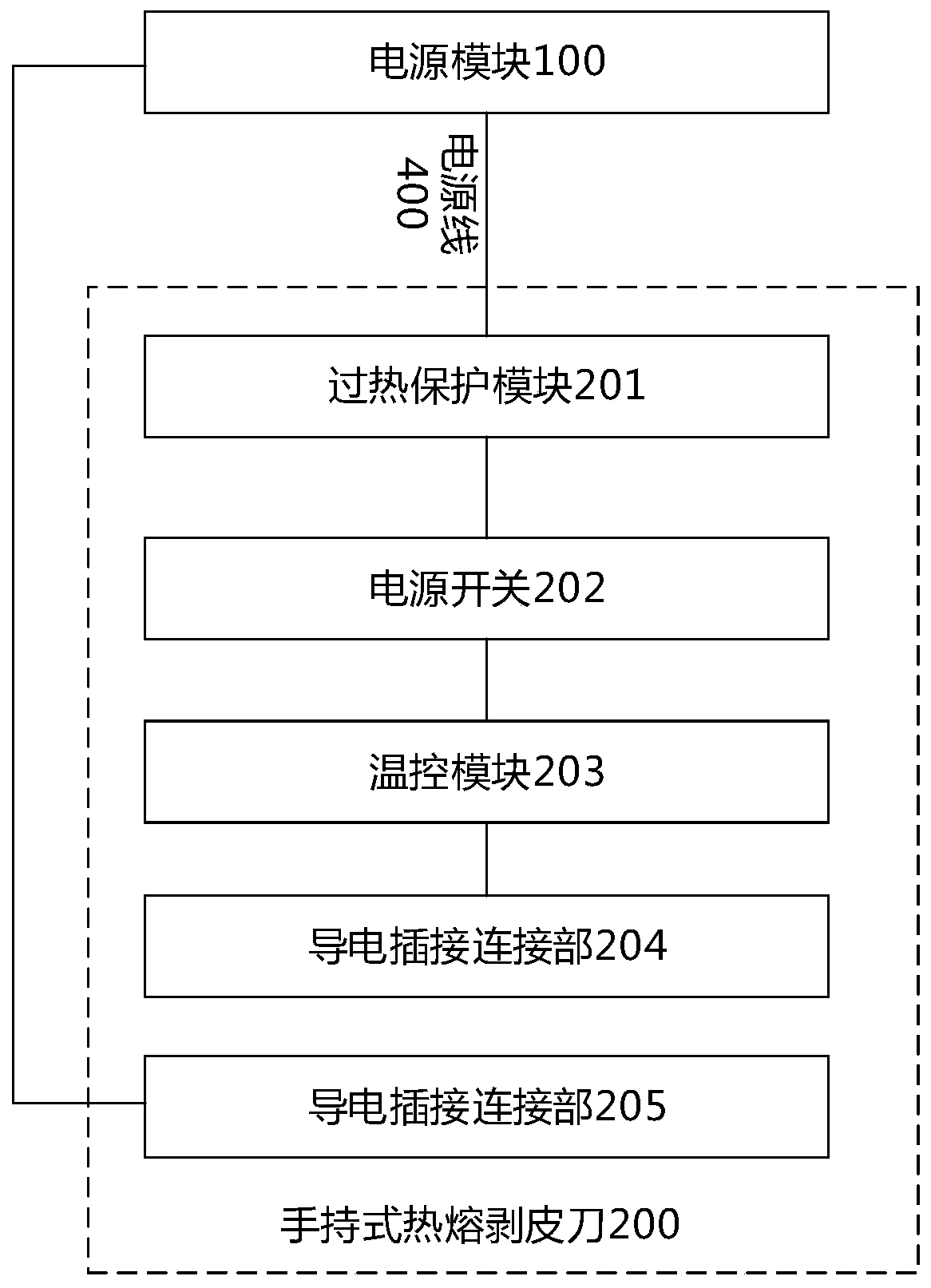

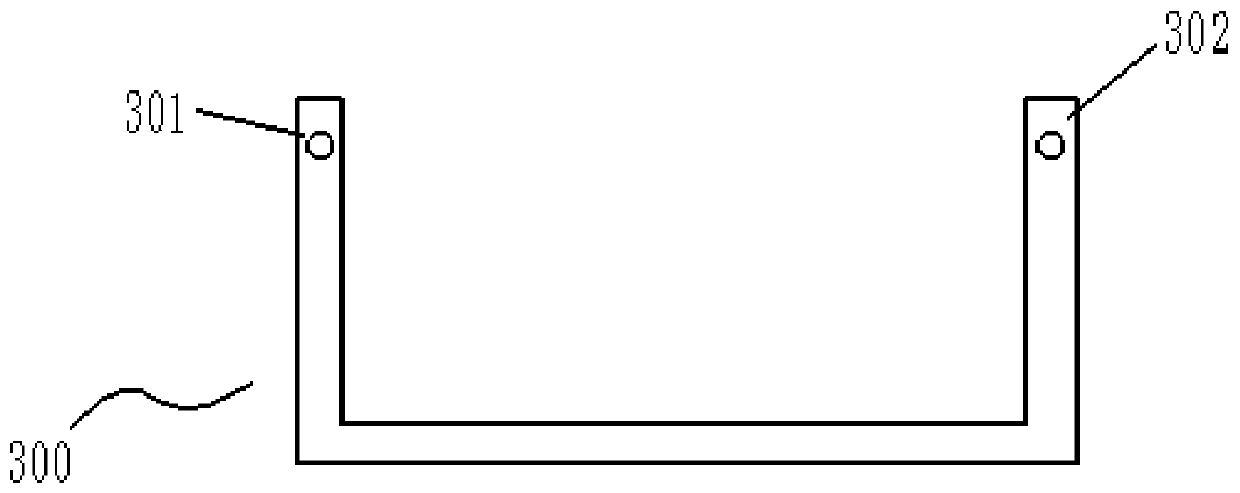

Overhead insulation lead hot melting peeling knife

InactiveCN110571720AFast peelingQuick Peeling TreatmentApparatus for removing/armouring cablesPower switchingHand held

The invention provides an overhead insulation lead hot melting peeling knife. The peeling knife comprises a power supply module and a hand-held hot melting peeling knife. The power supply module is connected with the hand-held hot melting peeling knife through a power line. The hand-held hot melting peeling knife comprises an insulating shell and a hot melting cutter. Two ends of the hot melting cutter are provided with conductive plug-in connection portions. A power supply switch is integrated on the insulating shell. An overheating protection module and two conductive bayonet sockets are integrated in the insulating shell, and through holes used in cooperation with the conductive bayonet sockets are arranged in the insulating shell. The conductive plug-in portions at the two ends of thehot melting cutter are plugged and connected with the two conductive bayonet sockets. The two conductive bayonet sockets are connected to a power output end of the power line in series through a connecting line. The overheating protection module and a power switch are installed on the connecting line. The power switch is used for controlling on and off of a current in the connecting line. The overheating protection module is used for cutting off power supply of a circuit where the overheating protection module is located when a detected temperature exceeds a preset temperature threshold value.The scheme is used for improving peeling efficiency of an insulated lead.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

Novel pea peeling device

The invention discloses a novel pea peeling device. A feeding hopper is arranged at the top end of a processing cabin; a horizontal peeling roller is arranged in the processing cabin; a friction ballis arranged on an outer wall of the horizontal peeling roller. A fixing plate is fixedly connected to left and right inner walls of the processing cabin; a vertical peeling roller is arranged on a rotary shaft; the upper end of the rotary shaft is movably connected onto the fixing plate; the lower end of the rotary shaft is movably connected to the bottom part of the processing cabin; a material falling opening is formed in the bottom end of the processing cabin; a driven belt wheel is arranged on the rotary shaft; a driving belt wheel is connected onto an output shaft of a motor; the motor ismounted on a right wall of the bottom end of the processing cabin; a belt is arranged on the driven belt wheel and the driving belt wheel; a dreg discharging opening and a draught fan are arranged onleft and right outer walls of the processing cabin respectively; a vibration sieve is arranged at the bottom end of the material falling opening. The domestic novel pea peeling machine disclosed by the invention can be used for rapidly finishing pea peeling work and has the advantages of rapid peeling speed, high efficiency and low labor intensity, and the production and manufacturing cost is reduced.

Owner:刘俊腾

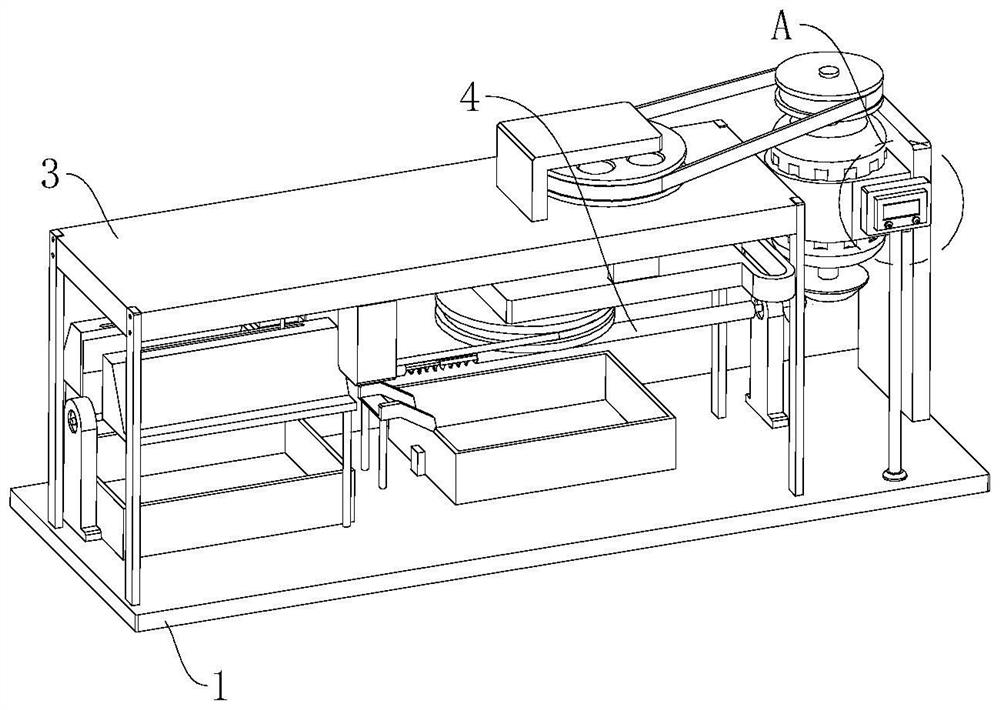

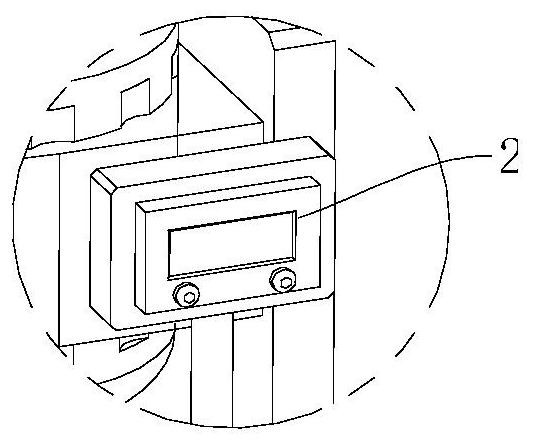

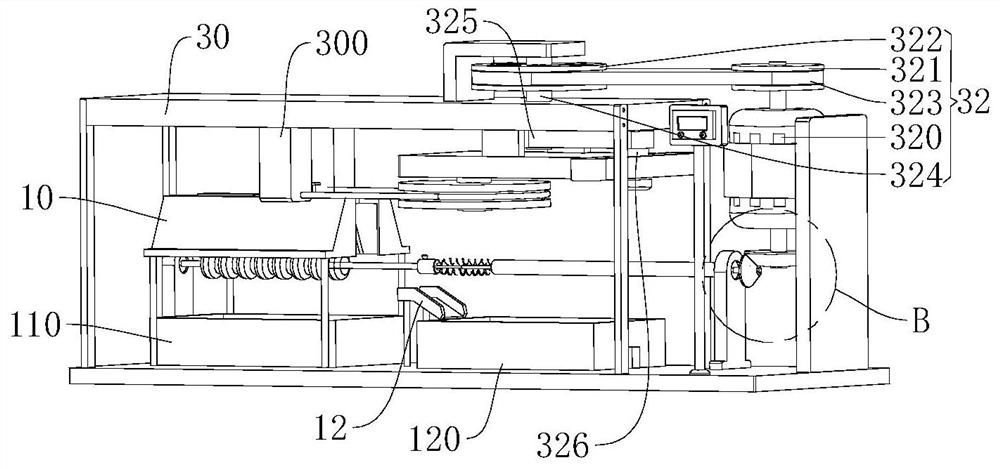

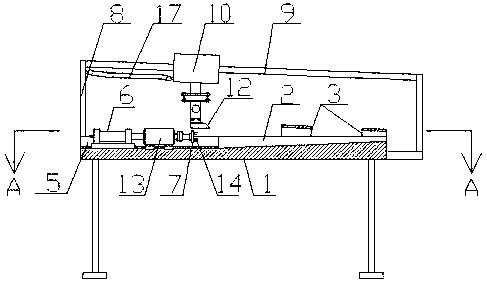

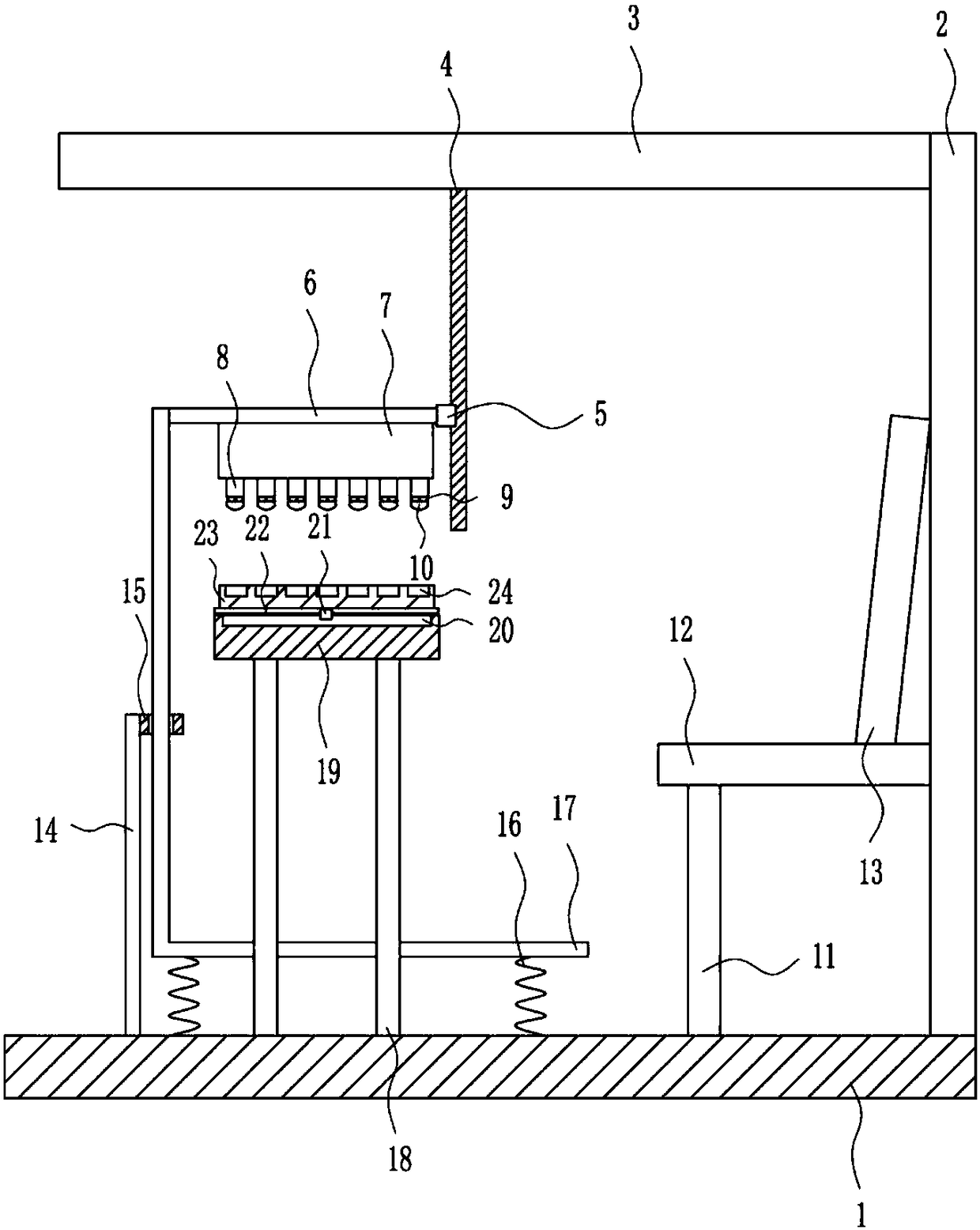

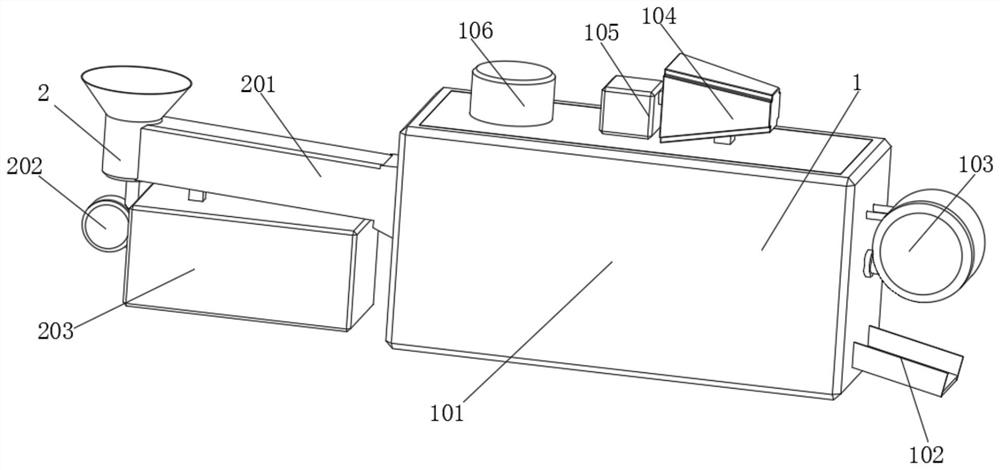

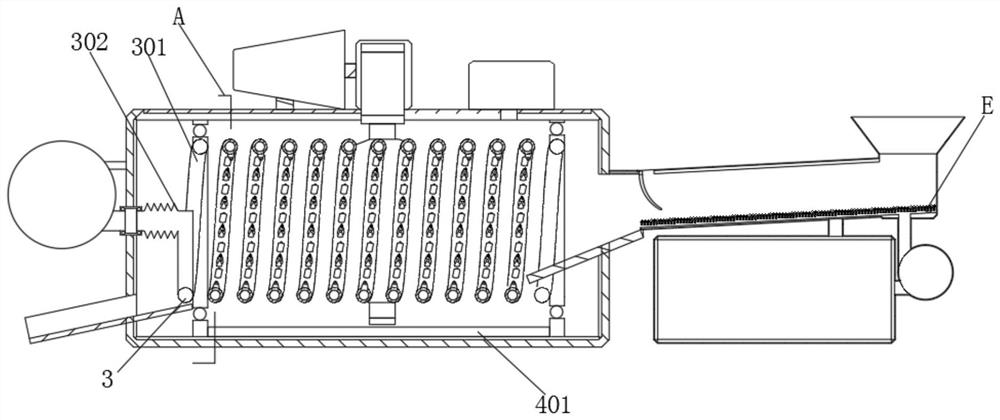

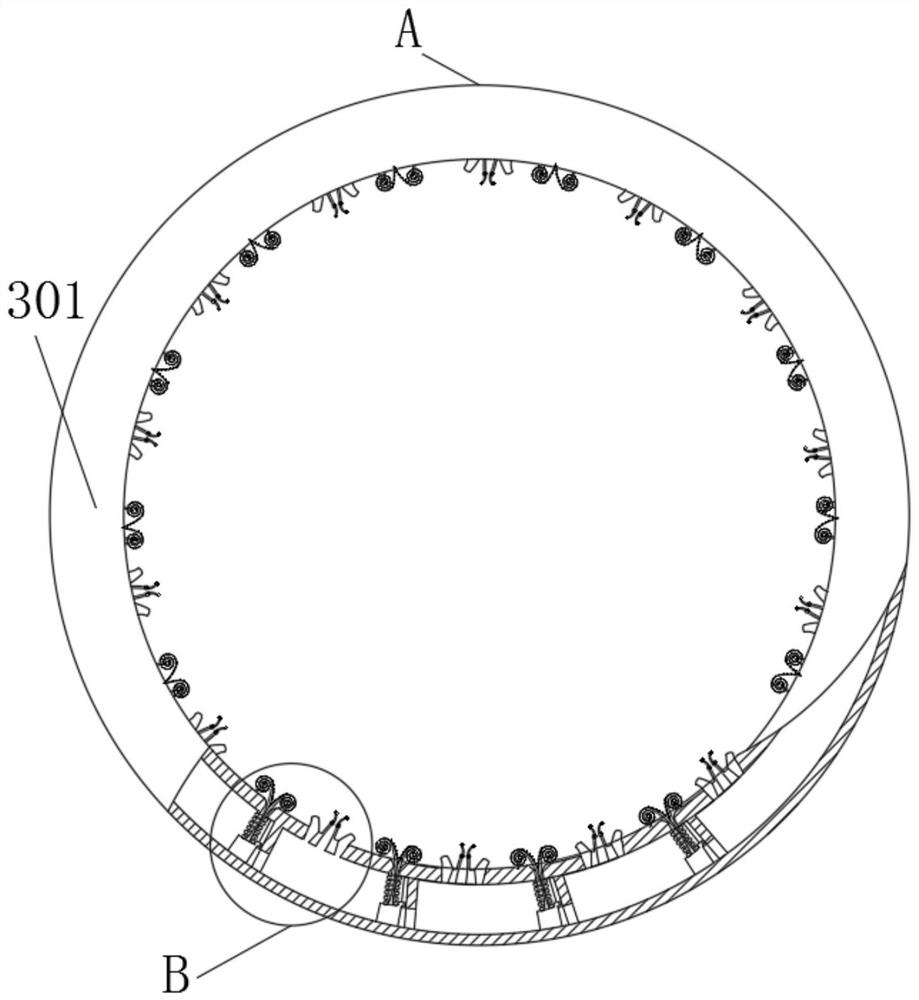

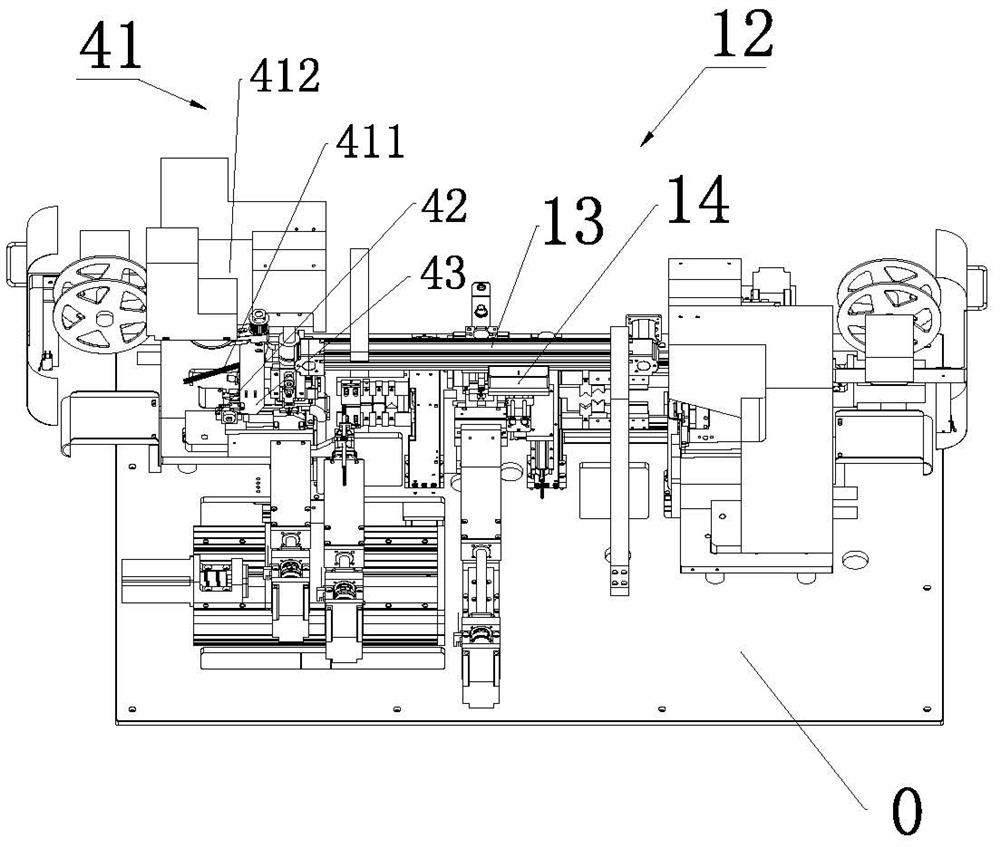

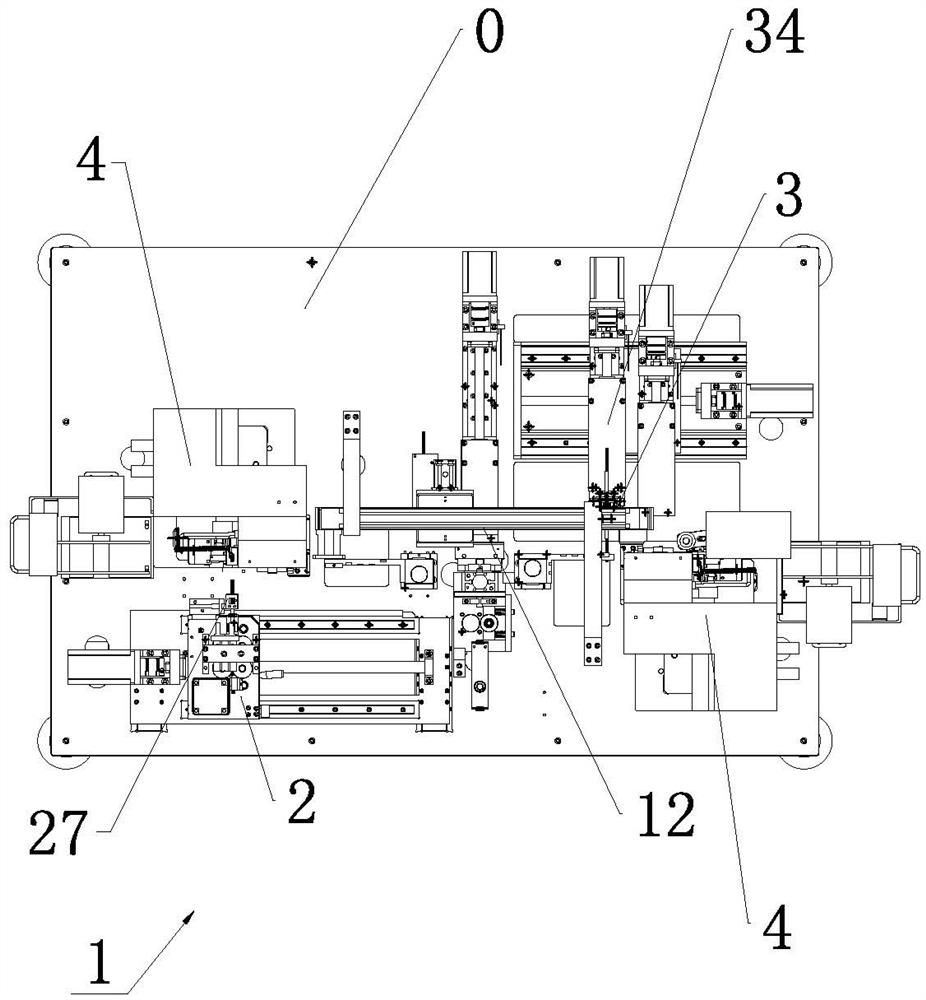

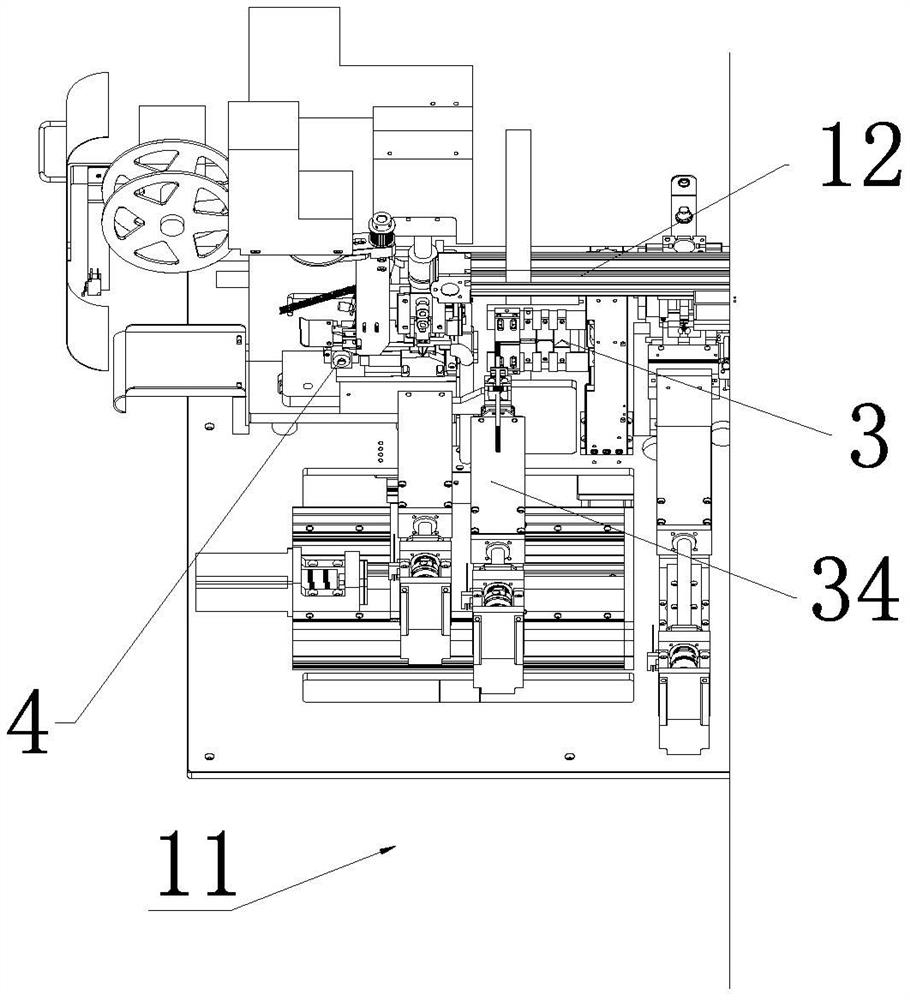

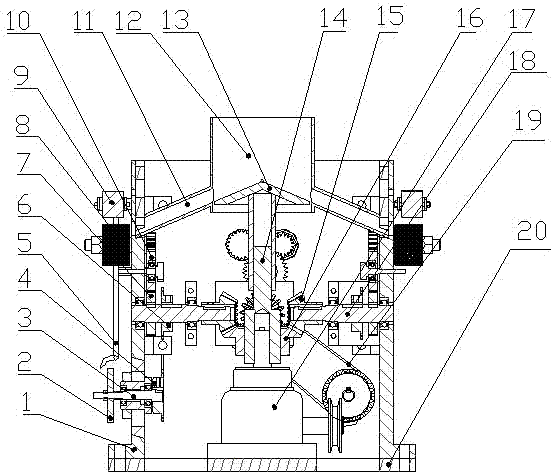

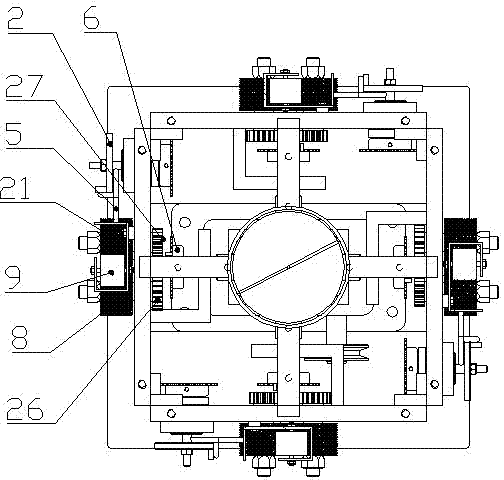

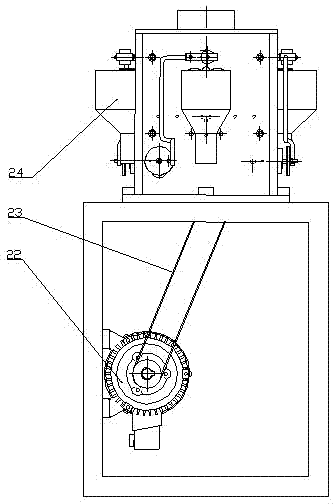

Automatic machining equipment for double-head terminal crimping sleeve

PendingCN111864649AIncrease the degree of integrated automationHigh degree of automationConnection formation by deformationApparatus for removing/armouring cablesManipulatorMachine tool

The invention relates to the technical field of non-standard automation and particularly relates to double-end terminal crimping sleeve automatic machining equipment. The equipment is characterized inthat a first machining tool composed of a wire feeding device, a wire stripping device and a sleeve device is arranged at one end of a workbench, the first machining tool sequentially carries out wire feeding, wire stripping, sleeve sleeving and other procedures on a wire, before each process, a conveying manipulator is used for clamping and conveying an electric wire, the machining tool can sequentially machine two ends of the electric wire, and the integrated automation degree is improved; a plurality of cutters arranged side by side are adopted in the wire stripping device to strip the electric wire so that the stripping speed is greatly increased; a plurality of wire pressing wheels are combined with a finger air cylinder, wires can be stably and tidily matched with the next procedure, and the cut wires are subjected to the heat-shrinkable sleeve sleeving procedure through the sleeve sleeving device. The equipment is high in automation degree, all procedures are connected in place, use cost is low, and machining efficiency is improved while the labor cost is controlled to a certain extent.

Owner:深圳市日研线束设备有限公司

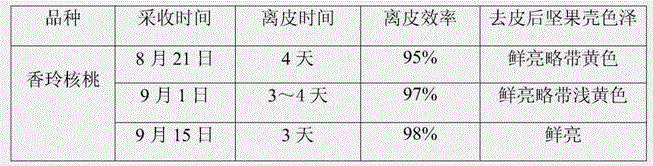

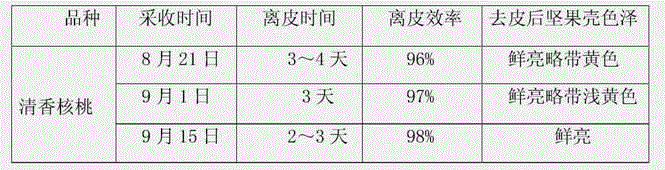

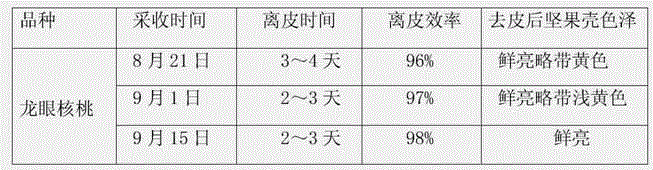

Method for skinning walnuts by hot-air drying and blowing and ethephon spraying

InactiveCN103598663AFast peelingNo infiltration into the nuts will occurHuskingHullingPolymer scienceEthephon

The invention discloses a method for skinning walnuts by hot-air drying and blowing and ethephon spraying. The method is characterized by including paving harvested green-skin walnuts on a layered block rack, spraying with ethephon by times prior to hot-air drying and blowing, and then stacking the green-skin walnuts in a cool place or indoors at the temperature of 30 DEG C and relative humidity of 80%-95% for 3-4 days, wherein skinning rate reaches above 98%. The method has the advantages of high skinning rate and high skinning degree.

Owner:王茜

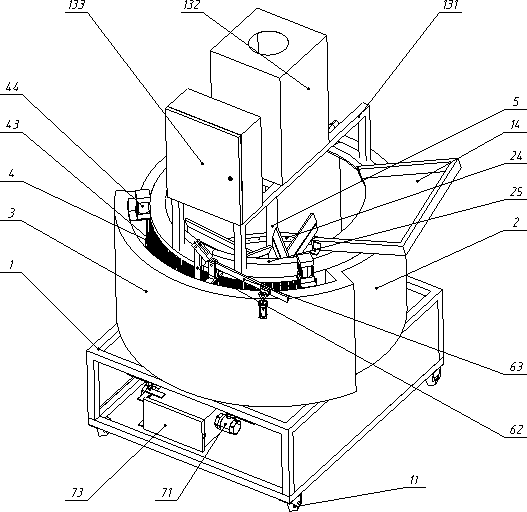

Self-adaptive camellia oleifera fruit peeling device

InactiveCN105273827AAvoid damageEasy to separateFatty-oils/fats productionCamellia oleiferaAgricultural engineering

The invention relates to a self-adaptive camellia oleifera fruit peeling device. The self-adaptive oil tea fruit peeling device is characterized by comprising a rack, wherein a box body is connected to the rack, a peeler is arranged on the upper portion of the box body, and a screening device is arranged on the lower portion of the box body; the peeler comprises a rotating shaft which is connected with the rack in a rotating mode, and the rotating shaft is sleeved with a roller; a cover connected with the box body is arranged on the upper portion of the roller, and a feed hopper is arranged on the cover; an arc plate connected with the box body in a rotating mode is arranged at the bottom of the cover; the arc plate is connected with one end of a regulating rod; the other end of the regulating rod is connected with the box body; the rotating shaft is connected with a driving device connected to the rack; the screening device comprises a stirring shaft connected with the rack in a rotating mode, and multiple stirring teeth are connected to the stirring shaft; a groove-shaped sieve is arranged below the stirring shaft, and the top of the groove-shaped sieve is connected with the box body; a discharge hopper is connected to the lower portion of the groove-shaped sieve; the stirring shaft is connected with another driving device connected to the rack. The self-adaptive camellia oleifera fruit peeling device is convenient to use and high in peeling rate and peeling speed and causes little damage to tea seeds.

Owner:中机康元粮油装备(北京)有限公司 +1

Small pineapple device for quickly peeling pineapple and removing pineapple eyes

The invention provides a small pineapple device for quickly peeling a pineapple and removing pineapple eyes. The small pineapple device comprises a fixing support block and a cutting block, wherein the cutting block is arranged on the top of the fixing support block, the fixing support block comprises a shell and a sponge bottom plate which is stuck to the bottom of the shell, and the cutting block comprises arc-shaped knives, external plates and elastic plates. The outer sides of the arc-shaped knives are fixedly connected with the external plates through splitting knives, and the bottoms ofthe external plates are fixedly connected with the elastic plates. An inner groove is embedded into the middle of the top of the shell, the top in the middle of the inner groove is fixedly connected with prismatic scraping knives, a sliding rail is embedded into the middle of the inner wall of the inner groove, a bearing plate is slidably connected with the inner side of the sliding rail, the middle of the bottom of the bearing plate is fixedly connected with a spring column, the bottom of the spring column is fixedly connected with a rotary plate, and a juice discharging groove is embedded into the periphery of the bottom of the inner groove. The whole device is stable in structure, the pineapple peeling speed and efficiency are high, the size is small, and the device is convenient and fast to use and operate.

Owner:于格酒业(广东)有限公司

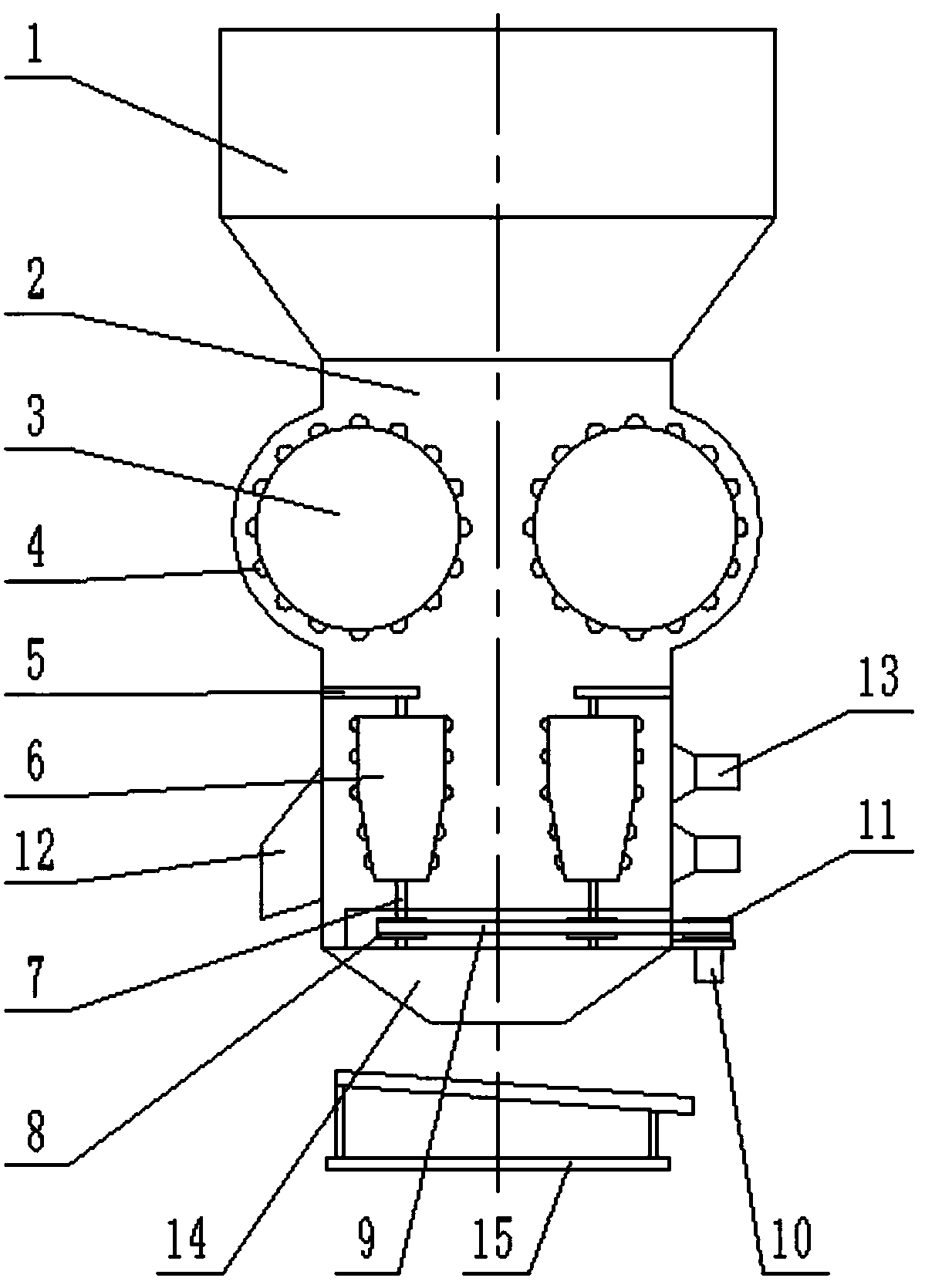

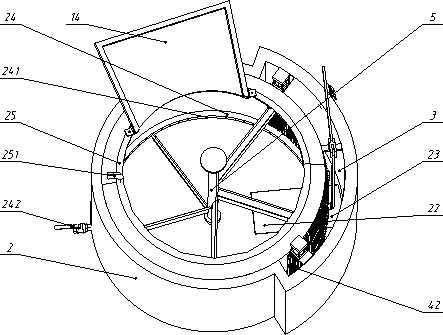

Energy-saving centrifugal conveying type multi-port lotus seed shucking machine

InactiveCN103110168ASmall footprintReduce damage rateHuskingHullingElectric machinerySmall footprint

The invention relates to food machining equipment, and in particular relates to an energy-saving centrifugal conveying type multi-port lotus seed shucking machine. According to the energy-saving centrifugal conveying type multi-port lotus seed shucking machine, a shucking device is respectively installed on four side edges of a square rack; the four shucking device are driven by a driving device; a feeding device is arranged in the center above the square rack; the feeding device is connected with the shucking devices; and blanking hoppers are arranged below the shucking devices. The energy-saving centrifugal conveying type multi-port lotus seed shucking machine has the advantages that the whole machine is compact in structure and small in occupied space when being used for production in large scale; the four shucking devices can be driven by one motor to carry out machining simultaneously, so that the production efficiency is high and the energy consumption is low; the feeding and discharging operations are continuous, and the machining process is approximately automatic, so that the labor management and maintenance cost is low; the shucking action is carried out rapidly, the shucking success rate is high, and the lotus seed damage rate is low; and the machine is simple to operate, reliable in principle and small in occupied space, and is applicable to large-scale and automatic lotus seed shucking for lotus seed machining companies.

Owner:湘潭隆胜湘莲有限公司

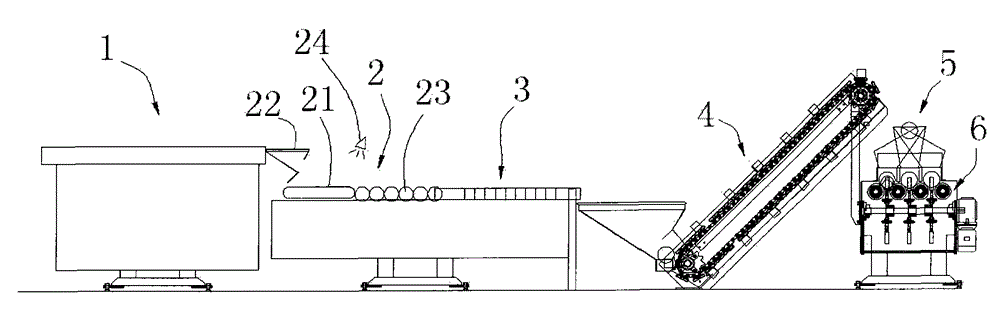

Onion peeling method and peeling machine

InactiveCN104413537AEasy to operateFast peelingFood treatmentAgricultural engineeringWorking environment

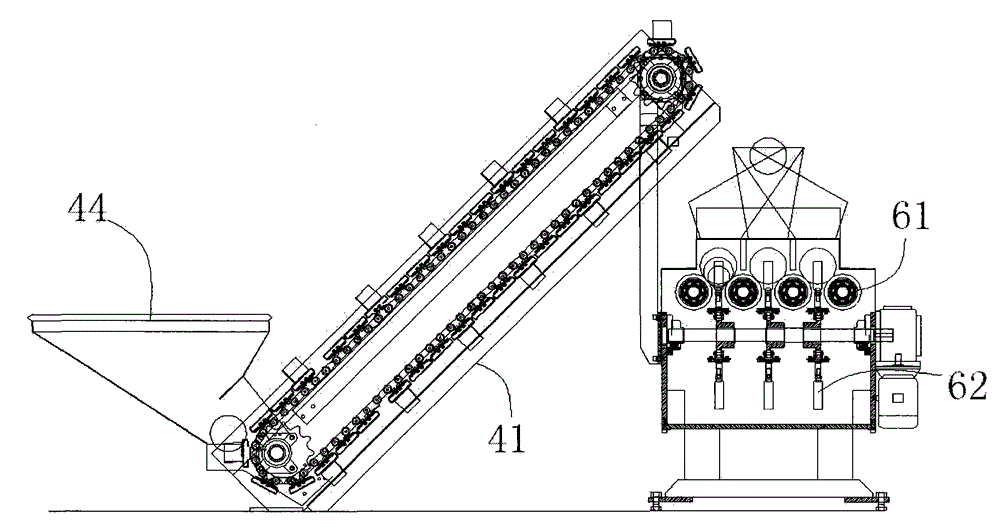

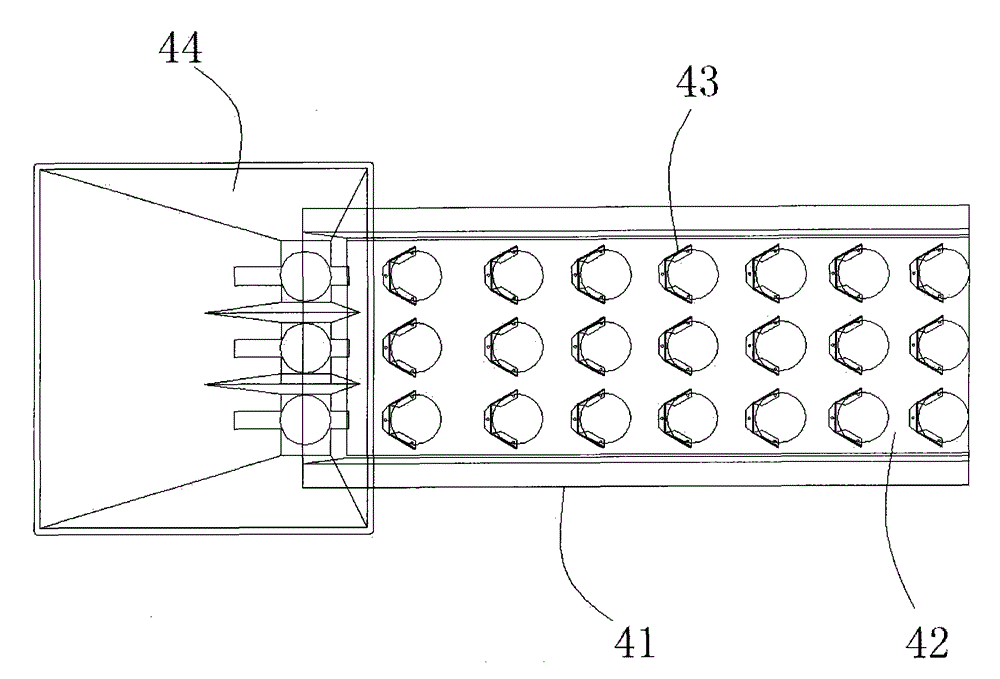

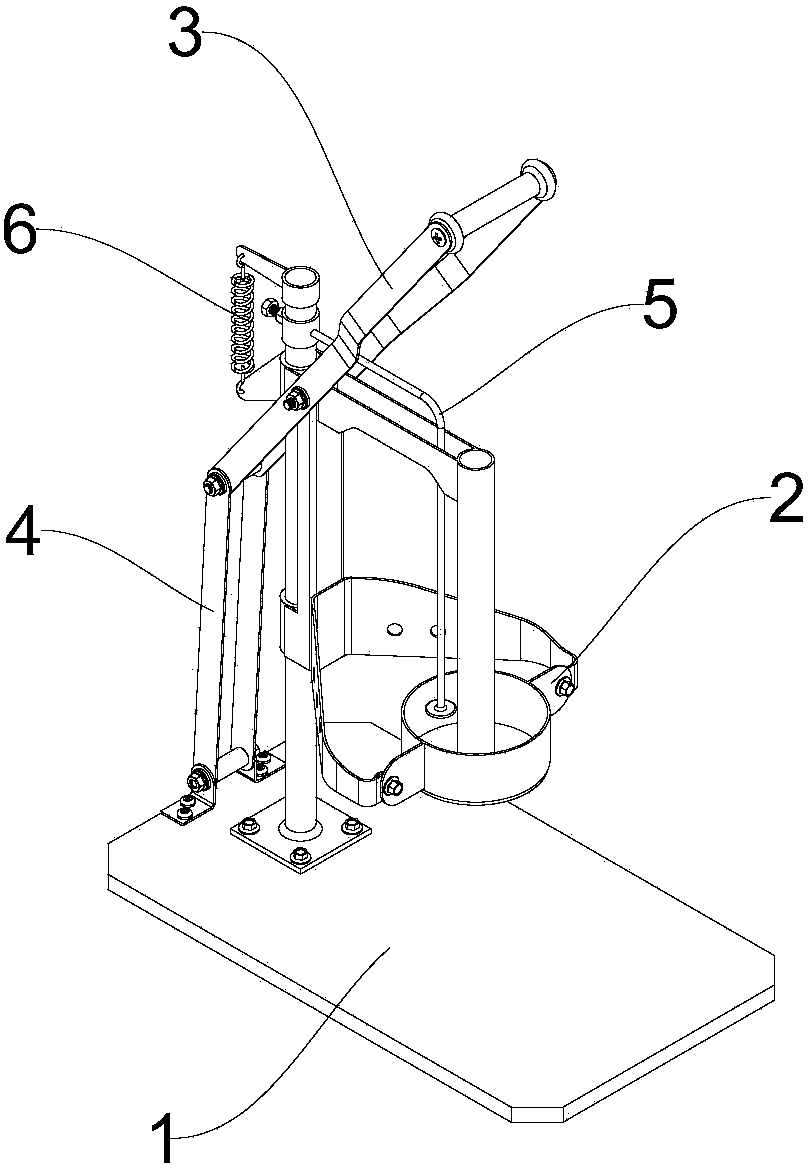

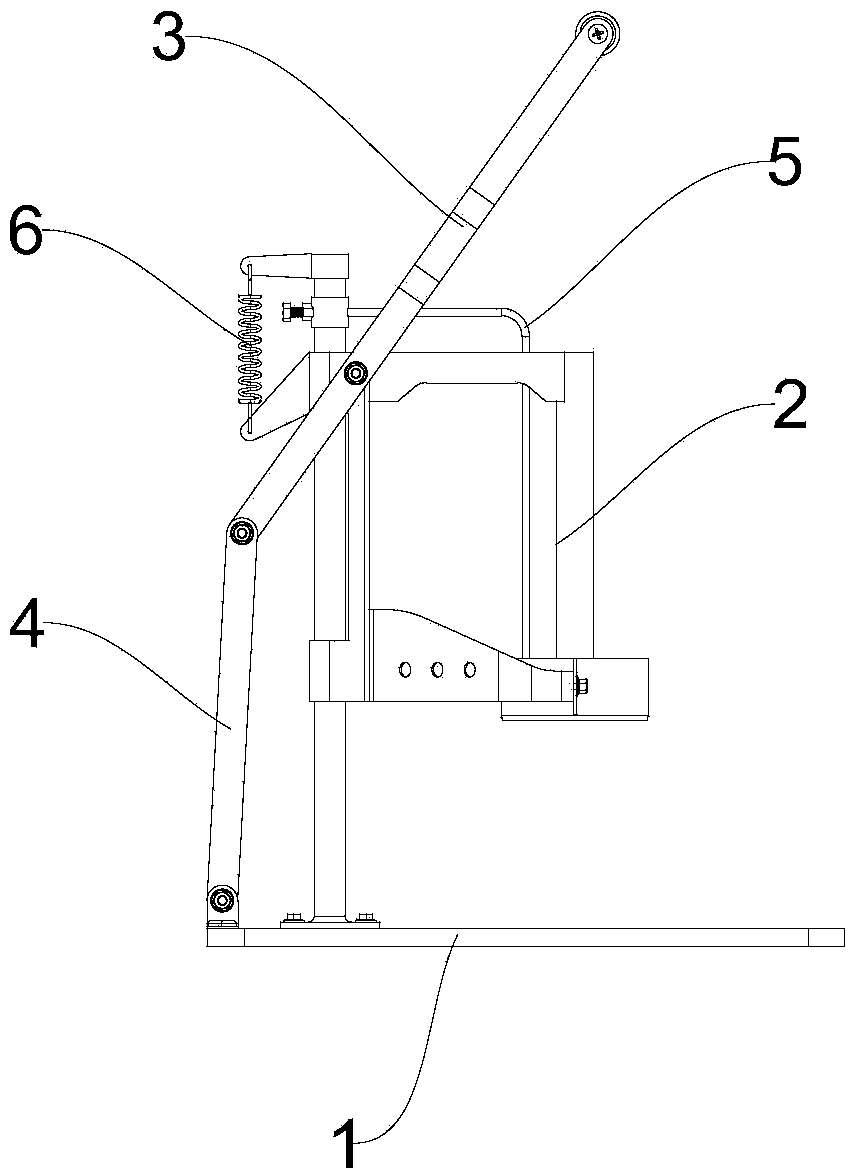

The invention discloses an onion peeling method and further discloses a peeling machine implementing the method. The peeling machine comprises a feeding platform, a cleaning and conveying platform, a classified screening mechanism, a lifting conveyor, an onion distributor, a cutting unit, a separator, a finished product conveyor and a return platform; the onion distributor is arranged above the cutting device; the feeding platform, the cleaning and conveying platform and the classified screening mechanism are arranged and connected in sequence; one end of the lifting conveyor is connected with the classified screening mechanism and the other end is connected with the onion distributor. The method provided by the invention has simple steps, is easy to realize and capable of quickly peeling onions and has good peeling effect and high work efficiency; the peeling machine provided by the invention has the advantages of smart and rational design, easy operation and high peeling effect; the work efficiency is the workload of about 20 persons, the work environment is improved greatly, the labor intensity is reduced greatly and the processing cost is saved; and the peeling machine is beneficial to enterprise development and beneficial to wide promotion and application.

Owner:高密圣泰机电科技有限公司

Pineapple peeler

InactiveCN104013296ALabor-saving operationAvoid stickingFruit coringPeelersEngineeringMechanical engineering

The invention discloses a pineapple peeler. The pineapple peeler comprises a base and a peeling knife assembly. The base comprises a bottom plate and a sliding rod, and the sliding rod and the bottom plate are vertically connected. The peeling knife assembly comprises an annular peeling knife, a guiding barrel and a first connecting frame. One end of the first connecting frame is connected with the annular peeling knife, the other end of the first connecting frame is connected with the guiding barrel, the annular peeling knife is vertically arranged, the lower end of the annular peeling knife is provided with a blade, and the guiding barrel is in sliding connection with the sliding rod. The pineapple peeler has the advantages that the annular peeling knife and a kernel removing barrel are arranged, and the peel and hard kernels of the pineapple can be removed at a time; a lever labor-saving structure is adopted, and the operation can be carried out in a labor-saving mode; an L-shaped push rod is adopted, and the pineapple peeler can be prevented from being jammed with the pineapple; a spring is adopted and can automatically rebound, using is convenient, the peeling speed is high, and the operation is easy.

Owner:王鼎兴

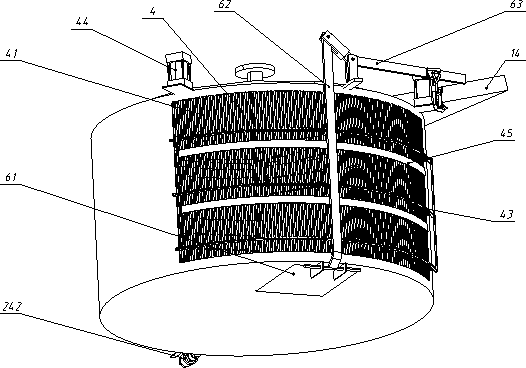

A kind of lotus seed peeling machine

ActiveCN109315794BAvoid easy cloggingImprove filtration efficiencyHuskingHullingEngineeringMechanical engineering

Owner:河北玉龙食品机械制造有限公司

Peeling equipment for soybean processing and working method thereof

InactiveCN111449261AEasy to sieveSolve technical problems with impurities and poor reliabilityGas current separationFood treatmentGear driveSoybean hulls

The invention discloses peeling equipment for soybean processing and a working method thereof. The equipment comprises a box body. A rotating outer cylinder is arranged on the inner side of the box body, a rotating inner roller is arranged on the inner side of the rotating outer cylinder, a collecting bin is arranged below the box body, a screen is fixedly arranged at the joint of the collecting bin and the box body, a material transporting rotating shaft is rotatably arranged on the inner side of a material transporting bin, material transporting blades are fixed on the material transportingrotating shaft, and a material conveying bin is fixedly arranged on one side of the box body. A lower lifting gear is in transmission connection with an upper lifting gear through a material conveyingchain, a plurality of material conveying grooves are fixedly formed in the material conveying chain, and the bottom end of a guide pipeline is connected with the upper surface of a storage bin. According to the peeling equipment, the rotating outer cylinder and the rotating inner roller rotate in opposite directions at the same time to remove soybean hulls, the effect is good, the working efficiency is high, soybeans are automatically conveyed and collected in the whole process, the soybeans and the soybean hulls are convenient to screen, and the reliability of the product is guaranteed.

Owner:徐健

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com