Method for skinning walnuts by hot-air drying and blowing and ethephon spraying

An ethephon, drying and blowing technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problem of difficult control of ethylene utilization, and achieve the effect of easy control of ethylene utilization, fast speed, and bright and beautiful skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

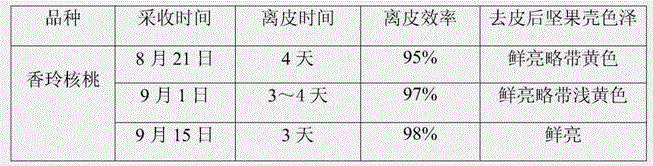

[0018] After harvesting fresh Xiangling walnuts, peel them according to the following steps:

[0019] (1) Place the harvested fresh Xiangling walnuts on a layered grid, and lay a layer of walnut fruit on each layer. The grid is made of fine iron wire, and the grid has 3 to 5 layers. The number of layers should not be too many to avoid incomplete spraying when spraying ethephon solution;

[0020] (2) After the walnut fruit is laid, spray the walnut fruit with a concentration of 0.3% to 0.5% ethephon solution. The spraying method is from bottom to top. The ethephon solution is sprayed at 0.5L per second, and the spraying time is controlled for half a minute. ;

[0021] (3) After spraying, turn on the hot air blower for hot air drying. The blowing temperature of the hot air blower is 200-250°C, and the hot air drying time is 20-30 minutes. Hot air blower;

[0022] (4) After the hot air drying is completed, spray with 0.1% to 0.3% ethephon solution. The method of spraying is fr...

Embodiment 2

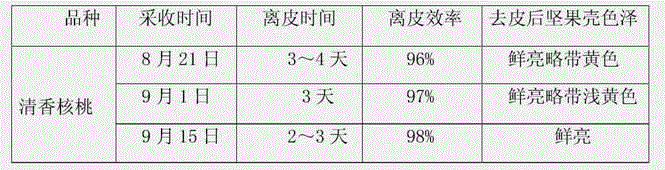

[0030] Harvest fresh fragrant variety walnuts, peel according to the peeling method of example 1, and its sample observation test result is shown in Table 2.

[0031]

Embodiment 3

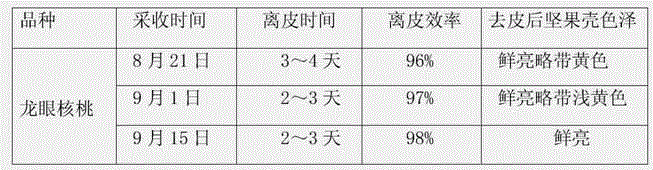

[0033] Harvest fresh longan variety walnuts, peel according to the peeling method of example 1, and its sample observation test results are shown in Table 3.

[0034]

[0035] Result analysis and discussion: From the sample observation results of examples 1 to 3, the walnut peeling efficiency is related to the harvest time and walnut variety. The later the harvest time, the better the peeling effect and the higher the peeling degree. , the present invention suggests that walnuts should be harvested in good time, generally in mid-September.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com