Energy-saving centrifugal conveying type multi-port lotus seed shucking machine

A peeling machine and feeding technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of unguaranteed safety, unsatisfactory cutting effect, unstable working performance, etc., and achieve rapid shelling action , Low labor management and maintenance costs, low labor maintenance and management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

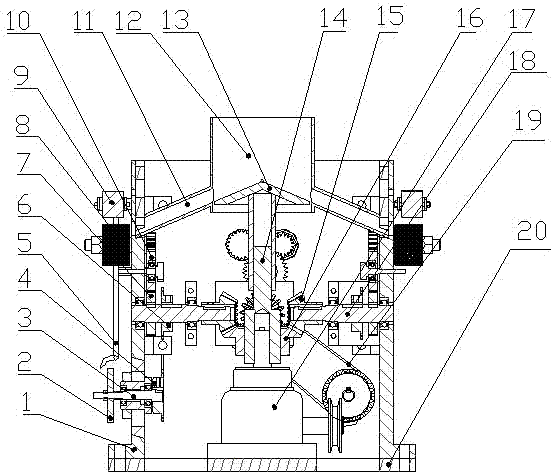

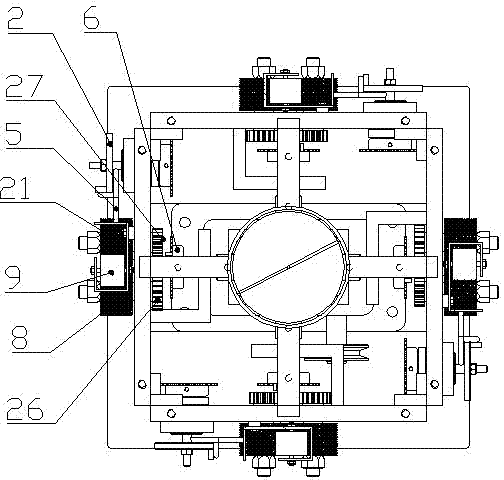

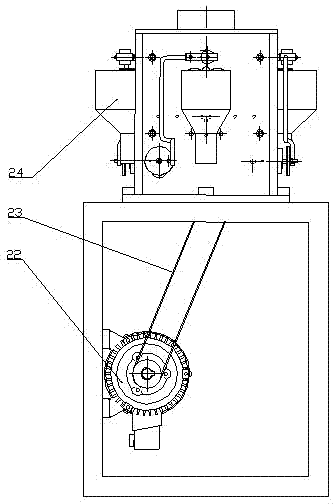

[0021] Such as Figure 1-Figure 7 Shown, the present invention's energy-saving centrifugal feeding type multi-port lotus seed peeling machine, it is respectively installed with a peeling device on four sides of square frame 1, and four peeling devices are driven by driving device, and on square frame 1 A feeding device is arranged at the center of the upper part, and the feeding device is connected to the peeling device, and the lower part of the peeling device is a hopper 24 .

[0022] Described peeling device comprises high-speed peeling roller 8, low-speed peeling roller 21 and the movable peeling roller 9 that the blade that alloy material is made is installed circumferentially; All are engraved with angular teeth, the gap between the two is less than the diameter of lotus seeds, and they are installed on the frame 1 at the same level, and the movable peeling roller 9 is installed directly above the high-speed peeling roller 8 and the low-speed peeling roller 21. " font...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com