Patents

Literature

602results about How to "Easy to sieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Use of roll compacted pyrogenically produced silicon dioxide in pharmaceutical compositions

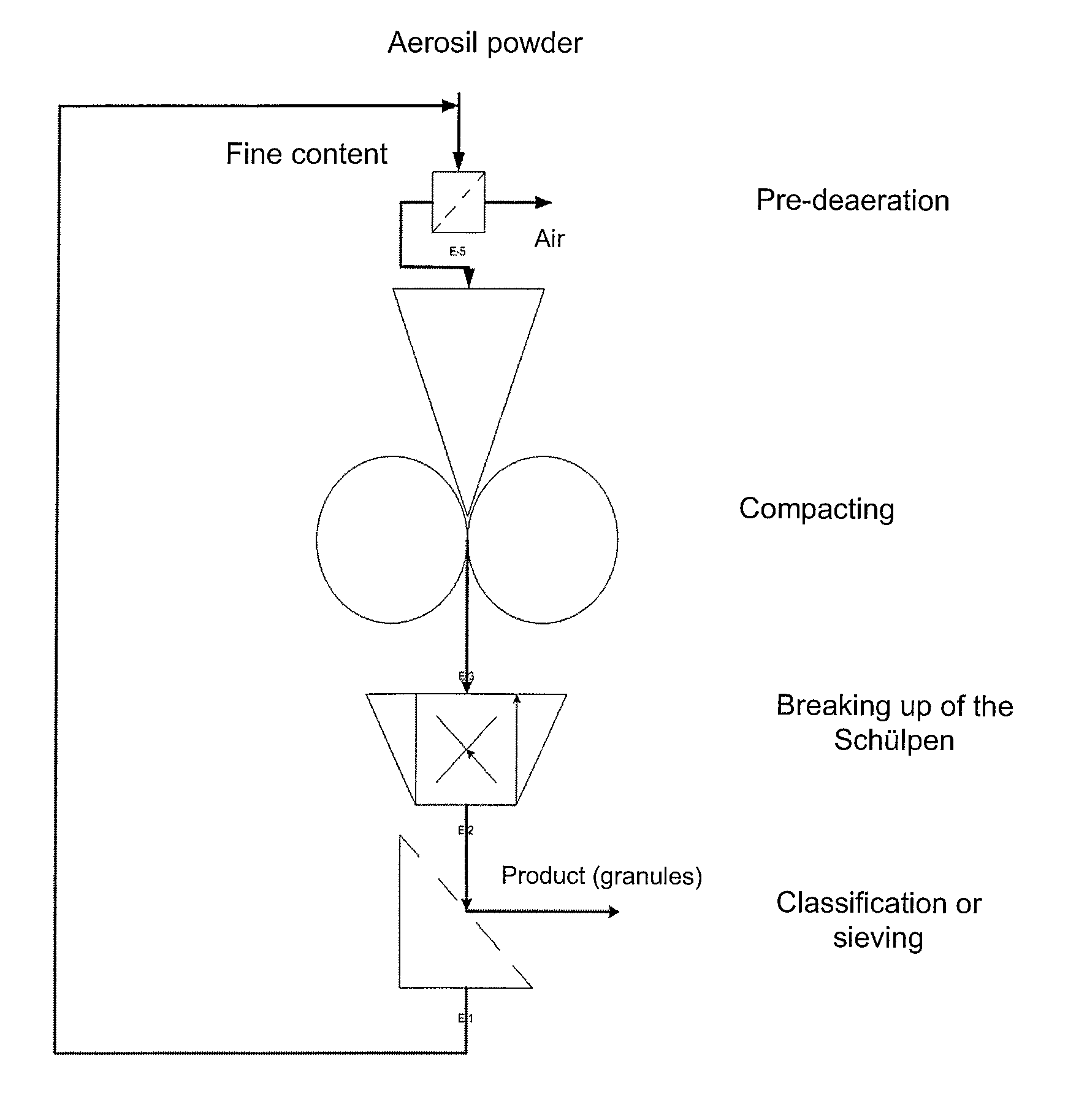

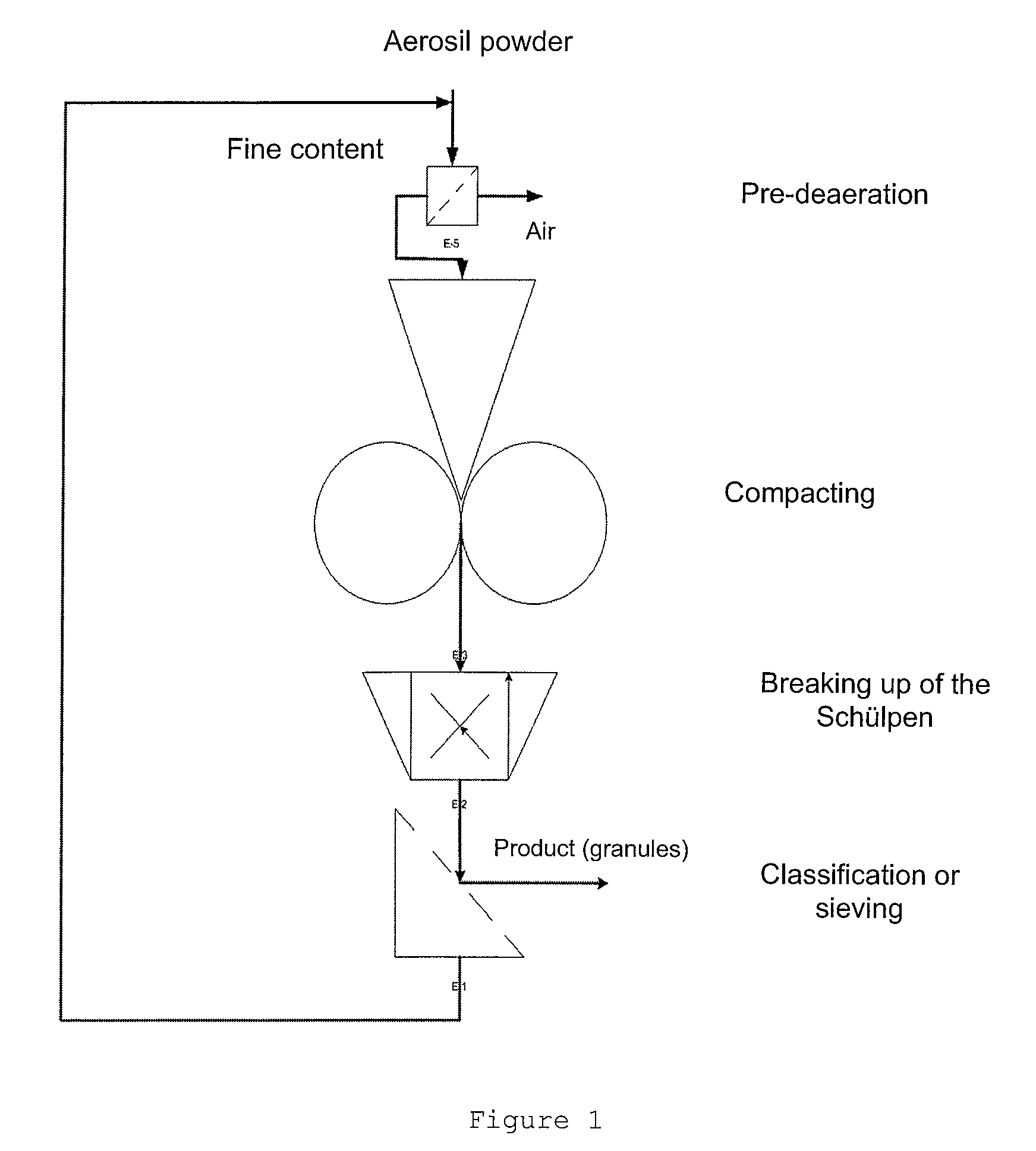

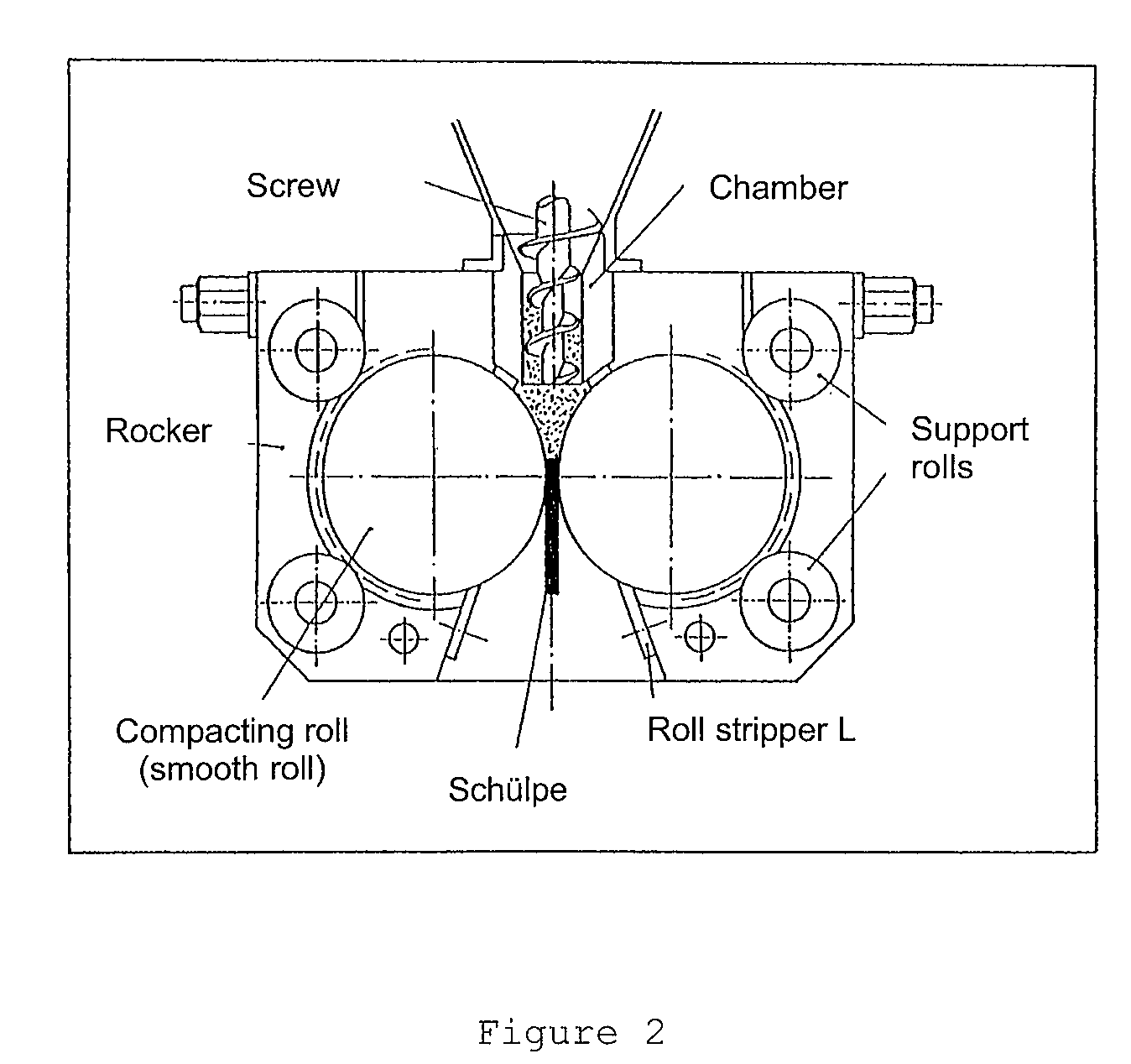

The use of Schülpen based on pyrogenically produced silicon dioxide in pharmaceutical compositions is described.

Owner:EVONIK DEGUSSA GMBH

Chemical separating method for aluminum foil in waste lithium ion battery positive plate

ActiveCN102412430AImprove solubilityLoose surface compositionSolid waste disposalWaste accumulators reclaimingActive agentEngineering

The invention discloses a chemical separating method for an aluminum foil in a waste lithium ion battery positive plate. The method comprises the following steps of: (1) adding the waste lithium ion battery positive plate into a surfactant solution, performing ultrasonic oscillation treatment to loosen surface components of the positive plate, washing, drying, filtering and recovering the positive plate; (2) putting the positive plate treated in the step (1) into a mixed solution of N, N-dimethylacetamide and N-methylpyrrolidone, heating, taking the positive plate out, and washing with water; (3) putting positive plate treated in the step (2) into water, performing ultrasonic oscillation till the aluminum foil as well as active substances of an anode, a conducting agent and a bonding agent; and (4) filtering a solution obtained in step (3), washing to obtain a mixture containing the active substances, the conducting agent, the bonding agent and the aluminum foil, and screening to obtain a dissociative aluminum foil sheet. In the method, the aluminum foil sheet can be recovered directly; and compared with the conventional method for extracting an aluminum foil after dissolving with alkali, the chemical separating method has the advantages: the process is simplified, and cost is lowered.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

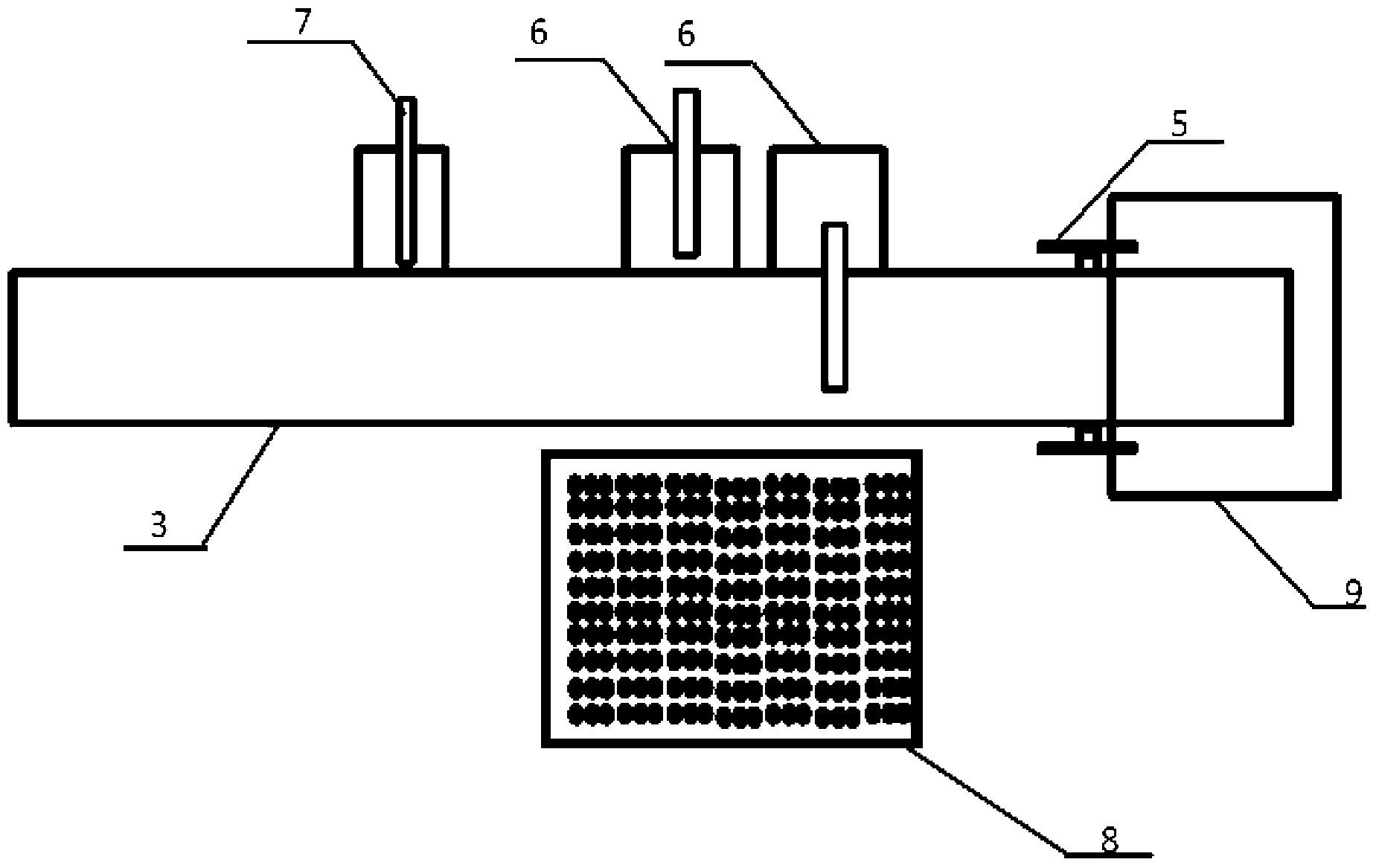

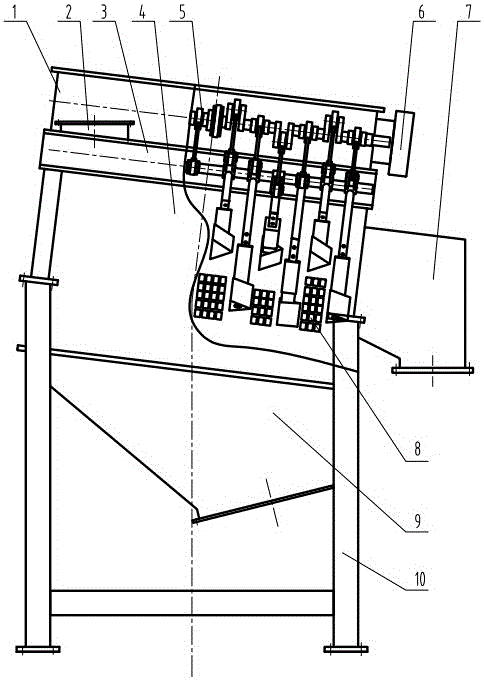

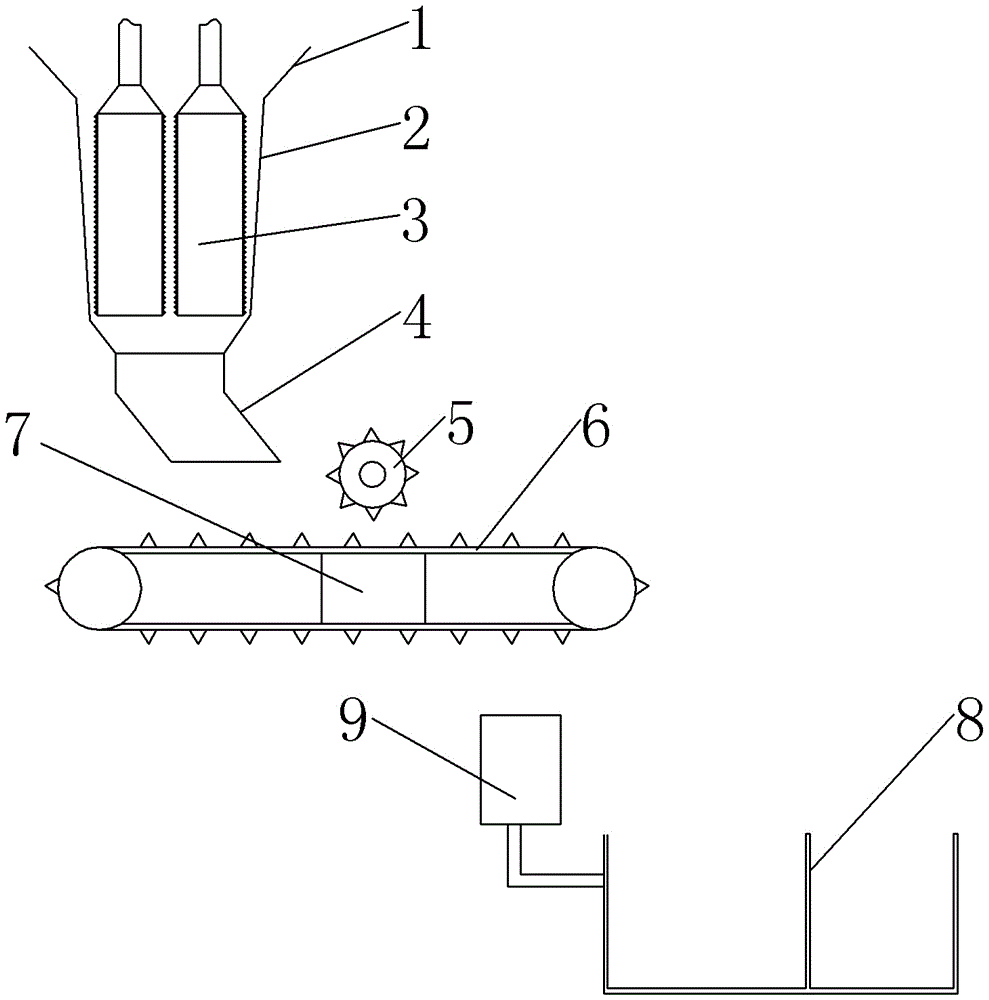

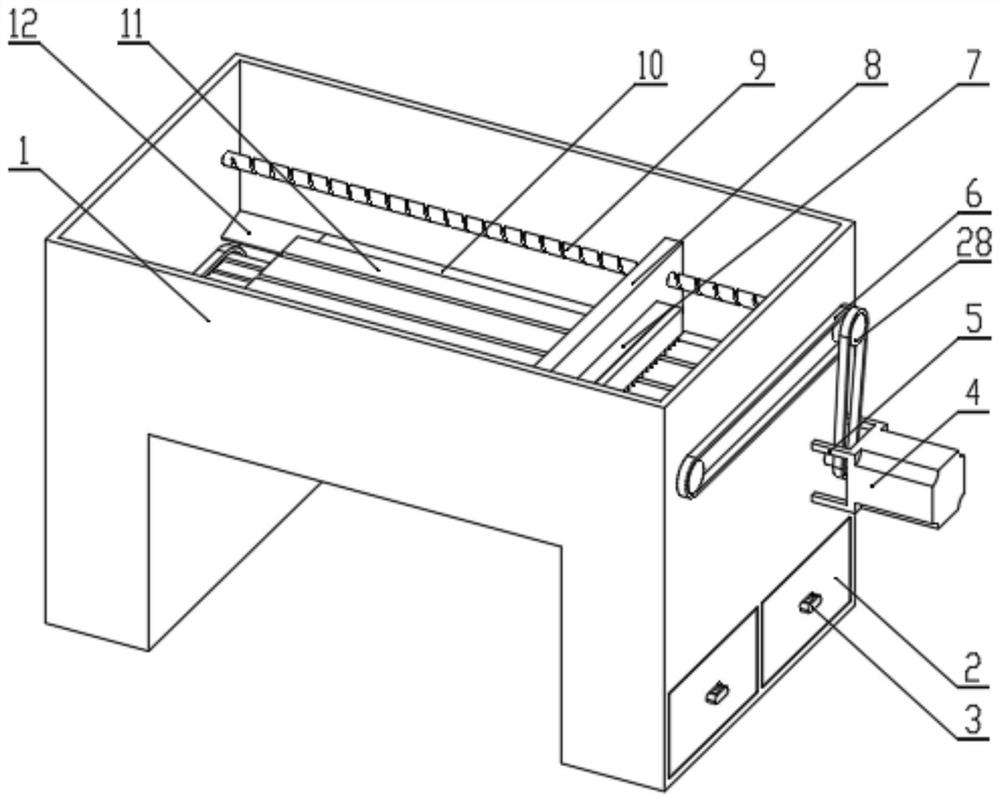

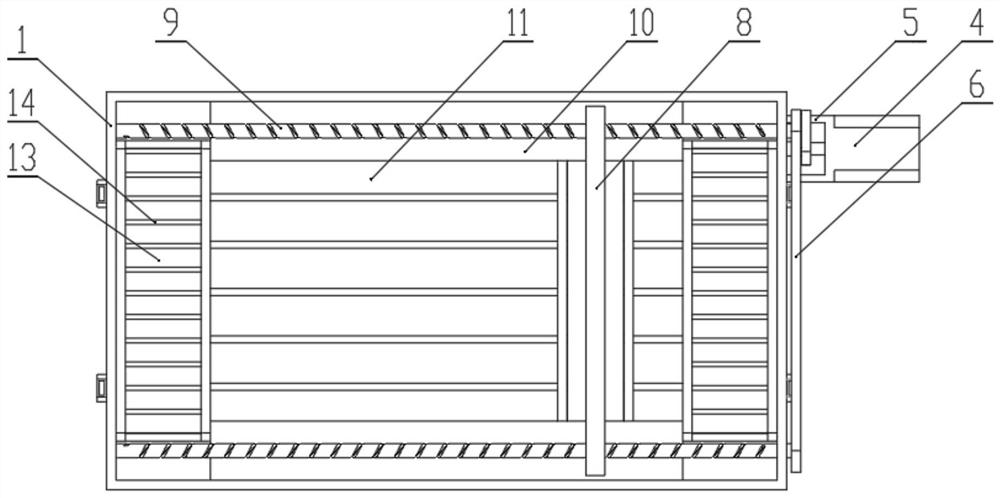

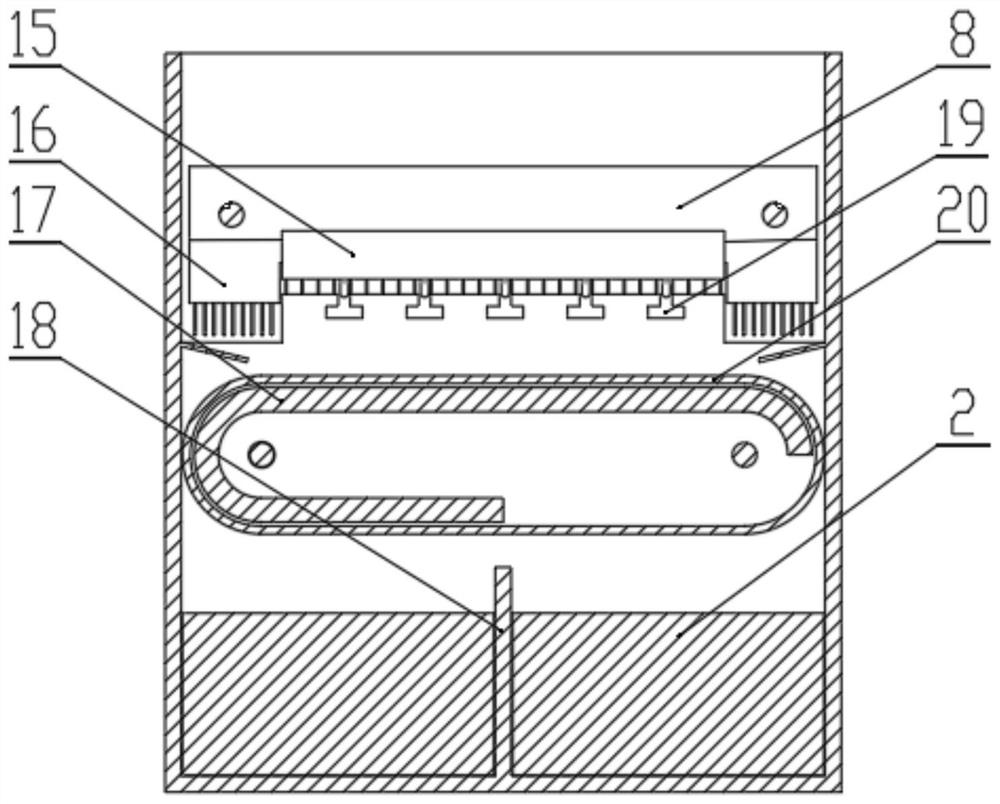

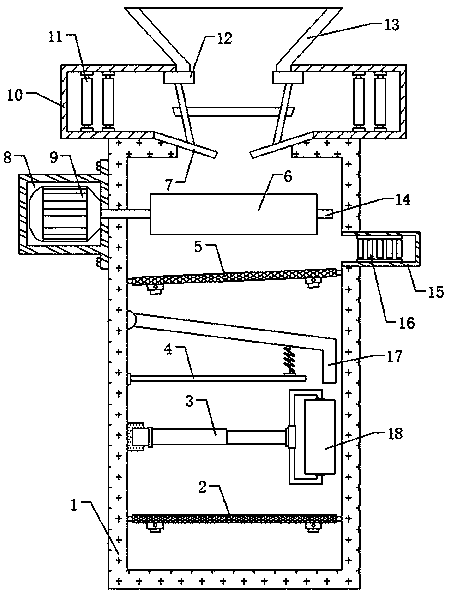

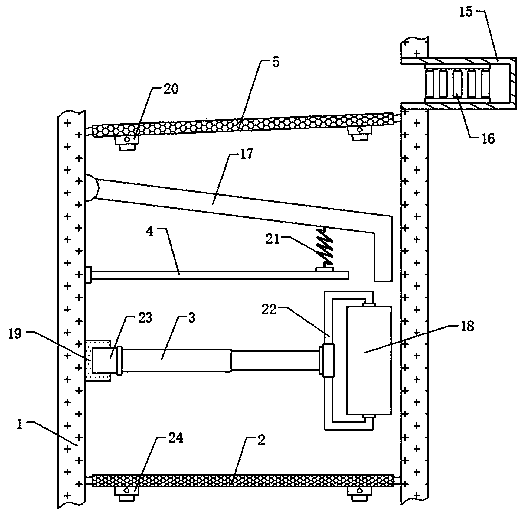

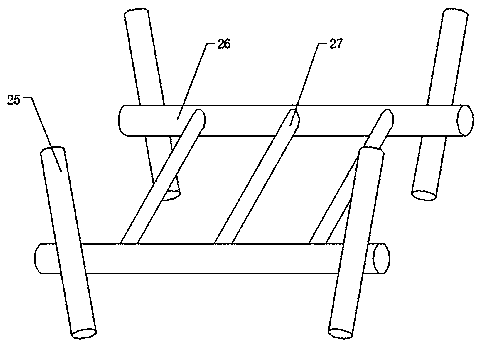

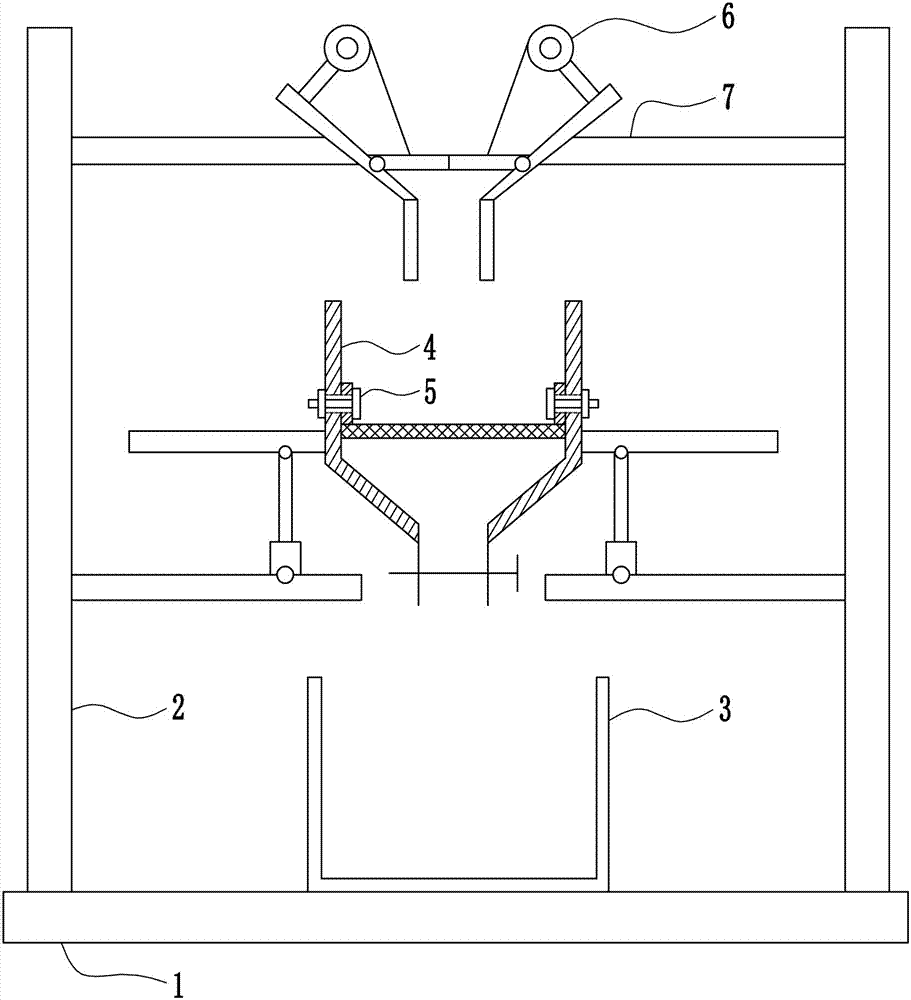

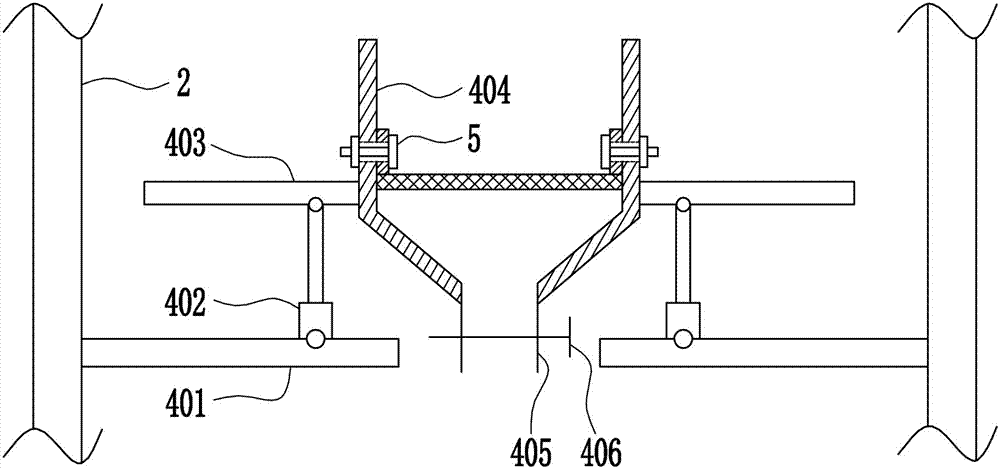

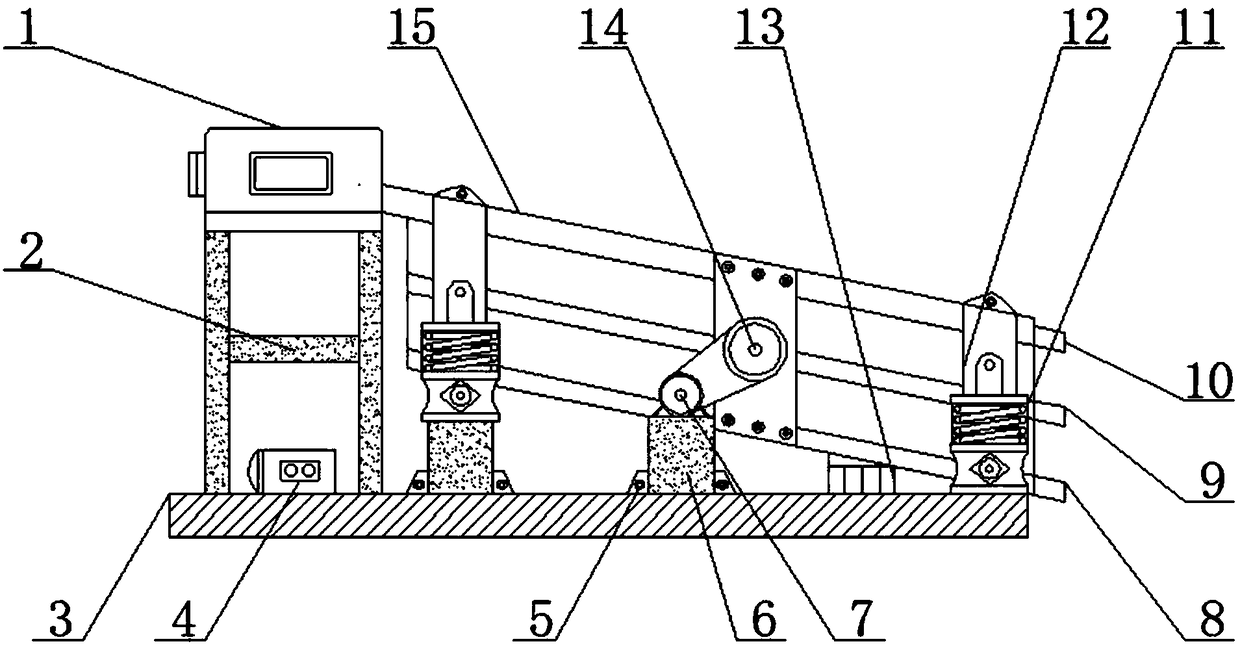

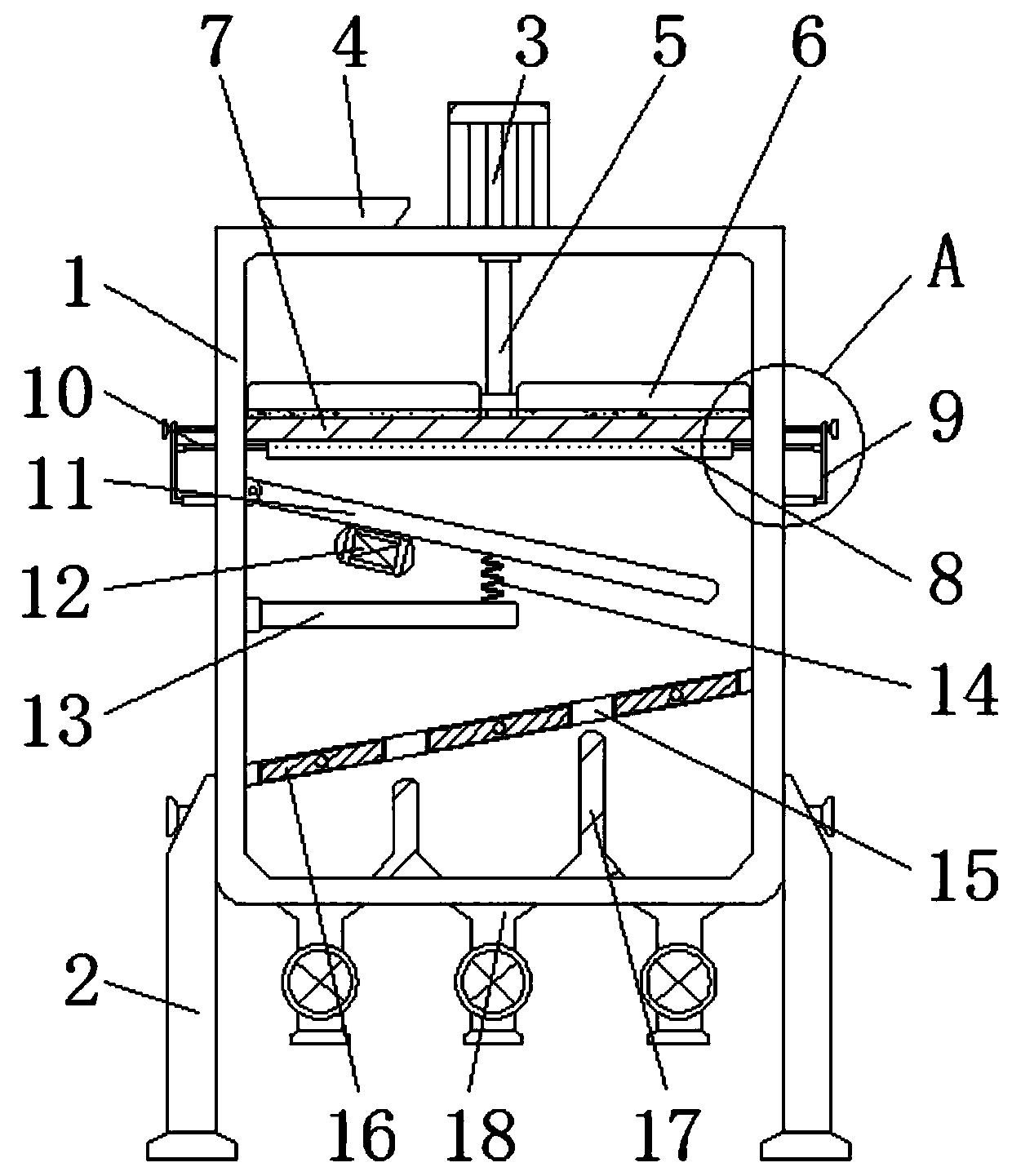

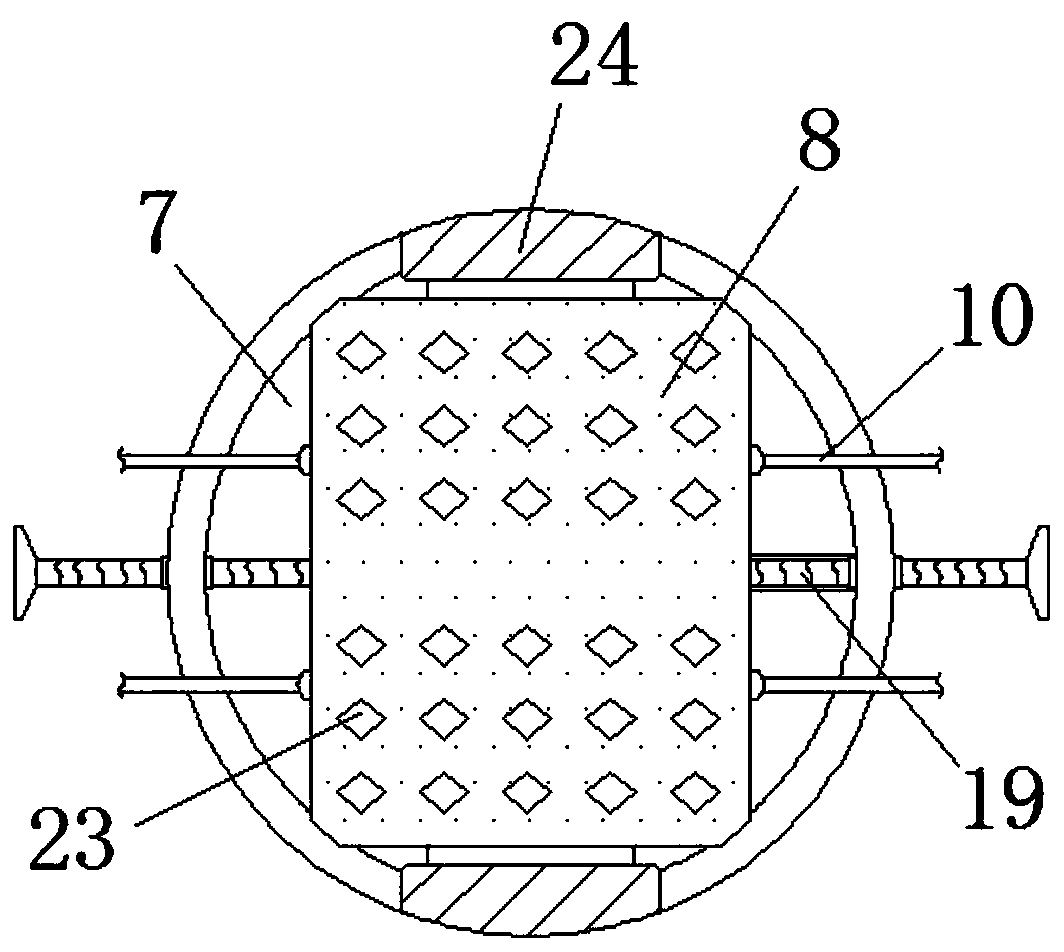

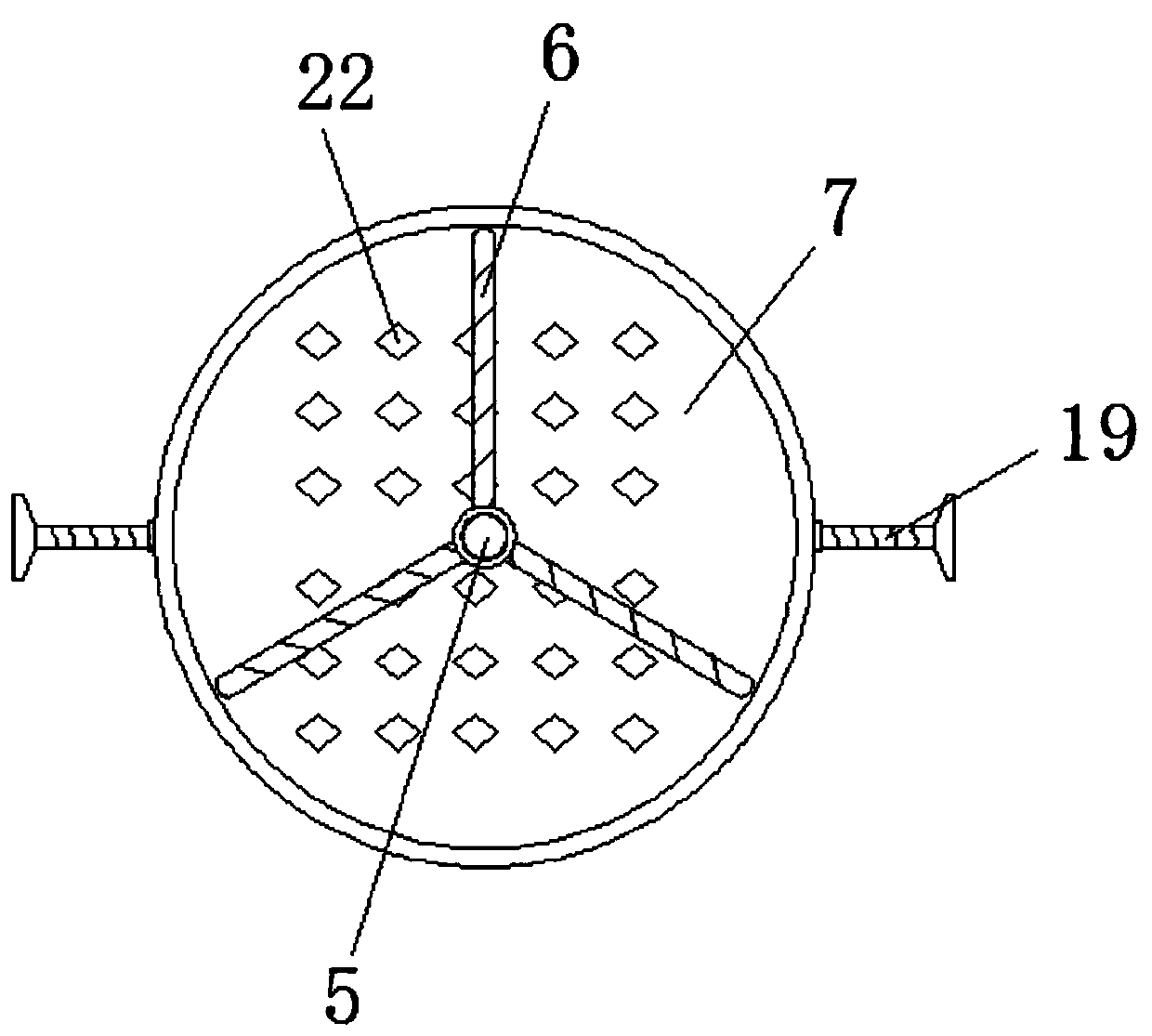

Automatic dismantling and separating device for waste dry cell and dismantling and separating method

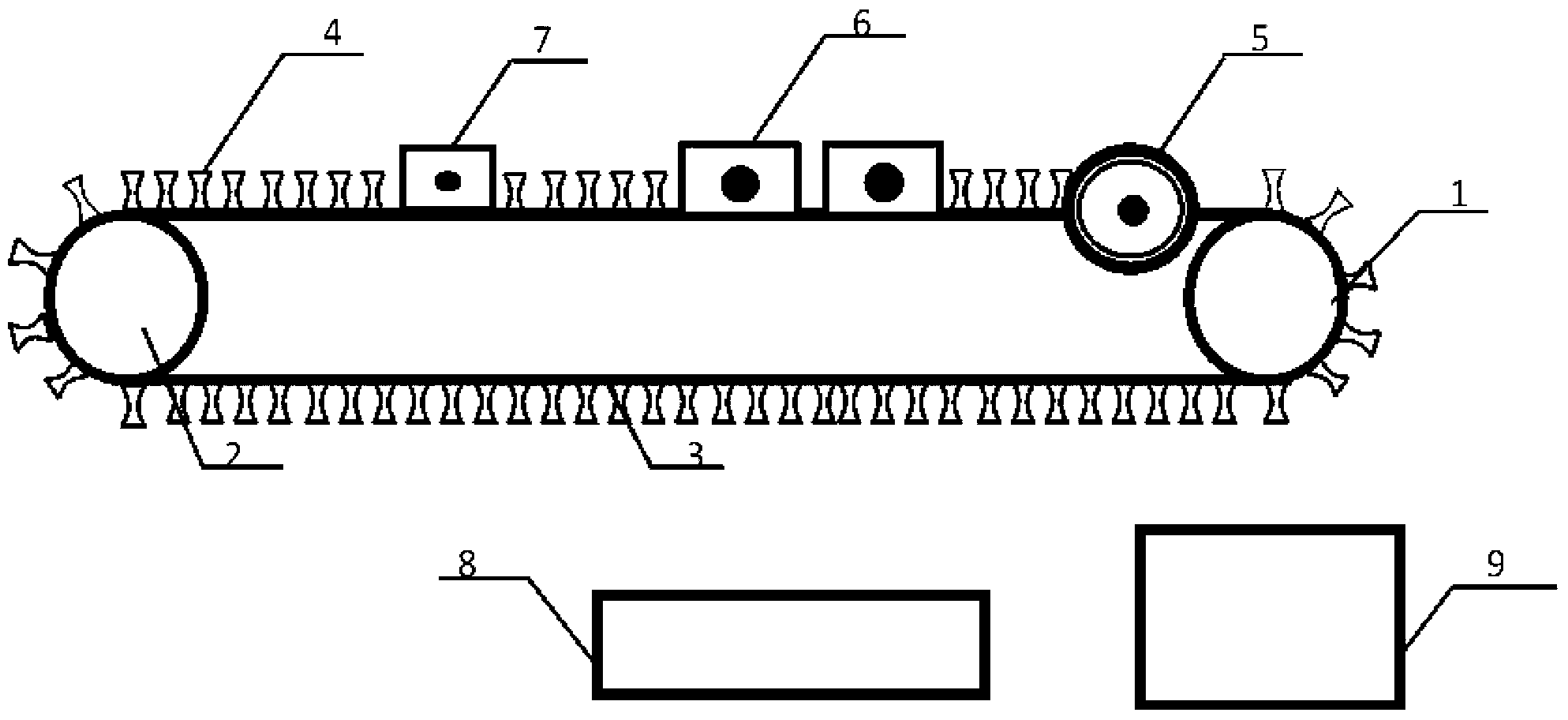

InactiveCN103296294AAvoid processing inefficienciesSolve follow-up processing difficultiesSolid waste disposalReclaiming serviceable partsProcess engineeringConveyor belt

The invention discloses an automatic dismantling and separating device for a waste dry cell and a dismantling and separating method, The automatic dismantling and separating device comprises a roller, a belt, a grinding wheel group, a firing pin, a cutter and a vibrating screen, wherein the conveyor belt is provided with a plurality of rubber partition plates; the grinding wheel group is arranged on the conveyor belt; the first side of the conveyor belt is provided with the cutter and the firing pin; the second side of the conveyor belt is provided with the vibrating screen. A first roller, a grinding wheel, the cutter and the firing pin are powered on; the waste dry cells are fixedly arranged between two adjacent partition plates of the belt one by one. Along with the movement of the belt, two ends of each waste dry cell are cut off by the grinding wheel rotating at high speed, paste and a carbon bar of the dry cell are pushed out of a shell of the dry cell through the firing pin, and a zinc skin is separated from a plastic skin through the cutter. The automatic dismantling and separating device and dismantling and separating method for the waste dry cell have the advantages that a paste electrolyte, a zinc drum and the carbon bar can be comprehensively recycled, and the processing working efficiency and a separation effect of the waste dry cell can be improved.

Owner:ANHUI UNIV OF SCI & TECH

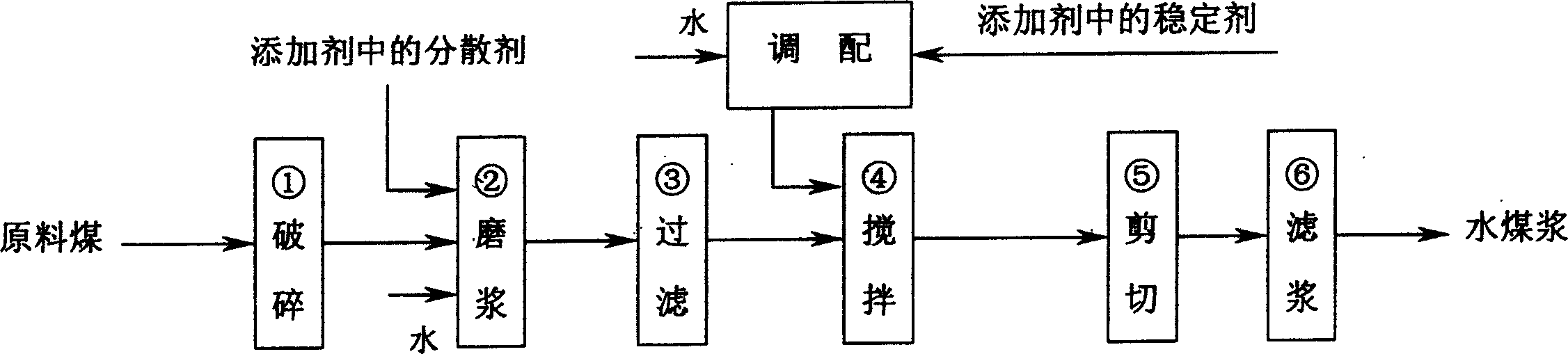

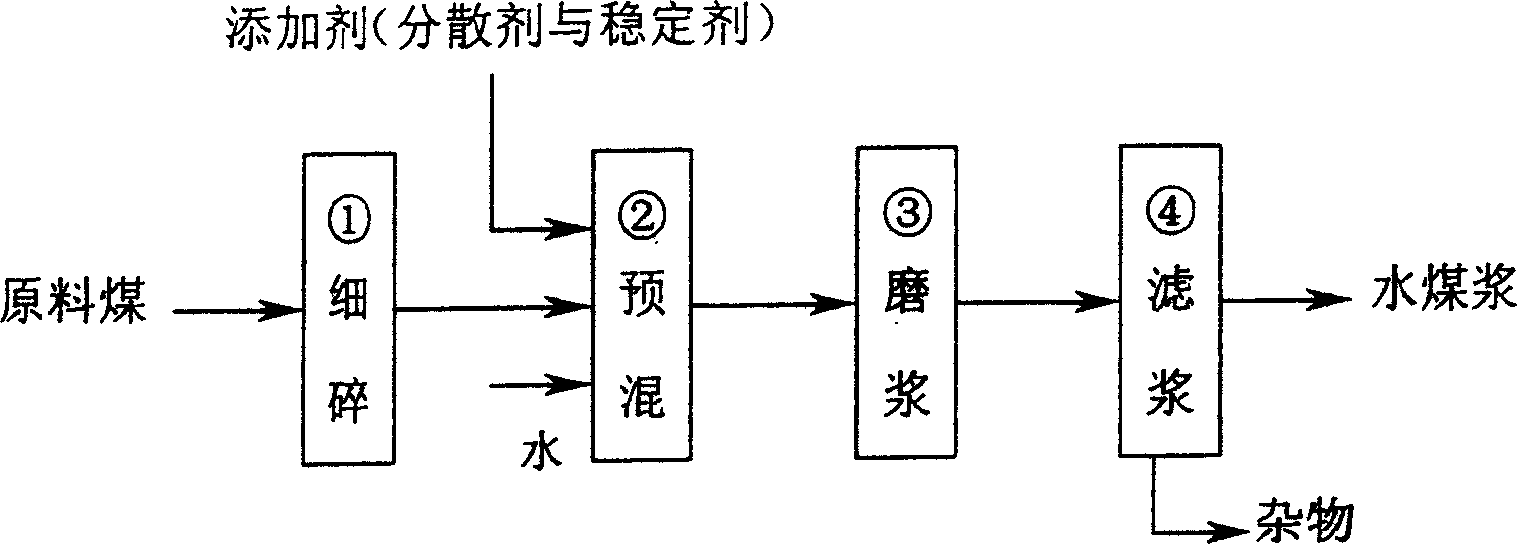

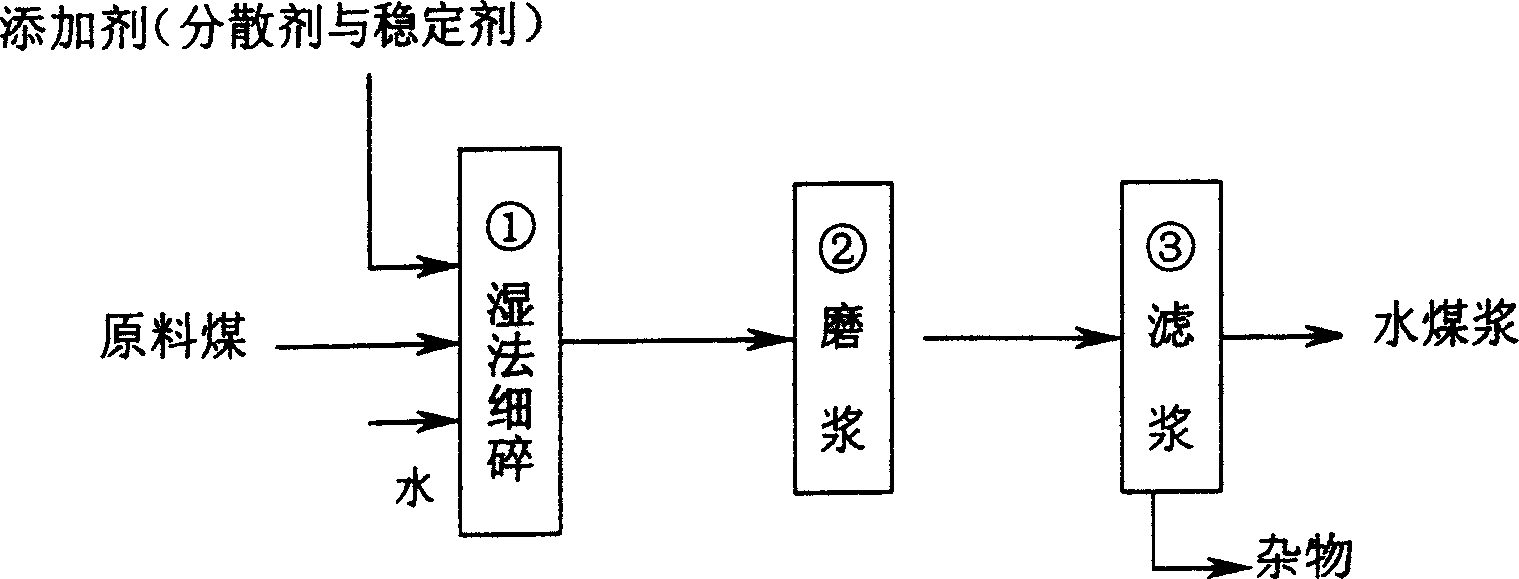

Preparation process of high producing rate, energy-saving water coal paste

InactiveCN1597878ASmall granularityAvoid efficiencyLiquid carbonaceous fuelsLump/pulverulent fuel preparationCoal waterFilling rate

The invention is a high-productivity energy-saving coal water fuel preparing method, relating to the ore wet-milling field, including the steps of finely crushing, premixing, pulp-milling and pulp-filtering, where the finely crushing step further reduces the particle size of raw material coal, the premixing step mixes raw material coal, coal water fuel additive and water together into a uniform strongly self-flowing pulp, the pulp-milling step has strong milling effect because of the increased filling rate of a miller, and the pulp-filtering step adopts centrifugal pulp filtering, so as to make the coal water fuel high-productivity and energy-saving.

Owner:北京柯林斯达能源技术开发有限公司

Gene chip for gynecologic malignant tumor early screening and detection method thereof

InactiveCN101230390AClear functionEasy to sampleMicrobiological testing/measurementMortality rateOvarian cancer

The invention provides a method of manufacturing an oligonucleotide gene chip for screening and diagnosing the normally gynecological malignant tumor in early phase and the method of detecting the same. The method uses the related genes of normally gynecological malignant tumor (breast cancer, ovarian cancer and uterine cancer) as control, and determines whether the patient has the malignant tumor by manufacturing the oligonucleotide and chip hybridizing and detecting. The invention provides a detecting method of screening and diagnosing the normally gynecological malignant tumor in early phase based on gene chip, which makes the characteristic gene of the normally gynecological malignant tumor into a gene chip so as to keep the consistence of the clinic detecting condition. The method can screen and diagnose the normally malignant tumor ASAP. With convenience in sampling and good consistence, the method of the invention is prone to popularize; by proper application, the cancer mortality can be reduced by 1 / 3.

Owner:HUBEI UNIV

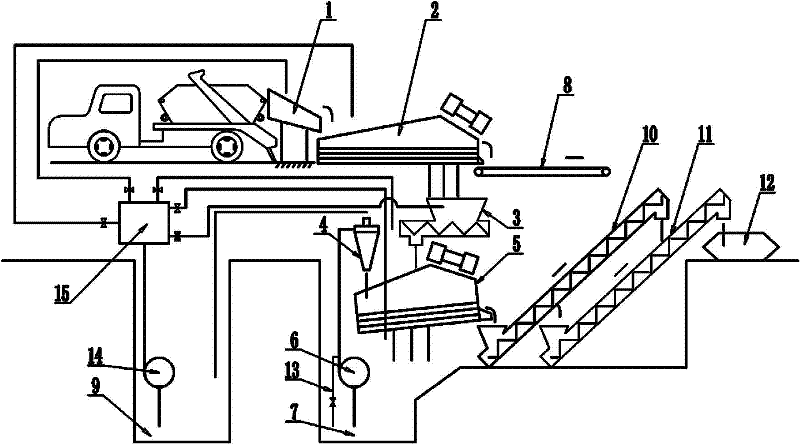

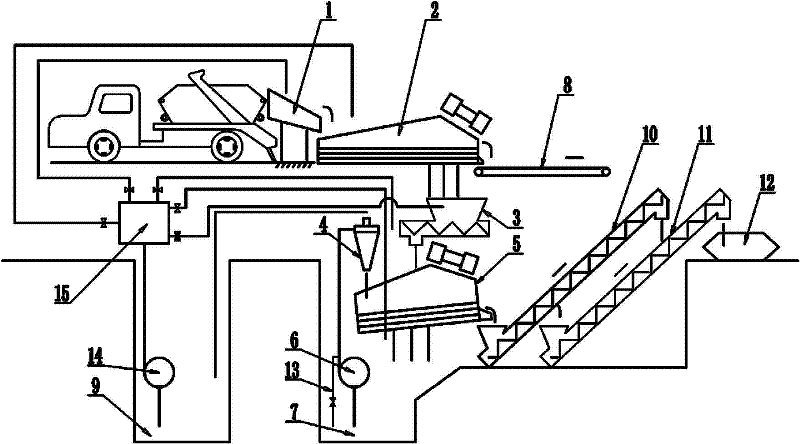

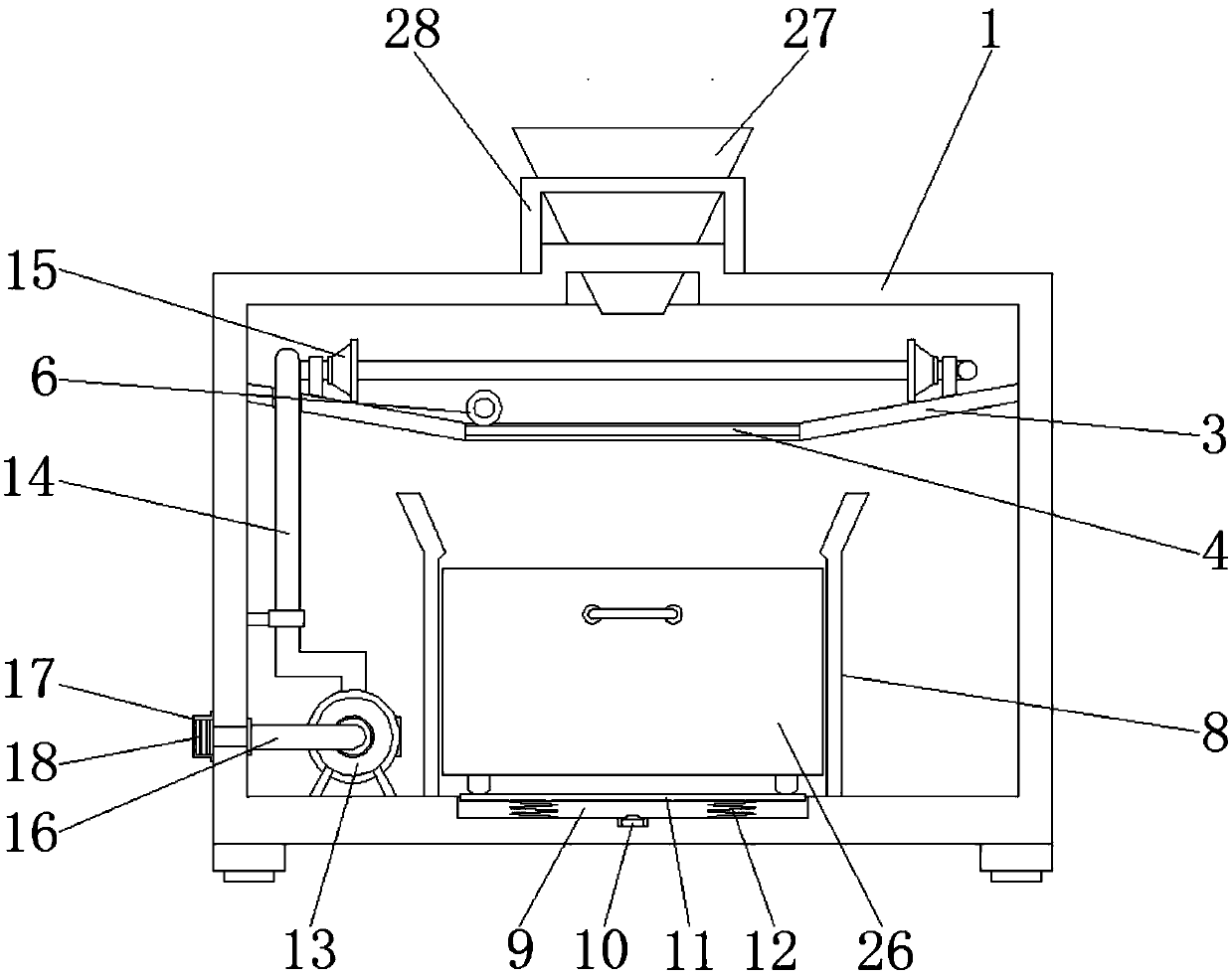

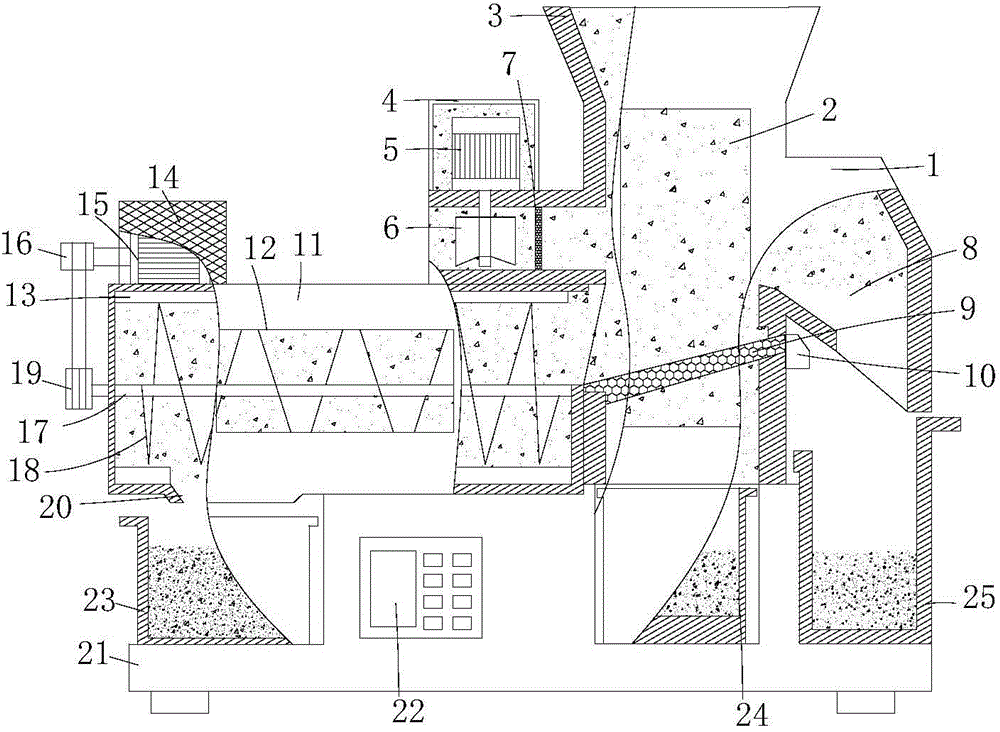

Sludge treatment method and device for urban drainage pipe network

ActiveCN102225834AReduce shipping costsPromote resource utilizationSludge treatment by de-watering/drying/thickeningDraining tubeSludge

A sludge treatment method for an urban drainage pipe network comprises the following steps of: 1) multi-stage screening; 2) conveying the separated slag into a garbage bucket by a conveying device; 3) conveying the separated sewage to a sewage-collecting pool; 4) arranging a first submersible sewage pump outlet on the sewage-collecting pool, wherein the pump is connected to a cyclone desander andis used to separate mud and sand with micro particle sizes, discharging the separated mud and sand through a sand-settling nozzle for the screening step, allowing the separated sewage to enter the underground drainage pipe network through an overflow pipe of the cyclone desander; 5) setting a reclaiming pool, pumping reclaimed water to a flushing distributor by a second submersible sewage pump, and conveying the reclaimed water to each screening device and each conveying device by the flushing distributor according to working conditions; slag with a water content of below 40%, and clear waterwhich is allowed to directly enter the underground drainage pipe network for circulation can be obtained through above steps. The invention can perform rapid dehydration treatment of sludge in a sewer well; the treated water is allowed to directly enter the drainage pipe network for circulation, while the slag can be transported by common vehicles. The purposes of high efficiency, environmental protection, and safe dredging are achieved.

Owner:SAFECLEEN TECH

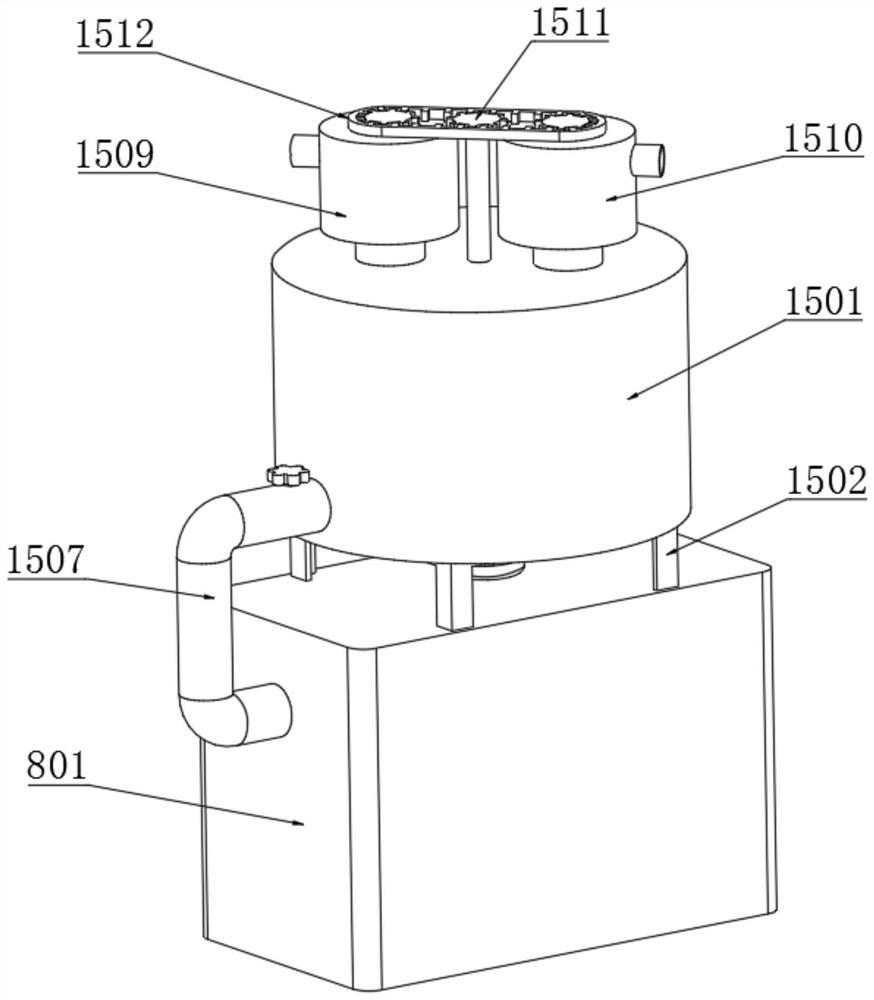

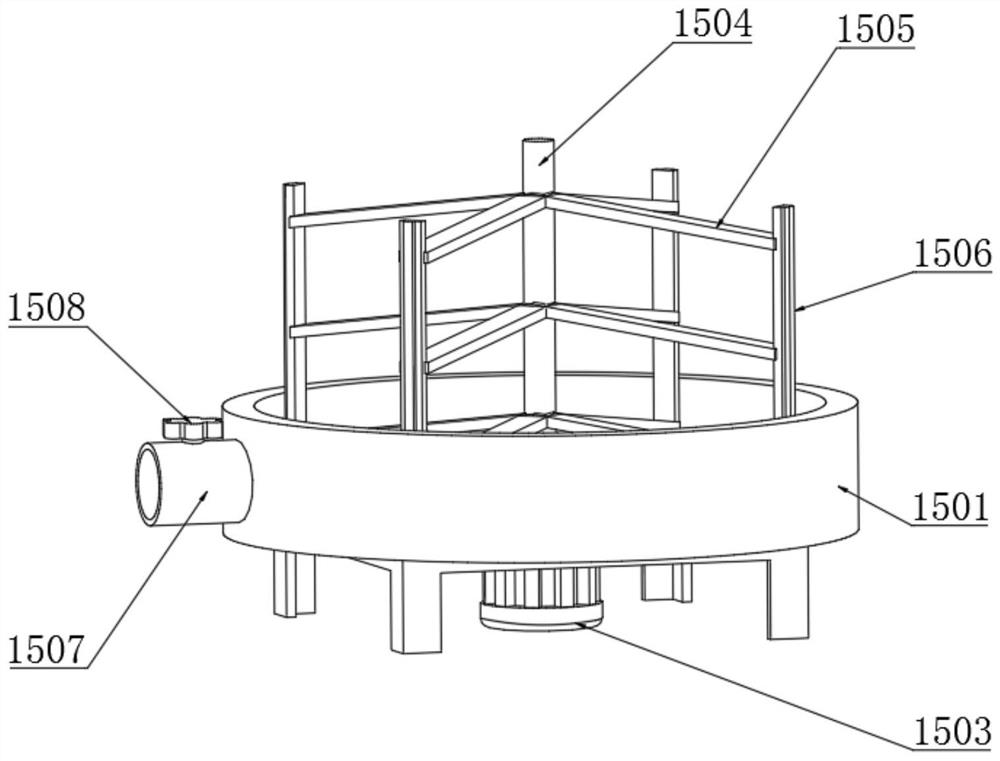

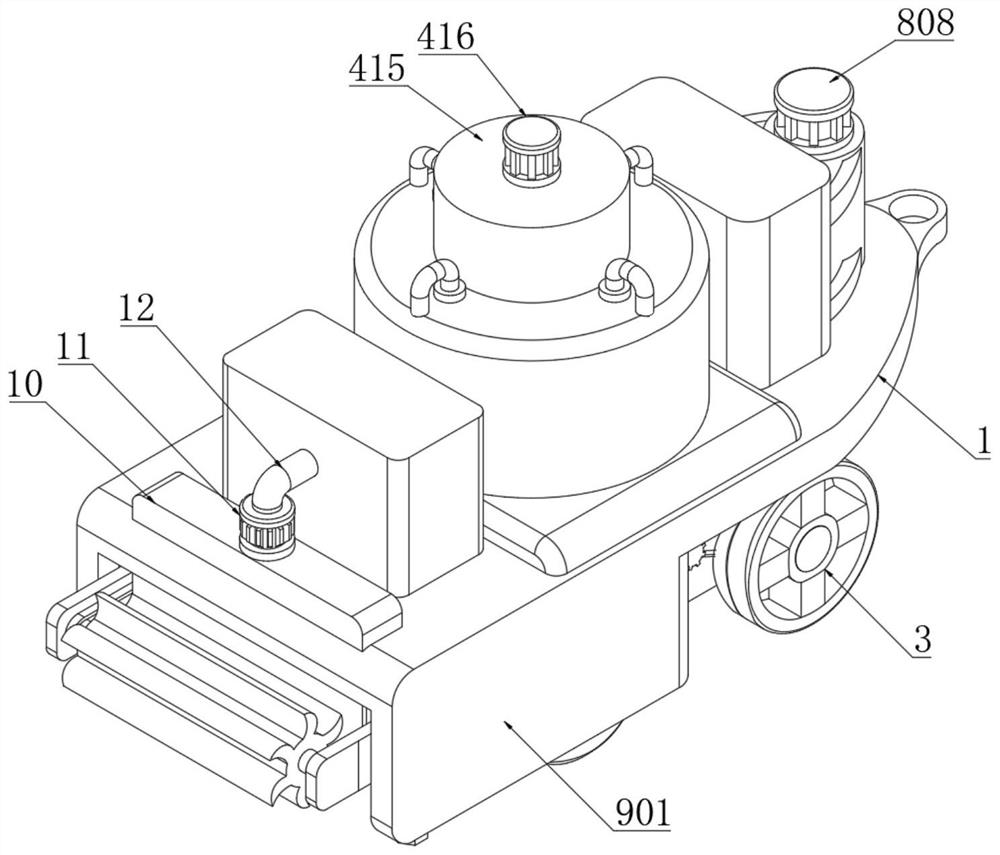

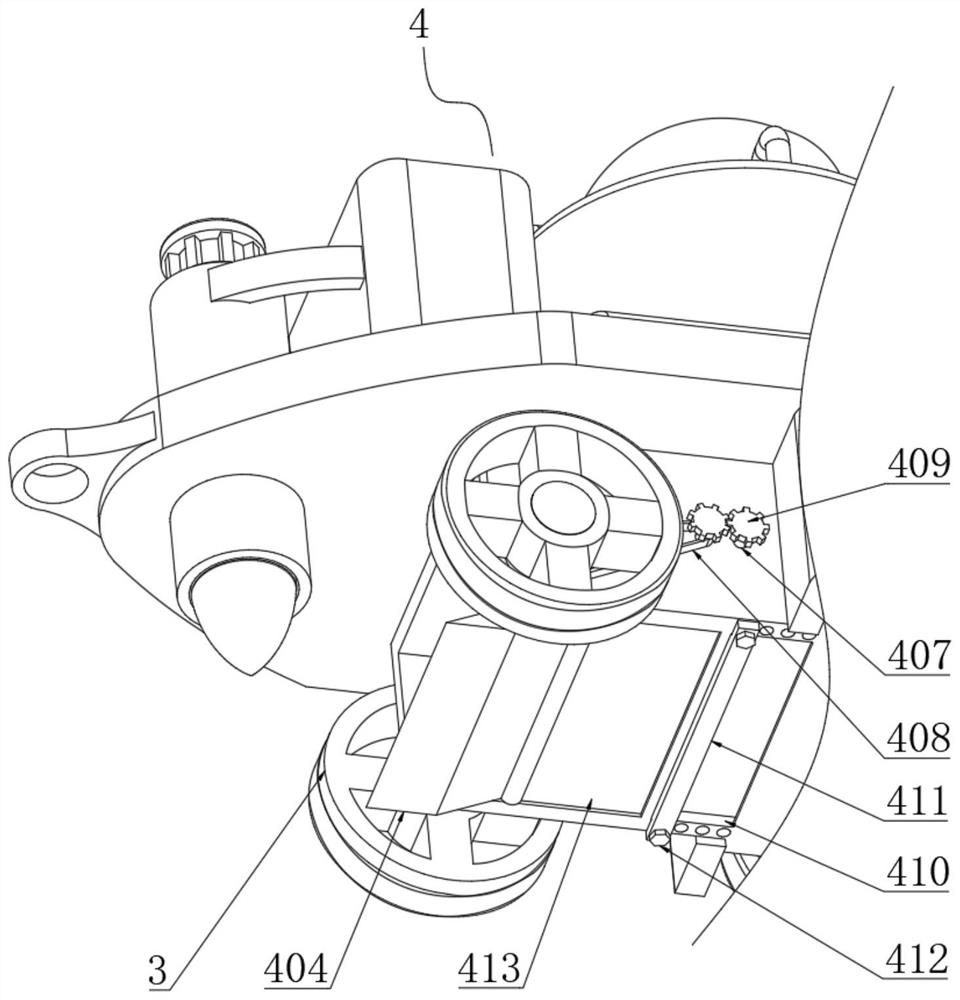

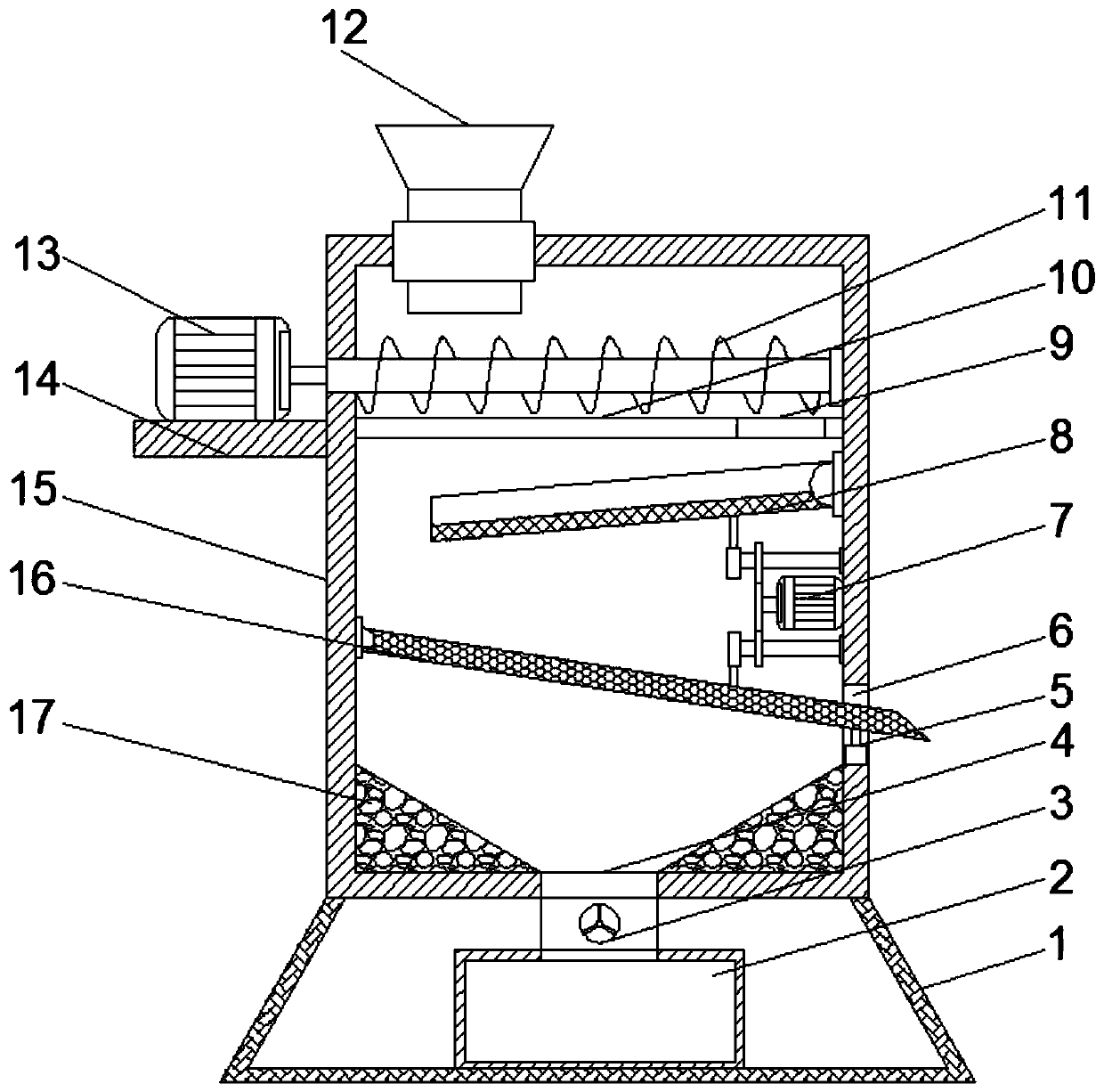

Soil remediation ecological moisturizing method based on efficient stirring

ActiveCN111804724AScientific and reasonable structureEasy to useSievingDispersed particle filtrationSoil remediationElectric machine

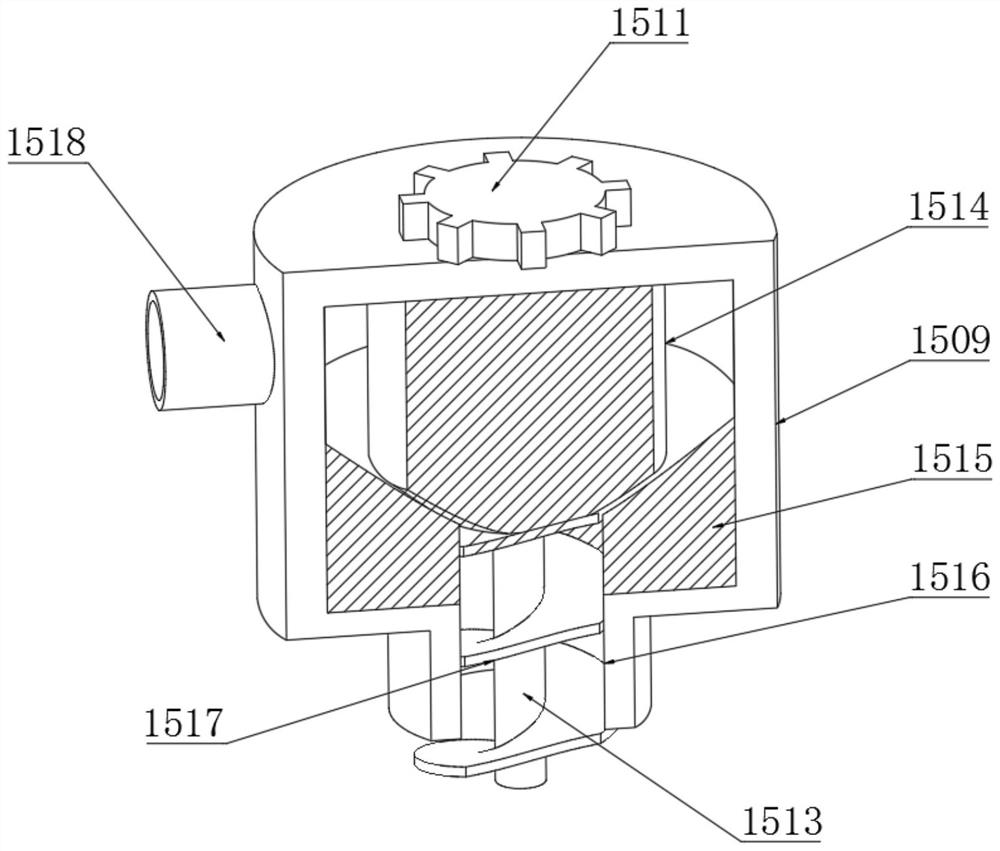

The invention discloses a soil remediation ecological moisturizing method based on efficient stirring. A solution mixing and effect-improving mechanism comprises a mixing cylinder, a bracket, a secondrotating motor, a stirring rod, a stirring frame, a shovel plate, a discharge pipe, a water stop valve, a charging barrel, a filtering barrel, a chain wheel, a chain, a rotating rod, an upper grinding block, a lower grinding block, a channel, a spiral feeding plate, a feeding pipe, a rotary vane, a filtering barrel, a water outlet and a water inlet pipe, the bottom end of the mixing cylinder is fixedly connected with a bracket, safe and convenient use is realized, a solution mixing and efficiency improving mechanism is arranged, the second rotating motor drives the stirring rod to rotate, andthe two rotating rods are driven to move and rotate through transmission of the chain wheels and the chains, so that the repairing agent is crushed through cooperation of the upper grinding block andthe lower grinding block, the repairing agent can be rapidly mixed with water, meanwhile, the rotary vane and the filtering barrel are matched to filter the water, impurities in the water are reduced, and the effect of the mixed repairing liquid is prevented from being affected by too many impurities.

Owner:合肥润田规划设计有限公司

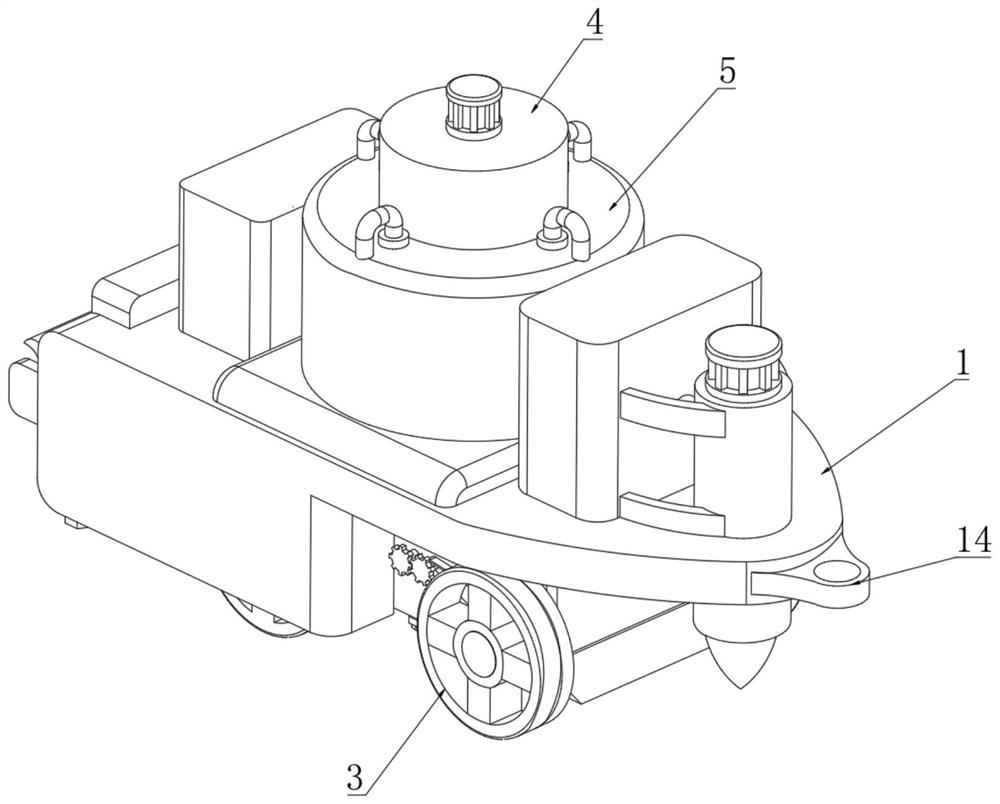

Soil remediation ecological moisturizing system

ActiveCN111842459AScientific and reasonable structureEasy to useSpadesSievingVehicle frameSoil remediation

The invention discloses a soil remediation ecological moisturizing system which comprises a vehicle frame, a hanging ring is fixedly connected to one end of the vehicle frame, fixing bases are fixedlyconnected to the bottom end of the vehicle frame, and rolling wheels are rotationally connected to the two ends of the two fixing bases. A soil collecting and crushing mechanism is installed in one fixing base, a heating cylinder is fixedly connected to the top end of the vehicle frame, a soil repairing and discharging mechanism is embedded in the heating cylinder, use is safe and convenient, thesoil collecting and crushing mechanism is arranged, and through cooperation of a positioning pin, a limiting block and a limiting groove, the angle of a shovel plate is conveniently adjusted, so thatthe angle of the shovel plate is adjusted according to the actual ground, the shovel plate is attached to the ground, severely polluted soil is conveniently shoveled up, the soil collection efficiency is improved, the soil remediation efficiency is improved, meanwhile, the labor pressure of workers is reduced, and a rotating shaft, a conveying belt, a rotating rod, a belt and a transmission gearare matched.

Owner:WUHU YUTIANRUN AGRI TECH CO LTD

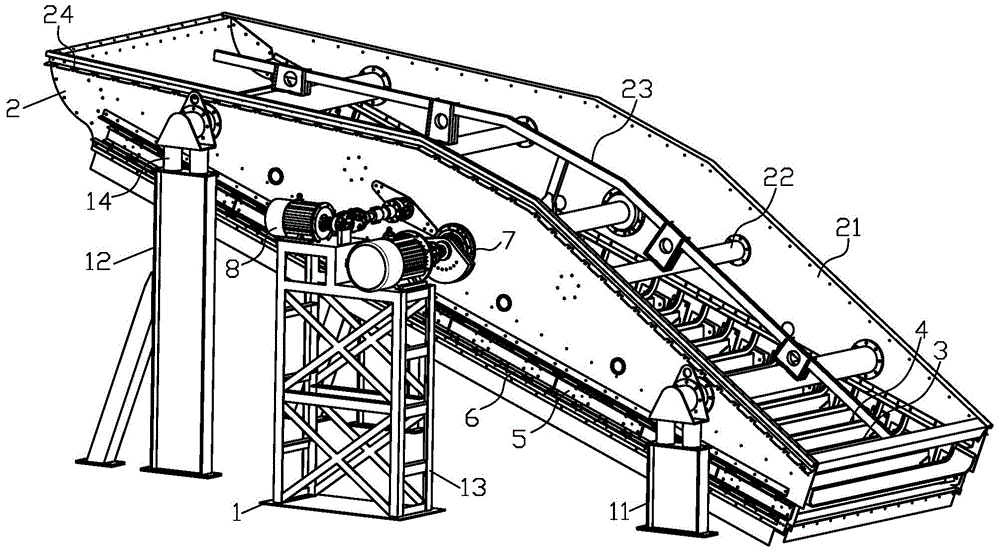

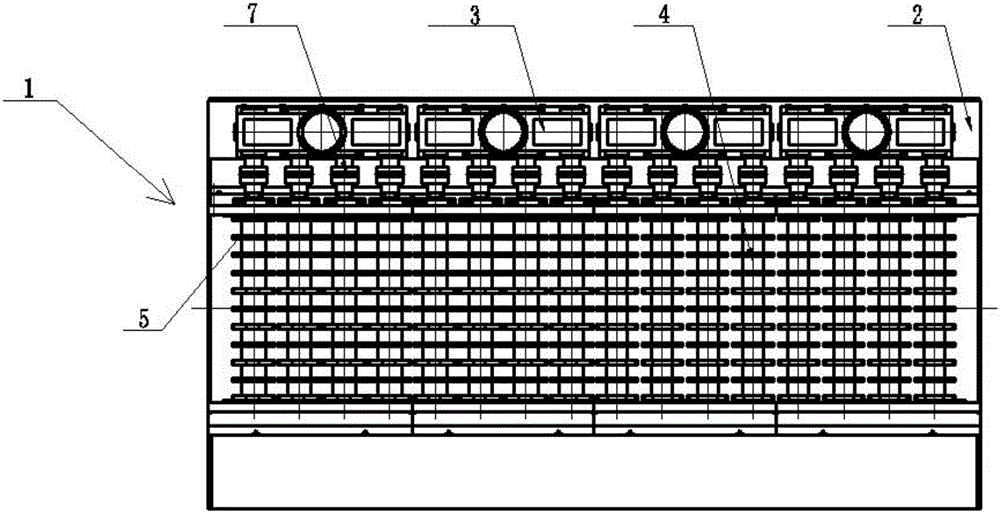

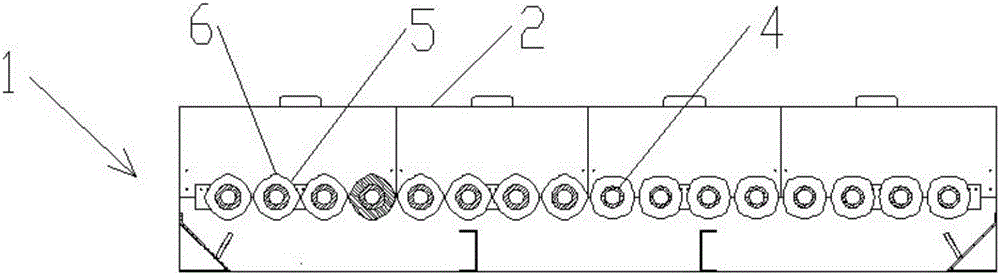

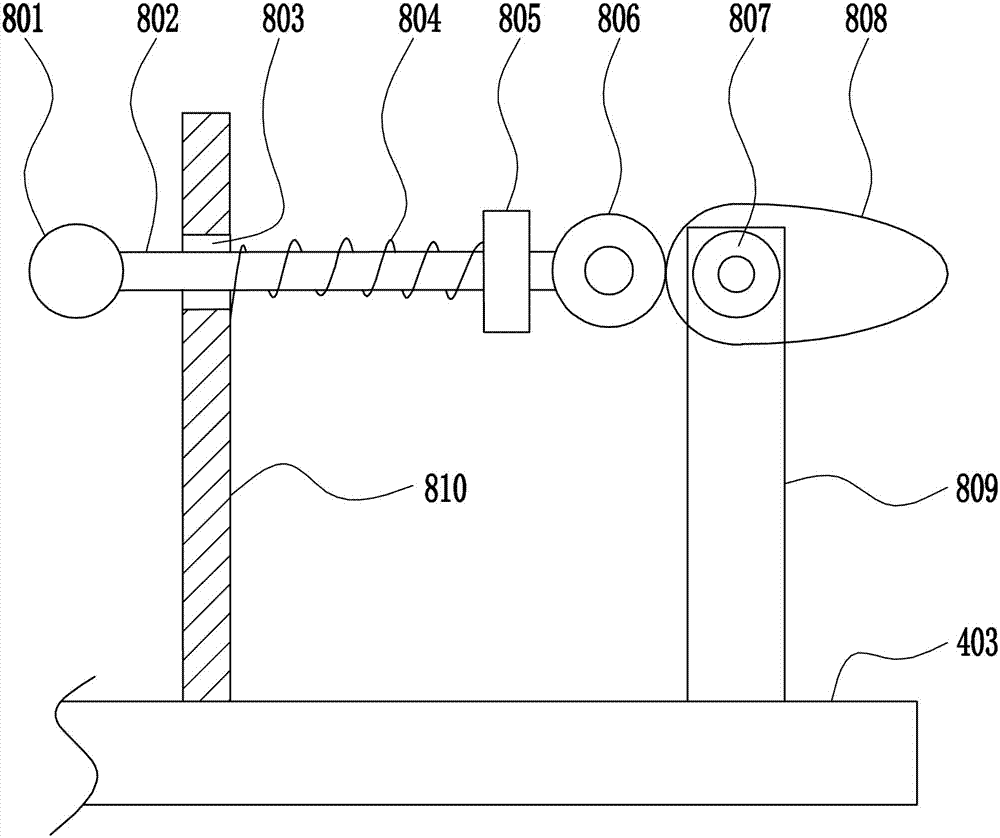

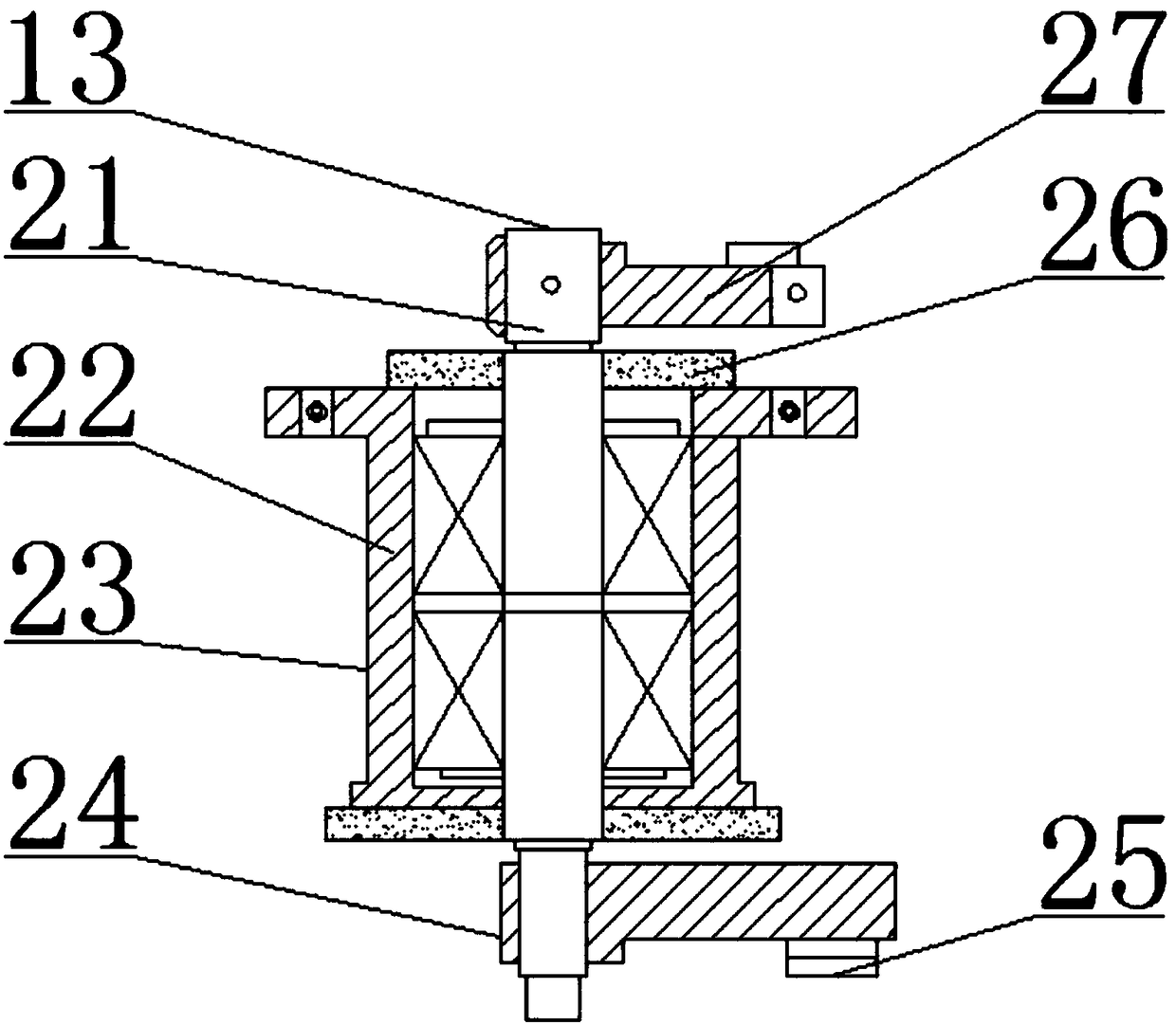

Three-degree-of-freedom flip-flow screen

InactiveCN104889057AOvercoming technical deficienciesGood dispersionSievingScreeningThree degrees of freedomGranularity

The invention discloses a three-degree-of-freedom flip-flow screen which comprises a support frame assembly, a screen box, a movable beam, a fixed beam, a rubber shearing spring, a movable beam connecting plate, an inertial exciting device, a transverse exciting device and a screen piece, wherein the support frame assembly is composed of a front support frame, a rear support frame and an exciter support frame. The screen box is supported on the front support frame and the rear support frame through a rubber damper spring. The fixed beam is fixedly connected with the screen box. The movable beam connecting plate with the movable beam is connected with the screen box through the rubber shearing spring. The two ends of the screen piece are respectively and fixedly connected with the movable beam and the fixed beam. The power end of the inertial exiting device and the power end of the transverse exciting device are fixedly installed on the top of the exciter support frame. The screen piece can obtain the vibrational excitation with three degrees of freedom, and the parameters of the inertial vibration and the transverse vibration can be adjusted separately. The three-degree-of-freedom flip-flow screen is particularly suitable for screening of humid materials with the fine granularity, and has the advantages of being compact in structure, long in service life, large in processing amount, high in efficiency and low in cost.

Owner:ANHUI UNIV OF SCI & TECH +1

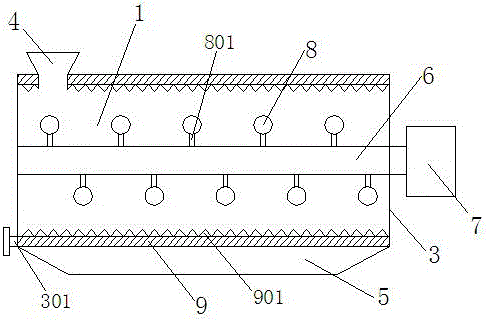

Screening and drying device for production of feed

The invention discloses a screening and drying device for the production of feed. The screening and drying device comprises a box body, wherein a partition is fixedly mounted in the box body, a support plate is fixedly mounted in the box body and in front of the partition, a screen mesh is fixedly mounted in the middle of the support plate, a rotating shaft is in slip connection between the frontwall of the box body and the support plate, and the surface of the rotating shaft is sheathed with a roller. The invention relates to the technical field of processing equipment of feed. According tothe screening and drying device for the production of feed, a rotating rod is driven by a motor to rotate to further drive a second slide bushing to rotate, the second slide bushing slides on a sliderod, so the slide rod moves left and right, the slide rod drives the rotating shaft to move left and right by virtue of a first slide bushing, feed on the screen mesh is ground by virtue of the rollersheathed on the surface of the rotating shaft, so blocky feed is ground and falls through the screen mesh into a collecting box for collection; and the screening and drying device is simple in operation, can grind agglomerated feed, is convenient for production and processing of the later period, and ensures the quality of the finished product of feed.

Owner:ZHEJIANG QIANGSHUN FEED CO LTD

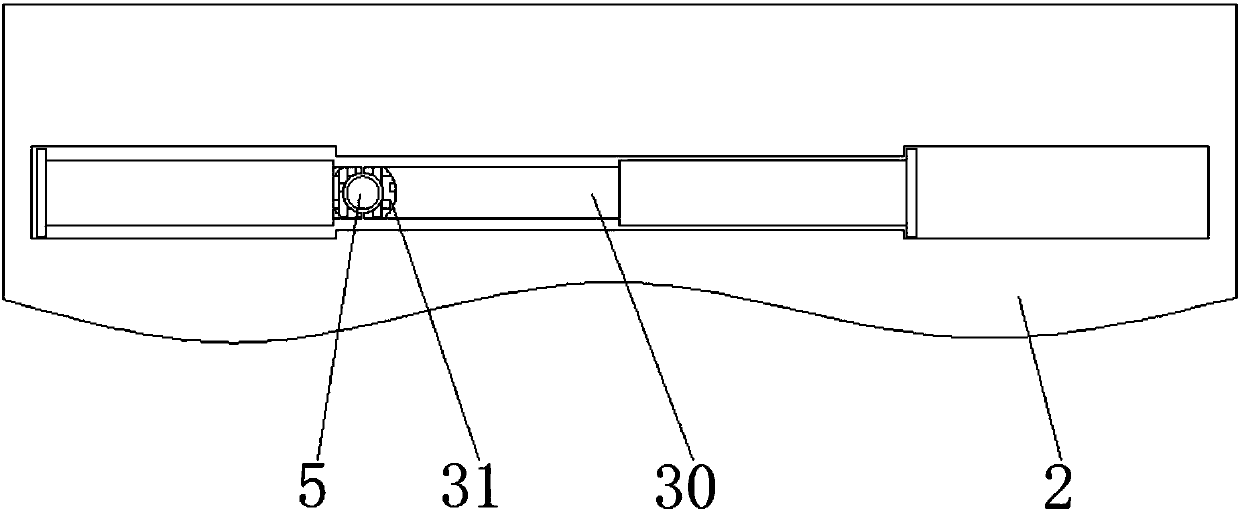

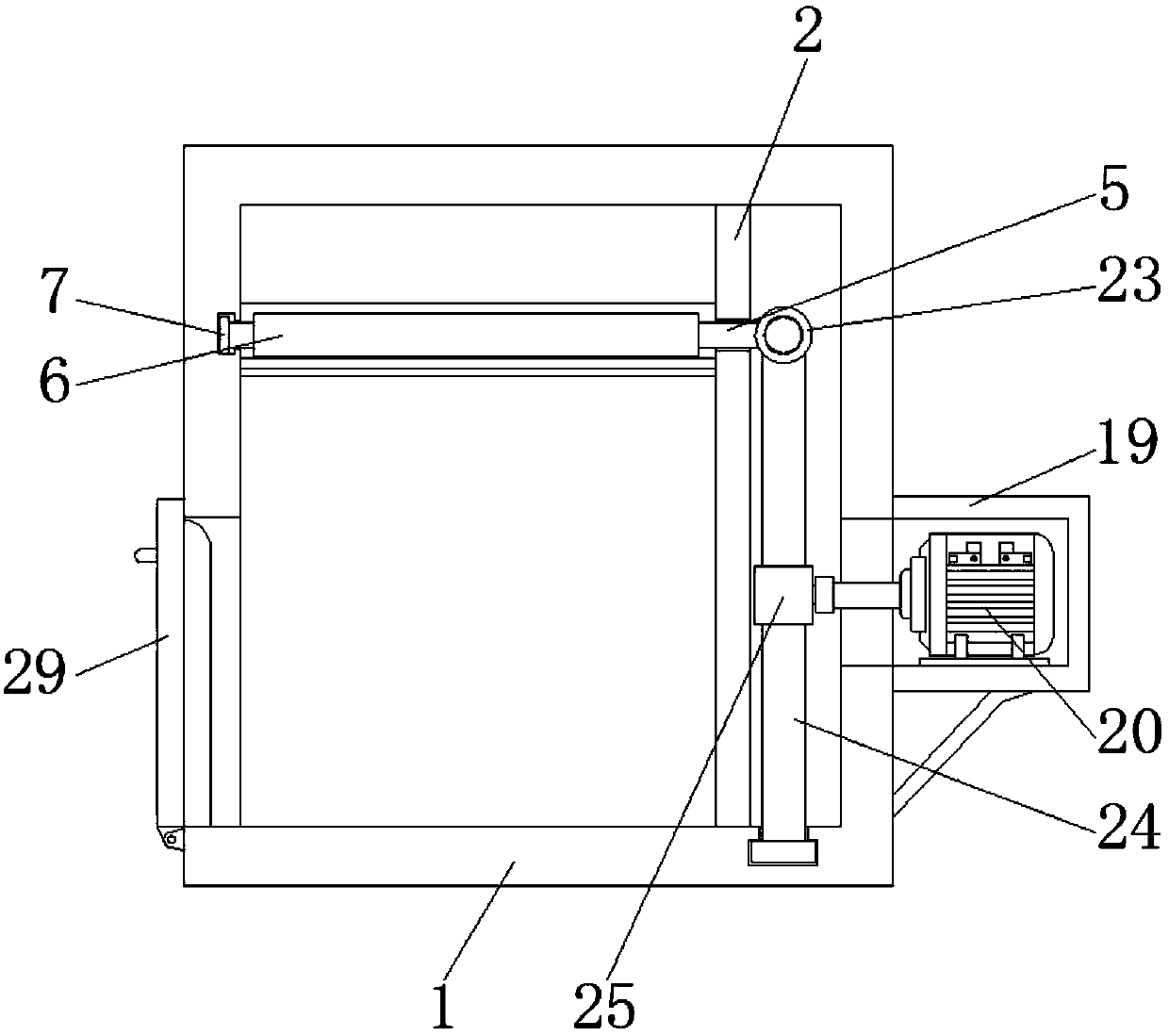

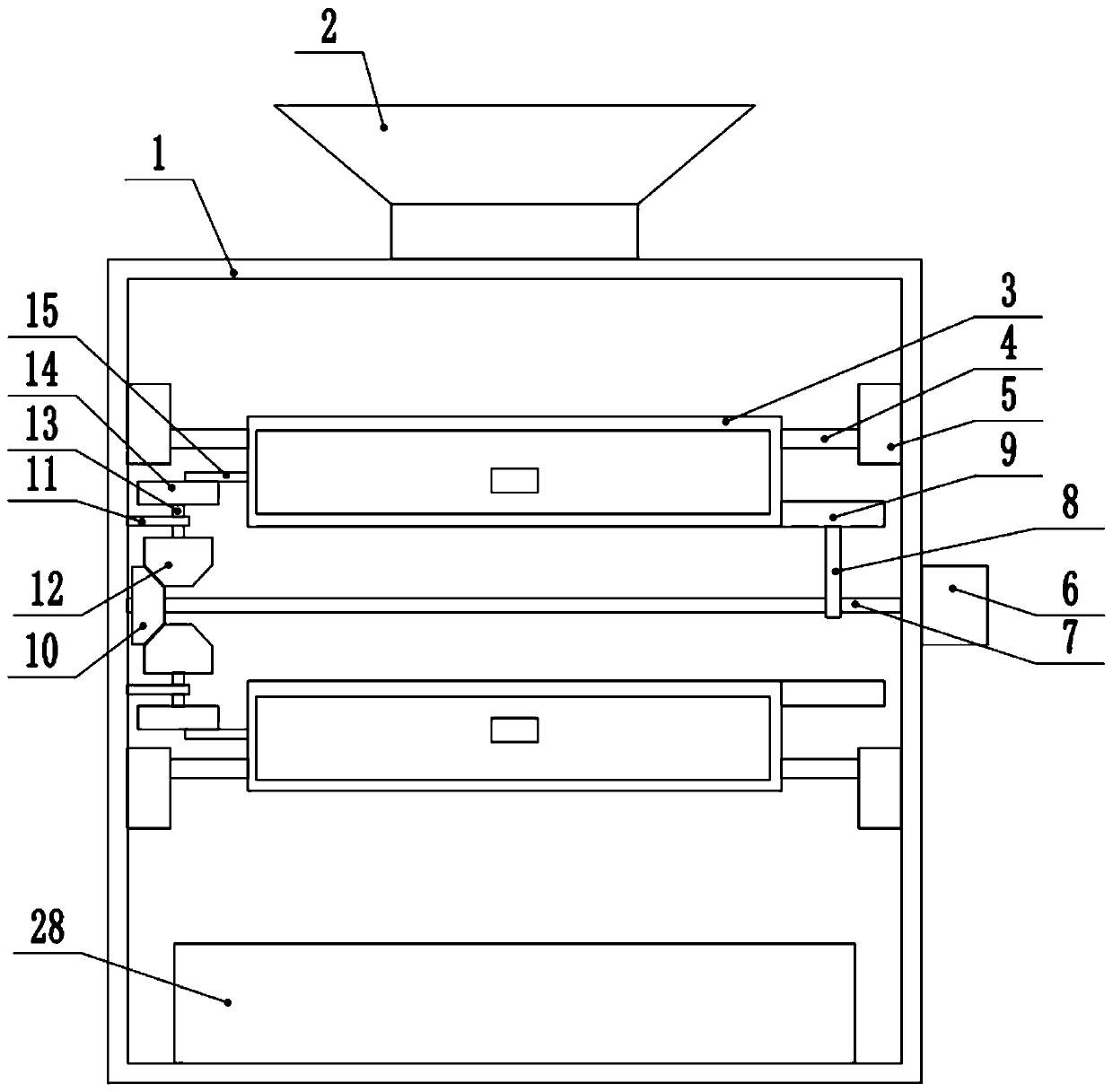

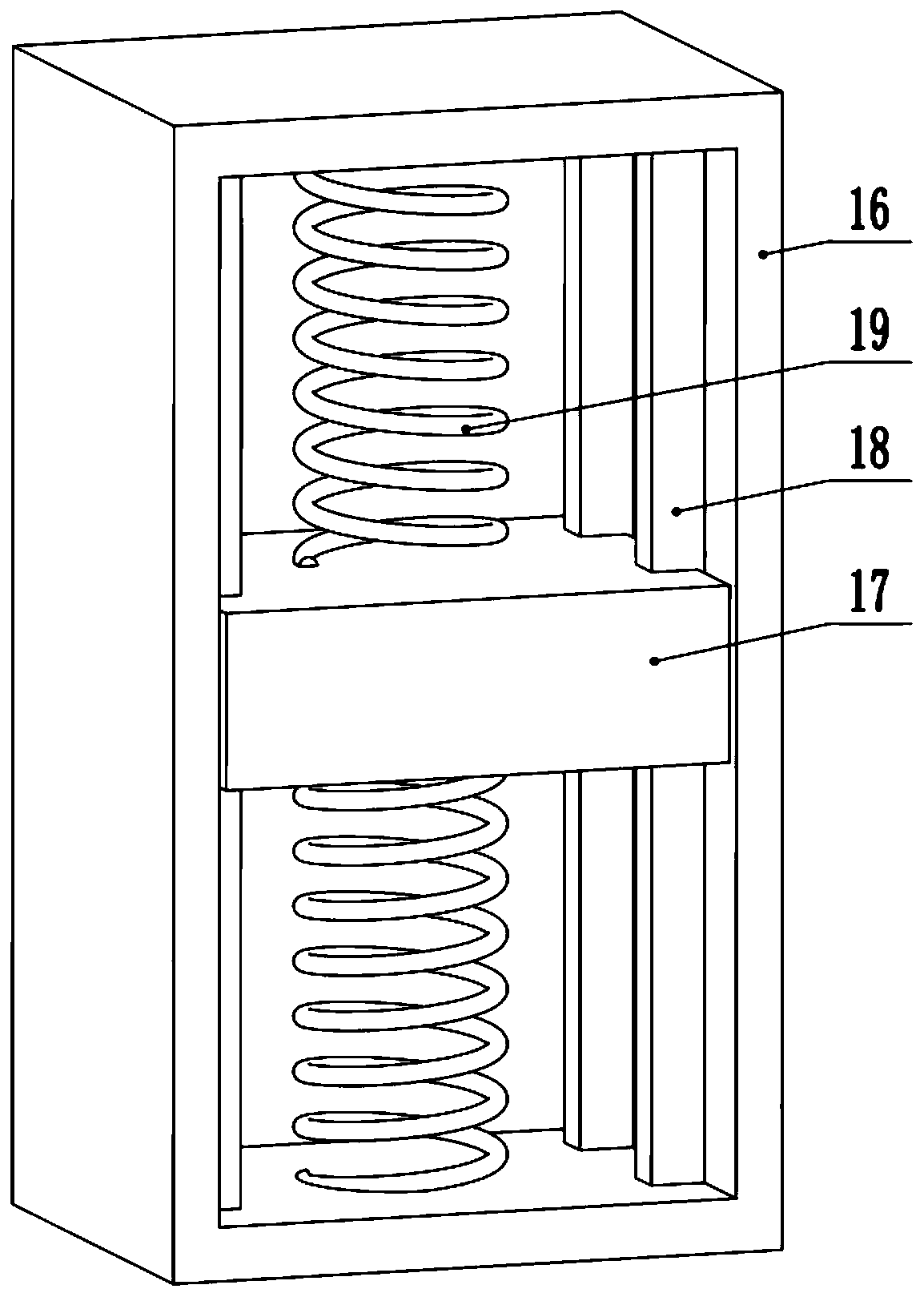

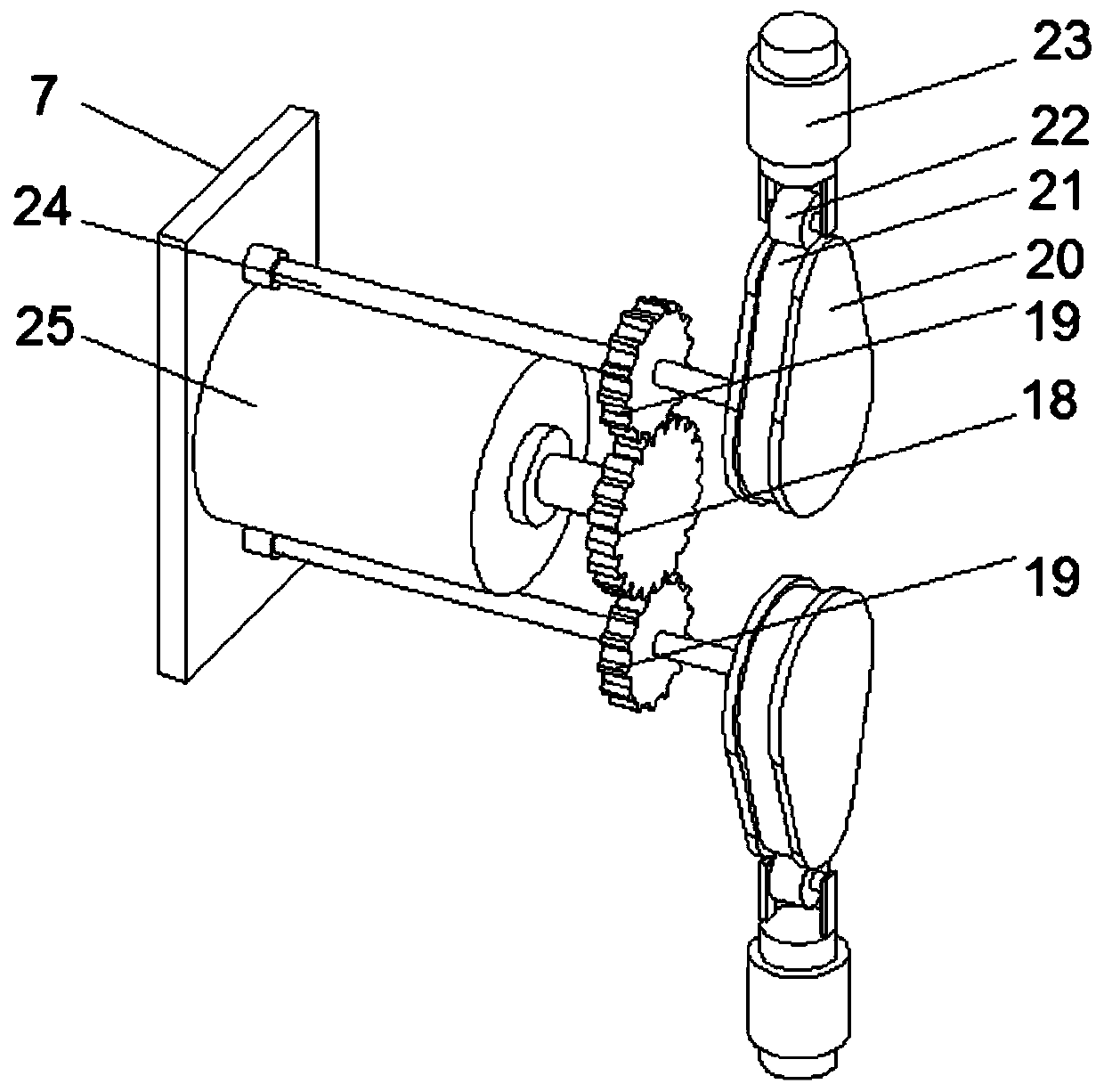

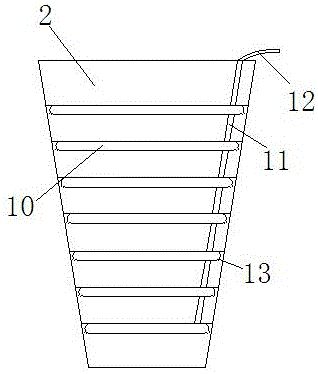

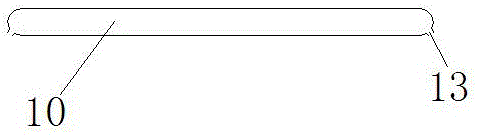

Multistage vibration type traditional Chinese medicine screening device

InactiveCN110711699AEasy to sieveImprove screening efficiencySievingScreeningReciprocating motionElectric machinery

The invention discloses a multistage vibration type traditional Chinese medicine screening device and relates to the technical field of traditional Chinese medicine processing. The multistage type traditional Chinese medicine screening device comprises a processing box. A drive motor is fixedly connected to one side of the processing box, and an output shaft of the drive motor is fixedly connectedwith a rotating rod. Material screening mechanisms are arranged above and below the rotating rod correspondingly. Each material screening mechanism comprises a fixing frame, wherein a material screening device is arranged in the fixing frame, and a lifting sliding rod and an ejection plate are fixedly connected to the two ends of the fixing frame correspondingly. The rotating rod is fixedly connected to a cam corresponding to the corresponding ejection plate. End portion reset devices are fixedly arranged at the positions, on one sides of the lifting sliding rods, of the processing box. By means of the multistage vibration type traditional Chinese medicine screening device, the drive motor is arranged for driving the cam to rotate, under the effect of the end portion reset devices, a screen plate can move in a reciprocating manner in the vertical direction, due to the arrangement of a first conical wheel, second conical wheels and eccentric wheels, the screen plate can move in a reciprocating manner in the left-right direction, and therefore the screen plate can move in the vertical direction and the horizontal direction, the material screening work is conducted conveniently, andthe screening efficiency and speed are increased.

Owner:湖南雨泉农业发展有限公司

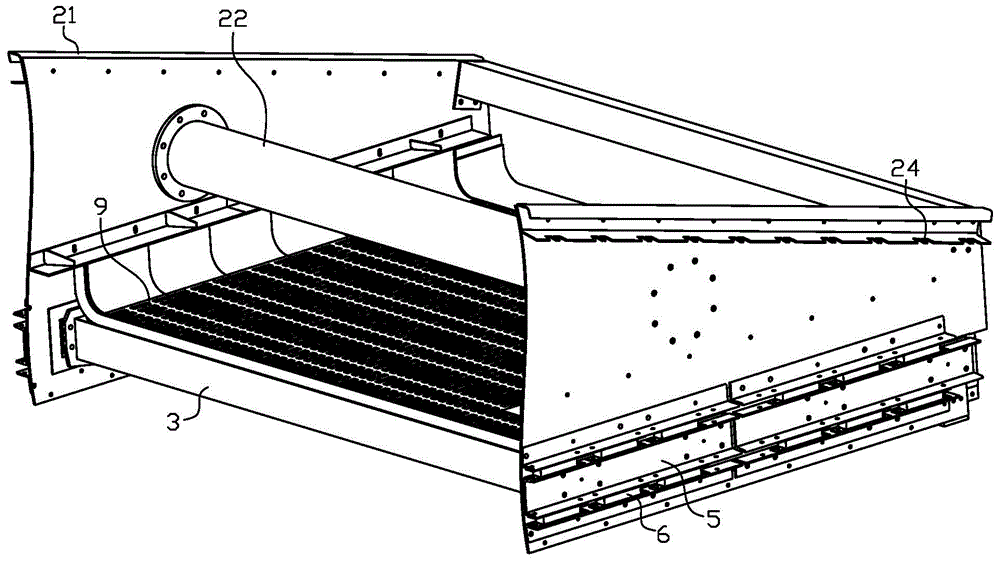

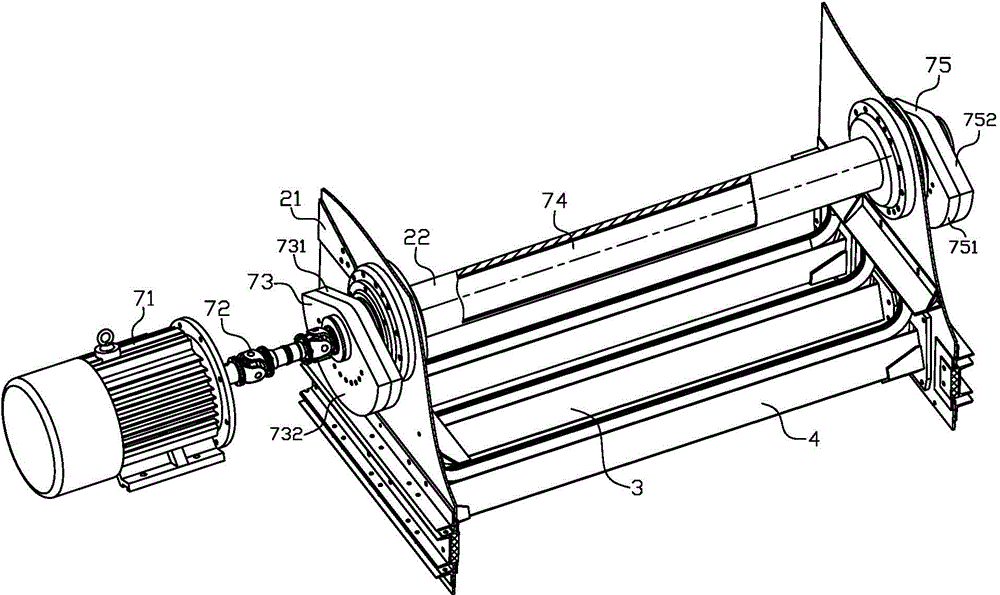

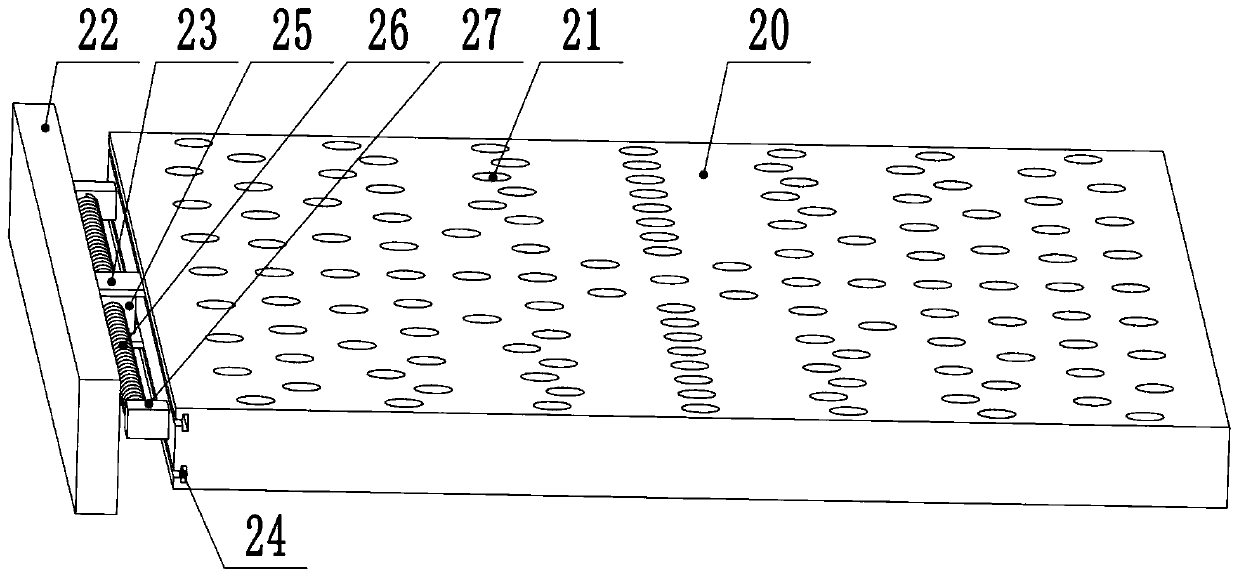

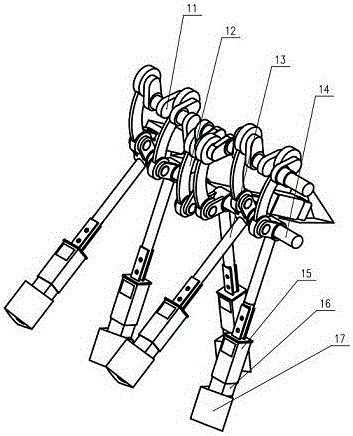

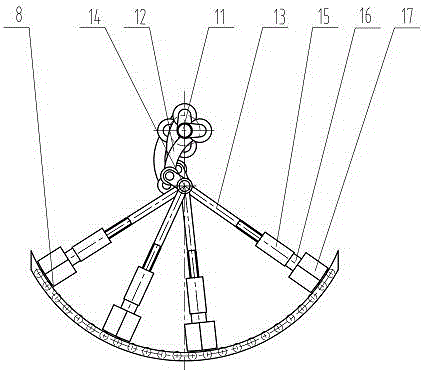

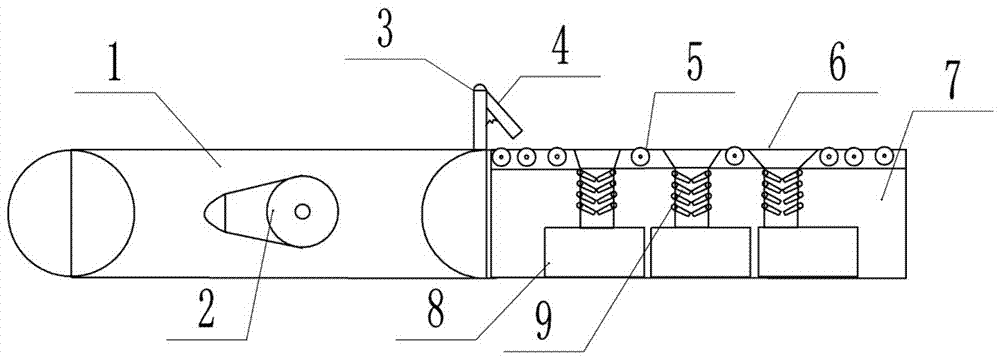

Kitchen waste pretreating and sorting device

ActiveCN106269498ADial material evenlyDial material without jammingSievingScreeningAnti jammingSieve

The invention provides a kitchen waste pretreating and sorting device and belongs to the field of waste treating equipment. The kitchen waste pretreating and sorting device solves the problems of jamming and hole blocking of an existing sorting machine and mainly comprises a machine frame, a box, a material pushing mechanism and a sieve plate. The material pushing mechanism is arranged in the box and installed on the machine frame in a tilting mode; a fixing shaft of the material pushing mechanism is below a crankshaft; a plurality of swing rods with crank arms are sequentially installed on the fixing shaft; each crank on the crankshaft driven by a hydraulic motor is connected with the corresponding crank arm on the swing rod through a connected rod; the included angle between every two adjacent cranks is 90 degrees; an anti-jamming spring extensible material pushing swing head is arranged at the lower end of each swing rod; the sieve plate is an arc-shaped dynamic sieve plate with rollers and comprises the rollers, roller shafts and arc-shaped roller baffles; the roller shafts are installed on the roller baffles correspondingly; and each roller is installed on the corresponding roller shaft between every two roller baffles. The kitchen waste pretreating and sorting device has the characteristics of even material pushing with no jamming, good sieve penetrating performance, high sieving and sorting efficiency, and the like, and is suitable for sieving and sorting of all kinds of kitchen waste.

Owner:鞍山鞍重矿山机械有限公司

Mechanical equipment for processing walnut powder

The invention discloses mechanical equipment for processing walnut powder. The mechanical equipment for processing walnut powder comprises a frame, wherein an accumulating chamber is inverted-cone-shaped, the taper of the accommodating chamber is 1:7-8, shell breaking rolls which are connected with a motor and a driving shaft are suspended in the accommodating chamber, and are two rolls which are distributed at intervals, the bottom of the accommodating chamber communicates with a discharging channel, the discharging channel is inclined rightwards, spines are uniformly distributed on an additional roll, the additional roll is mounted between the discharging channel and a conveying belt, a supporting frame is arranged between two belt pulleys, a storage tank is arranged below the conveying belt and comprises a front tank for storing walnut kernels and a rear tank for storing walnut shells, the front tank and the rear tank are separated from each other by a partition, a fan is mounted on the outer wall of the left side of the front tank, and air blown out from the fan is horizontally rightward. By the mechanical equipment for processing the walnut powder, shells can be broken fully, time and labor are saved, efficiency is high, and walnut shell breaking costs are greatly reduced; and the mechanical equipment has great promotion effect on development of the industry.

Owner:贵州天和农业发展有限公司

Sand accelerated drying and screening device based on cam transmission structure

The invention relates to the technical field of sand screening, and discloses a sand accelerated drying and screening device based on a cam transmission structure. The sand accelerated drying and screening device comprises a box body, wherein a discharging opening is formed in the bottom of the interior of the box body; and a base is fixedly connected to the bottom of the box body. According to the sand accelerated drying and screening device based on the cam transmission structure, sand in a lump is smashed through a stirring roller, and heating and screening of the sand are facilitated; through a gear transmission structure, two sets of cams can be driven by a second motor to synchronously rotate, and therefore synchronous vibration of a heating plate and a filtering plate is achieved, the heating and screening speed of the sand is increased, and the screening efficiency is improved; the flow speed of the sand on the heating plate is reduced through a gear rod, the heating time of the sand is prolonged, and the drying performance of the sand is enhanced; and a buffering base buffers vibration generated by the filtering plate, the situation that the filtering plate is damaged dueto too large amplitude is prevented, and the service life of the machine is prolonged.

Owner:杭州鑫赐贸易有限公司

Powdery compound feed for young Chinese softshell turtle stage and production and processing device

InactiveCN112220087AEasy to crushIncrease jitterFeeding-stuffFood processingAnimal scienceElectric machinery

The present invention relates to the technical field of aquatic feeds and particularly relates to powdery compound feed for a young Chinese softshell turtle stage and a production and processing device. The powdery compound feed comprises a box body, wherein the box body is provided with a cover plate, the cover plate is provided with a crushing structure and a stirring structure, the stirring structure comprises a driving motor, a first bevel gear, a first rotating rod, a stirring plate and second bevel gears. the box body is evenly and fixedly connected with shaking structures used for shaking filter plates in the circumferential direction below the filter plates, the box body is provided with a circulating structure, and a quantitative discharging structure used for quantitative discharging is arranged at the bottom of the box body. Crushing, stirring, circulating structures and screening are driven by a set of driving motors, so that use of electrical equipment is reduced, and theuse cost is reduced.

Owner:福建大昌盛饲料有限公司

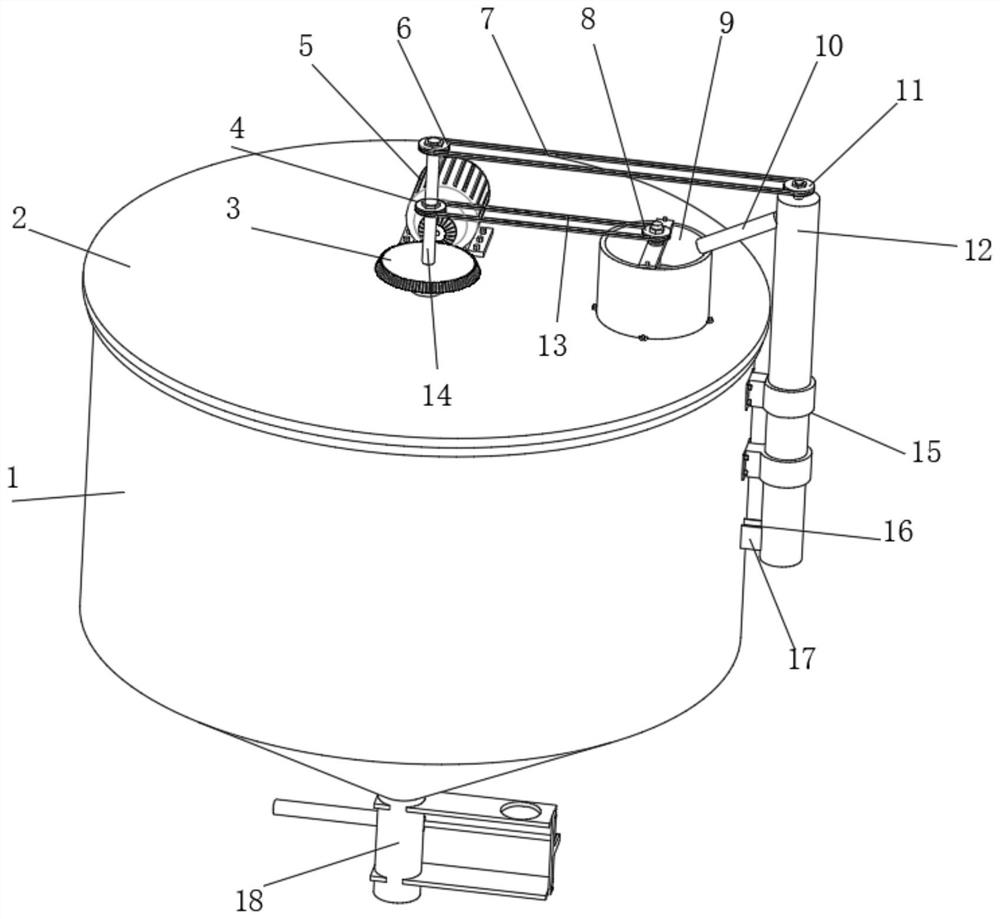

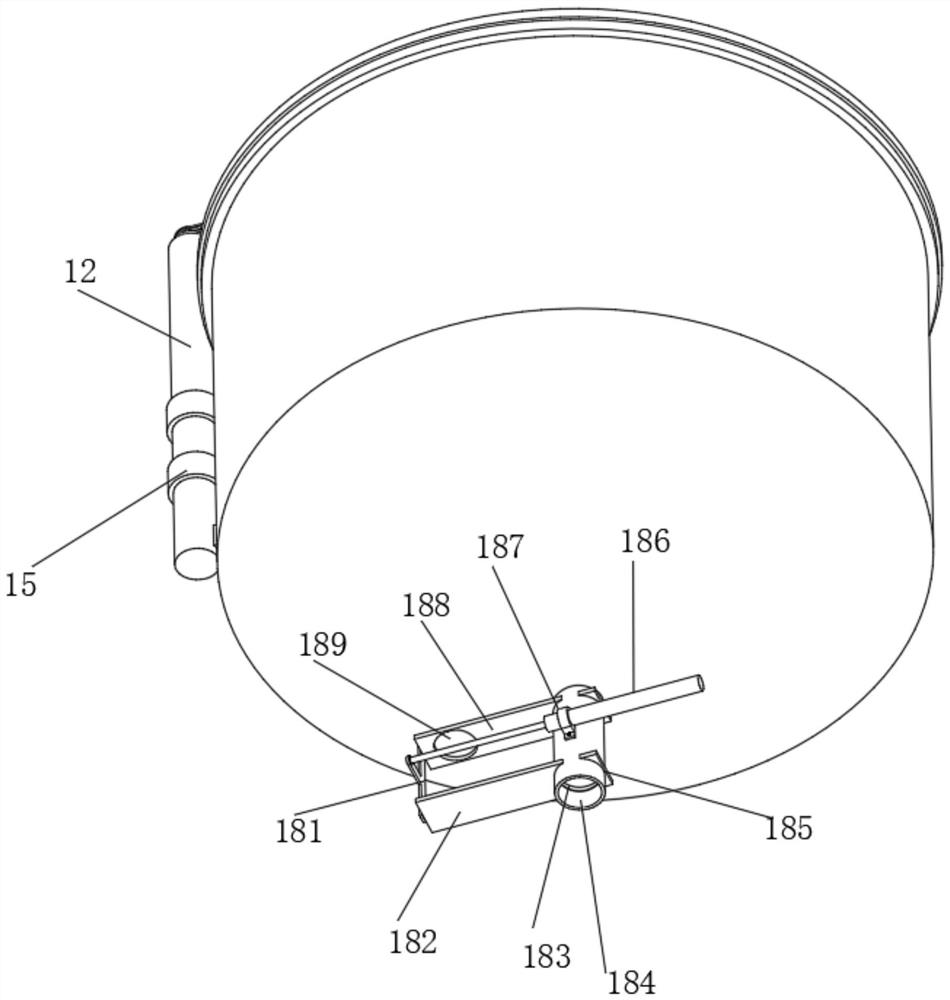

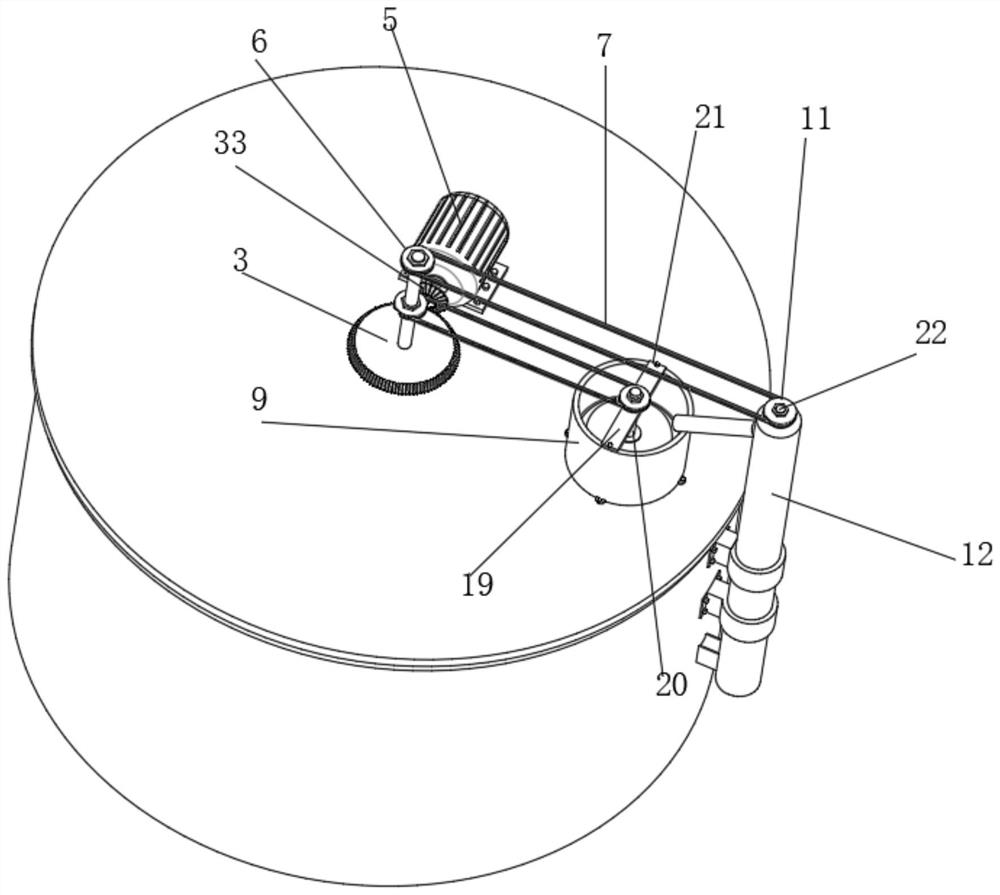

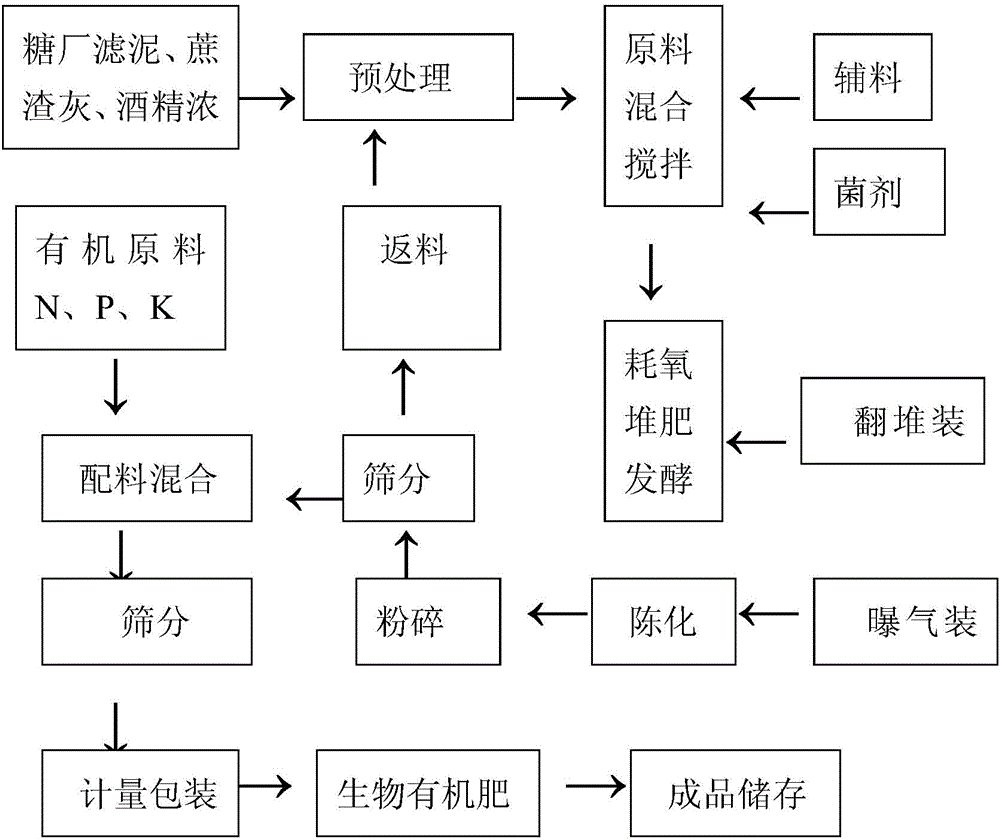

Bio-organic fertilizer and production method thereof

ActiveCN104045385AAccelerate the lossEasy to sieveBio-organic fraction processingOrganic fertiliser preparationFiltrationMoisture

The invention discloses bio-organic fertilizer. Through fermentation, the bio-organic fertilizer is prepared from 6-26wt% of filter mud produced by a sugar refinery, 55-75wt% of bagasse ash and 10-30wt% of ethanol concentrate. The production method comprises the following steps of 1, carrying out mixing stacking on filter mud produced by a sugar refinery, bagasse ash and ethanol concentrate, 2, removing moisture by filtration, 3, stacking the raw material mixture in a strip-shaped stack way, adding bifidobacterium, lactic acid bacteria, bacillus, saccharomycetes, actinomycetes and acetic bacteria into the stacked mixture, and carrying out fermentation, 4, keeping the primary fermented stack temperature above 60 DEG C and keeping material moisture content in a range of 40-45%, 5, increasing the height of the primary fermented stack, and carrying out secondary fermentation for aging until material moisture content is in a range of 30-35%, 6, adding the aged material into organic raw materials of N, P and K and carrying out mixing and 7, packaging the mixture to obtain the product. The bio-organic fertilizer has good fertilizer efficiency and is conducive to absorption by crops. The production method utilizes simple production equipment, has simple production processes and can be operated easily. The production method reduces a cost and has high income.

Owner:广西凭祥桂商现代农业投资有限公司

Automatic cleaning and chip removal device for machining

ActiveCN112123005AImproved cleaning efficiencyImprove cleaning efficiencyMaintainance and safety accessoriesWorkbenchElectrical and Electronics engineering

The invention discloses an automatic cleaning and chip removal device for machining. The automatic cleaning and chip removal device comprises a frame, wherein waste chip collecting boxes are arrangedinside the two sides of the lower end of the frame; handles are fixedly connected to the outer side surfaces of the waste chip collecting boxes; a bottom plate is arranged in the middle of the inner side of the frame; a workbench is fixedly connected to the bottom plate; a clamp mounting groove is formed in the upper surface of the workbench; screw rods are connected to the front side and the rearside of the interior of the frame through bearings; a moving plate is connected to the screw rods; air distribution blocks are fixedly connected to the left side surface and the right side surface ofthe moving plate; and the lower ends of the air distribution blocks are connected with air blowing heads. According to the automatic cleaning and chip removal device for machining, the workbench of amachine tool can be conveniently and automatically cleaned, so that the cleaning and chip removal efficiency of the workbench of the machine tool is improved, the clamp mounting groove can be conveniently cleaned, then a clamp can be accurately installed on the workbench, moreover, chips generated by machining can be conveniently screened, and then the classified chips can be conveniently subjected to later treatment.

Owner:绍兴柯桥皓悦纺织科技有限公司

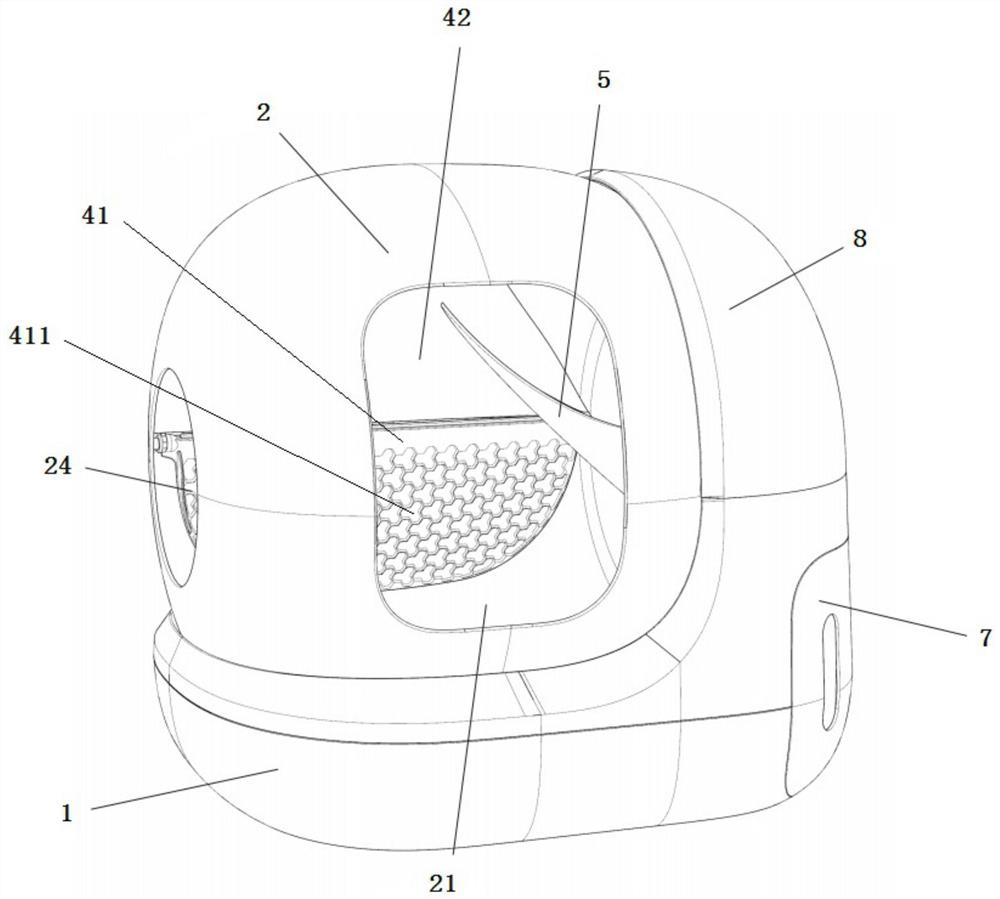

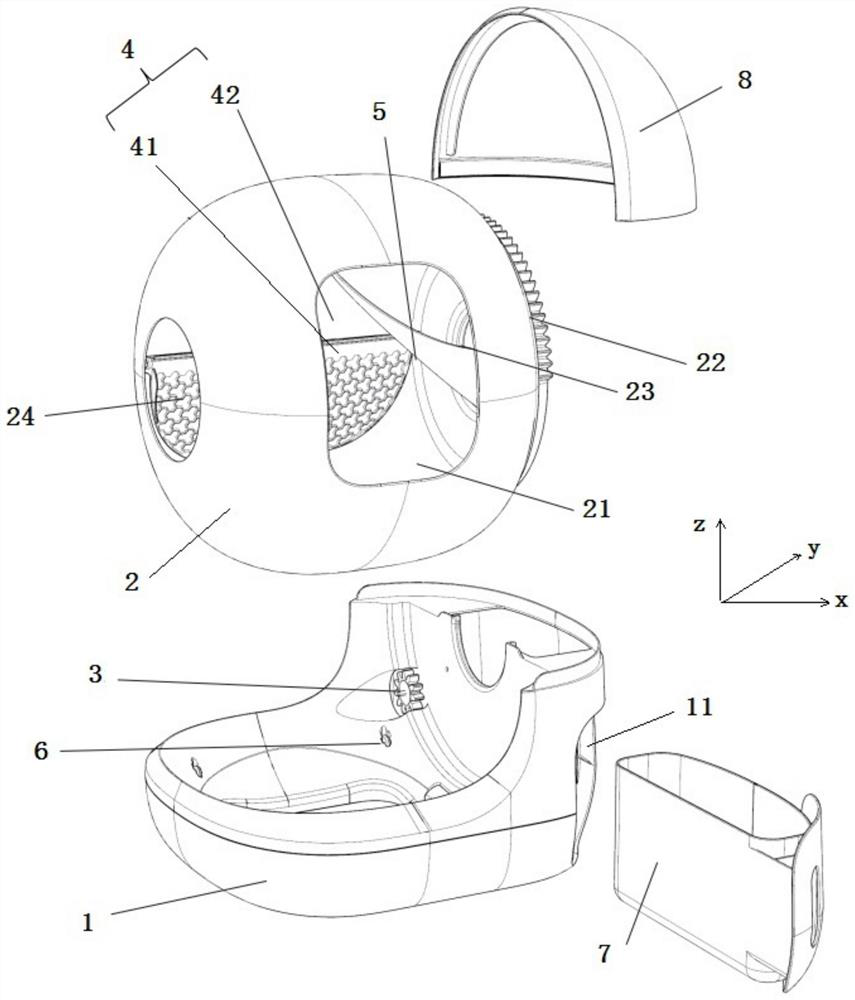

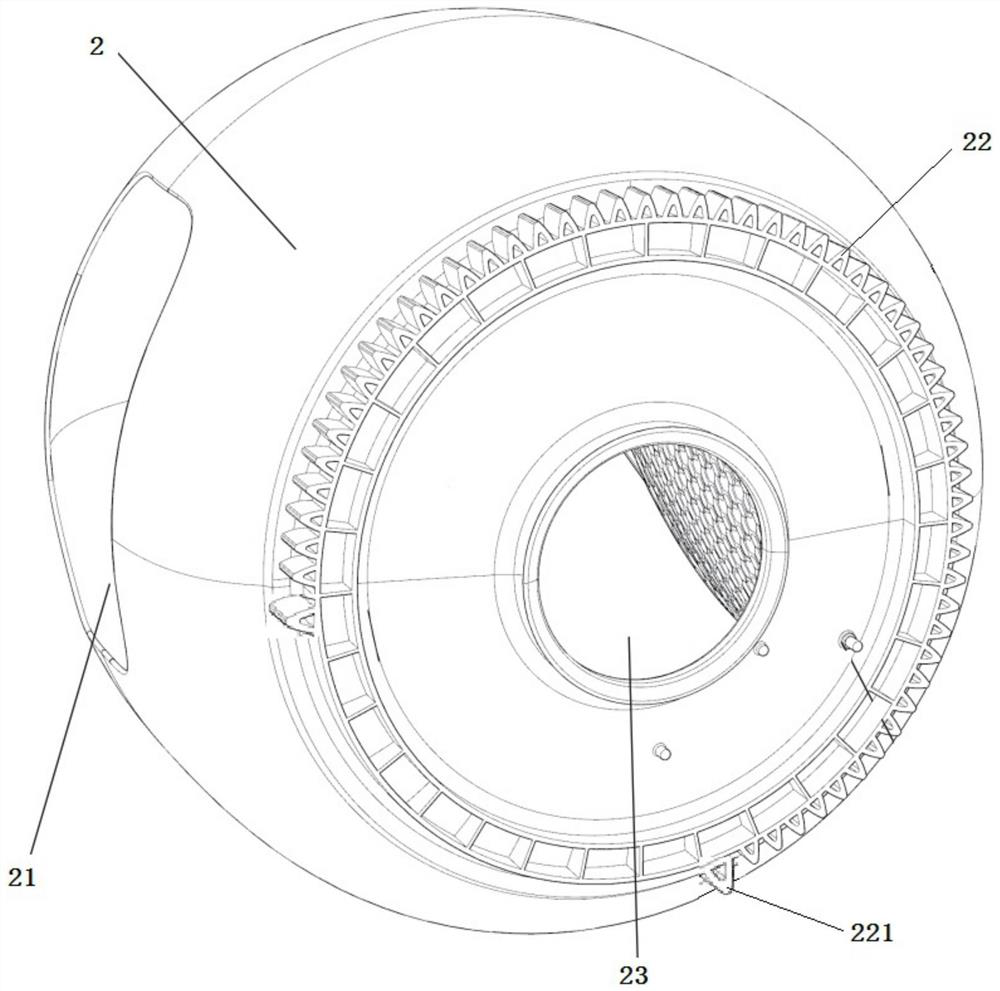

Pet cat excrement screening device

ActiveCN112452731AEnsure toilet safetyReduce volumeSievingScreeningCompanion animalMechanical engineering

The invention relates to the technical field of pet supplies, and discloses a pet cat excrement screening device. The pet cat excrement screening device comprises a supporting base and a roller rotationally installed on the supporting base, a roller driving device is installed on the supporting base, the roller can be driven by the roller driving device to rotate between a first position and a second position, and the rotating angle of the roller is smaller than 360 degrees; a pet inlet is formed in the side wall of a roller body of the roller and is always exposed out of the supporting base in the rolling process of the roller; and a screening mechanism is installed in the roller, a waste discharge port is formed in the rear end of the roller, the screening mechanism comprises a screeningnet and a spiral collecting bin, the spiral collecting bin is provided with a spiral surface spirally bent towards the waste discharge port, the screening net is used for screening excrement from catlitter to the spiral surface, and the spiral surface is used for guiding the excrement into the waste discharge port along with rotation of the roller. According to the pet cat excrement screening device, the pet inlet is always exposed out of the supporting base, and the safety of a pet cat is guaranteed when the roller rotates by mistake.

Owner:XIAOPEI NETWORK TECH SHANGHAI CO LTD

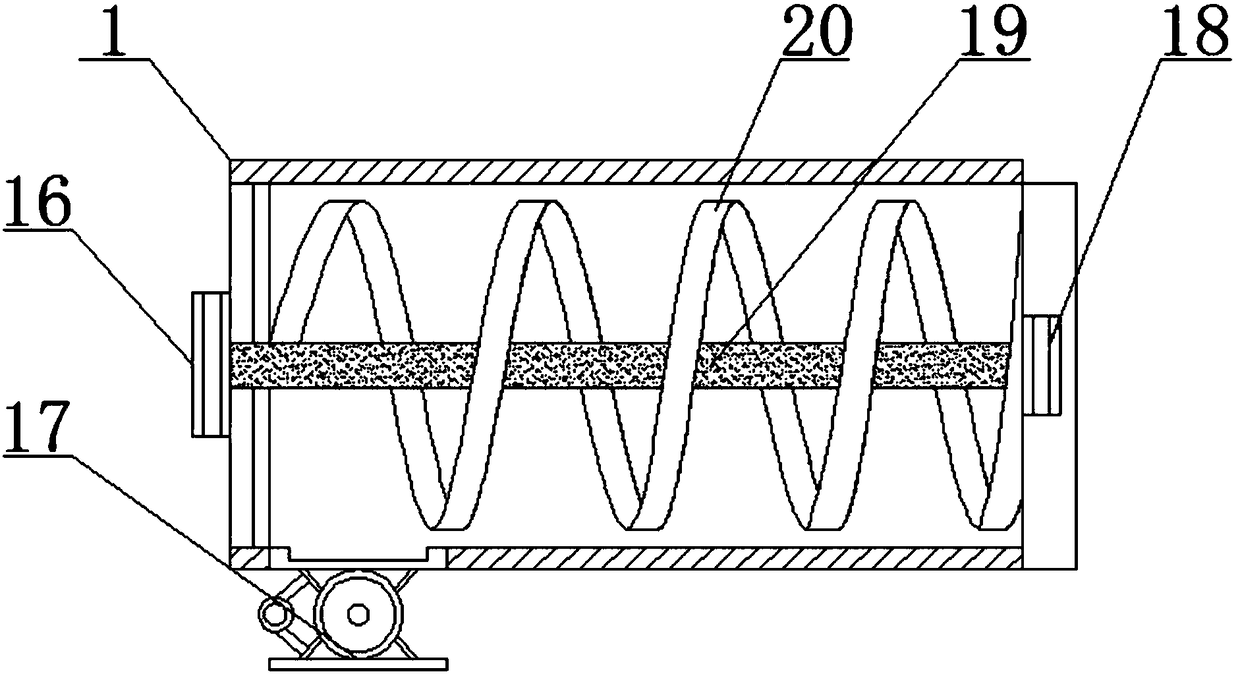

Cereal sorting device with drying effect

The invention discloses a cereal sorting device with drying effect. The cereal sorting device comprises a material cylinder and a drying cylinder body. A feeding table is arranged at the top of the material cylinder. A fan blade and a heating screen plate are arranged from left to right of an inner cavity of the material cylinder respectively. A screening net is arranged at the inner cavity of the material cylinder. A vibration exciter is arranged on the right side of the screening net. The drying cylinder body is arranged on the left side of the material cylinder. The inner wall of the drying cylinder body adheres to a heat conducting pipe. A main shaft is arranged in the middle of the inner cavity of the drying cylinder. Spiral blades are arranged on the periphery of the middle portion of the main shaft. A discharging opening is formed in the bottom of the left side of the drying cylinder body. A base is arranged at the bottom of the drying cylinder body. A control panel is arranged on the front face of the base. The cereal sorting device with the drying effect is good in sorting effect, during sorting, cereal is subjected to drying processing, using is convenient, and working efficiency is high.

Owner:HUBEI JIALIANG MACHINERY

A root-knot nematode biocontrol agent and its production process

InactiveCN102273487AFree from external influencesThe influence of external factors is convenientBiocideNematocidesBiotechnologyMicroorganism

Owner:MICROBIOLOGY INST OF SHAANXI

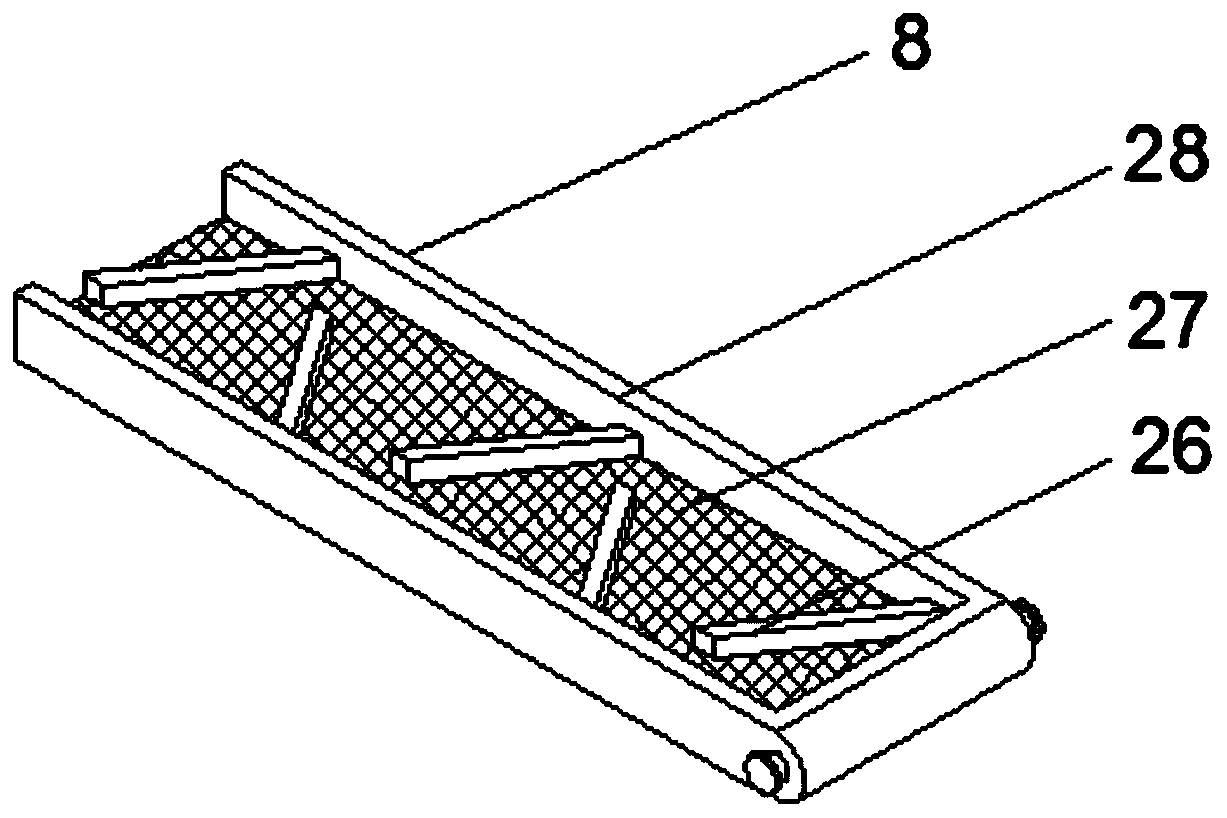

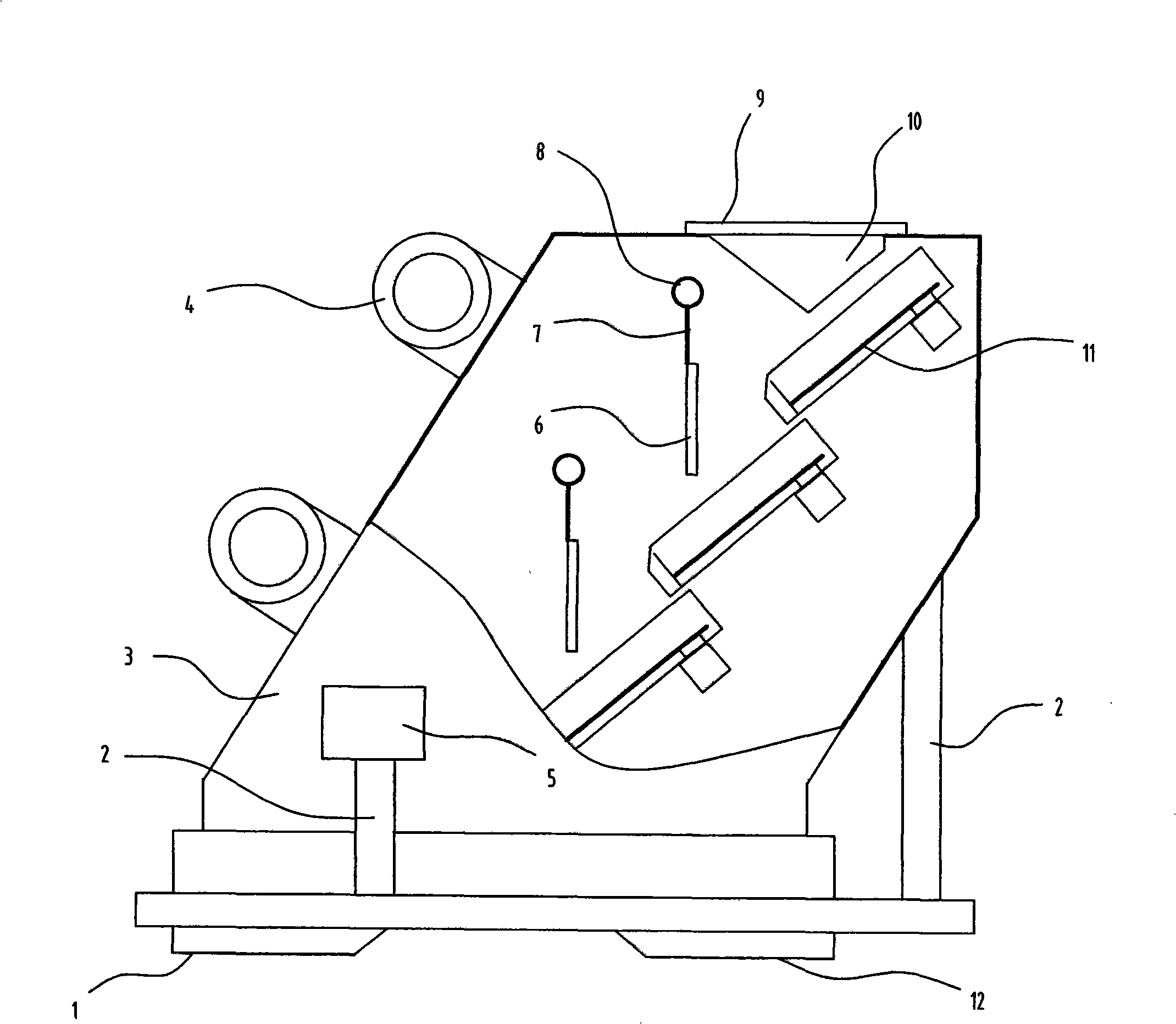

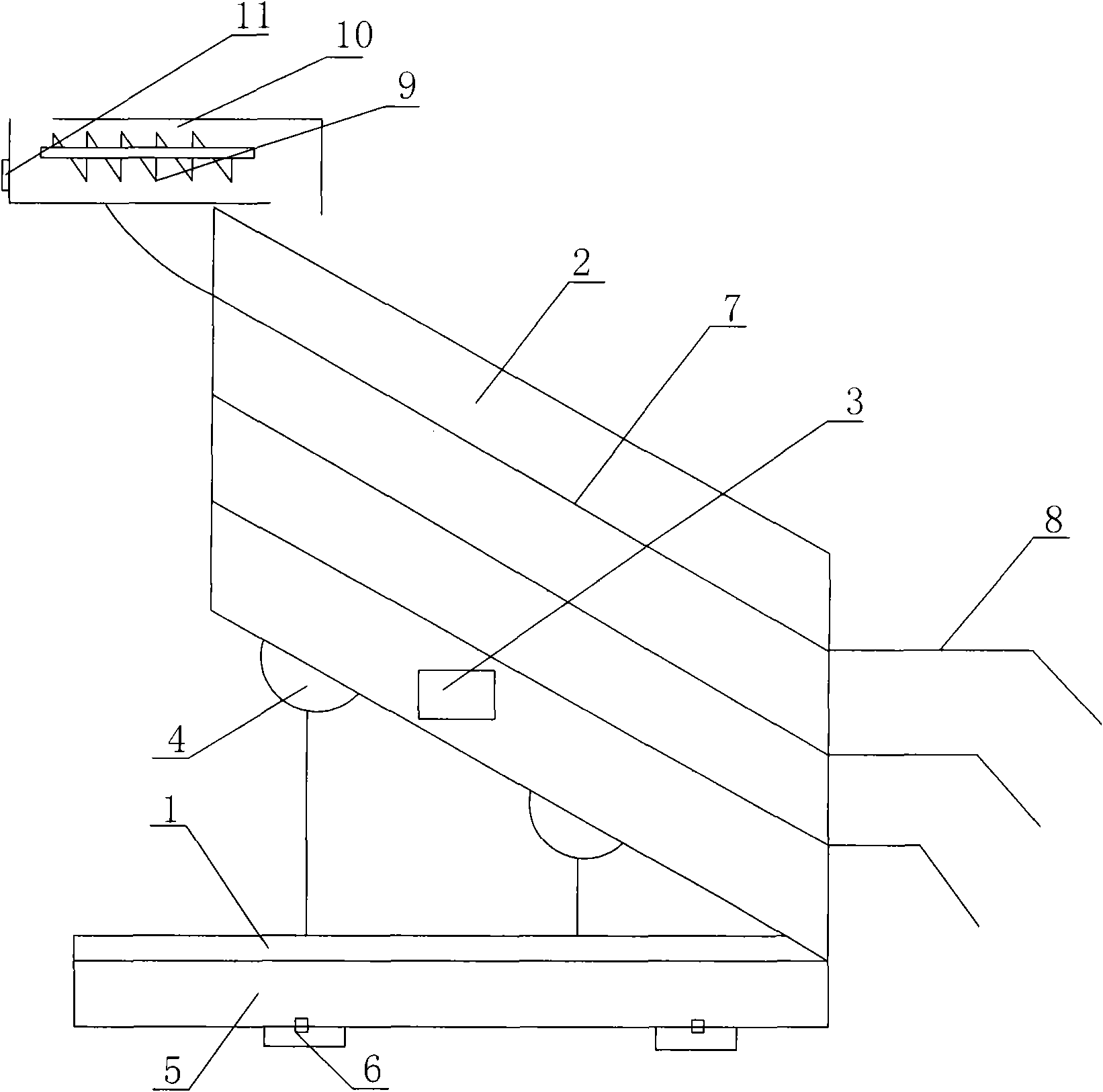

Counter play sifting method and screen employing drop energy of screening material

The invention provides a method for screening materials in industry and an industrial sieve, in particular to an impact sieving method using energy of falling materials to be sieved and a technical proposal of an impact sieve. The technical proposal is as follows: a plurality of inclined and step-like screens are arranged up and down, and an impact board is arranged corresponding to an upper material outlet of each screen and above the next screen; the falling material to be sieved strikes a first screen to be sieved for the first time, the material is rebounded by the first screen, falls down to strike the impact board, then the material is reflected with the counteraction of the impact board and strikes the next screen to be sieved for the second time, and sieving of the material goes on like this. The impact sieve is characterized by the at least two screens in an inclined and step-like arrangement, and the material outlet on the sieve corresponding each screen, and the impact board which is arranged corresponding to the material outlet of each screen and above the next screen, and is fixed on a cross beam of a box body through a connecting rod.

Owner:济南中燃科技发展有限公司

Waste recycling device for building construction

ActiveCN110404620APrevent slippingEasy to sieveGrain treatmentsArchitectural engineeringWaste recycling

The invention discloses a waste recycling device for building construction. In order to solve the problems that screening is not delicate enough and magnetic materials in construction waste are difficult to extract, the following scheme is proposed. The waste recycling device includes a box body, a storage box is welded to the outer wall of the top of the box body, a feeding hopper is welded to the middle position of the outer wall of the top of the storage box, and two pulverizing mechanisms are arranged at the positions, close to the storage box, of the outer wall of one side of the box body; and the box body, the storage box and the feeding hopper are in communication, a plurality of electromagnets are fixed on the two ends of the inner wall of the top of the storage box through bolts,inclined plates are welded to the two sides of the outer wall of the bottom of the storage box, and one end of each inclined plate is located inside the box body. The construction waste falls off fromthe feeding hopper and falls slowly under blocking of a blocking rod, a transverse rod and a spacer rod, the magnetic materials can be attracted after the electromagnets are activated, the construction waste is screened, and screening of coarse aggregate, fine aggregate and fine powder is facilitated.

Owner:中深建业建设集团有限公司

Oscillation screen

The invention discloses an oscillation screen. The oscillation screen comprises a base, a screen body, an elastic element and an oscillation motor, wherein the screen body is fixed on the base by virtue of the elastic element; the base is connected with a base lift stabilizing device; the screen body is tilted to the ground; a plurality of layers of screens are fixed in the screen body slantways, and an aggregating port is connected to the tail end of each layer of the screen; a material conveying device is arranged on the upper part of the screen body; and a speed controller is arranged on the material conveying device. The oscillation screen has the advantages of good screening effect and small screening noise.

Owner:张敏威

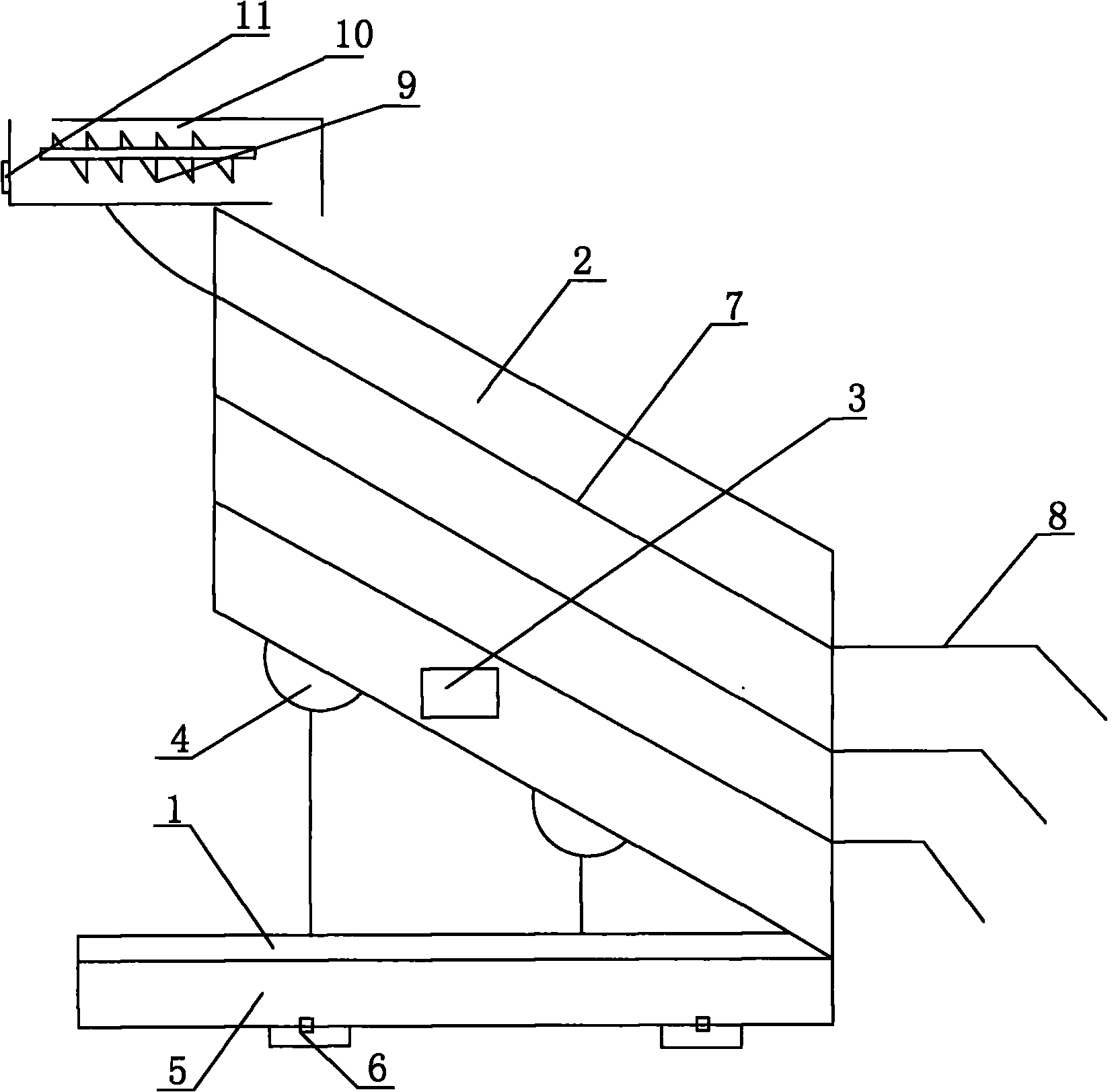

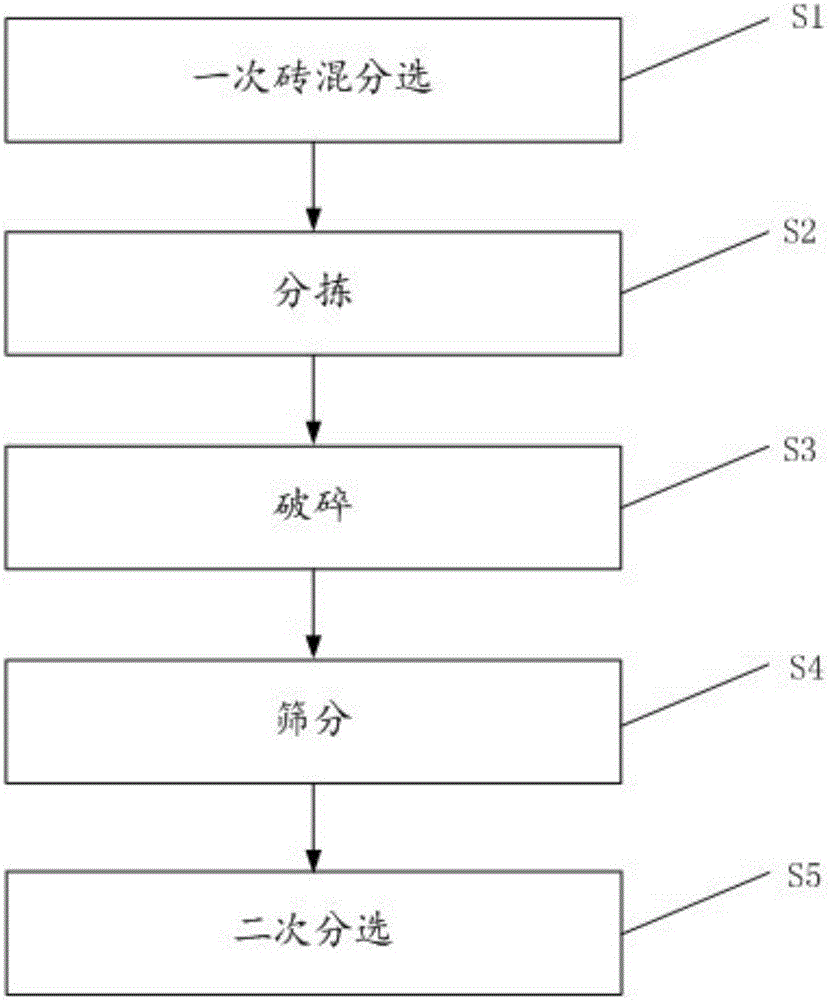

Two-time brick-concrete separating process for building wastes

The invention relates to a two-time brick-concrete separating process for building wastes. The two-time brick-concrete separating process for the building wastes comprises the following steps: S1, carrying out brick-concrete separation for the first time, namely separating raw materials of building garbage for the first time to obtain first materials, second materials and third materials; S2, sorting, namely sorting the first materials to remove sundries in the first materials; S3, breaking, namely conveying the sorted first materials to a breaker and breaking the sorted first materials; S4, screening, namely conveying the broken first materials to a first screening device and screening the broken first materials to obtain muck, first rough materials and first fine materials; and S5, separating for the second time, namely conveying the first fine materials to a first flotation device, and separating the first fine materials for the second time to obtain brick materials and concrete materials. By the two-time brick-concrete separating process for the building wastes, brick and concrete in the building wastes are separated from each other, value of recycling of the concrete can be utilized to a maximum degree, and the integral utilization value of the building wastes is increased.

Owner:HENAN WINNER VIBRATING EQUIP

Efficient soil screening and collecting device for potted plant planting

The invention relates to a screening and collecting device, in particular to an efficient soil screening and collecting device for potted plant planting, and aims at achieving the technical purpose of providing an efficient soil screening and collecting device for potted plant planting. In order to achieve the technical purpose, the efficient soil screening and collecting device for potted plant planting comprises a bottom plate and the like; supports are arranged on the left side and the right side of the top of the bottom plate respectively, a collecting tank is arranged in the middle of the top of the bottom plate, a swinging device is arranged between the left-side support and the right-side support, the bottom of the swinging device is located over the collecting tank, and a screening device is arranged in the swinging device and penetrates through the outer side of the swinging device. According to the efficient soil screening and collecting device for potted plant planting, the effect that soil coarseness and fineness screening can be effectively conducted, coarse soil blocks or stones unbeneficial to plant growth in soil are screened out, and then plant planting and growing are promoted is achieved, and the practicability is good.

Owner:吴文英

Production system of desulfurized stone powder

InactiveCN106824397AEfficient crushingImprove crushing effectSievingScreeningWear resistantStone dust

A production system for desulfurization stone powder. The raw materials are crushed by a crusher and then sent to a screening machine by a conveyor to screen the particle size of the raw materials. The fine-grained raw materials are sent to a pulverizer by a conveyor belt for grinding, and finally The powder that meets the requirements is sent to the silo through the elevator. The crusher includes the body, the feed bin and the outlet bin that are respectively arranged on the top and bottom of the body, the rotating shaft horizontally arranged in the inner cavity of the body, and the side of the body and the The motor connected by the rotating shaft is driven horizontally. There is a bottom plate sliding horizontally at the bottom of the machine body. The bottom plate is horizontally sliding to connect the inner cavity of the machine body with the discharge bin to realize the discharge of the crusher. Several breaker hammers are evenly arranged on the rotating shaft along its axial direction. The breaker is hinged on the rotating shaft through a connecting rod. A layer of wear-resistant crushing plate is evenly covered on the inner wall and bottom plate of the machine body, and crushing convex teeth for grinding and crushing are arranged on the surface of the wear-resistant crushing plate. The system of the invention has simple and practical structure and high efficiency.

Owner:刘涛

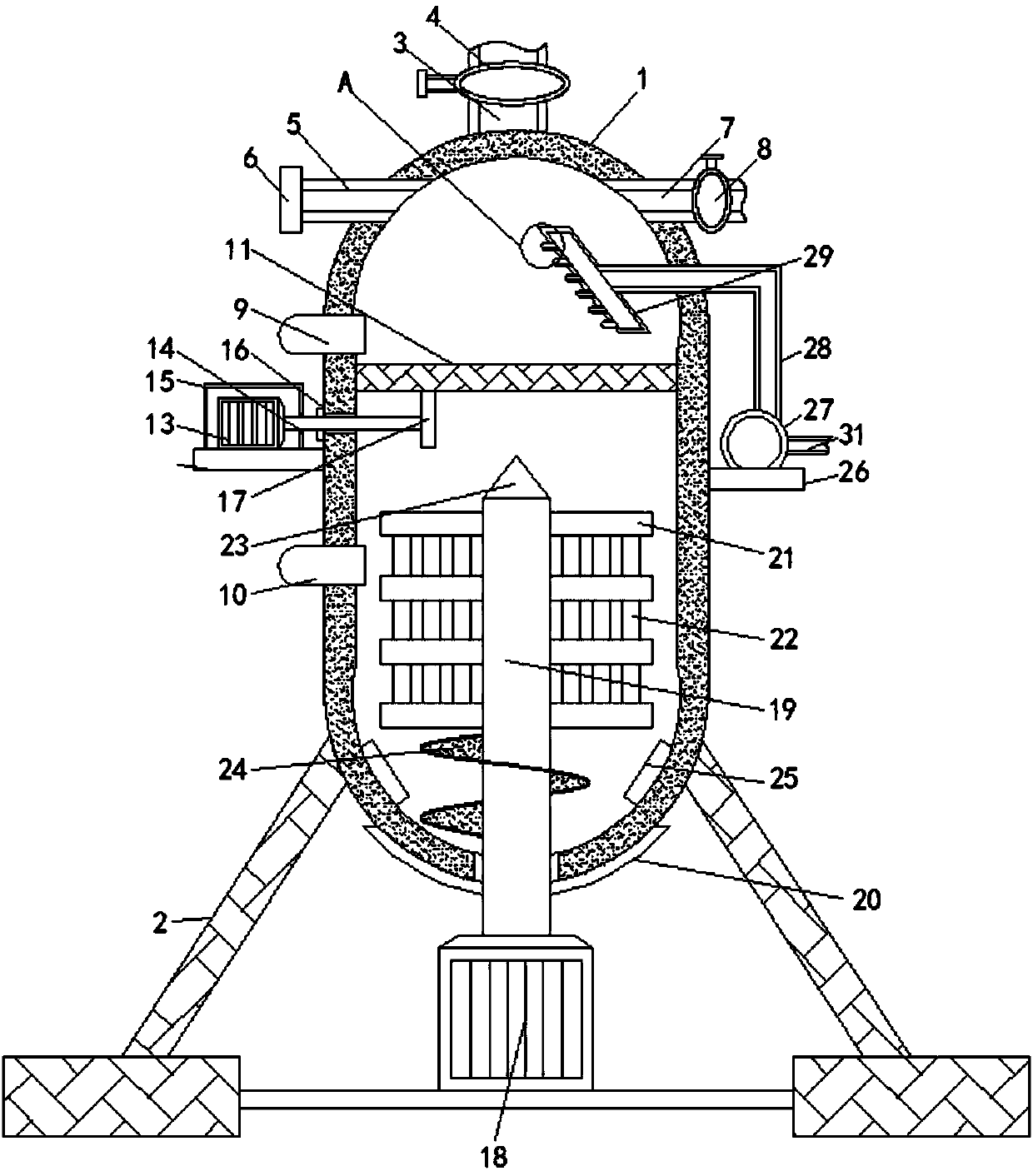

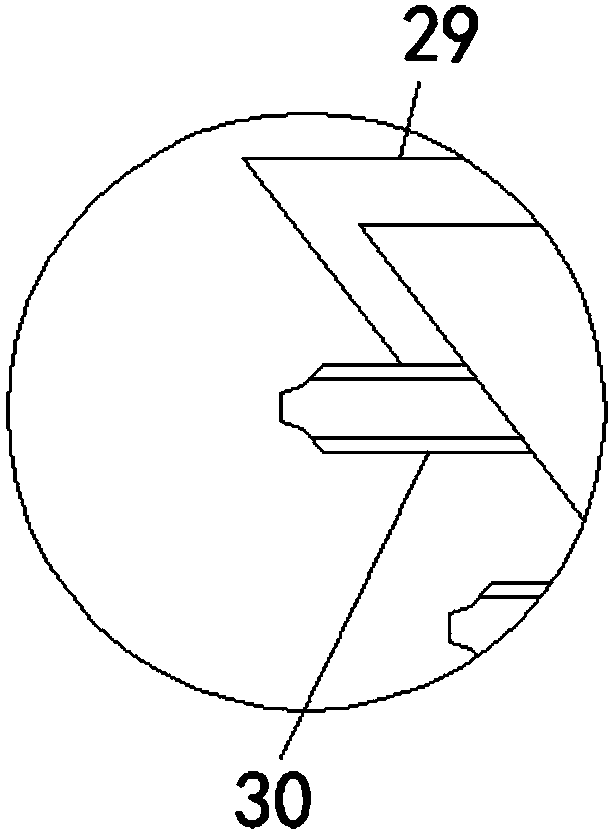

New energy material fermentation device

ActiveCN107828632AEasy to adjust and useImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsElectric machineryPiezometer

The invention belongs to the technical field of new energy, and discloses a new energy material fermentation device. The new energy material fermentation device comprises a fermentation tank; the leftside and the right side of the bottom of the fermentation tank are fixedly connected with support legs; the top of the fermentation tank is communicated with a gas exhaust pipe; the gas exhaust pipeis provided with a snuffle valve; the left side of the top of the fermentation tank is communicated with a fermentation material inlet pipe; the left end of the fermentation material inlet pipe is provided with a material blocking cover. According to the design, fermentation materials can be introduced into the fermentation tank through the fermentation material inlet pipe, a filter screen is usedfor effective filtering of the fermentation materials, a first drive motor is turned onto to drive a fist transmission shaft to rotate, and the filter screen is tapped by an eccentric block rhythmically, so that it is beneficial for screening and feeding of materials; a piezometer and a thermometer are used for effective monitoring on the gas pressure and temperature in the fermentation tank, sothat preferable adjusting and applications are realized, and fermentation broth energy production efficiency is increased.

Owner:泰州禾益新材料科技有限公司

Large and small material supply selection device for ore color sorter

The invention discloses a large and small material supply selection device for an ore color sorter. The large and small material supply selection device for the ore color sorter comprises a base and aspindle; a fixed frame is arranged on the left end of the base; a main motor is arranged below the fixed frame; a feeding machine shell is arranged on the fixed frame; a screen box is arranged belowthe right side of the feeding machine shell; and a first layer of screen net is arranged above the right side of the screen box. By adopting the large and small material supply selection device for the ore color sorter, a color sorter supply device is provided with screen nets, and when a materials enters labor, materials and machines, the size of the material can be distinguished through three layers of the screen nets; the color sorter supply device is provided with a feeding machine, the material is output into the screen box at a constant speed through matching of a spiral pushing sheet and a bearing in the feeding machine; the color sorter supply device is provided with a vibration exciter, and an exciting force can be generated on the equipment through the vibration exciter, so thatthe purpose that the material is better conveyed and screened, and use is safer and more convenient is achieved.

Owner:HEFEI MINGDE PHOTOELECTRIC TECH LTD

Shaft screening device

The invention belongs to the field of screening equipment, and particularly relates to a shaft screening device. The device comprises a conveying belt used for conveying shaft workpieces, a cam is rotatably connected into the conveying belt, an output pipe of the conveying belt is fixedly connected with a discharging frame, a baffle is hinged to the discharging frame, a spring connected with the side wall of the discharging frame is arranged on the baffle, the screening mechanism comprises a base, the top of the base and the upper surface of the conveying belt are equal in height, multiple transmission rollers are rotatably connected in the length direction of the upper surface of the base, and the distance of the gap between the transmission rollers is smaller than the diameter of a shaft, with the minimum shaft diameter, conveyed on the conveying belt, multiple screening grooves are formed in the base, diameters of the openings of the screening grooves are gradually increased in the length direction of the base, multiple sets of contact buffer plates are hinged to two sides of the inner wall of each screening groove, and a material box capable of sliding out of the base in a manner of being perpendicular to the length direction of the base is arranged at the bottom of each screening box. Manual operation is not needed, the shaft parts can be classified, and reworked re-checking is prevented.

Owner:宁波信基机械科技有限公司

Raw material sieving device with adjustable hole diameters and used for oil processing

ActiveCN110496769AEasy to adjustEffective sorting and recyclingSievingScreeningOil processingDrive motor

The invention discloses a raw material sieving device with adjustable hole diameters and used for oil processing. The raw material sieving device with the adjustable hole diameters and used for oil processing comprises a sieving box, a drive motor, a vibration motor, a discharge pipeline and a rotary rod, wherein support legs are fixedly installed below the sieving box, and the drive motor is installed above the sieving box; moreover, a charge port is formed above the left side of the sieving box; an output end of the drive motor is connected with a rotary shaft; a thread rod is connected above the sieving box, penetrates through a first sieve plate, and is connected with a movable block; first sieve holes and second sieve holes are formed in the surfaces of the first sieve plate and a second sieve plate separately; and a slide block is arranged on an end part of a discharge plate. The raw material sieving device with the adjustable hole diameters and used for oil processing is capableof facilitating to adjustment for the hole diameters of the sieve holes in the surfaces of the sieve plates, avoiding a blockage phenomenon of the sieve plates during sieving, and effectively recovering oil raw materials with different diameters in a classified manner, and is more convenient to use, and more suitable for being used by people.

Owner:湖南省康多利油脂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com