Oscillation screen

A vibrating screen and vibrating motor technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of not being too fast, entering the screen surface, violent vibration, etc., and achieve good screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

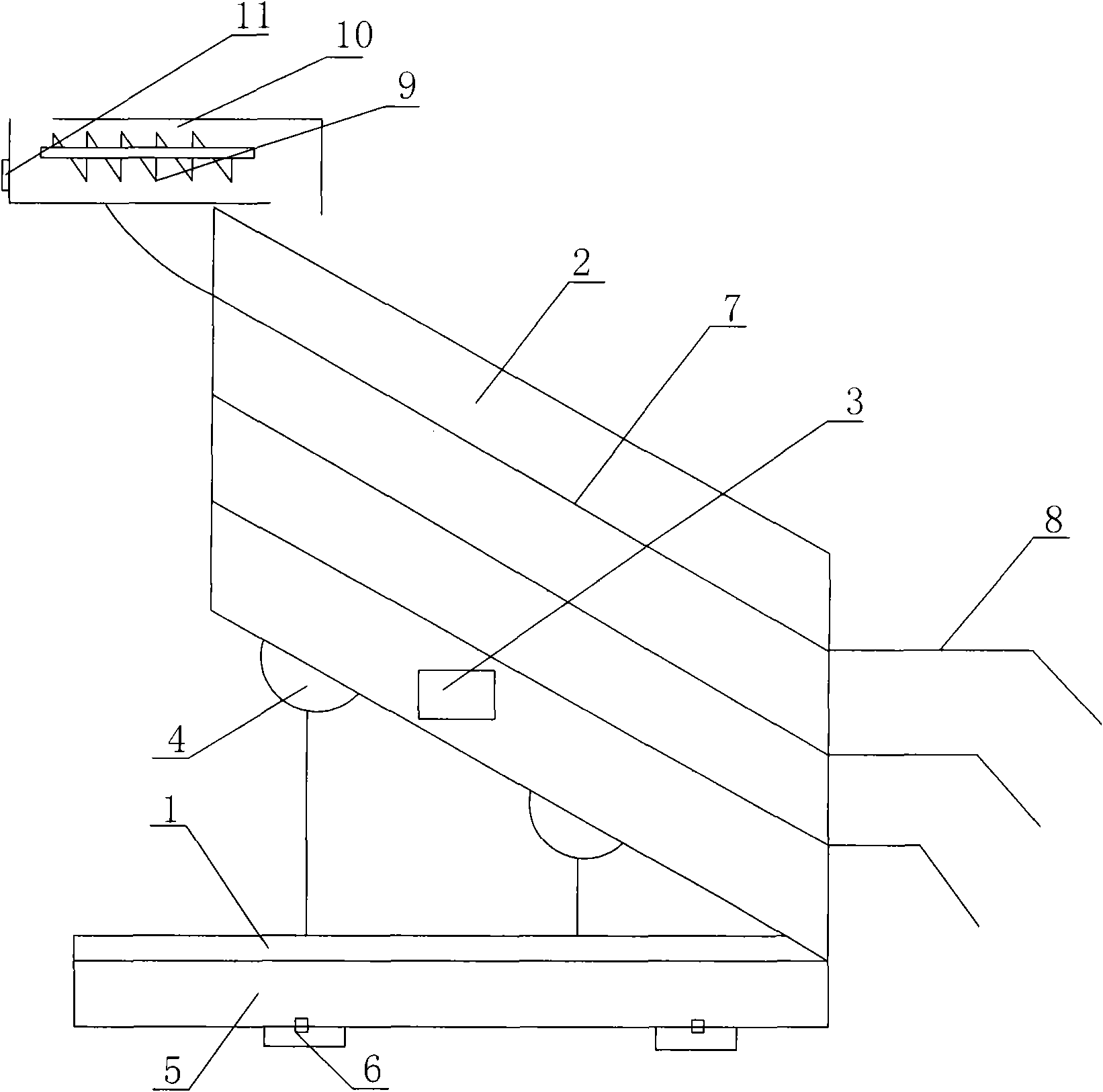

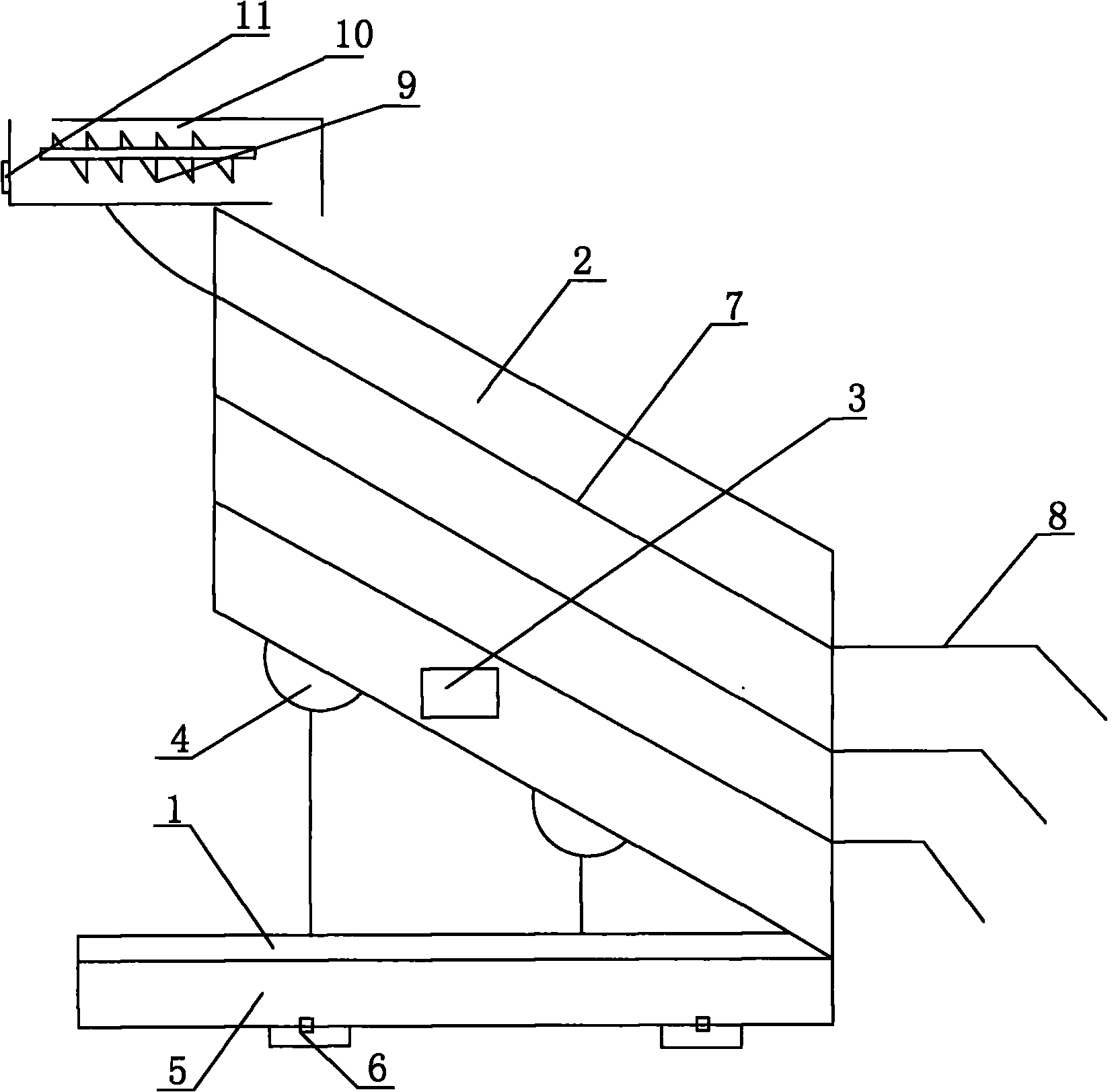

[0015] like figure 1 As shown, the vibrating screen of the present invention includes a base 1, a sieve body 2, a coil spring 4 and a vibrating motor 3, the screen body 2 is fixed on the base 1 by the coil spring 4, the base 1 is connected with the base lifting and stabilizing device, and the base lifting is stable The device includes a lifting platform 5 and a fixed support base 6 connected with the lifting platform 5, so that the base 1 can be stably fixed on the ground, and the height of the sieve body 2 can also be adjusted as required. There are 3-6 layers of screens 7, the inclination angle of the screen body 2 and the screen 7 is 30-60°, the screen body 2 and the screen 7 are set at an inclination, plus the gravity of the material, better screening, each layer The tail end of the screen 7 is connected with a collection port 8, and a material conveying device is installed on the top of the screen body 2. The material conveying device is a box 10 with an auger 9 inside, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com