Patents

Literature

36results about How to "Effective sorting and recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

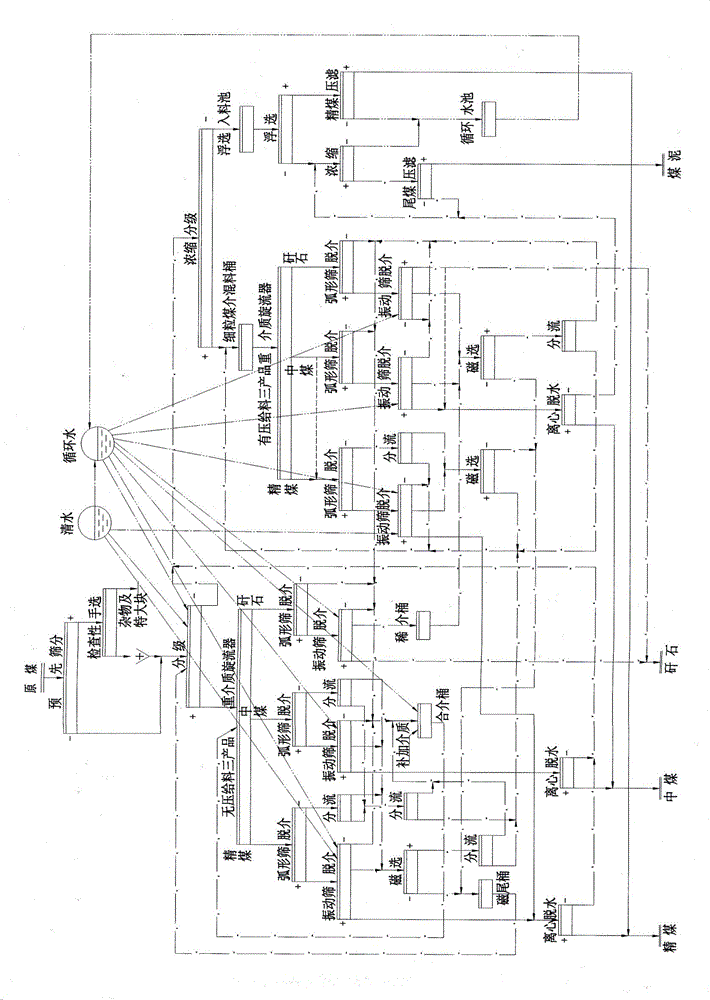

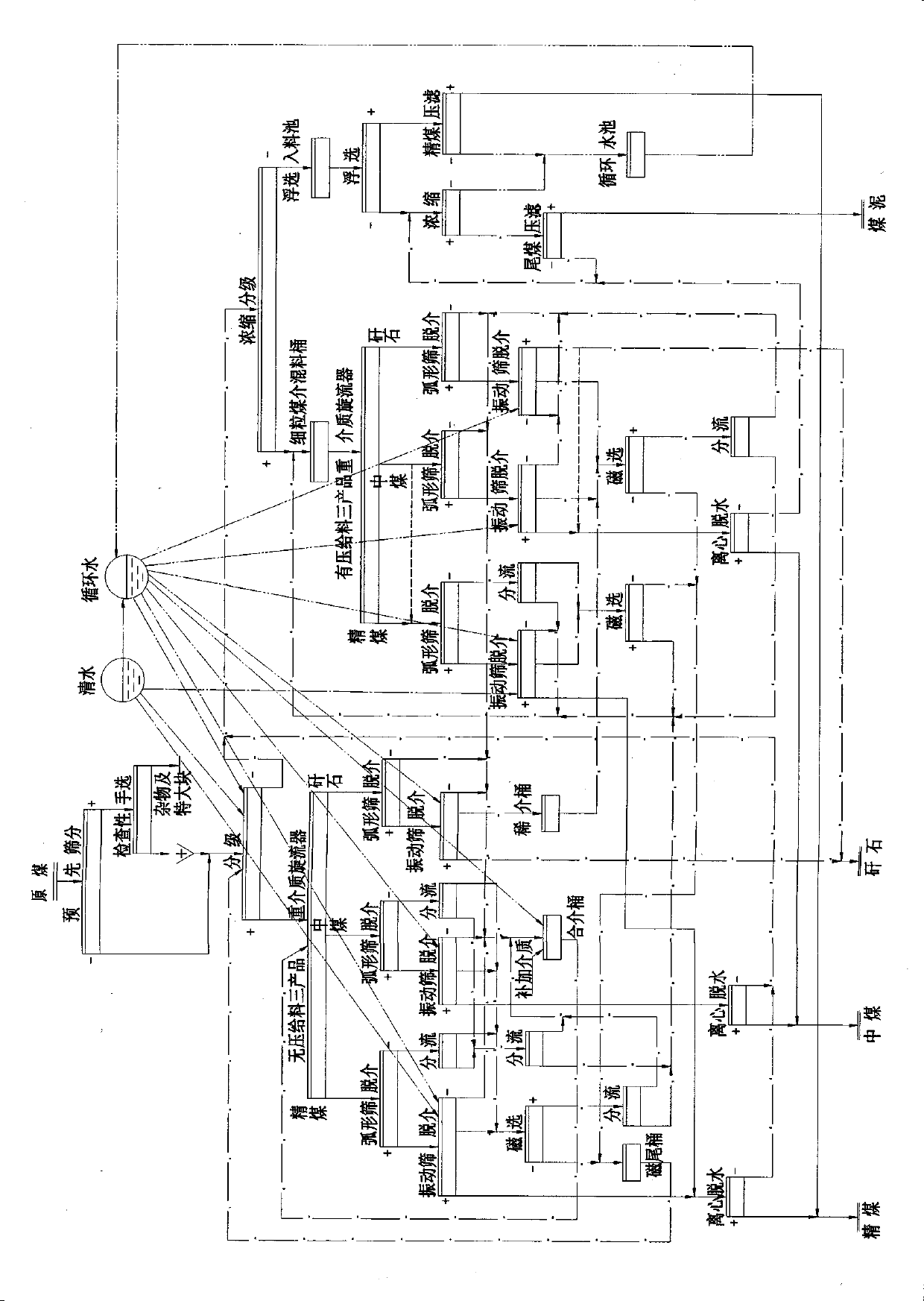

Wide-grain-grade double-dense-medium process for separating all coarse coal slime

The invention discloses a wide-grain-grade double-dense-medium process for separating all coarse coal slime. The wide-grain-grade double-dense-medium process includes that raw coal is preliminarily sieved, manually picked and graded, then oversize products can be used as coarse grain coal, the coarse grain coal is fed into a non-pressure tri-product dense-medium cyclone to be separated, undersize products are concentrated and graded and then are dehydrated in an underflow manner to be used as fine grain coal, the fine grain coal is fed into a pressure tri-product dense-medium cyclone to be separated, and excess flow is fed into a flotation filter-press system, so that the coal slime can be separated; qualified suspension liquid of a fine grain coal dense-medium separating system is provided by coarse grain clean coal of a coarse grain coal separating system, lower branches of coarse grain middling coal primary-section medium removing equipment and branches of coarse grain clean coal and coarse grain middling coal magnetic separation concentration; dilute suspension liquid of coarse grain gangue products and dilute suspension liquid of middling coal and gangue products of a fine grain coal system are treated together; magnetic separation tailings are used as wetting water or primary spray water for grading screens. The wide-grain-grade double-dense-medium process has the advantages that the fine grain coal dense-medium system has a medium automatic generating function, all the coarse coal slime can be efficiently separated by dense media, the suspension liquid is circulated in a closed-loop manner, the separation efficiency is high, the products are flexible in structure, and the production and operation costs are low.

Owner:TANGSHAN BRANCH COAL SCI ACAD

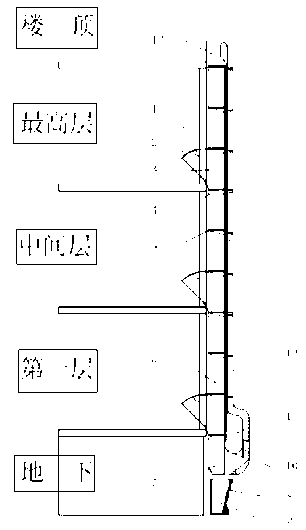

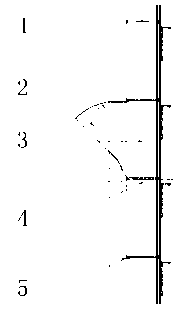

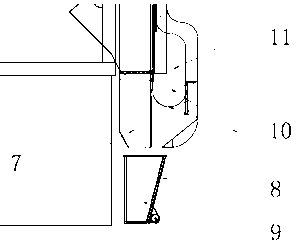

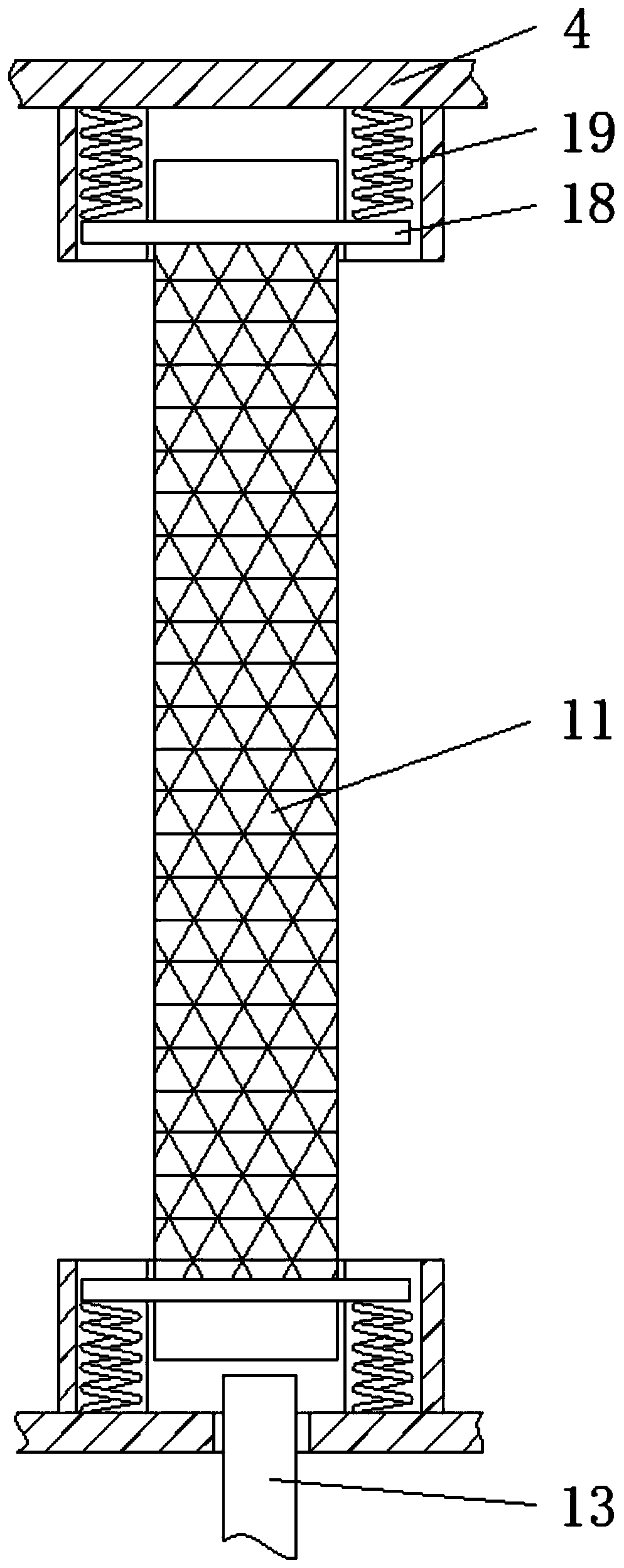

Automatic garbage sorting, putting and collecting system for building

InactiveCN102704658ARealization of classified deliveryIncrease motivationVertical ductsWaste managementWaste sorting

The invention relates to an automatic garbage sorting, putting and collecting system for a building. The automatic garbage sorting, putting and collecting system for the building at least comprises a building garbage channel, wherein a garbage sorting and collecting unit is arranged on the bottom of the building garbage channel; delivery mechanisms are arranged on the top and the bottom of the building garbage channel; the delivery mechanisms are provided with corresponding delivery units which are spaced according to the floor space; each of the delivery units is provided with a garbage putting hole on each layer, so that the garbage can be put into a garbage platform of the delivery units; the transmission mechanisms operate, so that the garbage or garbage bags on the garbage platform can be delivered to the garbage sorting and collecting unit; the garbage sorting and collecting unit puts the garbage or the garbage bags to a corresponding garbage sorting barrel according to the garbage sorting information. According to the system, the sorting treatment is carried out on the garbage from the source, so that the recyclable garage can be reutilized to the greatest extent, thereby reducing the garage treatment difficulty.

Owner:贾超

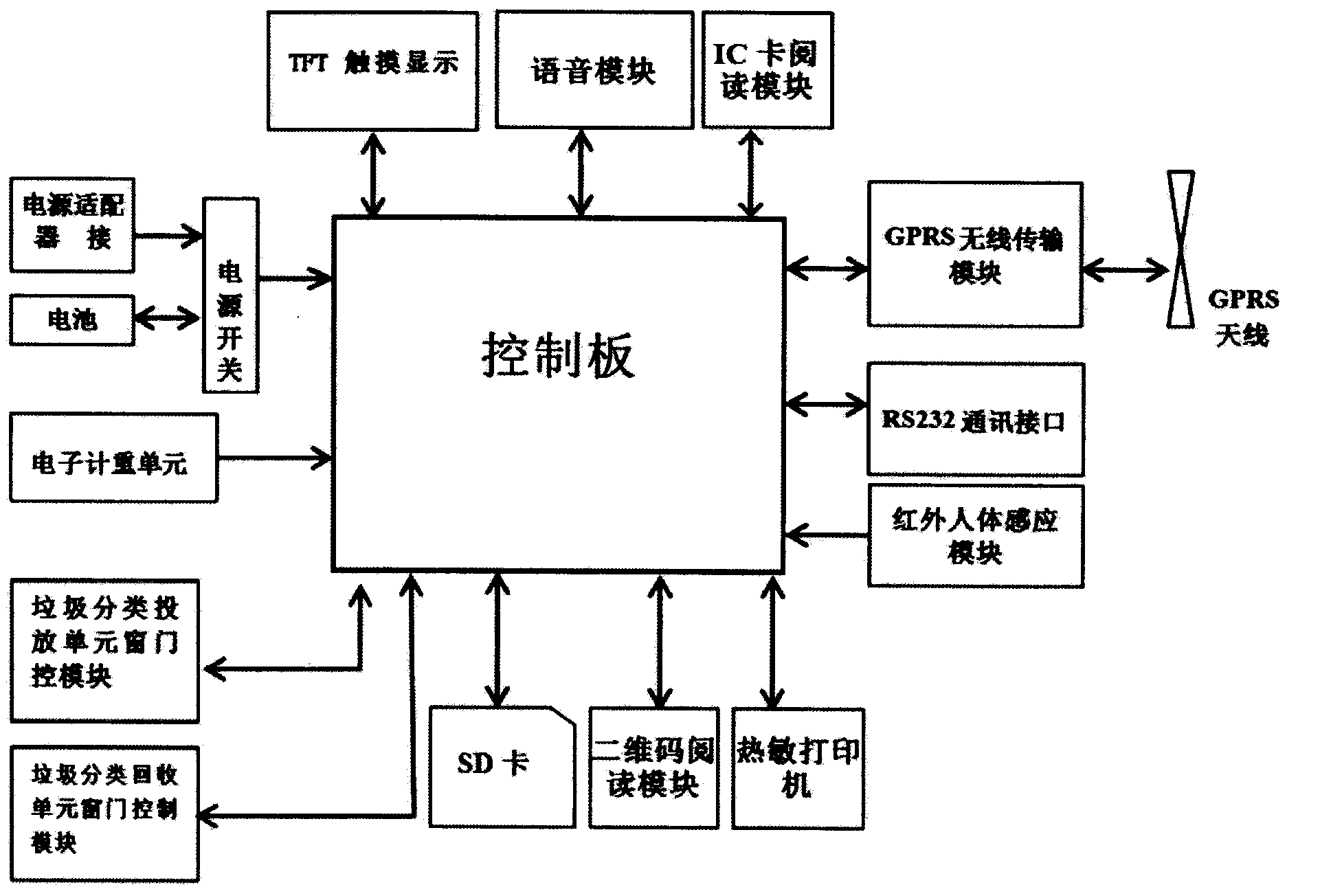

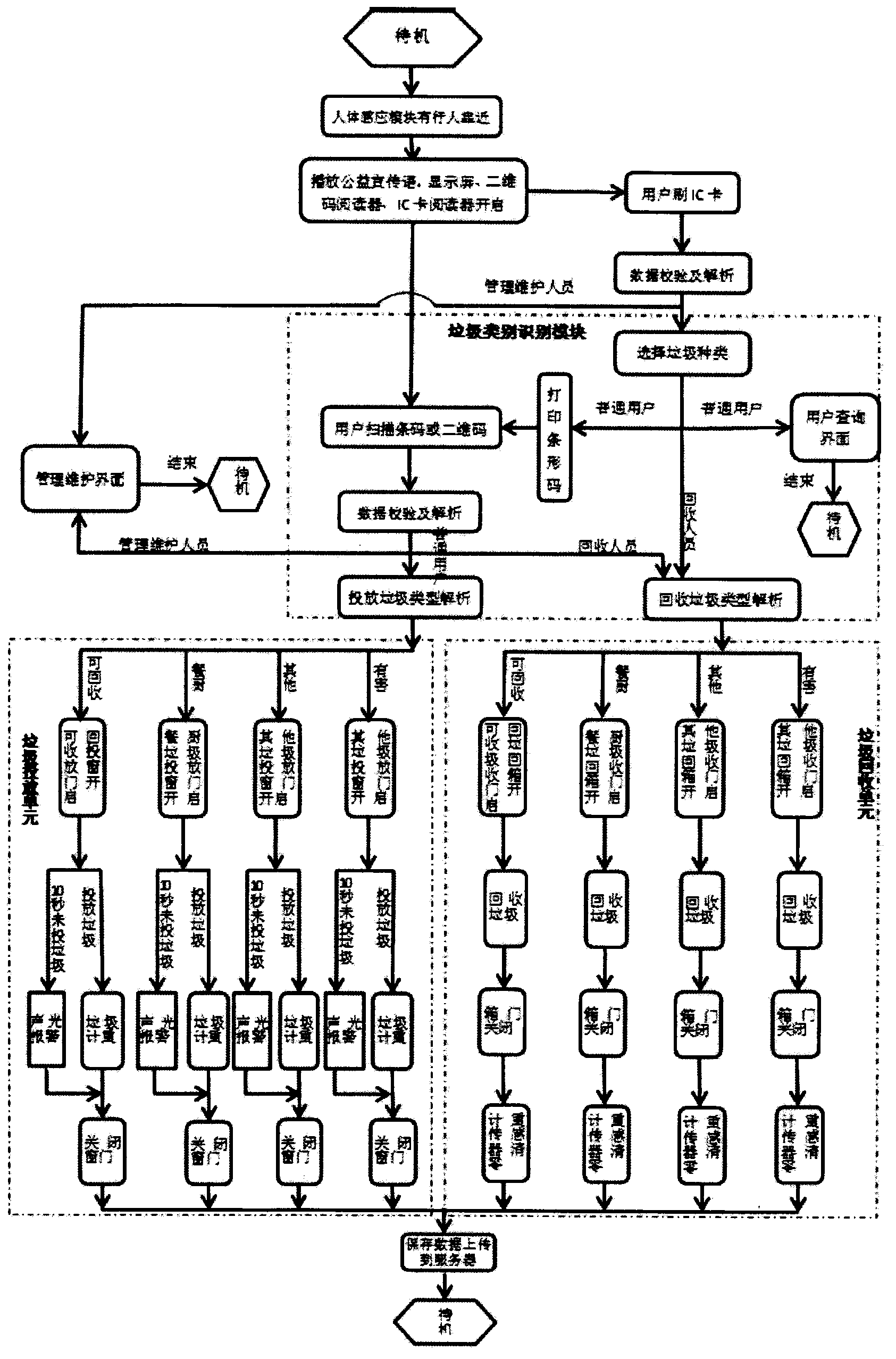

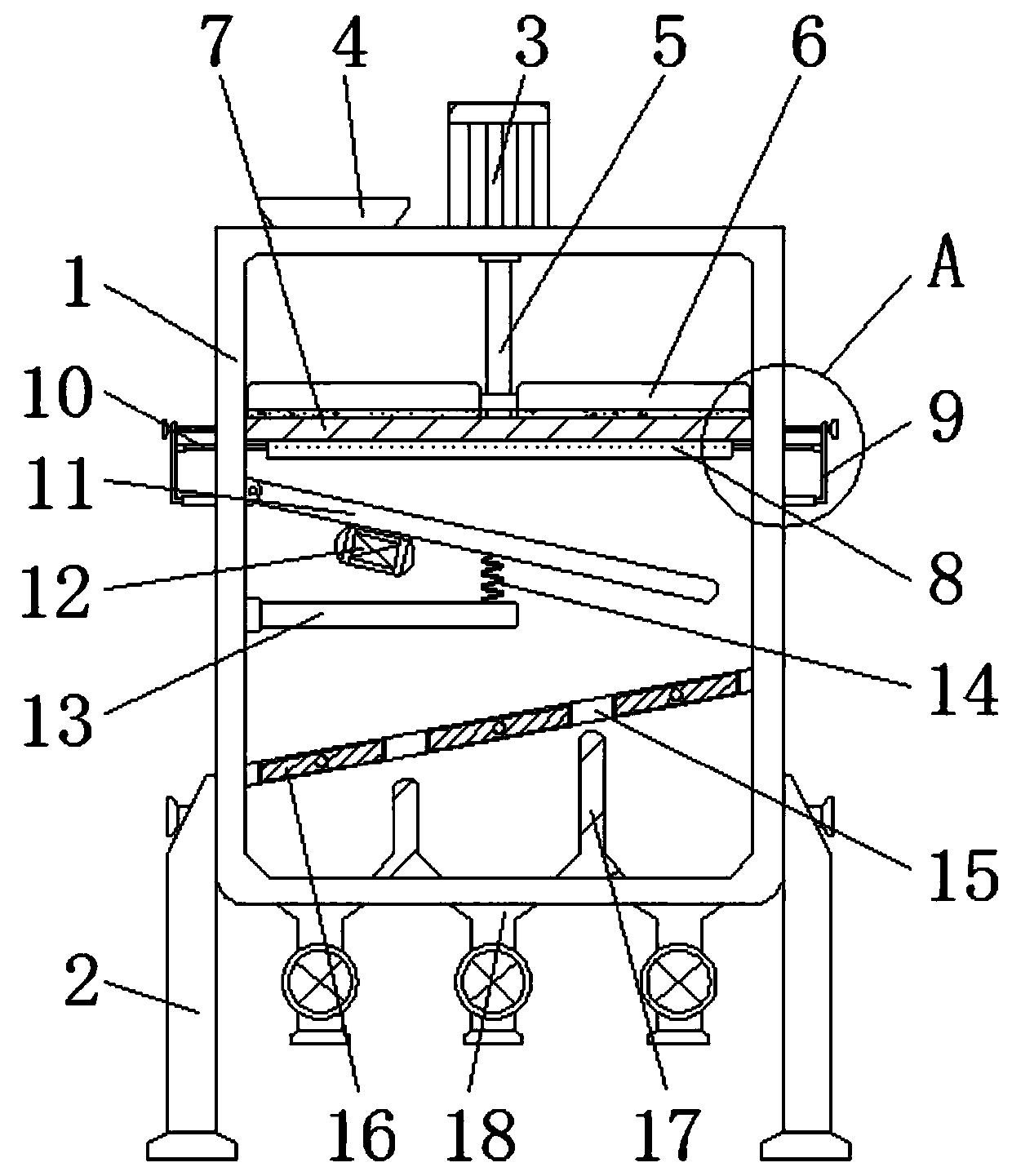

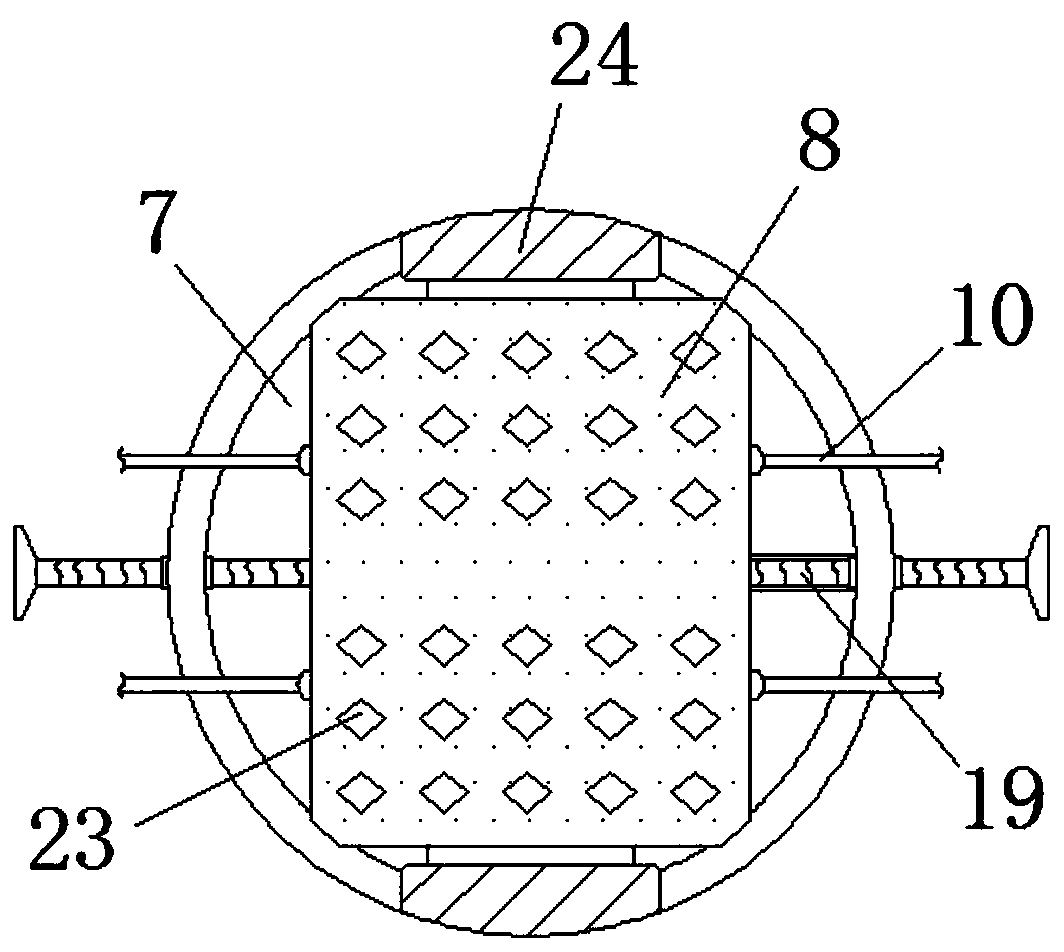

Intelligent waste classifying and recovering equipment

InactiveCN104355017AEfficient sorting and recyclingEasy to useWaste collection and transferRefuse receptaclesHeat sensitiveEngineering

The invention discloses intelligent waste classifying and recovering equipment which mainly comprises a waste type identification module used for identifying the types of wastes thrown by users and the identity information of the users, a waste classifying and throwing unit used for classifying and throwing the wastes by the users, a waste classifying and recovering unit used for classifying and recovering the wastes by waste recovery workers, a human body sensing module used for sensing pedestrians close to the equipment, a voice module used for playing an operation prompt voice and a publicity voice, an IC (integrated card) reading module used for reading user information, and a heat-sensitive printer used for printing the identity information of the users and the type information of the thrown wastes. Due to the adoption of the technical scheme, the equipment has the functions of sensing the pedestrians close to the equipment, making a voice prompt in the whole operation, intelligently identifying the waste types, automatically classifying and recovering the wastes and the like, and is easy and convenient to use and relatively high in waste classifying and recovering efficiency.

Owner:张志勇

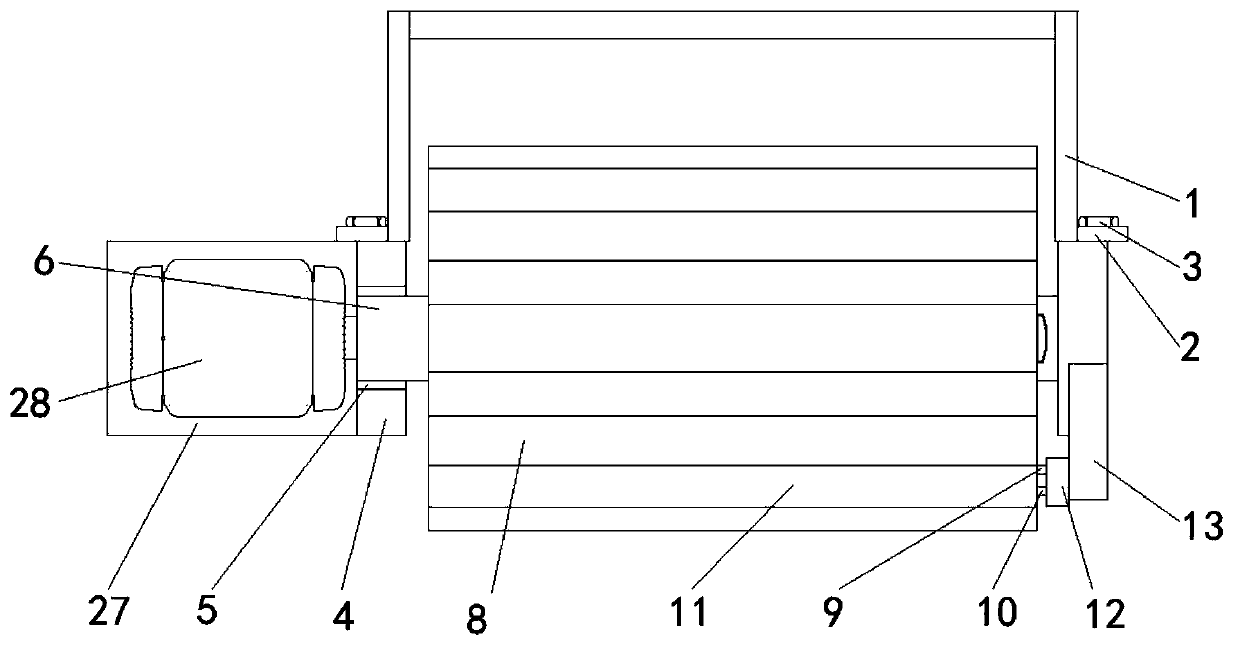

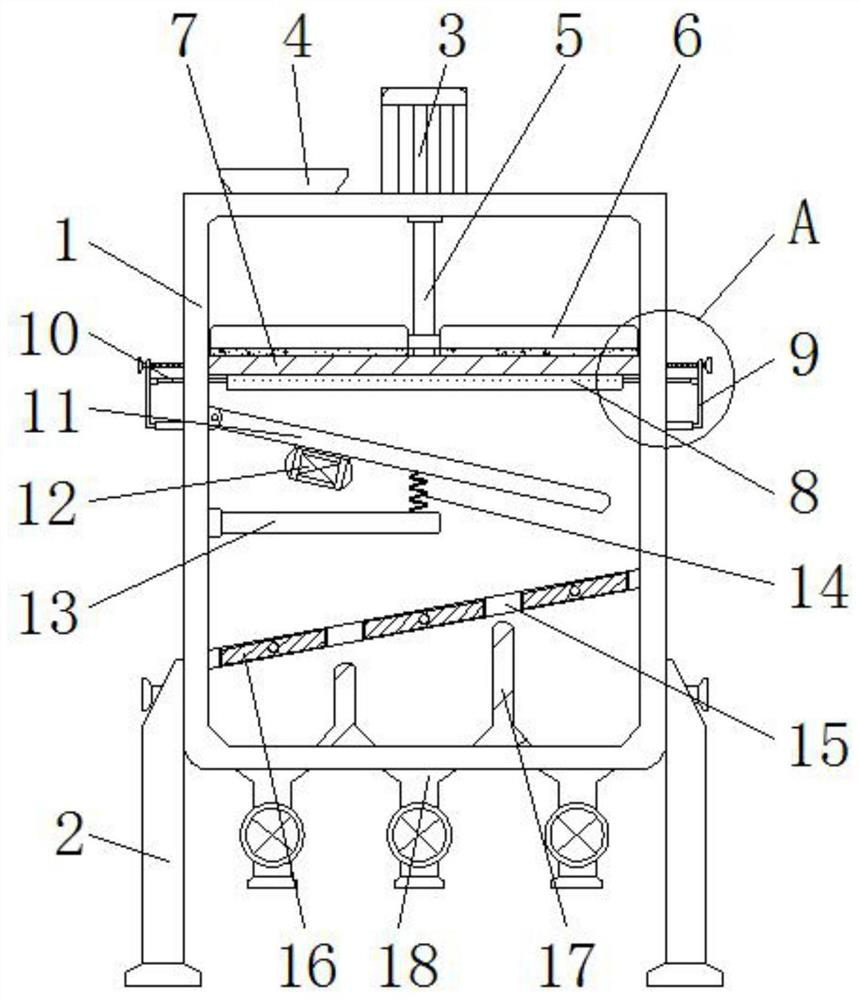

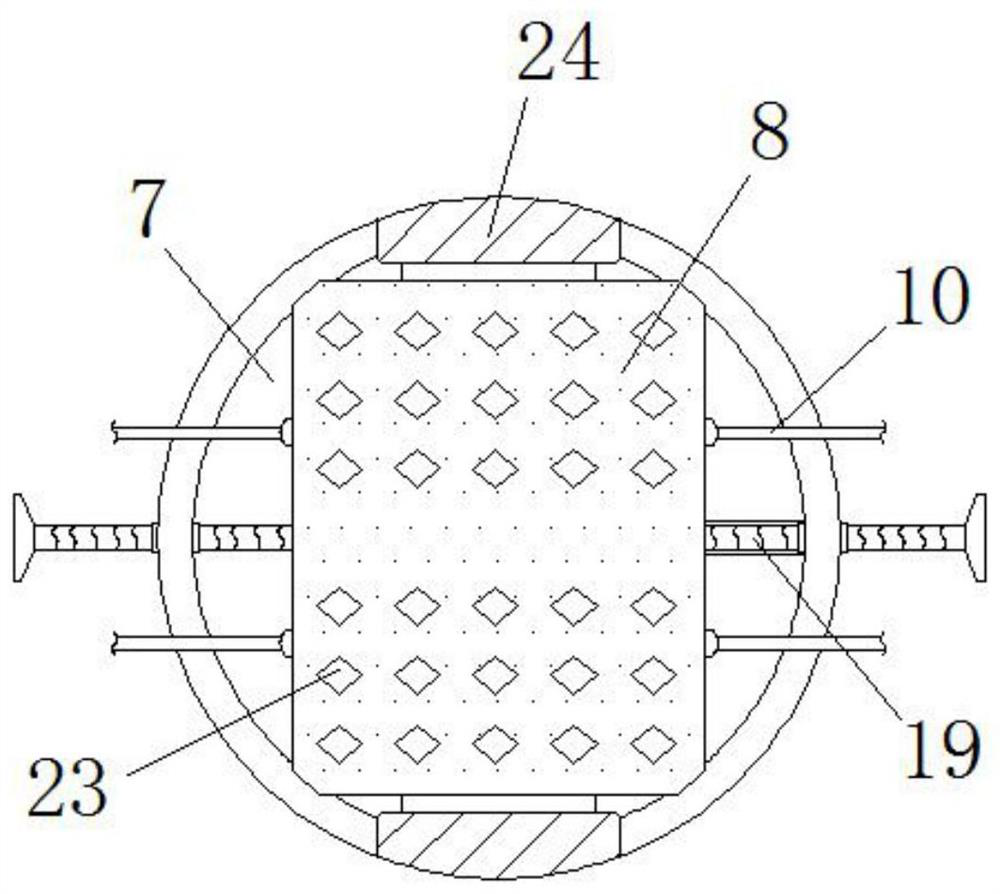

Raw material sieving device with adjustable hole diameters and used for oil processing

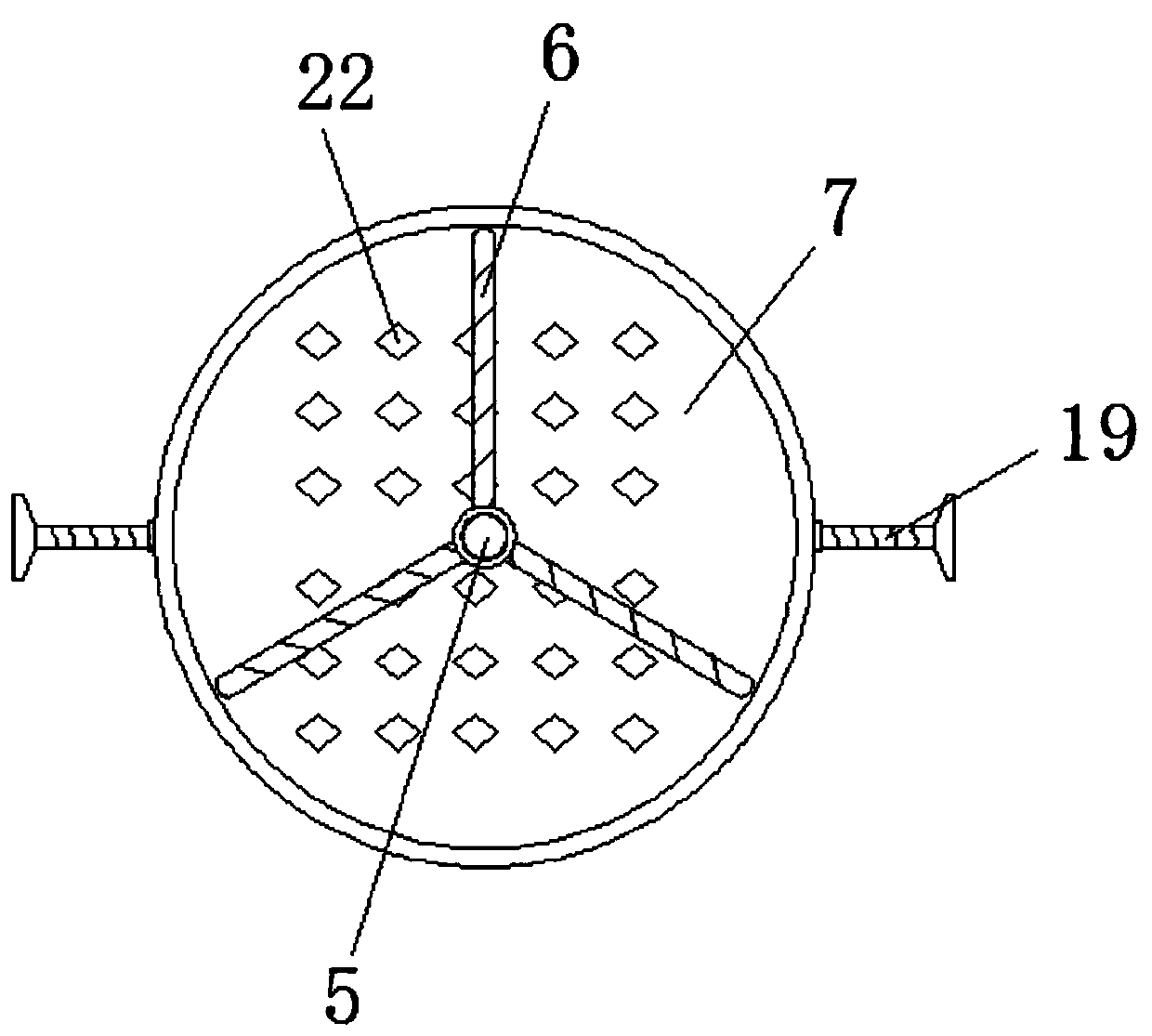

ActiveCN110496769AEasy to adjustEffective sorting and recyclingSievingScreeningOil processingDrive motor

The invention discloses a raw material sieving device with adjustable hole diameters and used for oil processing. The raw material sieving device with the adjustable hole diameters and used for oil processing comprises a sieving box, a drive motor, a vibration motor, a discharge pipeline and a rotary rod, wherein support legs are fixedly installed below the sieving box, and the drive motor is installed above the sieving box; moreover, a charge port is formed above the left side of the sieving box; an output end of the drive motor is connected with a rotary shaft; a thread rod is connected above the sieving box, penetrates through a first sieve plate, and is connected with a movable block; first sieve holes and second sieve holes are formed in the surfaces of the first sieve plate and a second sieve plate separately; and a slide block is arranged on an end part of a discharge plate. The raw material sieving device with the adjustable hole diameters and used for oil processing is capableof facilitating to adjustment for the hole diameters of the sieve holes in the surfaces of the sieve plates, avoiding a blockage phenomenon of the sieve plates during sieving, and effectively recovering oil raw materials with different diameters in a classified manner, and is more convenient to use, and more suitable for being used by people.

Owner:湖南省康多利油脂有限公司

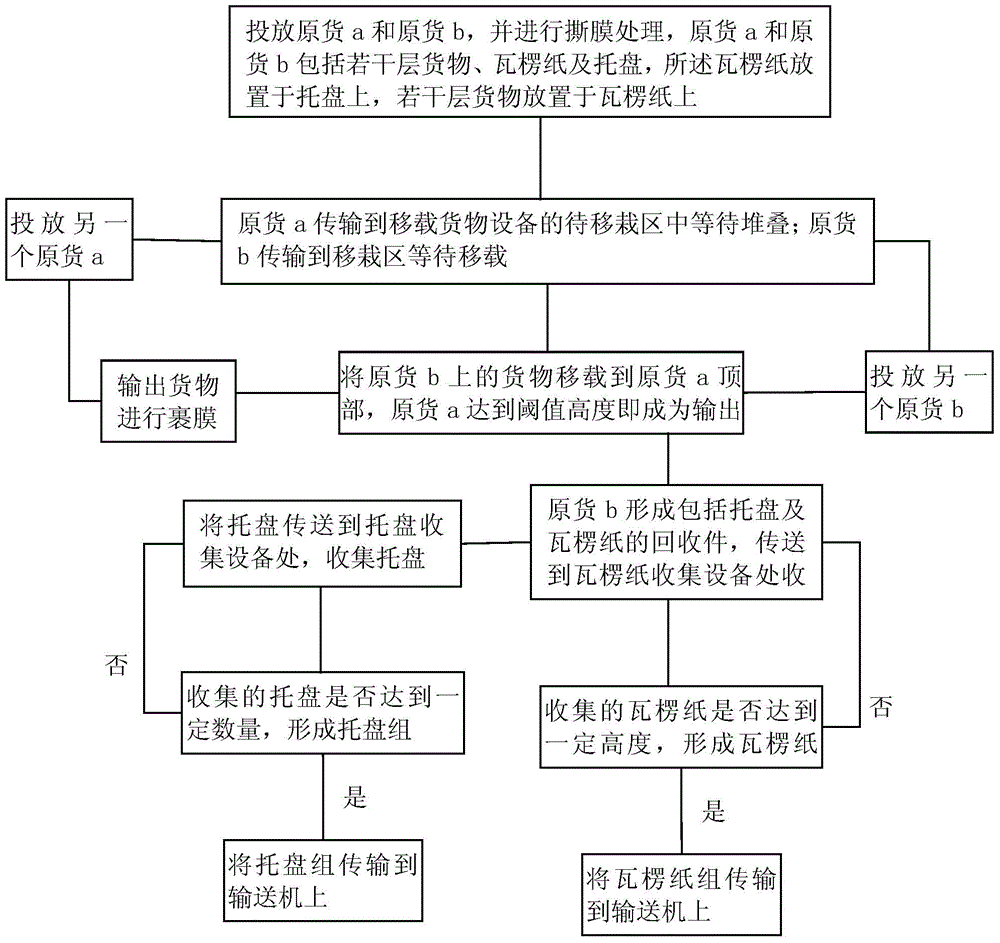

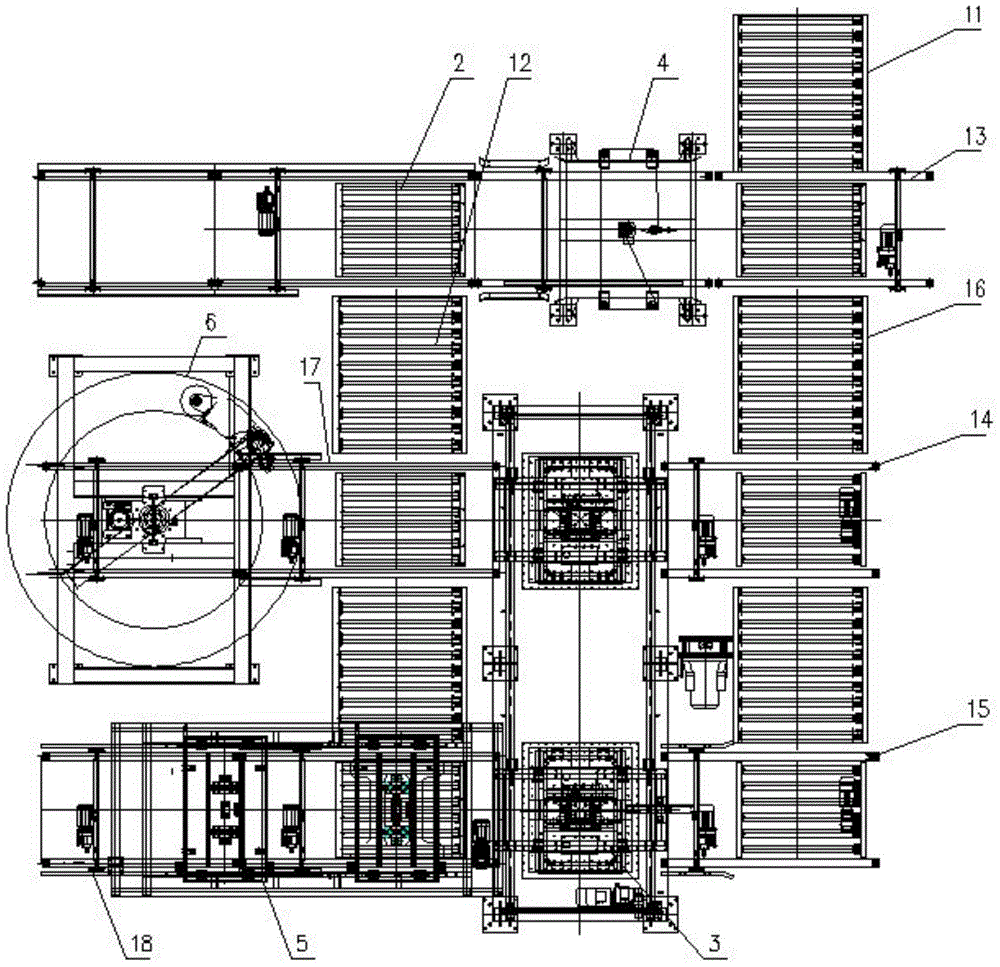

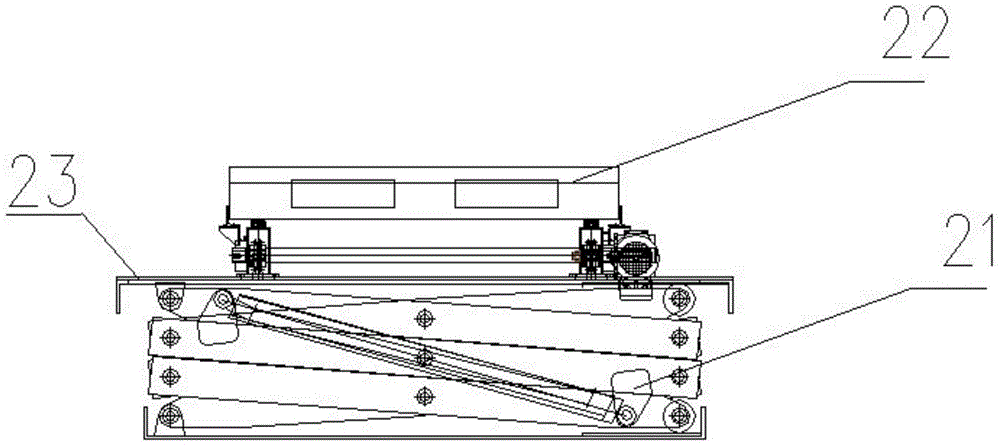

Transferring, shifting and collection method for goods

InactiveCN104609197AEffective sorting and recyclingEffective number of changesStacking articlesDe-stacking articlesLogistics managementCollection methods

Owner:KENMEC MECHA TRONICS (SUZHOU) CO LTD

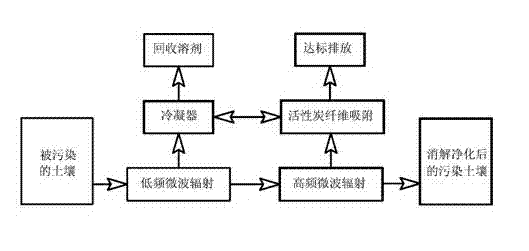

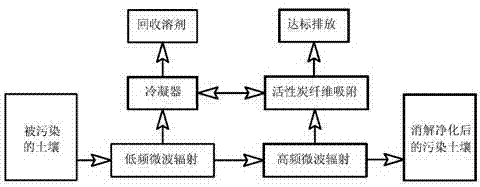

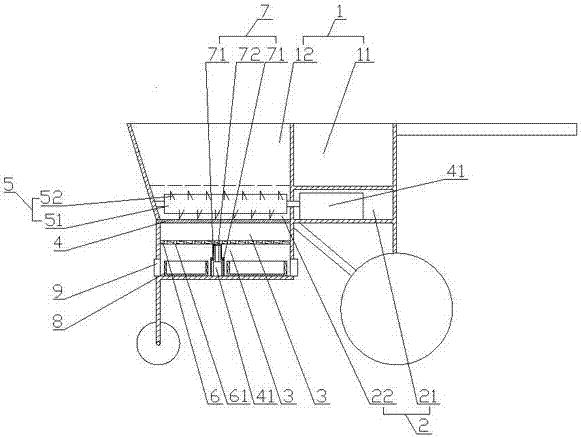

Method for clearing and purifying soil polluted by high polymer organic matters

InactiveCN102389892AAchieve purificationEfficient resource utilizationContaminated soil reclamationResource utilizationPollution soil

A method for clearing and purifying soil polluted by high polymer organic matters solves the technical problem of removing high polymer organic matters in soil. The method comprises the following steps: (1), a partially closed treatment space is formed on the ground; (2), a microwave generator is used for implementing microwave radiation to polluted soil, the high polymer organic matters overflow from soil in a steam form; (3), solvent for the high polymer organic matters overflowed in the steam form is collected and cooled so as to obtain recovered solvent; (4), microwave radiation for enhancing microwave intensity is implemented continuously so as to enable organic pollutants with high melting points to generate gaseous objects and residues, and the generated gaseous objects overflow from the soil; and (5), the gaseous objects are collected, and discharged after activated charcoal adsorption treatment. The invention has the benefits as follows: thorough and harmless treatment is performed, effective resource utilization is achieved, the process is simple, the operation is convenient and simple, and the period is short.

Owner:深圳市兖能环保科技有限公司

Garbage classification, recovery and treatment device

PendingCN107161575AEasy to collectEasy to take outRefuse receptaclesGrain treatmentsElectric machineryProcess engineering

The invention discloses a garbage classification, recovery and treatment device which comprises a cart body. The cart body is sequentially divided into a material inlet cavity, a processing cavity and a collecting cavity from top to bottom; the material inlet cavity is divided into a recovery cavity part and a kitchen garbage cavity part; the processing cavity is divided into a motor placement cavity part and a crushing tool placement cavity part in the horizontal direction; the kitchen garbage cavity part communicates with the crushing tool placement cavity part; the crushing tool placement cavity part communicates with the collecting cavity; a movable baffle is arranged between the crushing tool placement cavity part and the collecting cavity in an inserting mode; a motor is arranged in the motor placement cavity part; a crushing tool is arranged in the crushing tool placement cavity part; the motor drives the crushing tool; a squeezing plate is horizontally arranged in the collecting cavity; and a push rod motor driving the squeezing plate to move upward is arranged on the bottom face inside the collecting cavity. The garbage classification, recovery and treatment device has the beneficial effects that garbage can be effectively classified and recycled, and especially domestic garbage in a kitchen is processed, so that the capacity of the garbage loading quantity of the device is improved.

Owner:SICHUAN HEDING ENVIRONMENTAL PROTECTION ENG

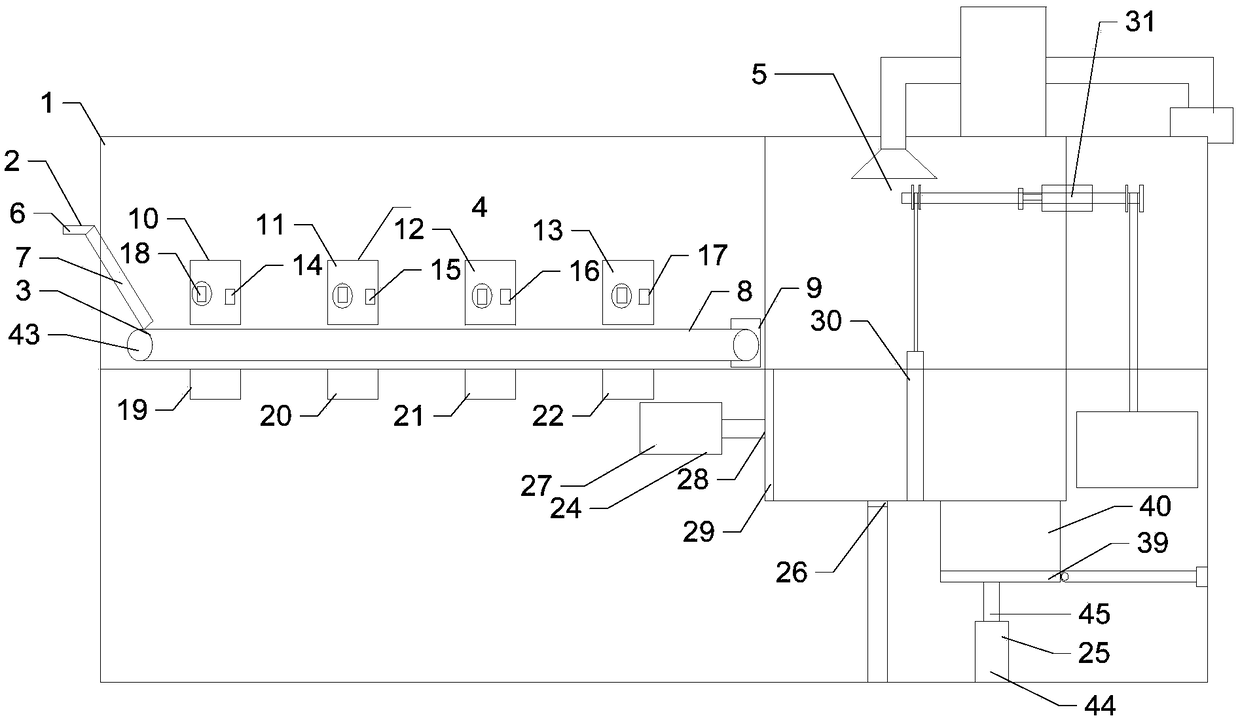

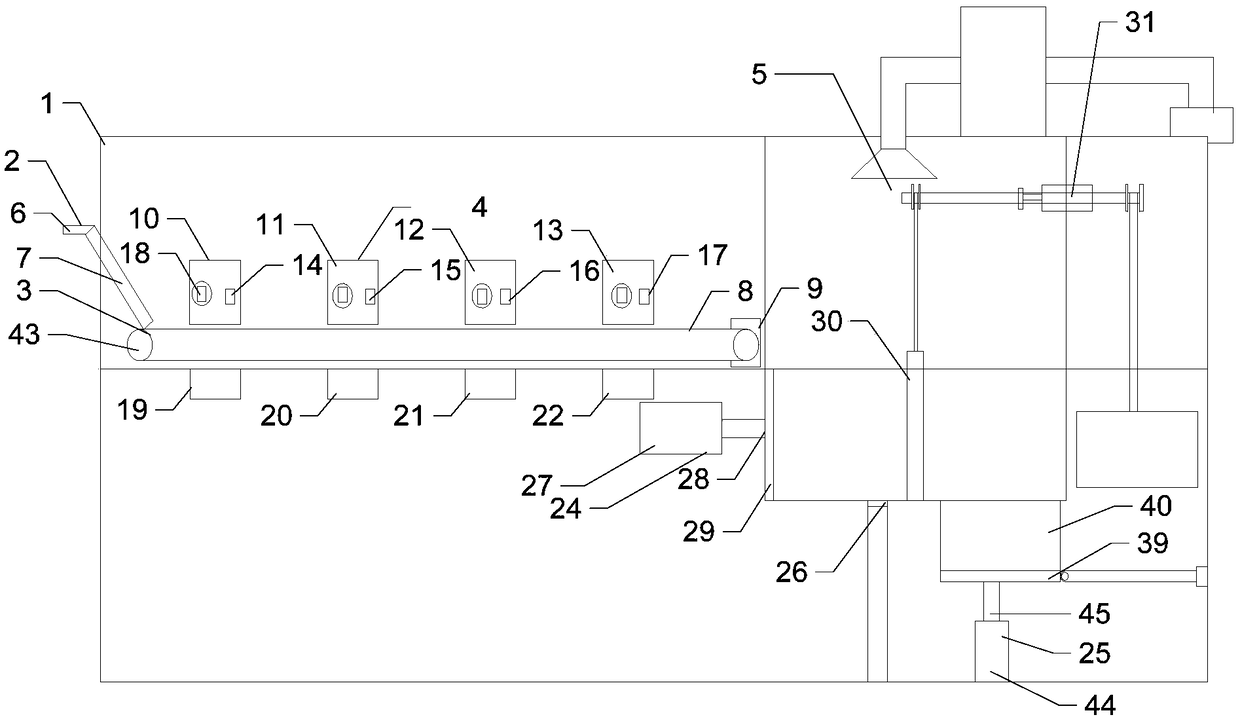

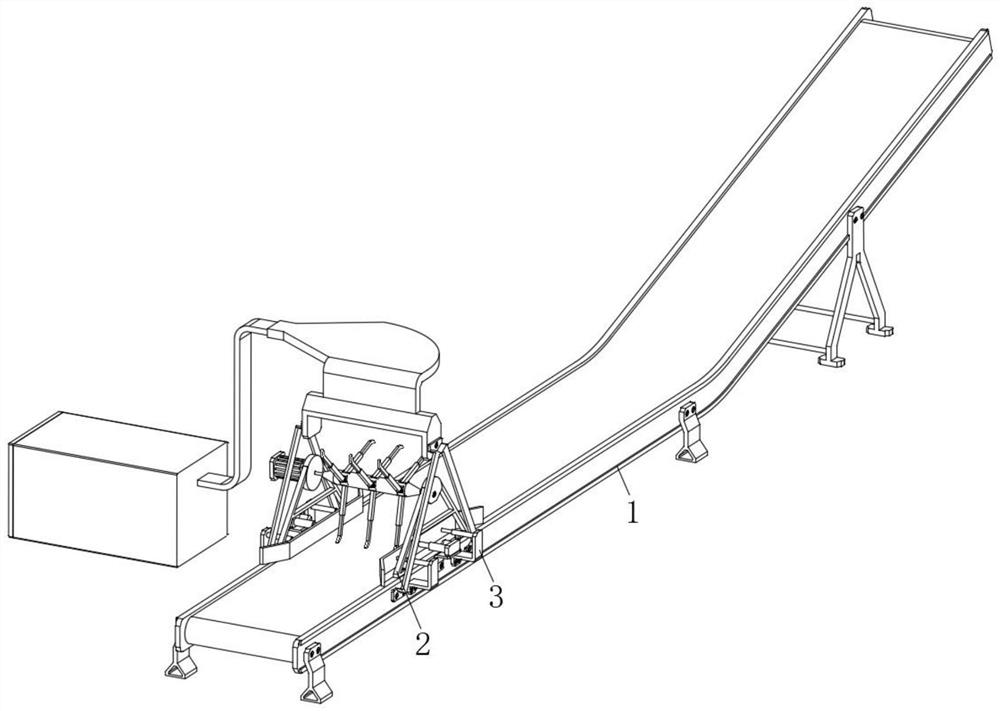

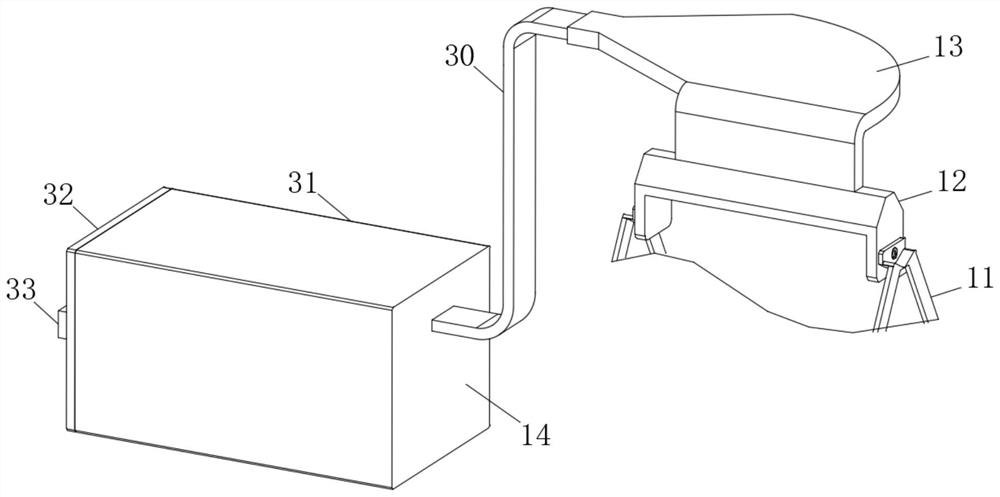

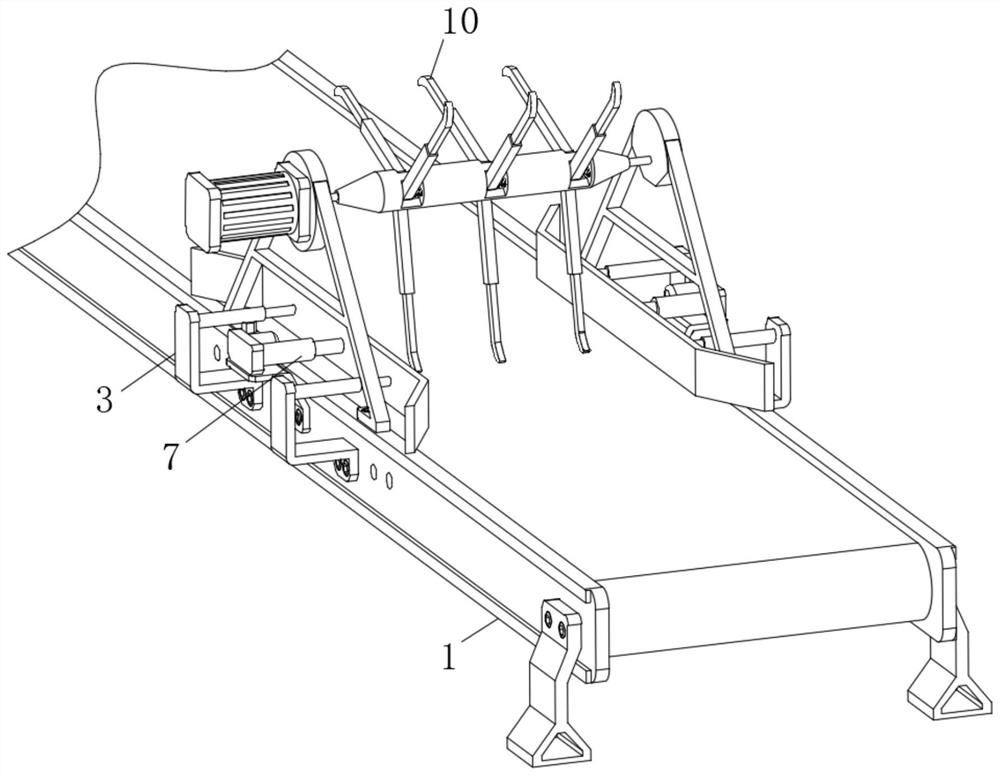

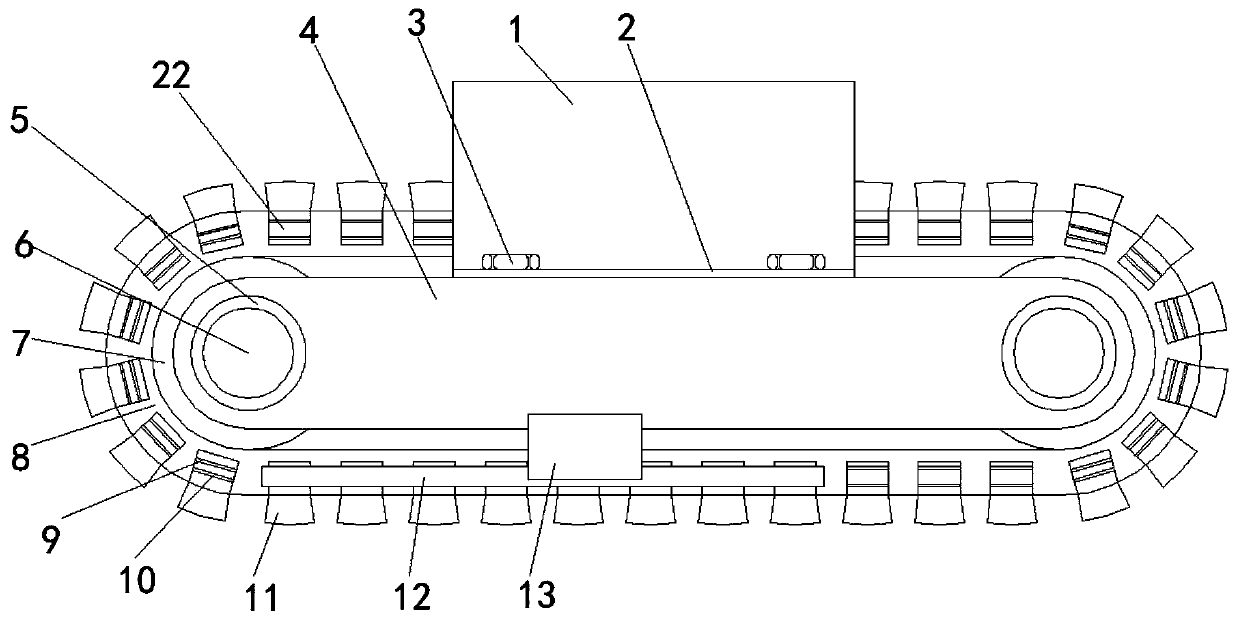

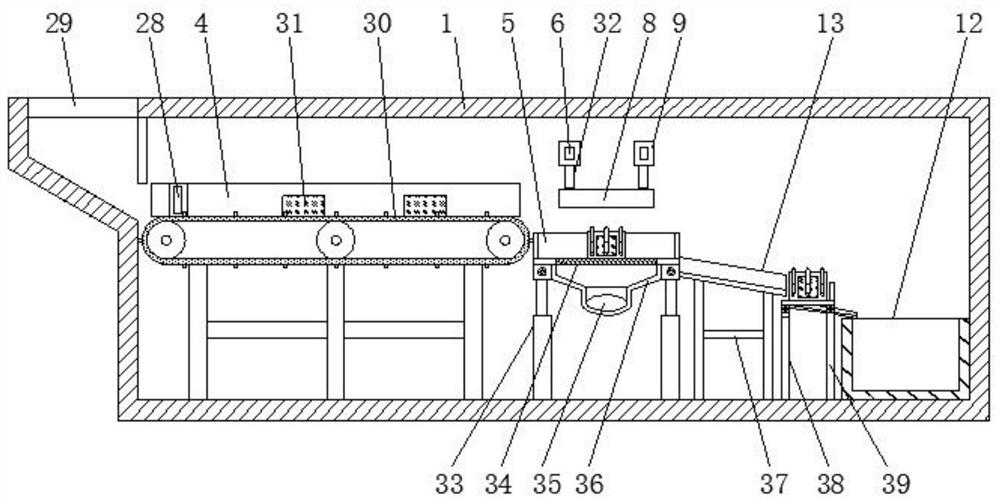

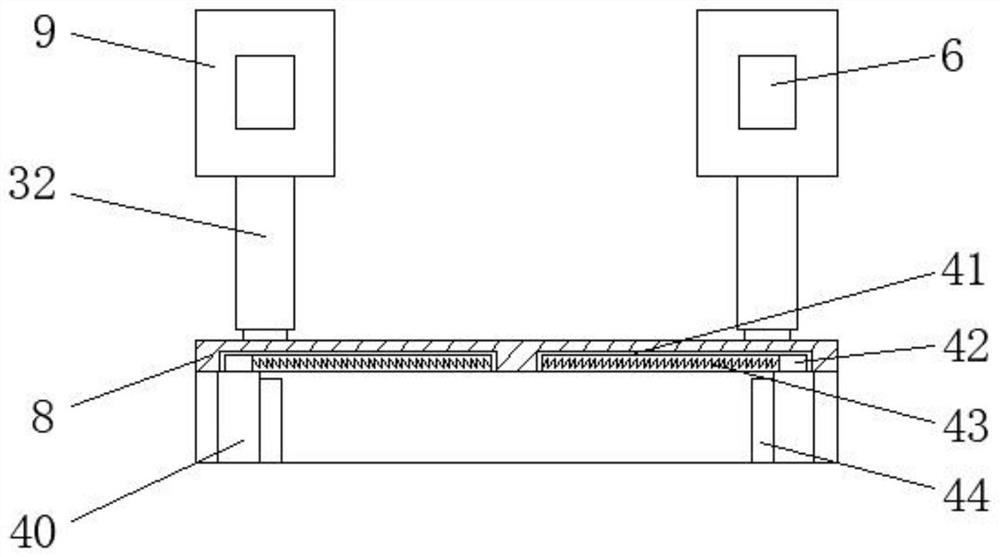

Classification system of garbage transfer station

InactiveCN109051474AAvoid dischargeClassification is highly targetedGlass recyclingPaper recyclingCardboardDrive motor

The invention discloses a classification system of a garbage transfer station. The classification system comprises a transfer station, wherein the transfer station comprises a garbage feeding device,a garbage conveying device arranged at the tail end of the garbage feeding device, a garbage classifying device arranged on the garbage conveying device, and a garbage disposing device arranged belowthe tail end of the garbage classifying device; the garbage conveying device comprises a belt arranged in the transfer station, transmission rollers arranged at the two ends of the belt in transmission connection, and a driving motor used for driving the transmission rollers; the garbage classifying device comprises a metal collecting assembly arranged on one side of the garbage conveying device,a plastic collecting assembly arranged on one side of the metal collecting assembly, a glass collecting assembly arranged on one side of the plastic collecting assembly, and a cardboard collecting assembly arranged on one side of the glass collecting assembly. According to the classification system, garbage can be effectively classified and recycled, meanwhile, and meanwhile, the non-recyclable garbage can be disposed, so that the classification system is convenient to popularize.

Owner:SHENZHEN FENGJUN INFORMATION TECH CO LTD

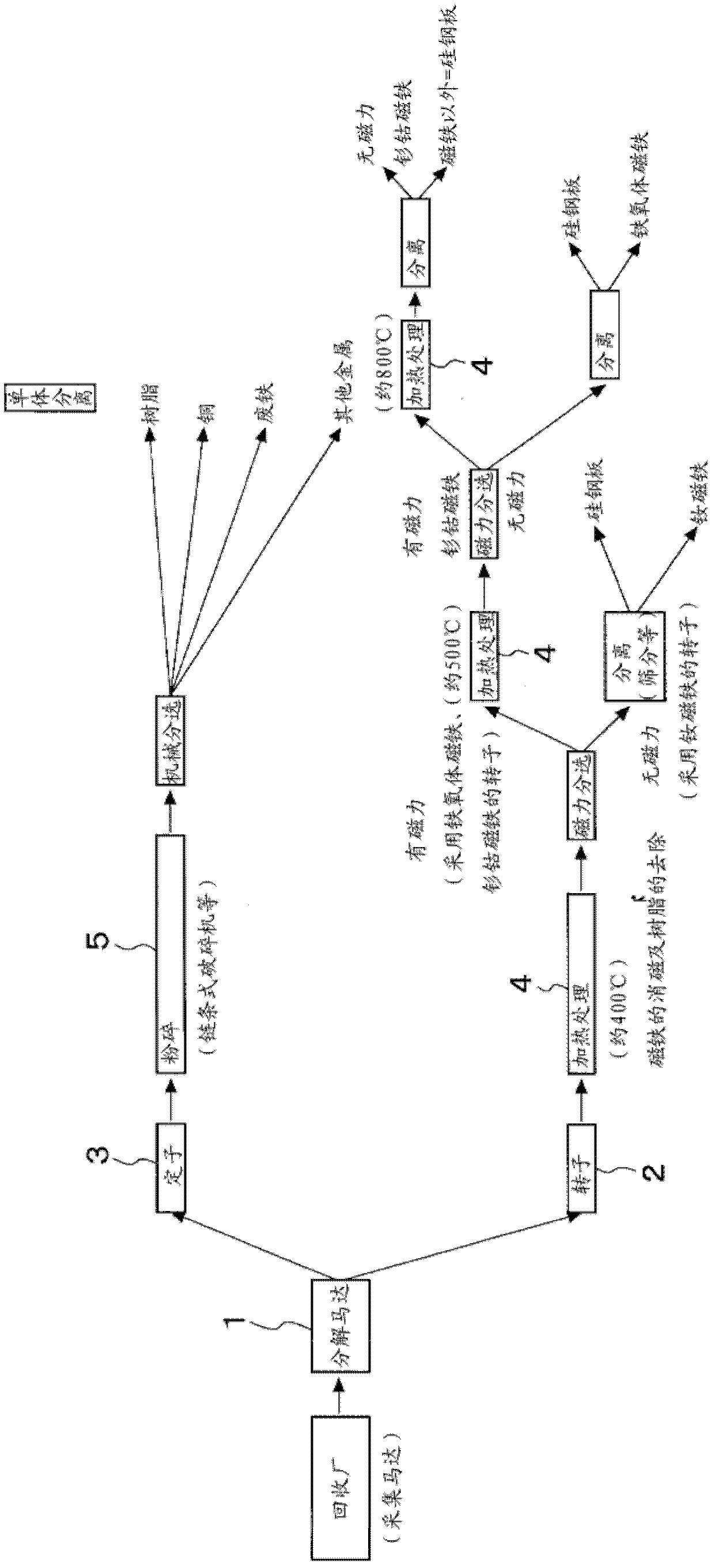

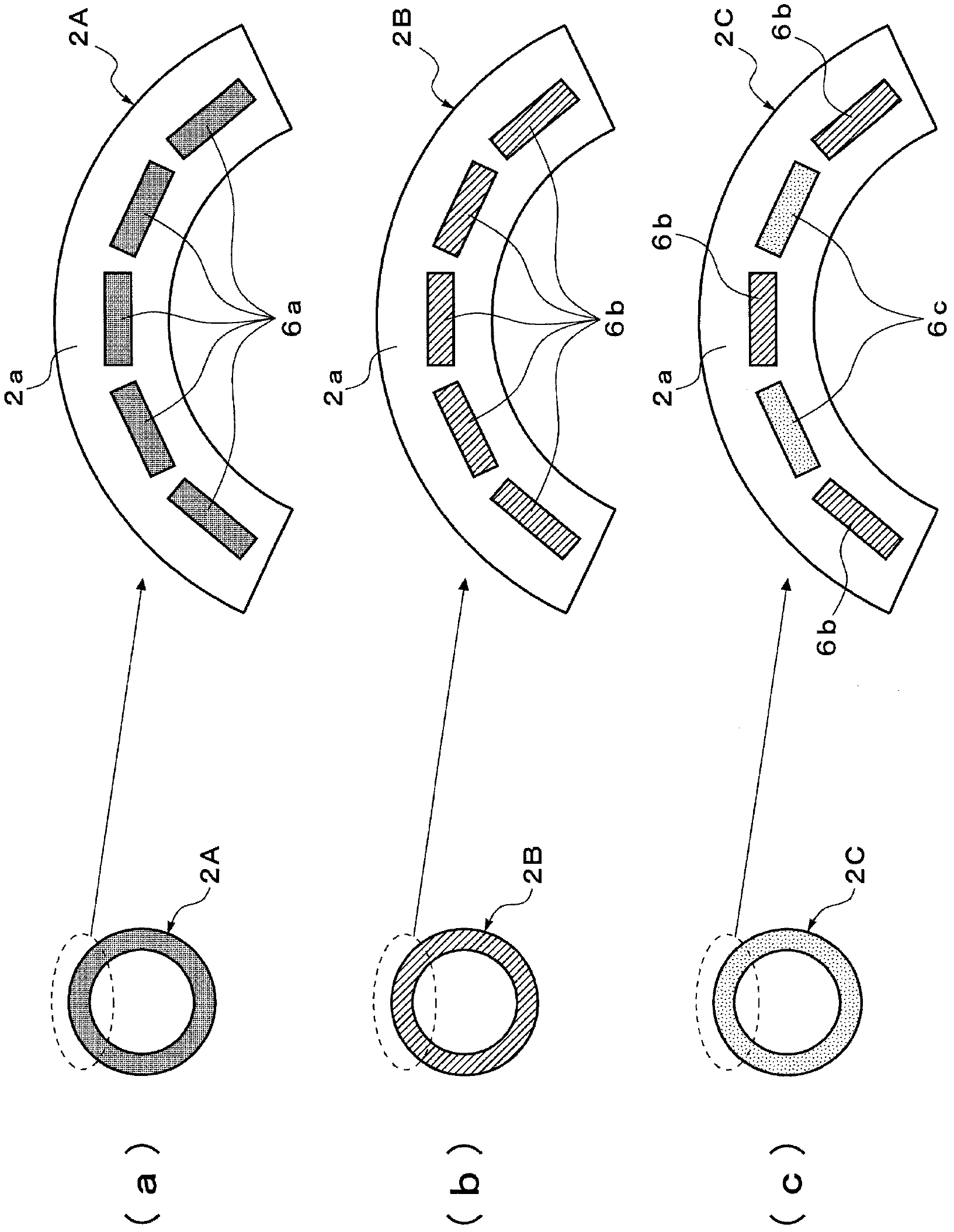

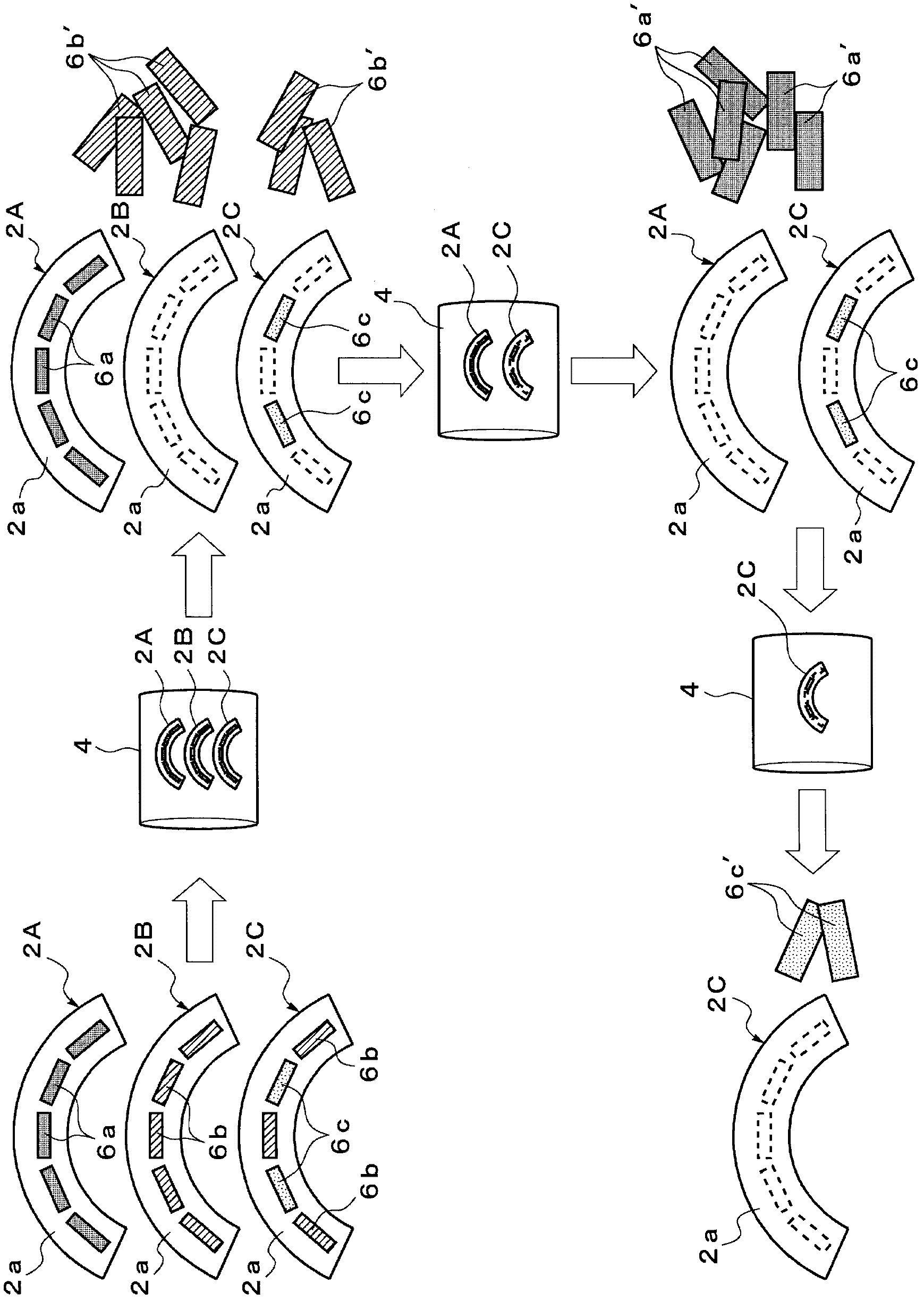

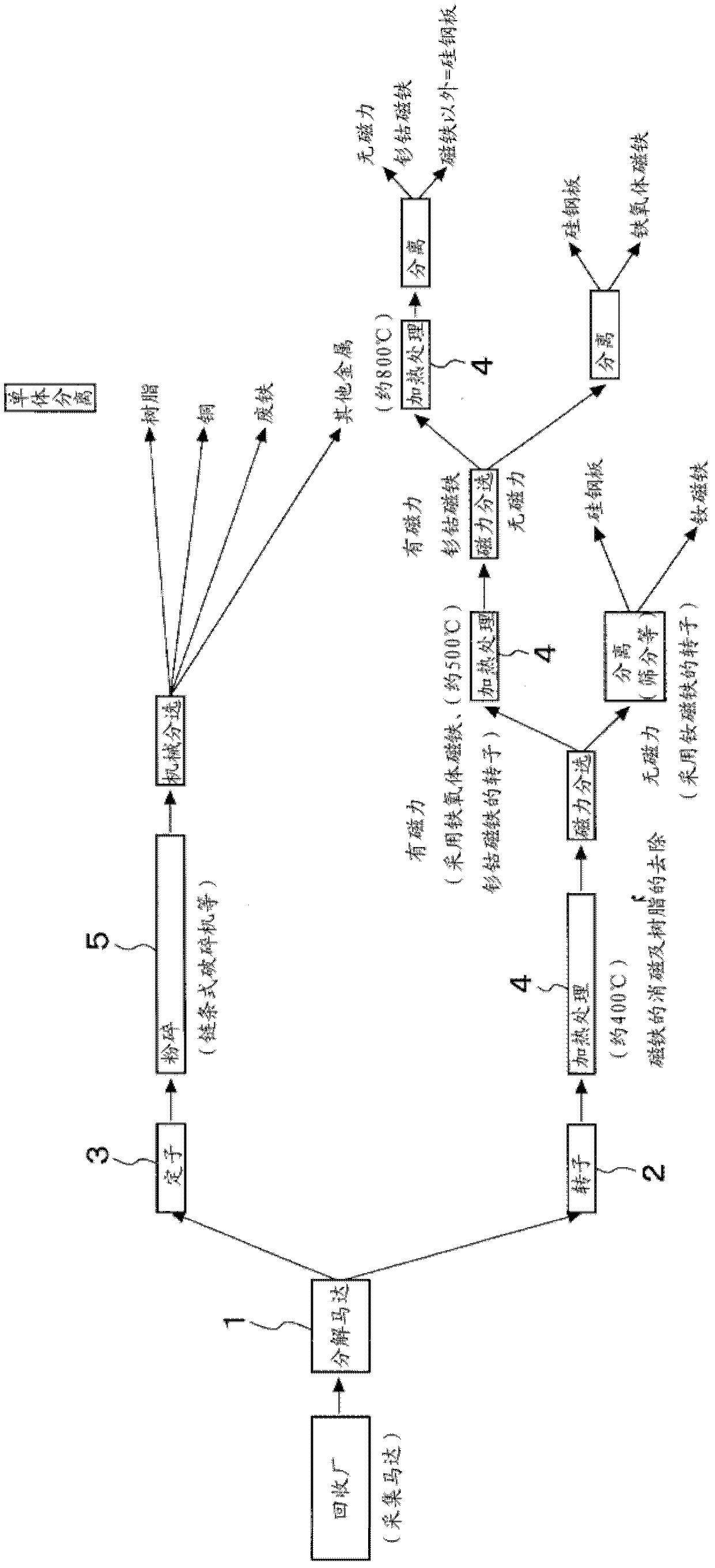

Method for recycling motor

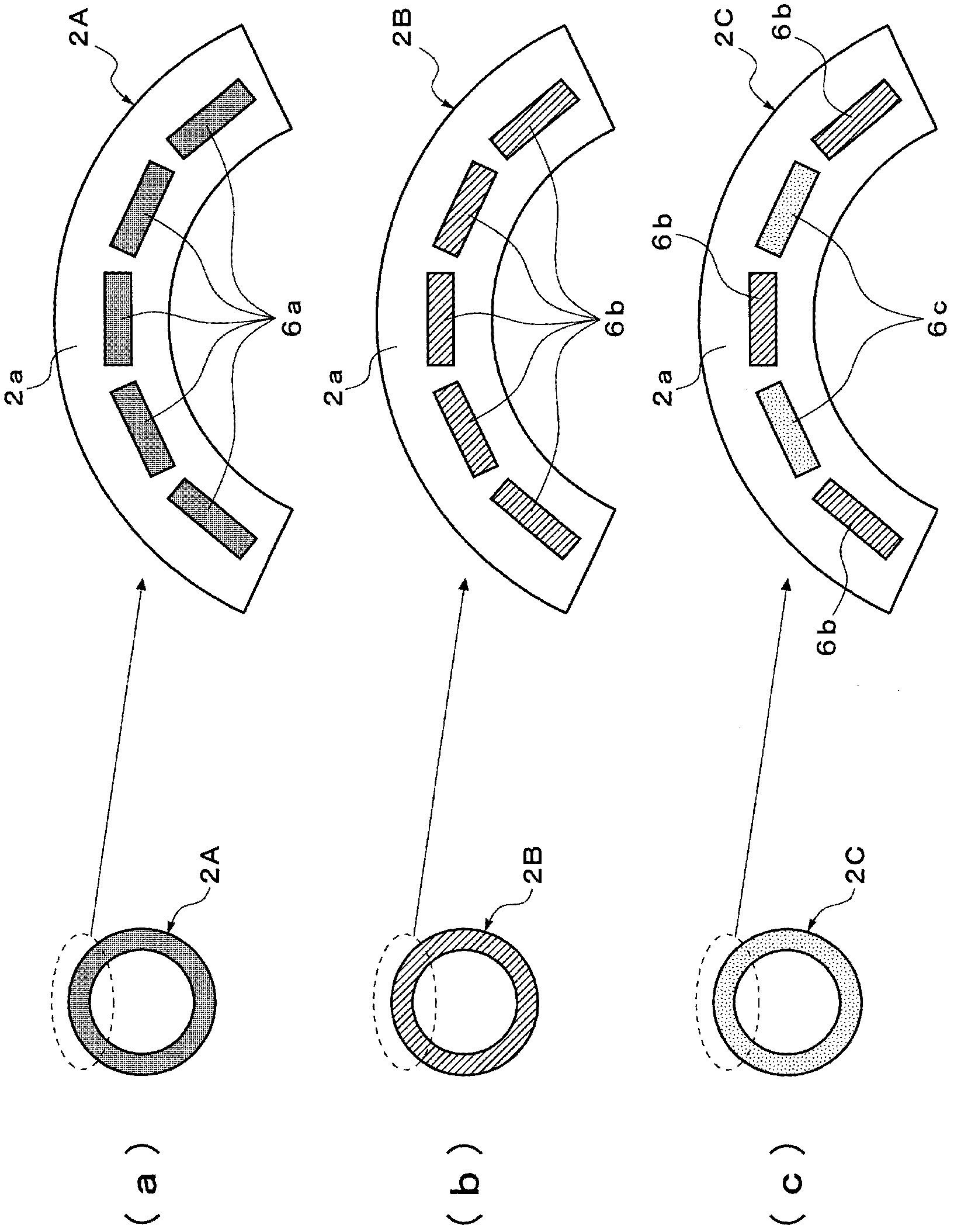

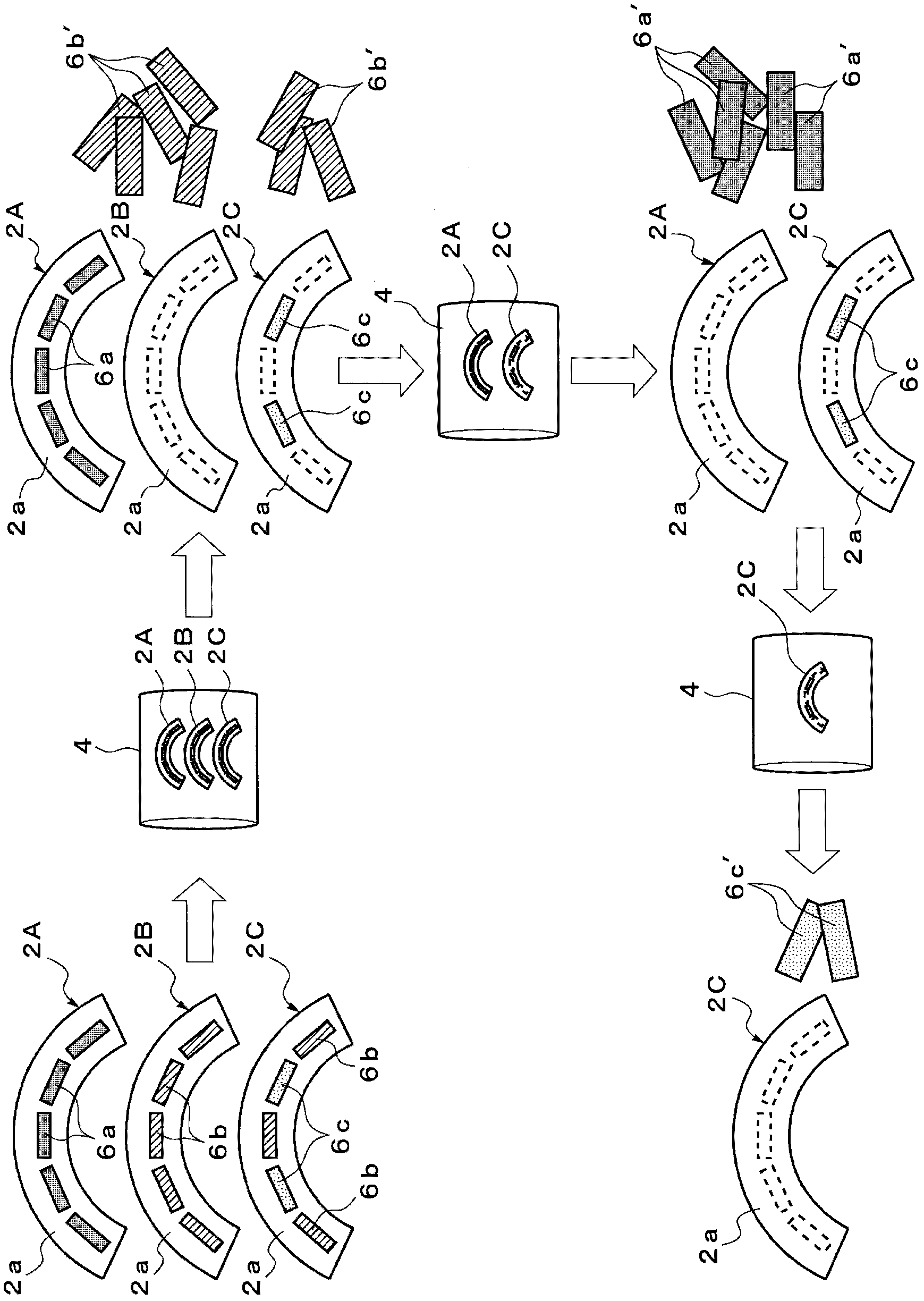

ActiveCN102594037ADegaussing easilyEffective sorting and recyclingElectric machinesManufacturing stator/rotor bodiesCurie temperatureEngineering

The invention proposes a method for reusing a motor, wherein after the recovered single kind or plural kinds of motors are separated into rotors and stators, magnets used in the rotors are recovered according to each kind of separated raw materials and the kinds of recycling. The method for reusing a motor comprises periodically heating the rotor cores (2a) of a plurality of motors (1) of different types of magnets (6) composed of a single kind of magnet raw materials (6 ') to a curie temperature corresponding to the type of the magnets (6); and in each stage, maintaining the predetermined time in accordance with the curie temperature corresponding to the magnets (6); and sequentially recycling magnet raw materials (6 ').

Owner:MITSUBISHI MATERIALS CORP

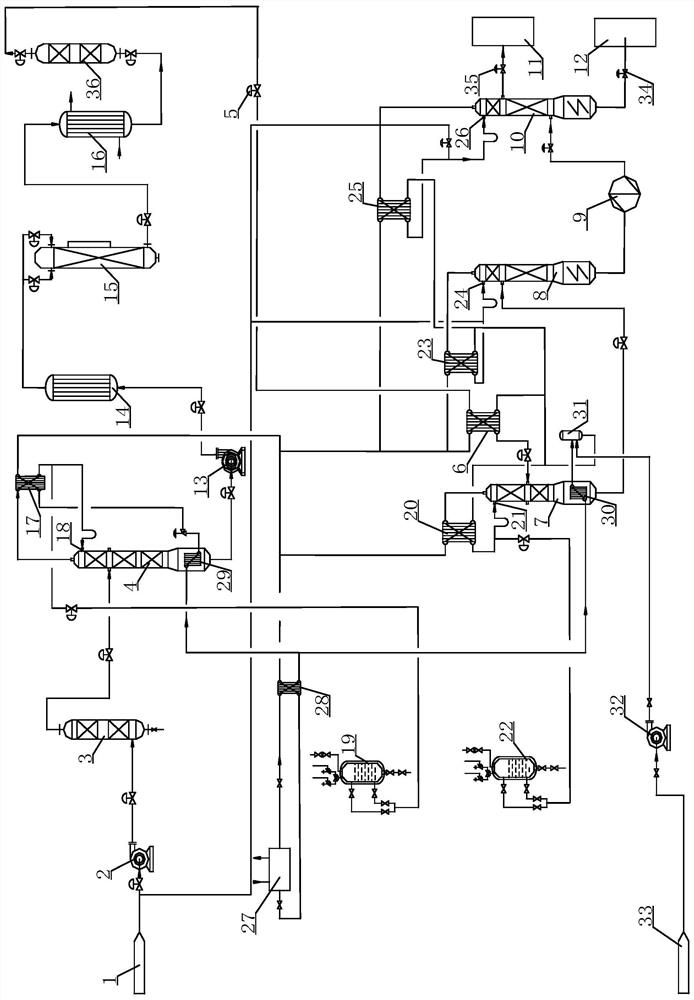

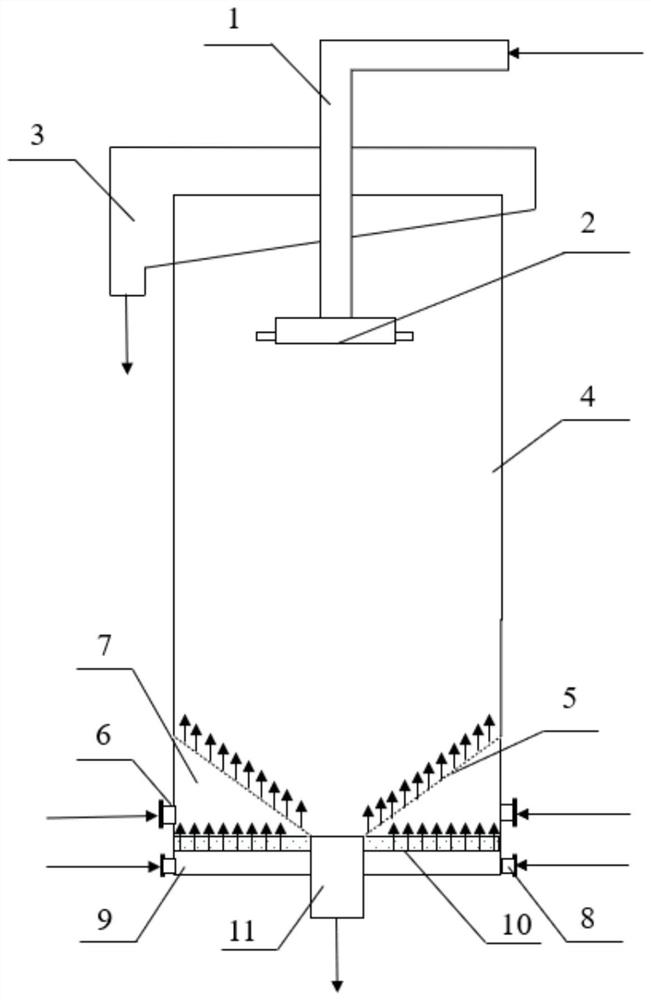

Device and process for refining rare gases of krypton and xenon and producing ultrapure oxygen

PendingCN111692838AReduce usageLower acquisition costsSolidificationLiquefactionKryptonCatalytic oxidation

The invention belongs to a device and a process for refining rare gases of krypton and xenon and producing ultrapure oxygen. The device comprises a liquid oxygen storage tank; the liquid oxygen storage tank is connected with a primary concentration tower through a liquid oxygen pump and a low-temperature adsorption tower; a tower bottom liquid phase outlet of the primary concentration tower is connected with a catalytic oxidation system with a high pressure throttle valve at the tail end; the high pressure throttle valve is connected to a krypton-xenon separation tower used for storing and separating krypton from xenon through a pipe side of a return cooler, a secondary concentration tower, a krypton-xenon deoxygenation tower, and a gas heating device in sequence; the bottom of the krypton-xenon separation tower is connected to an xenon charging system through a first valve; and the middle-upper part of the krypton-xenon separation tower is connected to a krypton charging system through a second valve. The device and the process for refining the rare gases of the krypton and the xenon and producing the ultrapure oxygen has the advantages of simple structure, reasonable flow design,relatively low cost, safe operation, high yield, high purity of the rare gases, economical efficiency, wide application range, and capacity of effectively classifying and recycling oxygen on the premise of preparing the krypton and the xenon.

Owner:HENAN XINLIANXIN SHENLENG ENERGY

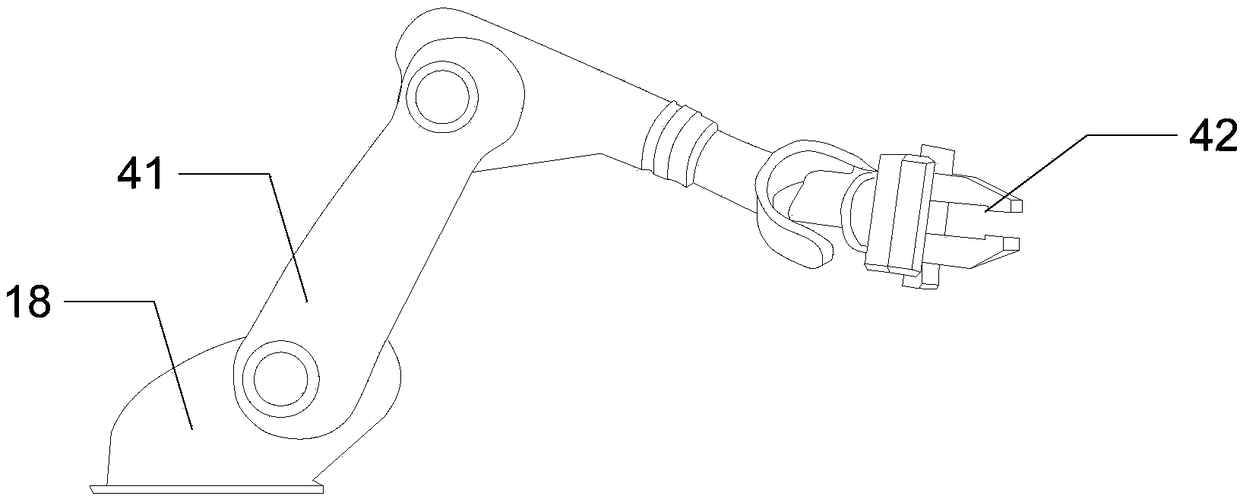

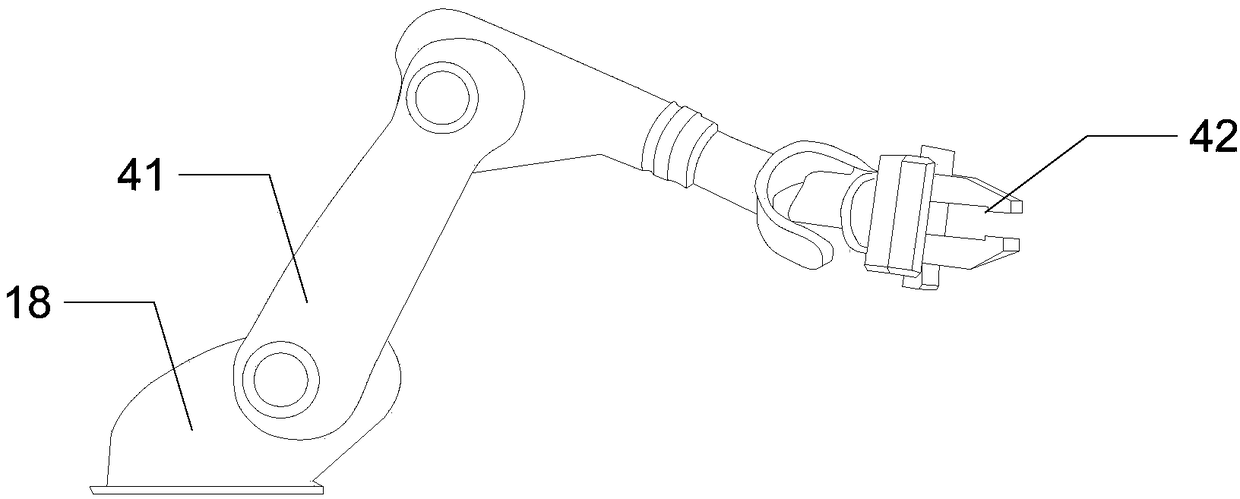

Intelligent garbage classification method

InactiveCN109230108AAvoid dischargeClassification is highly targetedGlass recyclingRefuse receptaclesClassification methodsEngineering

The invention discloses an intelligent garbage classification method. The method is applied to a garbage transfer station classification system. The method comprises the steps that garbage is poured in from a garbage feeding inlet, and garbage is conveyed to one end of a belt through a feeding groove; garbage is conveyed by the belt from one end to a garbage treatment device at the other end; in the belt conveying process of the garbage, metal sensed by a metal sensing module is grabbed and collected through multiple mechanical hands; under sensing of a plastic sensing module, plastic is grabbed and collected through a plurality of mechanical hands; glass is grabbed and collected through a plurality of mechanical hands under sensing of a glass sensing module; paper is grabbed and collectedthrough a plurality of mechanical hands under sensing of a paper sensing module; other garbage is conveyed to the garbage treatment device through the belt to be treated. Garbage can be effectively classified and recycled, meanwhile, unrecoverable garbage can be treated, and popularization is facilitated.

Owner:SHENZHEN FENGJUN INFORMATION TECH CO LTD

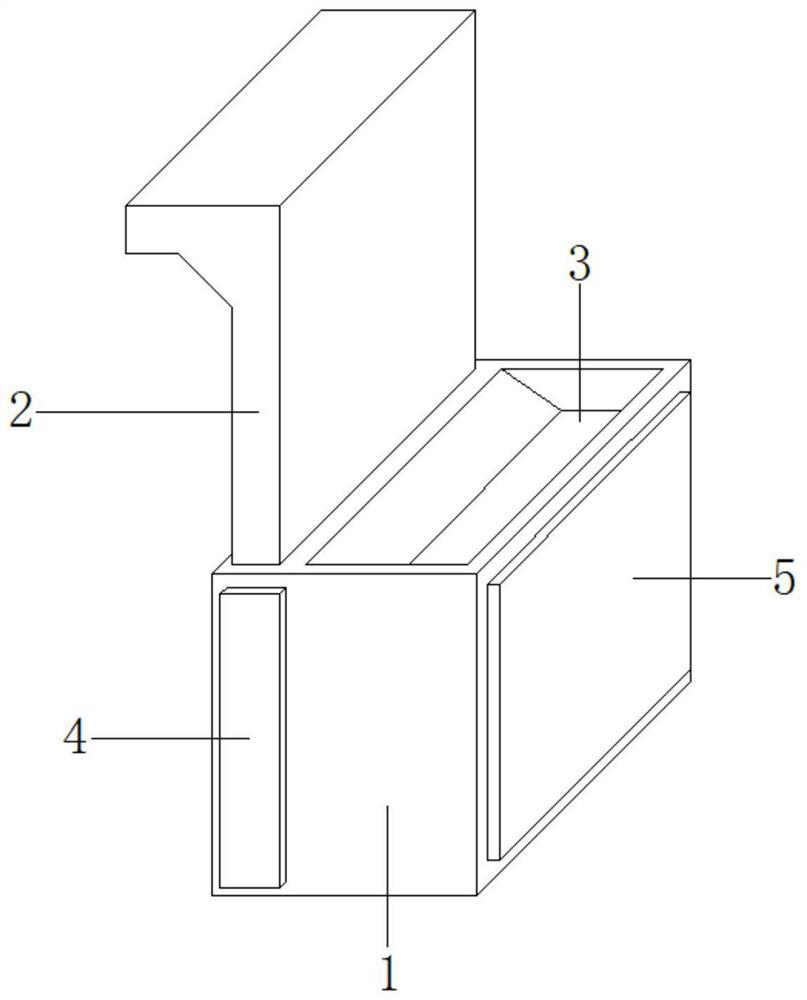

Civil engineering field waste classifying and recycling device based on environmental protection

The invention discloses a civil engineering field waste classifying and recycling device based on environmental protection. The civil engineering field waste classifying and recycling device comprisesa conveying belt used for real-time moving and conveying of building waste, wherein a sorting mechanism used for classifying and sorting of bricks, stone, light thin films and packaging bags is installed on the conveying belt, and a shaking mechanism for shaking displacement and stable classifying and sorting of building waste is fixed at the position, below the sorting mechanism, of the conveying belt. The civil engineering field waste classifying and recycling device based on environmental protection is different from the prior art, and therefore in the real-time moving and stacking processof building waste, packaging bags and light thin films mixed in the building brick and stone waste can be effectively and automatically classified and sorted synchronously, it is guaranteed that thepackaging bags and the light thin films in the building waste are effectively classified and recycled, and therefore environmental pollution caused by the building waste on a civil engineering site iseffectively avoided, and engineering project construction is idealized.

Owner:郭秋生

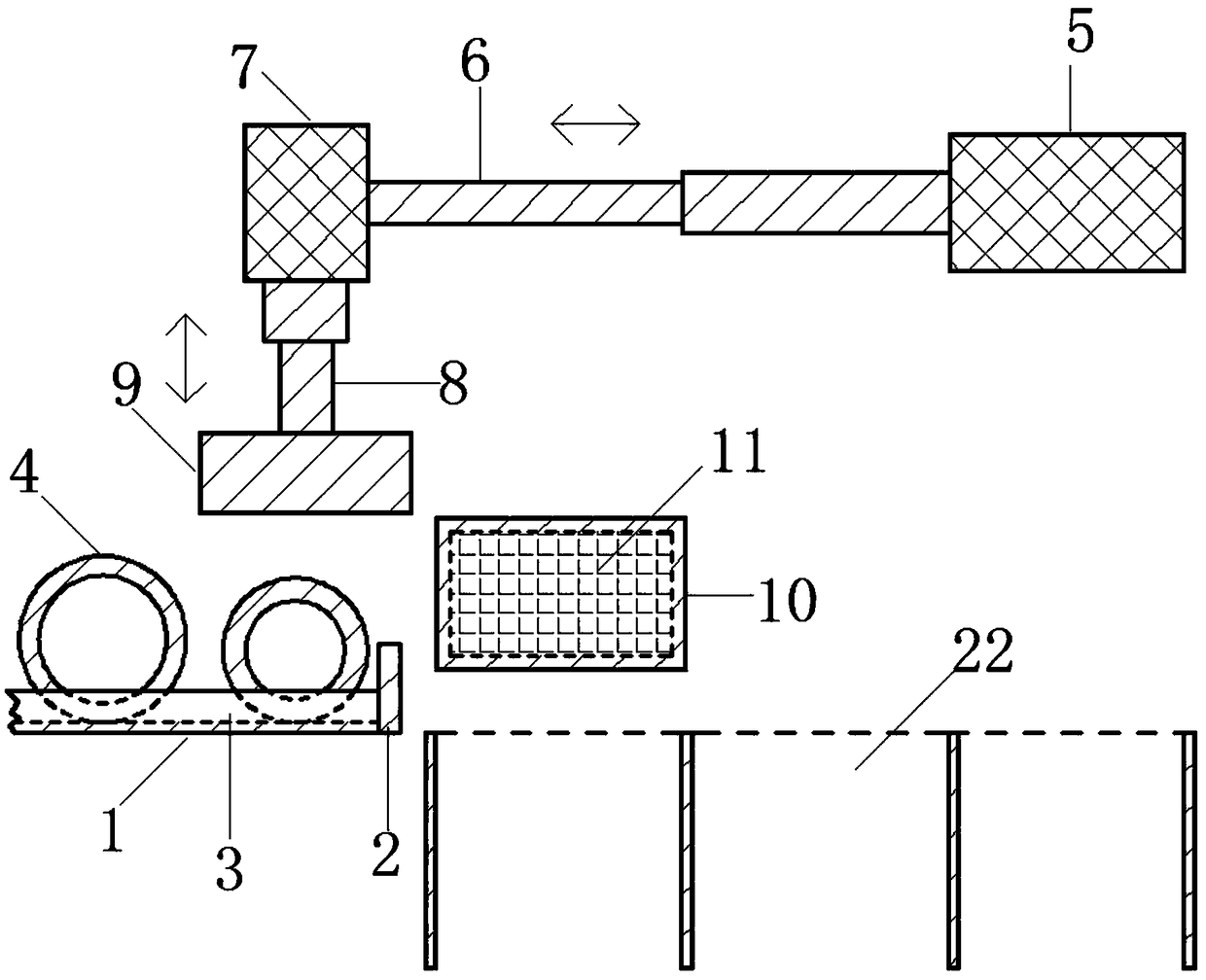

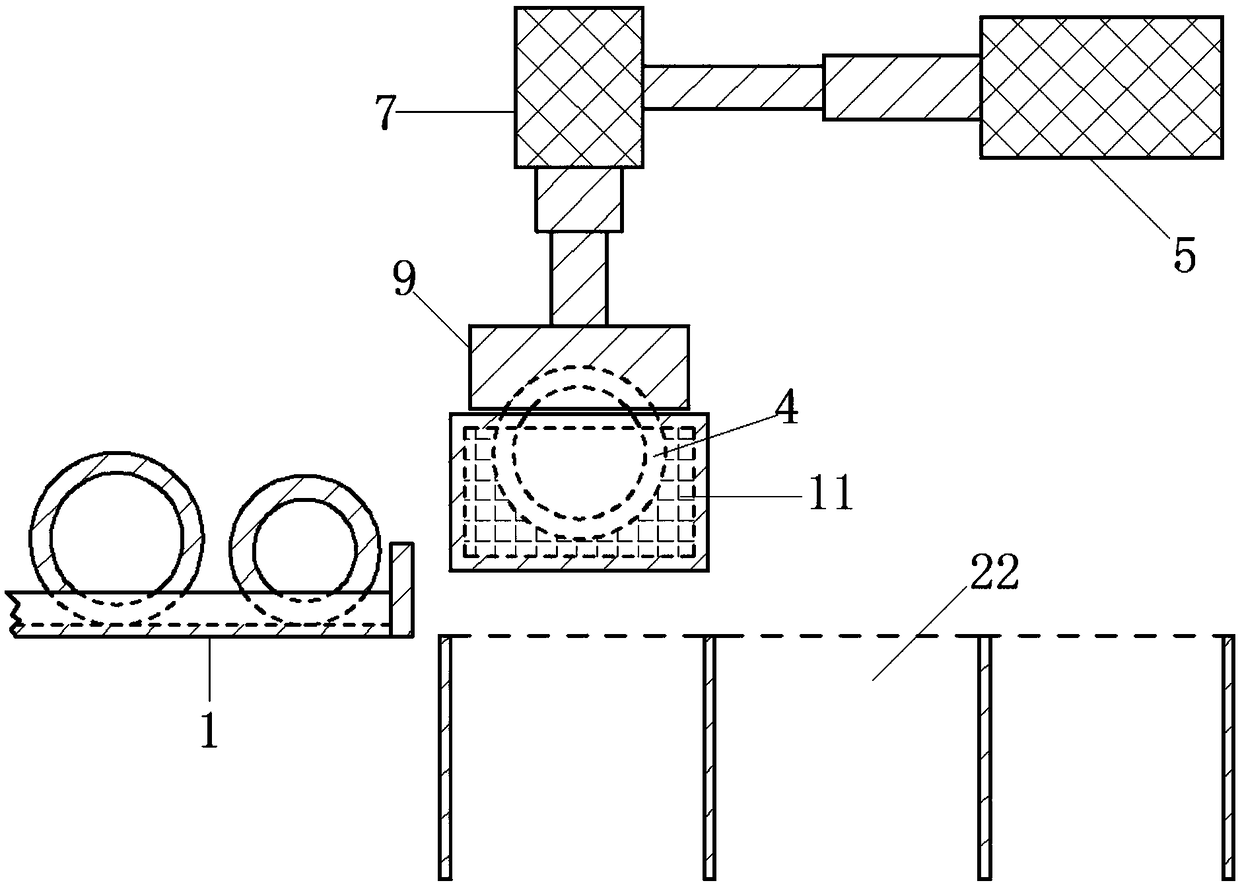

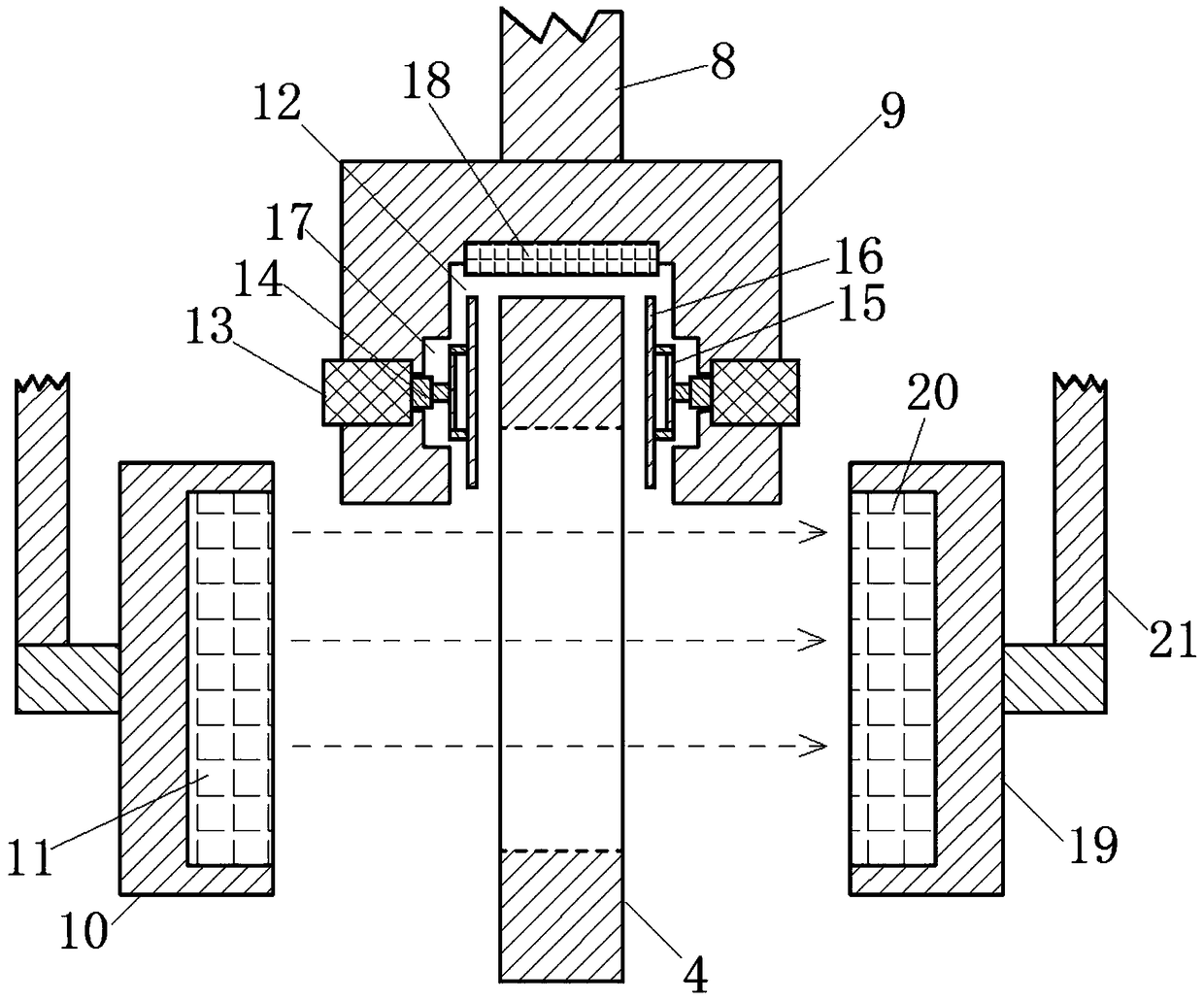

Photoelectric nut washer screening mechanism device

The invention discloses a photoelectric nut washer screening mechanism device, and relates to the field of photo-mechanical-electric application devices. In the photoelectric nut washer screening mechanism device, at least one pair of clamping power devices used for clamping nut washers is arranged on a washer clamping mechanism; a pressure sensing plate used for sensing that the positions of thenut washers are in place is arranged in the washer clamping mechanism; a photosignal transmitting mechanism is fixedly arranged on a first mounting panel; and a photosignal receiving mechanism is fixedly arranged on a second mounting panel. According to the photoelectric nut washer screening mechanism device, the position of the washer clamping mechanism is adjusted through a first transverse drive power device and a second longitudinal drive power device in a drive manner, the pressure sensing plate in the washer clamping mechanism is used for sensing the arriving positions of the nut washers, the clamping power devices are used for clamping the current nut washers in a drive manner, the photosignal transmitting mechanism and the photosignal receiving mechanism are used for detecting thesizes of annular gaps of the nut washers, and therefore the nut washers of different specifications are effectively classified and recycled, and the efficiency of subsequent nut fixing operation is improved.

Owner:日照三兴食品集团股份有限公司

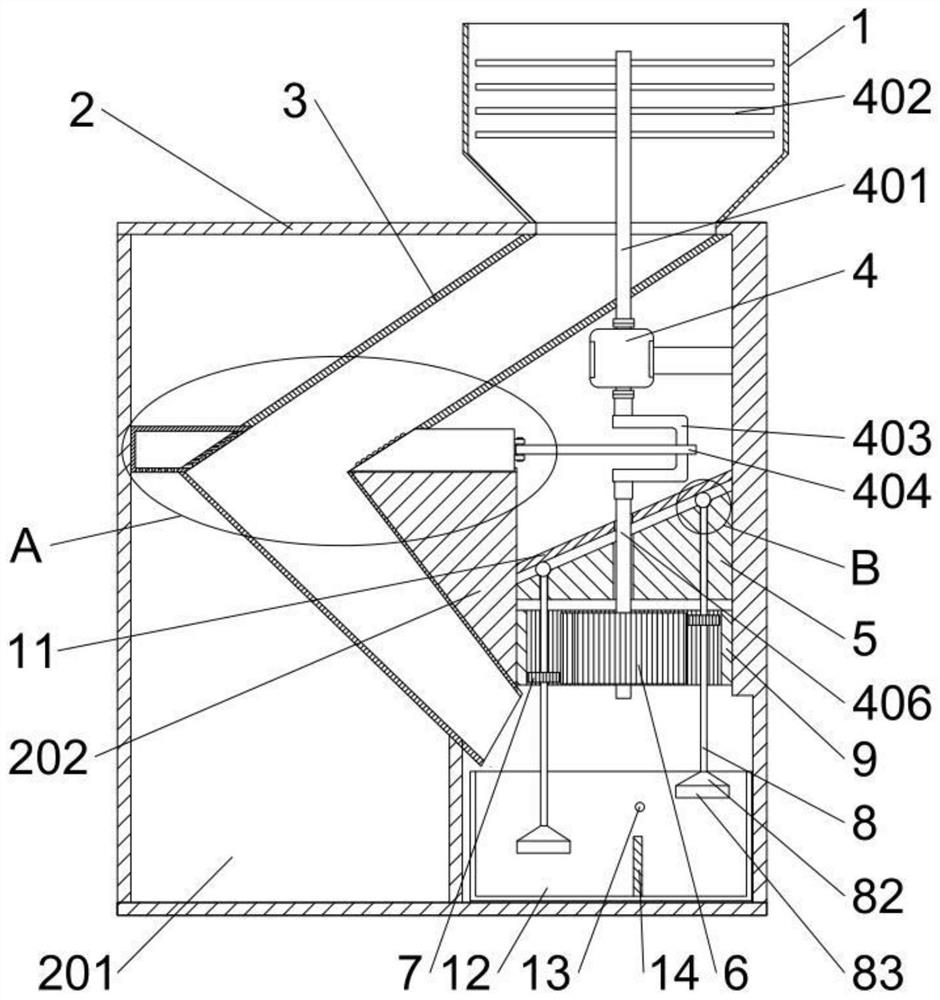

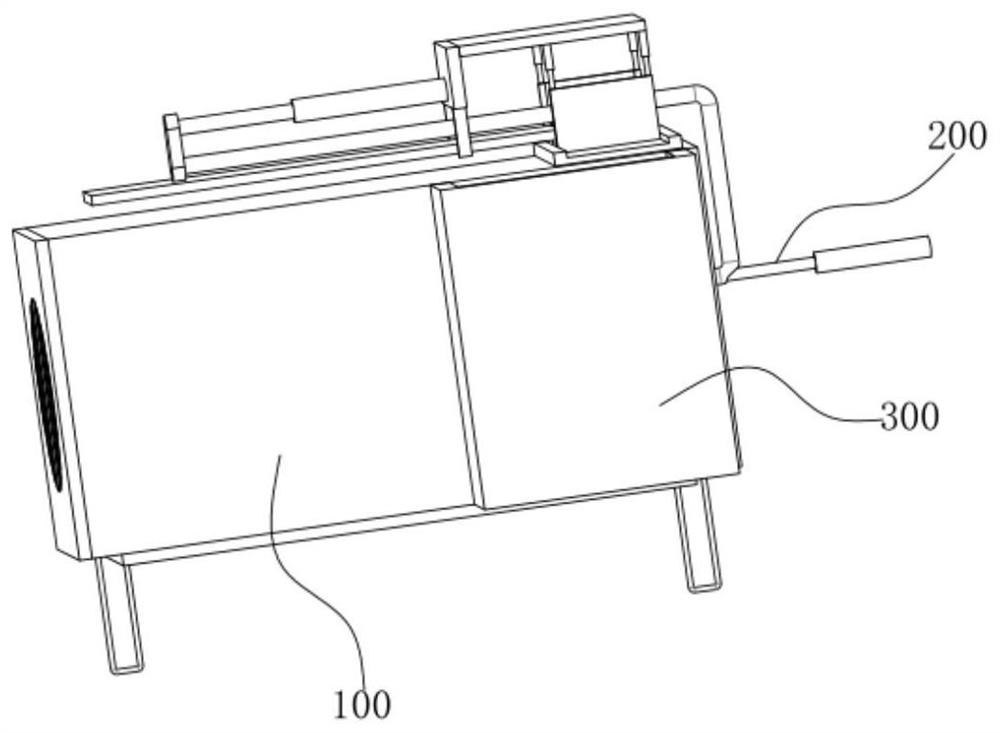

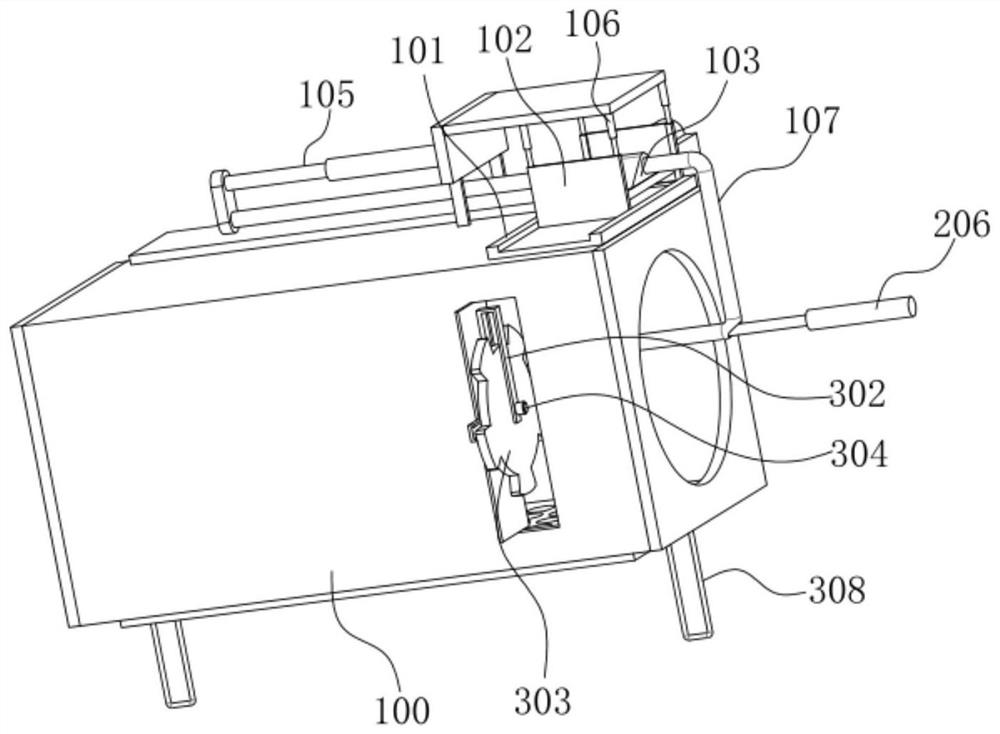

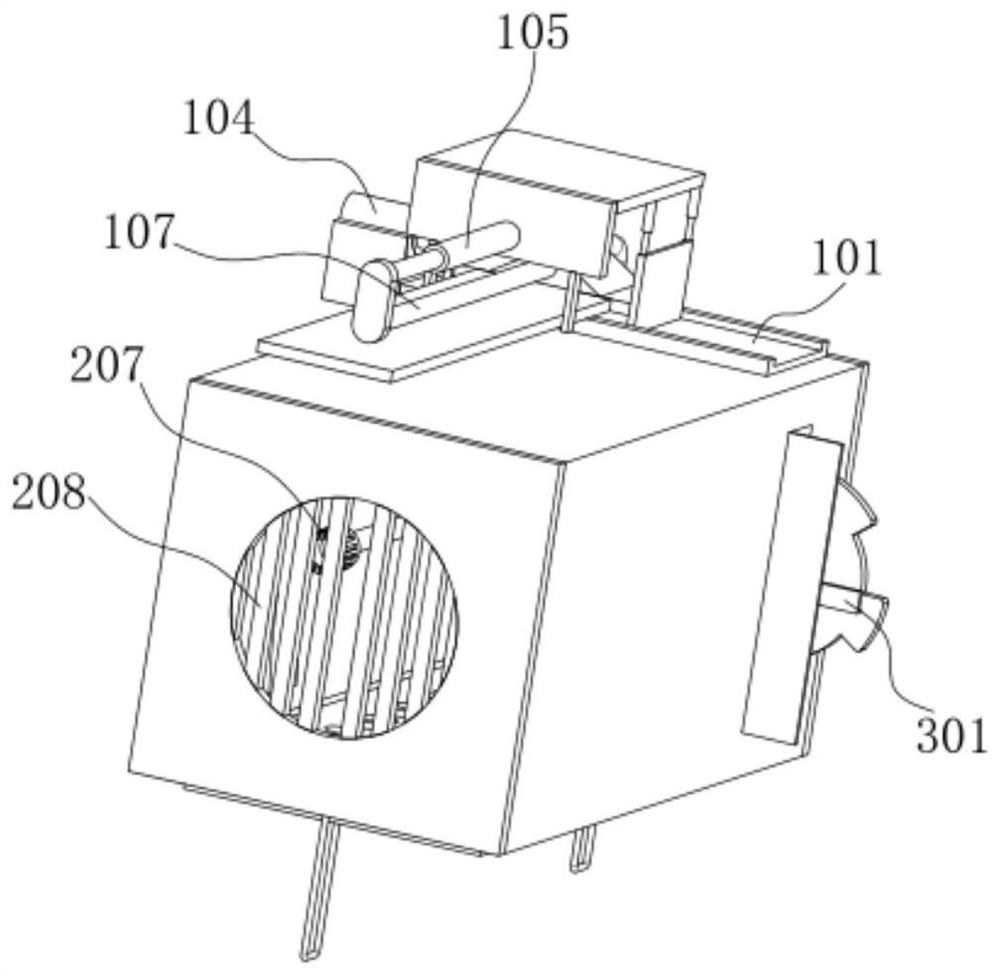

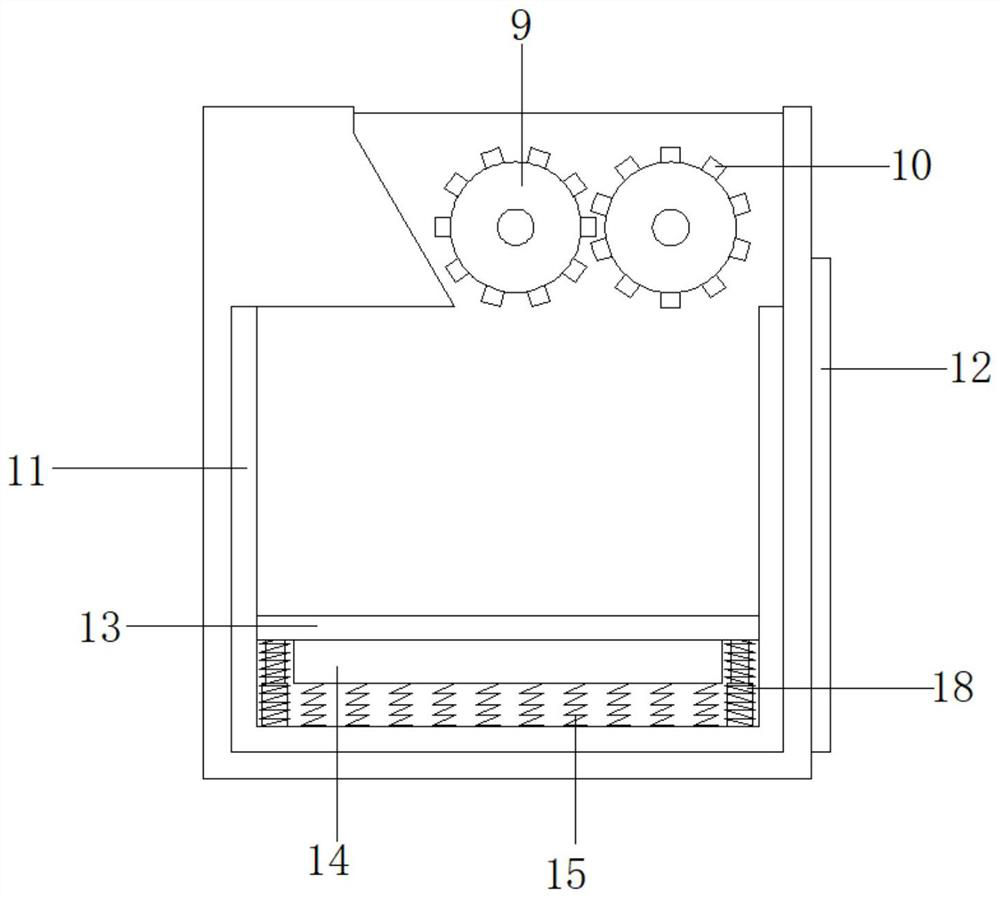

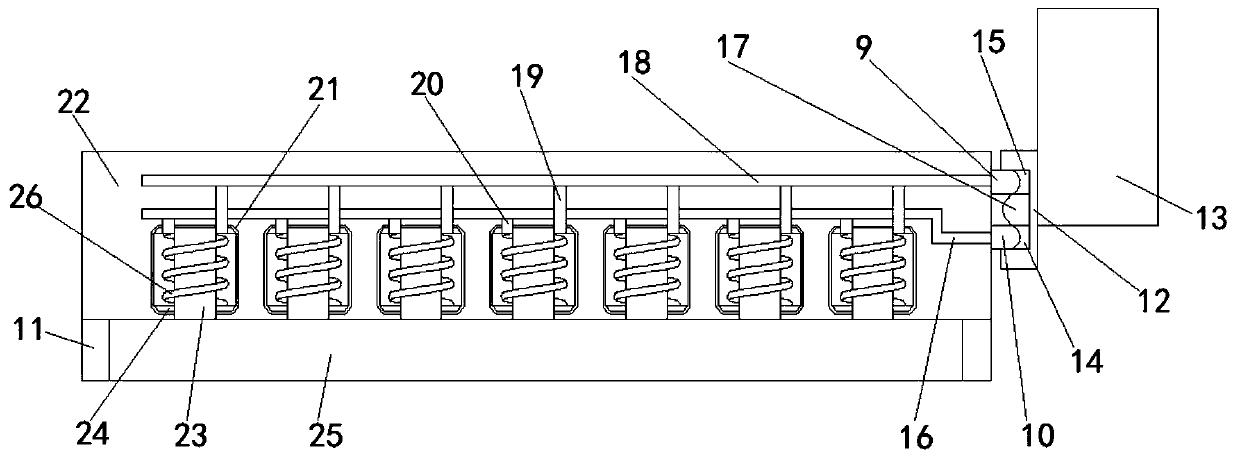

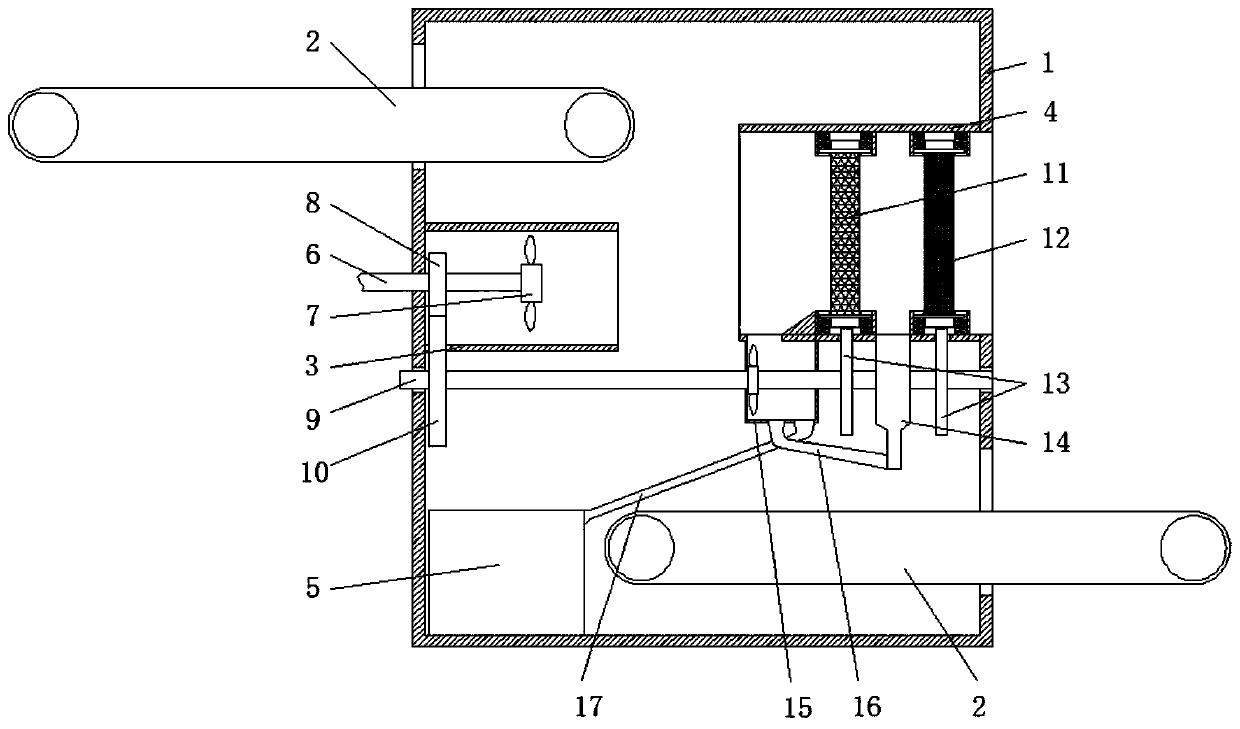

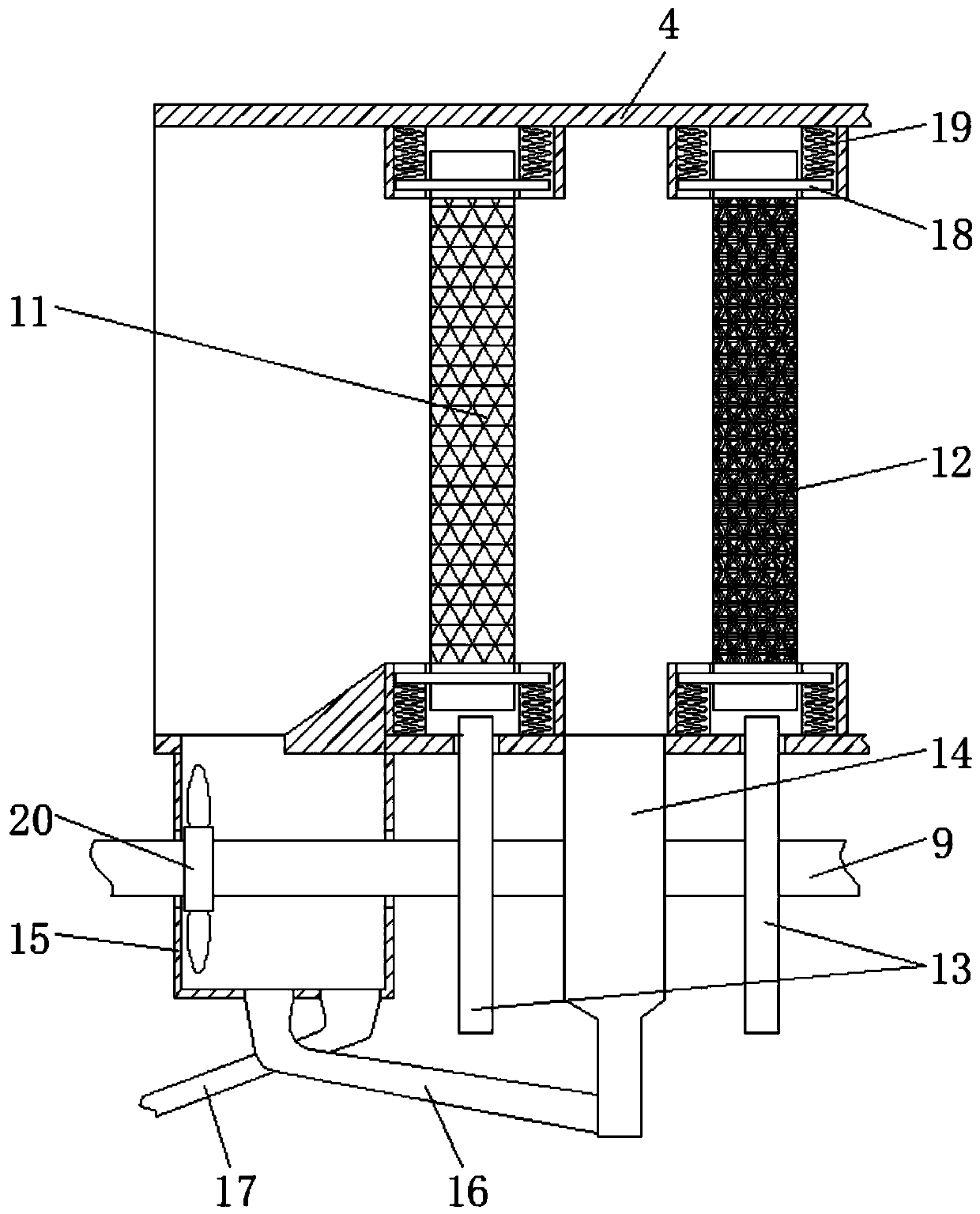

A kind of energy-saving domestic garbage recovery treatment device

ActiveCN113019614BEffective sorting and recyclingAvoid wastingGrain treatmentsPressesElectric machineryProcess engineering

The invention discloses an energy-saving domestic garbage recovery treatment device, which comprises a treatment box with a feeding port on the top, a garbage sorting tank and a sorting mechanism, the garbage sorting tank is arranged on the inner bottom surface of the processing box, and the garbage sorting tank There is a partition inside; the sorting mechanism is set above the garbage sorting tank and is used to separate the magnetic metal in the garbage. The sorting mechanism includes a motor, a first shaft, a cylinder, a second shaft, a controller and testing facility. The sorting mechanism in the invention can separate and process the garbage containing magnetic metals and the garbage not containing magnetic metals in the garbage sorting tank, effectively classify and recycle resources, and avoid waste. The sorting mechanism, the rubbish crushing mechanism and the liquid separation mechanism in the invention can realize the operation of the three mechanisms synchronously only by using one motor for output, which saves energy and funds and has strong practicability.

Owner:SUQIAN COLLEGE

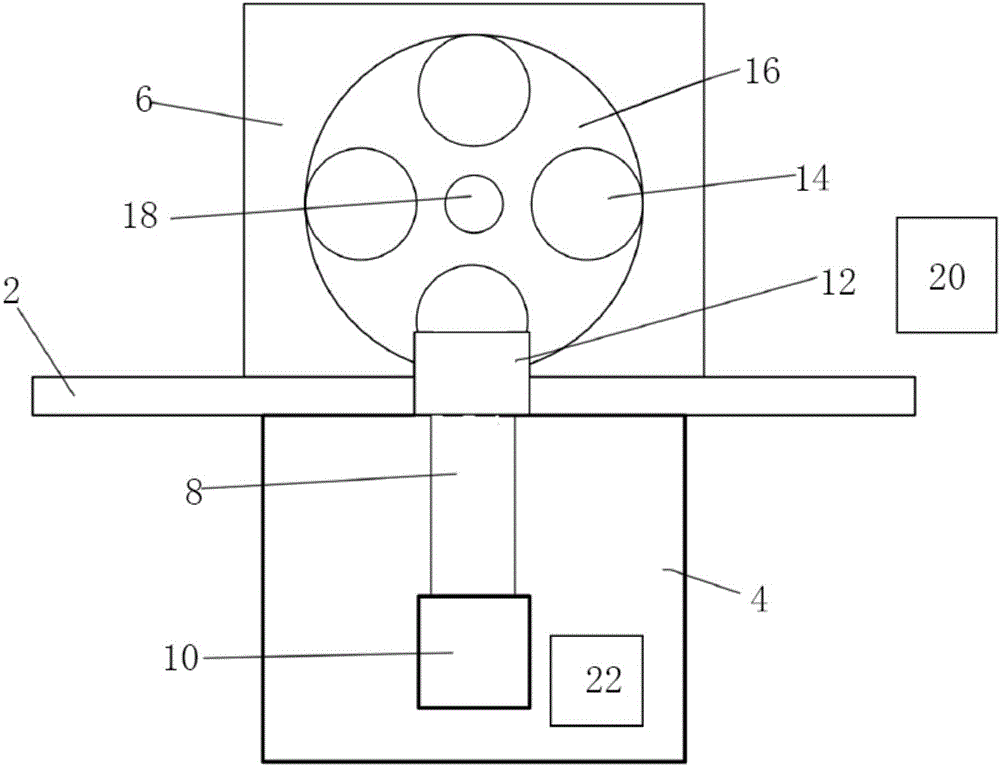

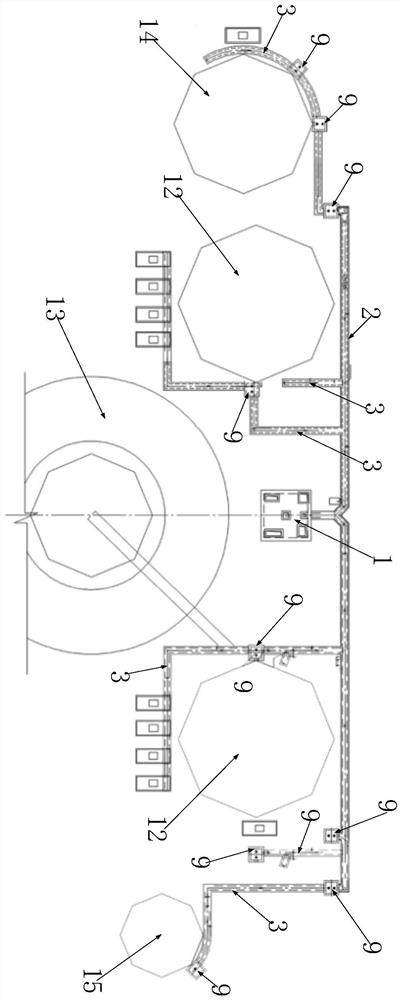

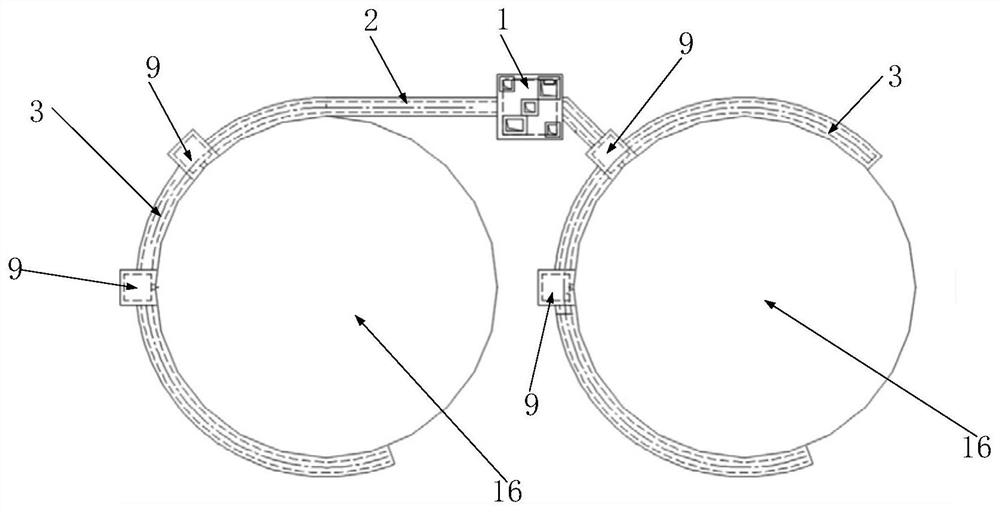

Rotary type automatic waste collection system

The invention relates to a rotary type automatic waste collection system which comprises a separating wall, a material feeding channel and a plurality of waste collection devices, wherein the separating wall is used for forming a first room and a second room which are mutually separated; the material feeding channel penetrates through the separating wall and is connected with the first room and the second room, the outlet, which is connected with the first room, of the material feeding channel forms a feeding port, and the outlet, which is connected with the second room, of the material feeding channel forms a discharging port; the plurality of waste collection devices are located in the second room; the rotary type automatic waste collection system is characterized by comprising a rotary device which is arranged in the second room and used for driving the waste collection devices to rotate, so that one of the waste collection devices is arranged in alignment with the discharging port. According to the rotary type automatic waste collection system, medical waste can be recycled in classification efficiently and accurately, the own structure is compact, the occupied area is small, the requirement on the installation site is low, and a lot of time and energy of medical workers can be saved after the system is used.

Owner:SUZHOU DERPIN MEDICAL SCI & TECH CO LTD

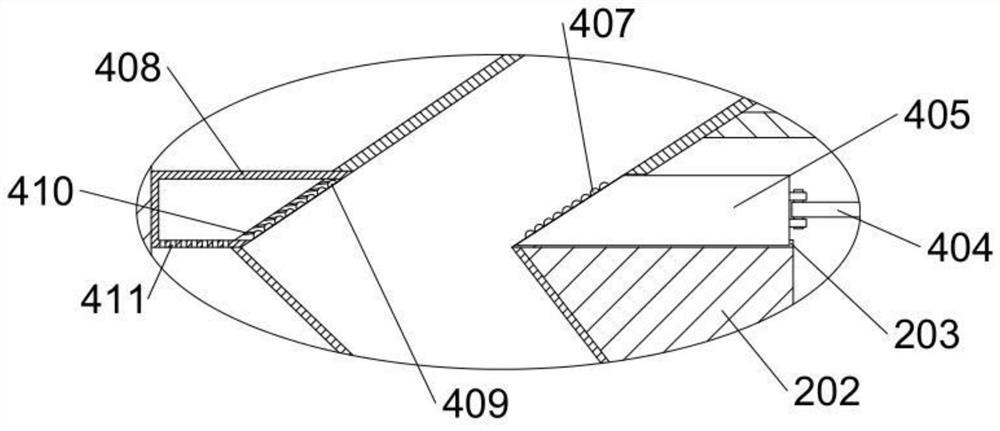

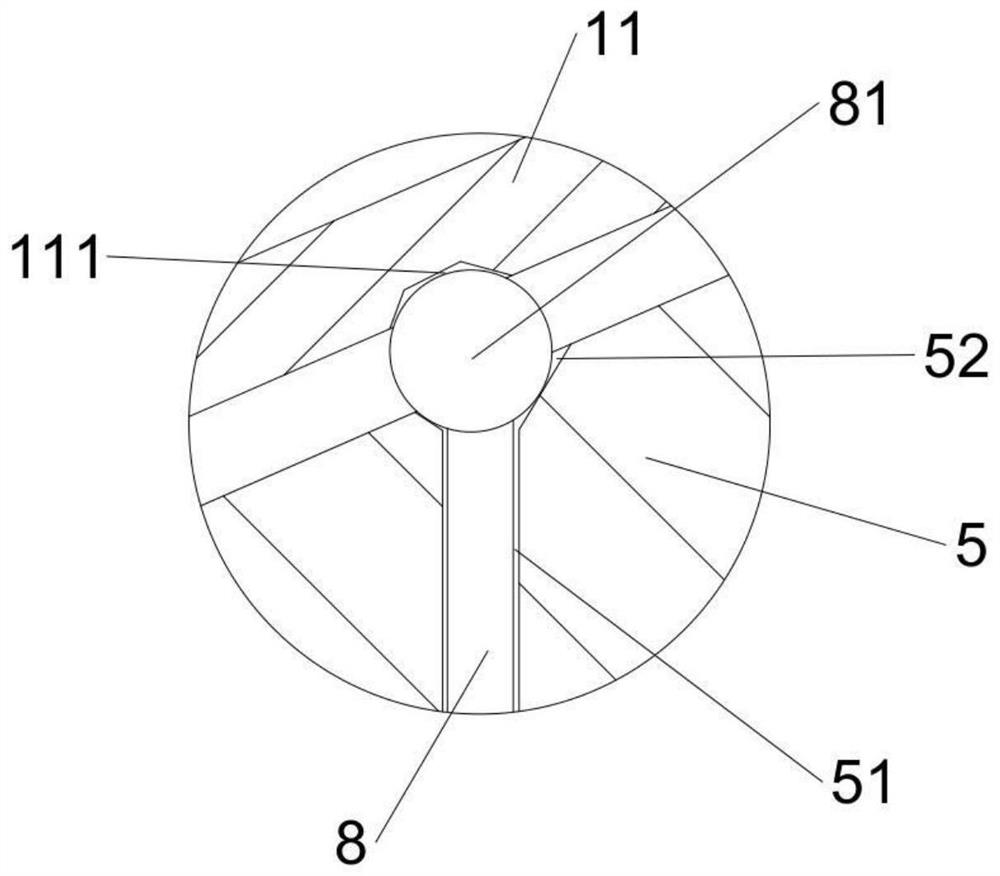

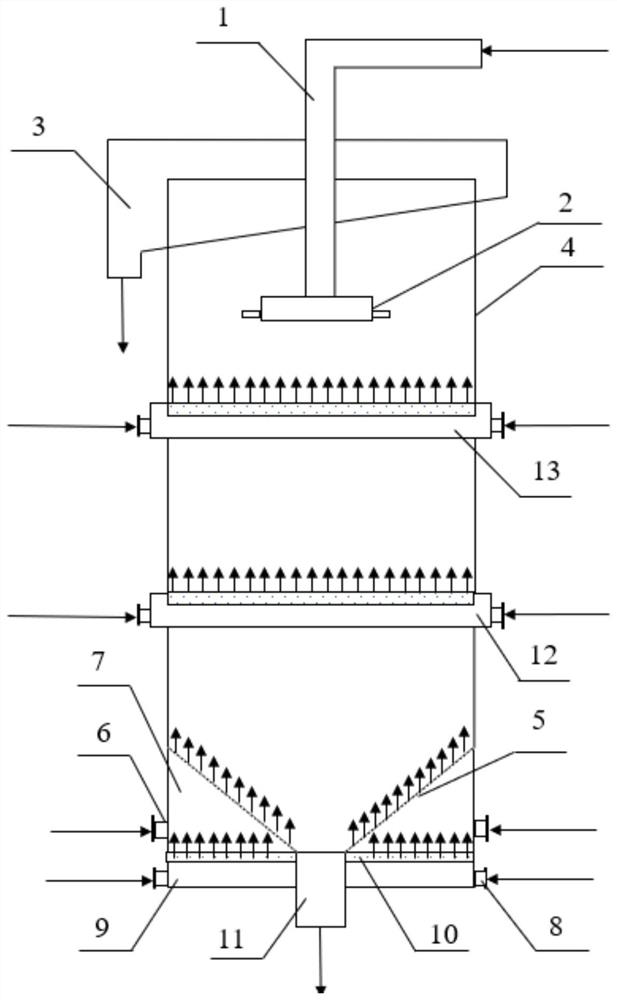

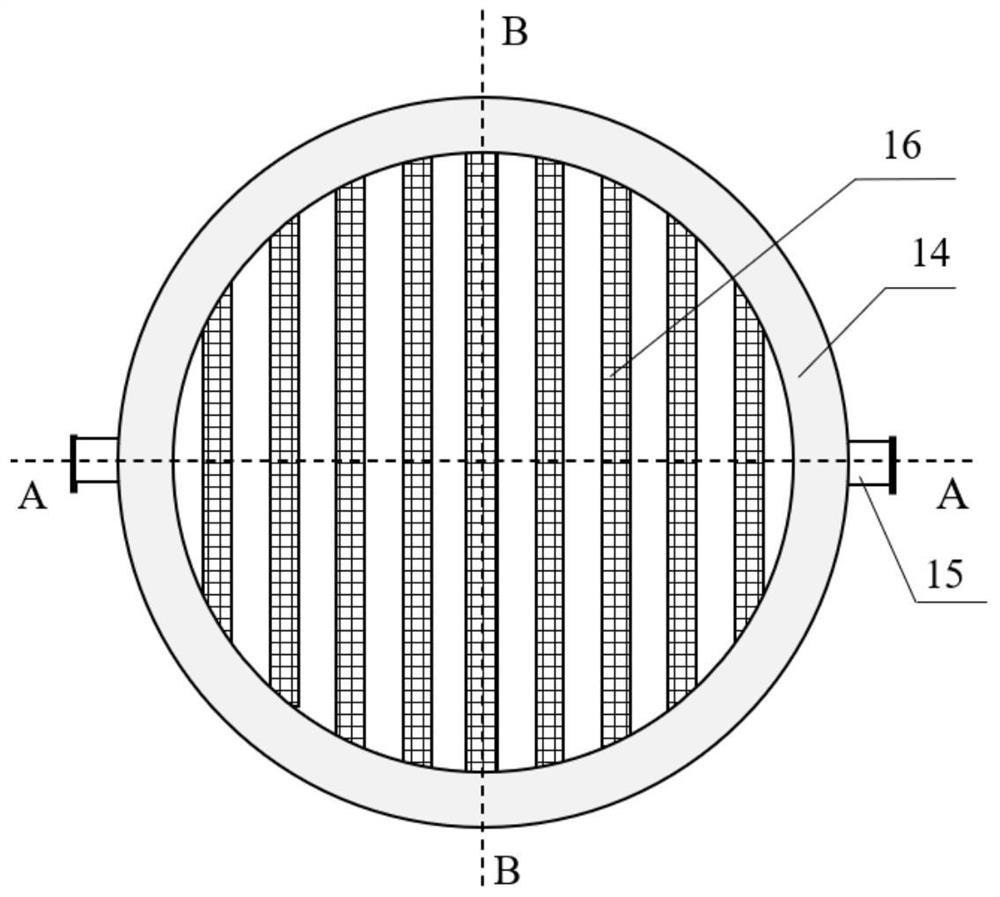

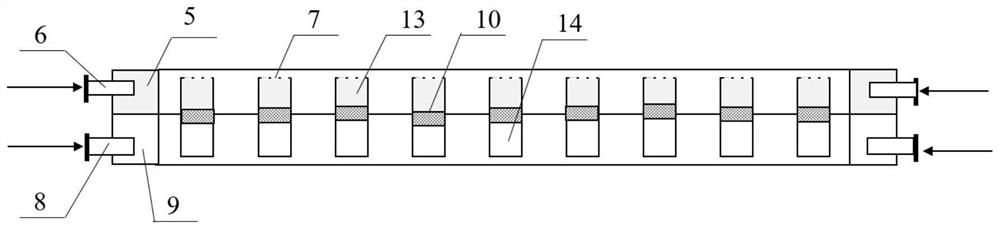

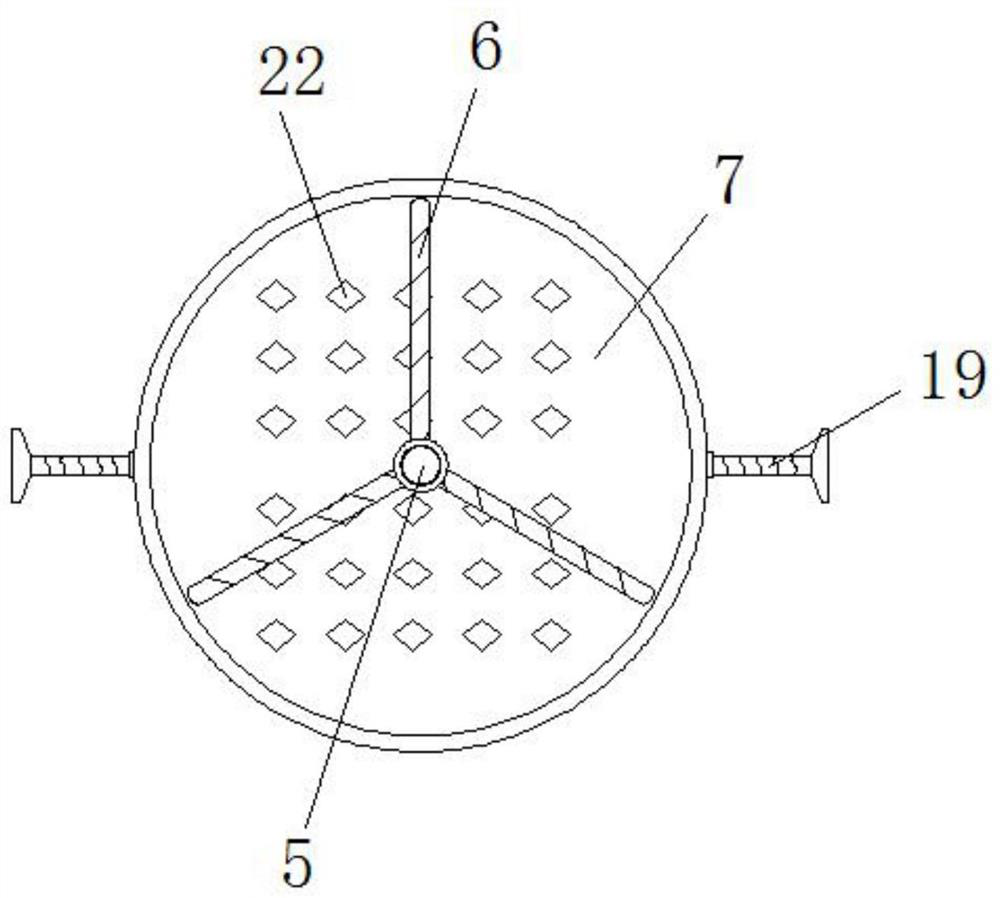

Gradient air inlet coarse particle fluidization flotation device and method

PendingCN114700182AReduce the probability of desorptionImprove stabilityFlotationMechanicsThermodynamics

The invention relates to a coarse particle fluidization flotation device and method with gradient air inlet, belongs to the technical field of mineral separation and recovery, and solves the problems of low coarse slime recovery rate and poor separation precision in the prior art. The multi-stage gas distribution device comprises a flotation column and a multi-stage gas distribution unit, the multi-stage gas distribution unit and the flotation column are concentrically arranged, and the gas flow is sequentially reduced from the lower portion of the flotation column to the upper portion of the flotation column. Gradient air inlet is conducted on ore pulp in the flotation column through the multiple stages of air distribution units, the flotation environment which is suitable for coarse grain flotation and is small in fluid disturbance and sufficient in microbubble content is constructed, and then efficient separation of coarse slime is achieved.

Owner:CHINA UNIV OF MINING & TECH

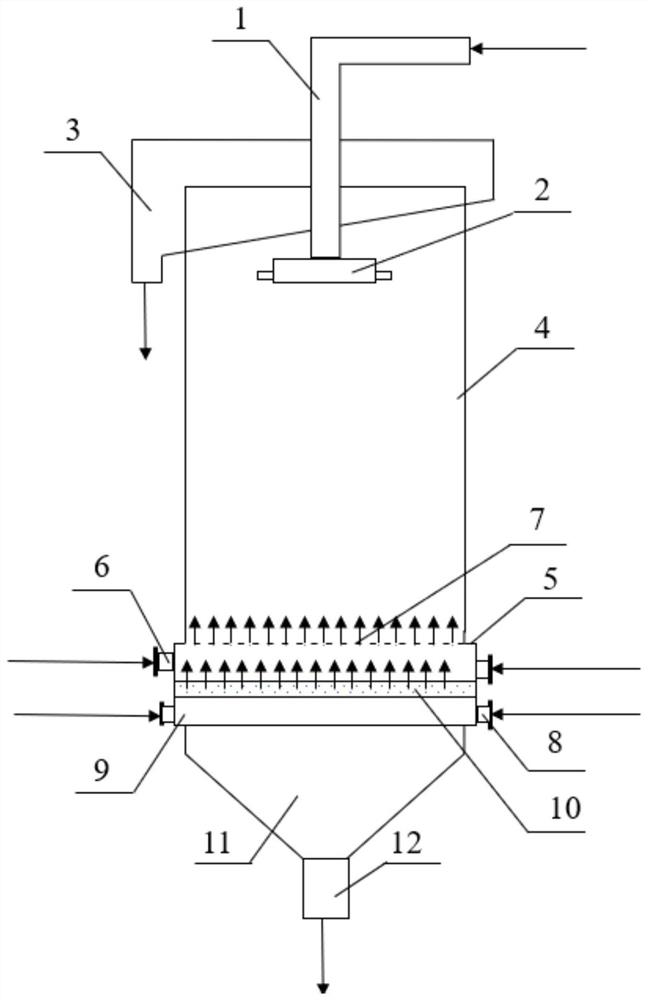

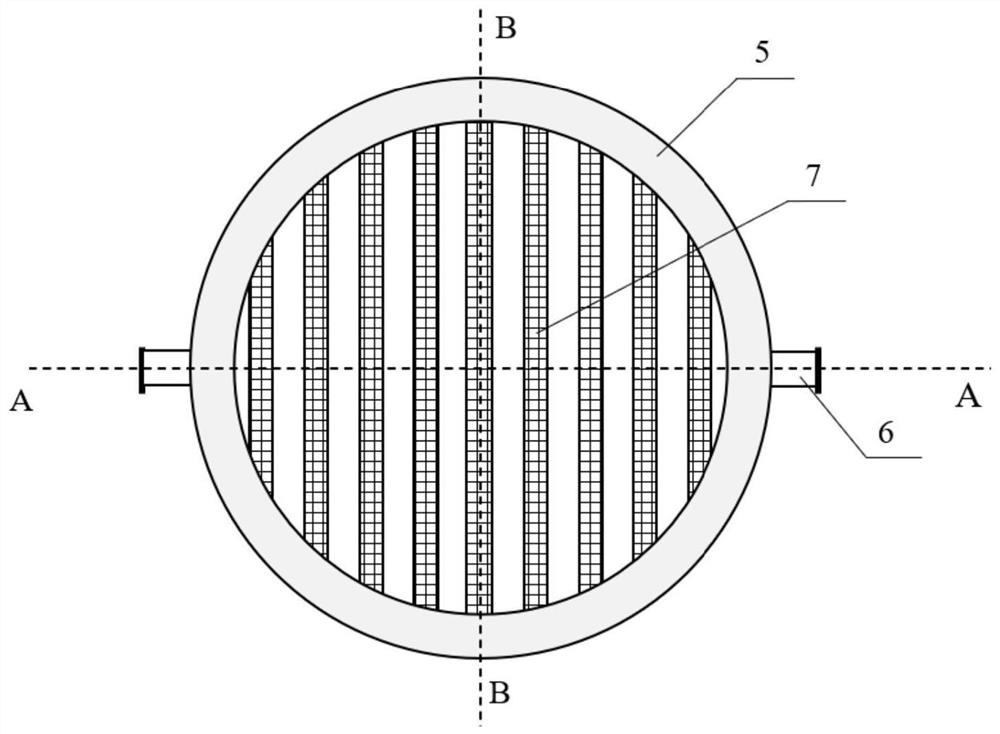

Flotation device and method suitable for coarse slime separation

ActiveCN114700181AAchieve individual controlAchieve creationFlotationThermodynamicsProcess engineering

The invention relates to a flotation device and method suitable for coarse slime separation, belongs to the technical field of mineral separation and recovery, and solves the problems of low coarse slime recovery rate and poor separation precision in the prior art. The device comprises a flotation column and a gas-water distribution unit, the gas-water distribution unit is located on the lower portion of the flotation column and concentrically arranged, the gas-water distribution unit comprises a first gas distribution unit and a gas-water mixed distribution unit, and the gas-water mixed distribution unit is located above the first gas distribution unit. The device is simple in structure and good in sorting effect.

Owner:CHINA UNIV OF MINING & TECH

Control type reinforcing steel bar embedded columnar construction waste treatment device

The invention discloses a control type reinforcing steel bar embedded columnar construction waste treatment device in the technical field of construction, which is characterized by comprising a shell, wherein the top surface of the shell is provided with a longitudinal guide rail arranged along the width direction of the shell, and a guide table is vertically and movably arranged between movable plates; a punching assembly, wherein a pipe body is fixedly connected with the end part of a U-shaped branch pipe; and a detection assembly which is embedded in the side wall of the shell. After columnar construction waste is placed in an inner cavity of the shell to be limited, the cross section of the columnar construction waste is crushed through a crushing disc, and when the columnar construction waste is tunneled to the position where reinforcing steel bars are embedded, a ring-shaped punching head is driven to abut against the end face of the columnar construction waste and gradually tunneled inwards to crush slag materials embedded around the reinforcing steel bars, the reinforcing steel bars gradually extend into an inner cavity of the U-shaped branch pipe through the pipe body, so that the problem of damage caused by rigid contact with a crushing structure during recycling treatment of the construction waste is avoided, the maintenance cost of equipment is reduced, the construction waste can be effectively classified and recycled, and the recycling efficiency is improved.

Owner:孙团伟

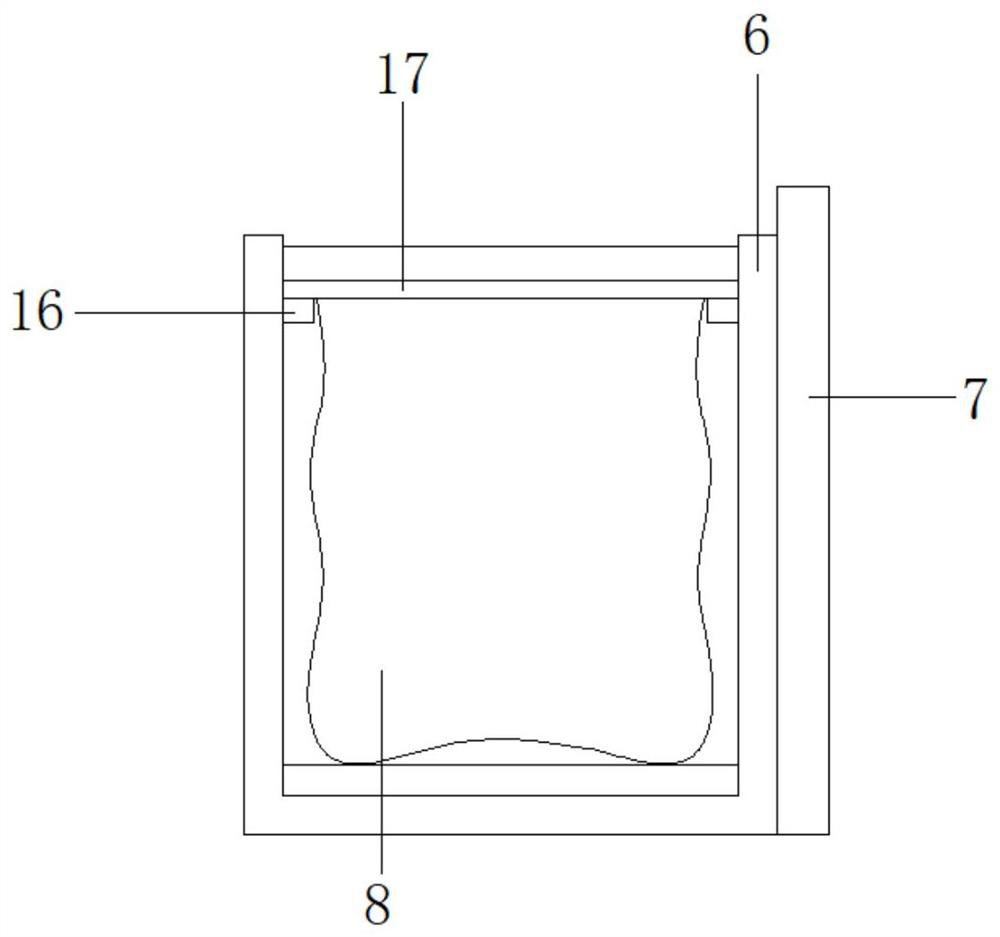

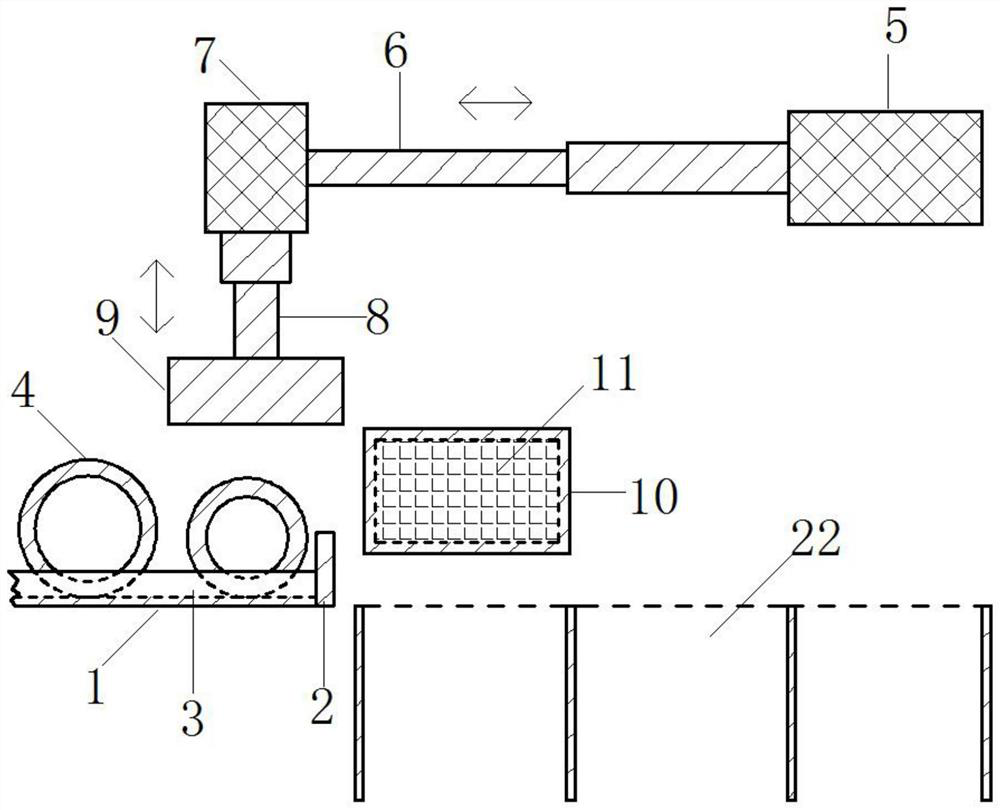

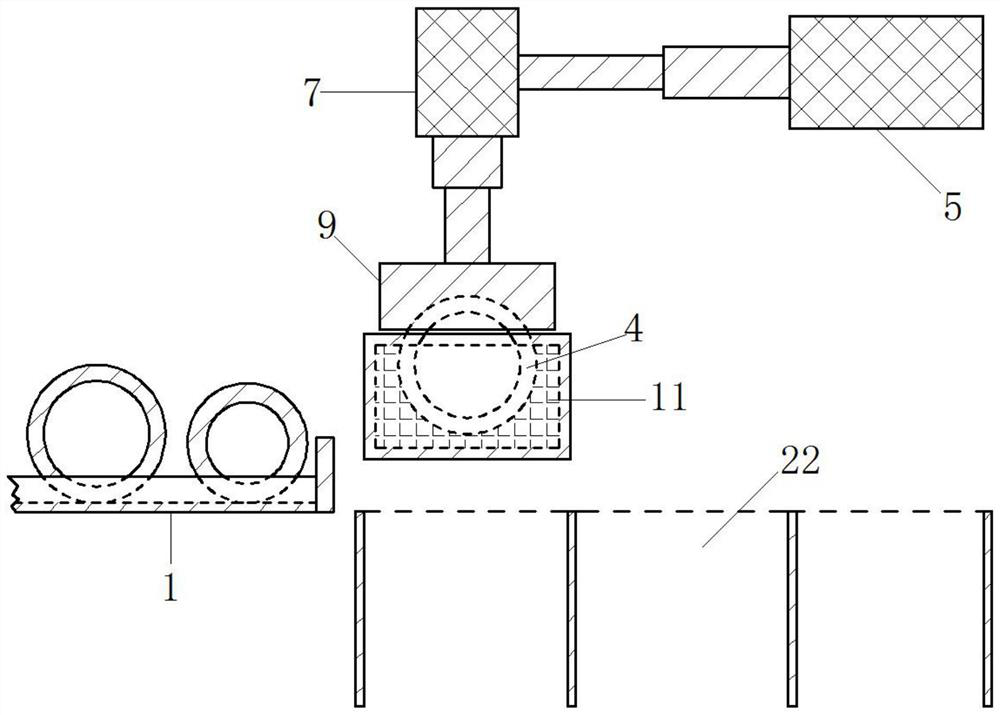

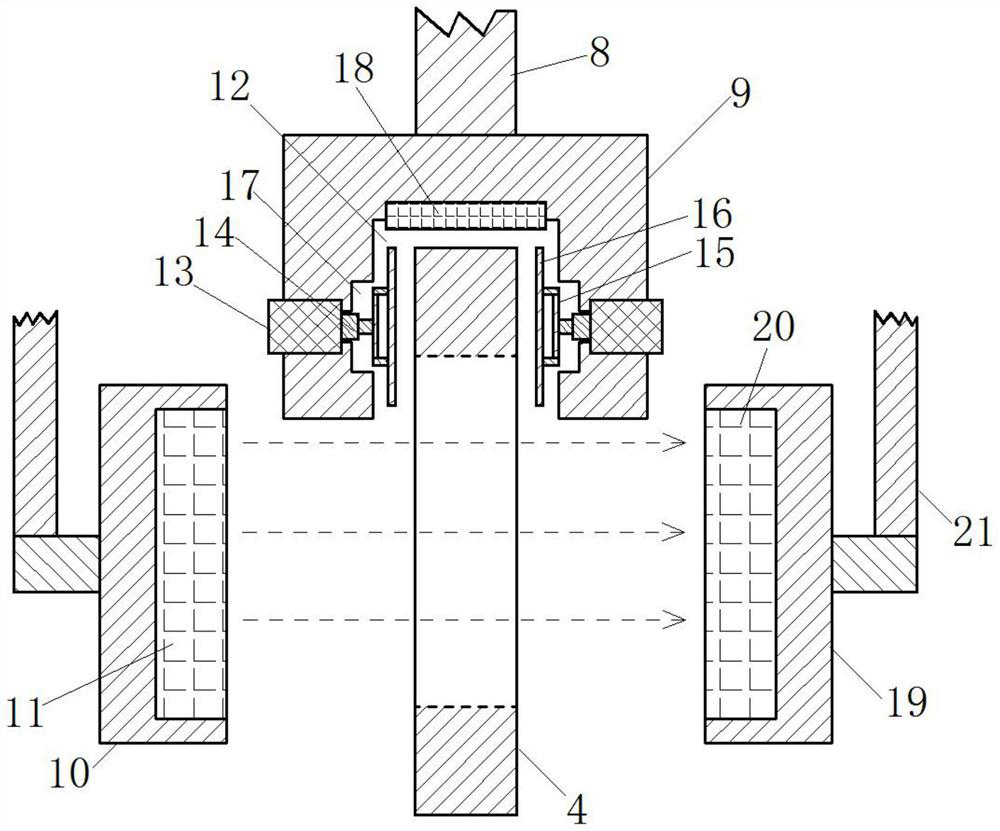

Waste recovery device of wire cut electrical discharge machining machine tool

InactiveCN112372727AEffective sorting and recyclingImprove work efficiencyPlastic recyclingGrain treatmentsWire cuttingProcess engineering

The invention relates to a waste recovery device of a wire cut electrical discharge machining machine tool. The waste recovery device of the wire cut electrical discharge machining machine tool comprises a box body, wherein a dust collecting pipe is connected to the left side of the top side of the box body in a penetrating mode, a feeding port is formed in the right side of the top of the box body in a penetrating mode, a dust collecting box is movably connected to the front side of the box body, and a waste collecting box is movably connected to the right side of the box body. The waste collecting box comprises a first box body and a first mounting plate, wherein the outer side of the first box body is fixedly connected with the first mounting plate, and a dust collecting bag is movablyconnected into an inner cavity of the first box body. Rotating rollers are symmetrically arranged between the inner walls of the box body, and cutting knife rings are arranged on the outer wall of each rotating roller at equal intervals. The waste recovery device of the wire cut electrical discharge machining machine tool can effectively conduct classified recovery of dust and large waste materials, the cleaning and recycling work efficiency of workers is greatly improved, the situation that the quantity of waste stored in the second box body is reduced due to the fact that the occupied spaceis large in the waste recycling and storing process is avoided, and the practicability of the whole device is greatly improved.

Owner:泰州市江南机械制造有限公司

One can realize the wide -grained dual -agent all rough clay sorting process

ActiveCN105597915BImprove sorting effectRaise the lower limit of sortingSolid separationClosed loopEngineering

The invention discloses a wide-grain-grade double-dense-medium process for separating all coarse coal slime. The wide-grain-grade double-dense-medium process includes that raw coal is preliminarily sieved, manually picked and graded, then oversize products can be used as coarse grain coal, the coarse grain coal is fed into a non-pressure tri-product dense-medium cyclone to be separated, undersize products are concentrated and graded and then are dehydrated in an underflow manner to be used as fine grain coal, the fine grain coal is fed into a pressure tri-product dense-medium cyclone to be separated, and excess flow is fed into a flotation filter-press system, so that the coal slime can be separated; qualified suspension liquid of a fine grain coal dense-medium separating system is provided by coarse grain clean coal of a coarse grain coal separating system, lower branches of coarse grain middling coal primary-section medium removing equipment and branches of coarse grain clean coal and coarse grain middling coal magnetic separation concentration; dilute suspension liquid of coarse grain gangue products and dilute suspension liquid of middling coal and gangue products of a fine grain coal system are treated together; magnetic separation tailings are used as wetting water or primary spray water for grading screens. The wide-grain-grade double-dense-medium process has the advantages that the fine grain coal dense-medium system has a medium automatic generating function, all the coarse coal slime can be efficiently separated by dense media, the suspension liquid is circulated in a closed-loop manner, the separation efficiency is high, the products are flexible in structure, and the production and operation costs are low.

Owner:TANGSHAN BRANCH COAL SCI ACAD

Electronic product waste part recycling device facilitating classified recycling

InactiveCN110813532AImprove isolationEffective isolationMagnetic separationEnvironmental engineeringElectronic waste

The invention relates to the technical field of electronic product waste part recovery, and discloses an electronic product waste part recycling device facilitating classified recycling. The device comprises two racks. Mounting plates are fixedly mounted at the bottoms of the two racks. Mounting frames are fixedly mounted at the bottoms of the two mounting plates through bolts. Two bearings whichare distributed in a bilateral symmetry mode are fixedly mounted in each of the two mounting frames. Rotating shafts with one ends fixedly connected with the interiors of the two back bearings are fixedly mounted in the two front bearings respectively. Rollers located on the opposite sides of the two mounting frames are fixedly mounted on the outer sides of the two rotating shafts. The electronicproduct waste part recycling device facilitating classified recycling has the advantages of iron waste part sorting and recycling. The problem that part of iron waste parts are treated along with waste and the function of recycling iron waste parts is not achieved because existing electronic waste treatment equipment lacks the function of classifying iron waste parts is solved.

Owner:陕西安易信息科技有限公司

Raw refuse sorting process

InactiveCN110125136AAccurate removalEfficient sortingConstruction waste recoverySolid waste disposalLitterCrusher

The invention relates to a raw refuse sorting process. The raw refuse sorting process includes the following steps that raw refuse is transported into a material bin; the refuse in the material bin isconveyed to a bag breaking device to be subjected to bag breaking treatment; the refuse after being subjected to bag breaking treatment is conveyed to a building waste sorting system, and stone, glass and metal in the refuse are separated out; the refuse with the stone, the glass and the metal separated out is conveyed to a breaker, breaking and dust screening are performed, and the dust after screening treatment is used for compost; and the refuse after being broken is conveyed to a sorting system, and classified collecting is performed. Totally, the raw refuse sorting process is reasonablein design, and has the beneficial effects of being exquisite in classifying, high in screening efficiency, high in plastic substance reutilizing rate and environment-friendly and harmless.

Owner:河南锦程过滤设备有限公司

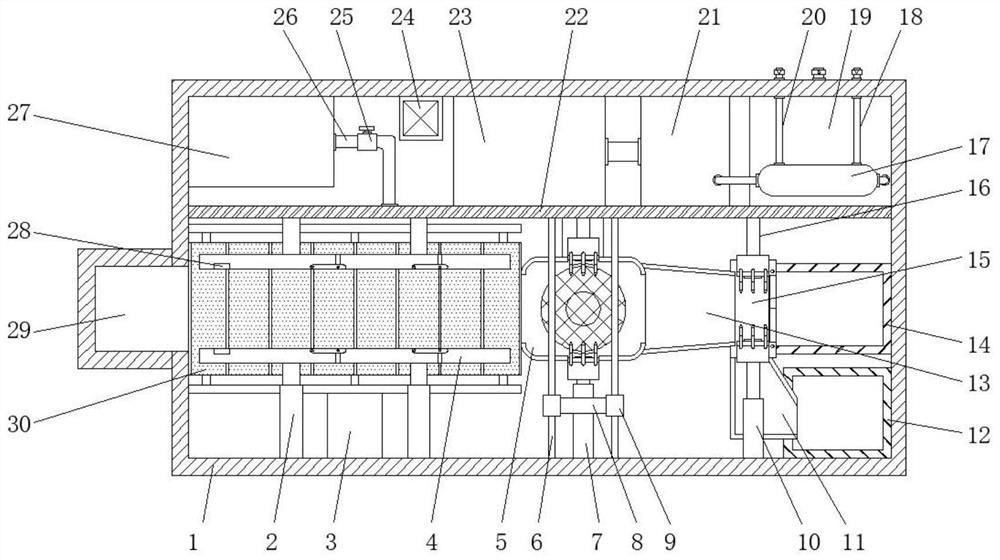

A method and device for safely dismantling and recycling lithium-ion batteries

ActiveCN110142280BAvoid the effects of separationImprove applicabilitySolid waste disposalWaste accumulators reclaimingPower batteryEnvironmental engineering

The invention discloses a lithium-ion battery safe dismantling recovery method and its device, which belong to the field of lithium-ion power battery recovery. The inert gas in the tank is passed into the body through the trachea as a protective gas; Step 2: Put the lithium-ion battery into the body through the waste battery inlet, so that the waste battery falls smoothly on the transport mechanism for transportation; Step 3: The waste battery passes through the transport mechanism Transport to the fixing mechanism to cut the waste battery; step 4: slide the cut waste battery to the separation mechanism through the conveying plate, so that the shell and core of the waste battery are separated; step 5: make the separated shell fall into the shell box for collection, so that the core slides through the blanking plate into the core box for collection. The invention can effectively ensure the stability of the waste battery during disassembly, and avoid the phenomenon that the high temperature generated at the cutting position ignites the battery material and causes fire.

Owner:赣州市康达新能源材料有限公司

A raw material screening device for oil processing with adjustable aperture

ActiveCN110496769BEasy to adjustEffective sorting and recyclingSievingScreeningOil processingOil and grease

The invention discloses a raw material screening device for oil processing with adjustable aperture, which comprises a screening box, a driving motor, a vibrating motor, a discharge pipe and a rotating rod. A driving motor is installed on the top of the sub-box, and a feed inlet is opened on the upper left side of the screening box, the output end of the driving motor is connected with the rotating shaft, a threaded rod is connected above the screening box, and the thread The rod passes through the first sieve plate and connects with the movable block, the surfaces of the first sieve plate and the second sieve plate are respectively provided with a first sieve hole and a second sieve hole, and the end of the discharge plate is provided with a slider . The aperture-adjustable raw material screening device for oil processing can facilitate the adjustment of the sieve hole diameter on the surface of the sieve plate, and can avoid the clogging of the sieve plate during screening, and can effectively classify and recycle oil raw materials with different diameters, making the use more convenient. Convenient and more suitable for people's use.

Owner:湖南省康多利油脂有限公司

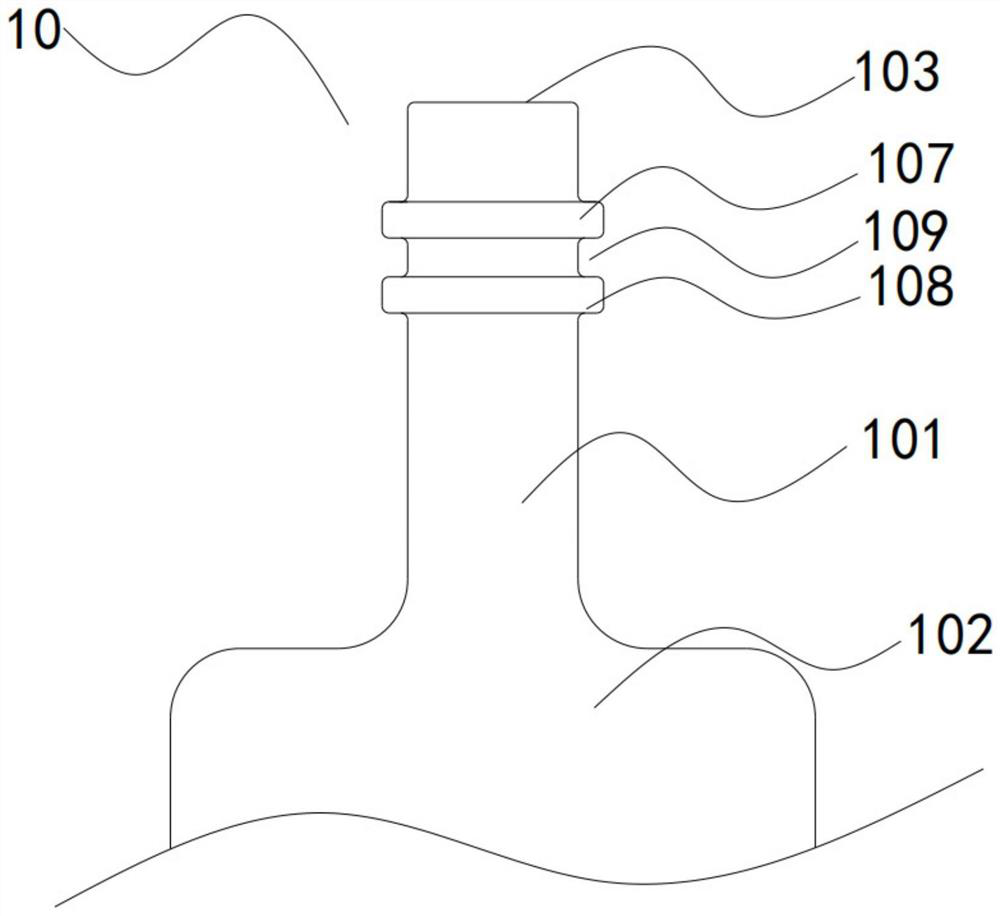

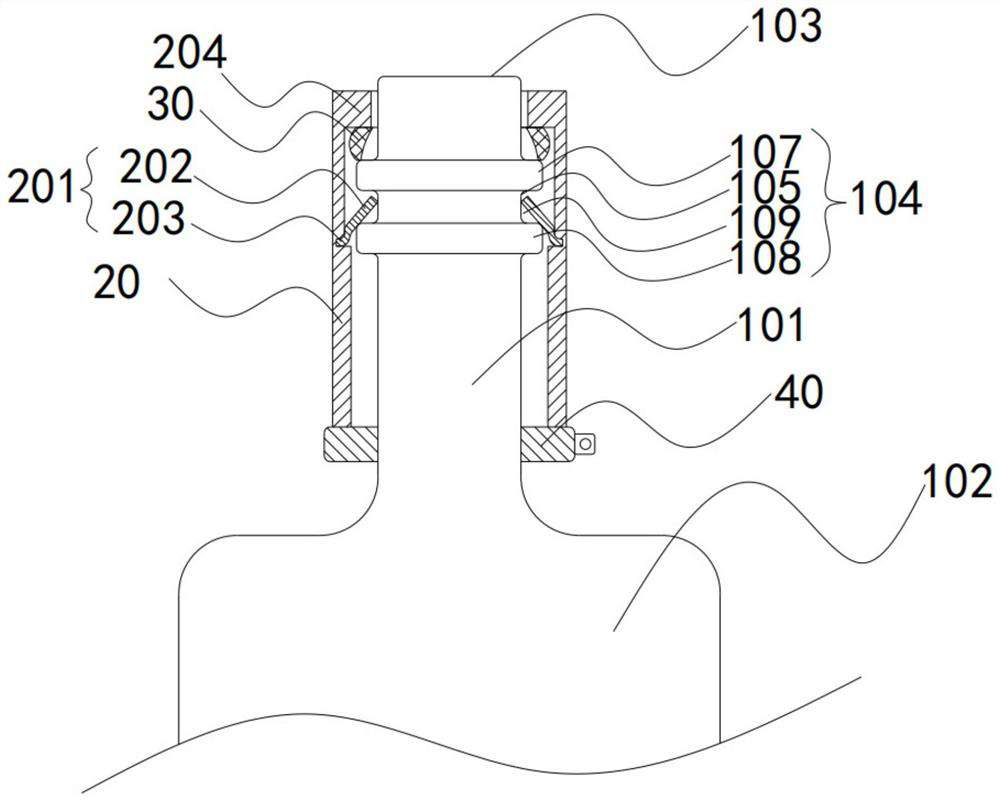

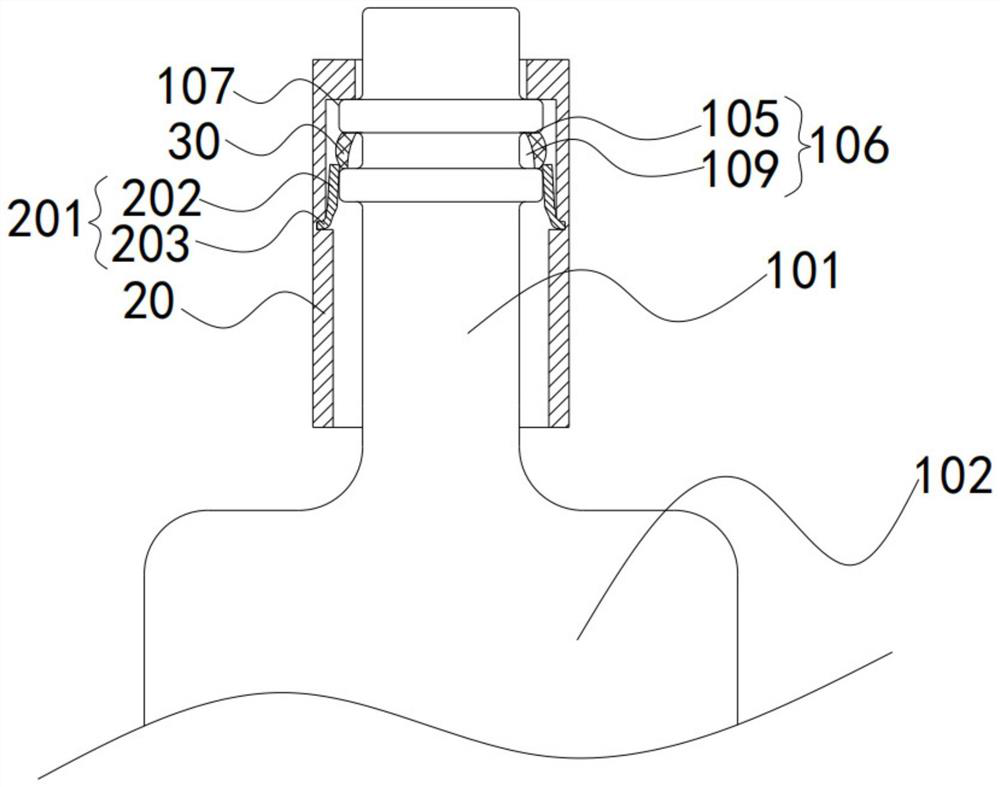

Packaging bottle convenient to recycle

PendingCN114275274AActive connectionEasy to separatePackage recyclingCapsStructural engineeringBottle neck

The invention discloses a packaging bottle convenient to recycle. The packaging bottle comprises a bottle body, an outer cover and an elastic piece. The bottle body comprises a bottle neck part, the bottle neck part comprises a limiting part, the limiting part is provided with a locking surface, and a locking area is formed on the bottle neck part; the outer cover sleeves the bottleneck part and linearly moves on the bottleneck part, an elastic clamping block is arranged on the inner side of the outer cover, the elastic clamping block abuts against the locking face of the limiting part when located in the locking area, the elastic piece is arranged on the upper side of the elastic clamping block, the outer cover downwards moves relative to the bottleneck part to drive the elastic piece to move to the locking area, and the elastic piece is located in the locking area and abuts against the locking face. The side face of the elastic piece forms a guiding outer face, and when the outer cover drives the elastic clamping block to move upwards from the locking area, the elastic clamping block can pass through the space between the side of the limiting part and the outer cover. According to the packaging bottle, bottle caps and bottle bodies which are made of different materials can be effectively connected, the bottle caps and the bottle bodies which are made of different materials can be conveniently separated during classified recycling, effective classified recycling is achieved, and the utilization rate of recyclable materials is further increased.

Owner:RIZHAO KAIFULE PACKAGING PROD

A photoelectric nut washer screening mechanism device

ActiveCN109351657BEffective sorting and recyclingImproving the efficiency of stationary operationsSortingEngineeringWasher

The invention discloses a photoelectric nut washer screening mechanism device, and relates to the field of photo-mechanical-electric application devices. In the photoelectric nut washer screening mechanism device, at least one pair of clamping power devices used for clamping nut washers is arranged on a washer clamping mechanism; a pressure sensing plate used for sensing that the positions of thenut washers are in place is arranged in the washer clamping mechanism; a photosignal transmitting mechanism is fixedly arranged on a first mounting panel; and a photosignal receiving mechanism is fixedly arranged on a second mounting panel. According to the photoelectric nut washer screening mechanism device, the position of the washer clamping mechanism is adjusted through a first transverse drive power device and a second longitudinal drive power device in a drive manner, the pressure sensing plate in the washer clamping mechanism is used for sensing the arriving positions of the nut washers, the clamping power devices are used for clamping the current nut washers in a drive manner, the photosignal transmitting mechanism and the photosignal receiving mechanism are used for detecting thesizes of annular gaps of the nut washers, and therefore the nut washers of different specifications are effectively classified and recycled, and the efficiency of subsequent nut fixing operation is improved.

Owner:日照三兴食品集团股份有限公司

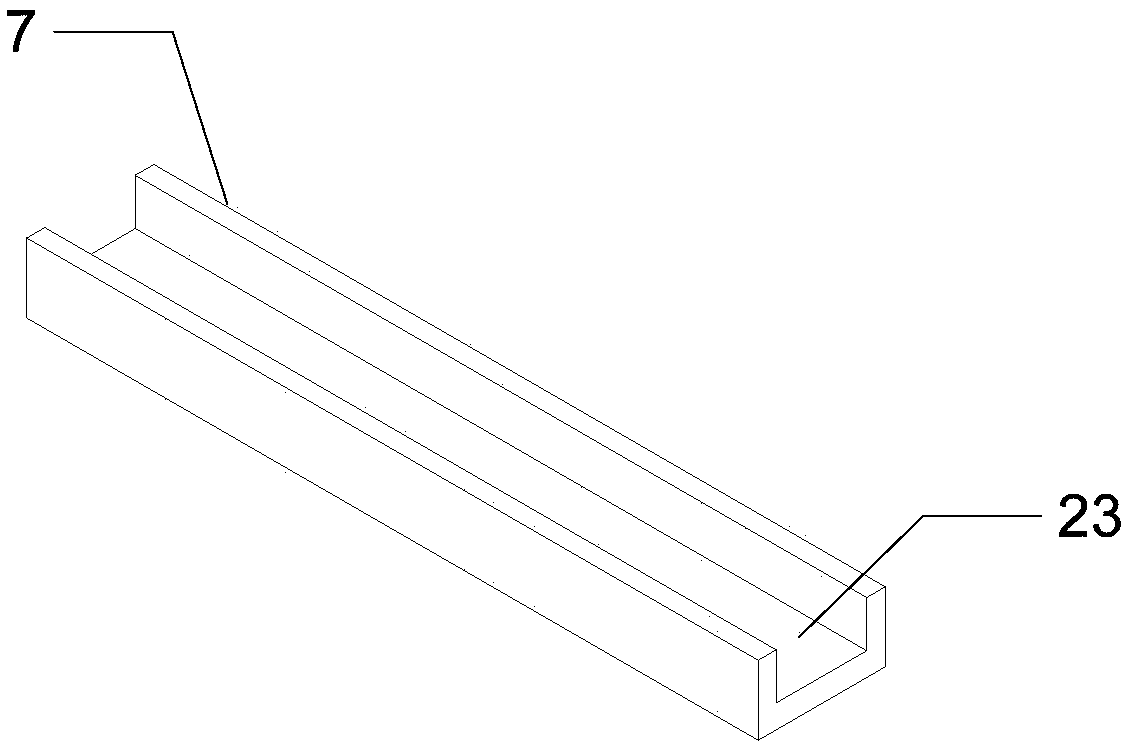

Drainage recycling channel device for desulfurization island and desulfurization island drainage recycling system

PendingCN113457400AReduce water consumptionReduce processing costsCesspoolsFatty/oily/floating substances removal devicesWater resourcesEngineering

The invention relates to a drainage recycling channel device for a desulfurization island and a desulfurization island drainage recycling system. The drainage recycling channel device comprises a drainage pit, a main drainage ditch and a plurality of recycling ditch assemblies used for recycling drainage of desulfurization facilities of the desulfurization island, and each recycling ditch assembly comprises a plurality of recycling ditches; the recycling ditch is arranged on the peripheral side of the desulfurization facility, the water outlet end of the recycling ditch is communicated with a main drainage ditch, and the water outlet end of the main drainage ditch is communicated with the drainage ditch. Compared with the prior art, the water consumption of the desulfurization system can be reduced, the treatment cost of recycled water is reduced, and waste of water resources is prevented.

Owner:HUANENG POWER INT INC

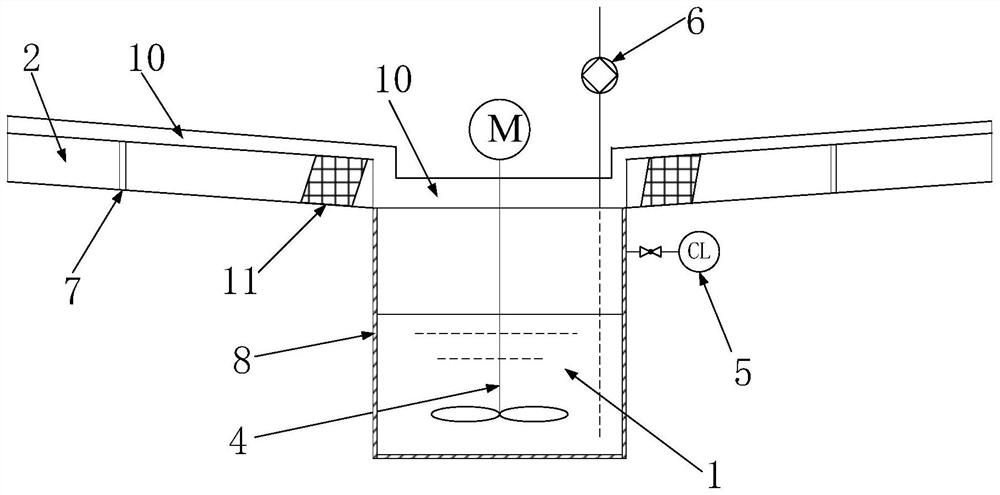

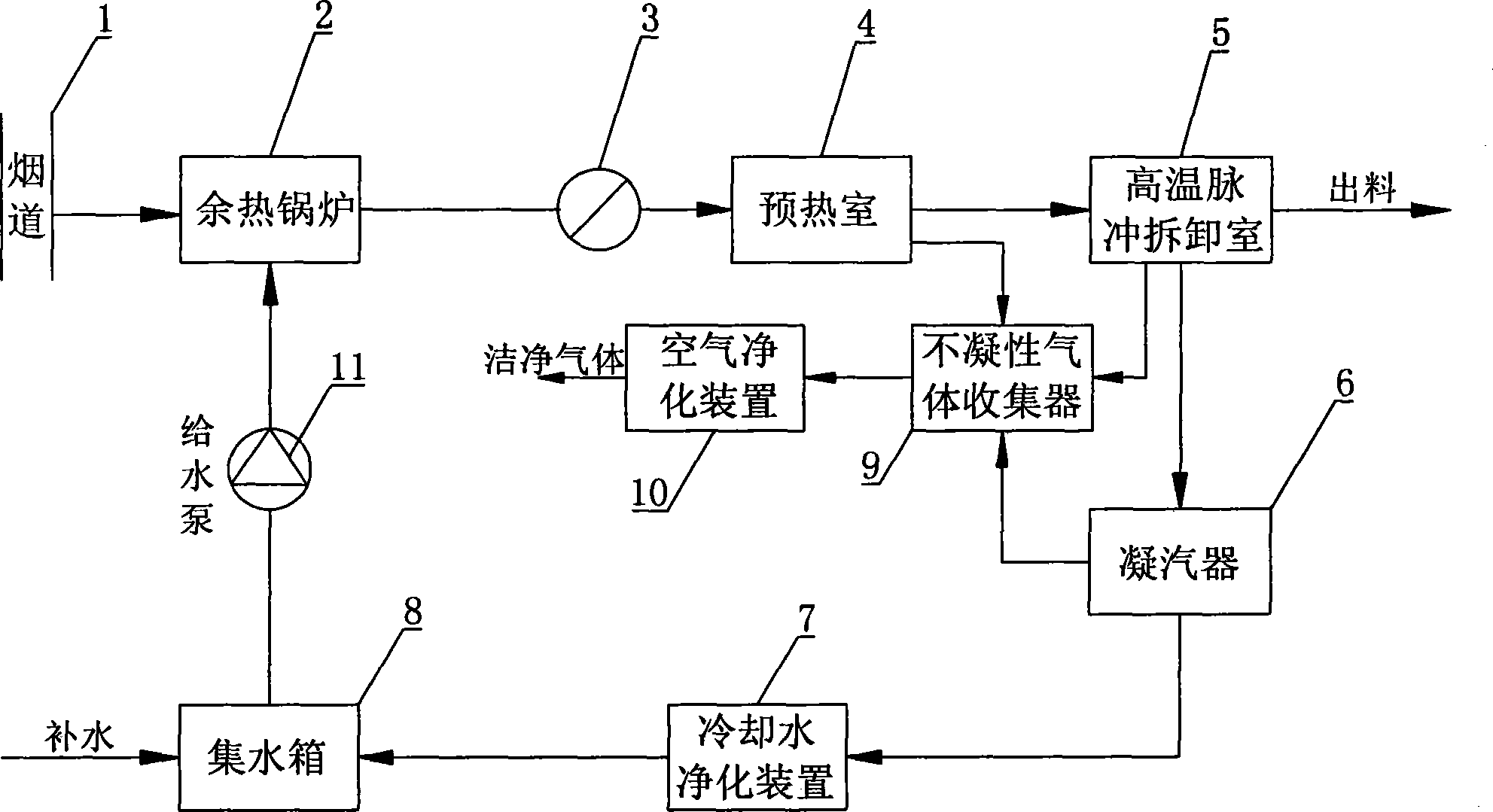

Method for automatic disassembly and recovery of waste printed circuit boards by using industrial waste heat

InactiveCN102284471BEasy to separateEffective sorting and recyclingSolid waste disposalElectronic waste recyclingLower gradeLow graded

The invention discloses a method for automatically dismantling and recovering electronic components on waste printed circuit boards by using industrial waste heat. It uses industrial waste heat to prepare low-grade superheated steam through the waste heat boiler, and then uses the superheated steam as the heat source and power to realize the automatic disassembly of waste printed circuit board electronic components through high-temperature pulse injection of superheated steam; the superheated steam after work is condensed After the device is properly treated, it is returned to the waste heat boiler for recycling; the gas generated during operation is collected by a non-condensable gas collection device, and then directly discharged after proper treatment. The invention proposes to use the superheated steam prepared by industrial waste heat as the heat source and power to realize the automatic disassembly and recovery of waste printed circuit board electronic components, and at the same time realize the resource utilization of industrial waste heat and waste printed circuit boards, which conforms to the principle of green, low-carbon and environmental protection, and has the advantages of Significant socio-economic and environmental benefits.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for recycling motor

ActiveCN102594037BEffective sorting and recyclingPursue recyclingElectric machinesManufacturing stator/rotor bodiesEngineeringCurie temperature

The invention proposes a method for reusing a motor, wherein after the recovered single kind or plural kinds of motors are separated into rotors and stators, magnets used in the rotors are recovered according to each kind of separated raw materials and the kinds of recycling. The method for reusing a motor comprises periodically heating the rotor cores (2a) of a plurality of motors (1) of different types of magnets (6) composed of a single kind of magnet raw materials (6 ') to a curie temperature corresponding to the type of the magnets (6); and in each stage, maintaining the predetermined time in accordance with the curie temperature corresponding to the magnets (6); and sequentially recycling magnet raw materials (6 ').

Owner:MITSUBISHI MATERIALS CORP

Device for removing wood bits and plastic in building rubbish

PendingCN110743793AFilter up toAvoid emissionsSievingGas current separationArchitectural engineeringStructural engineering

The invention relates to the technical field of building rubbish recycling, and discloses a device for removing wood bits and plastic in building rubbish. The device for removing the wood bits and theplastic in the building rubbish comprises a sorting box, wherein conveyor belts are arranged on two sides of the sorting box; an air box is fixedly connected to the inner left wall of the sorting box; a filter box is fixedly connected to the inner right wall of the sorting box; a storage box is arranged on the inner bottom part of the sorting box; a drive rod is movably connected to the position,located in the air box, on the left inner wall of the sorting box; a first fan is fixedly connected to the right end of the drive rod; a driving wheel is fixedly connected to the position, located inthe air box, on the outer side of the drive rod; and a linkage rod is connected to the inner walls of two sides of the sorting box in a penetrating way. Through the cooperative use between the firstfan and a screen, air blown out by the first fan blows the wood bits and the plastic with lighter mass in the building rubbish to the filter box, and the wood bits and the plastic can be filtered through the screen in the filter box, so that an effect on filtering the wood bits and the plastic in the building rubbish is achieved.

Owner:刘美琴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com