Device and process for refining rare gases of krypton and xenon and producing ultrapure oxygen

A rare gas and production device technology, applied in refrigeration and liquefaction, liquefaction, solidification and other directions, can solve the problems of insufficient oxygen recovery and waste of resources, and achieve the effects of simple structure, sufficient combustion and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

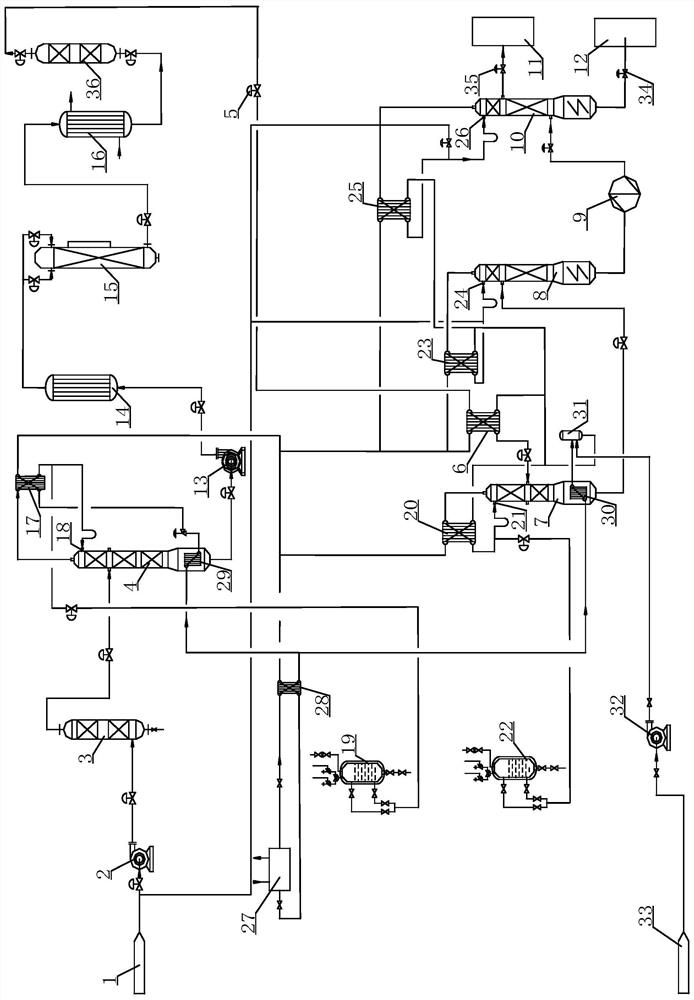

Embodiment 1

[0045] A production device for refining rare gas krypton and xenon and ultra-pure oxygen, comprising a liquid oxygen storage tank 1, the liquid oxygen storage tank 1 is connected to a primary concentration tower 4 through a liquid oxygen pump 2 and a low-temperature adsorption tower 3; the primary concentration The outlet of the liquid phase at the bottom of tower 4 is connected to the catalytic oxidation system with a high-pressure throttle valve 5 at the end; 8 and the gas heating device 9 are connected with the krypton-xenon separation tower 10 for storing and separating krypton-xenon, the bottom of the krypton-xenon separation tower 10 is connected with the xenon filling system 12 through the first valve 34, and the middle and upper part of the krypton-xenon separation tower 10 is passed through The second valve 35 is connected to the krypton filling system 11 . The catalytic oxidation system includes a high-pressure liquid oxygen pump 13, which is connected to a water-bat...

Embodiment 2

[0059]A production device for refining rare gas krypton and xenon and ultra-pure oxygen, comprising a liquid oxygen storage tank 1, the liquid oxygen storage tank 1 is connected to a primary concentration tower 4 through a liquid oxygen pump 2 and a low-temperature adsorption tower 3; the primary concentration The outlet of the liquid phase at the bottom of tower 4 is connected to the catalytic oxidation system with a high-pressure throttle valve 5 at the end; 8 and the gas heating device 9 are connected with the krypton-xenon separation tower 10 for storing and separating krypton-xenon, the bottom of the krypton-xenon separation tower 10 is connected with the xenon filling system 12 through the first valve 34, and the middle and upper part of the krypton-xenon separation tower 10 is passed through The second valve 35 is connected to the krypton filling system 11 . The catalytic oxidation system includes a high-pressure liquid oxygen pump 13, which is connected to a water-bath...

Embodiment 3

[0073]A production device for refining rare gas krypton and xenon and ultra-pure oxygen, comprising a liquid oxygen storage tank 1, the liquid oxygen storage tank 1 is connected to a primary concentration tower 4 through a liquid oxygen pump 2 and a low-temperature adsorption tower 3; the primary concentration The outlet of the liquid phase at the bottom of tower 4 is connected to the catalytic oxidation system with a high-pressure throttle valve 5 at the end; 8 and the gas heating device 9 are connected with the krypton-xenon separation tower 10 for storing and separating krypton-xenon, the bottom of the krypton-xenon separation tower 10 is connected with the xenon filling system 12 through the first valve 34, and the middle and upper part of the krypton-xenon separation tower 10 is passed through The second valve 35 is connected to the krypton filling system 11 . The catalytic oxidation system includes a high-pressure liquid oxygen pump 13, which is connected to a water-bath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com