Patents

Literature

30results about How to "Realize graded recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

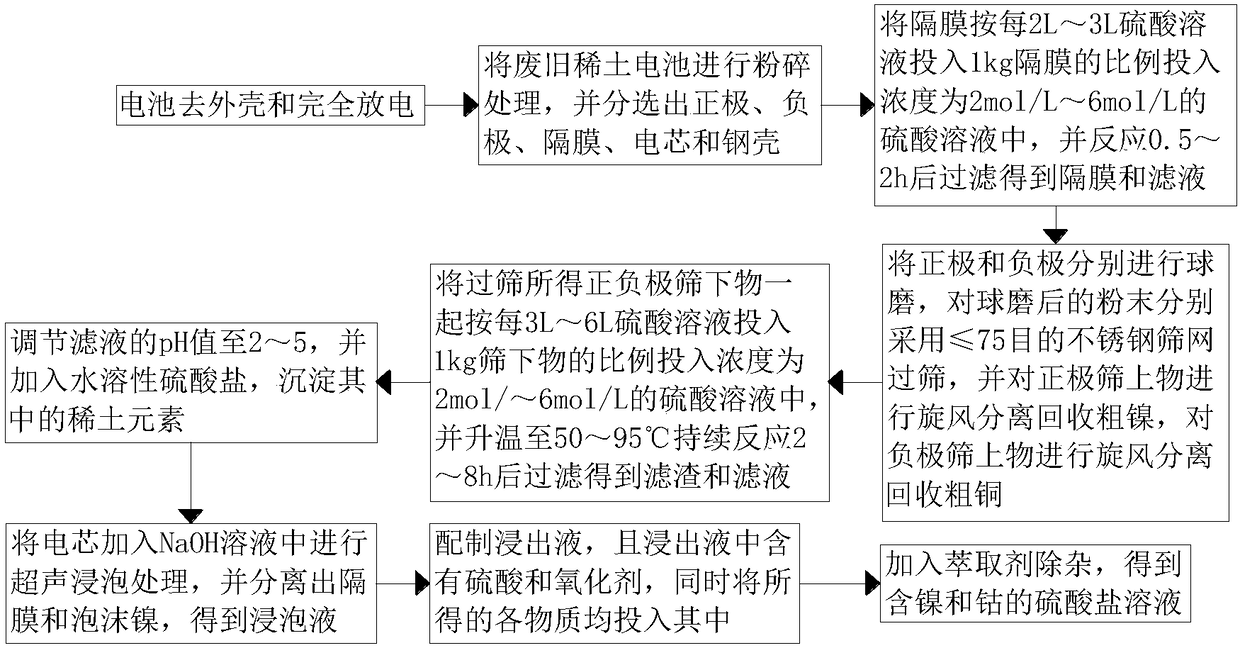

Comprehensive recovery method of waste rare earth batteries

InactiveCN108588423ARealize graded recyclingAchieve separationWaste accumulators reclaimingProcess efficiency improvementRecovery methodChemical reaction

The invention discloses a comprehensive recovery method of waste rare earth batteries. The recovery method comprises the following steps that A, outer shells of the batteries are removed, and the batteries completely discharge; B, the waste rare-earth batteries are subjected to crushing treatment, and positive poles, negative poles, diaphragms, battery cores and steel shells are separated out; andC, the diaphragms are put into a sulfuric acid solution with the concentration of 2 mol / L to 6 mol / L according to the proportion that 1 kg of the diaphragms are put into 2 L to 3 L of the sulfuric acid solution, further a reaction is carried out for 0.5-2 hours, and then filtering is carried out to obtain the diaphragms and a filtrate. According to the comprehensive recovery method of the waste rare earth batteries, crude copper, crude nickel and other valuable substances are separated from positive and negative pole pieces through a physical method, furthermore, classification recovery of battery parts and battery materials is realized, separation and reutilization of rare earth and cobalt are realized, meanwhile, the using amount of chemical reaction reagents is reduced in the whole process, the reaction time is shortened, energy consumption is reduced, the technology is simple, the recovery rate is high, a foundation is established for the dynamic storage of rare resources such asthe rare earth and the nickel, and furthermore, the method is low in cost and obvious in economic benefit.

Owner:ANHUI HAIRONG POWER SOURCE

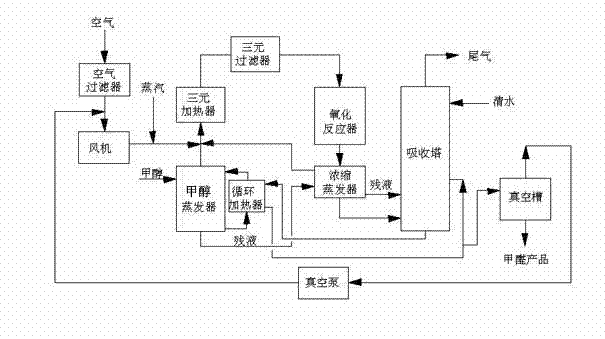

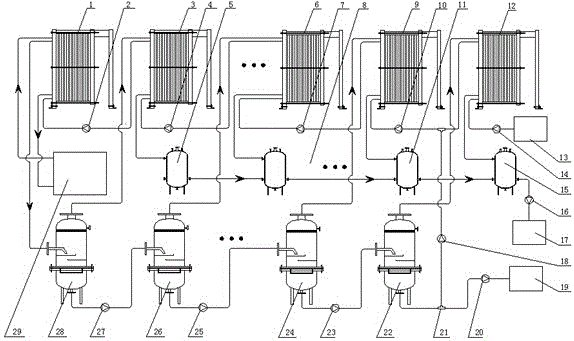

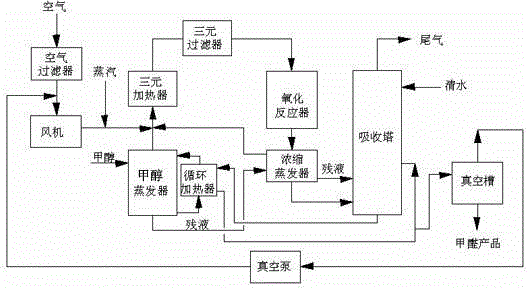

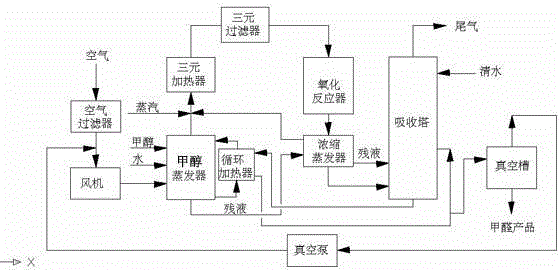

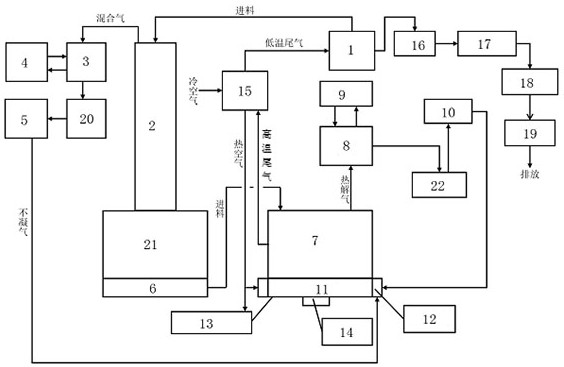

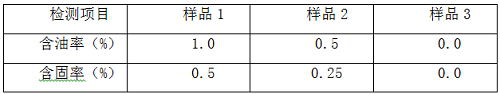

Method and device for reducing methanol content in formaldehyde process by silver method

ActiveCN103086854ANo backmixingReduce loadOrganic compound preparationChemical industryEnvironmental resistanceFormox process

The invention relates to a method and a device for reducing methanol content in a formaldehyde process by a silver method, and belongs to the technical field of chemical production. The technical scheme is that the method comprises the following steps of: after thermally recovering and cooling a formaldehyde liquid at the bottom of an absorption tower in the formaldehyde process by the silver method, extracting and feeding part of the formaldehyde liquid to a vacuum groove; conveying gas analyzed at the top of the vacuum groove to an inlet of an air fan; arranging a concentration evaporator between the outlet of an oxidation reactor and the inlet of the absorption tower; evaporating and condensing residual liquid of the evaporator by reaction waste heat at 90-110 DEG C; evaporating methanol in the residual liquid with water; recovering mixed gas of vapor and methanol steam to material gas; and recovering methanol which is less than 0.5% in percentage by weight in the condensed residual liquid to the absorption tower. According to the invention, the inlet temperature of the absorption tower is reduced, while the heat recovery efficiency of the system is improved. The load of a water cooler of the absorption tower is reduced, and the consumption of cooling water is reduced, so that the residual liquid is recovered in grades by 100%, and methanol recovered is free from backmixing, therefore, the energy-saving, consumption reducing and environmental protecting purposes are realized.

Owner:HEBEI KAIYUE CHEM GROUP

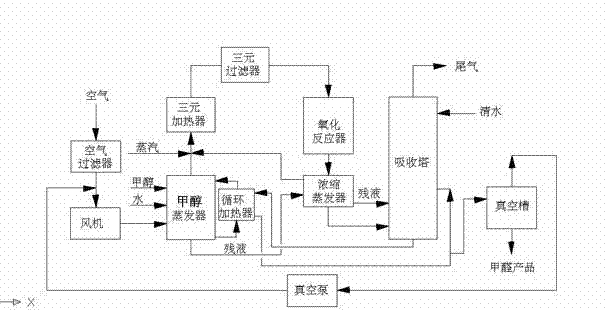

A method for producing concentrated brine from sea salt

ActiveCN107954528BRealize graded reuseReduce graded reuseSemi-permeable membranesGeneral water supply conservationSaline waterWater flow

The invention provides a brine concentration method for sea salt production and belongs to the technical field of sea salt production. The method comprises steps as follows: seawater enters a pretreatment device for removal of impurities and enters a nanofiltration device for removal of divalent ions, nanofiltration producing water enters a multi-stage high-pressure reverse osmosis device for highconcentration, and high-concentration saline water is prepared; part of high-pressure reverse osmosis producing water is subjected to low-pressure reverse osmosis for preparation of pure water, and the other part of water flows back to a seawater desalting plant. The multi-stage high-pressure reverse osmosis device is formed through series connection of high-pressure reverse osmosis membrane groups in a form of continuous section groups, producing water of each section of the high-pressure reverse osmosis membrane groups flows back for use or enters a pure water preparation process, concentrated water of each section of the high-pressure reverse osmosis membrane groups enters the downstream high-pressure reverse osmosis membrane groups, the purpose of high concentration is finally achieved through continuous series connection, and strong brine is prepared. According to the method, more efficient concentration is realized, factory brine preparation is realized, the tedding area for salt making is greatly reduced, graded reuse of producing water is realized, utilization efficiency of the producing water is improved, and treatment cost is reduced.

Owner:山东省盐业集团有限公司

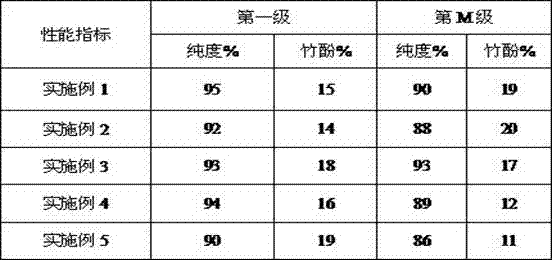

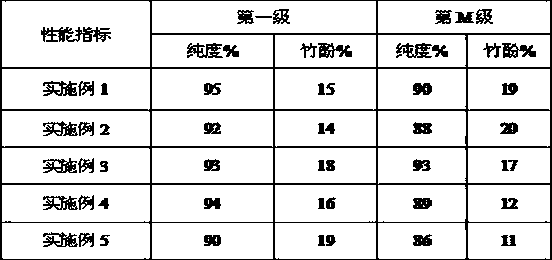

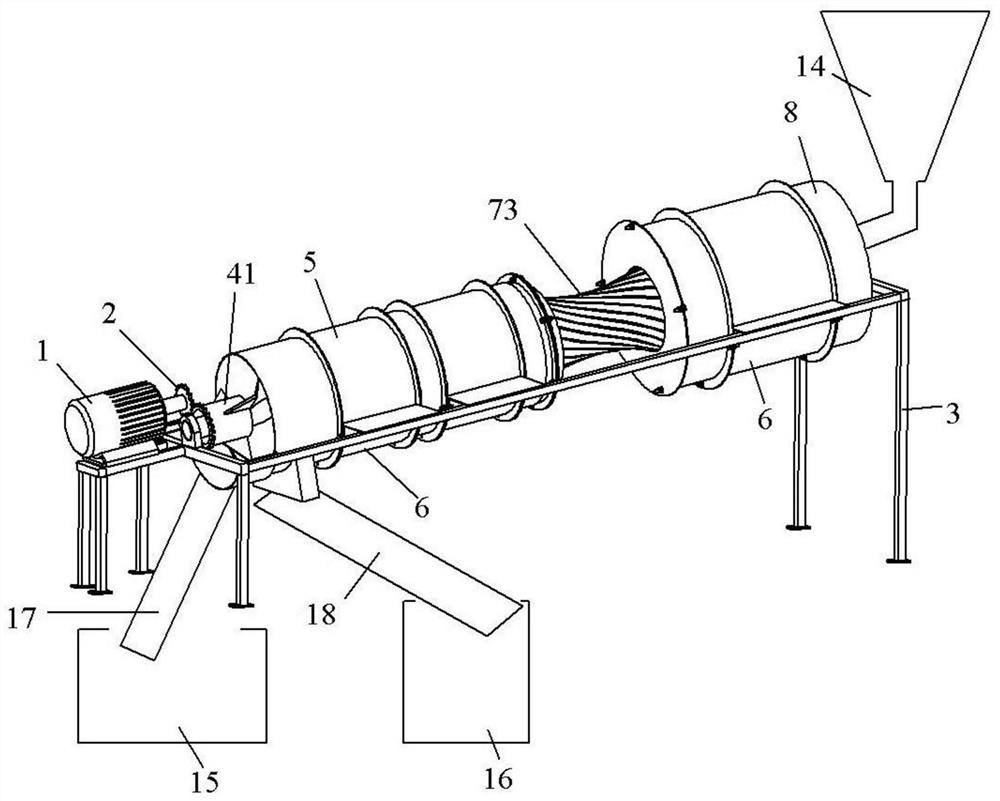

Method for co-preparation of bamboo activated carbon, bamboo vinegar and bamboo tar

The invention provides a method for co-preparation of bamboo activated carbon, bamboo vinegar and bamboo tar. The method for co-preparation of the bamboo activated carbon, the bamboo vinegar and the bamboo tar takes bamboo wood as raw materials, and through multi-stage machining of a three-stage conical screw extruder, achieves graded recovery of by products of the bamboo vinegar and the bamboo tar and overcomes the technical defect in the prior art that, due to difference in technical conditions, collecting methods and processing methods, obtained bamboo vinegar and bamboo tar are large in quality discrepancy and incapable of achieving effective separation and purification. Therefore, the method for co-preparation of the bamboo activated carbon, the bamboo vinegar and the bamboo tar achieves graded recovery of the by-products of the bamboo vinegar and the bamboo tar, obtains the bamboo vinegar and the bamboo tar of different grades and greatly improves the value added of the by-products of bamboo activated carbon production.

Owner:浙江富来森能源科技有限公司

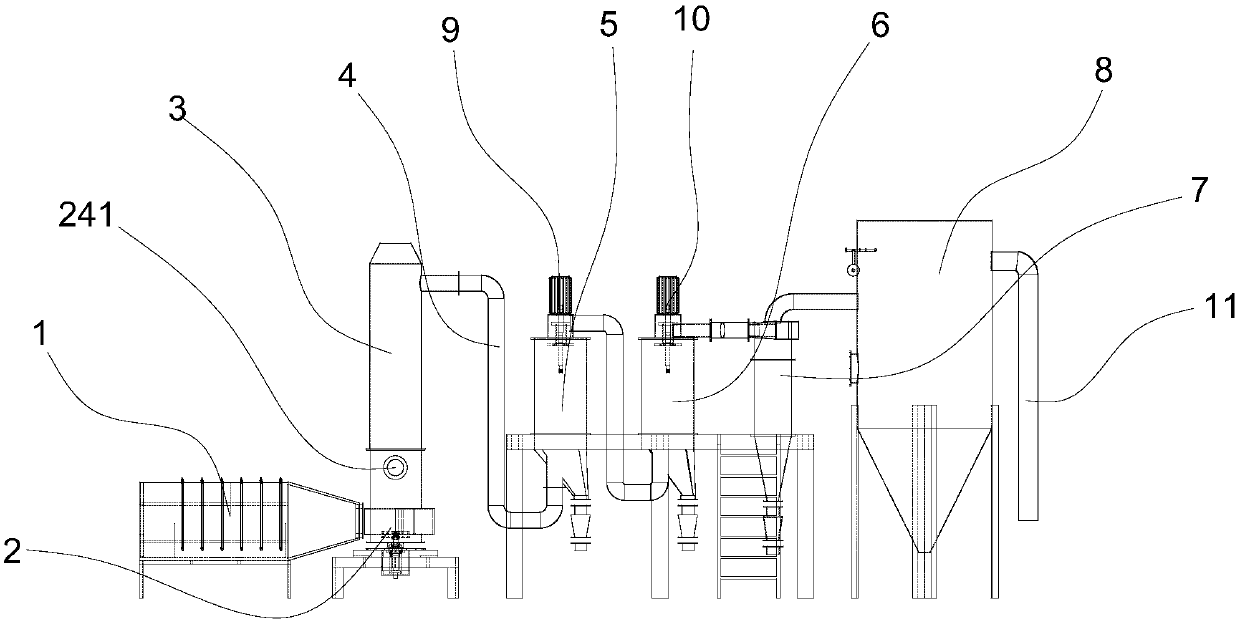

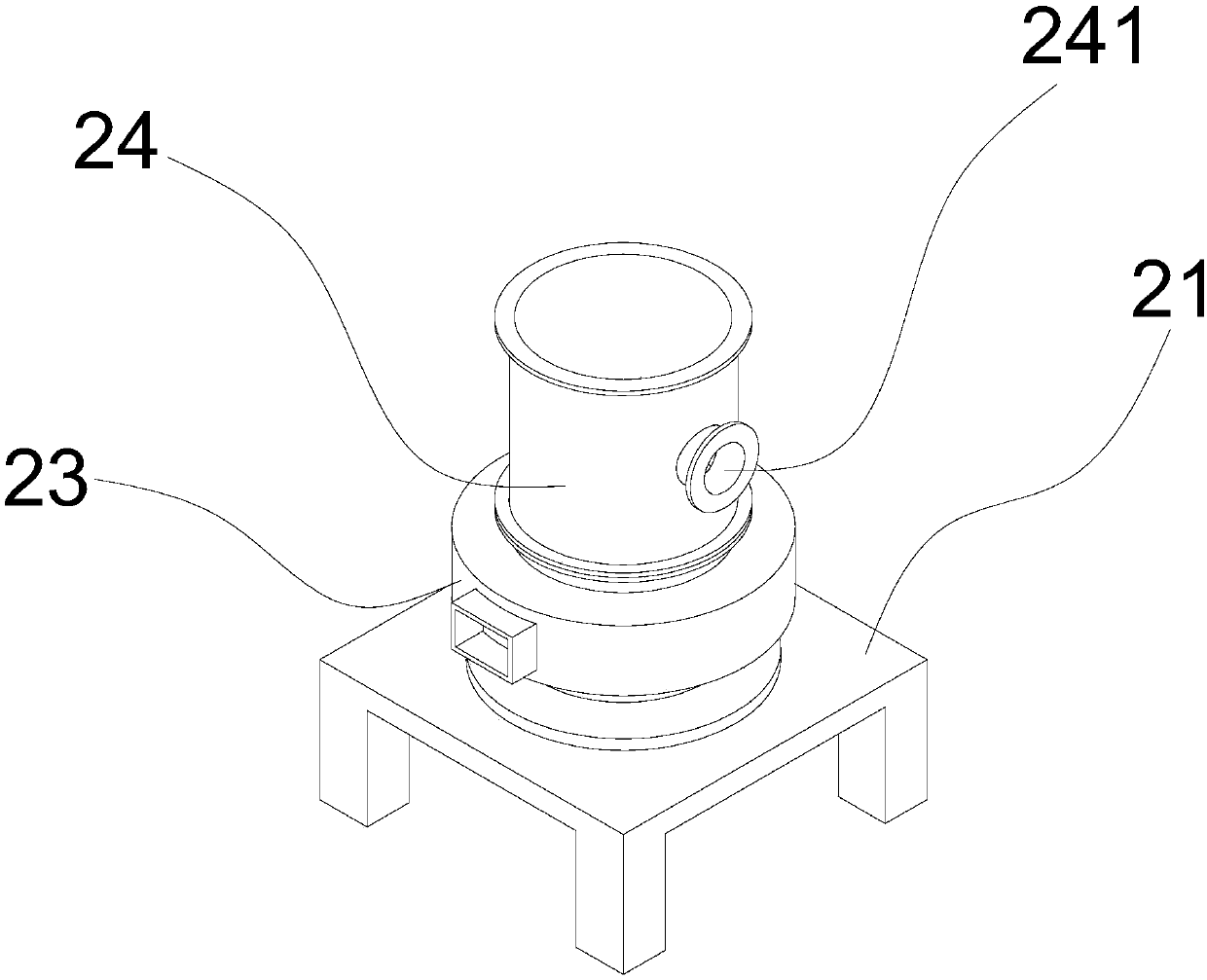

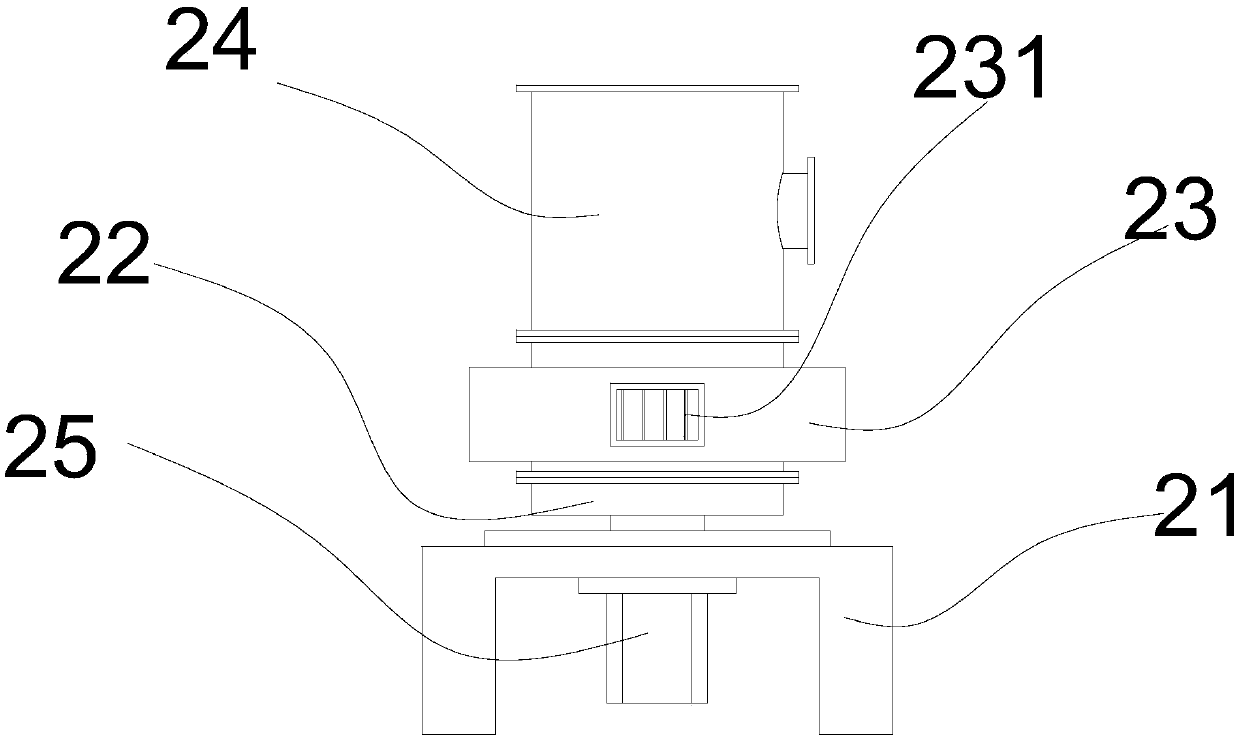

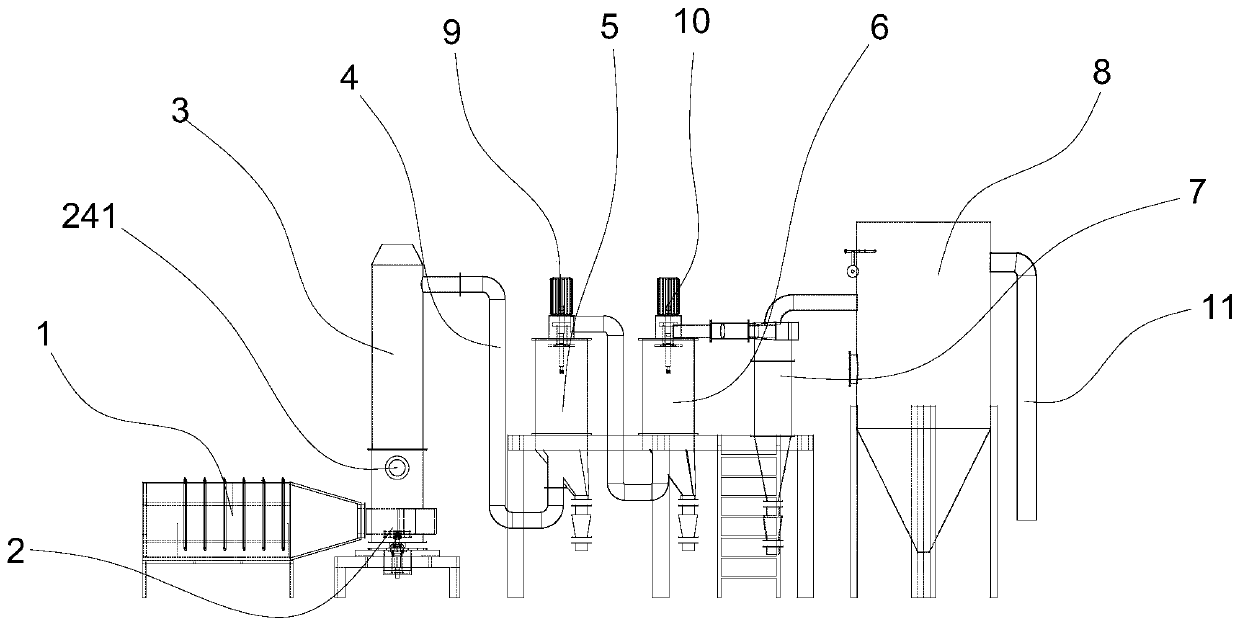

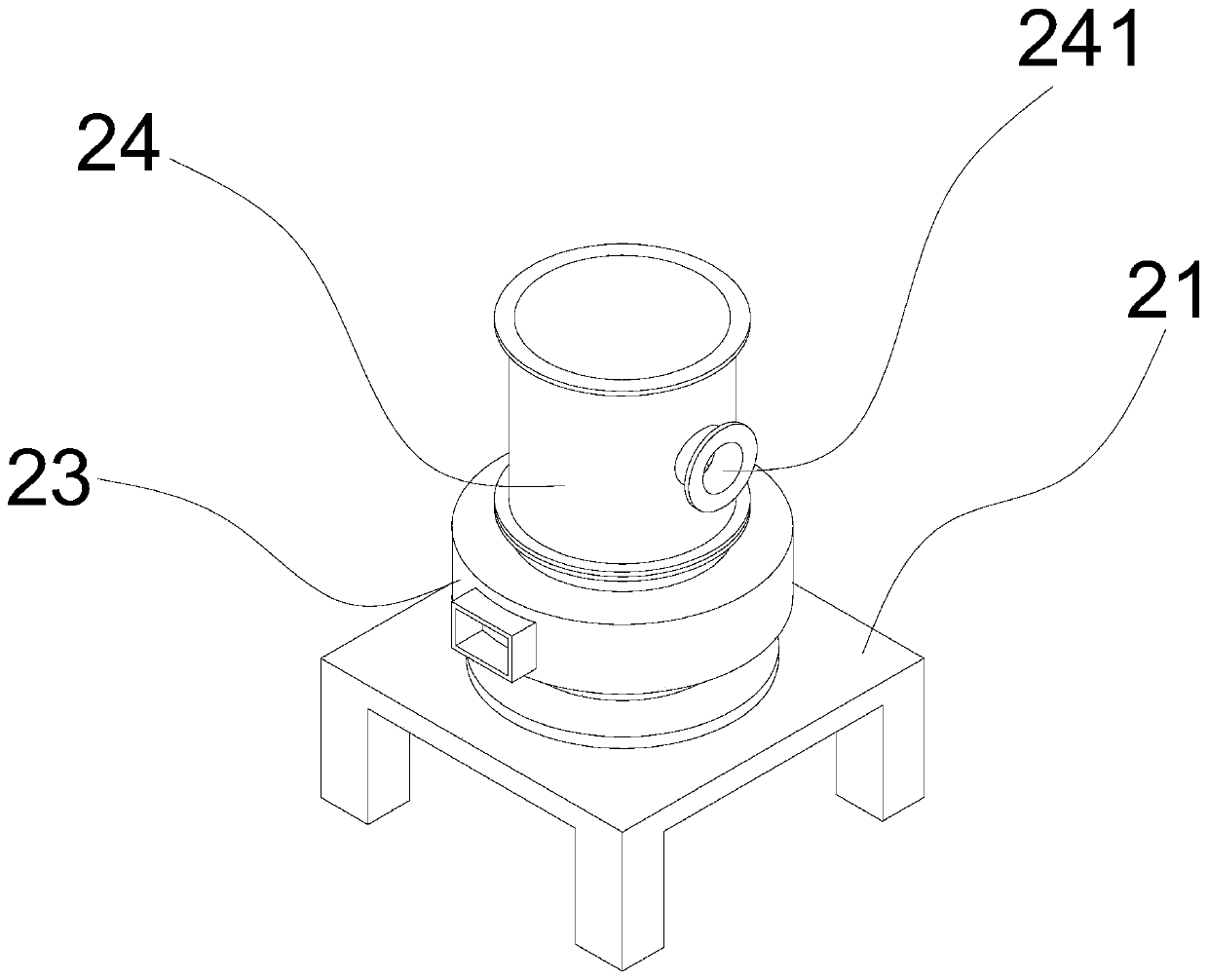

Silicon material scattering and recycling system

ActiveCN107930772AGuaranteed recyclingGuaranteed to clearGrain treatmentsMaterial scatteringMegasonic cleaning

The invention discloses a silicon material scattering and recycling system. The silicon material scattering and recycling system is capable of realizing graded recovery of crushed silicon material, the recycled silicon material particles are guaranteed to be small, and impurities are removed thoroughly after the silicon material is recycled. The silicon material scattering and recycling system comprises a hot air tank, a scattering machine, an air outlet barrel, a connecting pipeline, a first material collecting tank, a first fan, a second material collecting tank, a second fan, a cyclone separator and a third material collecting tank communicating with one another in sequence. According to the silicon material scattering and recycling system, the crushed silicon material is scattered by the arranged scattering machine, then four-stage powder separation is realized through the first material collecting tank, the second material collecting tank, the cyclone separator and the third material collecting tank so that the crushed waste silicon material can be classified and recycled, the received silicon material powder particles are guaranteed to be small enough, and therefore alkali washing and ultrasonic cleaning in the follow-up process steps can be guaranteed to remove the waste silicon material impurities, recycling of the waste silicon material can further be ensured, and theproduct quality is further improved.

Owner:LESHAN TOPRAYCELL

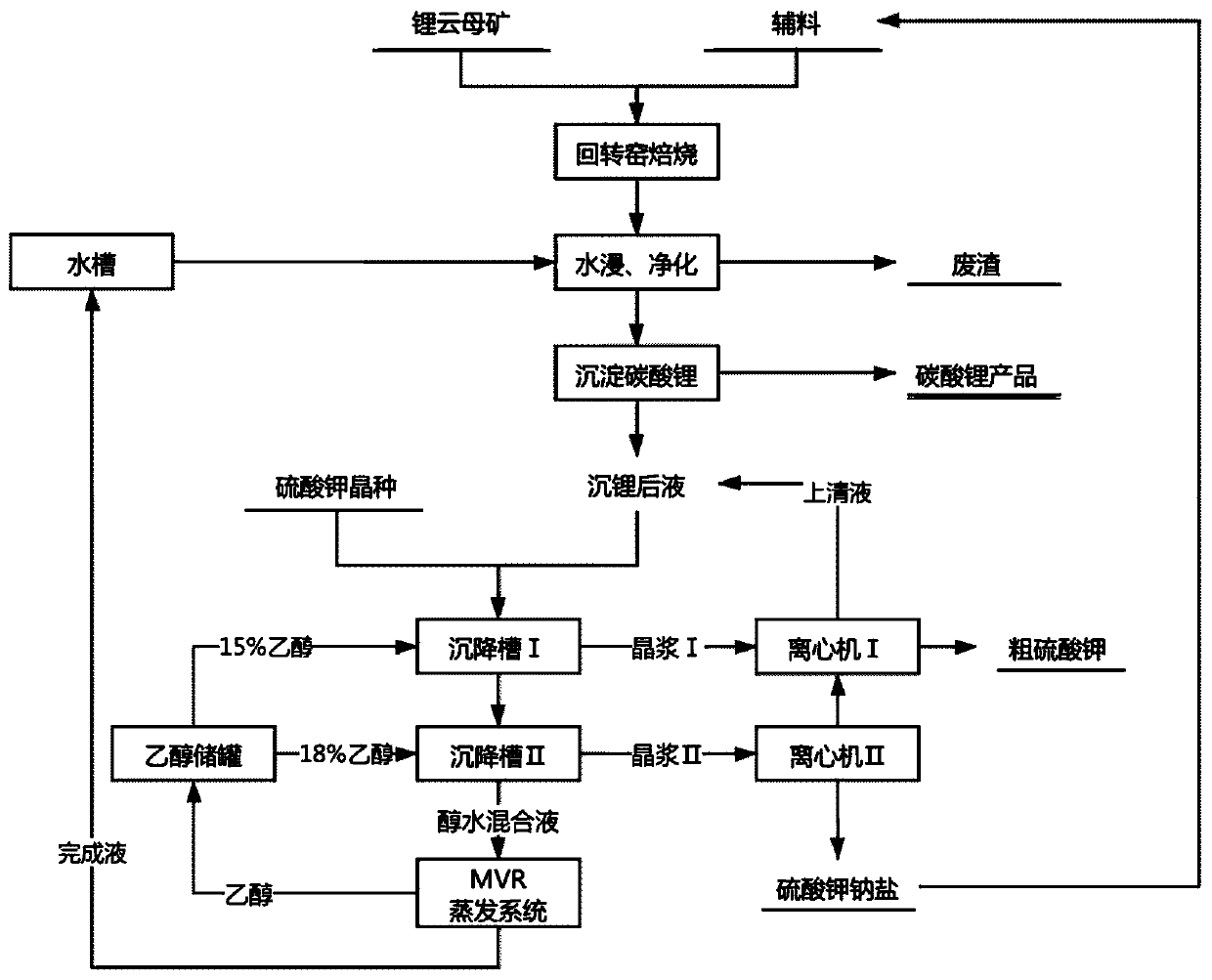

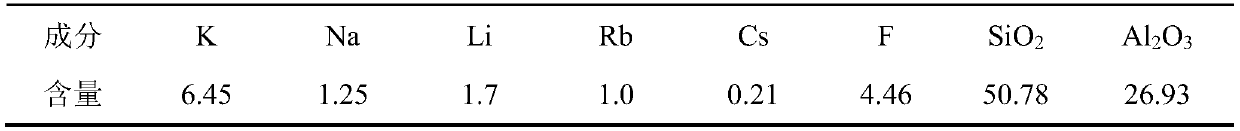

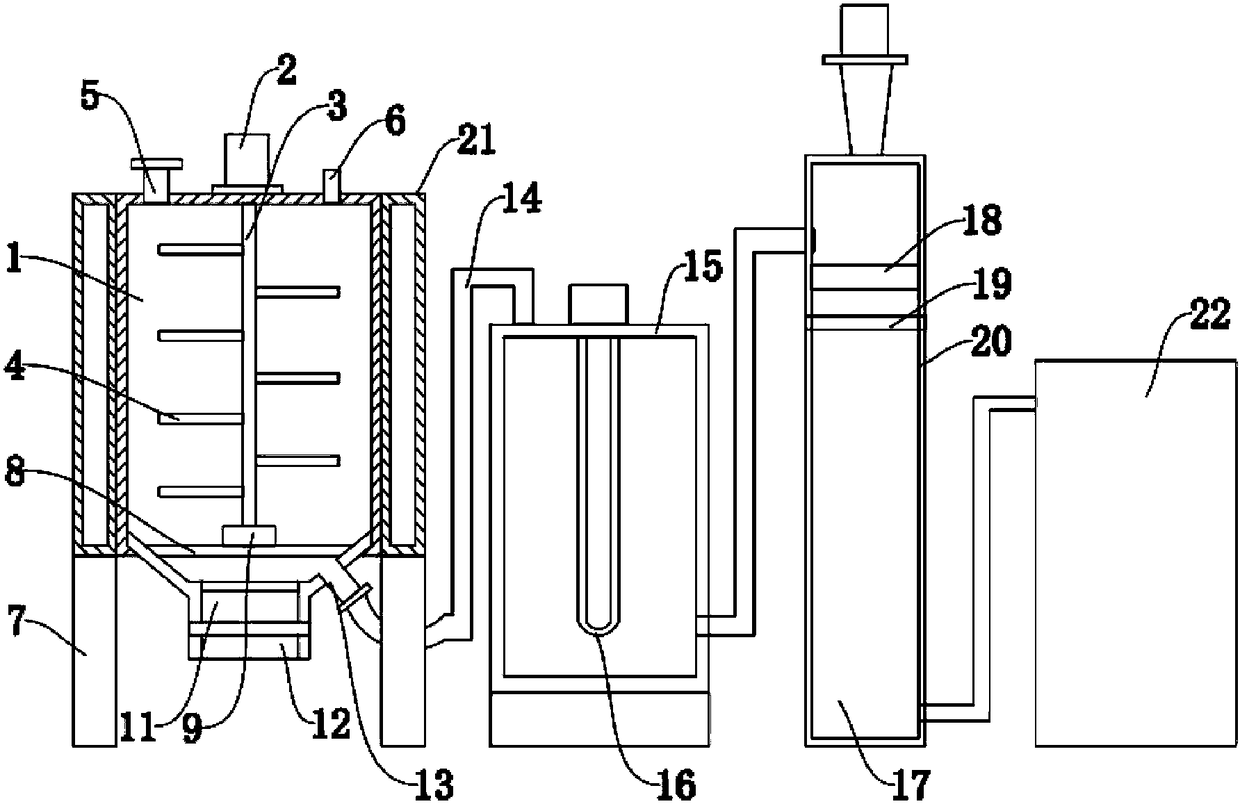

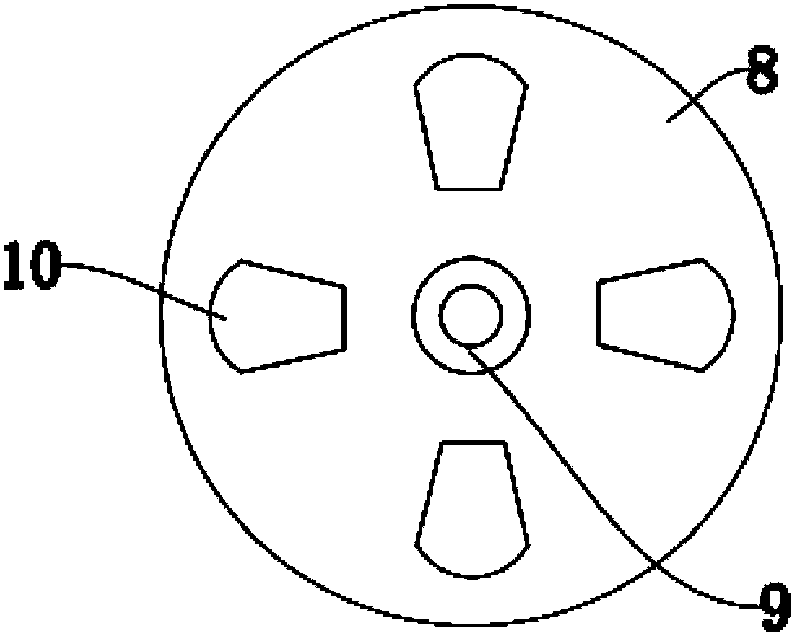

Technology for recycling potassium and sodium salts from lithium-precipitated liquid of lepidolite by means of ethanol

PendingCN110923452AReduce energy consumptionEasy to industrializeProcess efficiency improvementLithium carbonateIndustrial water treatment

The invention relates to a technology for recycling potassium and sodium salts from lithium-precipitated liquid of lepidolite by means of ethanol, and belongs to the technical field of industrial water treatment. The technology comprises the technological steps of ore roasting, water leaching, purifying, lithium carbonate precipitating, lithium-precipitated mother liquid and ethanol mixing sedimentation, induced crystallization, centrifugal separation of crystal magma, MVR evaporation separation of ethanol-water mixed liquid and the like. According to the technology, classified recycling of the potassium and sodium salts and cyclic utilization of ethanol and water are achieved by adding ethanol with different volumes and potassium sulfate seed crystals according to the characteristics thatpotassium sulfate and potassium and sodium sulfate salts are supersaturated to be separated out and lithium sulfate is not separated out through the salting-out effect of ethanol, and the technologyhas the advantages of being low in energy consumption, environmentally friendly, efficient and easy to industrialize.

Owner:CENT SOUTH UNIV +1

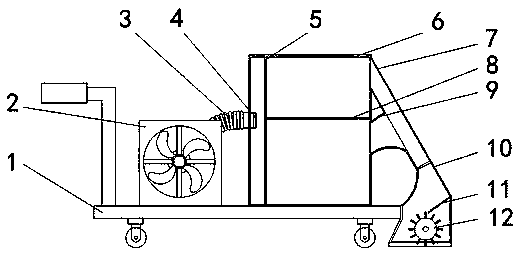

Used lubricating oil recycling device

PendingCN108465292AStir wellWell mixedEvaporator accessoriesFiltration circuitsEngineeringStorage tank

The invention discloses a used lubricating oil recycling device. The device comprises a tank, wherein a first motor is mounted above the tank, a stirring rod is connected to an output end of the firstmotor, a casing is welded to the outer side of the tank in a sealed manner, a vacuum layer is arranged between the casing and the tank, a filter box is connected below the tank, a support plate is welded fixedly above the filter box, openings are formed in the support plate, a bearing block is fixedly connected to the middle above the support plate, an emptying port is connected below the conicalfilter box, the filter box is connected with an oil outlet in one side of the emptying port, the other end of the oil outlet is connected with an intermediate box through a connecting pipe, the otherside of the intermediate box is connected with a film evaporator through a pipeline, and one side of the film evaporator is connected with an oil storage tank. The used lubricating oil recycling device is reasonable in design, recycling of used lubricating oil is convenient to realize, and the device is worth spreading.

Owner:东营市安凯石油化工有限公司

Device and process for refining rare gases of krypton and xenon and producing ultrapure oxygen

PendingCN111692838AReduce usageLower acquisition costsSolidificationLiquefactionKryptonCatalytic oxidation

The invention belongs to a device and a process for refining rare gases of krypton and xenon and producing ultrapure oxygen. The device comprises a liquid oxygen storage tank; the liquid oxygen storage tank is connected with a primary concentration tower through a liquid oxygen pump and a low-temperature adsorption tower; a tower bottom liquid phase outlet of the primary concentration tower is connected with a catalytic oxidation system with a high pressure throttle valve at the tail end; the high pressure throttle valve is connected to a krypton-xenon separation tower used for storing and separating krypton from xenon through a pipe side of a return cooler, a secondary concentration tower, a krypton-xenon deoxygenation tower, and a gas heating device in sequence; the bottom of the krypton-xenon separation tower is connected to an xenon charging system through a first valve; and the middle-upper part of the krypton-xenon separation tower is connected to a krypton charging system through a second valve. The device and the process for refining the rare gases of the krypton and the xenon and producing the ultrapure oxygen has the advantages of simple structure, reasonable flow design,relatively low cost, safe operation, high yield, high purity of the rare gases, economical efficiency, wide application range, and capacity of effectively classifying and recycling oxygen on the premise of preparing the krypton and the xenon.

Owner:HENAN XINLIANXIN SHENLENG ENERGY

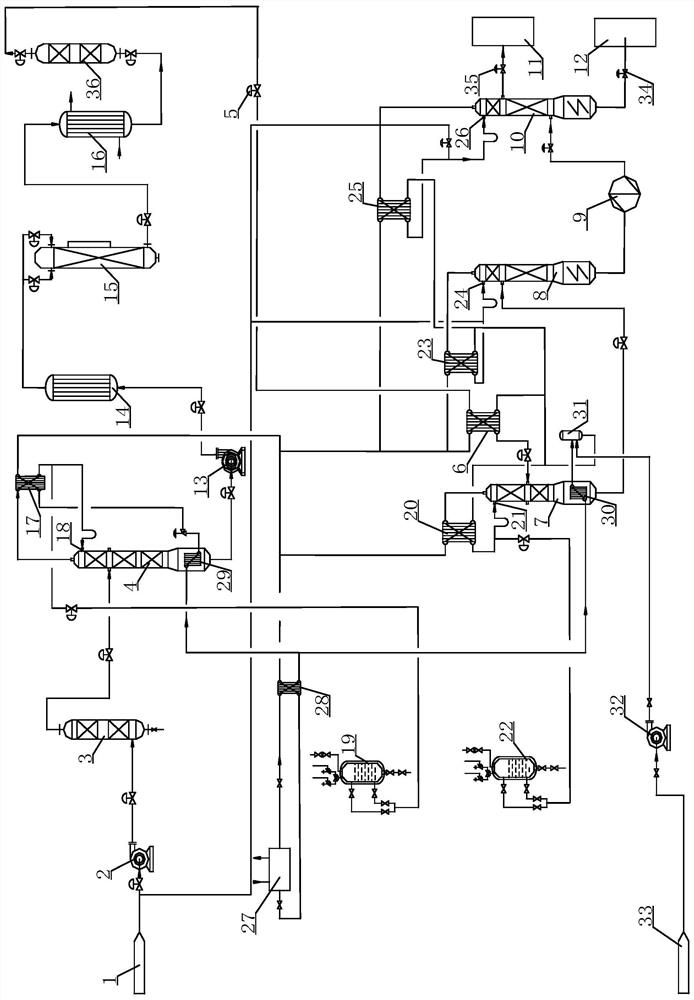

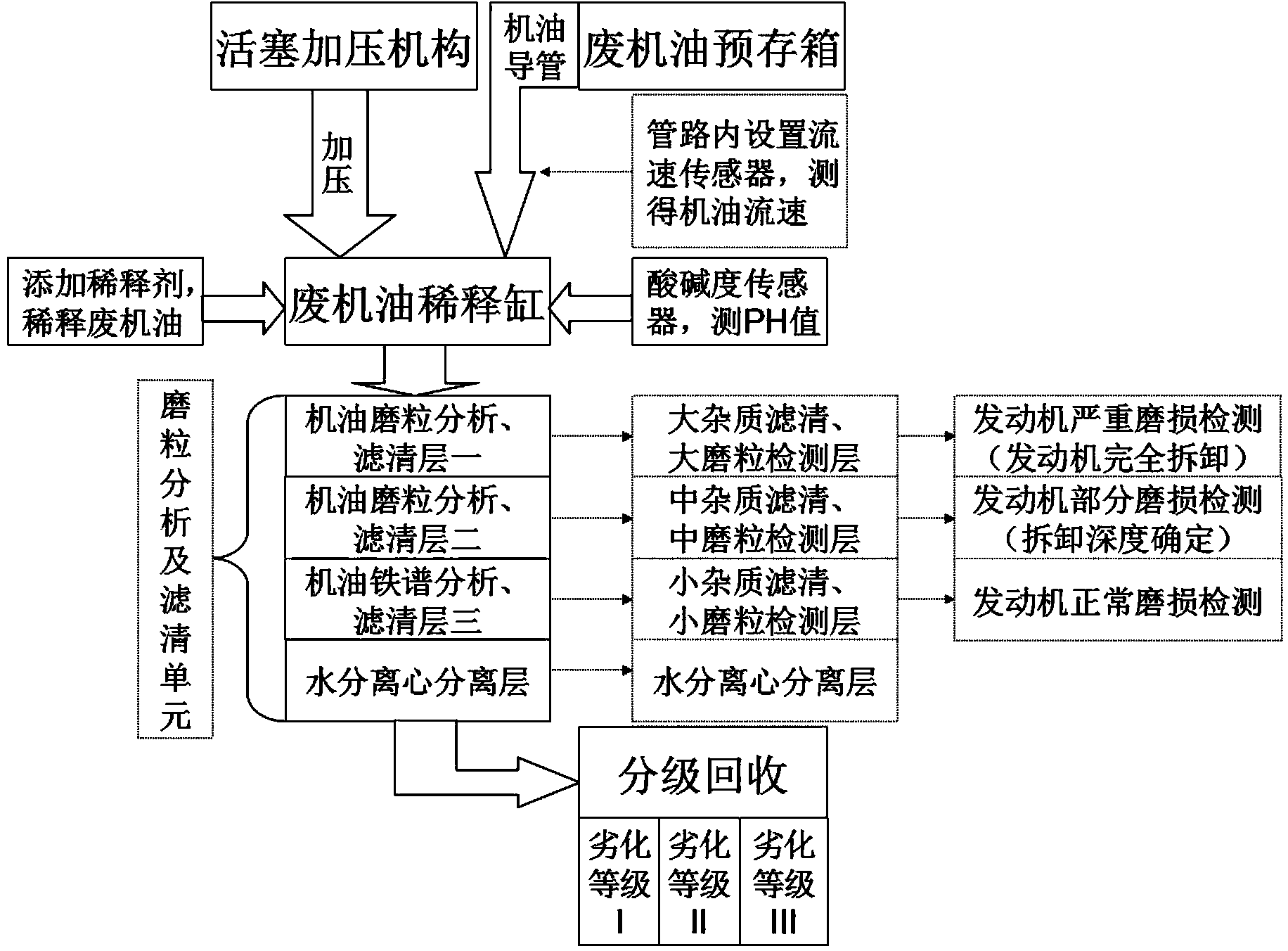

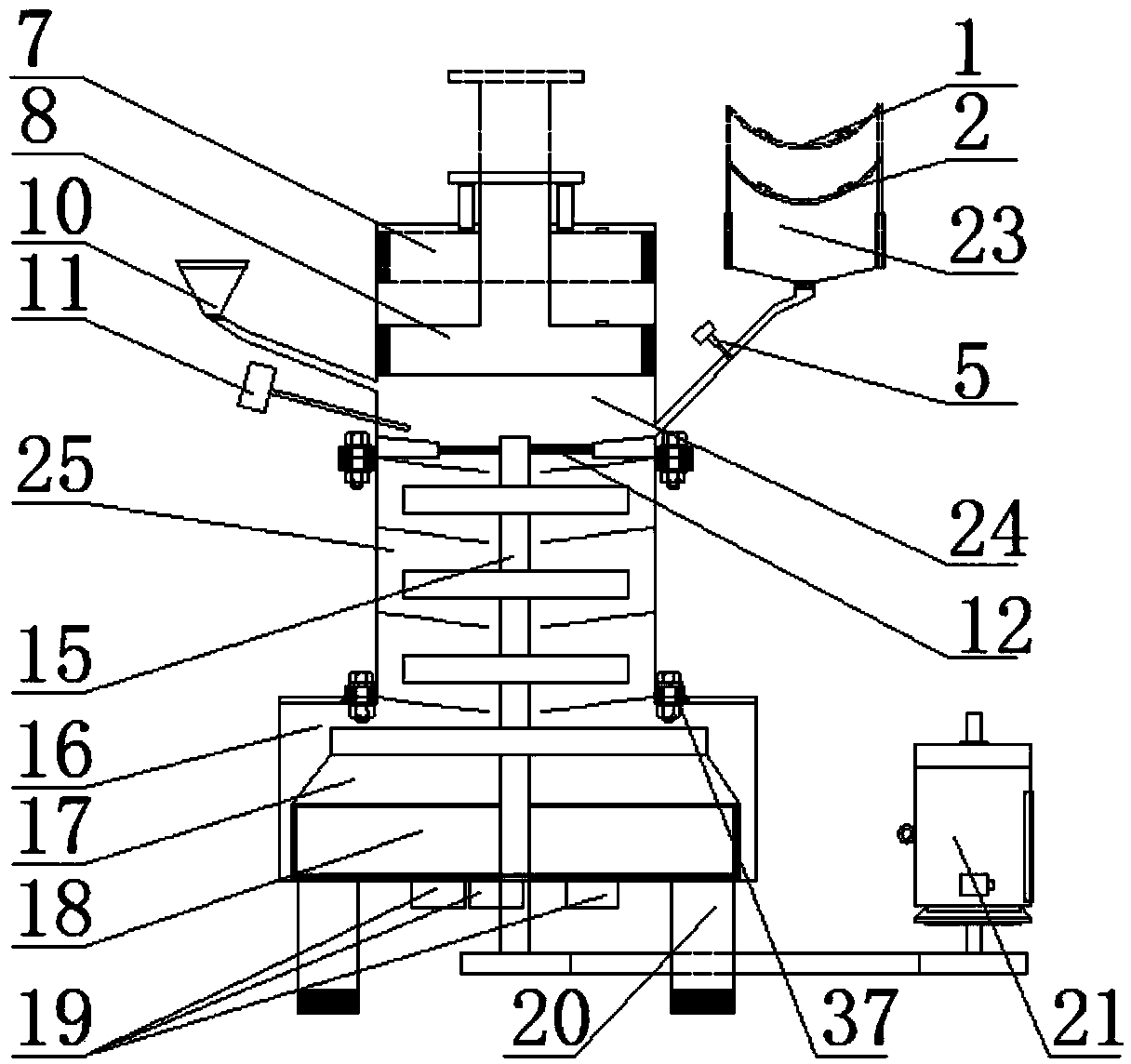

Engine oil recovery and pretreatment device of vertical retired passenger car

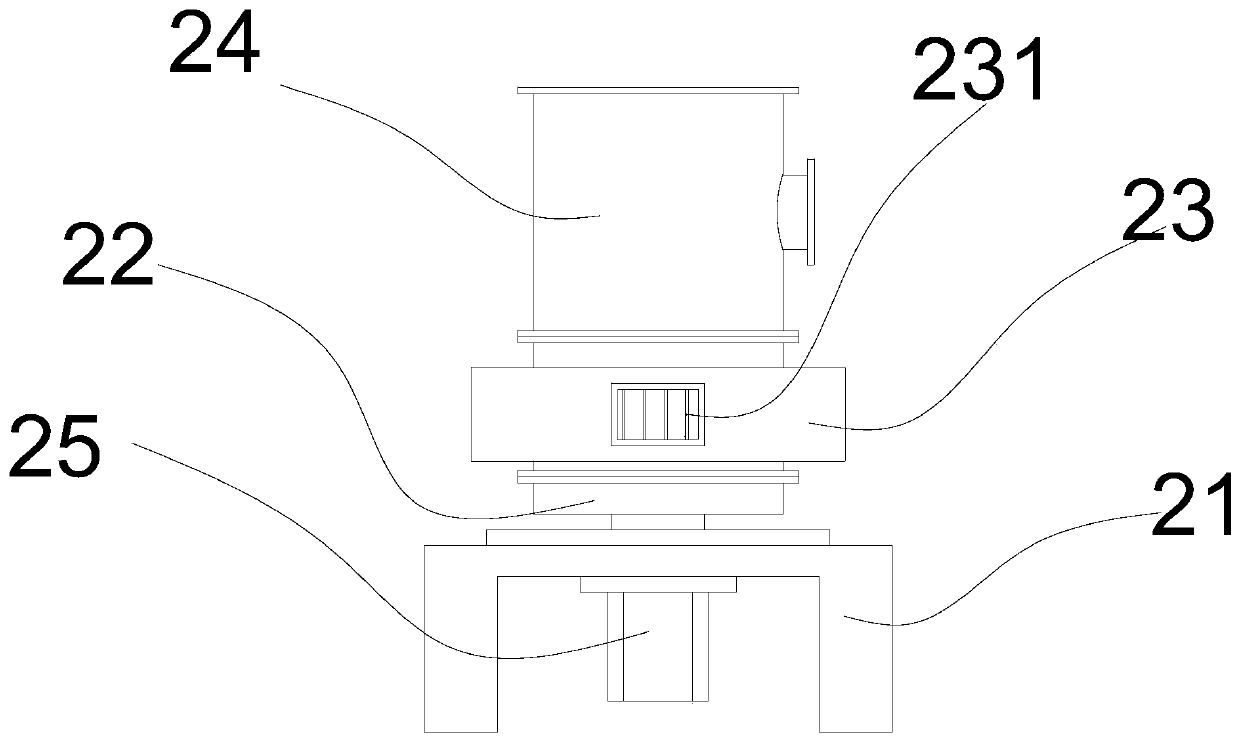

ActiveCN103710132AHigh feasibilityImprove efficiencyLubricant compositionDrive shaftChemical property

The invention discloses an engine oil recovery and pretreatment device of a vertical retired passenger car. The engine oil recovery and pretreatment device comprises a physical and chemical property detection unit, an abrasive particle analyzing and filtering unit and a grading recovery unit, wherein the physical and chemical property detection unit is composed of a waste engine oil deposit tank (23) and a waste engine oil diluting cylinder (24) which is communicated with the waste engine oil deposit tank (23) through a conduit; the abrasive particle analyzing and filtering unit is composed of an abrasive particle analyzing and filtering cylinder (25) and a drive shaft (15); the grading recovery unit is composed of a centrifugal separating cover (16), and a waste engine oil grading recovery cylinder (18) embedded at the bottom of the separating cover through a locating round slot (51); a plurality of abrasive particle analyzing and filtering rotary layers (13) driven by the drive shaft are arranged inside the abrasive particle analyzing and filtering cylinder; a centrifugal separating layer (34) driven by the drive shaft is arranged at the bottom; annular drainage baffles (14) are distributed at the periphery of the abrasive particle analyzing and filtering cylinder; the abrasive particle analyzing and filtering cylinder is arranged at the lower end of the waste engine oil diluting cylinder; and the upper part of the centrifugal separating cover is connected with the bottom of the abrasive particle analyzing and filtering cylinder. The engine oil recovery and pretreatment device has the advantages of being simple in structure, good in practicability, significant in filtering and recovering effects and the like.

Owner:WUHAN UNIV OF TECH

A kind of coproduction prepares the method for bamboo activated carbon and bamboo vinegar liquid, bamboo tar

ActiveCN107416826BRealize graded recyclingIncrease added valueCarbon compoundsBiofuelsActivated carbonThree stage

The invention provides a method for co-preparation of bamboo activated carbon, bamboo vinegar and bamboo tar. The method for co-preparation of the bamboo activated carbon, the bamboo vinegar and the bamboo tar takes bamboo wood as raw materials, and through multi-stage machining of a three-stage conical screw extruder, achieves graded recovery of by products of the bamboo vinegar and the bamboo tar and overcomes the technical defect in the prior art that, due to difference in technical conditions, collecting methods and processing methods, obtained bamboo vinegar and bamboo tar are large in quality discrepancy and incapable of achieving effective separation and purification. Therefore, the method for co-preparation of the bamboo activated carbon, the bamboo vinegar and the bamboo tar achieves graded recovery of the by-products of the bamboo vinegar and the bamboo tar, obtains the bamboo vinegar and the bamboo tar of different grades and greatly improves the value added of the by-products of bamboo activated carbon production.

Owner:浙江富来森竹炭有限公司

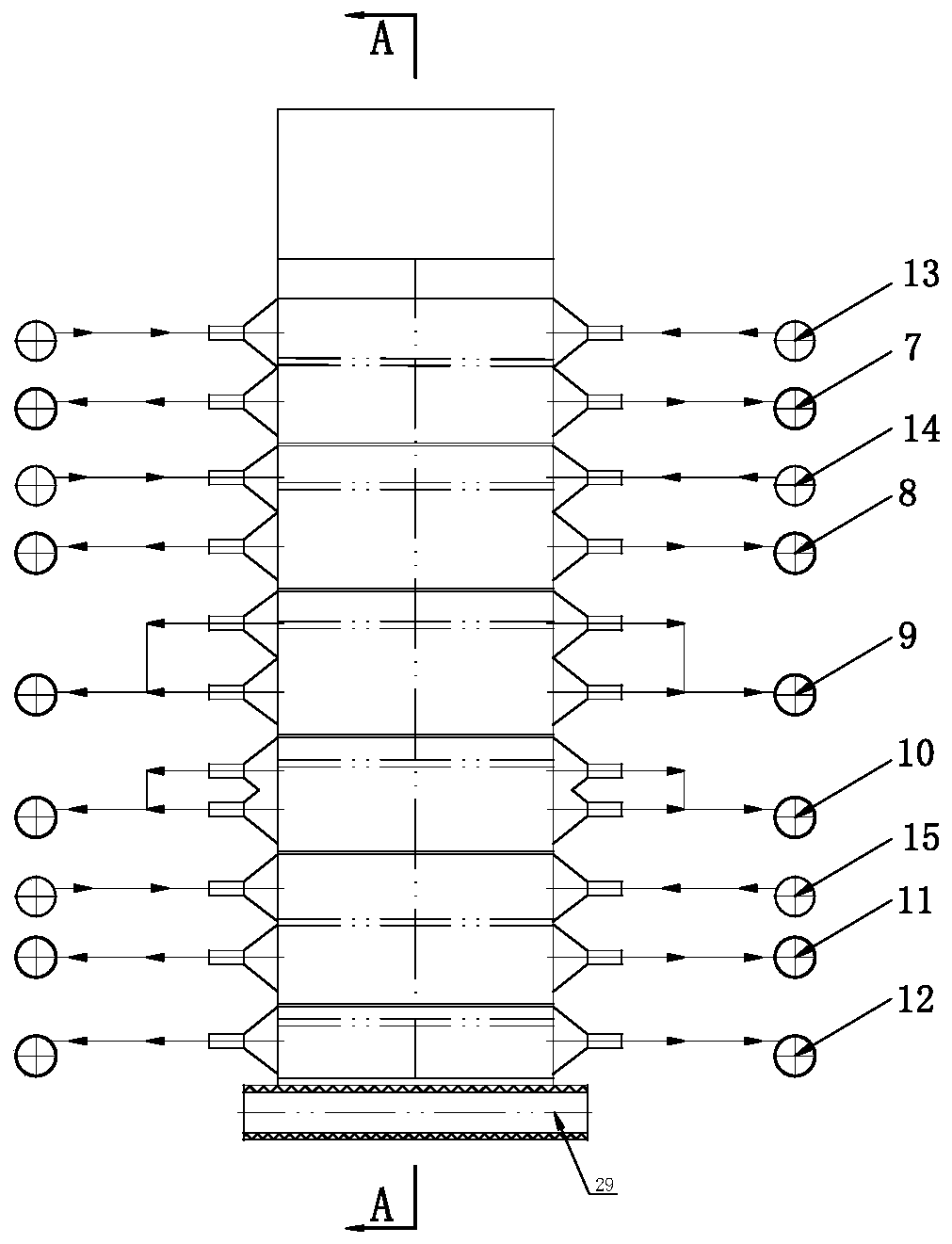

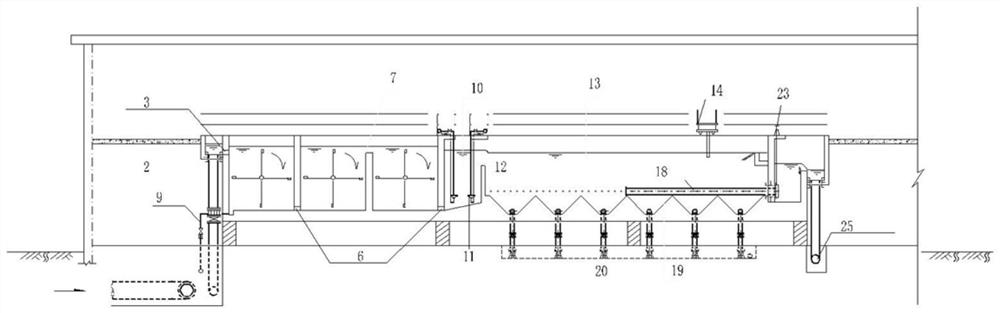

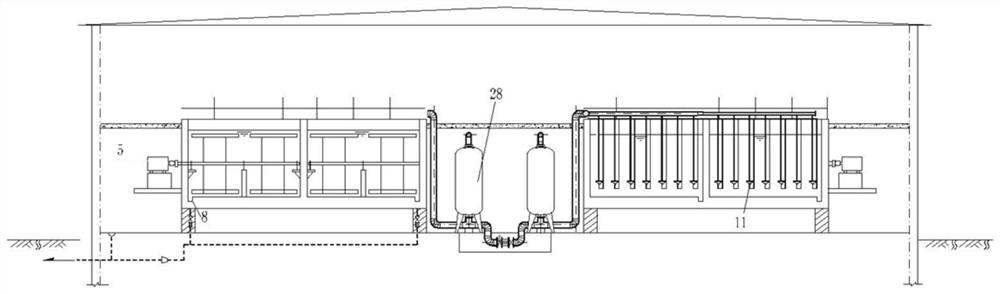

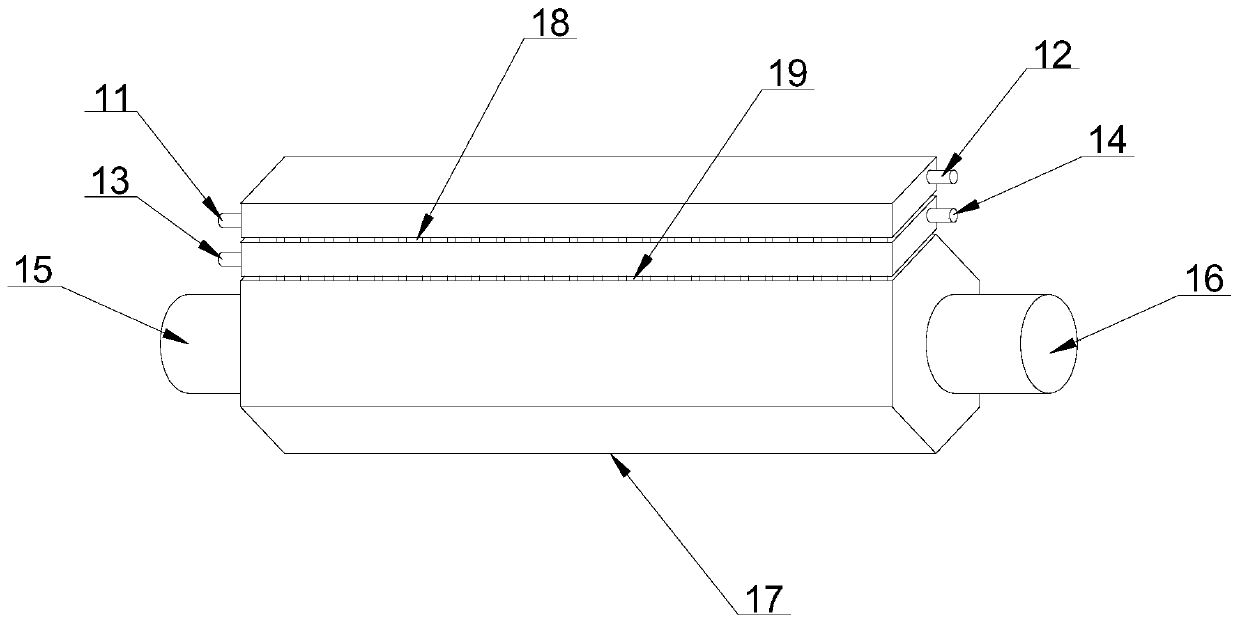

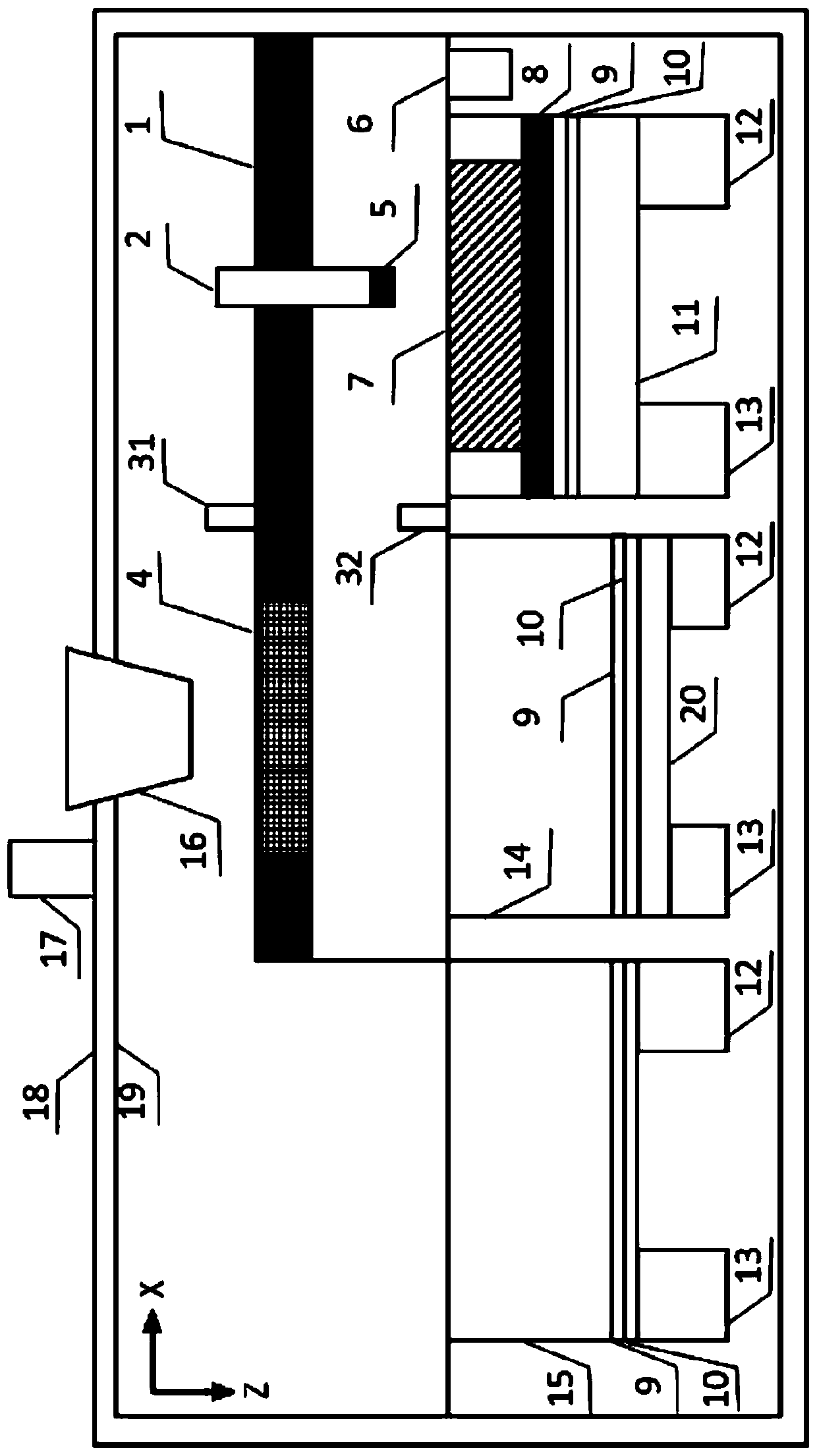

A plate type multi-stage flash desulfurization wastewater treatment and recovery device and its method

ActiveCN104402159BAchieving "Zero Emissions"Reduce consumptionMultistage water/sewage treatmentWater/sewage treatment by heatingHigh concentrationDistillation

Provided are a plate-type multi-stage flash distillation apparatus for desulfurization wastewater treatment and recovery and a method therefor. The apparatus is mainly composed of plate-type heat exchangers, a plate-type condenser (12), a boiler (29), flash distillation tanks, freshwater tanks, water pumps and stainless steel pipelines. A pretreated desulfurization wastewater is brought into the plate-type heat exchanger stage by stage, heated to a certain temperature, and then brought into a first stage flash distillation tank (5) for flash distillation, the secondary steam is brought into the next-stage plate-type heat exchangers and condensed to release the latent heat to preheat the desulfurization wastewater, the concentrated desulfurization wastewater is brought into the next-stage flash distillation tank for flash distillation, and the process is carried out in sequence to the final stage, in which the secondary steam is brought into the plate-type condenser (12), the condensed fresh water in each stage is brought into a freshwater pool (17) for recycling, a part of the concentrated desulfurization wastewater is used as a circulating liquid to maintain the continuous proceeding of the flash distillation process, and a part thereof is brought into a concentrated liquid treating pool (19) and subjected to a centralized treatment. The apparatus and method can recover the latent heat of the secondary steam, has a high concentration multiple, a small occupation area and a low energy consumption, and can achieve zero release of the desulfurization wastewater.

Owner:ZHEJIANG UNIV

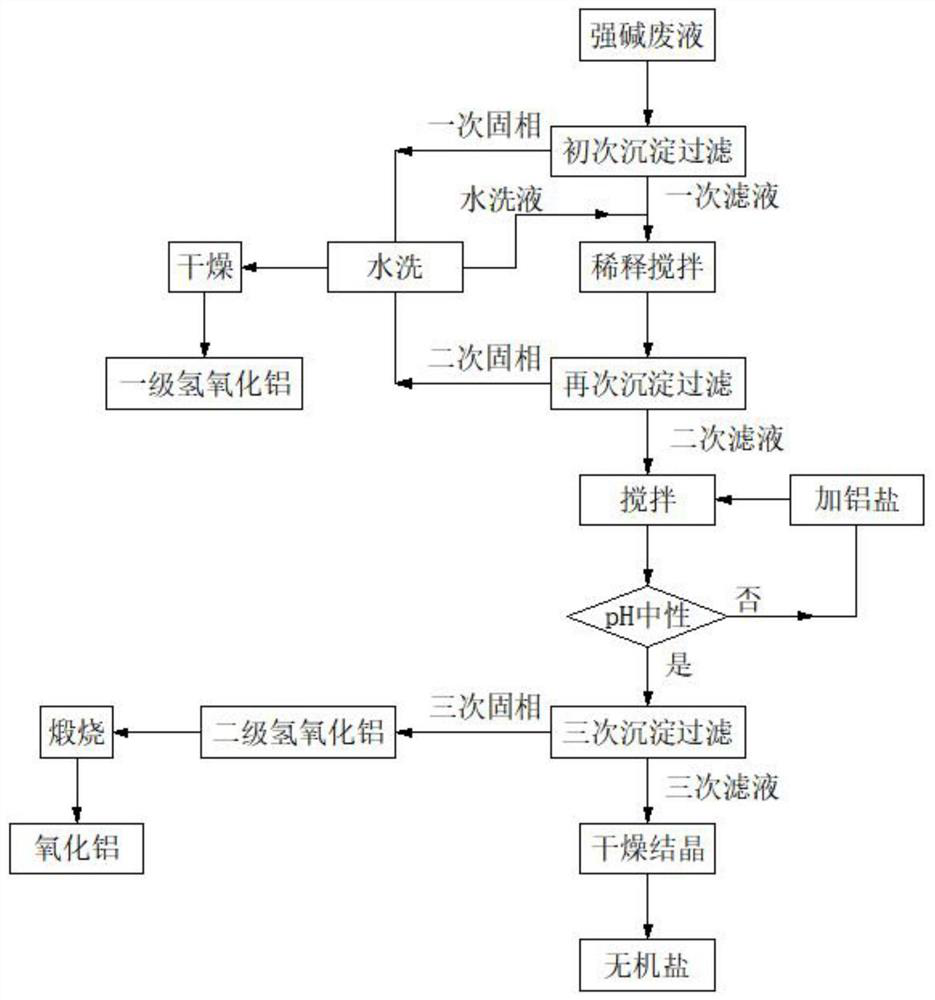

Waste liquid treatment method of aluminum-air battery

PendingCN112624168ADoes not cause strong alkali corrosion problemsRealize graded recyclingAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali metal chloridesInorganic saltsAluminium hydroxide

The invention discloses a waste liquid treatment method of an aluminum-air battery, which comprises the following steps: S1, after the discharge of the aluminum-air battery is finished, changing electrolyte into strong alkali waste liquid containing aluminum hydroxide precipitate and metaaluminate; s2, performing primary precipitation and filtration to obtain a primary solid phase and a primary filtrate; s3, washing the primary solid phase with water to obtain primary aluminum hydroxide particles, diluting the primary filtrate with a water washing solution, precipitating and filtering again to obtain a secondary solid phase and a secondary filtrate, and washing the secondary solid phase with water; and S4, adding an aluminum salt into the secondary filtrate, adjusting the pH value to be neutral, carrying out tertiary precipitation and filtration to obtain a tertiary solid phase and a tertiary filtrate, drying the tertiary solid phase to obtain secondary aluminum hydroxide particles which can be directly used as a raw material or calcined to obtain an aluminum oxide product, and drying and crystallizing the tertiary filtrate to obtain an inorganic salt product. According to the aluminum-air battery waste liquid treatment method, harmless treatment of waste liquid can be achieved, graded recycling of high-value aluminum hydroxide is achieved, and meanwhile by-products of inorganic salt products are obtained.

Owner:宁波烯铝新能源有限公司

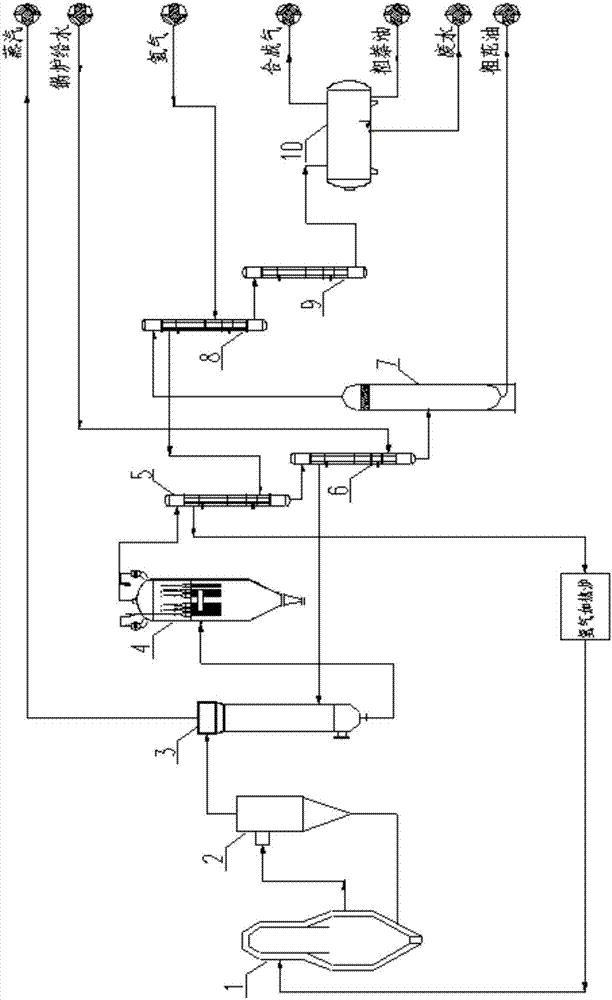

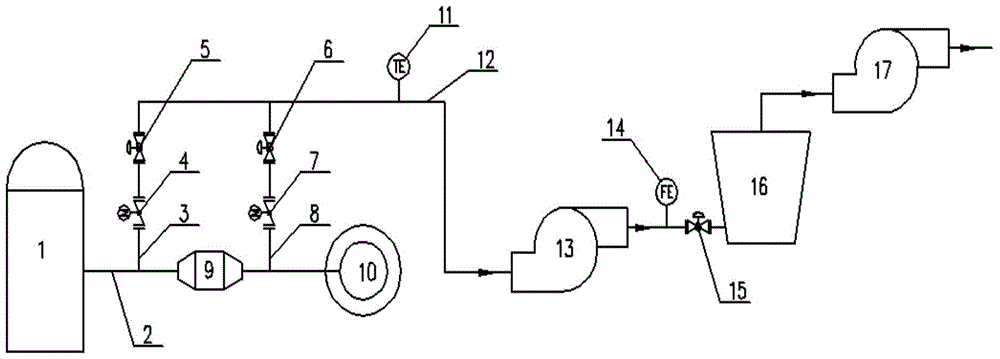

Purification separation system for hydrogasification synthesis gas and process of purification separation system

ActiveCN107353936ARealize graded recyclingReduce separation energy consumptionEnergy inputGasification processes detailsSyngasGas passing

The invention discloses a purification separation system for hydrogasification synthesis gas. The purification separation system mainly comprises a synthesis gas system, a hydrogen system and a boiler water system, wherein the synthesis gas system comprises a gasifier; the synthesis gas of the synthesis gas system is separated by using a cyclone separator, is further fed into a synthesis gas waste heat boiler, and further passes through a synthesis gas filter, a secondary hydrogen heater, a boiler water supply preheater and a primary separation tank in sequence; the synthesis gas passing through the primary separation tank is further fed into a secondary separation tank after passing through a primary hydrogen heater and a circulation water cooler; the hydrogen system comprises a hydrogen pipeline which is communicated with a primary hydrogen heater and a secondary hydrogen heater; heated hydrogen is introduced into the gasifier;the boiler water system comprises a water supply pipeline introduced to a boiler water supply preheater andthe synthesis gas waste heat boiler. By adopting the purification separation system, the effective purification of the hydrogasification synthesis gas, reasonable graded utilization of energy and classified recycling of products are achieved, and the purposes that the energy consumption is reduced, the equipment investment is lowered and the service life of equipment is prolonged are achieved.

Owner:EAST CHINA ENG SCI & TECH +2

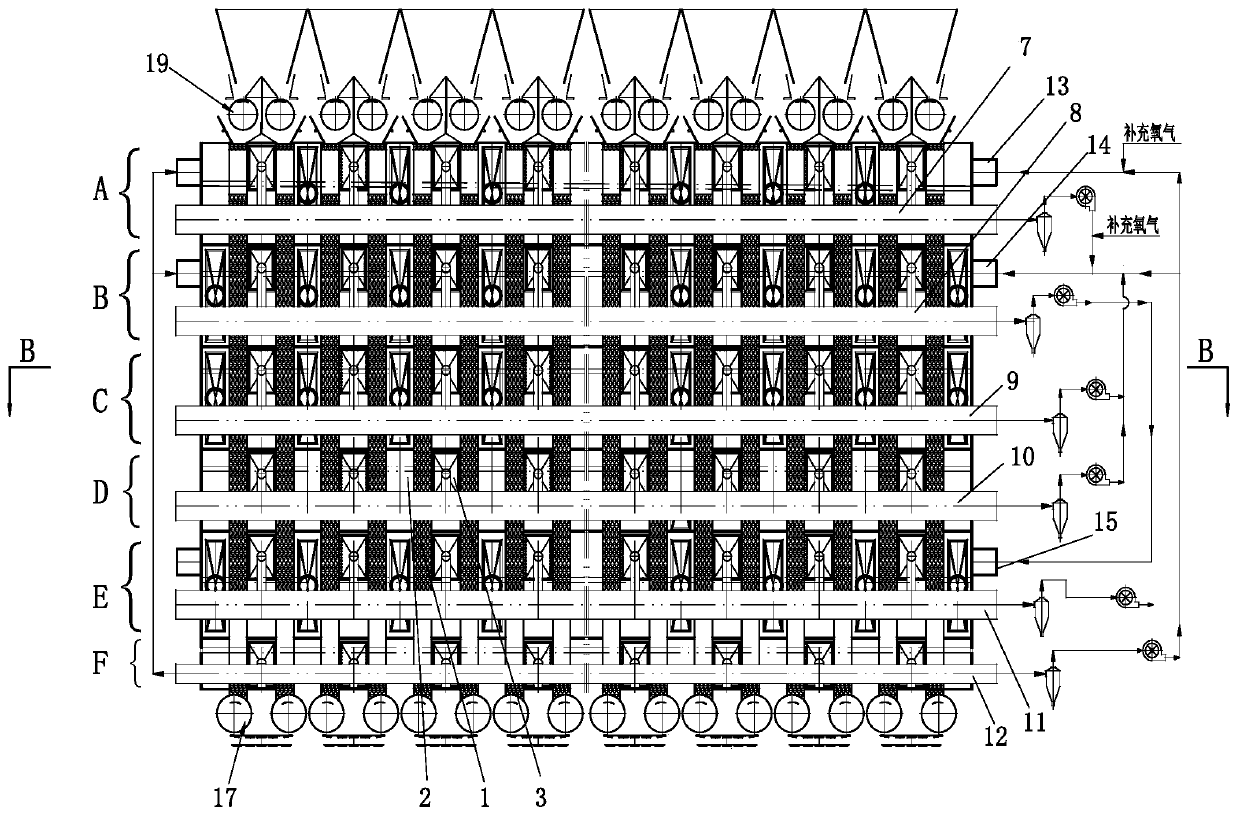

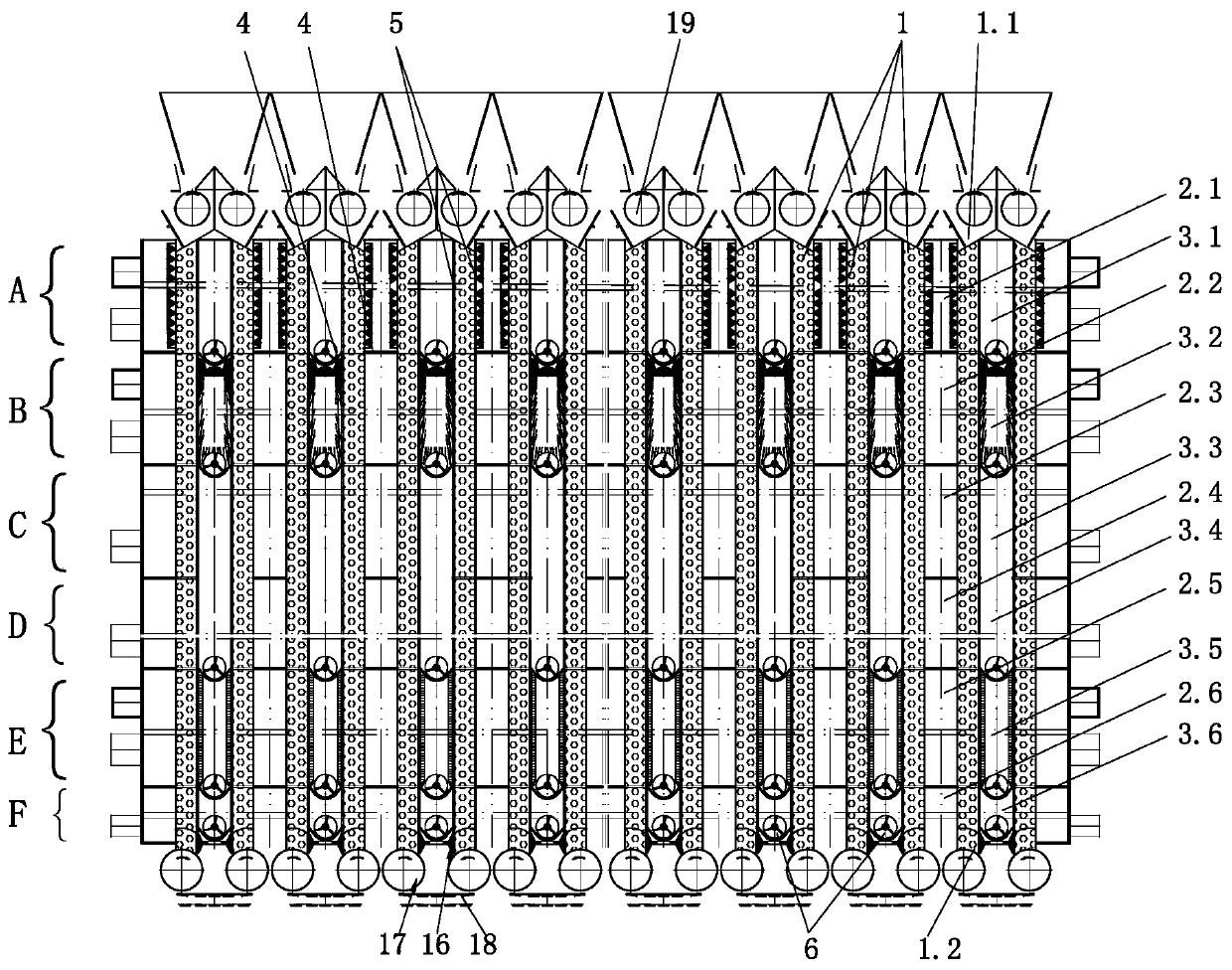

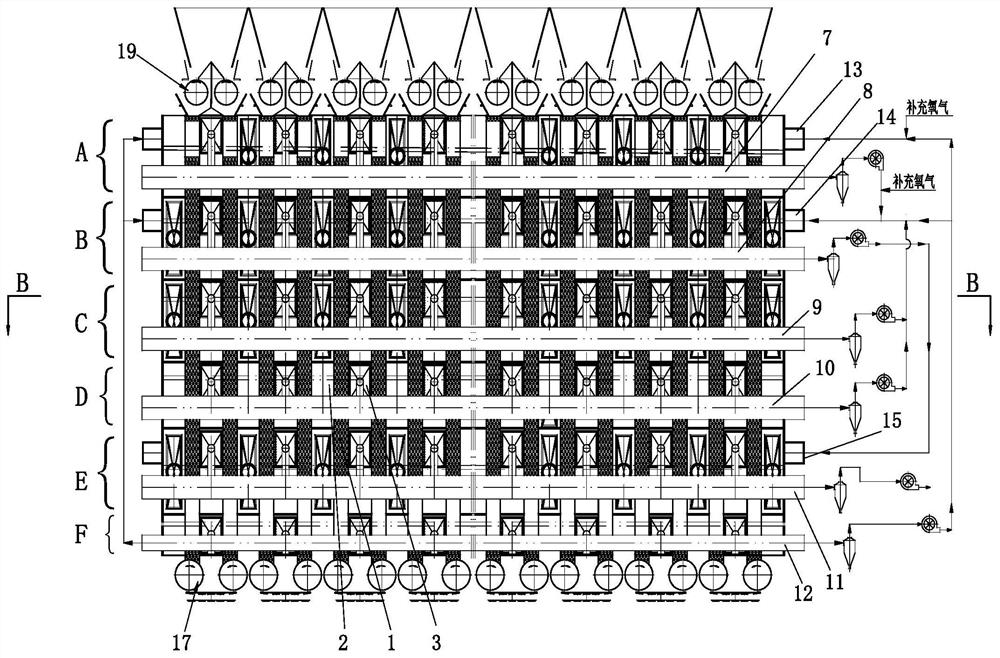

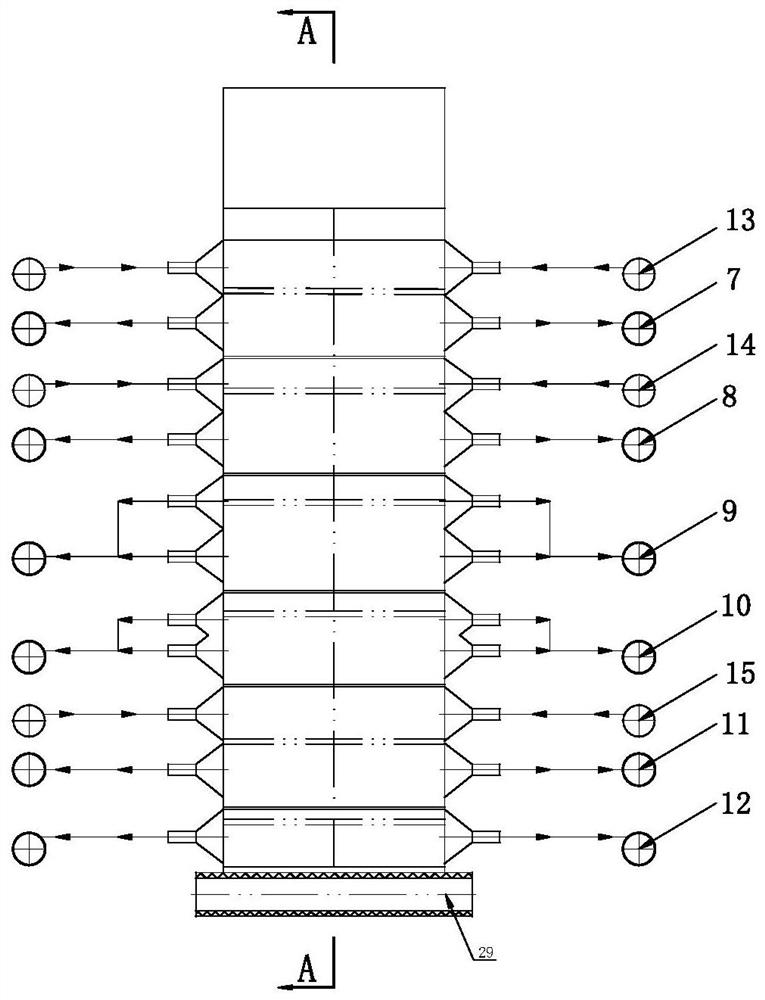

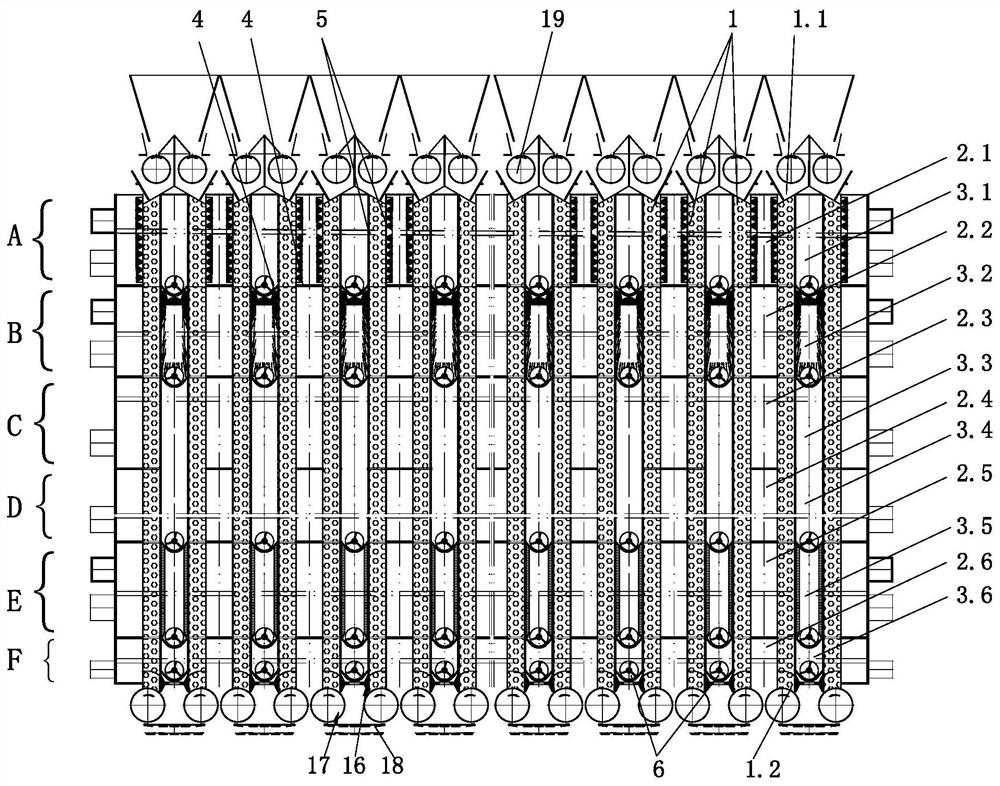

Vertical air extraction sintering machine and sintering process

ActiveCN111426208AImprove breathabilityGood air permeabilityMaintainance of heating chambersCharge manipulationMetallurgyExhaust heat

The invention discloses a vertical air extraction sintering machine and a sintering process. The sintering machine comprises at least two sintering chambers which are vertically arranged at intervals;the top of each sintering chamber is a feeding end, and the bottom of each sintering chamber is a discharging end; one side of each sintering chamber is communicated with an air inlet channel througha grate bar, and the other side of each sintering chamber is communicated with an air outlet smoke channel through a grate bar; and two adjacent sintering chambers share an air inlet channel and / or an air outlet smoke channel. The sintering process is characterized by adding a sintering mixed material from the feeding end of the top of each sintering chamber, finally obtaining sintered ore and discharging the sintered ore out of the discharging end of the bottom of each sintering chamber. Combustion-supporting gas enters each sintering chamber through the air inlet channel in one side of eachsintering chamber via the grate bar along a horizontal direction; the smoke in each sintering chamber enters the air outlet smoke channel through the grate bar in the other side of each sintering chamber under the negative-pressure action; and two adjacent sintering chambers share an air inlet channel and / or an air outlet smoke channel. The vertical air extraction sintering machine is simple in structure, small in smoke generation amount, free of air leakage, high in stability, small in occupied area and high in waste heat utilization rate; the quality of the sintered ore is improved; the energy is saved; and the consumption is reduced.

Owner:WUHAN WUTUO TECH

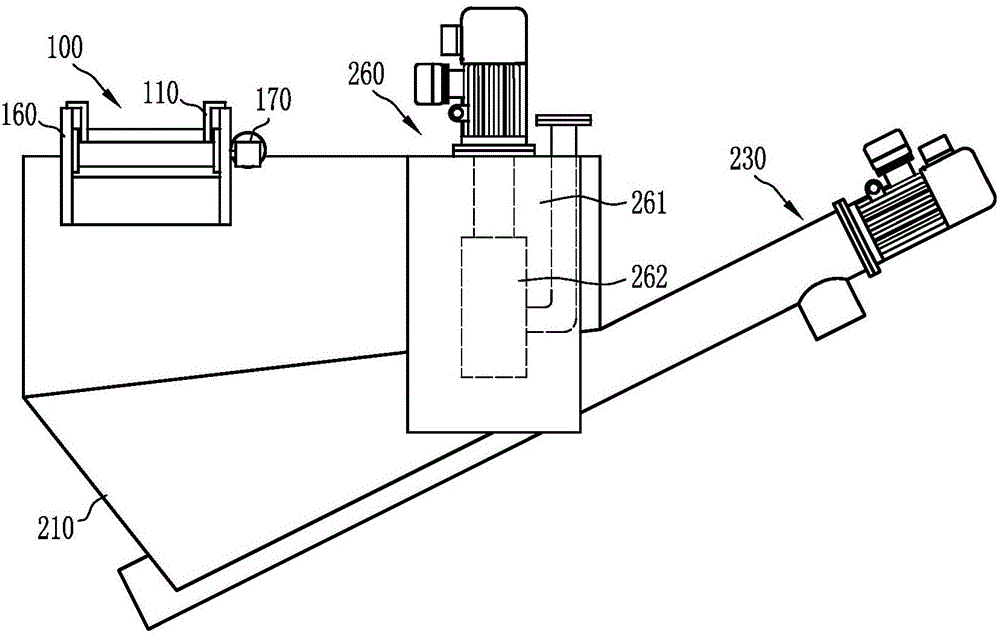

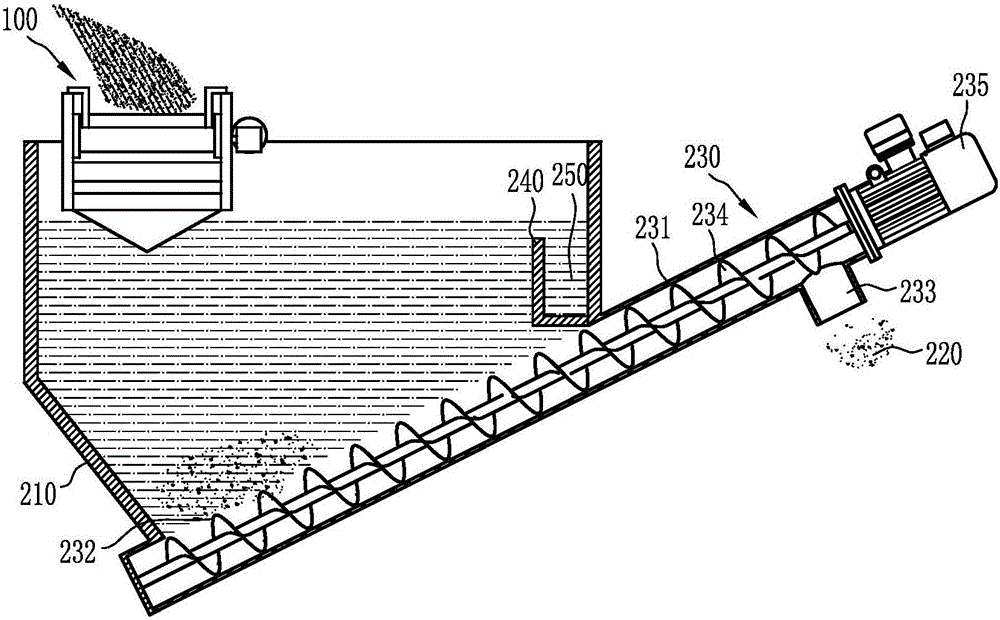

Stone material cutting sewage coarse sand precipitation sand discharging system

PendingCN106746142AAvoid environmental pollutionImprove resource managementSettling tanks feed/dischargeMultistage water/sewage treatmentEngineeringPrecipitation

The invention discloses a stone material cutting sewage coarse sand precipitation sand discharging system, which comprises a coarse sand precipitation pool with the big upper end and the small lower end, wherein a sewage dressing device is arranged in a position of a water inlet of the coarse sand precipitation pool; a spiral coarse sand conveying device used for conveying precipitation coarse sand to a position outside the coarse sand precipitation pool is arranged at the bottom of the coarse sand precipitation pool; a sand blocking flow separation plate is arranged in the coarse sand precipitation pool; a fine sand sewage outlet chamber is formed between the sand blocking flow separation plate and the pool wall of the coarse sand precipitation pool; a fine sand sewage conveying device is arranged in a position outside the fine sand sewage outlet chamber. The system can realize the grading recovery and utilization of ore powder (iron powder) and coarse sand in the sewage; the environment pollution is avoided; the resource treatment of the stone material cutting sewage is facilitated.

Owner:日照市勇明环保科技有限公司

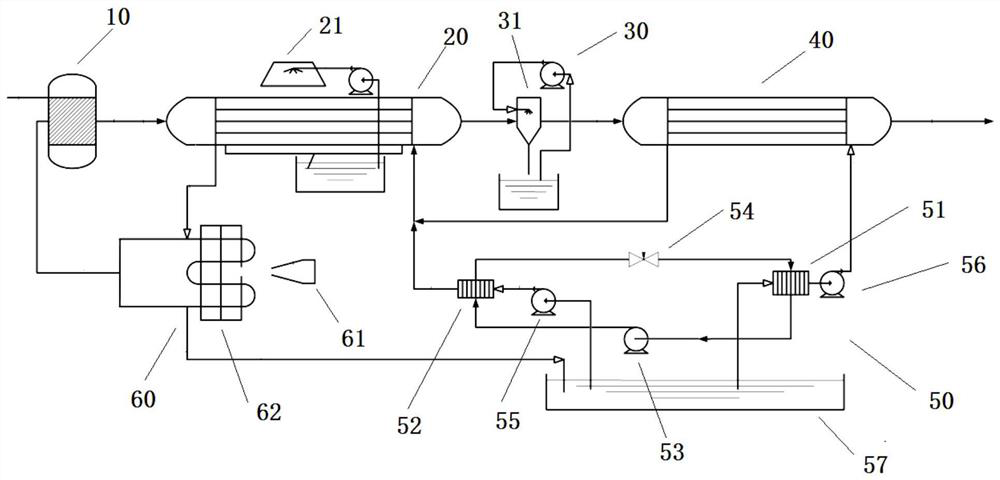

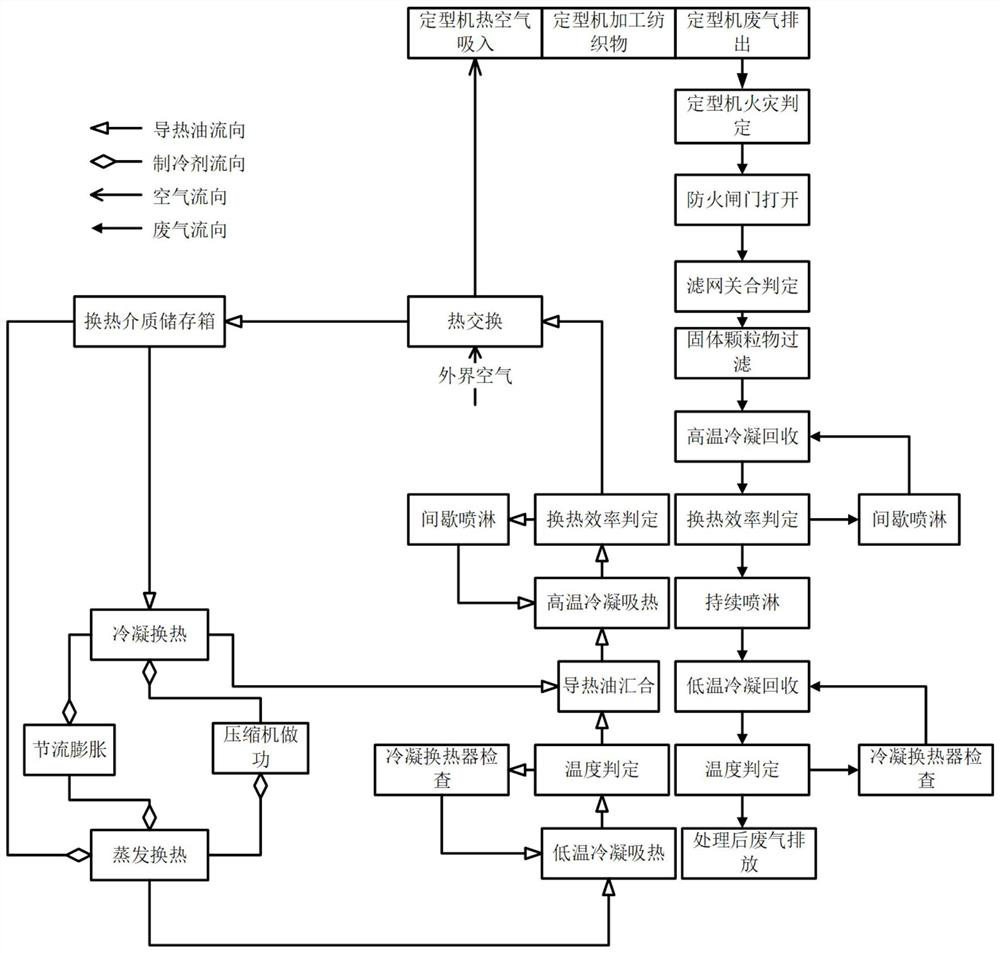

Waste heat recovery system and process of setting machine

PendingCN113654372AImprove recycling efficiencyRealize graded recyclingMechanical apparatusClimate change adaptationProcess engineeringRefrigeration

The invention relates to a waste heat recovery system and process of a setting machine. The waste heat recovery system comprises a first condensation recovery assembly and a second condensation recovery assembly which are sequentially arranged at the downstream of the setting machine, and a refrigeration assembly is arranged between a heat exchange inlet pipe of the first condensation recovery assembly and a heat exchange inlet pipe of the second condensation recovery assembly. A hot air conversion assembly is connected between a heat exchange outlet pipe of the first condensation recovery assembly and the setting machine. According to the waste heat recovery system, the waste heat recovery efficiency and utilization rate of the setting machine can be remarkably improved, and meanwhile, waste gas is cleaned, so that the production process is more energy-saving and environment-friendly.

Owner:浙江尤佳节能科技有限公司

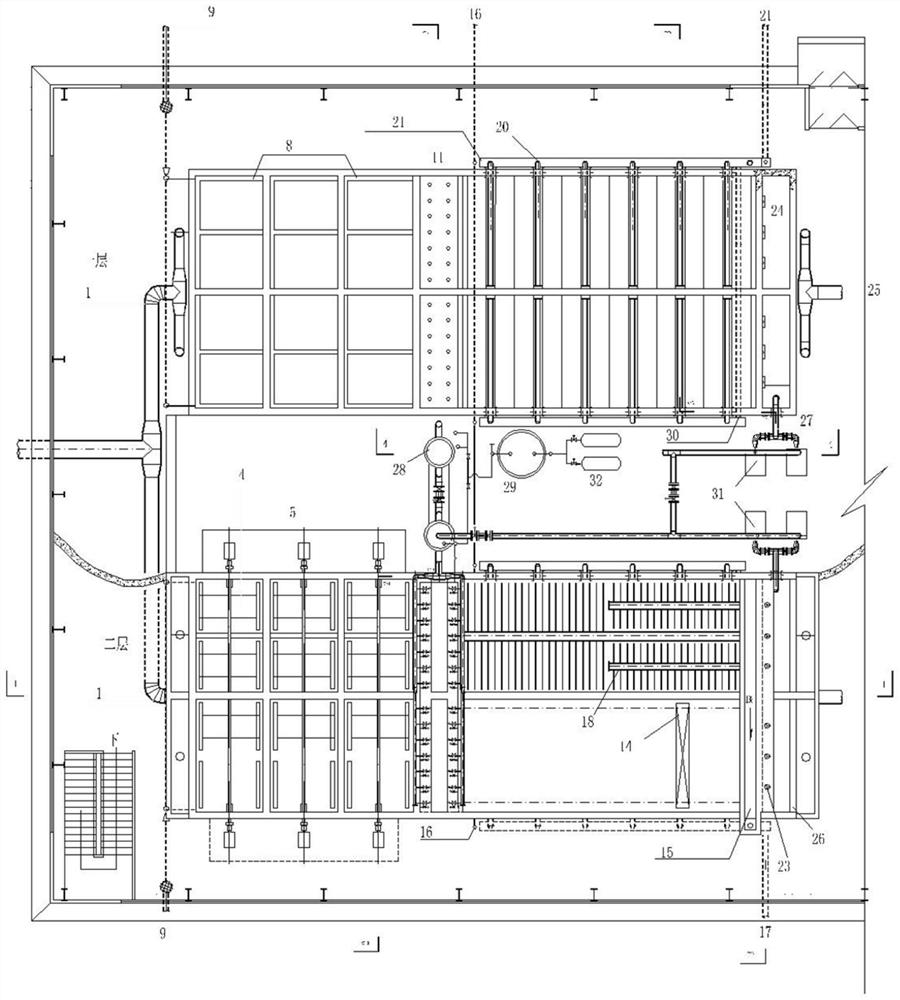

Ionic mine wastewater treatment device and operation method thereof

PendingCN114477353AInhibitionGuaranteed uptimeWater contaminantsWater/sewage treatment by flocculation/precipitationWater flowSewage

The invention relates to an ionic mine wastewater treatment device and an operation method thereof. The ionic mine wastewater treatment device comprises a combined air floatation system consisting of four rectangular flocculation tank body units and four rectangular air floatation tanks, the combined air flotation system comprises a water inlet area, a flocculation area, a contact area, an air flotation area, a water outlet area, a dissolved air tank and a backflow pipeline area which are sequentially arranged in the water flow direction. According to the treatment device and the operation method thereof, by reasonably controlling the sulfide content, the pH value and the air flotation deslagging process in the acid wastewater at different stages, neutralization precipitation and valuable metal grading recovery of the whole system are achieved; the system has the advantages of simple process, convenience in maintenance, low treatment cost and small occupied area, and the treated wastewater reaches the discharge standard of class 3 water bodies of surface water. The ionic type mine wastewater treatment device can still operate well even under the conditions of unstable water inflow and high pollution load, it is guaranteed that sewage is effectively purified, and the effluent quality is good.

Owner:北京东方利禾景观设计有限公司

Silicon material breaking and recycling system

ActiveCN107930772BGuaranteed recyclingGuaranteed to clearGrain treatmentsMaterial scatteringMegasonic cleaning

The invention discloses a silicon material scattering and recycling system. The silicon material scattering and recycling system is capable of realizing graded recovery of crushed silicon material, the recycled silicon material particles are guaranteed to be small, and impurities are removed thoroughly after the silicon material is recycled. The silicon material scattering and recycling system comprises a hot air tank, a scattering machine, an air outlet barrel, a connecting pipeline, a first material collecting tank, a first fan, a second material collecting tank, a second fan, a cyclone separator and a third material collecting tank communicating with one another in sequence. According to the silicon material scattering and recycling system, the crushed silicon material is scattered by the arranged scattering machine, then four-stage powder separation is realized through the first material collecting tank, the second material collecting tank, the cyclone separator and the third material collecting tank so that the crushed waste silicon material can be classified and recycled, the received silicon material powder particles are guaranteed to be small enough, and therefore alkali washing and ultrasonic cleaning in the follow-up process steps can be guaranteed to remove the waste silicon material impurities, recycling of the waste silicon material can further be ensured, and theproduct quality is further improved.

Owner:LESHAN TOPRAYCELL

Method and device for reducing methanol content in formaldehyde process by silver method

ActiveCN103086854BNo backmixingReduce loadOrganic compound preparationChemical industryProduct gasTower

The invention relates to a method and a device for reducing methanol content in a formaldehyde process by a silver method, and belongs to the technical field of chemical production. The technical scheme is that the method comprises the following steps of: after thermally recovering and cooling a formaldehyde liquid at the bottom of an absorption tower in the formaldehyde process by the silver method, extracting and feeding part of the formaldehyde liquid to a vacuum groove; conveying gas analyzed at the top of the vacuum groove to an inlet of an air fan; arranging a concentration evaporator between the outlet of an oxidation reactor and the inlet of the absorption tower; evaporating and condensing residual liquid of the evaporator by reaction waste heat at 90-110 DEG C; evaporating methanol in the residual liquid with water; recovering mixed gas of vapor and methanol steam to material gas; and recovering methanol which is less than 0.5% in percentage by weight in the condensed residual liquid to the absorption tower. According to the invention, the inlet temperature of the absorption tower is reduced, while the heat recovery efficiency of the system is improved. The load of a water cooler of the absorption tower is reduced, and the consumption of cooling water is reduced, so that the residual liquid is recovered in grades by 100%, and methanol recovered is free from backmixing, therefore, the energy-saving, consumption reducing and environmental protecting purposes are realized.

Owner:HEBEI KAIYUE CHEM GROUP

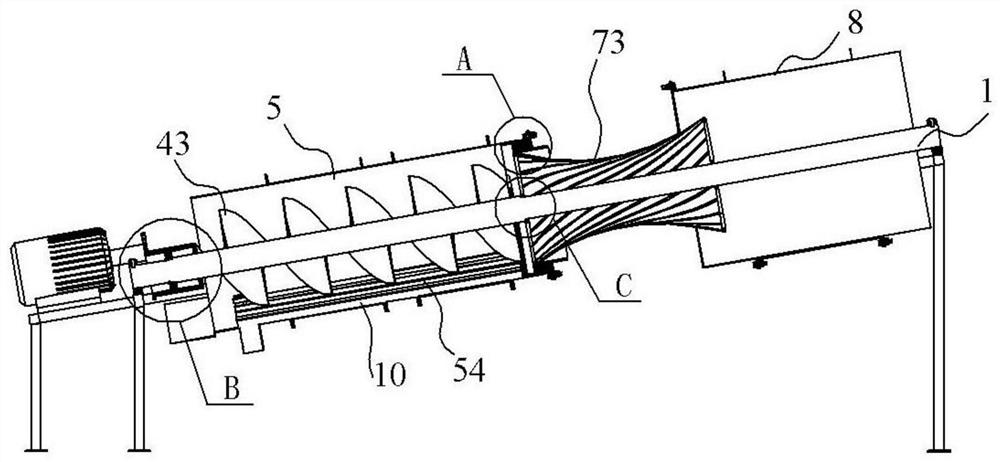

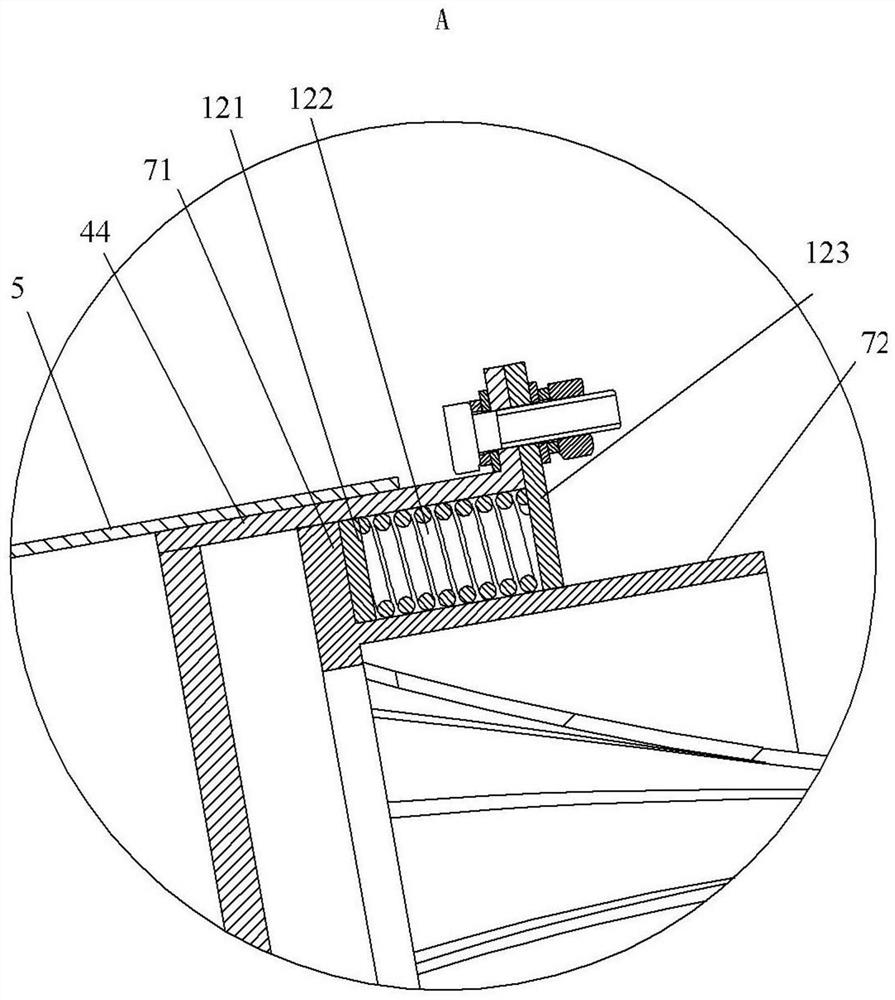

A domestic garbage grading collection device and collection system

ActiveCN113560168BEasy accessHigh speedSievingTransportation and packagingCollection systemHelical blade

The invention relates to the technical field of household garbage collection, in particular to a household garbage grading collection device and a collection system. A household garbage classification collection device includes a bracket, a support shaft, a material storage cylinder, an auger conveyor, a feeding auxiliary device and a transmission friction part. The auger conveyor includes a feeding barrel and a screw blade group. The feeding auxiliary device includes a plurality of elastic strips and two support rings, so that when the screw blade group is stuck by garbage, the pitch of the screw blade group on the front side of the jam point increases, and the screw blade group on the back side of the jam point increases the pitch of the screw blade group Decrease, the helix angle increases, so that the transmission speed of the garbage behind the jam point becomes slower. When the helical blade group rotates normally, the hole diameter of the holes formed by the multiple elastic strips becomes larger, so as to increase the flow rate of the garbage from the storage cylinder. The speed and capacity of entering the feeding cylinder, when the shape of the feeding auxiliary device is stable, the support ring on the rear side rotates with multiple elastic strips to agitate the garbage in the storage cylinder and accelerate the speed of the garbage entering the feeding auxiliary device.

Owner:苏州凯利洁环保科技有限公司

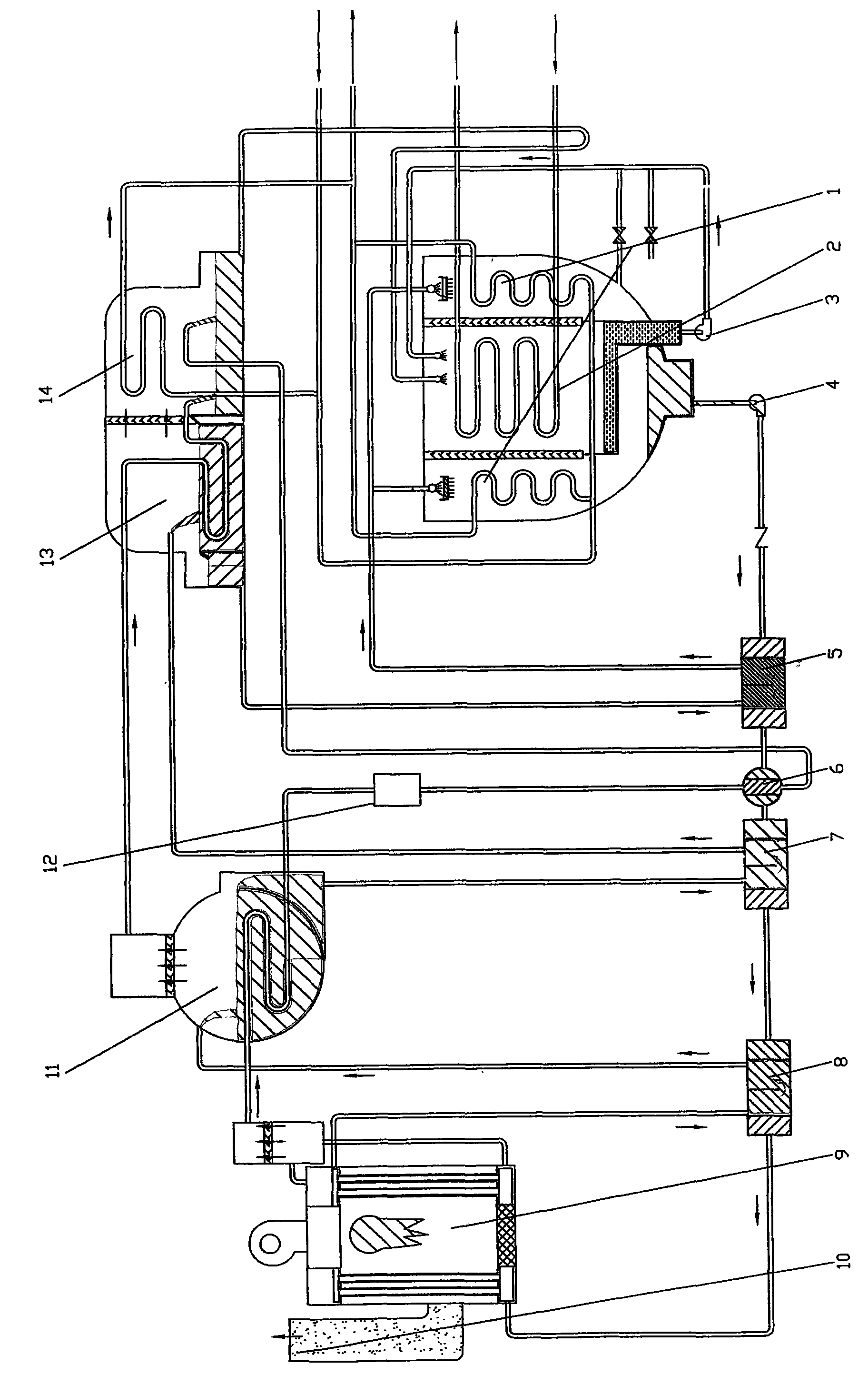

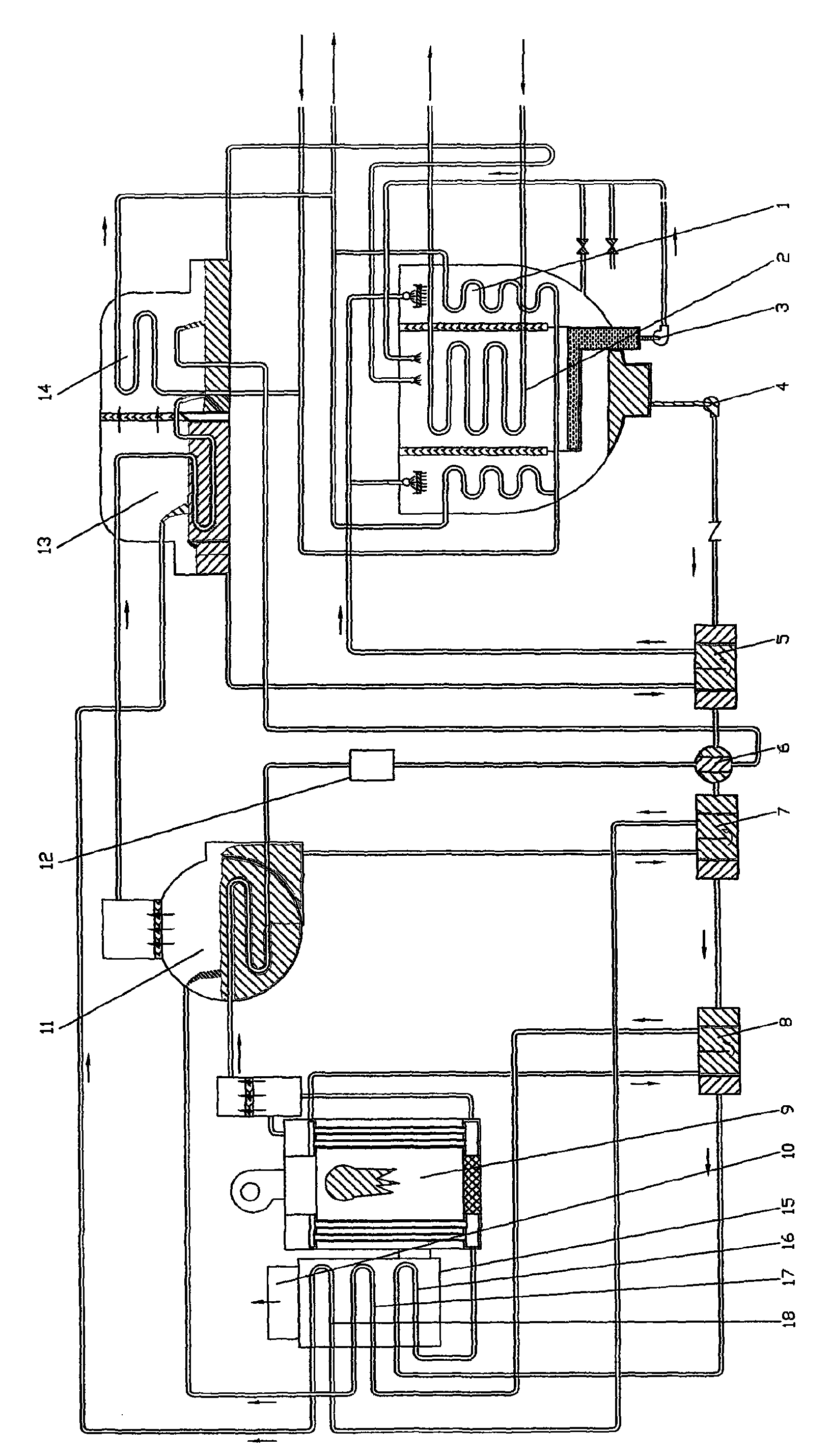

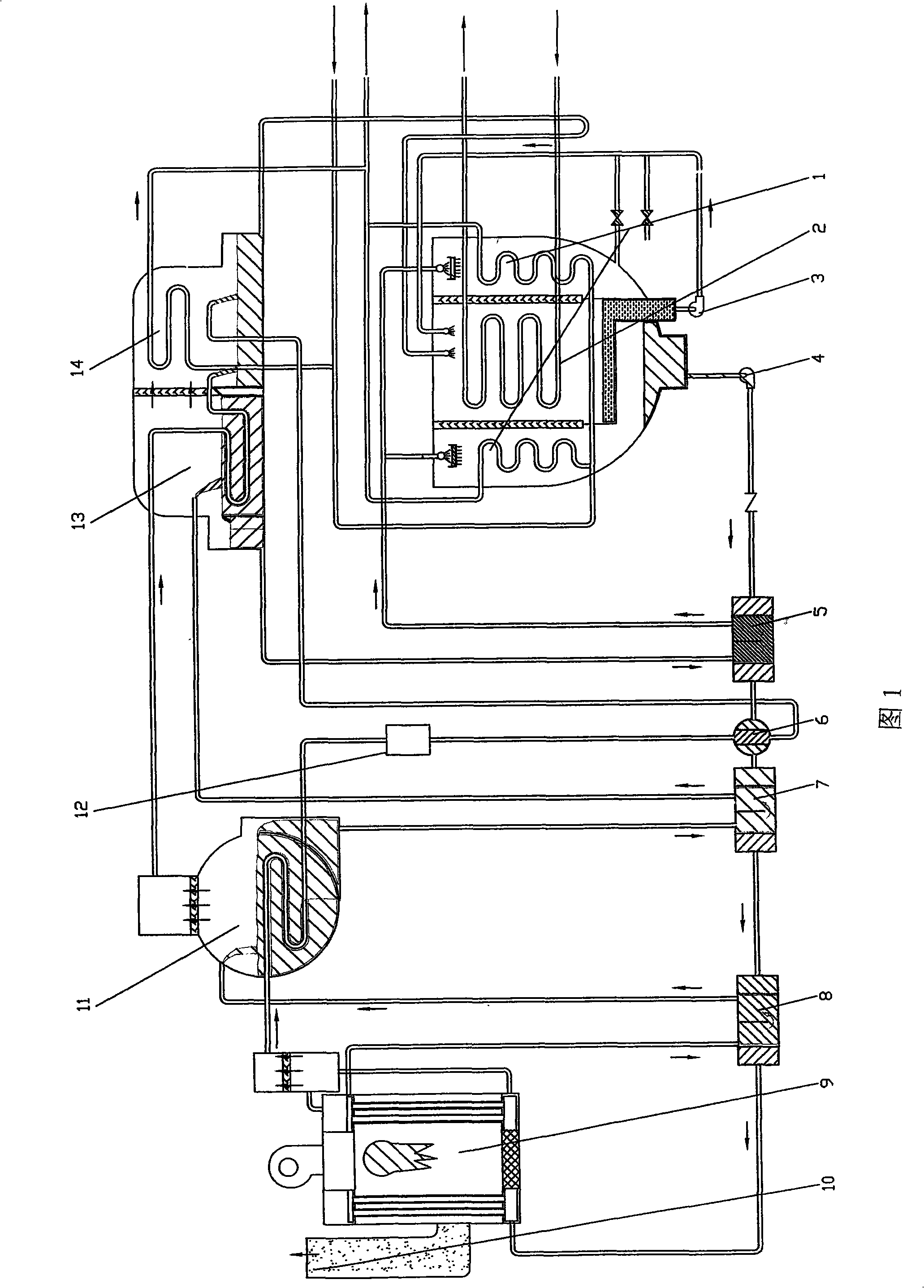

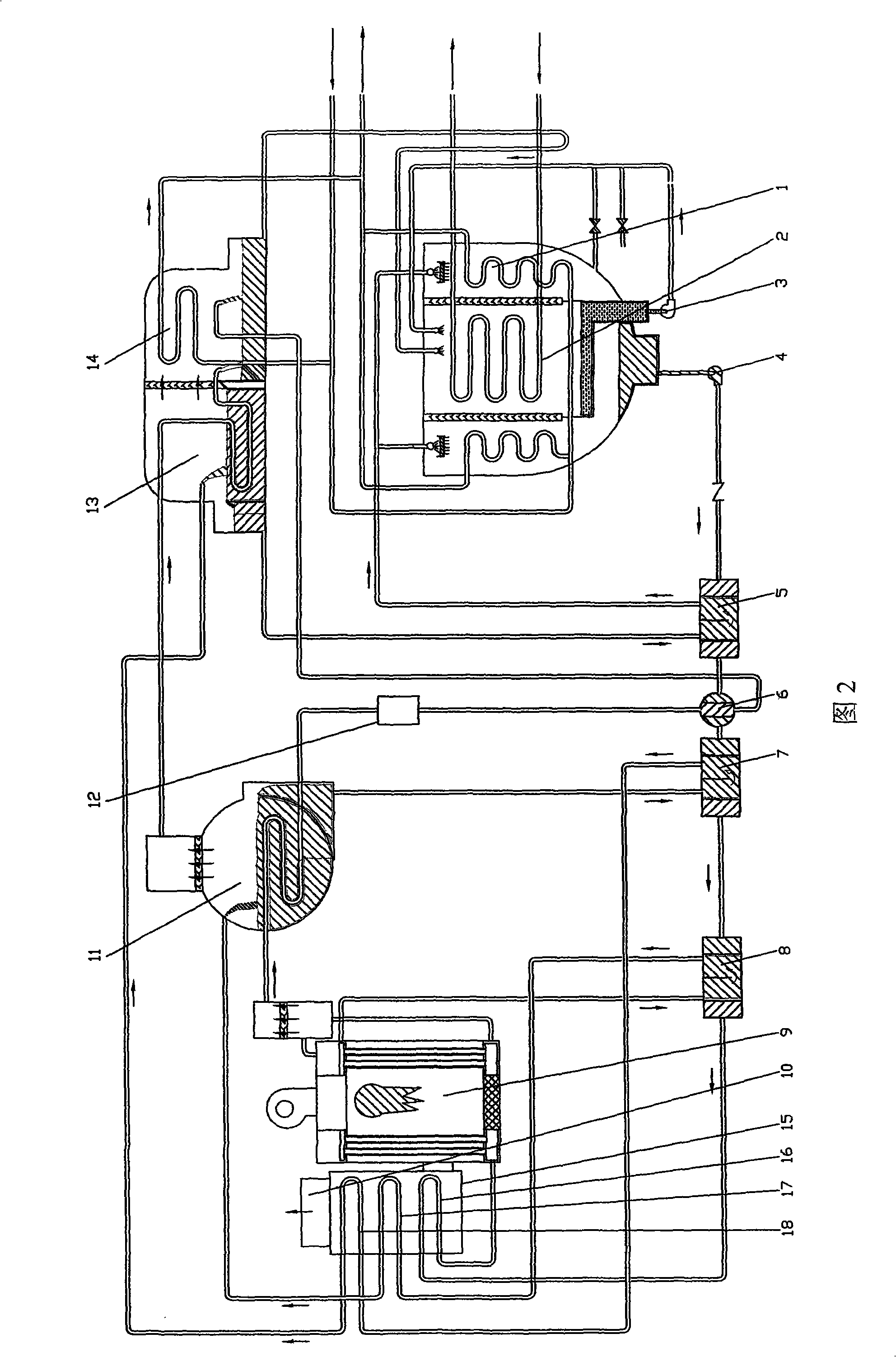

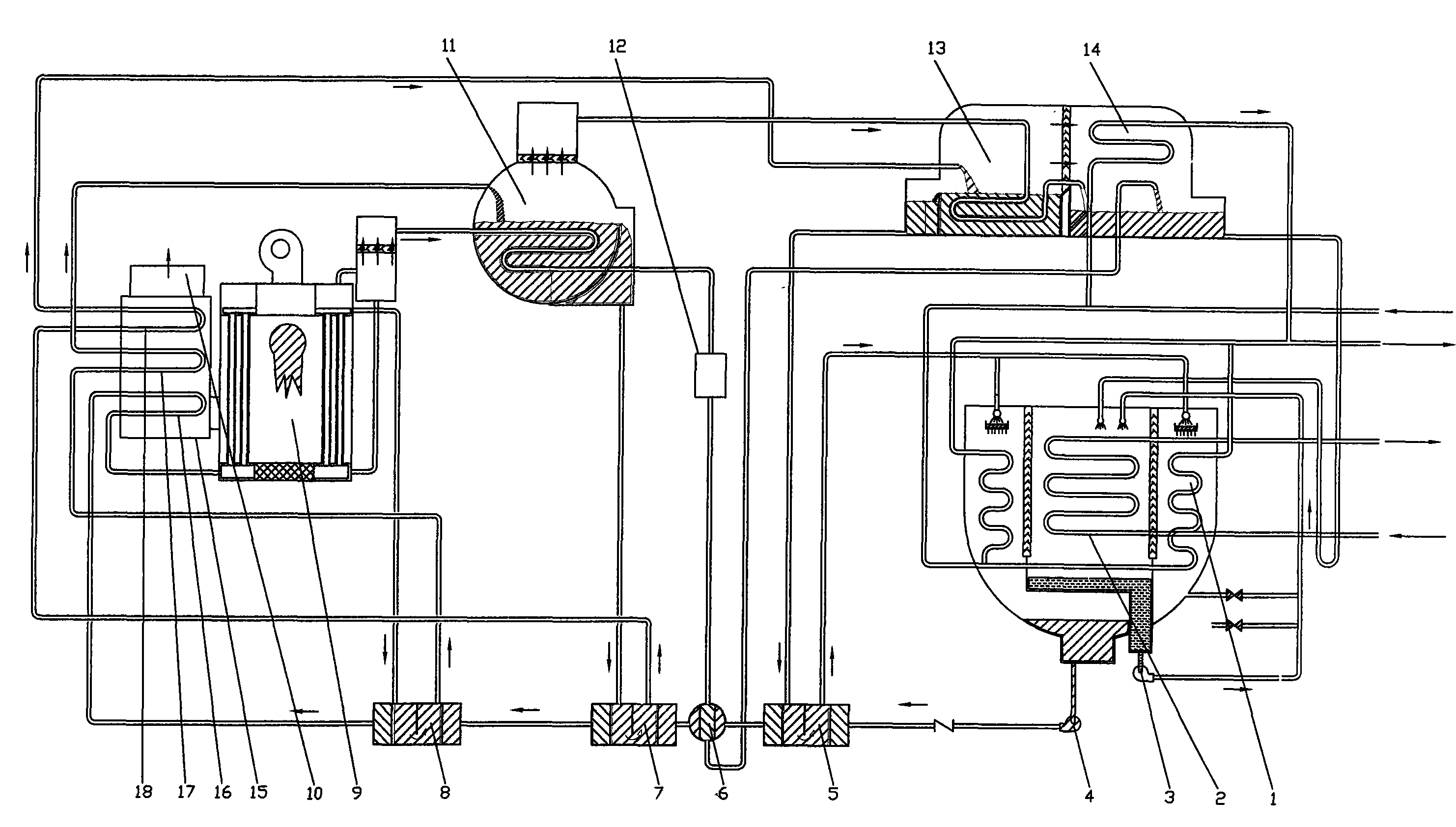

Smoke exhaust heat utilization device of directly-fired triple effect machine

ActiveCN101539351AReduce consumption costsLow running costClimate change adaptationMachines using waste heatEngineeringHeat losses

The invention relates to a smoke exhaust heat utilization device of a directly-fired triple effect machine, comprising a directly-fired high pressure generator (9), a medium pressure generator (11), a low pressure generator (13), a high temperature solution heat exchanger (8), a medium temperature solution heat exchanger (7) and a low temperature solution heat exchanger (5). A smoke outlet pipe (10) of the directly-fired high pressure generator (9) is internally and additionally provided with a smoke exhaust heat utilization device (15); the shell side of the smoke exhaust heat utilization device (15) is sequentially provided with a high temperature smoke heat exchange tube bundle (16), a medium temperature smoke heat exchange tube bundle (17) and a low temperature smoke heat exchange tube bundle (18) upwards along the smoke flow direction; the tube side of the high temperature smoke heat exchange tube bundle (16) is arranged in series on a solution pipeline for entering and exiting the directly-fired high pressure generator (9); the tube side of the medium temperature smoke heat exchange tube bundle (17) is arranged in series on a solution pipeline for entering the medium pressure generator (11); and the tube side of the low temperature smoke heat exchange tube bundle (18) is arranged in series on a solution pipeline for entering the low pressure generator (13). The invention can further improve the fuel heat utilization ratio of the directly-fired triple effect machine, reduce the temperature of smoke exhaust and reduce the heat loss of smoke exhaust.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

Garment processing surplus material collecting device

The invention discloses a garment processing surplus material collecting device comprising a base. The outer wall of the top of the base is connected with a negative pressure fan and a collecting boxby bolts, and the inner wall of the collecting box is connected with a dust screen by bolts; the inner wall of the middle part of the collecting box is welded with a separating plate, and one side ofthe collecting box is provided with a first air hole which is in dowel joint with a collecting pipe; the side, close to the collecting box, of the collecting pipe is welded with a branch pipe, and oneside of the collecting box is provided with a second air hole of which the inner wall is in dowel joint with the branch pipe; the inner wall of the bottom of the collecting pipe is in dowel joint with a collecting head, and the center position of the other side of the collecting box is provided with a third air hole; and an air inlet of the negative pressure fan is in dowel joint with an exhaustpipe of which the other end is connected with the third air hole in an inserted manner, and the outer wall of one end of the exhaust pipe is in threaded connection with a dust cover. According to thegarment processing surplus material collecting device, the grading recovery of garment processing surplus materials is achieved, and the smoothness of the exhaust pipe is ensured through the double dust-proof structure of the dust screen and the dust cover properly; and the recovery effect is better through a special collecting tank.

Owner:阜宁县腾达服饰有限公司

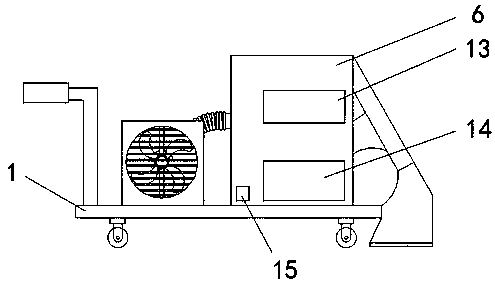

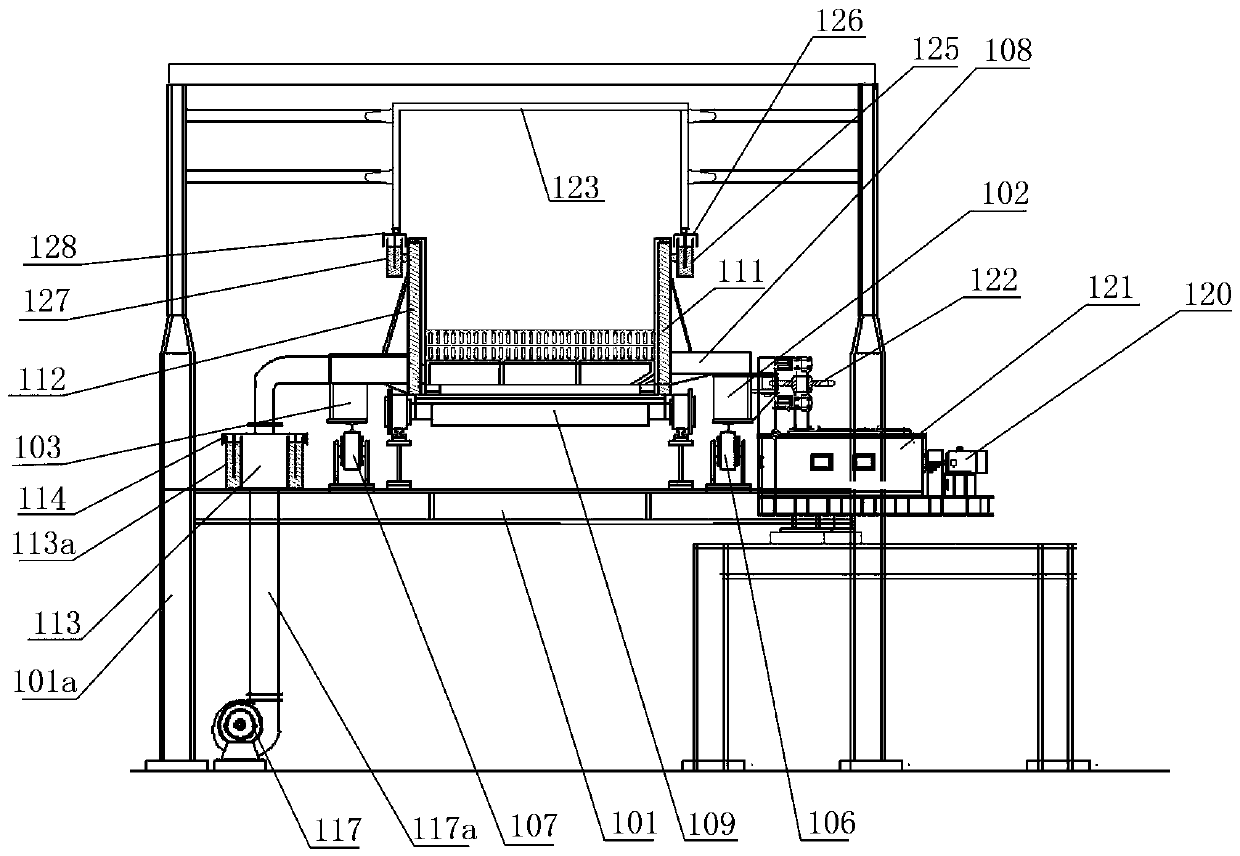

N-stage stepped sealing and 360-degree flue gas recovery system for circular cooler trolley

PendingCN111578731AAchieve sealingIncrease profitIncreasing energy efficiencyHandling discharged materialCold airFlue gas

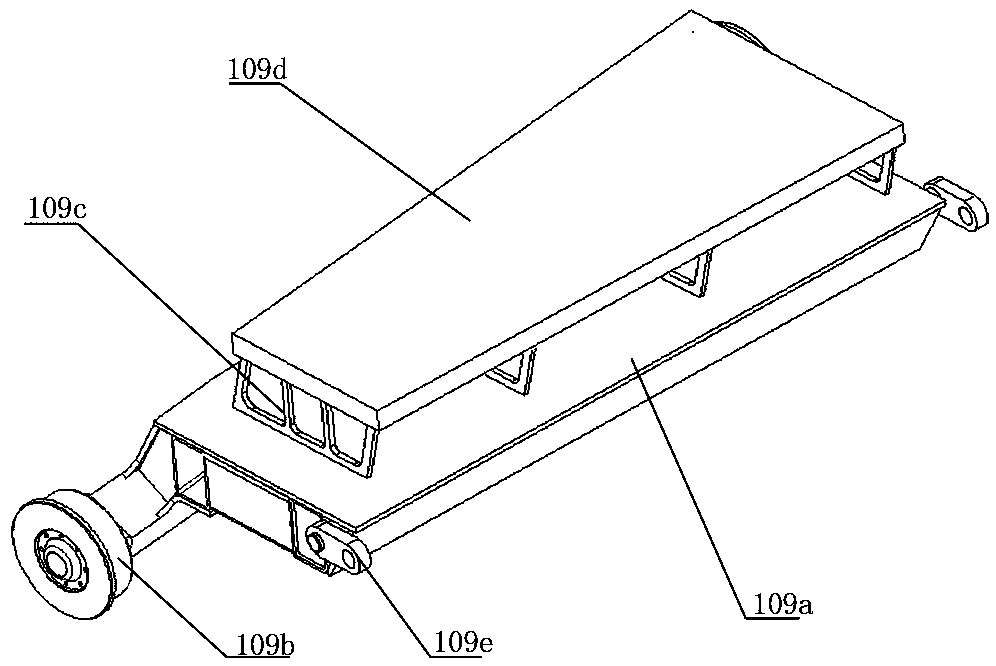

The invention discloses an N-stage stepped sealing and 360-degree flue gas recovery system for a circular cooler trolley. The N-stage stepped sealing and 360-degree flue gas recovery system for the circular cooler trolley comprise connecting beams 108, trolleys 109 are installed between the adjacent connecting beams 108, inner side baffle plates 111 are installed between longitudinal wing plates,located on the inner sides, of the adjacent connecting beams, outer side baffle plates 112 are installed between the longitudinal wing plates, located on the outer sides, of the adjacent connecting beams 108; and the bottom of each inner side baffle plate 111 is connected with an inner side sealing plate 111a used for sealing the inner side of the corresponding trolley 109, the bottom of each outer side baffle plate 112 is connected with an outer side sealing plate 112a used for sealing the outer side of the corresponding trolley 109, and a sealing plate I 108c used for sealing the rear side of the front trolley and a sealing plate II 108d used for sealing the front side of the rear trolley are correspondingly arranged on the bottom surface of each connecting beam 108. According to the N-stage stepped sealing and 360-degree flue gas recovery system for the circular cooler trolley, improving a circular cooler at multiple positions is carried out, rotary sealing of the circular cooler isenhanced, the cold air utilization rate is increased, energy consumption is reduced, graded recycling of flue gas is achieved, and energy conservation and emission reduction are achieved.

Owner:张志良

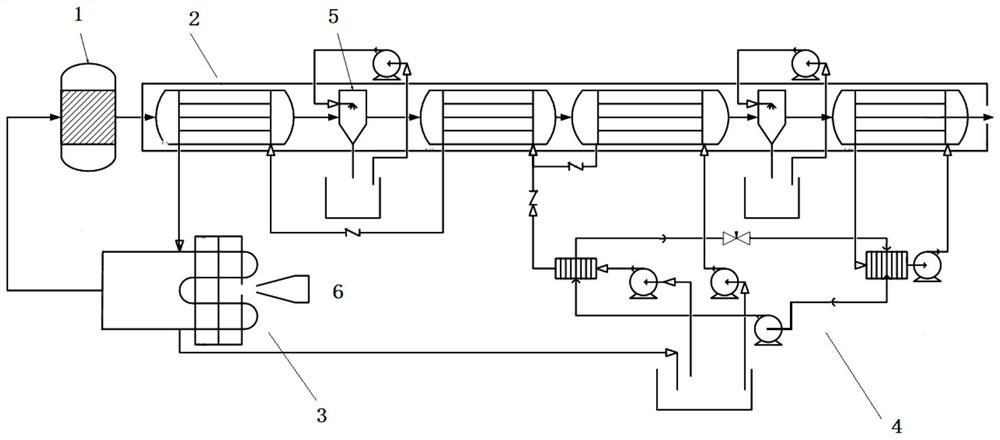

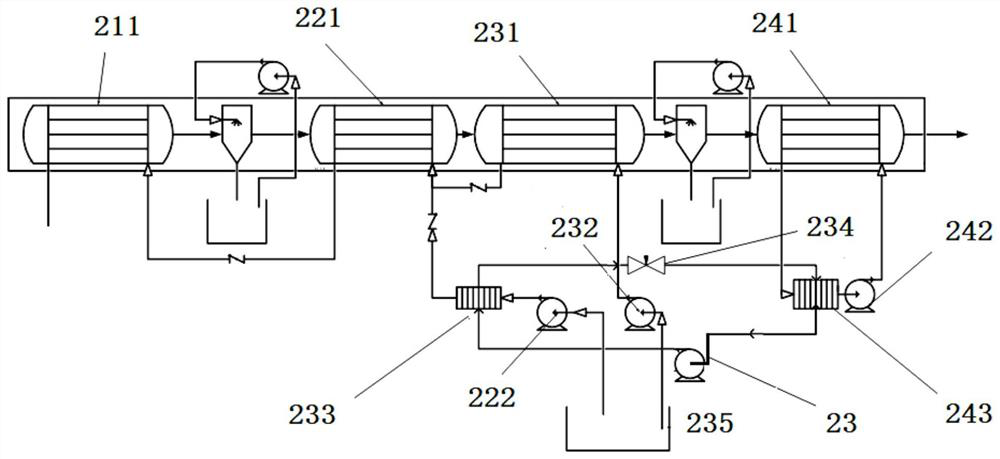

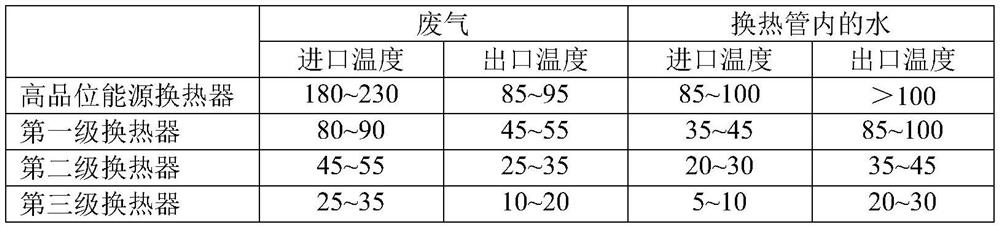

Waste heat recovery system of setting machine

ActiveCN113587672AImprove recycling efficiencyRealize graded recyclingMechanical apparatusClimate change adaptationConvertersProcess engineering

The invention relates to a waste heat recovery system of a setting machine. The waste heat recovery system of the setting machine comprises a multi-condensation assembly arranged at the downstream of the setting machine, the multi-condensation assembly comprises a high-grade energy heat exchanger and a multi-stage heat exchanger which are arranged in sequence to achieve waste heat recovery, a heat exchange pipe outlet of the high-grade energy heat exchanger is connected with a heat energy converter, the heat energy converter is connected to an inlet of the setting machine to achieve utilization of waste heat, and refrigeration assemblies can be arranged between heat exchange pipes of the multi-stage heat exchanger to achieve clean treatment of waste gas. The waste heat recovery system of the setting machine has the advantages of high waste heat recycling efficiency and high waste gas stage treatment capacity.

Owner:浙江尤佳节能科技有限公司

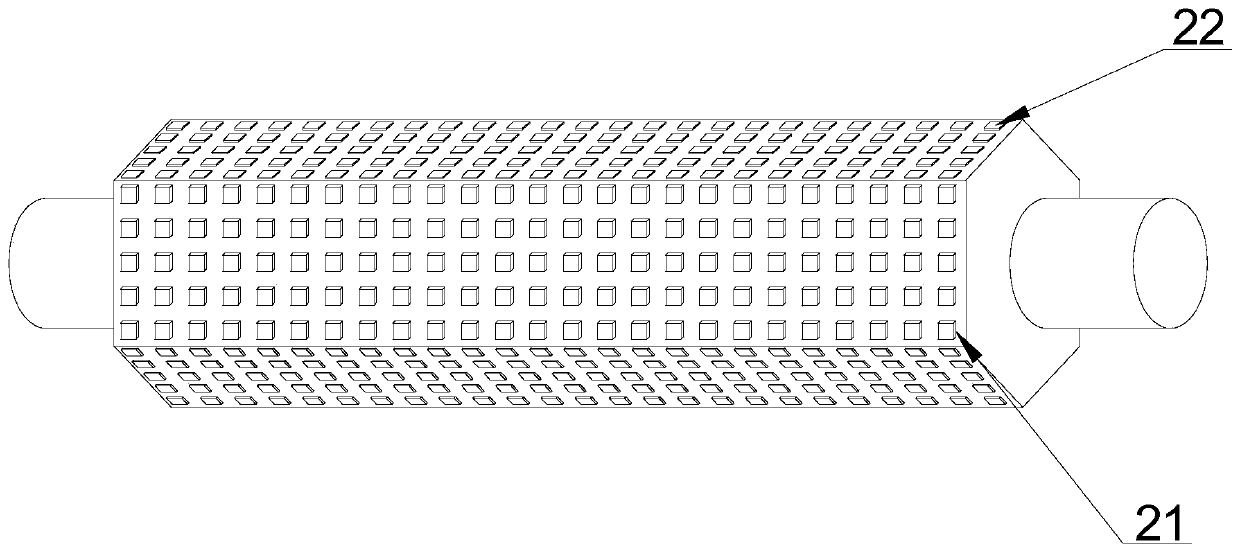

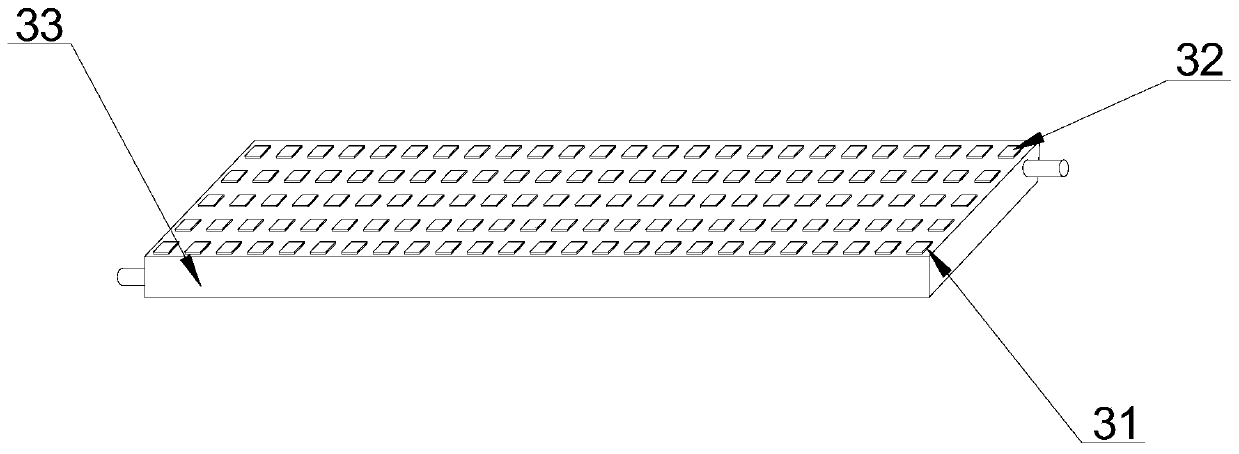

Ship waste heat recovery two-stage thermoelectric power generation device

ActiveCN107612426BIncrease utilizationIncrease device powerGenerators/motorsElectric energyEngineering

The invention discloses a two-stage thermoelectric power generation device for ship waste heat recovery and a power generation method. The device comprises a fume pipeline, a hexahedral structure, a thermoelectric power generation mechanism and a cooling plate structure; a section of pipeline is cut from the middle of a ship incinerator exhaust pipe and replaced with the fume pipeline; the front end of the fume pipeline is a fume inlet, the rear end of the fume pipeline is a fume outlet, and the outside of the fume pipeline is wrapped with the hexahedral structure; the thermoelectric power generation mechanism comprises two-stage thermoelectric power generation units; the cooling plate structure comprises two-stage cooling plates; the first-stage thermoelectric power generation unit is tightly close to the outer wall of the hexahedral structure, and the first-stage cooling plate, the second-stage thermoelectric power generation unit and the second-stage cooling plate are arranged on the outside of the first-stage thermoelectric power generation unit sequentially. According to the two-stage thermoelectric power generation device for ship waste heat recovery and the power generationmethod, a way of efficiently recycling ship incinerator high-temperature exhaust gas waste heat in stages and using the waste gas for power generation is provided, the high-temperature exhaust gas waste heat can be directly converted into electric energy, energy gradient utilization is realized, the utilization amount of the waste heat is increased, and the device power is improved.

Owner:DALIAN MARITIME UNIVERSITY

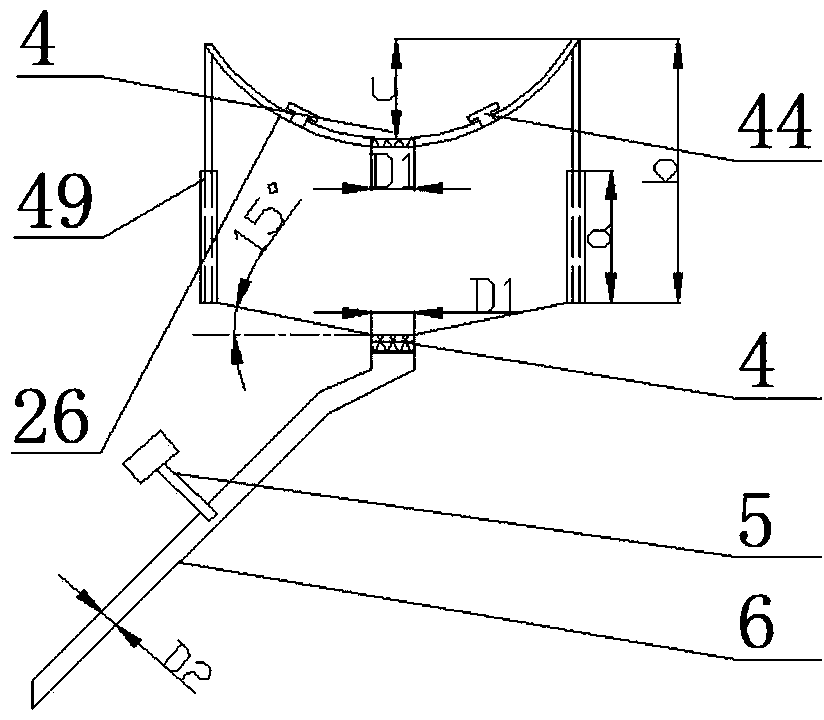

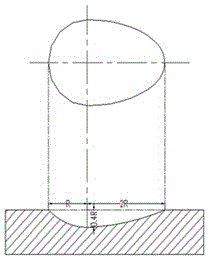

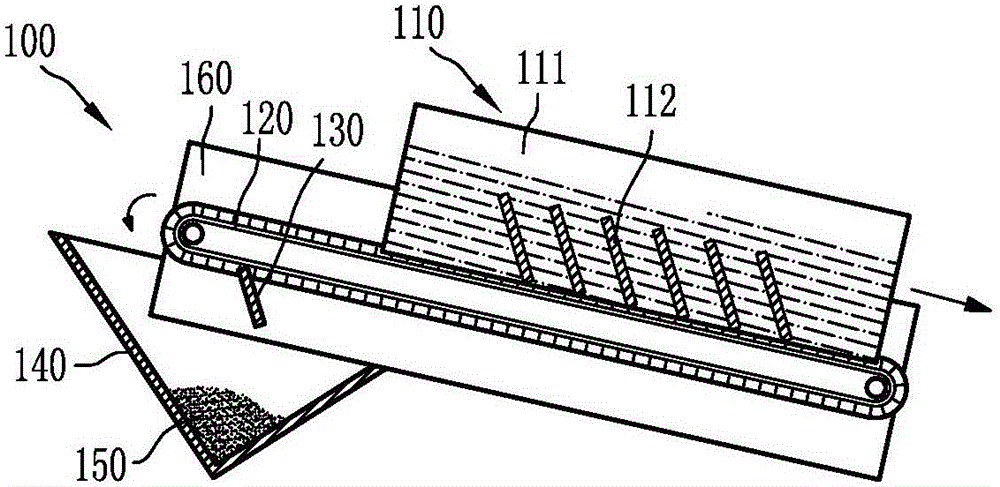

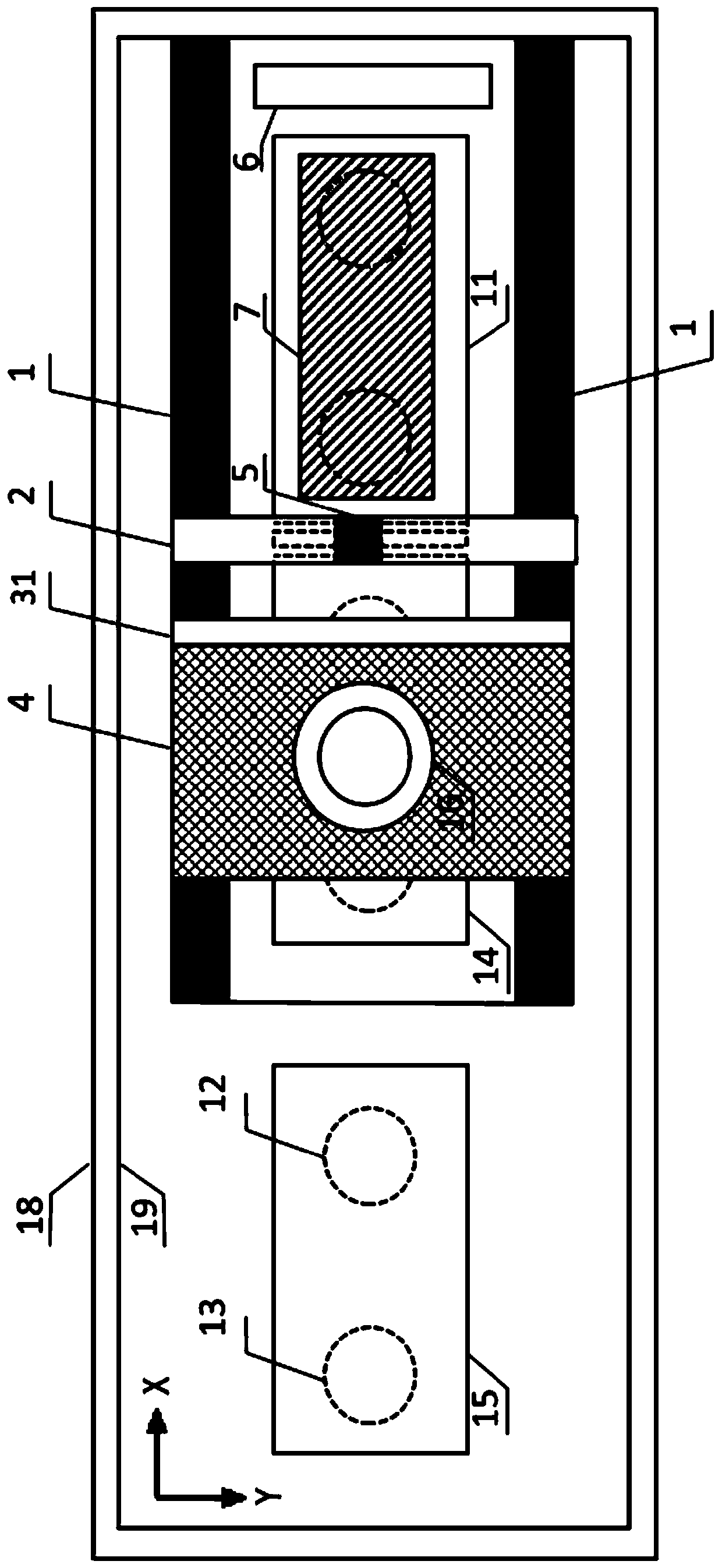

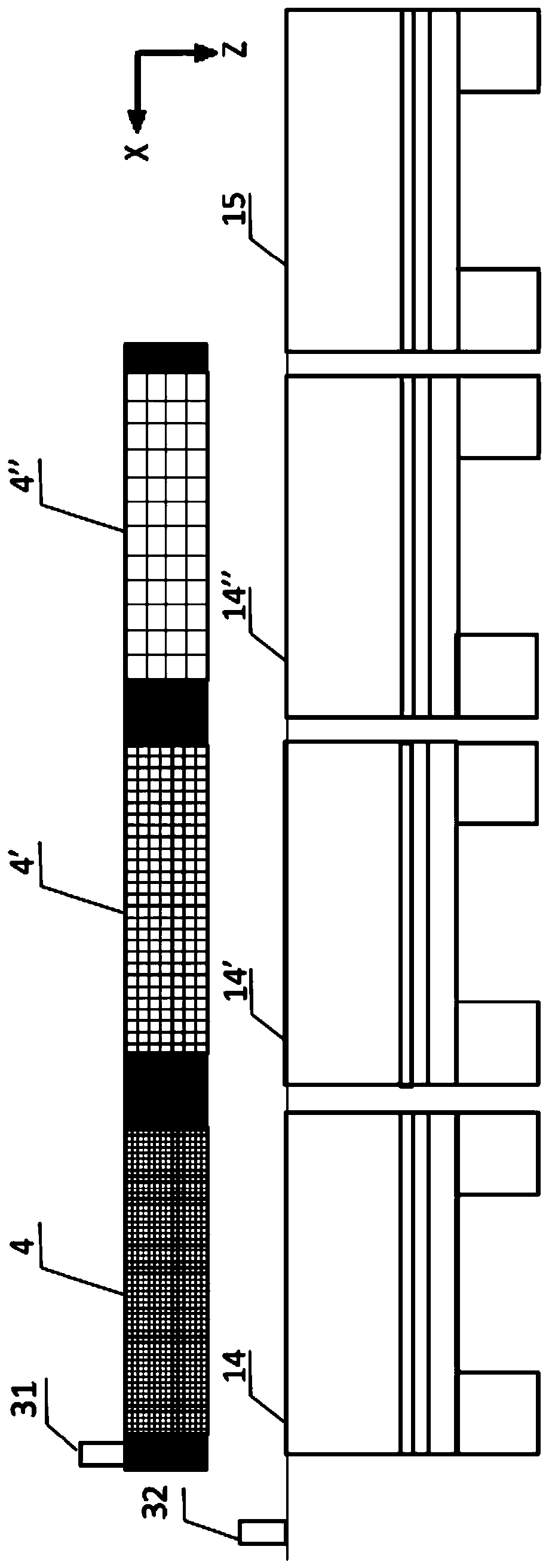

In-situ 3D printing device for lunar surface resources for microgravity vacuum environment

ActiveCN110039771BSolve supply problemsReduce manufacturing costManufacturing enclosuresManufacturing material handlingManufacturing cost reductionLunar soil

The invention discloses a microgravity vacuum environment oriented lunar surface in-situ resource 3D printing device, and belongs to the manufacturing field of spatial additive manufacturing. The device is characterized in that the obtaining and screening of surface particular materials of lunar soil, lunar dust and the like are achieved by a lunar surface in-situ resource grabbing and screening unit; a 3D printing shaping unit is formed through ink jetting, 3D printing is conducted by using screened particular materials, and the device is suitable for lunar surface microgravity vacuum environment and the 3D printing manufacturing of large components of future lunar base. The device has the advantages that the lunar surface in-situ resources are taken as printing consuming materials, the materials do not need to be carried to the moon through spatial transportation, so that transportation energy consumption is greatly reduced, the manufacturing cost is reduced, and the device is particularly suitable for the production of components of lunar base building facilities, mechanical parts and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Vertical ventilation sintering machine and sintering process

ActiveCN111426208BRealize graded recyclingReduce effluxMaintainance of heating chambersCharge manipulationMetallurgyFlue gas

The invention discloses a vertical draft sintering machine and a sintering process. The sintering machine includes at least two sintering chambers arranged vertically at intervals. The top of the sintering chamber is the feeding end and the bottom is the discharging end. The grates are connected to the gas outlet flue, and the air inlet channel and / or the gas outlet flue are shared between two adjacent sintering chambers. The sintering process is to add the sintering mixture from the feed end of the top of the sintering chamber, and finally the sintered ore is discharged from the discharge end of the bottom of the sintering chamber; In the sintering chamber, the flue gas in the sintering chamber enters the gas outlet flue on the other side of the sintering chamber through the grate bar under the action of negative pressure and is discharged. The air inlet channel and / or the gas outlet flue are shared between two adjacent sintering chambers. The invention has the advantages of simple structure, small smoke generation, no air leakage problem, good stability, small occupied area, high waste heat utilization rate, improved sintered ore quality, energy saving and consumption reduction.

Owner:WUHAN WUTUO TECH

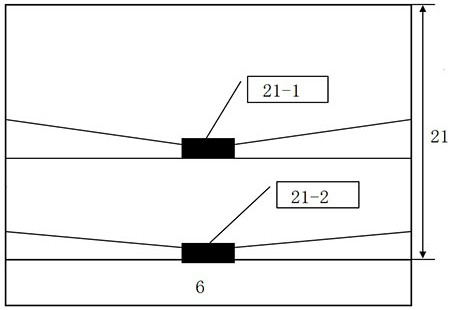

A kind of oil-based drilling fluid regeneration treatment method

ActiveCN114426853BEasy to handleReduce energy consumptionHydrocarbon dewateringCombustion chamberFluid phase

The invention discloses a method for regeneration treatment of oil-based drilling fluid, which comprises the following steps: S1. Pump waste oil-based drilling fluid to a vacuum low-temperature high-efficiency film evaporator for rapid evaporation, and the evaporated mixed gas is cooled into a liquid phase and then enters The first collection tank is recovered; S2, the oil and solid mixture in the vacuum low-temperature high-efficiency film evaporator is pumped into the circulating thermal desorption device for pyrolysis, and the pyrolysis gas enters the controllable condenser to generate condensate; S3, the circulating heat The combustion chamber of the hydrolysis device produces high-temperature tail gas, and the high-temperature tail gas exchanges heat with the normal-temperature air through an air-gas indirect heat exchanger to obtain hot air and low-temperature tail gas; S4, the tail gas is discharged up to the standard; S5, the circulating thermal desorption device discharges the solid phase through the high-temperature spiral ; S6, mixing the recovered liquid phase collected by the first collection tank in step S1 and the condensate collected by the second collection tank in step S2 at a ratio of 5:1 to obtain a mixed solution, and recovering oil and recovered water by processing the mixed solution.

Owner:河北迪运化工科技有限公司

Smoke exhaust heat utilization device of directly-fired triple effect machine

ActiveCN101539351BReduce consumption costsLow running costClimate change adaptationMachines using waste heatHeat lossesEngineering

The invention relates to a smoke exhaust heat utilization device of a directly-fired triple effect machine, comprising a directly-fired high pressure generator (9), a medium pressure generator (11), a low pressure generator (13), a high temperature solution heat exchanger (8), a medium temperature solution heat exchanger (7) and a low temperature solution heat exchanger (5). A smoke outlet pipe (10) of the directly-fired high pressure generator (9) is internally and additionally provided with a smoke exhaust heat utilization device (15); the shell side of the smoke exhaust heat utilization device (15) is sequentially provided with a high temperature smoke heat exchange tube bundle (16), a medium temperature smoke heat exchange tube bundle (17) and a low temperature smoke heat exchange tube bundle (18) upwards along the smoke flow direction; the tube side of the high temperature smoke heat exchange tube bundle (16) is arranged in series on a solution pipeline for entering and exiting the directly-fired high pressure generator (9); the tube side of the medium temperature smoke heat exchange tube bundle (17) is arranged in series on a solution pipeline for entering the medium pressure generator (11); and the tube side of the low temperature smoke heat exchange tube bundle (18) is arranged in series on a solution pipeline for entering the low pressure generator (13). The inventioncan further improve the fuel heat utilization ratio of the directly-fired triple effect machine, reduce the temperature of smoke exhaust and reduce the heat loss of smoke exhaust.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

Drying gas temperature and flow self-regulating control device and method in coke drying system

ActiveCN103940213BRealize self-adjusting functionRealize graded recyclingDrying gas arrangementsFlue gasEconomic benefits

Owner:CISDI ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com