Silicon material scattering and recycling system

A recovery system and dispersing technology, applied in grain processing, etc., can solve problems such as unqualified product quality, incomplete removal of impurities, and uneven waste, so as to improve quality and ensure recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

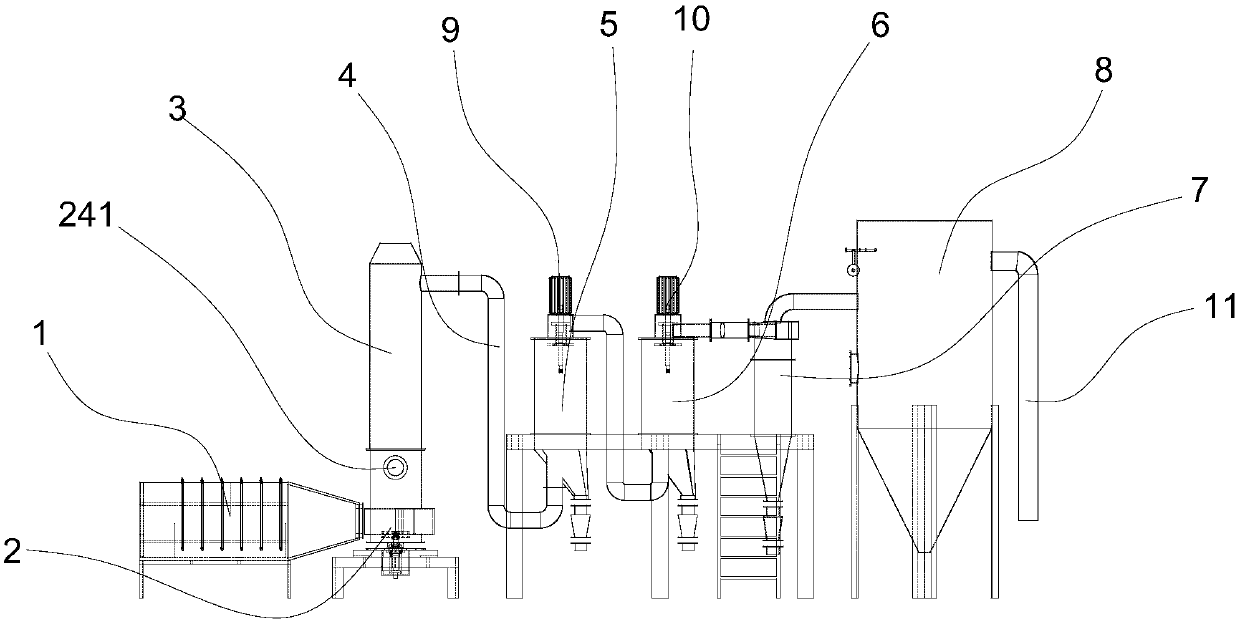

[0030] Such as figure 1 As shown, the silicon material breaking and recycling system of the present invention includes a hot blast tank 1, a breaking machine 2, an air outlet tube 3, a connecting pipeline 4, a first collecting tank 5, a second collecting tank 6, a cyclone separation Device 7, the third collecting tank 8;

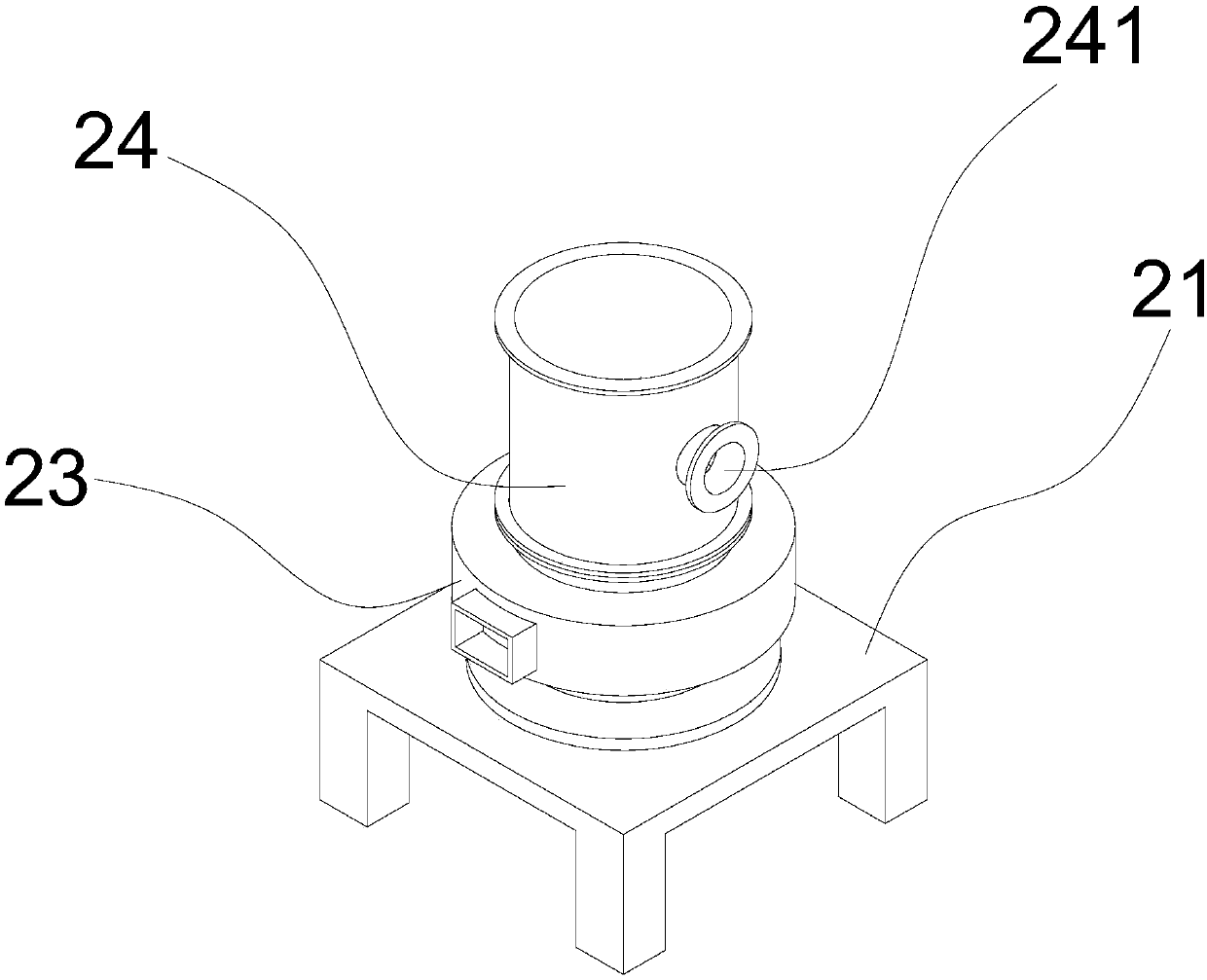

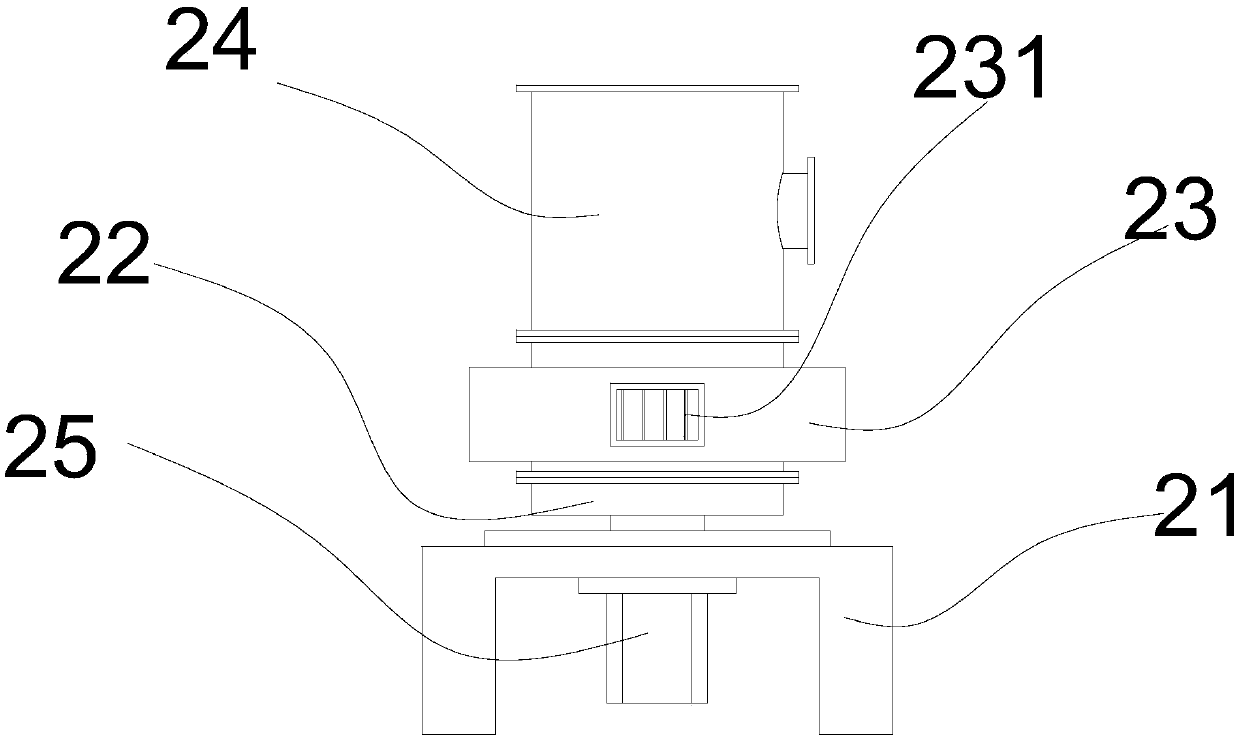

[0031] The breaking machine 2 includes a base 21, a breaking cylinder 22, and a feeding cylinder 24, and an annular air inlet ring 23 is arranged on the outer circumferential surface of the breaking cylinder 22;

[0032] The breaking cylinder 22 is arranged on the base 21, the breaking cylinder 22 is provided with a breaking turntable 28, and the bottom of the base 21 is provided with a driving device 25 for driving the breaking turntable 28 to rotate;

[0033] The breaking up turntable 28 is provided with breaking pieces 281 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com