Patents

Literature

337 results about "Material scattering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

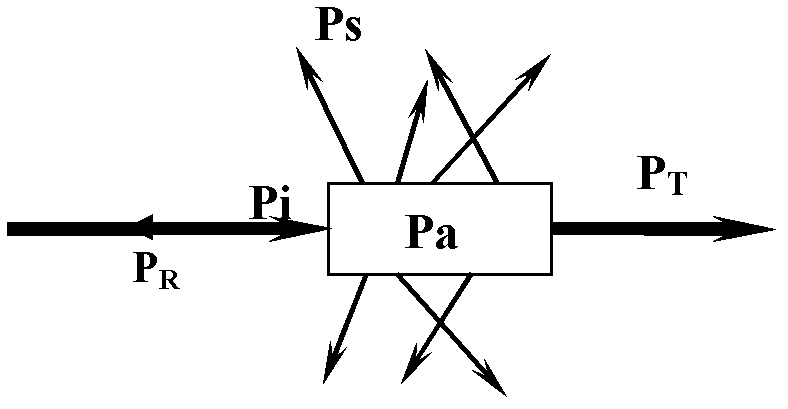

Material scattering of an electromagnetic wave is scattering that is attributable to the intrinsic properties of the material through which the wave is propagating. Ionospheric scattering and Rayleigh scattering are examples of material scattering. In an optical fiber, material scattering is caused by micro-inhomogeneities in the refractive indices of the materials used to fabricate the fiber, including the dopants used to modify the refractive index profile. This article incorporates public domain material from the General Services Administration document "Federal Standard 1037C".

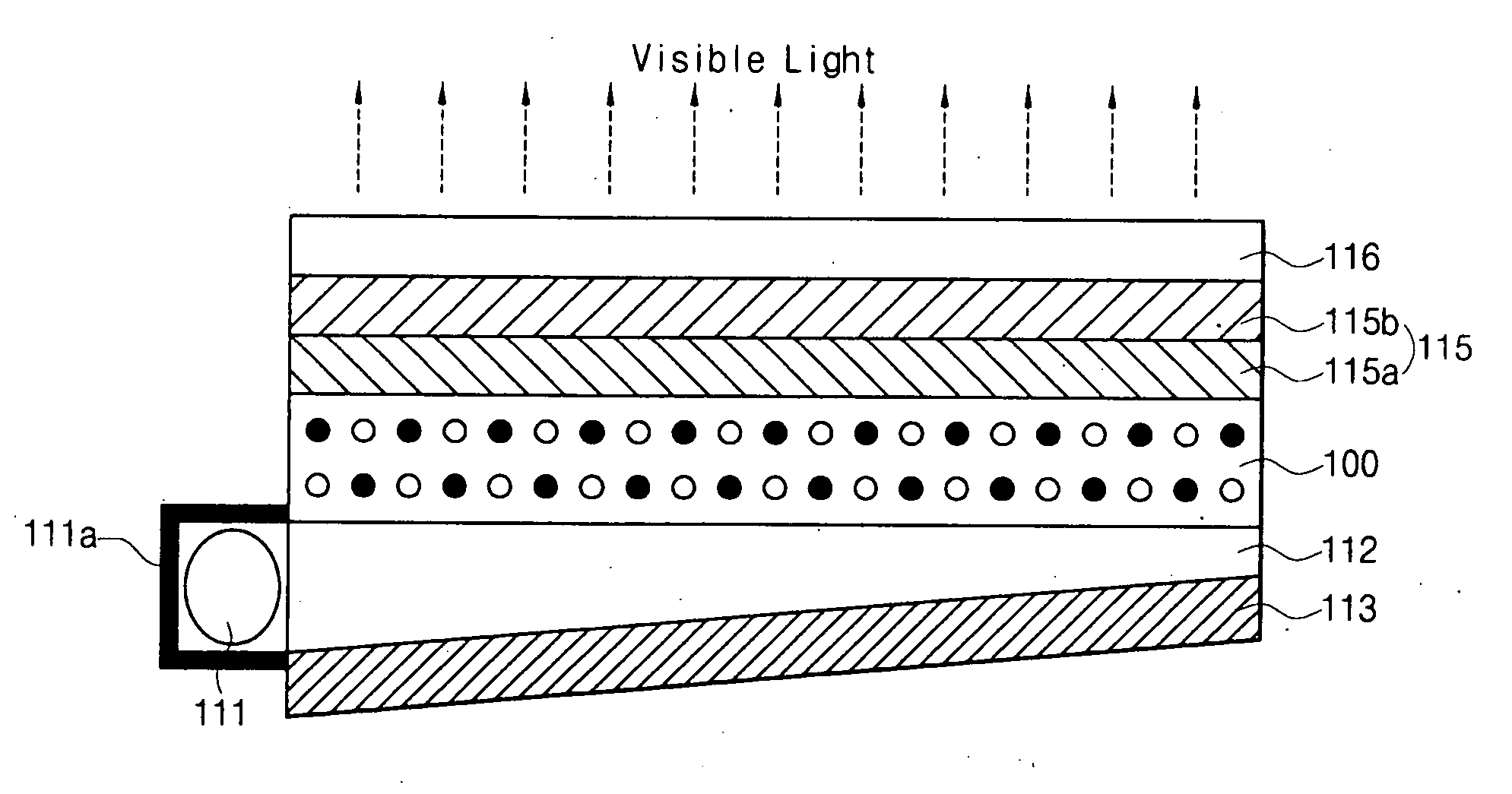

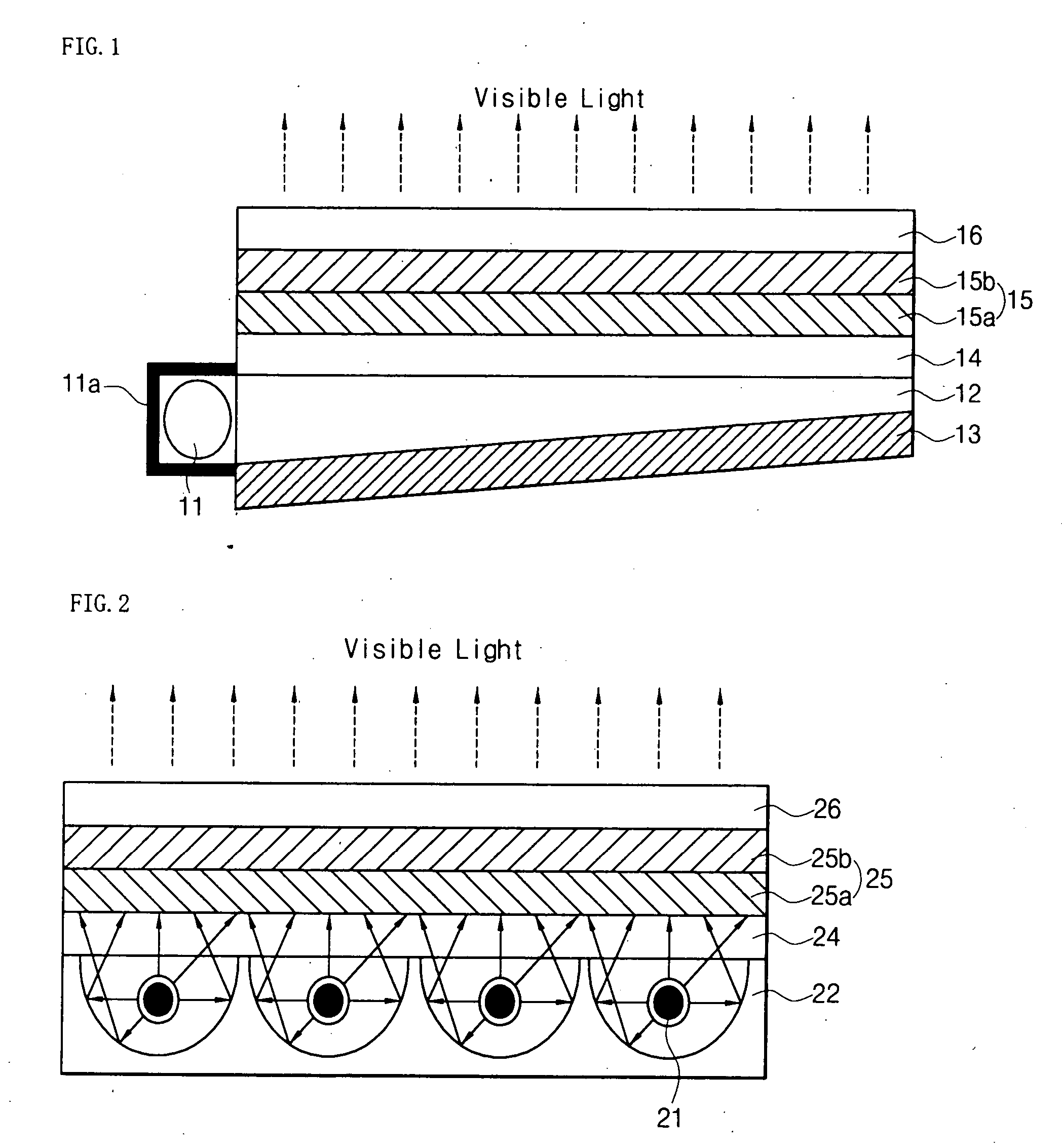

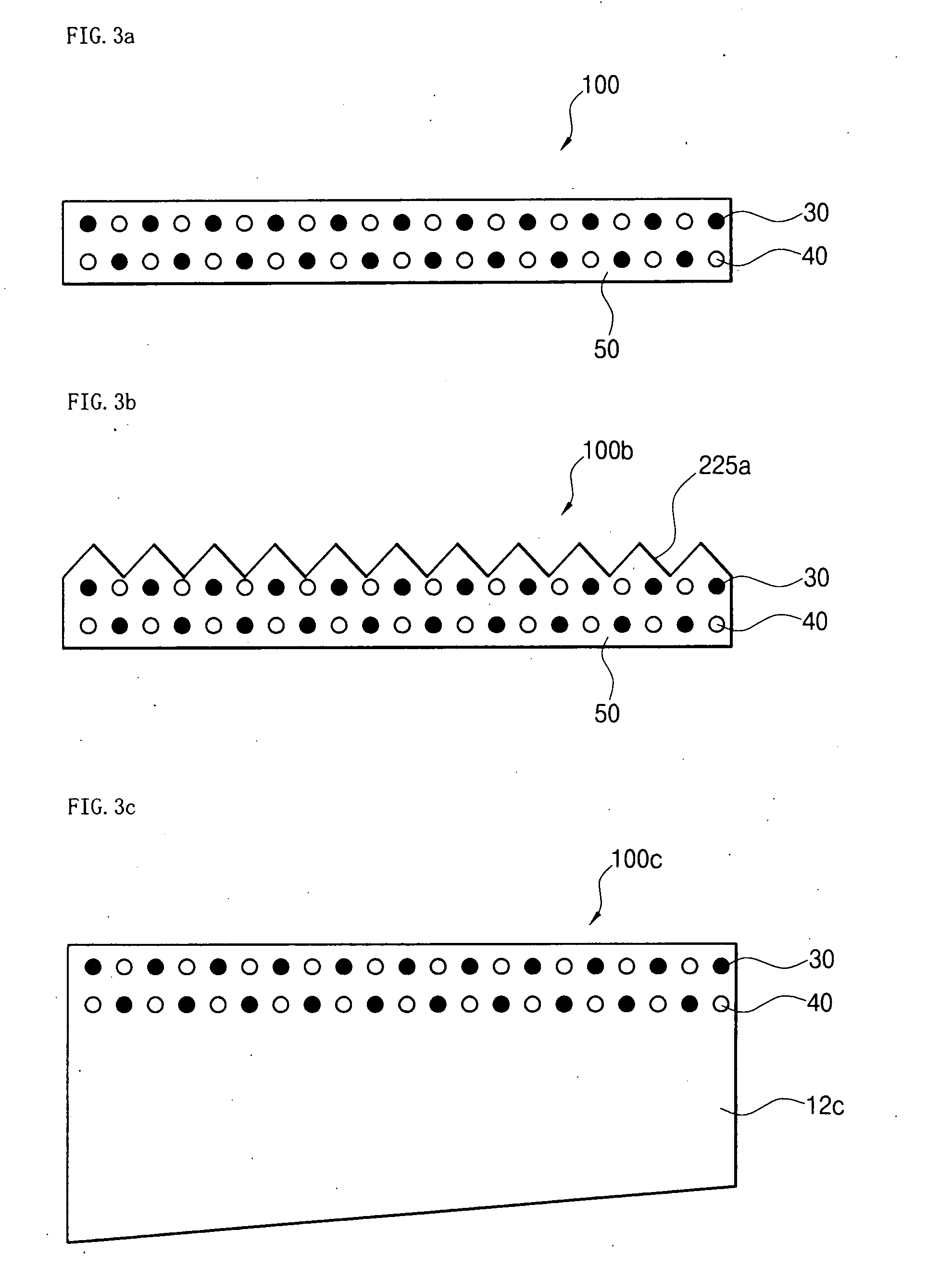

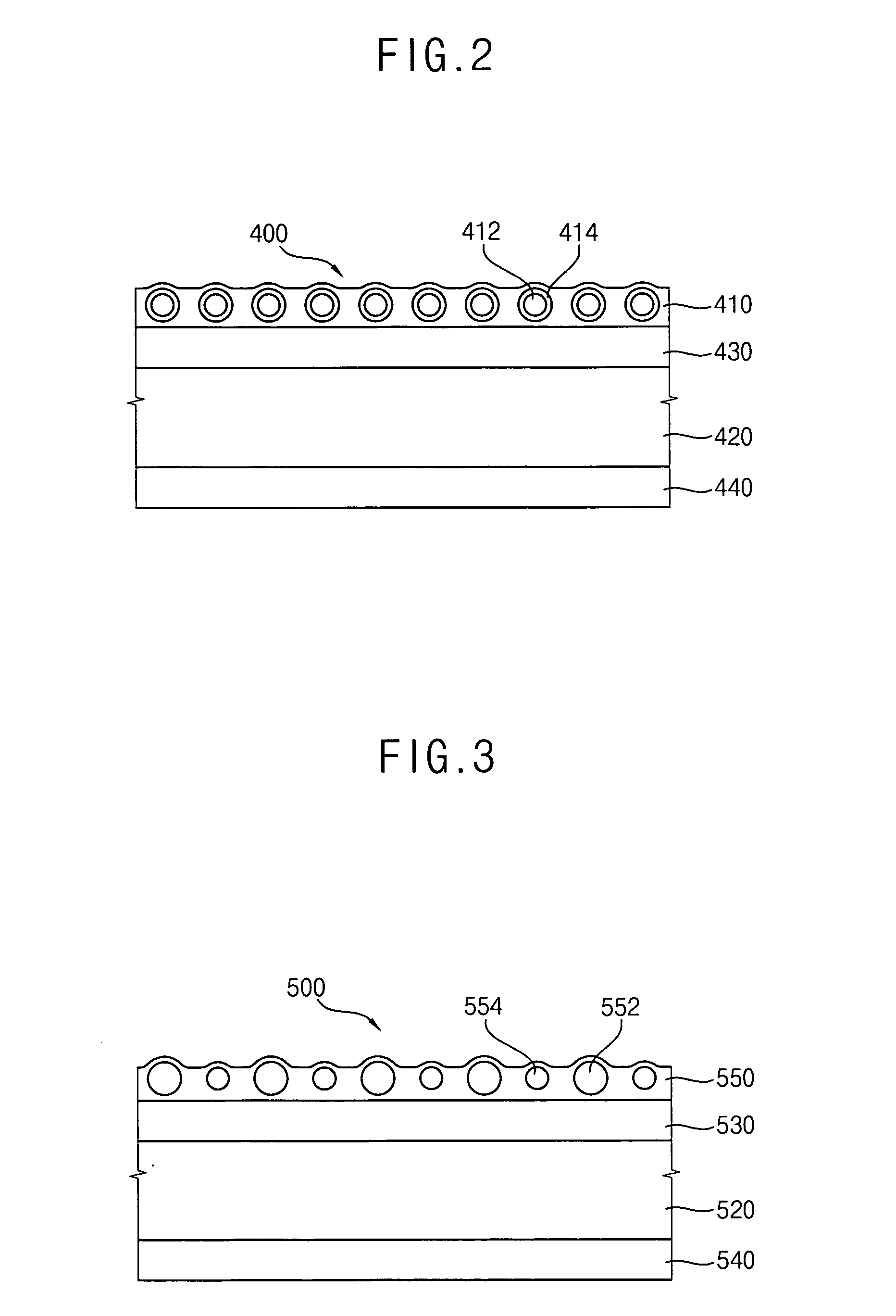

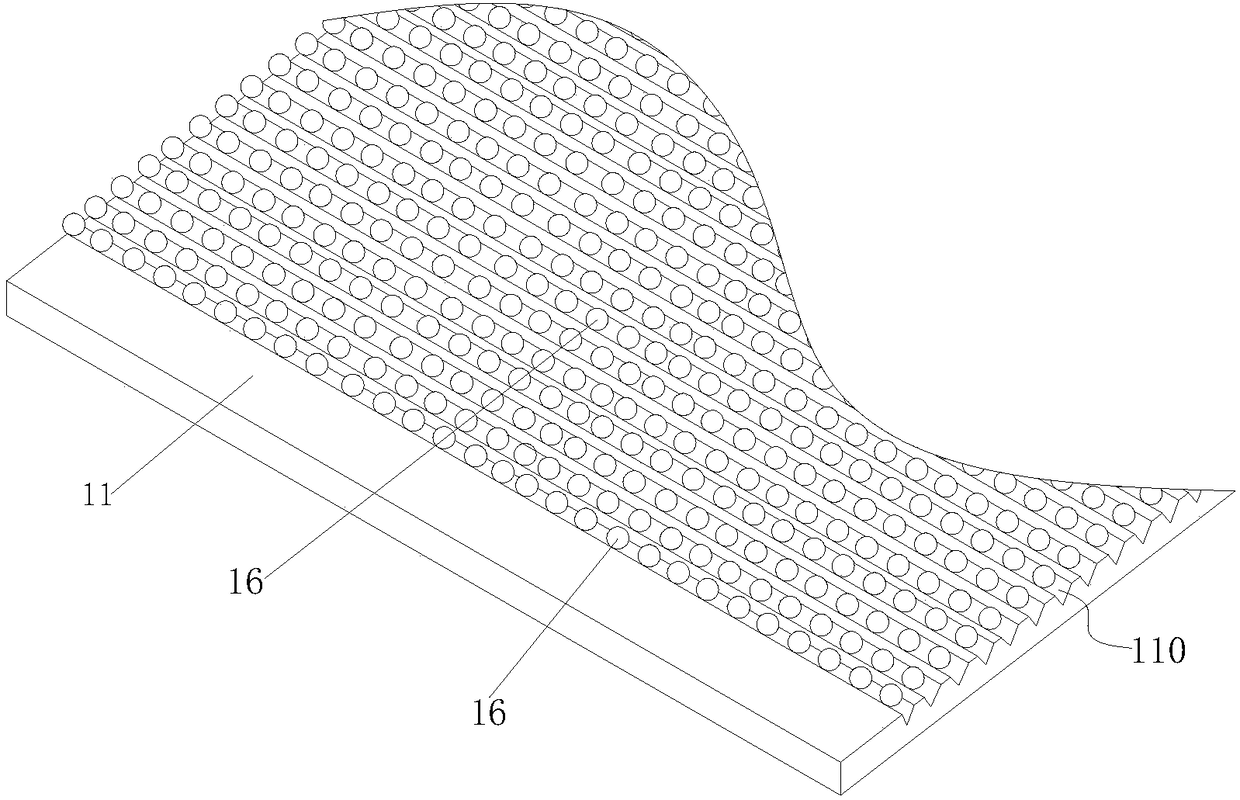

Light excitation-diffusion sheet for backlight unit and backlight unit for liquid crystal display using the same

InactiveUS20060109682A1High color purityImprove lighting efficiencyOptical light guidesNon-linear opticsLiquid-crystal displayMaterial scattering

A light excitation diffusion sheet for a backlight unit adapted to absorb a portion of light emitted from a light source of a blue wavelength or a mixed wavelength of a blue wavelength and at least one other wavelength, to emit light at different wavelengths from the light emitted from the light source, and to allow the rest of the light emitted from the light source to penetrate the sheet The light excitation-diffusion sheet comprises a light-exciting material exciting and amplifying the light from the light source and a light-diffusing material scattering and diffusing the light from the light source. The light-exciting material and the light-diffusing material are uniformly distributed in the light excitation-diffusion sheet The use of the light excitation-diffusion sheet enables production of edge light type and direct light type backlight units having diffusion and prism functions, good color purity and improved light efficiency at reduced costs.

Owner:KDT

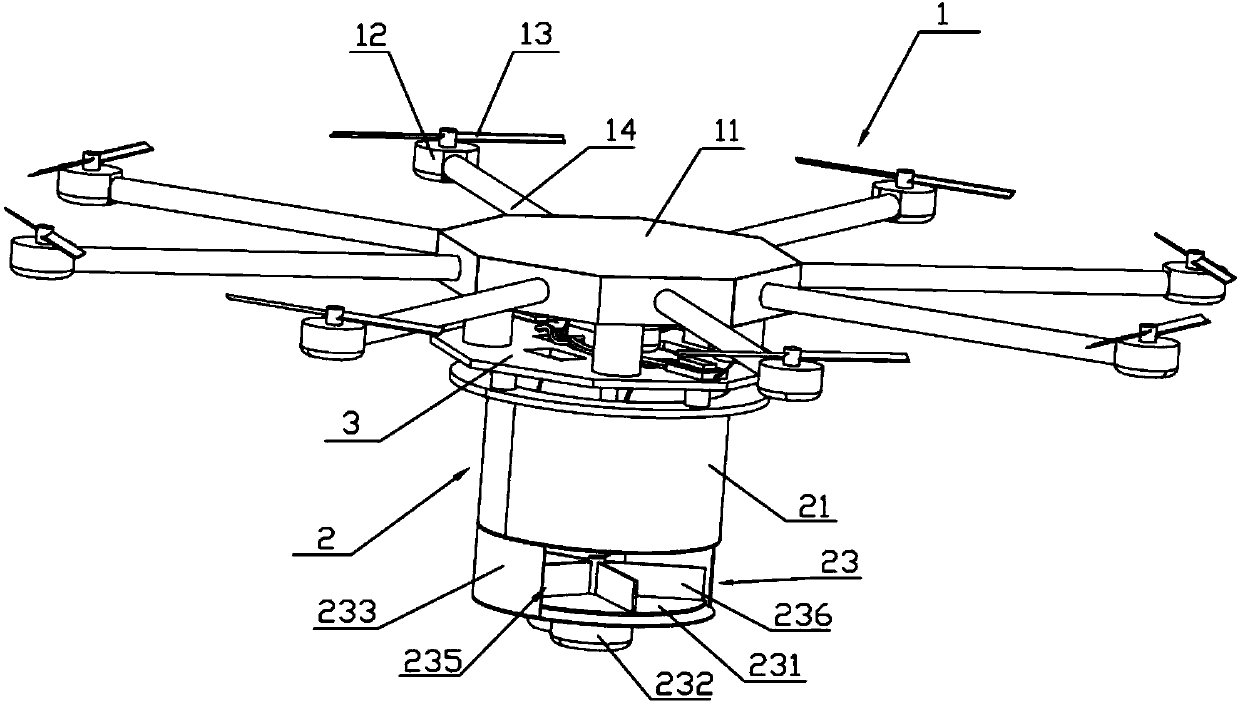

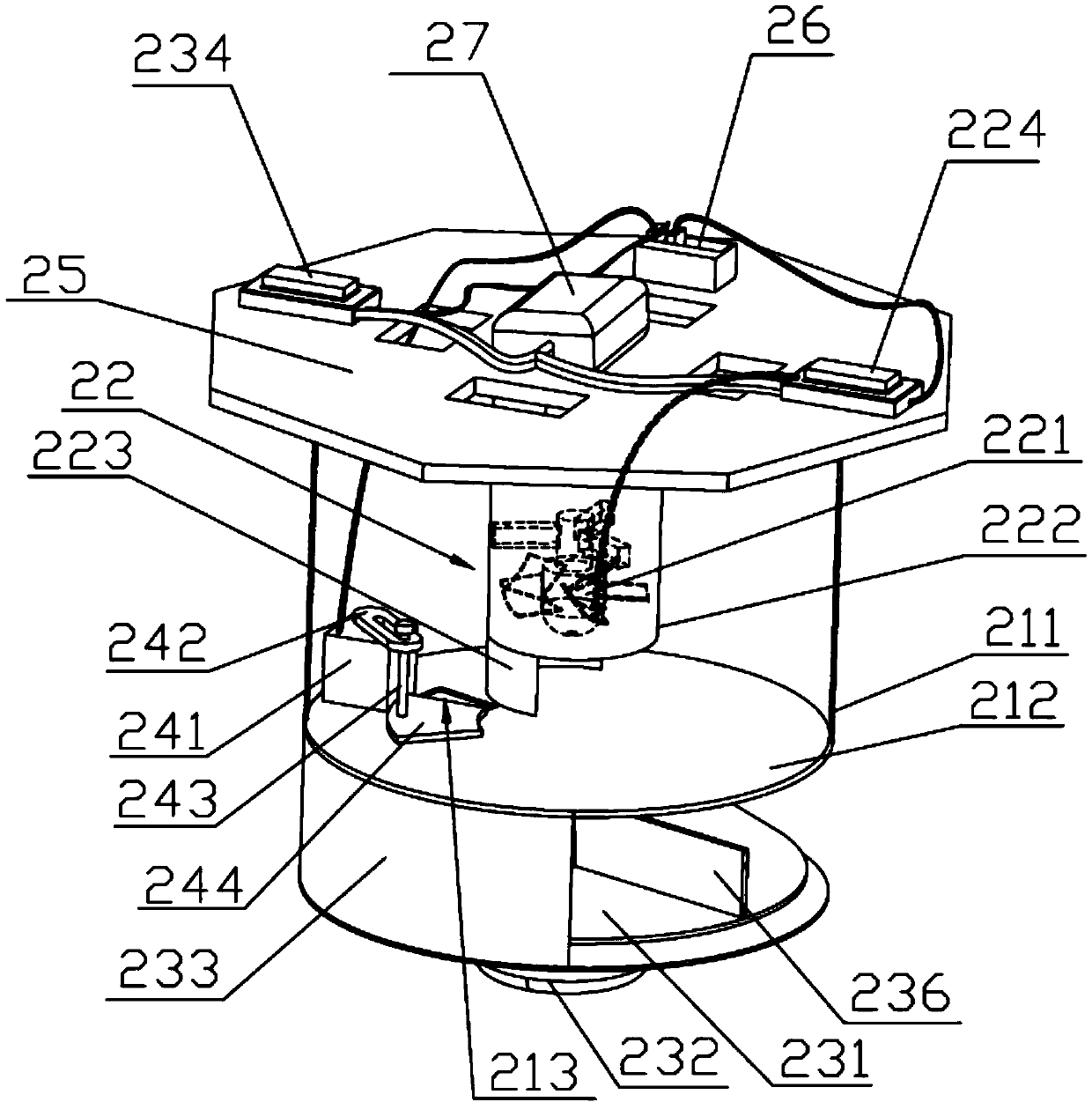

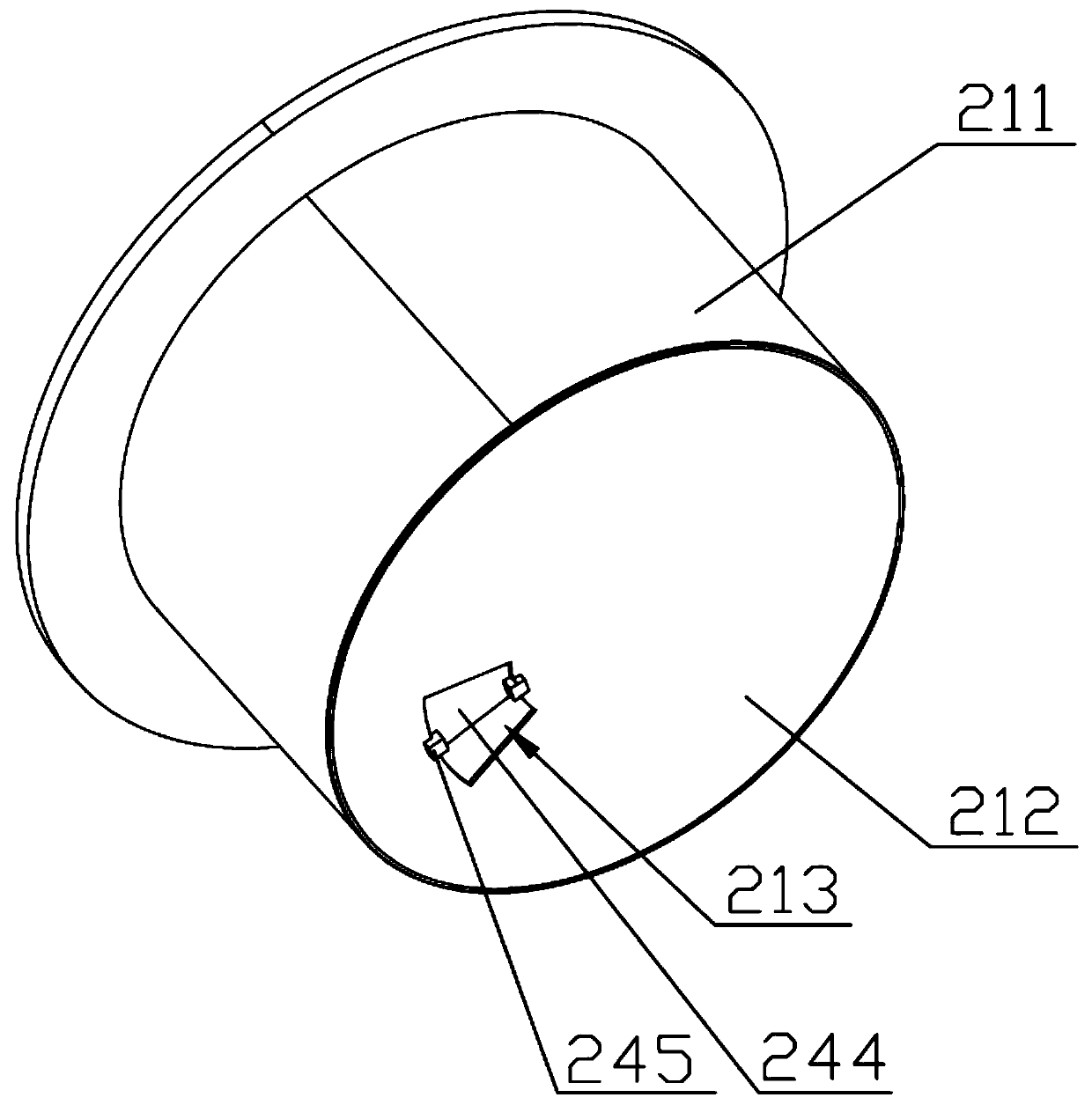

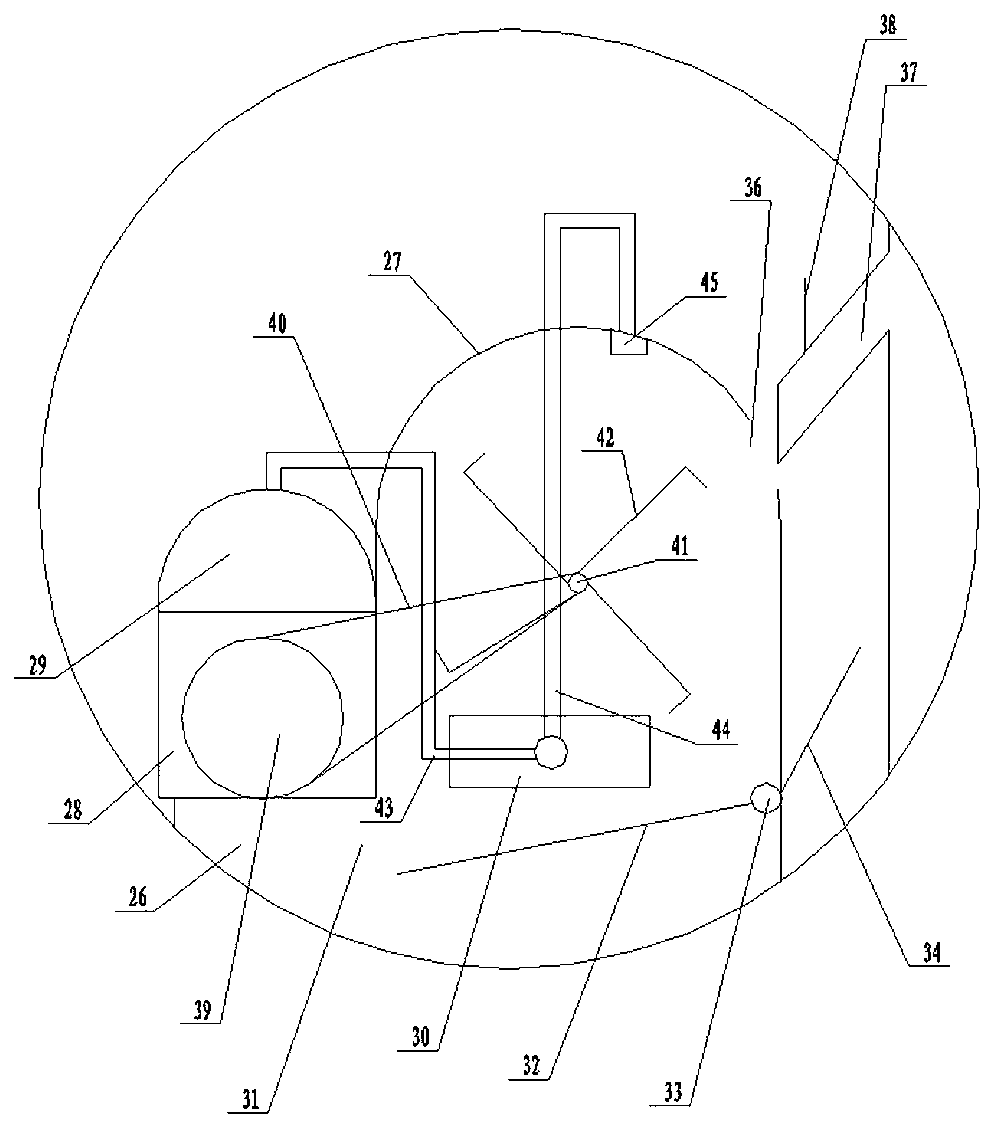

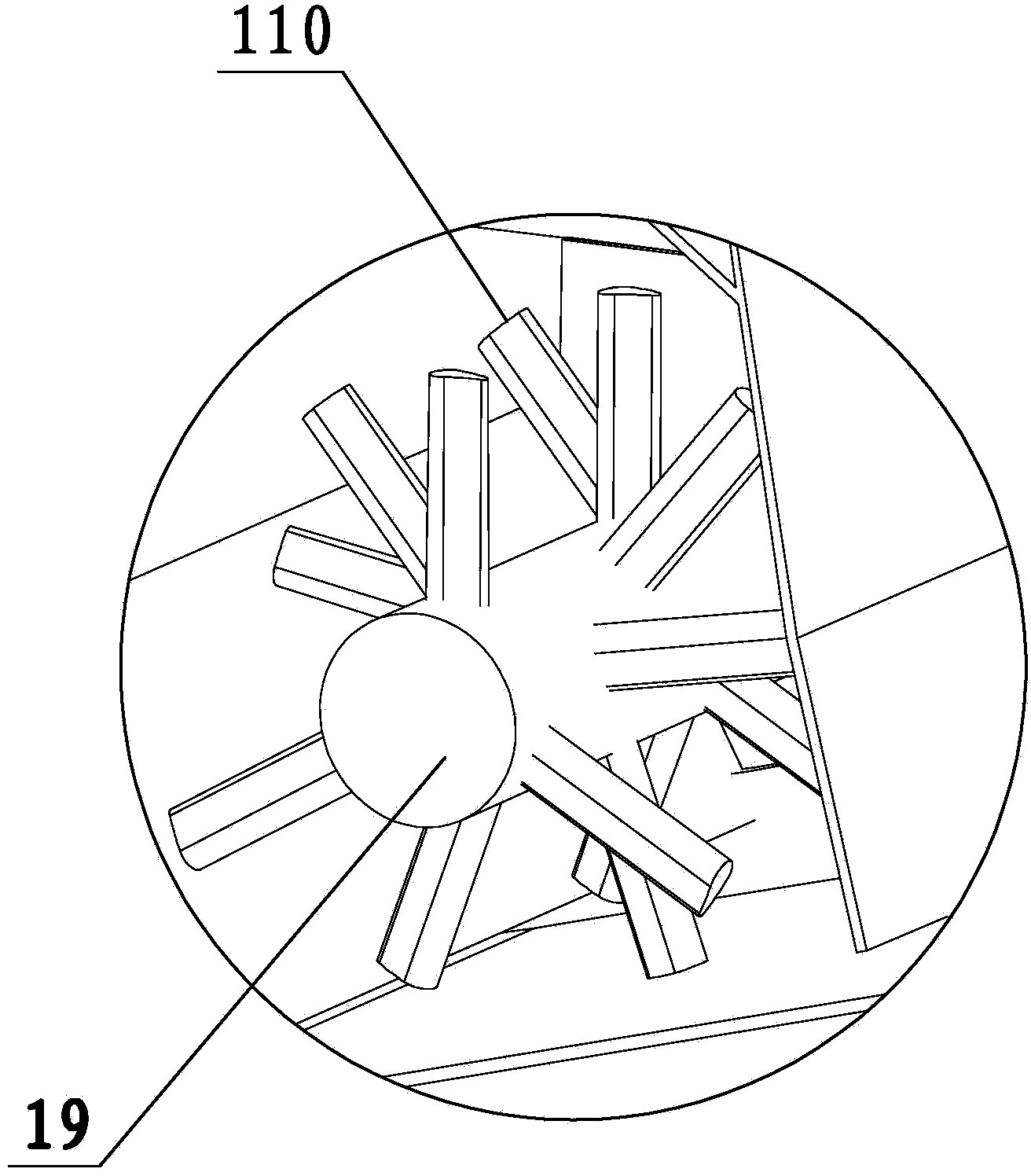

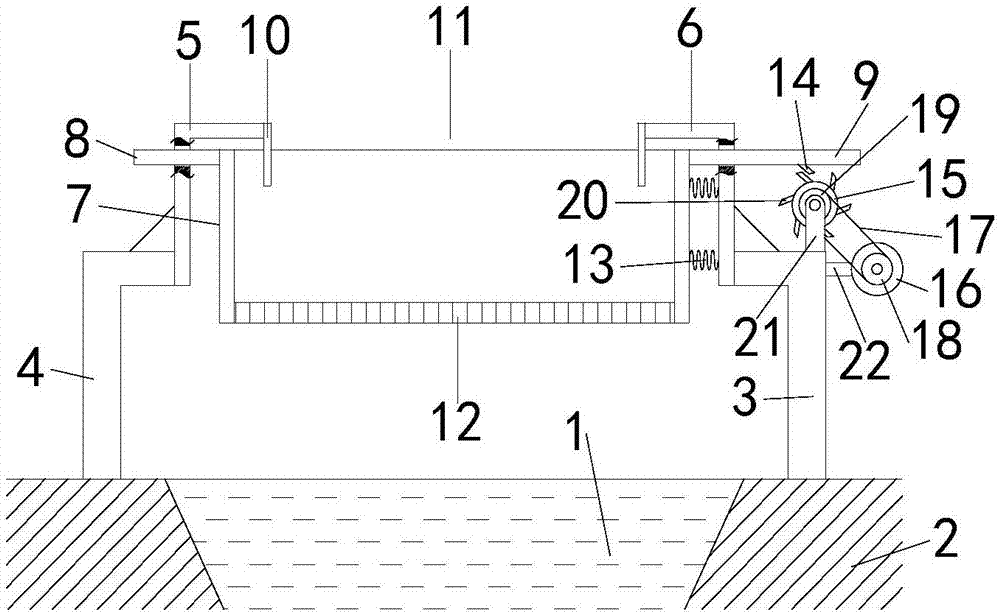

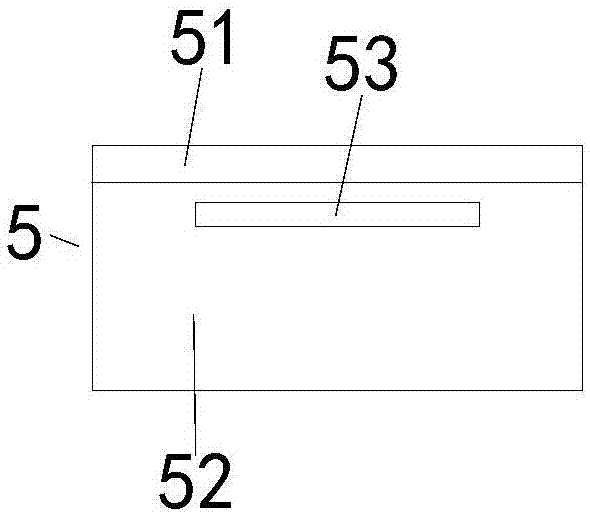

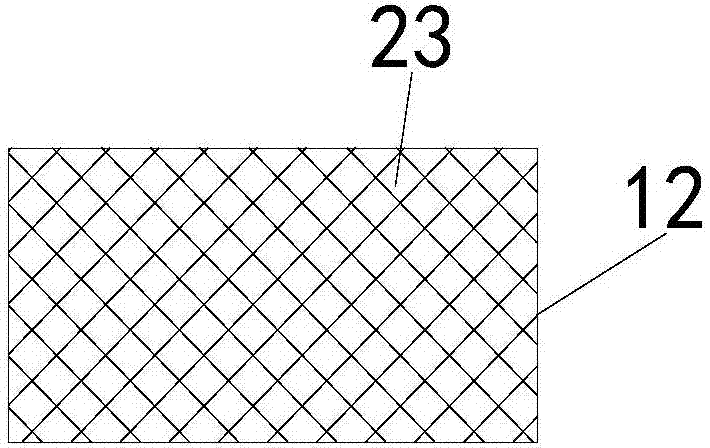

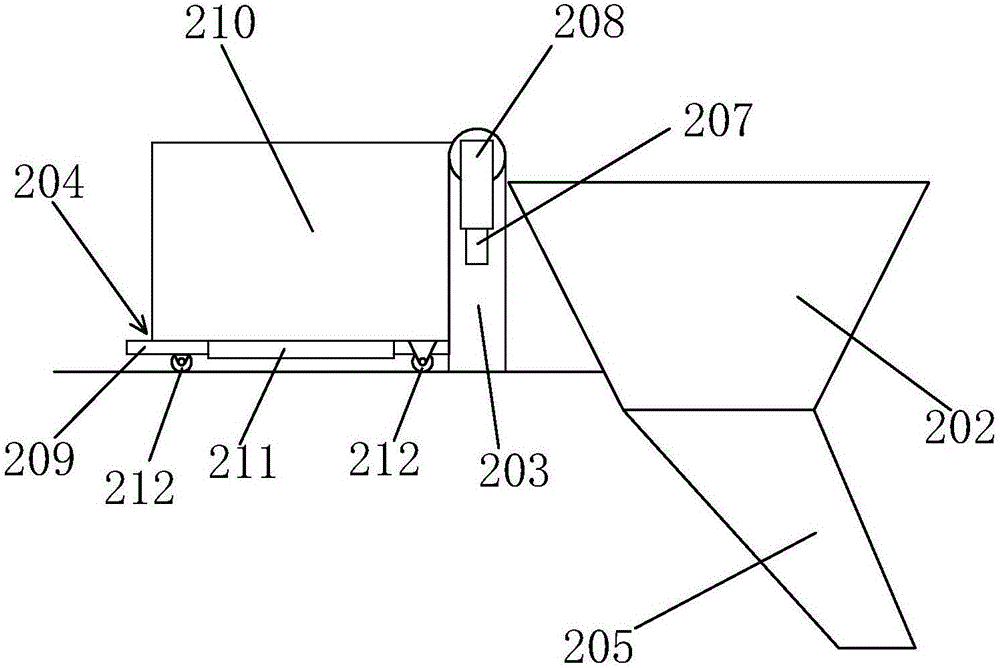

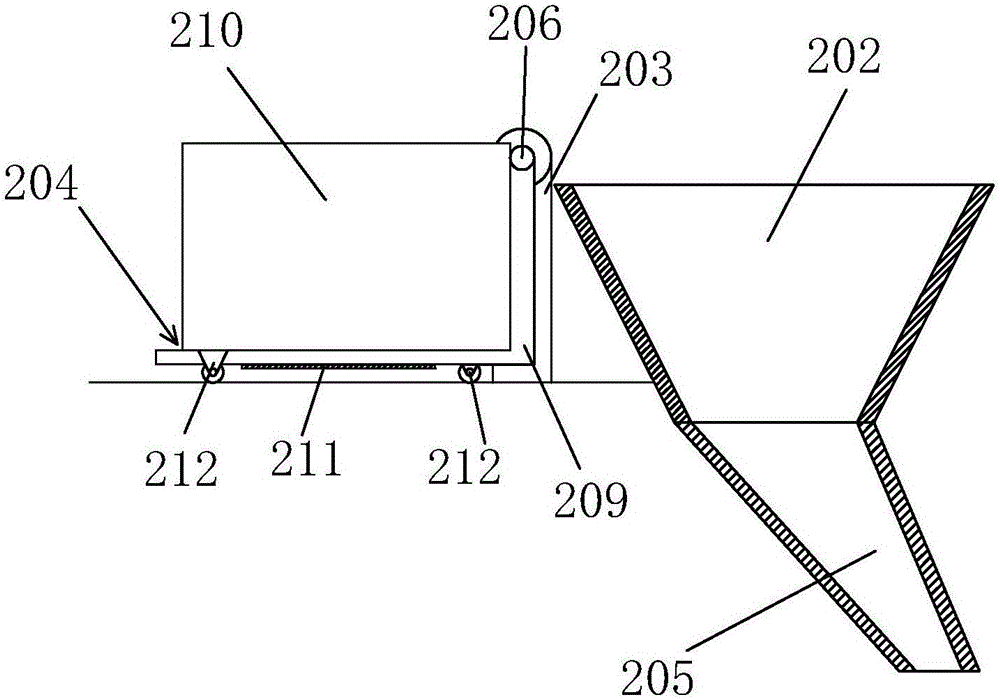

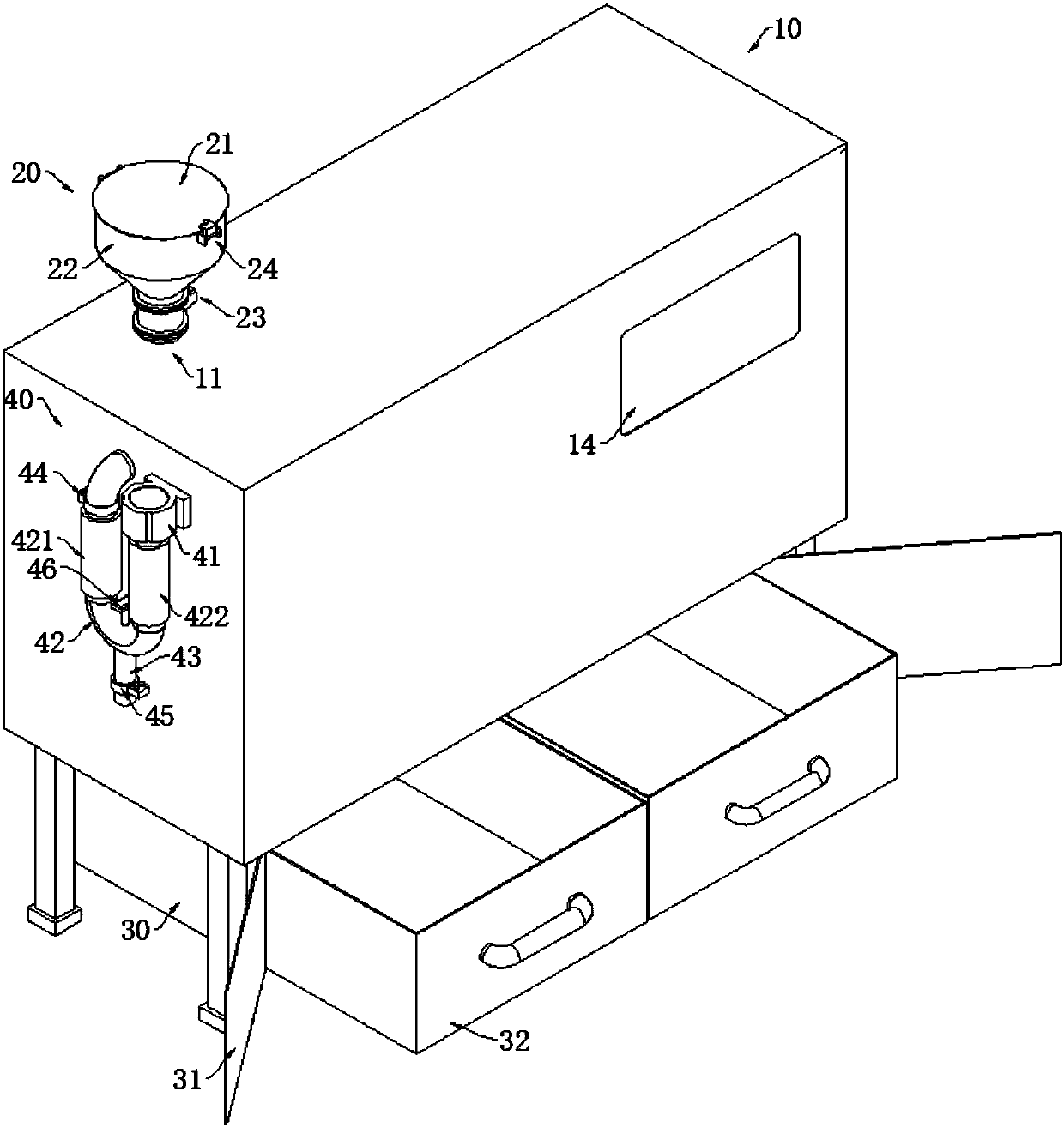

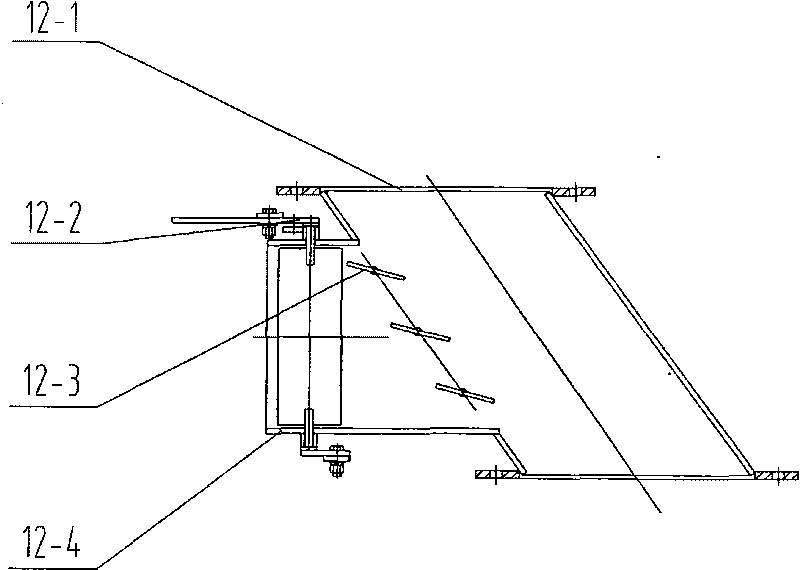

Onboard device suitable for sowing job of unmanned aerial vehicle and sowing method

ActiveCN104176254AReduce volumeLow costAircraft componentsLaunching weaponsBaseboardMaterial scattering

The invention discloses an onboard device suitable for the sowing job of an unmanned aerial vehicle and a sowing method. The onboard device comprises a scattering device arranged below the unmanned aerial vehicle, wherein the scattering device comprises a material box, a material stirring mechanism, a material discharging adjusting mechanism and a material scattering mechanism; the material stirring mechanism is arranged inside the material box; the material scattering mechanism is arranged below the material box; the material box comprises a box wall and a baseboard; a ventage is formed in the baseboard; the material discharging adjusting mechanism comprises a switch baffle arranged in the ventage and an actuating mechanism used for pushing the switch baffle to move in the ventage and adjusting the size of the leak; the material scattering mechanism comprises a side plate connected to the bottom of the material box, a wheel disc motor and a wheel disc connected with the wheel disc motor; the wheel disc is arranged on the inner side of the side plate; a scattering openings are formed in the side plate. According to the invention, the onboard device has the advantages of being small in size, low in cost, high in flexibility and convenient for controlling.

Owner:SOUTH CHINA AGRI UNIV

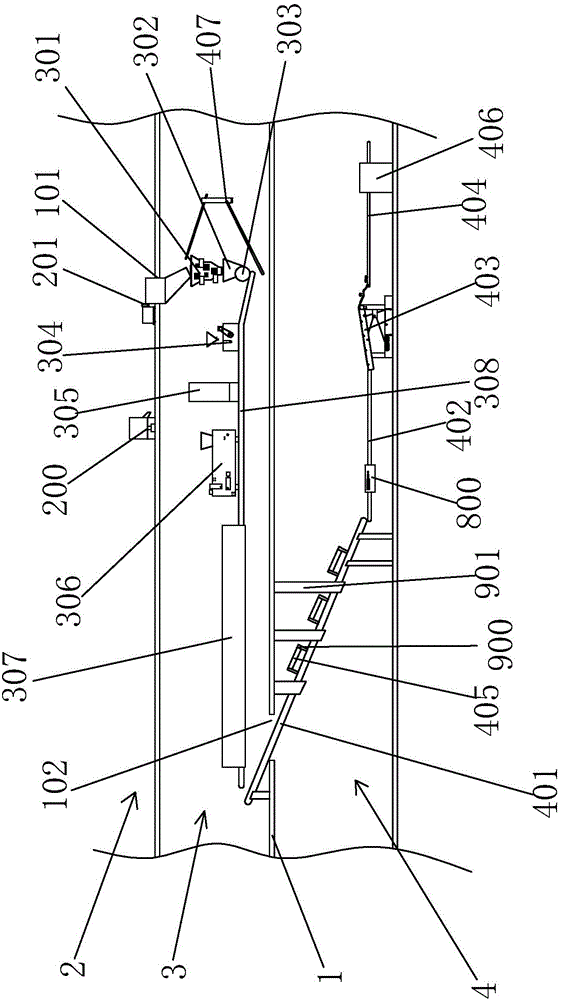

Intelligent feeding device for aquaculture

ActiveCN103340171AReduce wasteFeeding amount is reasonablePisciculture and aquariaAquatic productMaterial scattering

The invention discloses an intelligent feeding device for aquaculture. The intelligent feeding device for the aquaculture comprises a material loading device, a material storing device, a conveying device and a material scattering device, wherein the conveying device is connected with the lower end of the material storing device, and the material scattering device is mutually connected with the conveying device. The intelligent feeding device for the aquaculture has the advantages that fodder is saved, pollution to environment is reduced, labor force is saved, the automation degree is high, waste of the fodder is relatively less, the fodder can be weighed, feeding amount of the fodder is reasonable, assimilation and absorption of the fodder are greatly improved, the fodder is directly transported by an automobile and poured into a feeding port, and woven bags are not needed. When drug needs to be sprayed, liquid drug is directly mixed with the fodder and is directly conveyed to a feeding machine in the middle of a fish pond for feeding through a pipeline after being stirred evenly.

Owner:江苏爱斯特能源科技有限公司

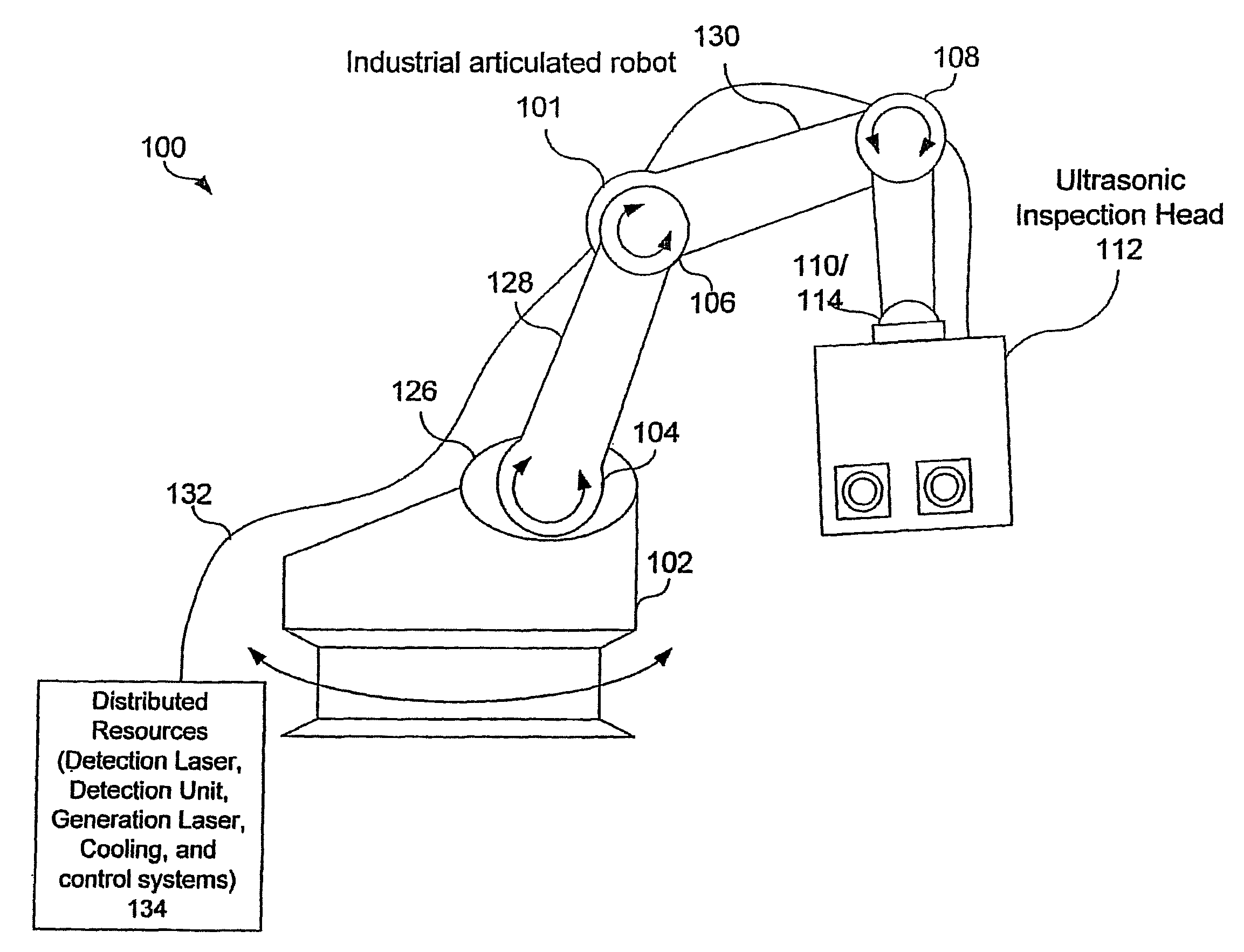

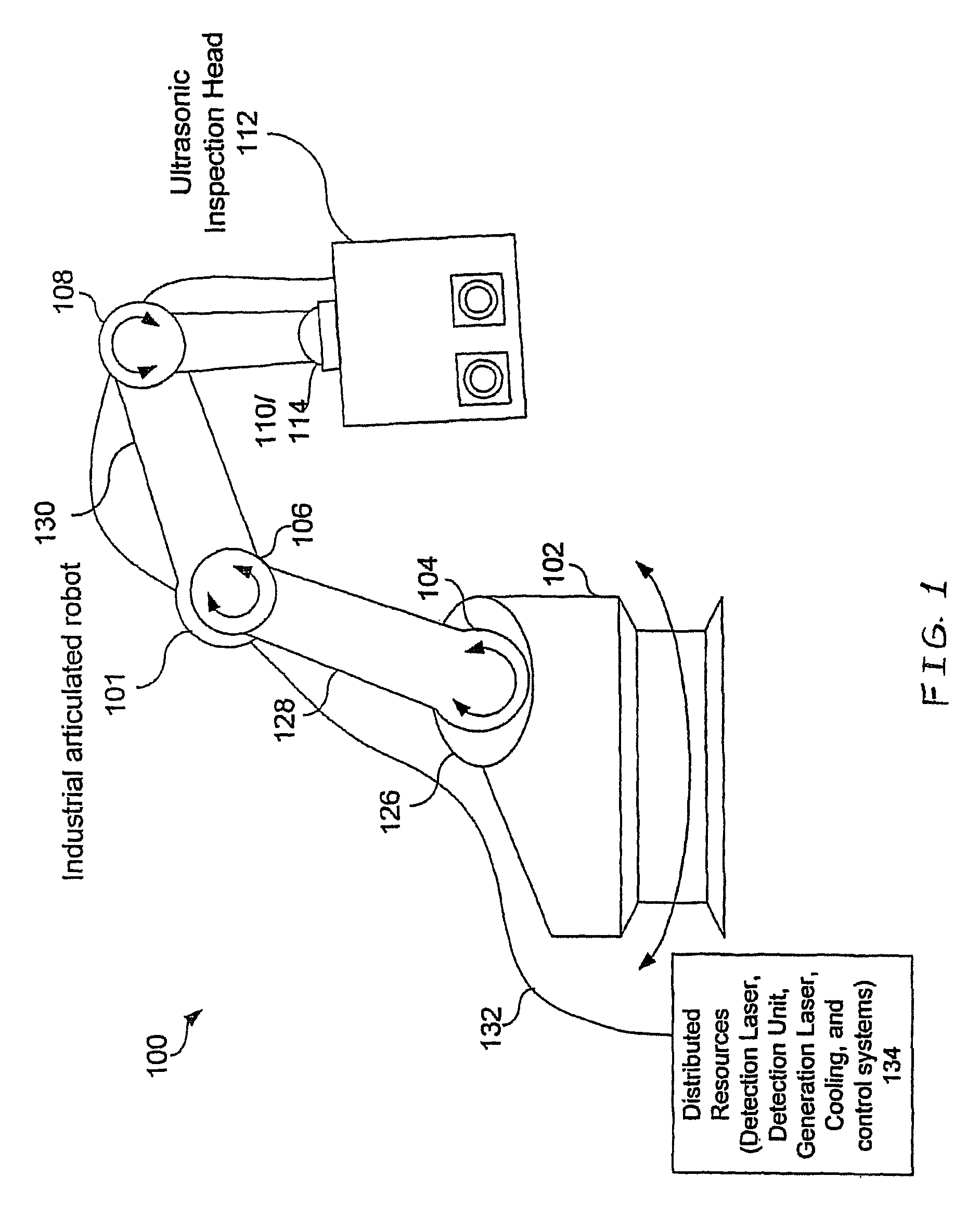

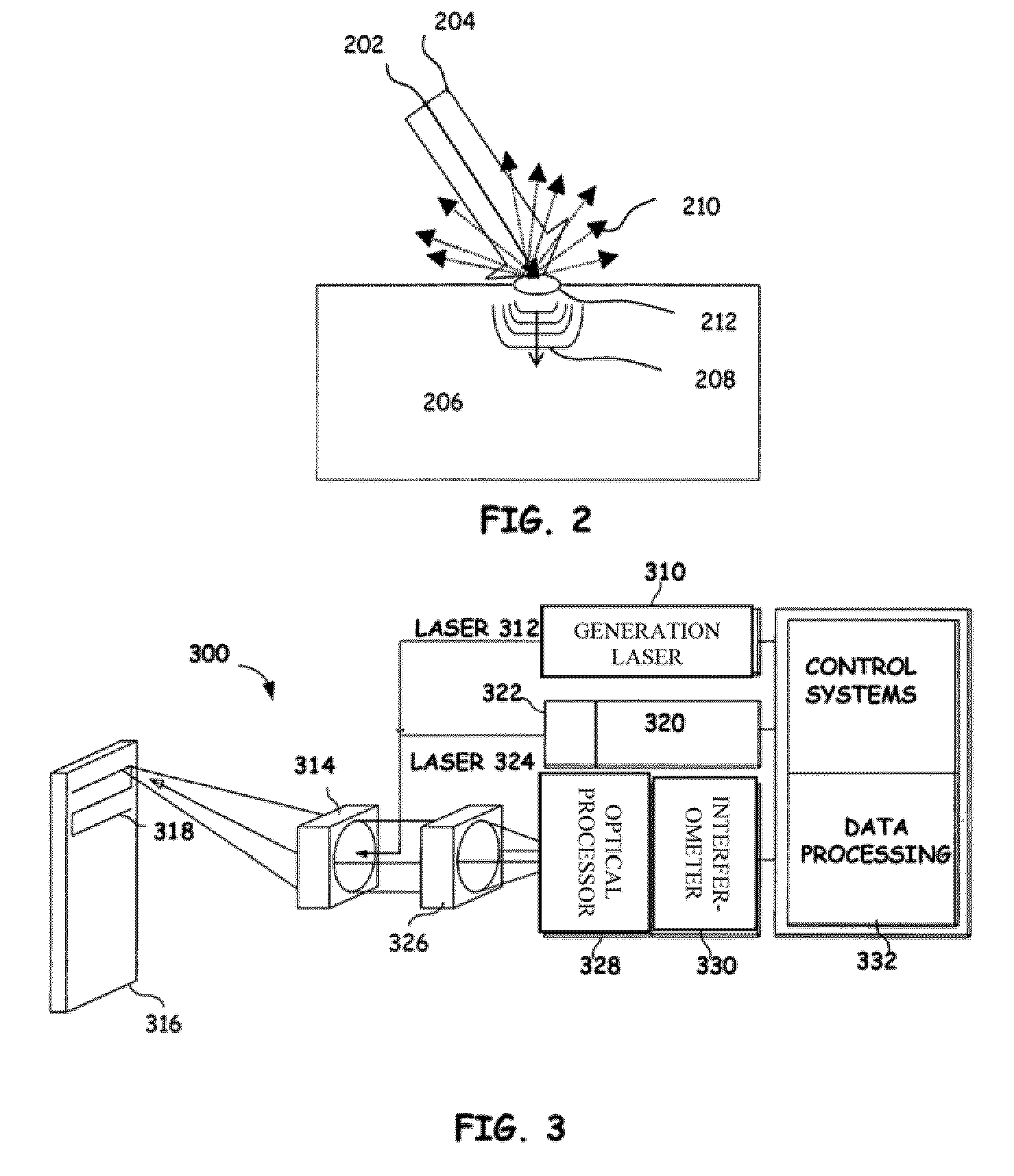

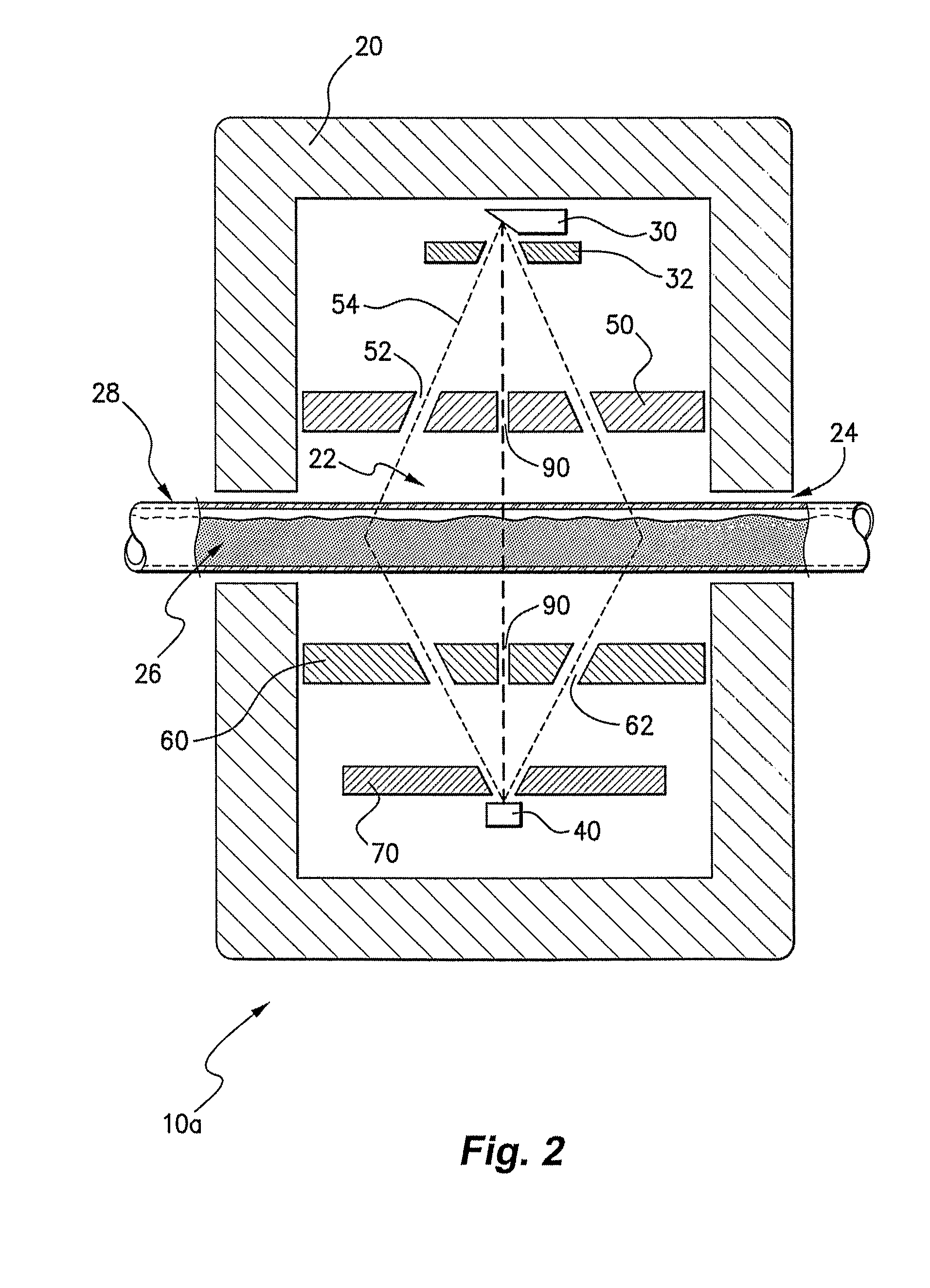

Articulated robot for laser ultrasonic inspection

ActiveUS7784348B2Cost-effectiveMore compact robotsAnalysing solids using sonic/ultrasonic/infrasonic wavesLaser using scattering effectsNon destructiveUltrasound sonography

An ultrasonic non-destructive evaluation (NDE) system operable to inspect target materials is provided. This ultrasonic NDE system includes an articulated robot, an ultrasound inspection head, a processing module, and a control module. The ultrasound inspection head couples to or mounts on the articulated robot. The ultrasound inspection head is operable to deliver a generation laser beam, a detection laser beam, and collect phase modulated light scattered by the target materials. The processing module processes the phase modulated light and produces information about the internal structure of the target materials. The control module directs the articulated robot to position the ultrasound inspection head according to a pre-determined scan plan.

Owner:LOCKHEED MARTIN CORP

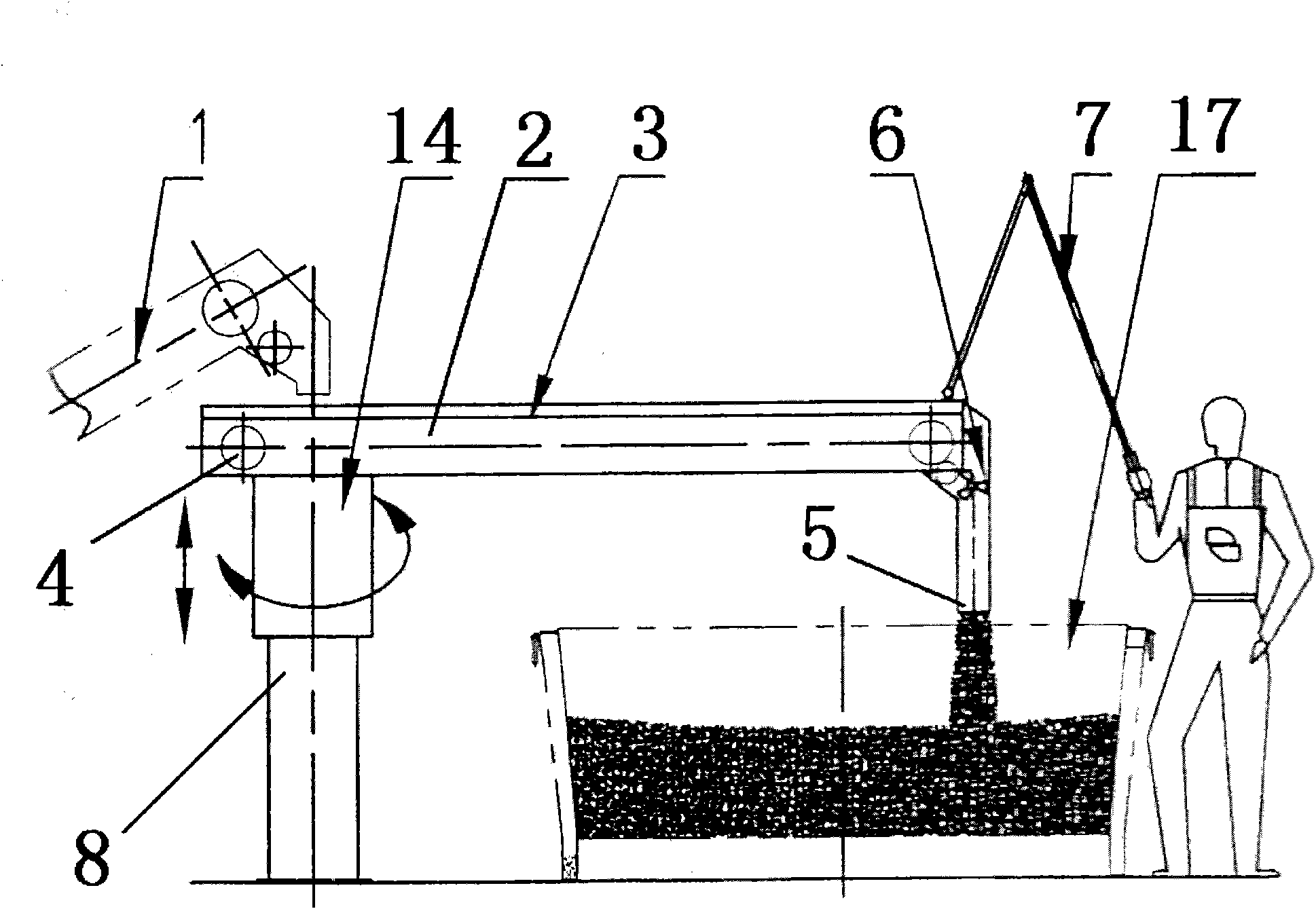

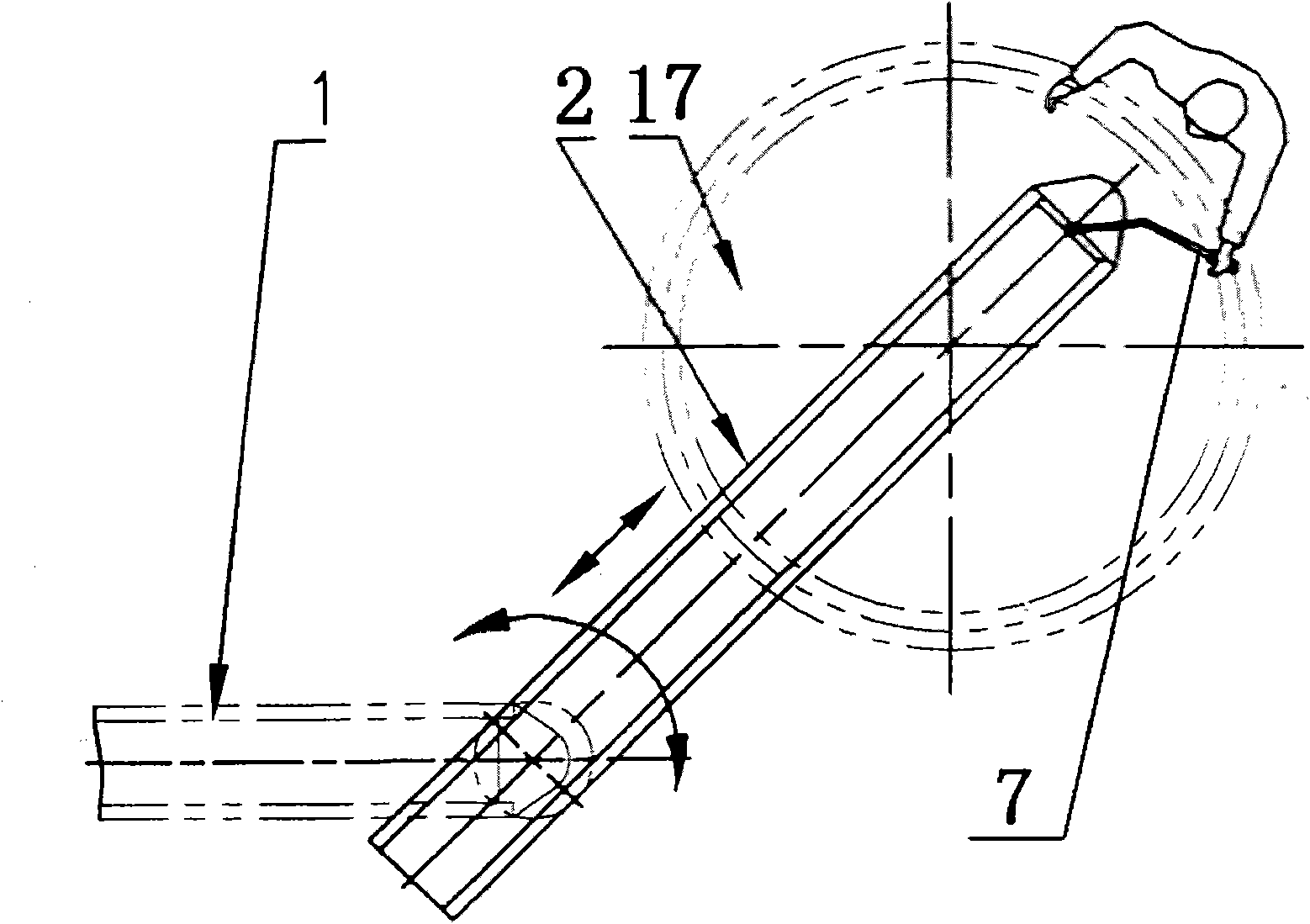

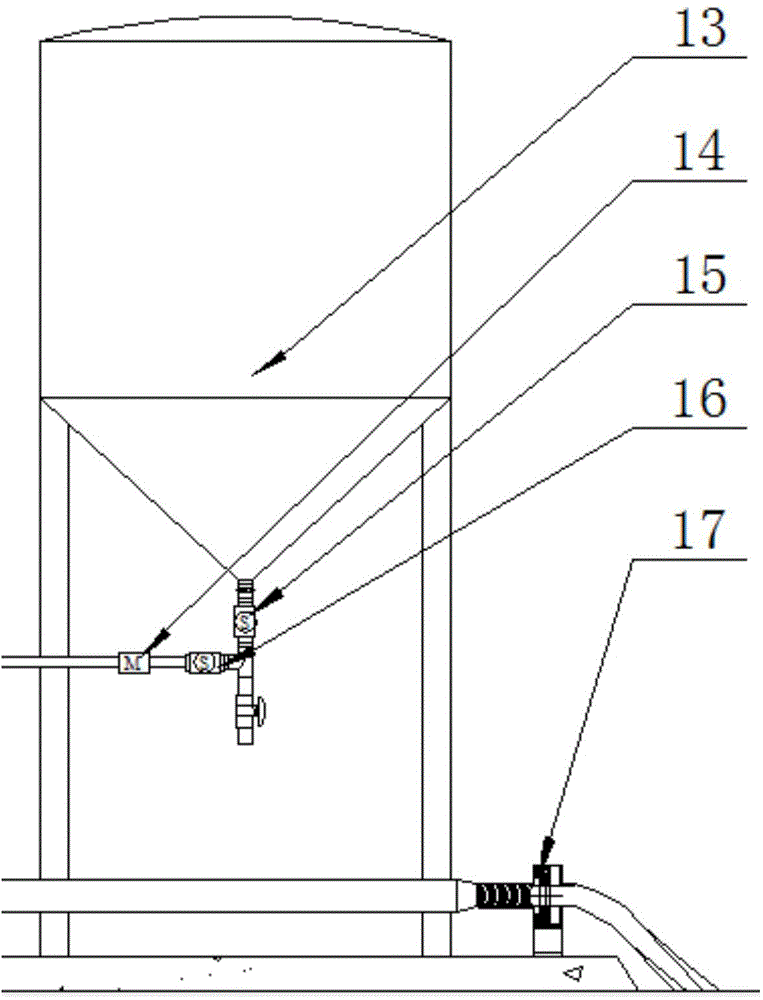

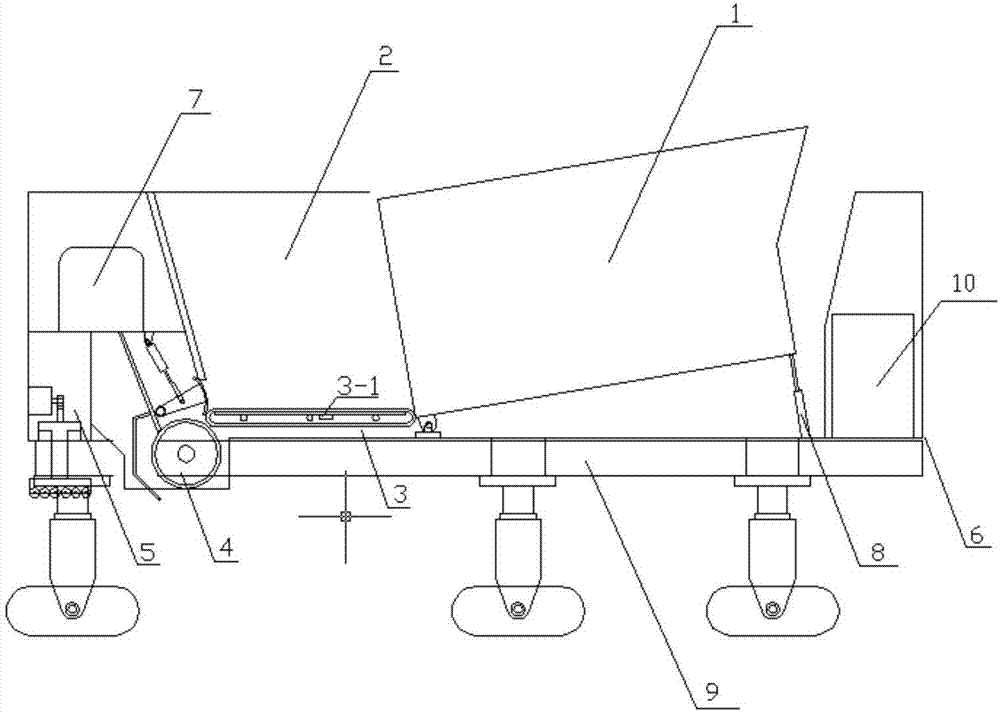

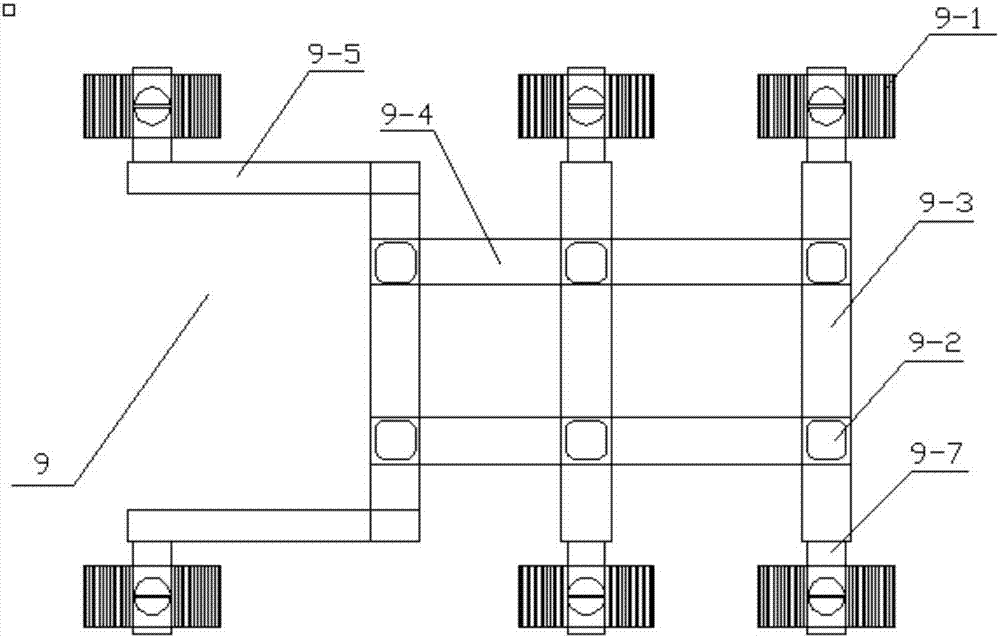

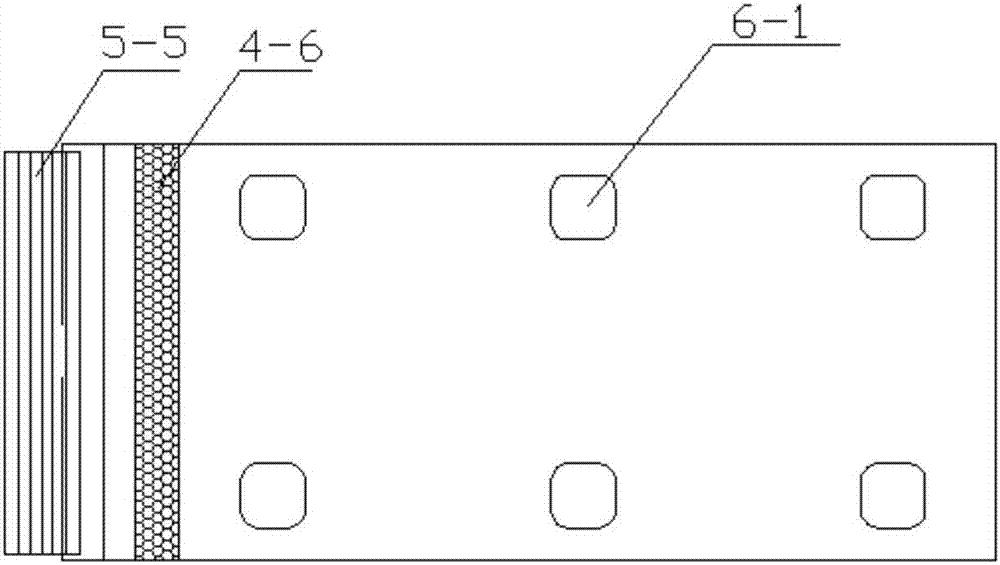

Semi-automatic rice steamer loading device of solid brewing grain tank

InactiveCN102070025AQuality assuranceGuaranteed outputLoading/unloadingSemi automaticMaterial scattering

The invention discloses a semi-automatic rice steamer loading device of a solid brewing grain tank, which is characterized in that: a vertical shaft is arranged and connected with a conveying channel through a hinge support; a feeding opening is formed on the tail end of the conveying channel; a scattering device is arranged in the conveying channel; a handle is connected with the conveying channel; and the conveying channel can move up and down and back and forth and rotate relative to the vertical shaft. The device has the advantages that: the structure is simple; the operation is convenient; the device can completely replace people to load the rice steamer; and all the time, area, thickness and loosening degree of material scattering can be realized by operating the device manually; the past precious experience is utilized; the labor intensity is greatly reduced; and thus, the rice steamer loading quality can be guaranteed absolutely to further guarantee the quality and yield of the liquor.

Owner:四川宜宾岷江机械制造有限责任公司

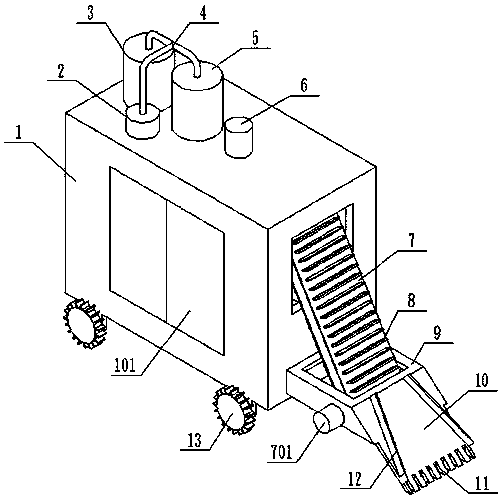

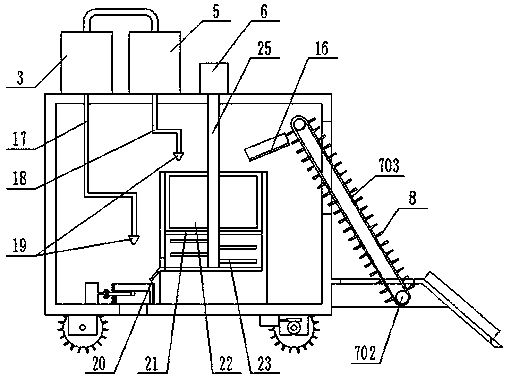

Eco-friendly soil-restoration processing device for greening of municipal garden

ActiveCN107836153ARealize automatic collectionRealize automatic movementSoil lifting machinesSievingGreeningMaterial scattering

The invention discloses an eco-friendly soil-restoration processing device for greening of a municipal garden. The device comprises an outer box body. The bottom of the outer box body is equipped witha driving mechanism. One side of the outer box body is equipped with a support rack. One side of the support rack is provided with a soil shoveling board. The interior of the support rack is equippedwith a transport mechanism. The upper end of the outer box body is provided with a pressuring pump and a stirring motor. The end part of the pressuring pump is equipped with a pressuring pipe. The bottom in the outer box body is provided with a material scattering mechanism and a drum. The interior of the drum is equipped with a stirring shaft. The interior of the drum is provided with a filter net. A material poking scraping plate and stirring blades are installed on the stirring shaft. The eco-friendly soil-restoration processing device for greening of the municipal garden has the followingbeneficial effects: through the driving mechanism, automatic movement of the device is achieved; automatic collection of soil is realized through the soil shoveling board and the transport mechanism;the device is used for orderly filtering, spraying medicine and stirring; the device has a compact structure and suitable for construction of the municipal garden; and the material scattering mechanism is used for scattering processed soil on the ground so that soil is kept smooth and flat and convenient for subsequent application.

Owner:福建坤加建设有限公司

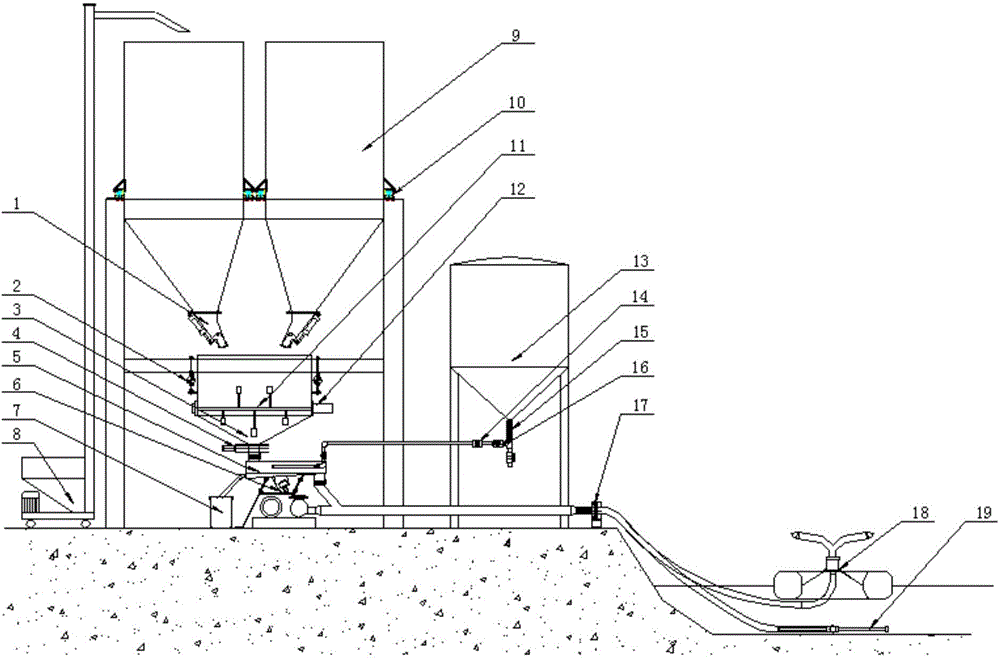

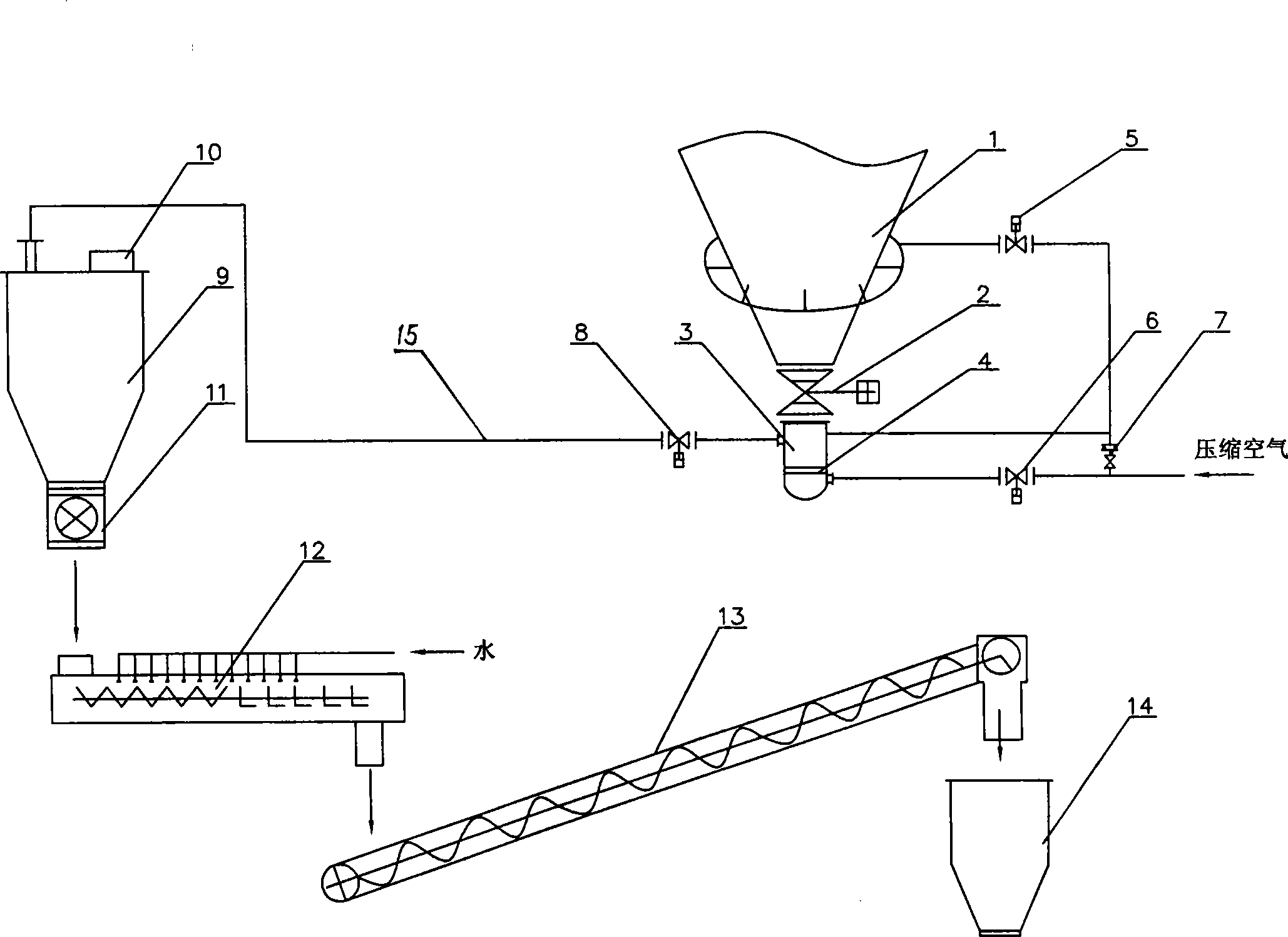

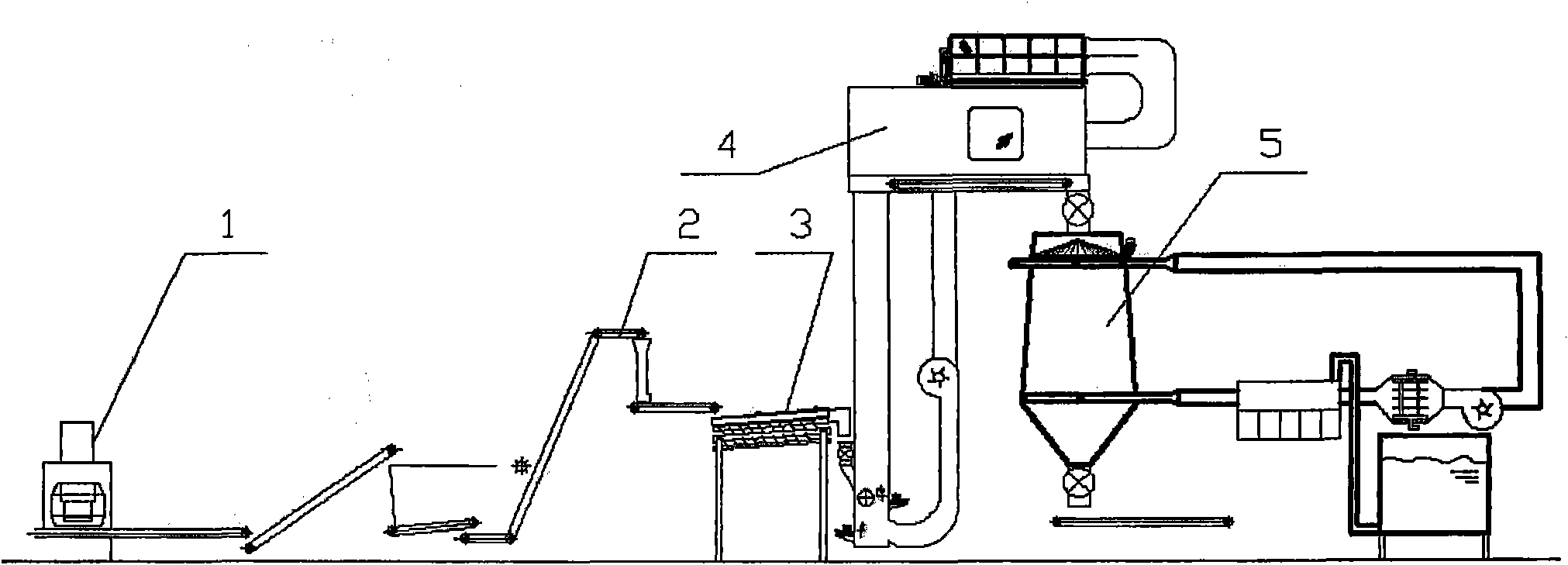

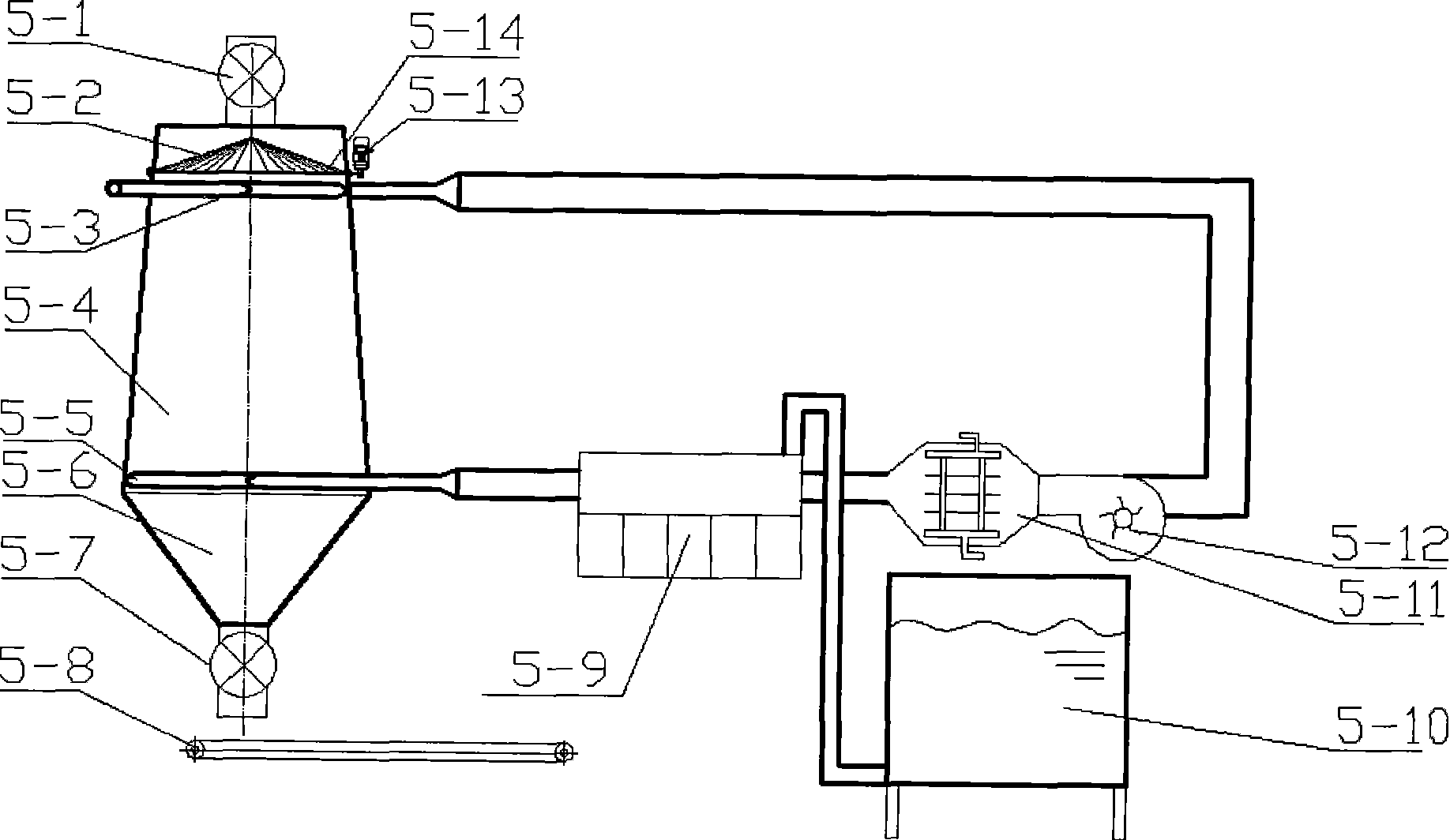

Automatic mixing, adjusting and feeding system for aquaculture feed

InactiveCN104823900APrecise Automatic MixingNot easy to sprayClimate change adaptationPisciculture and aquariaHigh densityMaterial scattering

The present invention relates to an automatic mixing, adjusting and feeding system for an aquaculture feed, wherein a feed bin weighing module which is used for automatically feeding back and controlling loading weight and unloading weight is arranged on a combined feed bin; a pneumatic valve on the bottom of the combined feed bin is aligned to a proportioning bin below; an air brake on the bottom of the proportioning bin is aligned to a feed mixing bin below; a vibrating conveyer is arranged in a mixing bin; and the vibrating conveyer is used for filtering a powdery feed to a powdery material collecting barrel; a bacterial (liquid) barrel is communicated with the mixing bin through a liquid conveying pipeline to add a bacterial liquid or a medicinal liquid into the feed, and to uniformly mix by virtue of the vibrating conveyer; the bottom of the vibrating conveyer is communicated with an air pump conveying pipeline through a pipeline; a fan is divided into two air paths through a pneumatic three-way joint, one path is used for blowing the feed and annularly scattering the feed through a rotary material scattering machine floating on the water surface while the other path is used for aerating and oxygenating a water body in a feed feeding region through an underwater aeration pipe in a material scattering region of the material scattering machine so as to improve dissolved oxygen demand of a high-density feeding fish school in the feed feeding region.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Dedusting dry powder recycling process

InactiveCN101224363ASimplify the recycling processNo spreading problemHuman health protectionDispersed particle filtrationDusting powdersMaterial scattering

The invention relates to a dust-removal dry powder recycling process. The process procedure consists of dust-removal ash hoppers, dust powder transferring devices, exhaust collecting cavities, wet ball machines and sealed transferring devices of each dust removal points of smelters or ironworks. The process includes three steps: dusts removing-transferring, dusts collecting and wet ball transferring, i.e. a set of dust powder air-transferring device is arranged below the dust-removal ash hopper of the dust catcher; compressed air is adopted for transferring the dust through a sealed transferring device into the dust collecting cavity far away, and then a ration feeding machine is adopted for transferring the dust to the wet ball machine; after wetting and balling by the wet ball machine, the finished small balls are finally transferred to a storing bin through a sealed transferring device as recycled materials for application. The invention adopts the novel dust disposal process of dust-removal dry powders to simplify the process procedure; a sealed state is guaranteed before wetting and balling and during the transferring process so as to avoid dust rising and material scattering; the recycling treatment is simple, thus saving investigation and manpower, and being environment-protective.

Owner:BAOSTEEL ENG & TECH GRP

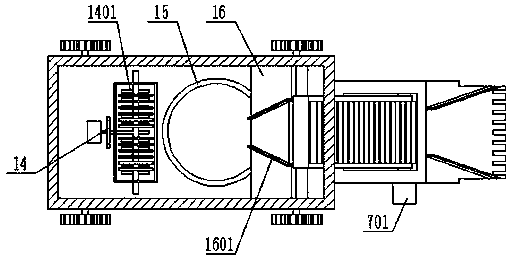

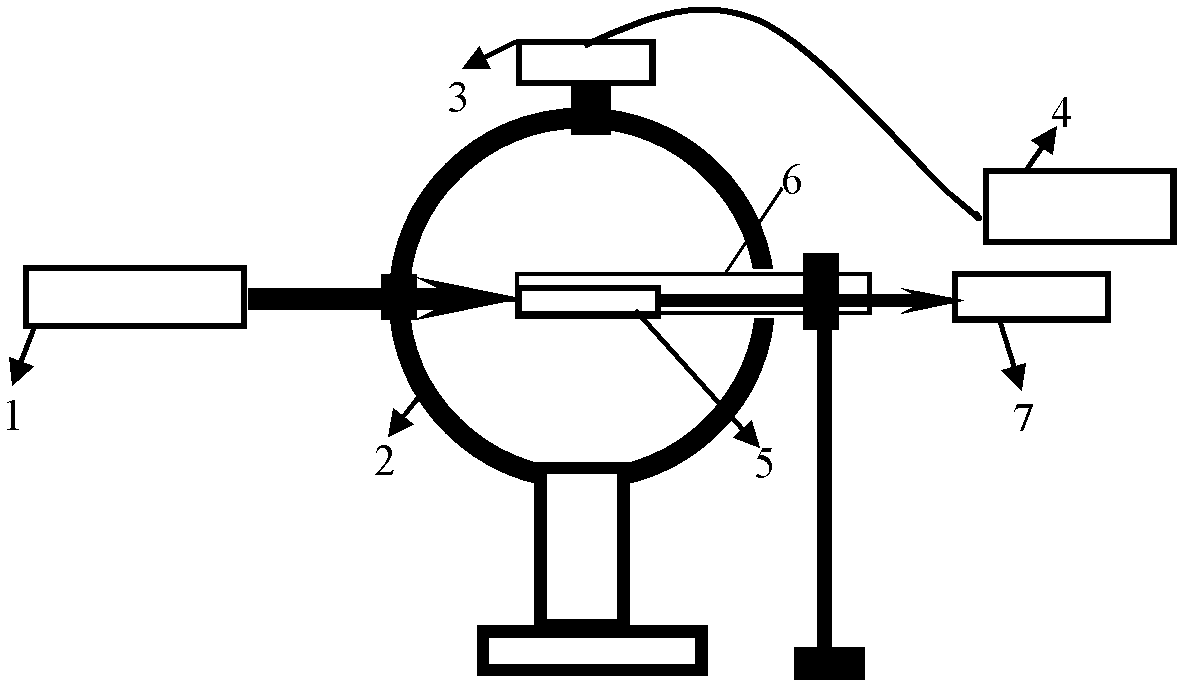

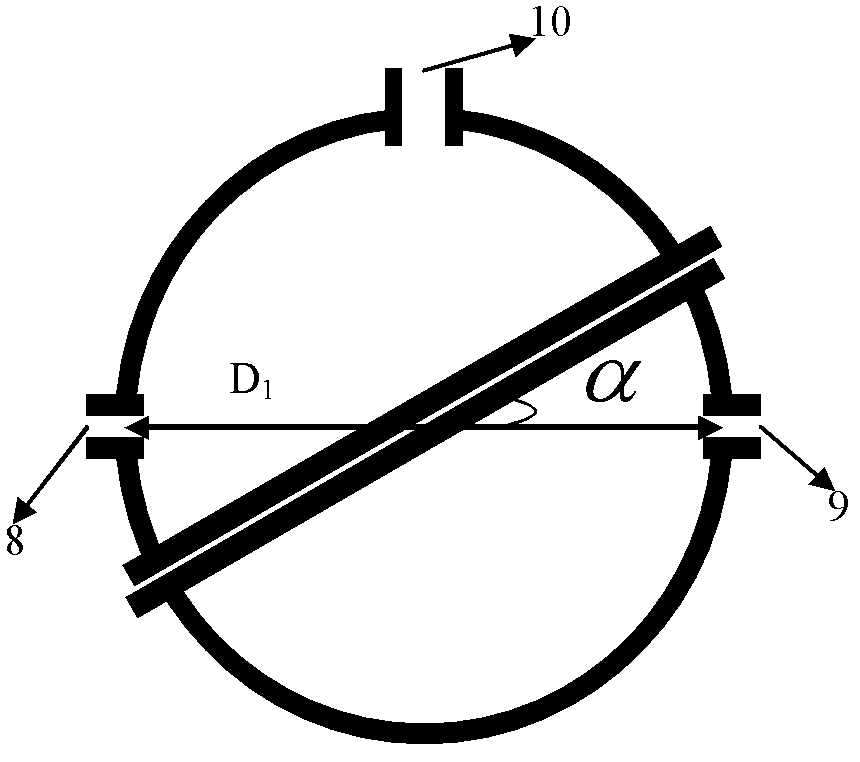

Device for measuring scattering coefficients and absorption coefficients of laser working media

ActiveCN102890071AScattering properties measurementsColor/spectral properties measurementsPhotovoltaic detectorsTransmittance

A device for measuring scattering coefficients and absorption coefficients of laser working media consists of a testing laser device, an integrating sphere, a photoelectric detector, a laser power meter and an oscilloscope, wherein a white diffusion reflection layer is coated on the inner wall of the hollow integrating sphere; a light entering hole, a light exiting hole and a detecting hole are formed in the spherical wall of the integrating sphere; the light entering hole and the light exiting hole are positioned in the left side spherical wall and the right side spherical wall of the integrating sphere; a connecting line of centers of the light entering hole and the light exiting hole is a horizontal line and penetrates through the center of the integrating sphere; the testing laser device and the laser power meter are respectively placed on the outer side of the light entering hole and the outer side of the light exiting hole; the photoelectric detector is positioned on the outer side of the detecting hole and is connected with the detecting hole; a laser working medium sample to be measured is fixed in the center of the integrating sphere; testing laser emitted from the testing laser device enters the light entering hole, perpendicularly reaches one end surface of the sample, and exits from the other end surface of the sample and the light exiting hole; the loss coefficient of the sample to be measured is obtained by using a total transmittance measured value, a total diffusivity measured value and a calculation formula for the scattering coefficients and the absorption coefficients; and accuracy is high, and the optical performance of the laser working media can be well showed.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

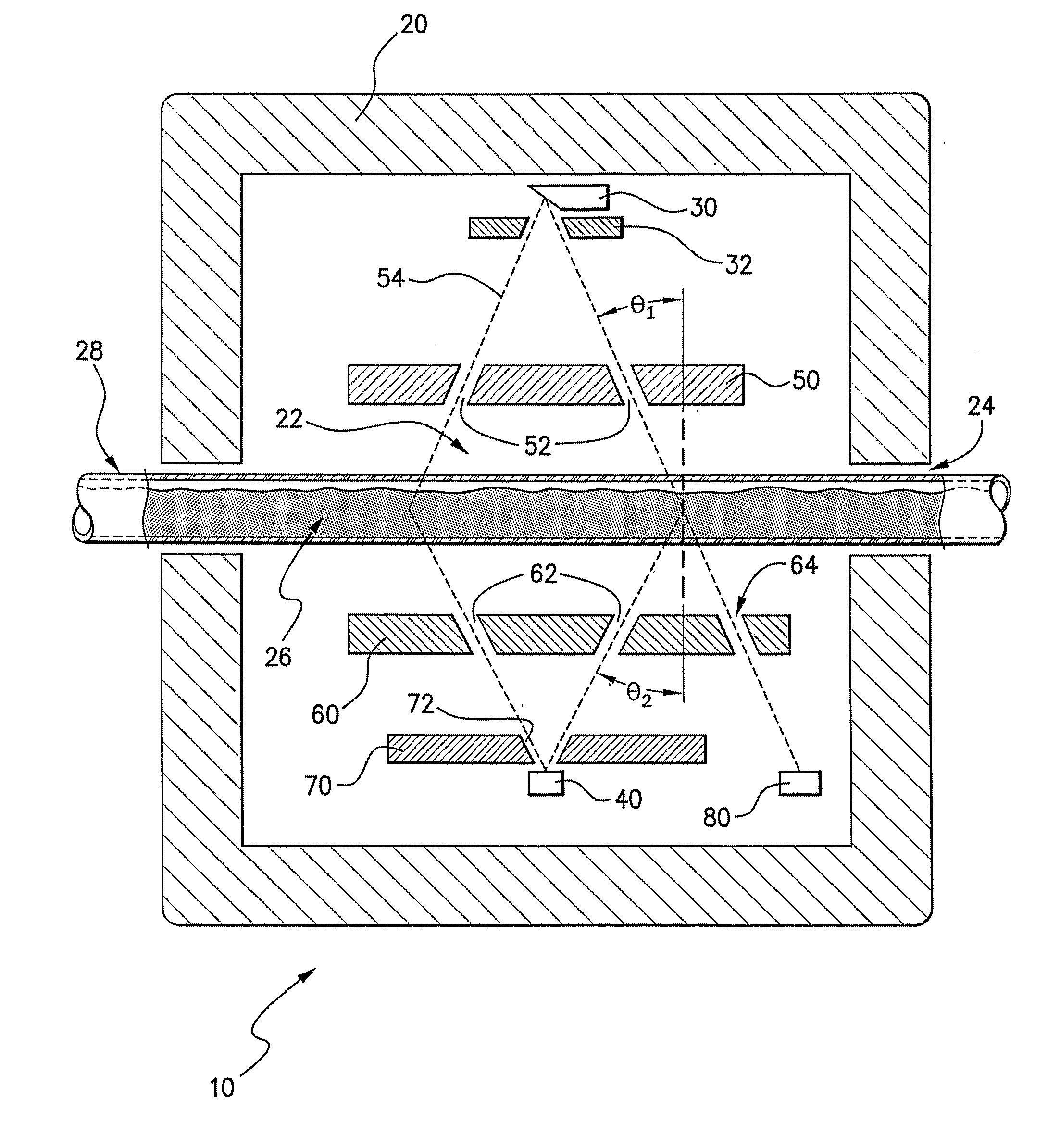

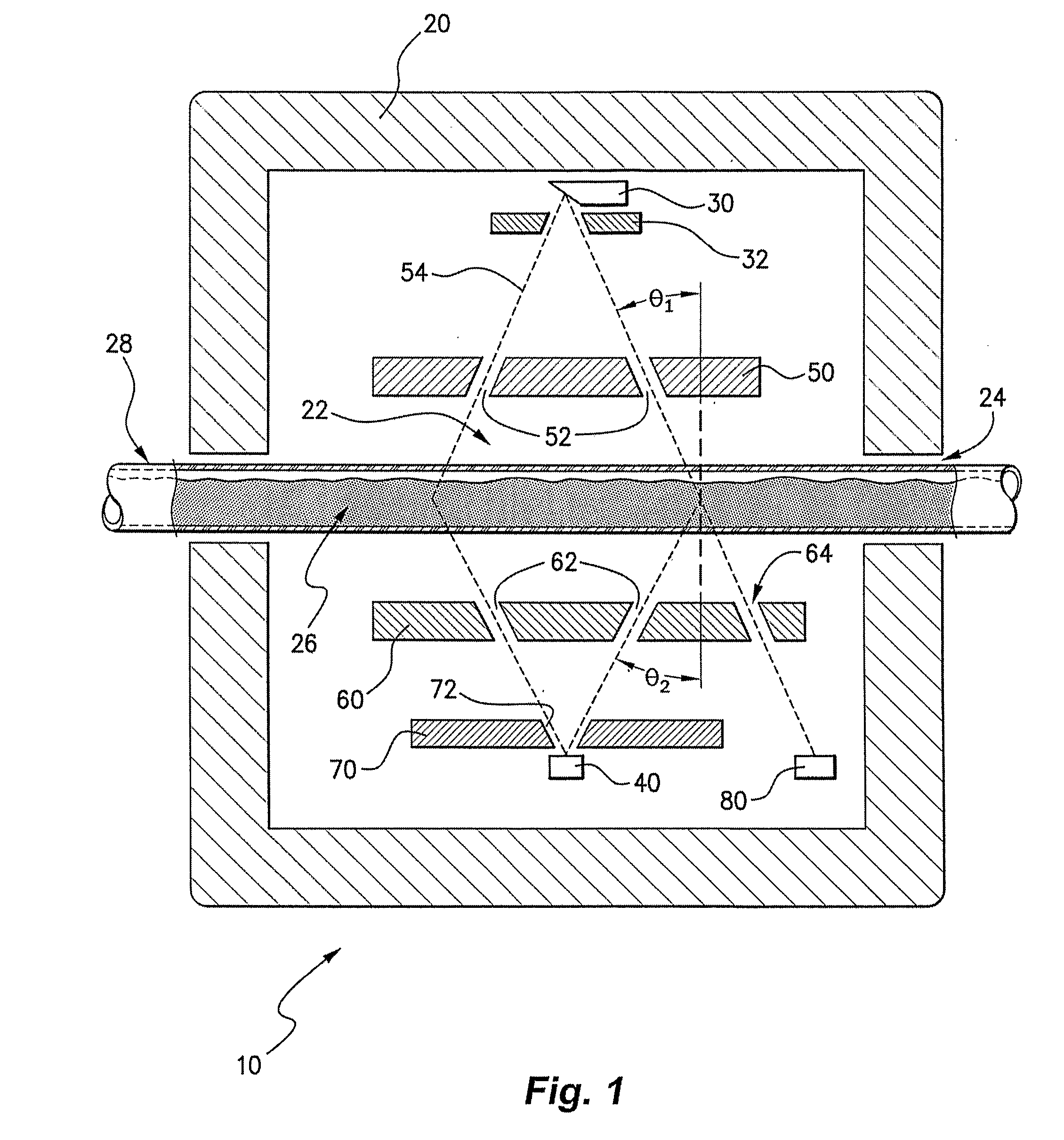

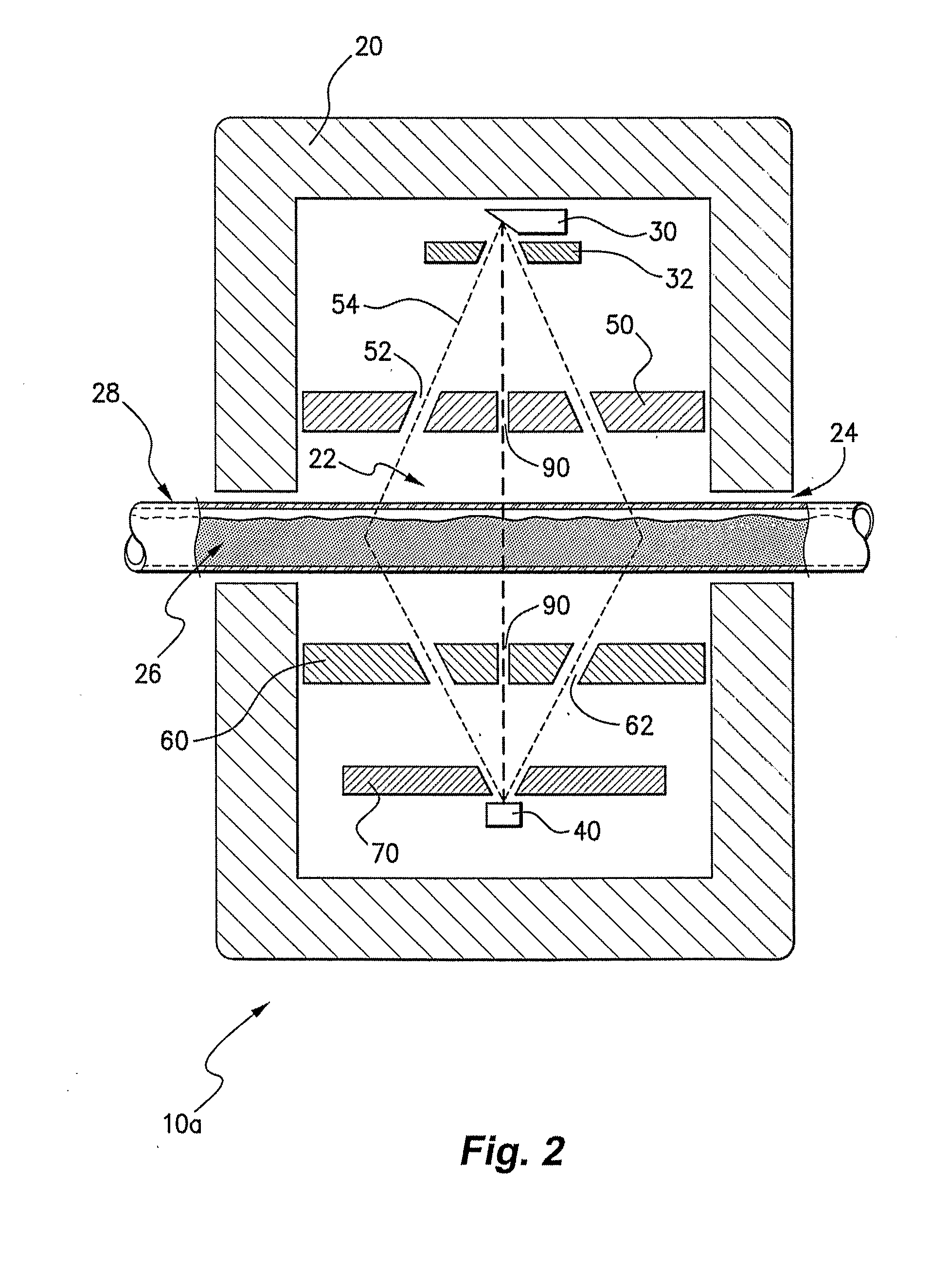

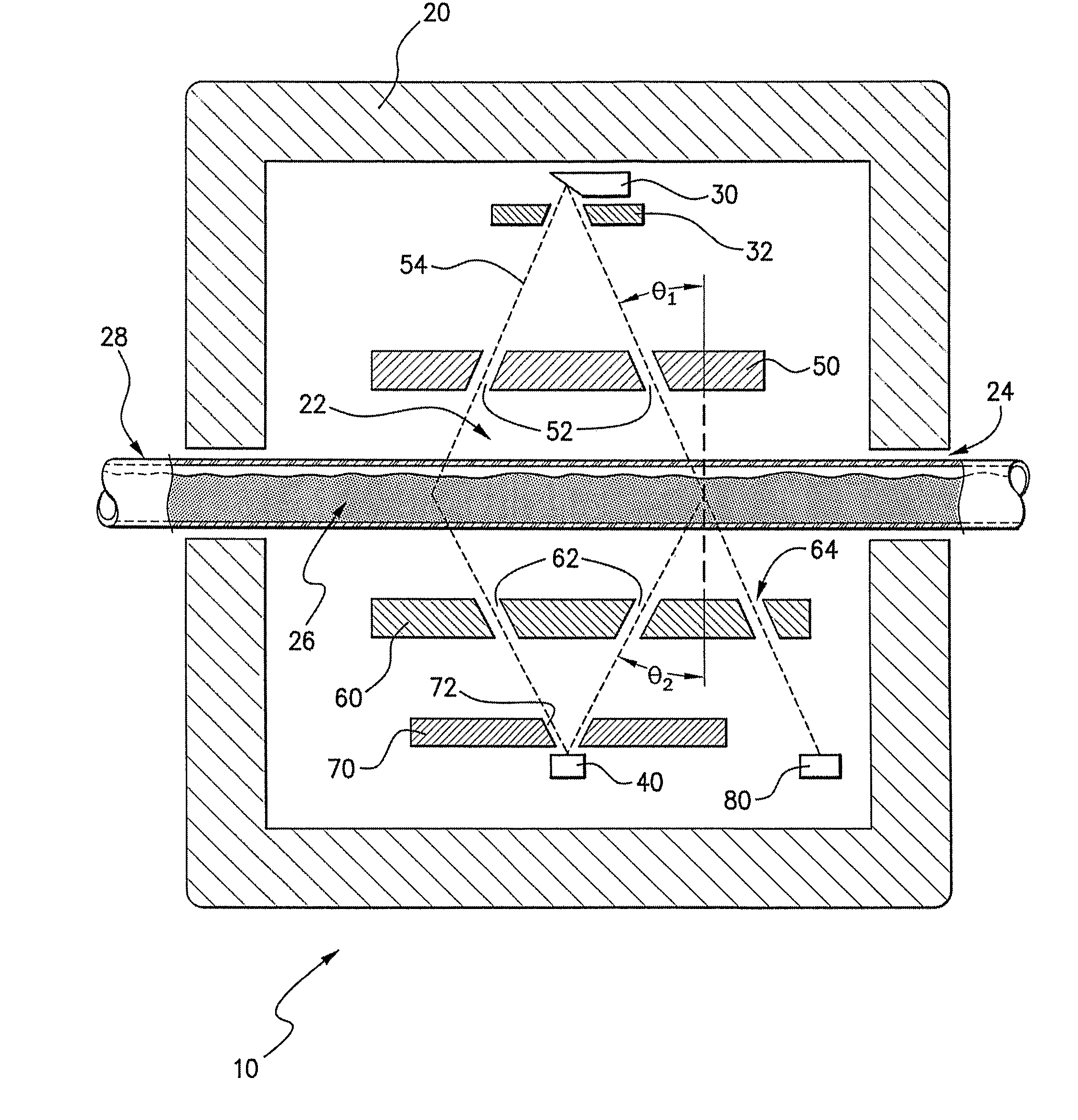

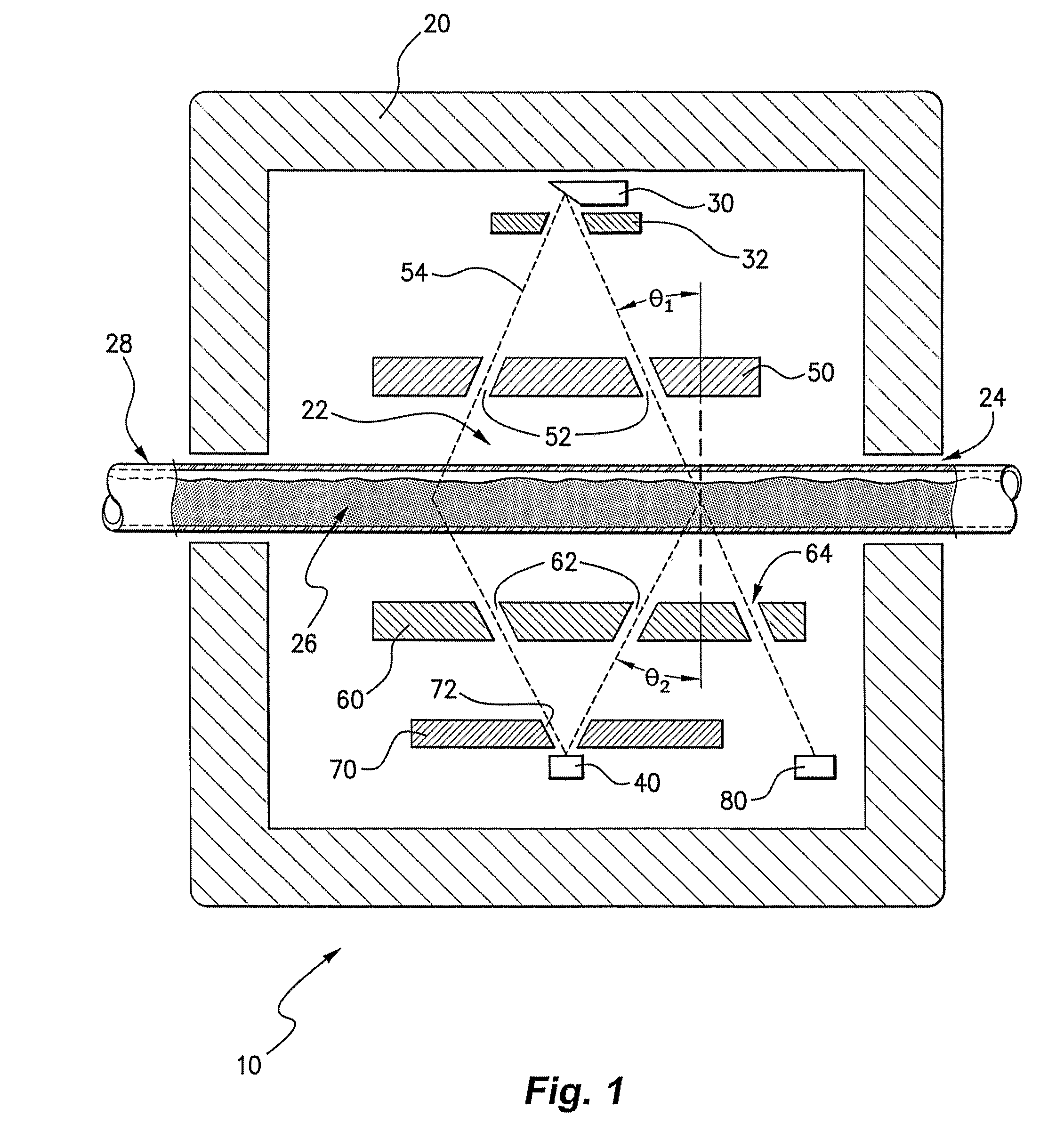

Online energy dispersive X-ray diffraction analyser

ActiveUS20100303206A1Reduce background scatterReduce voltageX-ray spectral distribution measurementMaterial analysis using radiation diffractionX-rayMaterial scattering

An on-line EDXRD analyser including (i) a housing defining an analysis zone and having a passageway through it to allow transport of material in a process stream to pass through the analysis zone, (ii) a collimated source of polychromatic X-rays, (iii) an energy-resolving (ER)X-ray detector, (iv) a primary beam collimator disposed between the source of X-rays and the (ER)X-ray detector comprising an annular slit which defines an incident beam of polychromatic X-rays to irradiate a portion of the analysis zone, (v) a scatter collimator disposed between the primary beam collimator and the ERX-ray detector, the scatter collimator comprising an annular slit which defines a diffracted beam of X-rays scattered by the material to converge towards the ERX-ray detector, and (vi) a detector collimator comprising a conical opening which further defines the diffracted beam of X-rays scattered by the material. The ERX-ray detector measures an energy spectrum of the diffracted X-rays at a predetermined diffraction angle defined by the relative positioning of (ii) to (vi), and where one of (iv) and (v) comprises an aperture arranged to enable a detector to measure the transmission of a direct beam of X-rays through the material.

Owner:COMMONWEALTH SCI & IND RES ORG

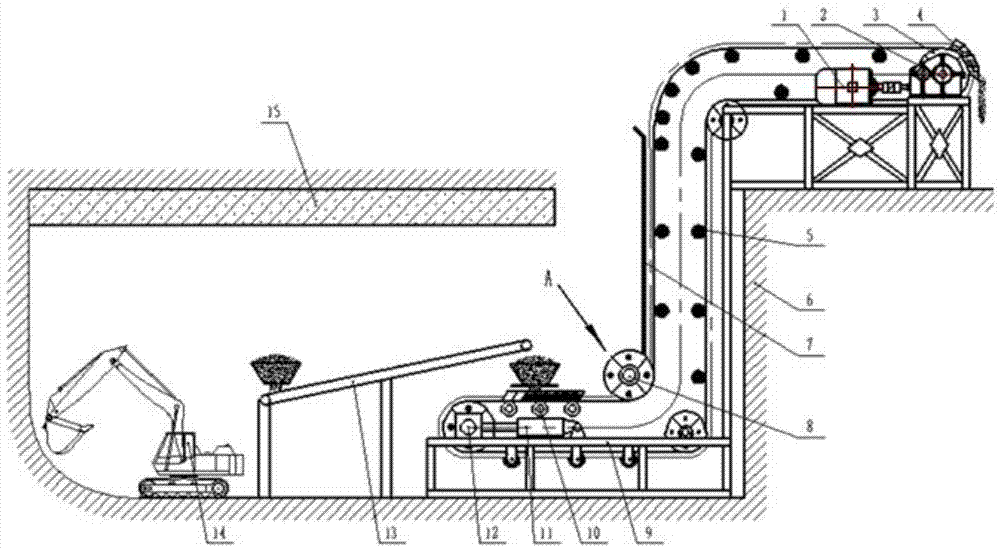

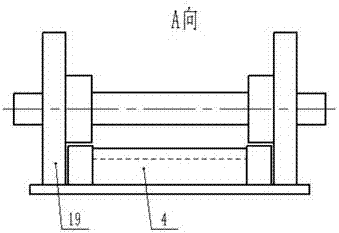

Construction method for vertical-type hoisting deep-shaft tunnel ballast-soil

InactiveCN107161599AImprove transportation efficiencyReduce construction costsConveyorsOperational costsWave shape

A construction method for vertical lifting of muck in a deep shaft tunnel. A set of corrugated belt conveyors is arranged in the opening of the deep shaft. The corrugated belt conveyor is composed of a horizontal head, a vertical fuselage and a horizontal tail. The head mainly includes the motor, reducer, driving drum, upper frame and upper idler and undertakes the task of muck unloading; the vertical fuselage mainly includes the anti-spray side plate and the vertical frame and undertakes the task of vertical lifting of muck; the horizontal tail It mainly includes redirecting device, lower frame, buffer roller, tensioning oil cylinder, tensioning roller and lower roller and undertakes the task of muck loading. The invention realizes the vertical lifting of muck, saves the occupied space on the ground, In order to avoid interference with other construction equipment, it can realize continuous and uninterrupted operation, transport a large amount of dregs, high muck transportation efficiency, require a small number of workers, and have low operating costs, which can effectively reduce the construction cost of deep shaft tunnels.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

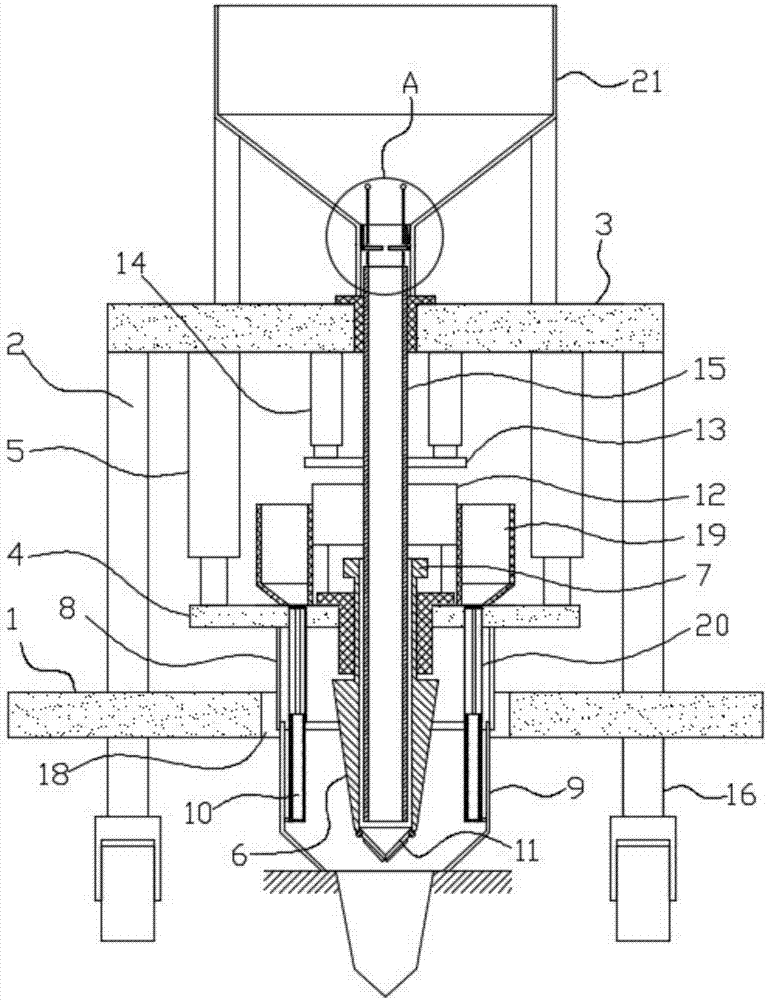

Full-automatic pit digging, fertilization, discharge and planting device

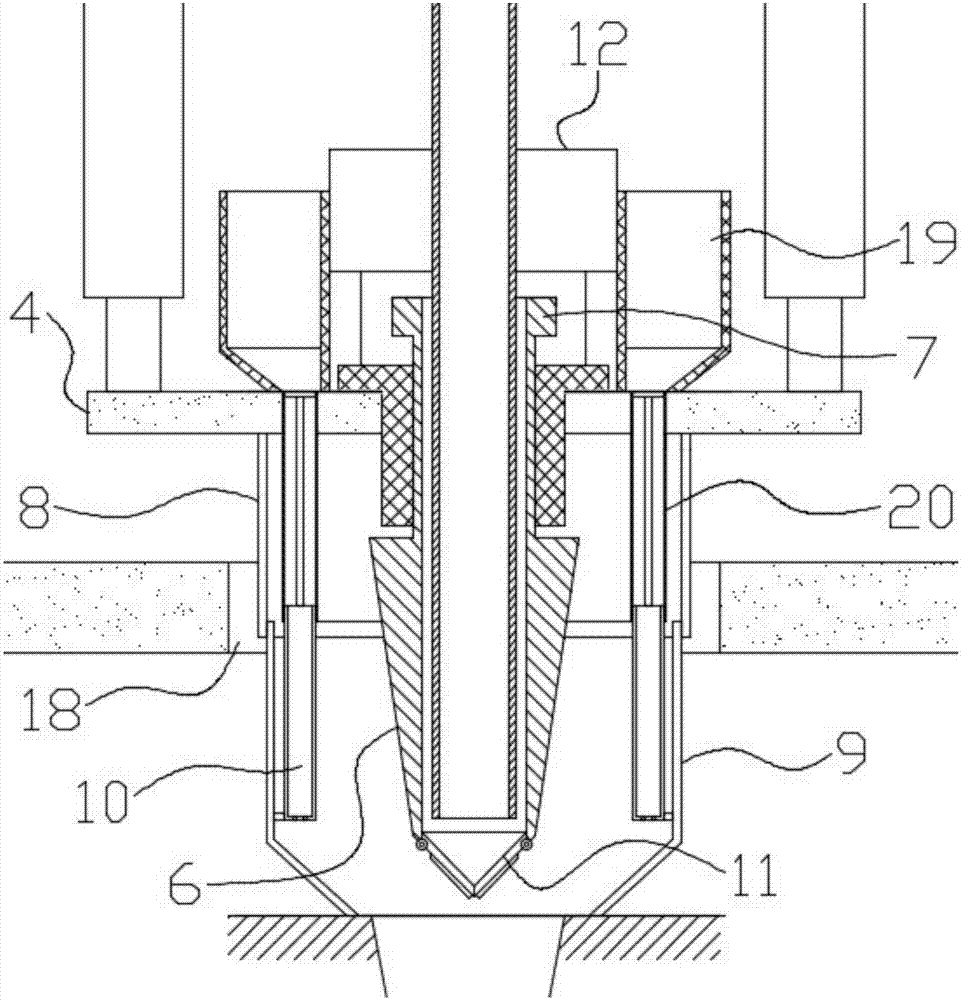

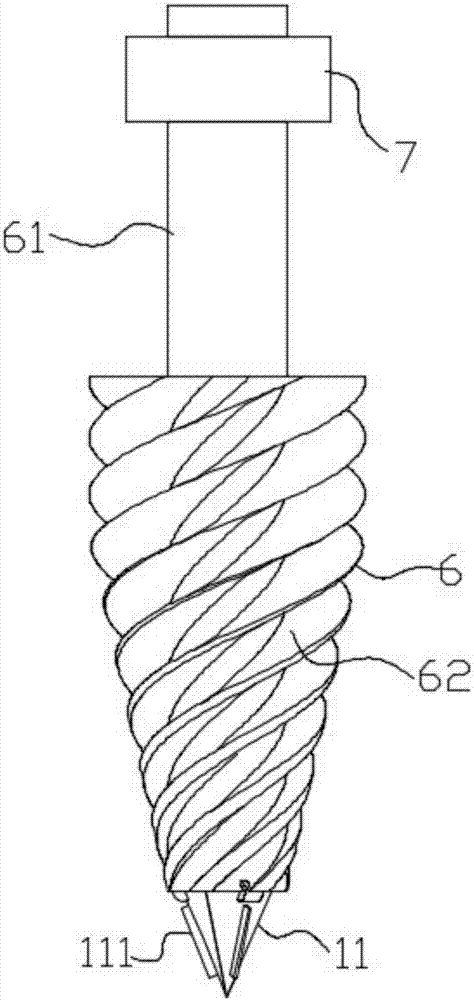

PendingCN107371493ARealize one actionImprove planting efficiencyPlantingFurrow making/coveringMaterial scatteringMaterial storage

The invention discloses a full-automatic pit digging, fertilization, discharge and planting device. The upper end of a base is connected to an upper seat plate, the bottom surface of the upper seat plate is provided with an auxiliary oil cylinder, the auxiliary oil cylinder is connected to a lifting plate, the center of the lifting plate is provided with a drill bit, the bottom of the lifting plate is provided with a fixed cylinder, a telescopic cylinder is arranged in the fixed cylinder, the upper end surface of the lifting plate is provided with a material storage box, a lower end port of the material storage box is connected to a material guide sleeve, the material guide sleeve sleeves a material scattering box, the material scattering box is provided with a material scattering hole, the material scattering box is fixed in the telescopic cylinder, the drill bit is located in the fixed cylinder, a casing pipe shaft is arranged in the drill bit and is connected to the auxiliary oil cylinder, the auxiliary oil cylinder is connected to the upper seat plate, the casing pipe shaft is arranged in a feeding hopper, a feeding plate is arranged in a discharge pipe, the feeding plate is provided with a material blocking plate, the feeding plate is provided with a sliding hole, the casing pipe shaft is provided with a pull rod, the lower end of the drill bit is provided with an opening / closing head and the base is provided with a work hole passing through the fixed cylinder. The device realizes automatic pit digging, automatic mass planting and automatic soil covering and greatly improves the efficiency of crop planting.

Owner:蒋文

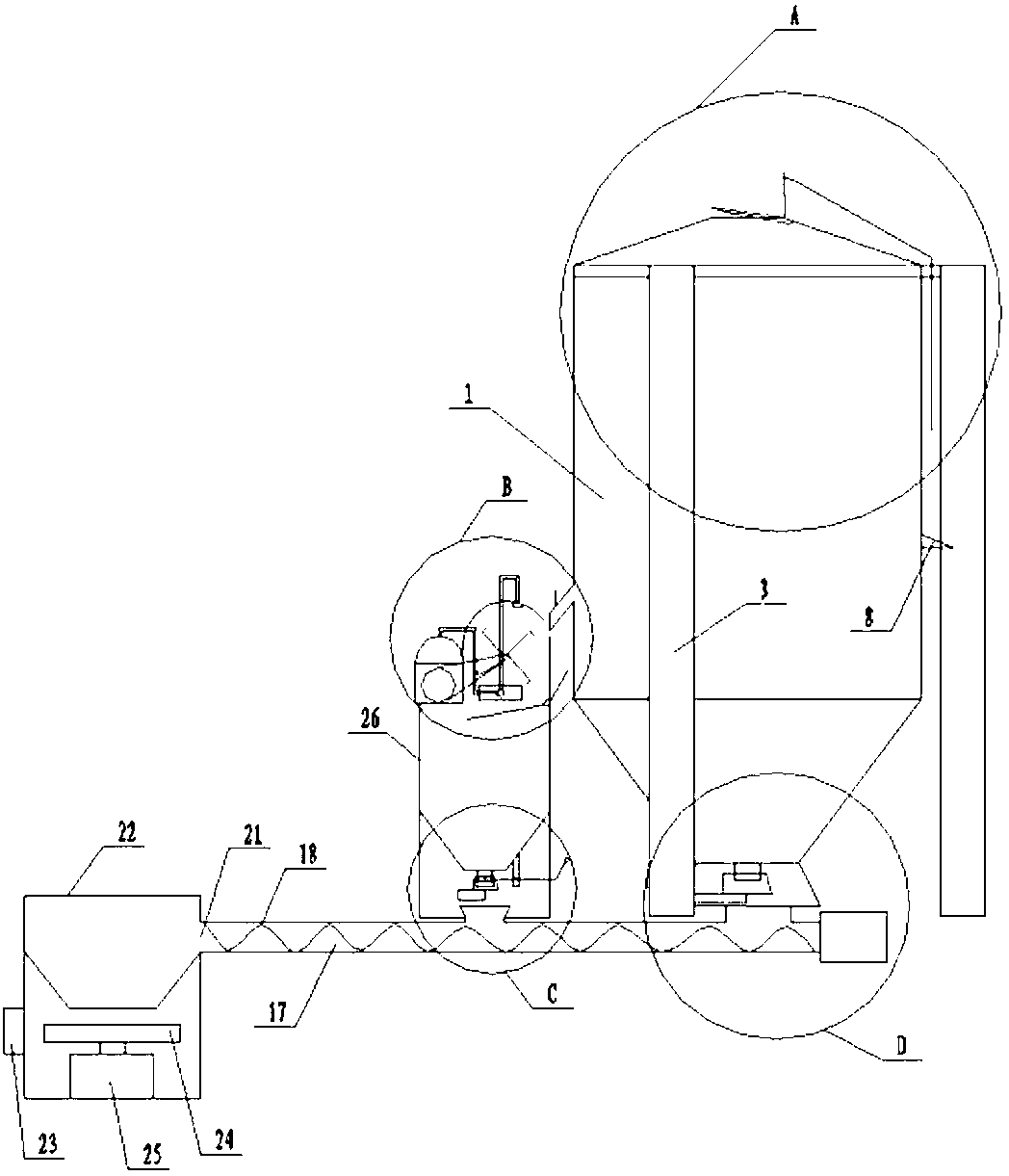

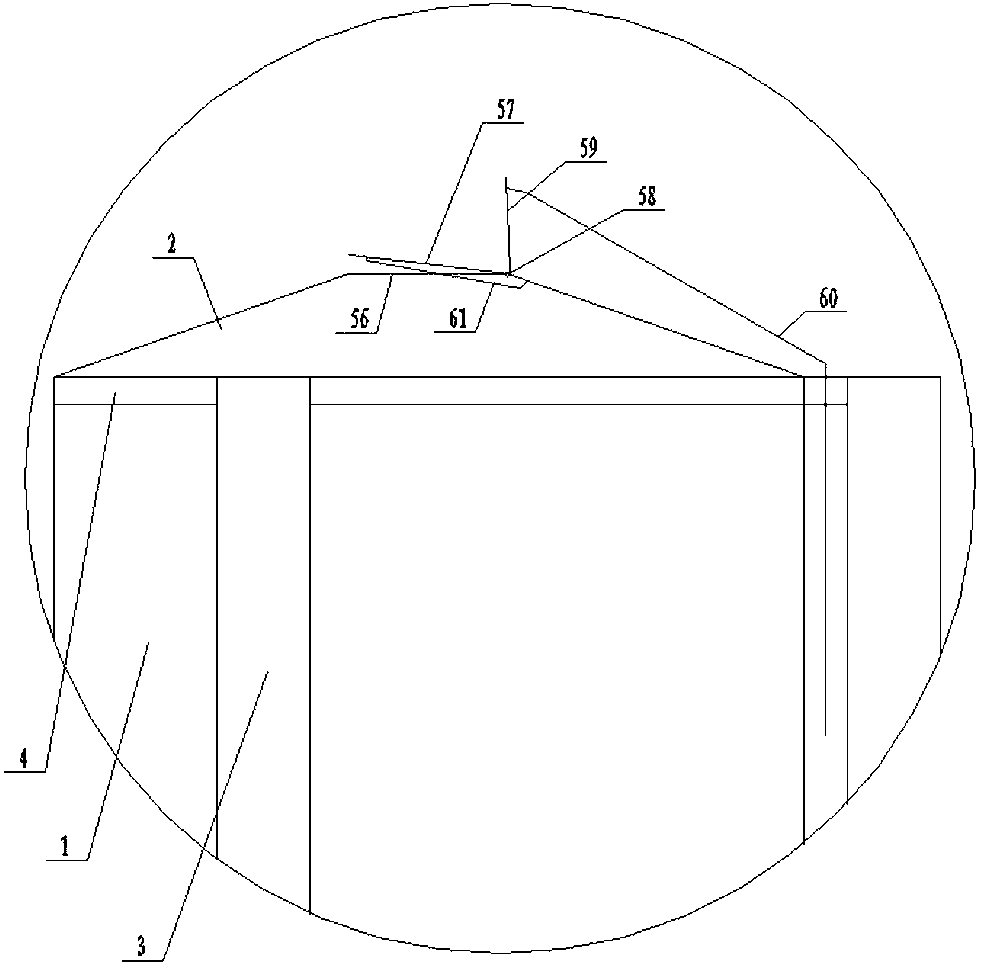

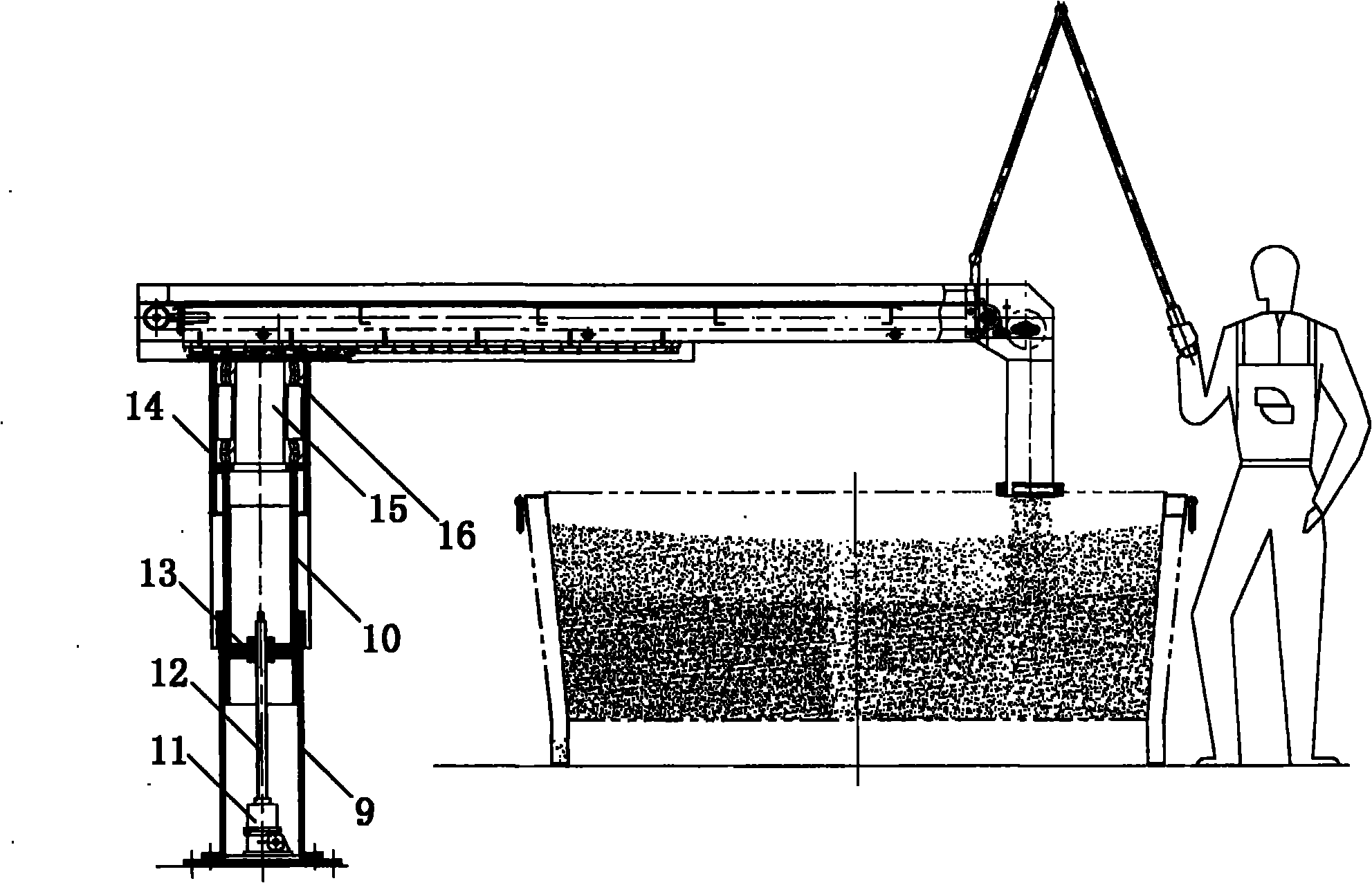

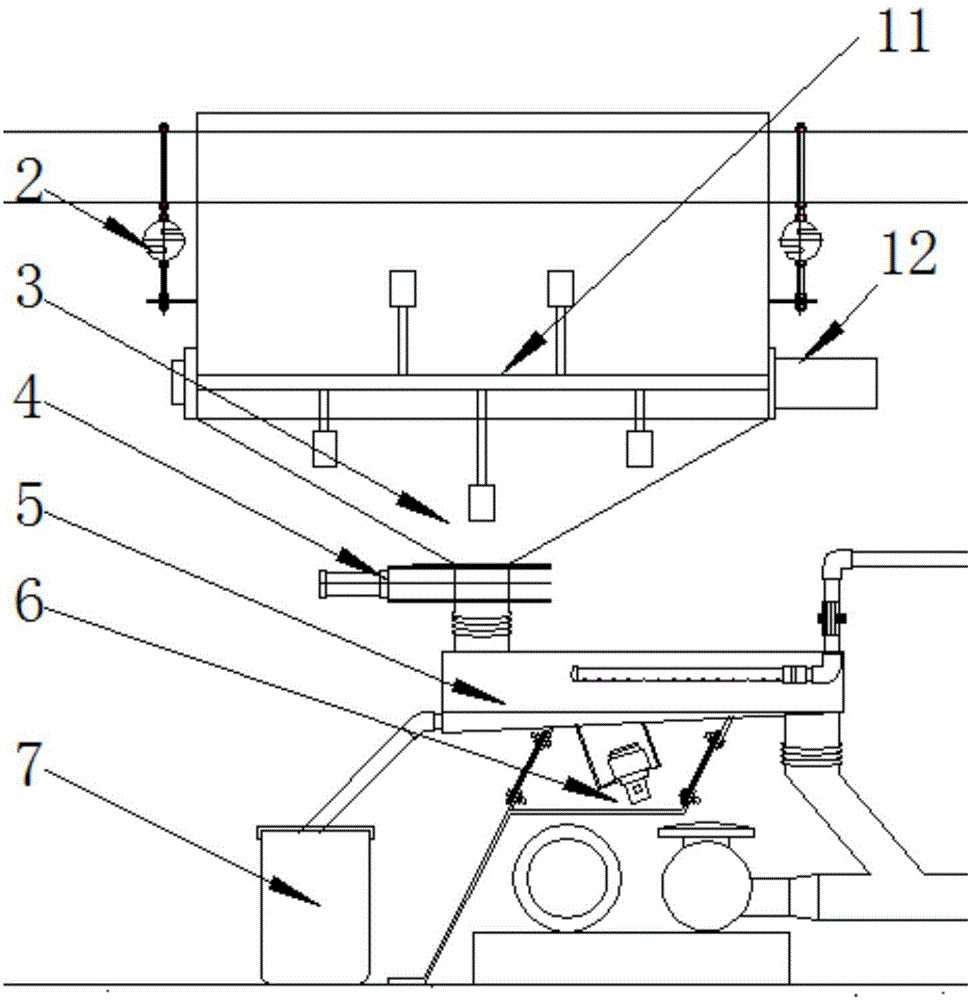

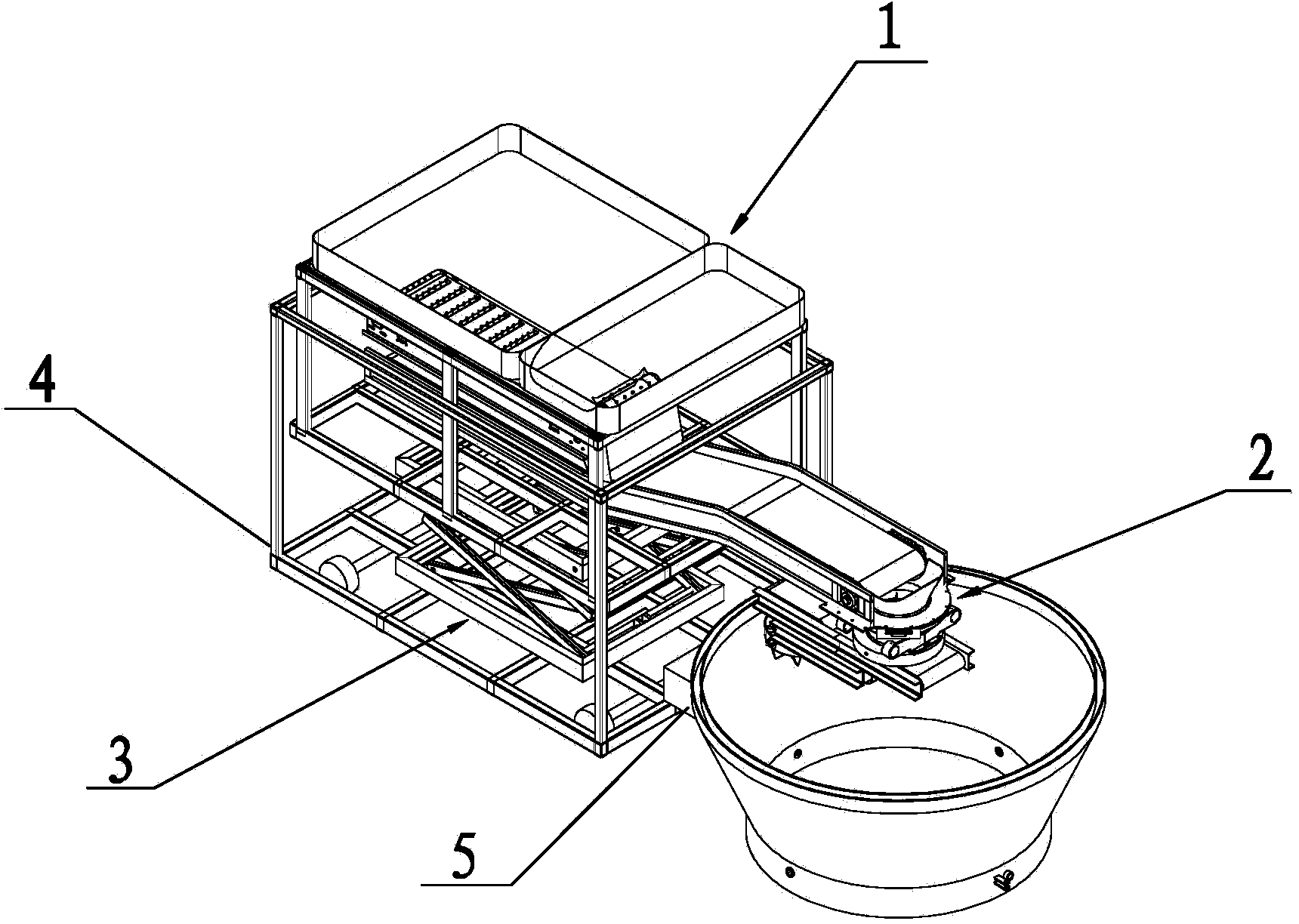

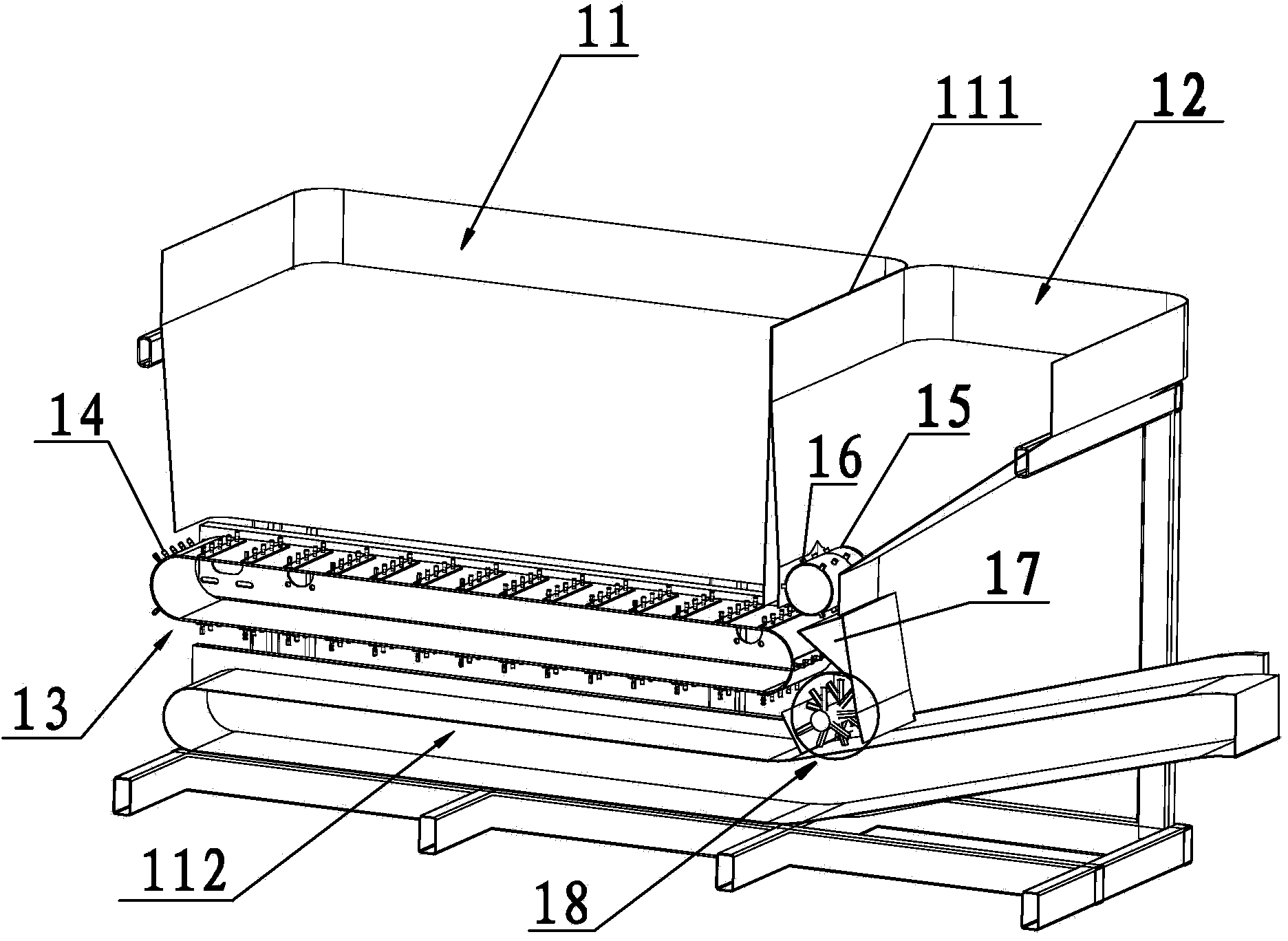

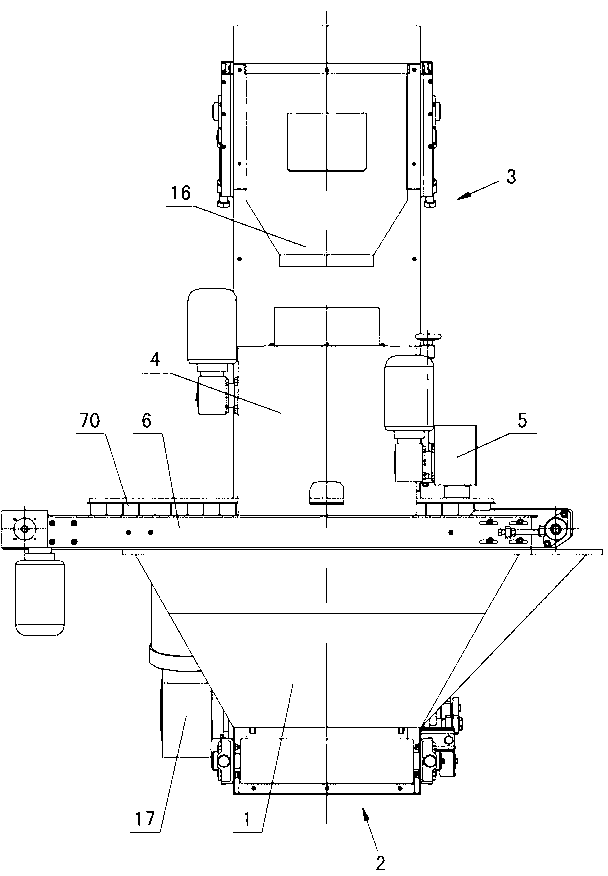

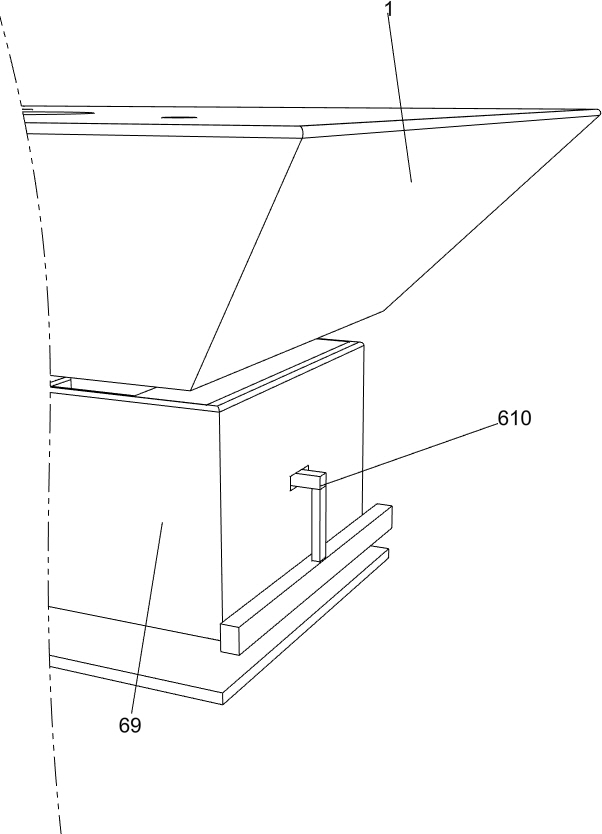

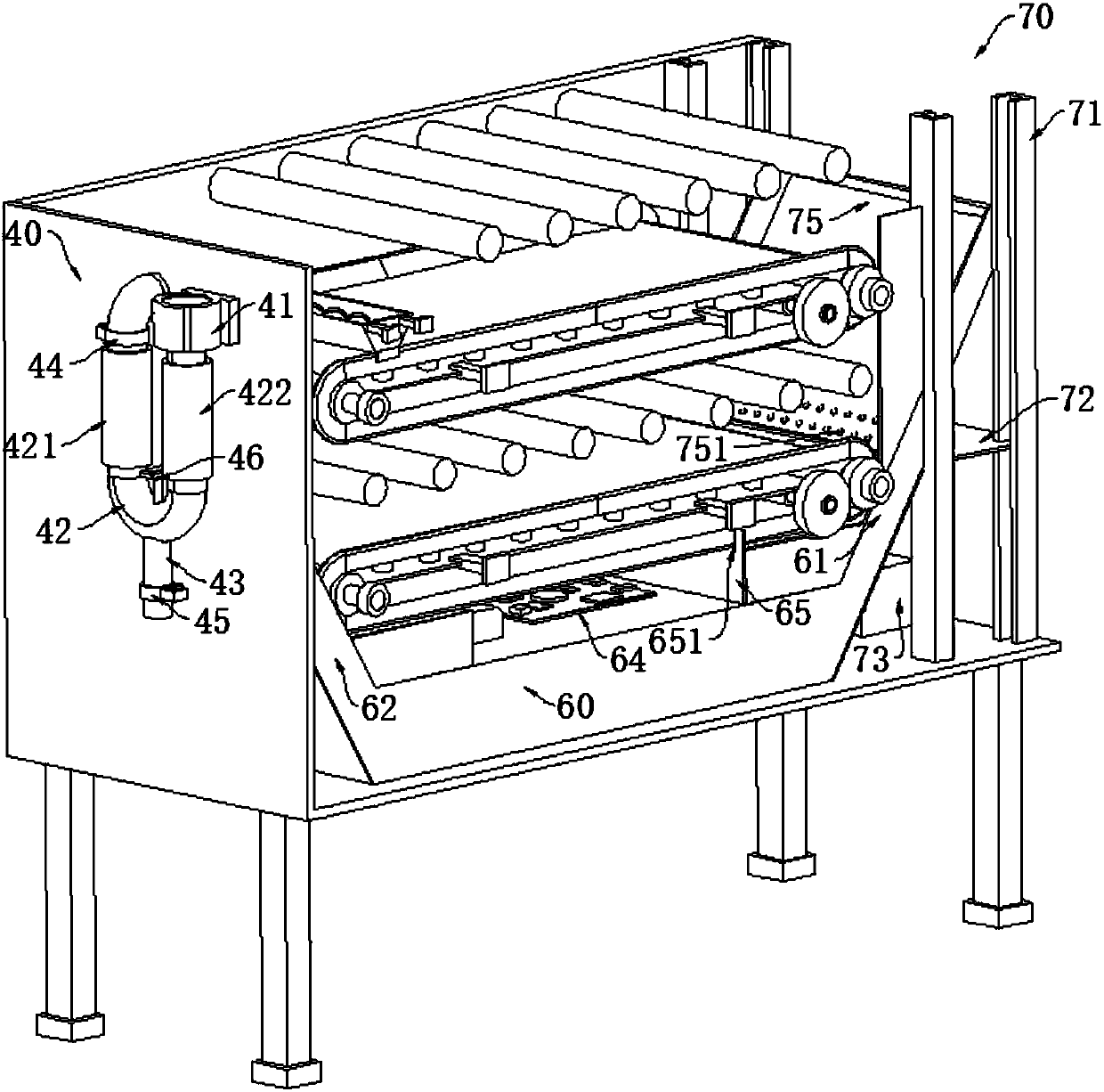

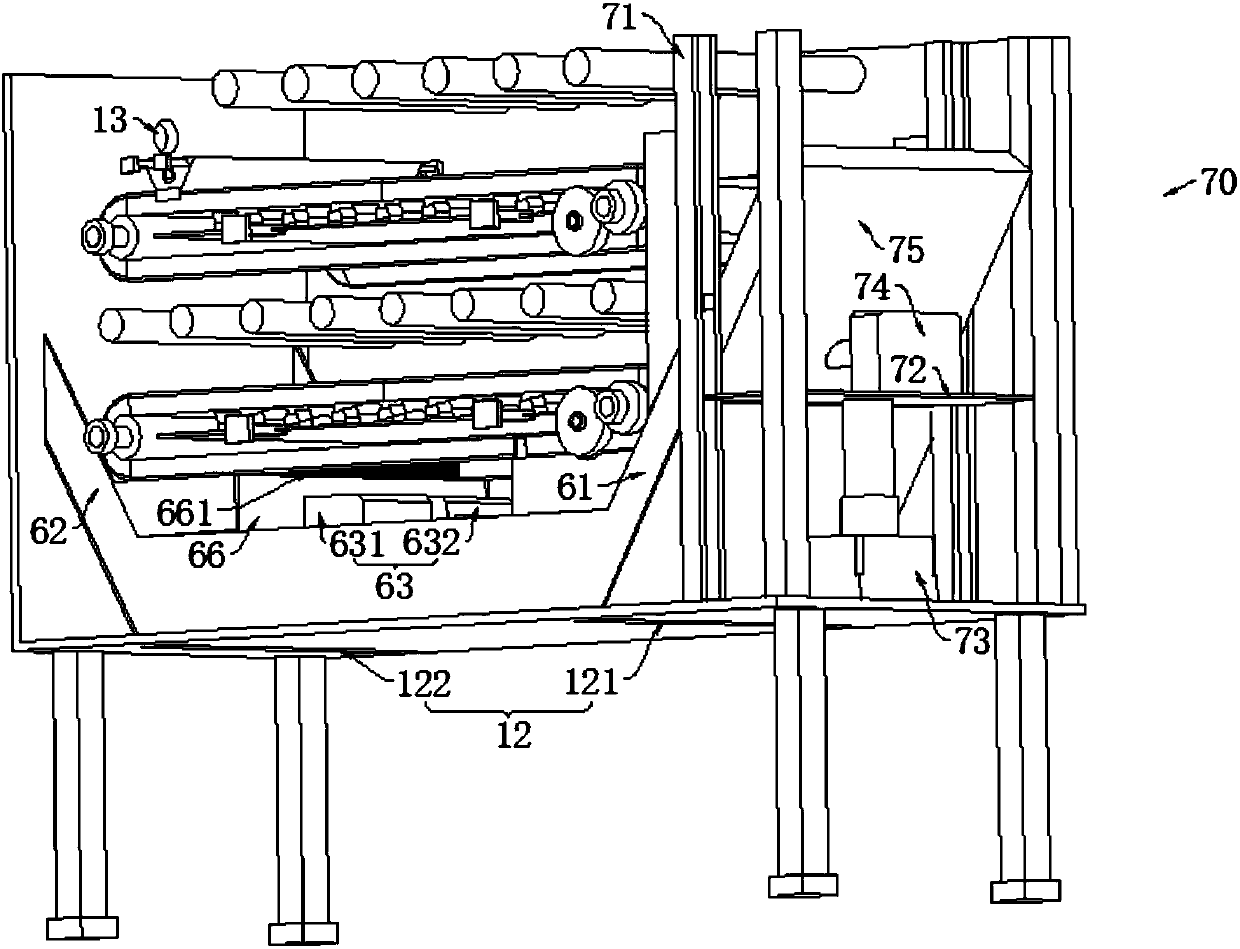

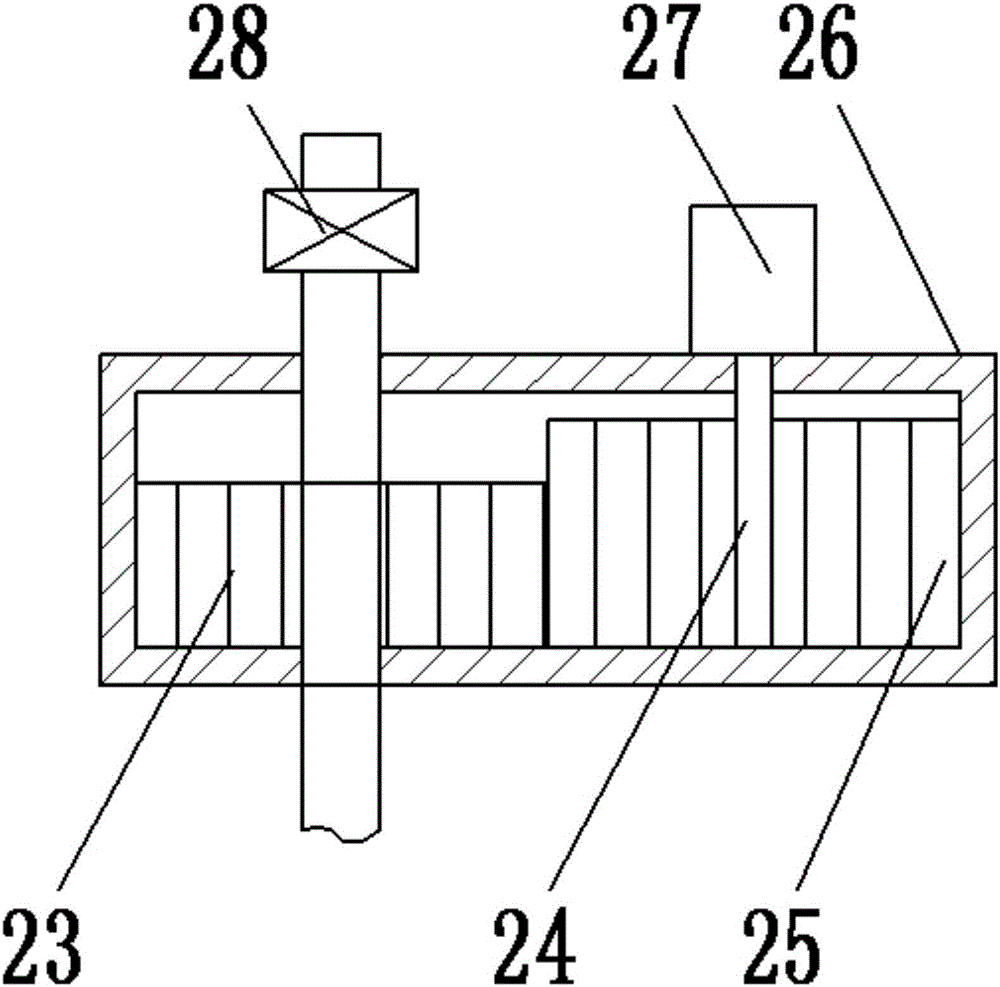

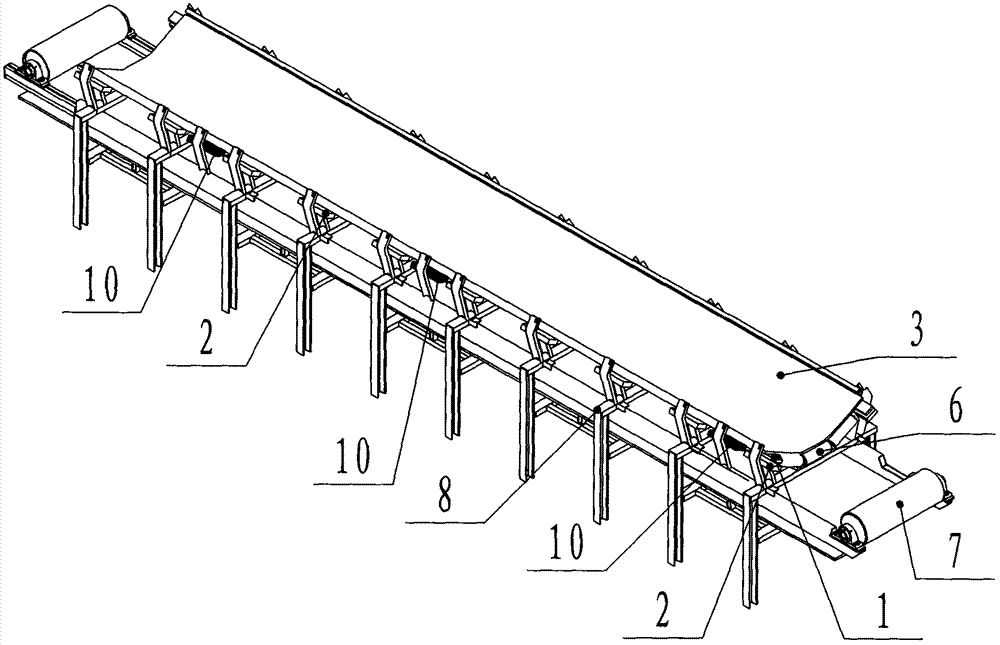

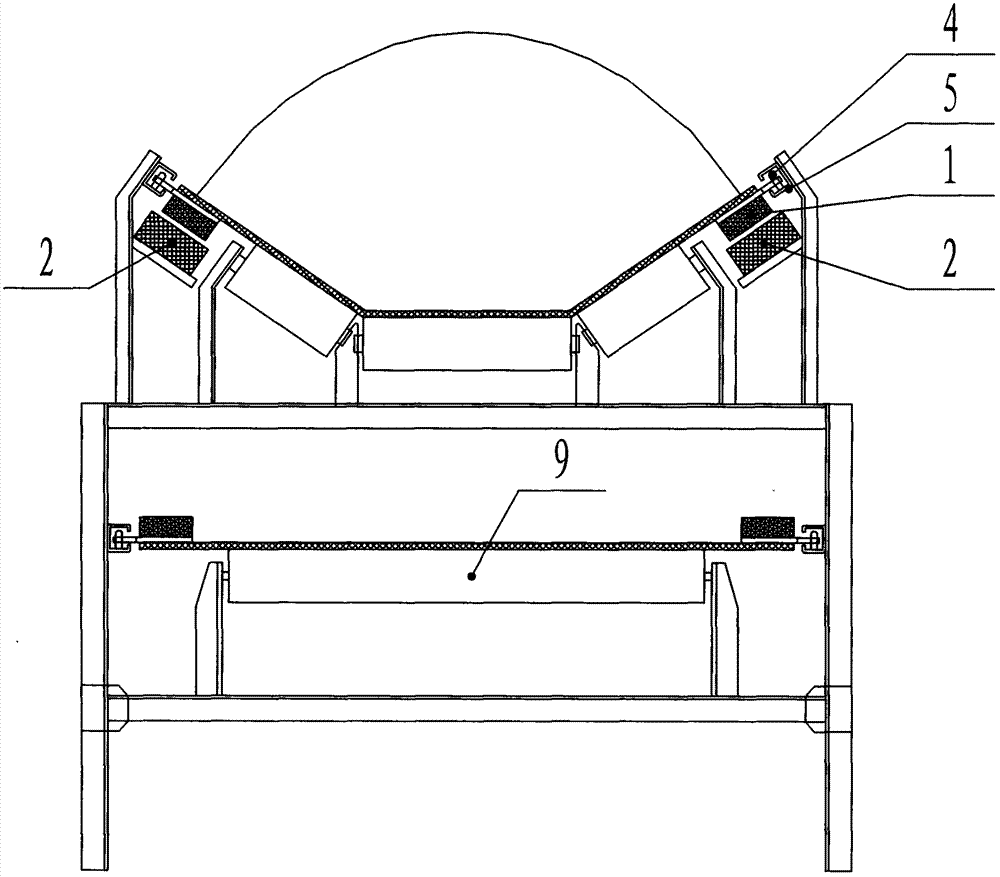

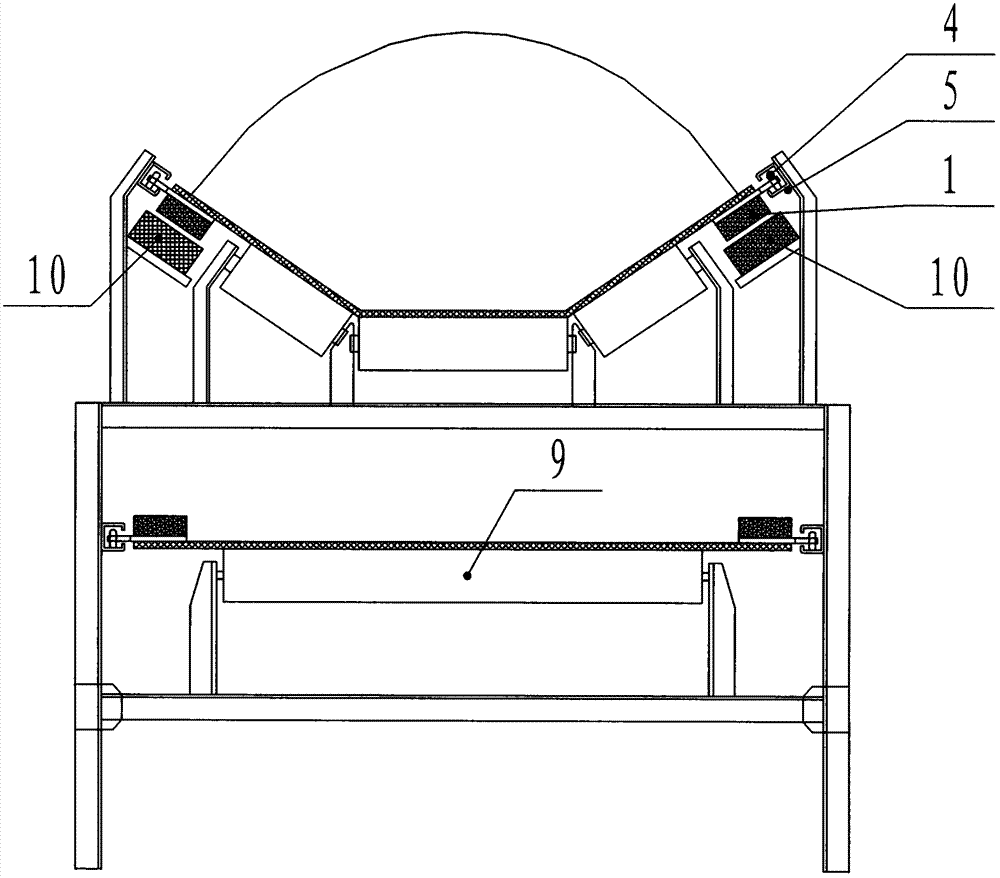

Automatic steamer filling machine

ActiveCN104291122AQuality improvementImprove efficiencyLoading/unloadingMaterial scatteringEngineering

The invention relates to the brewing field, in particular to an automatic steamer filling machine. The automatic steamer filling machine comprises a mixing conveying device and a steamer filling material scattering device, wherein the steamer filling material scattering device comprises a rotation mechanism, a material scattering machine and a conveying belt, the conveying belt is arranged below the rotation mechanism, the material scattering machine is fixedly arranged below a terminal of the conveying belt, the rotation mechanism drives the material scattering machine to move above a steamer barrel in rotation mode through self rotation and horizontal movement of the conveying belt, and fermented grains can fall into the steamer filling material scattering device through the mixing conveying device so as to achieve steamer filling material scattering. By adopting the technical scheme, the automatic steamer filling machine achieves automatic steamer filling of the fermented grains.

Owner:绍兴赤兔龙机械科技有限公司

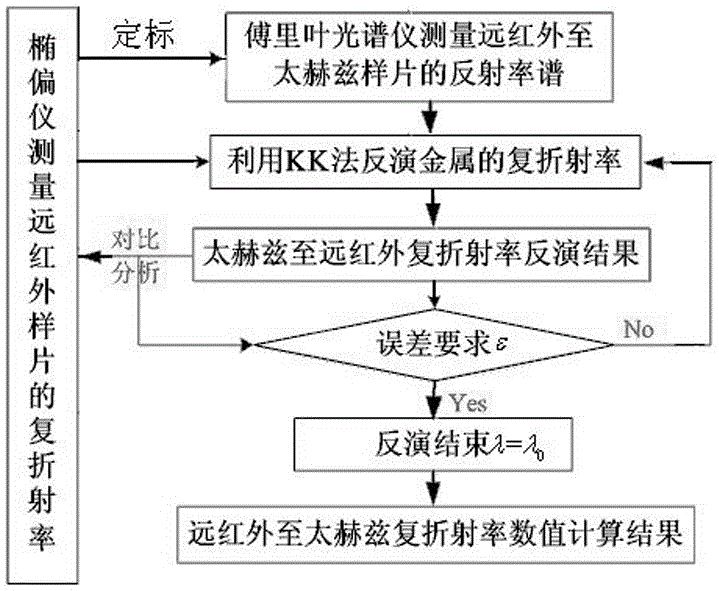

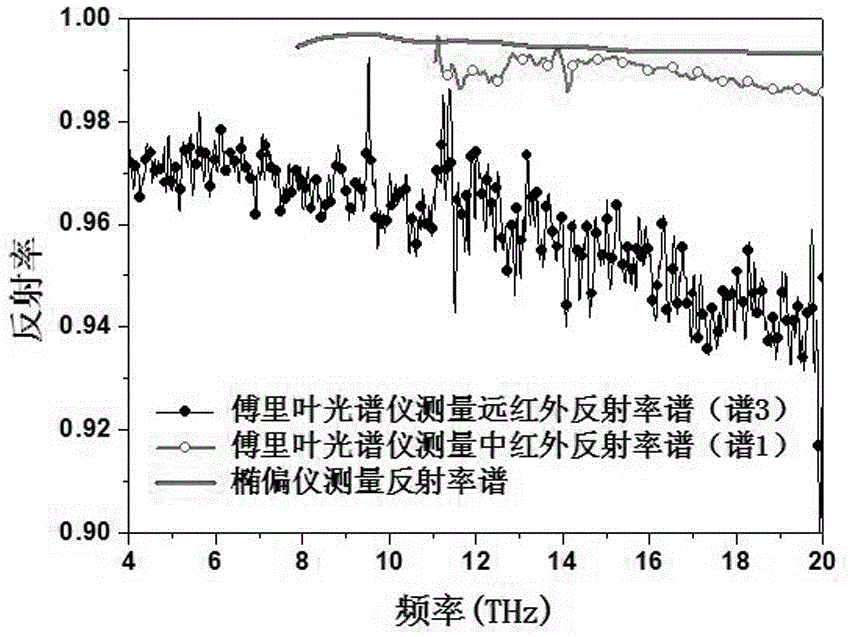

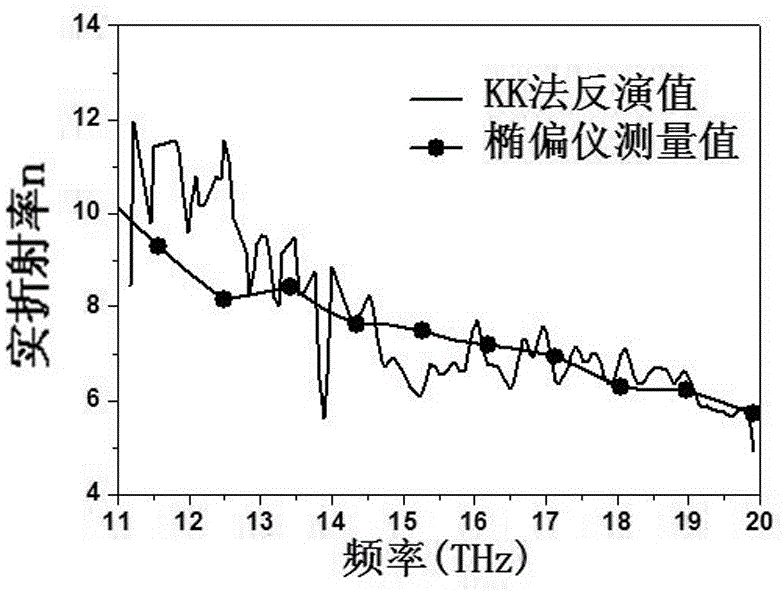

Joint inversion method for metal terahertz-far infrared complex refractive indexes

ActiveCN105823756AOvercome stabilityOvercome the shortcomings of limited measurement frequencyPhase-affecting property measurementsMaterial scatteringRefractive index

The invention provides a joint inversion method for metal terahertz-far infrared complex refractive indexes. A far infrared ellipsometer is used for measuring exact solutions of the complex refractive indexes with the wave number range of 262 cm<-1>-7,946 cm<-1>; in combination with a far infrared Fourier spectrograph, reflectivity spectrums of metal within the wave number range are measured; the complex refractive index, close to the terahertz high-frequency end, measured by the ellipsometer is selected as an experiment initial value, index extrapolation parameters are adjusted through the KK relation between the reflection coefficient range and phases till the inversion result and the ellipsometer complex refractive index calibration result meet error requirements, and the complex refractive indexes of the terahertz-far infrared metal are obtained. The accuracy of the inversion result is verified by comparing the inversion result with measured values at the same frequency band of the ellipsometer. According to the method, theories and experiments verify one another, the inversion result is high in reliability, the defect that complex refractive indexes of THz frequency bands are difficult to measure is overcome, and a research basis is provided for terahertz material scattering properties and development of the terahertz radar imaging technology.

Owner:XIDIAN UNIV

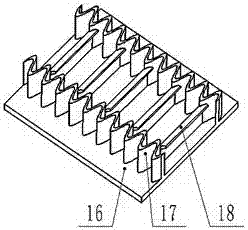

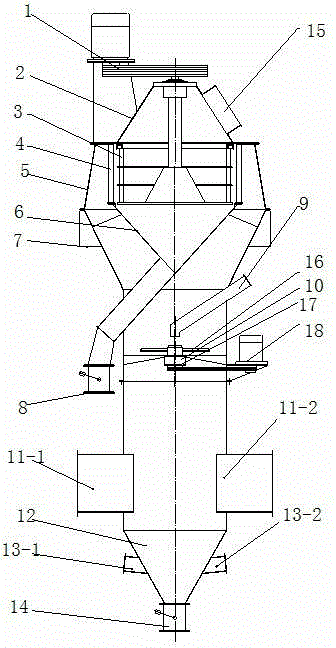

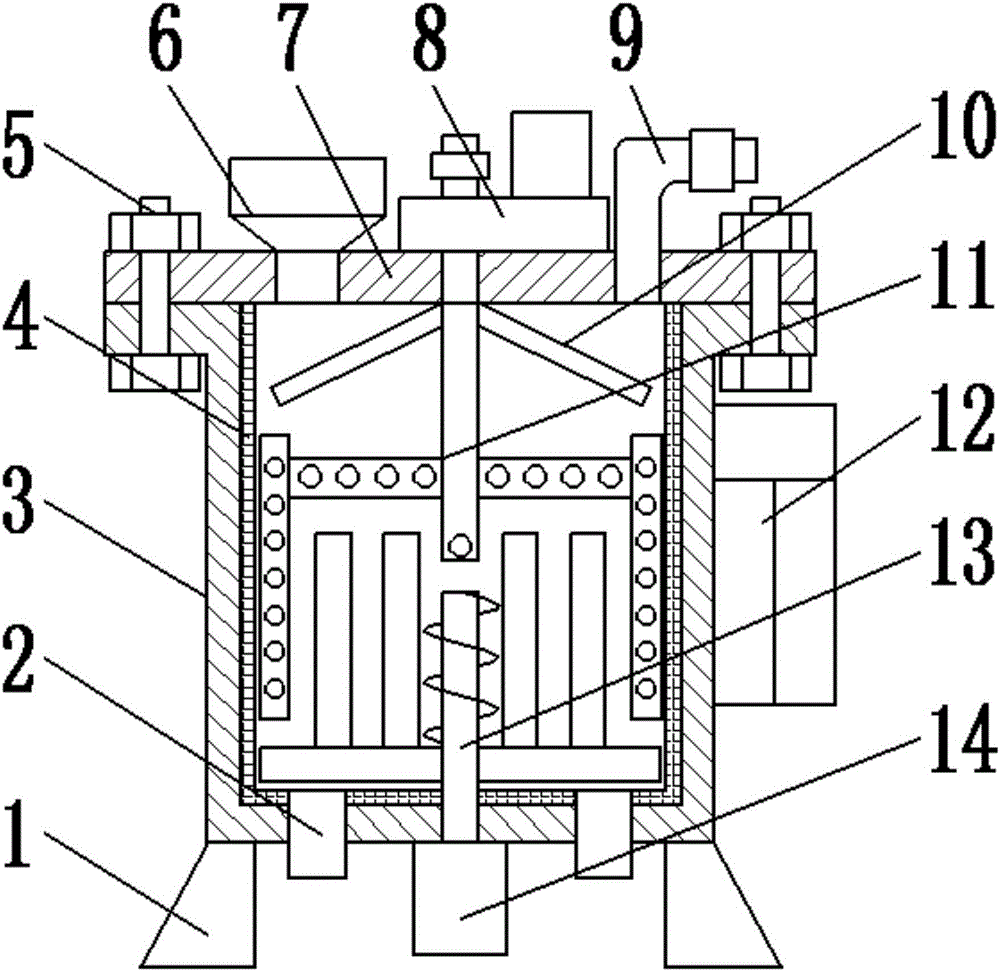

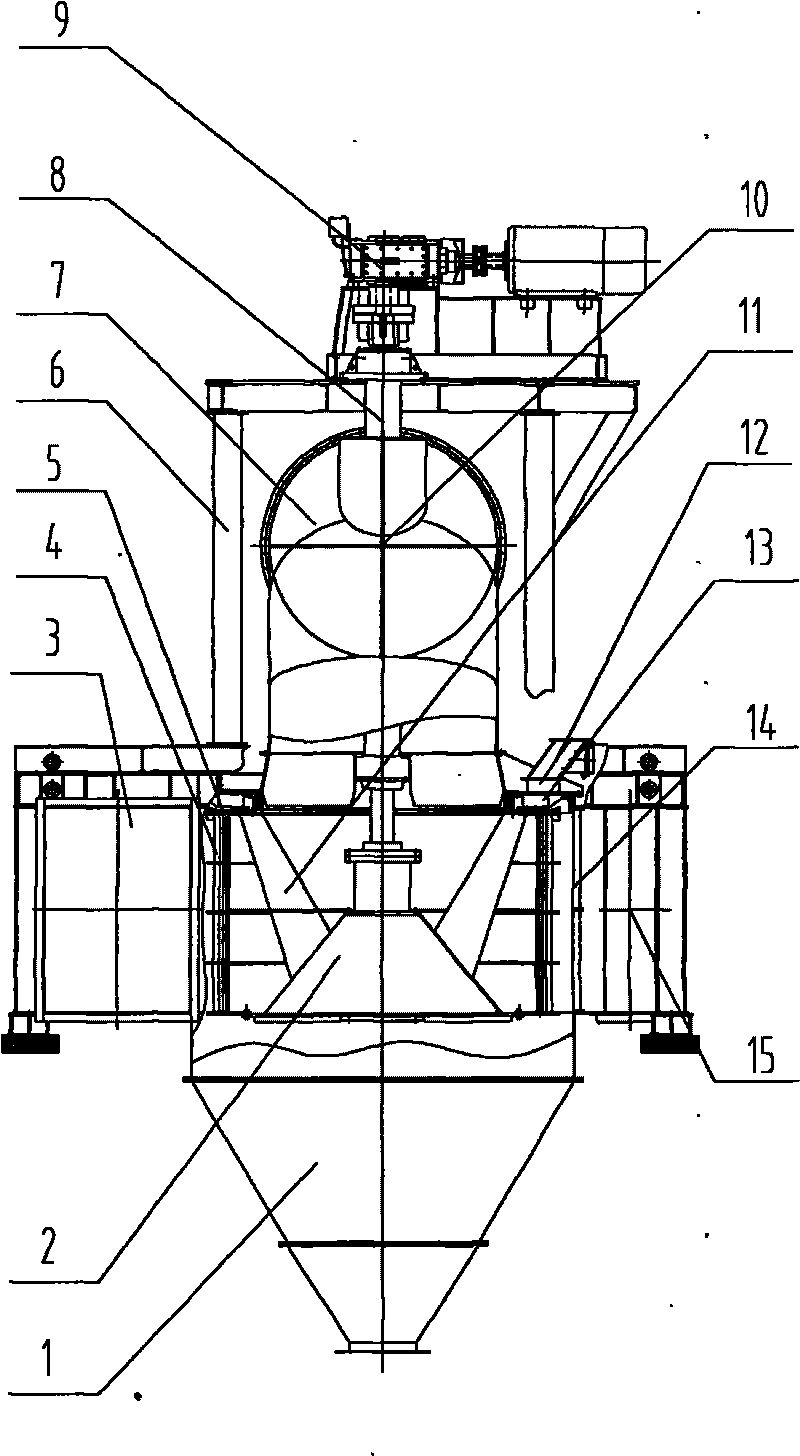

Efficient powder selecting machine with power material scattering device

InactiveCN104624499AFully dispersedFlow field stabilityGas current separationMaterial scatteringMechanical engineering

The invention provides an efficient powder selecting machine with a power material scattering device. A lower part power material scattering device (10) is arranged at the lower part of the powder selecting machine; the lower part power material scattering device (10) is composed of a material scattering disc (16), a supporting device (17) connected with the material scattering disc (16), and a second transmission device (18) connected with the supporting device (17). The efficient powder selecting machine has the following technical effects that the power material scattering device is arranged at the lower part so that powder materials to be selected are sufficiently dispersed, and a stable and uniform flow field is provided for rotor grading the next step; the powder selecting efficiency is improved by 10%-15%; feeding is carried out at a lower part: the power selecting concentration of a rotor of the powder selecting machine is greatly reduced and the power consumption of the rotor is reduced by 15%-20%; discharging is carried out at the lower part: large-particle materials and iron blocks are directly discharged from the lower part of a discharging opening, the upper part sealing is not blocked, and the abrasion of an upper guide blade is small.

Owner:JIANGSU XINYE HEAVY IND

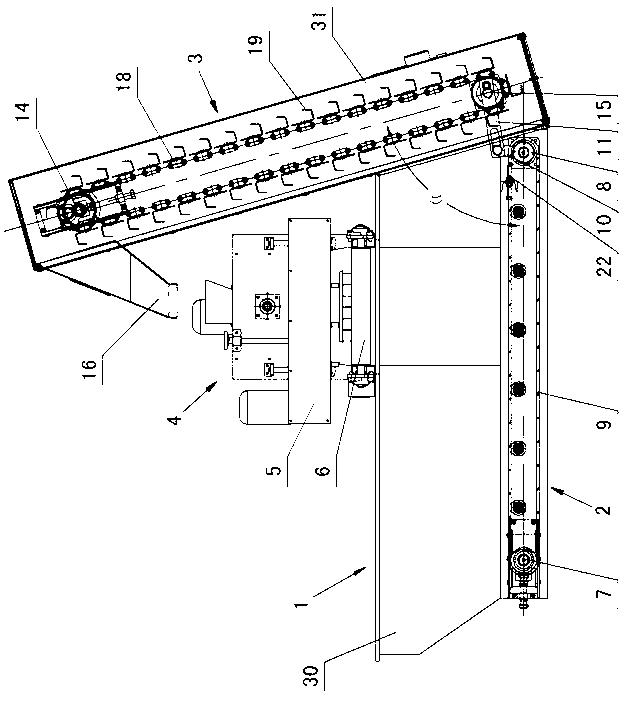

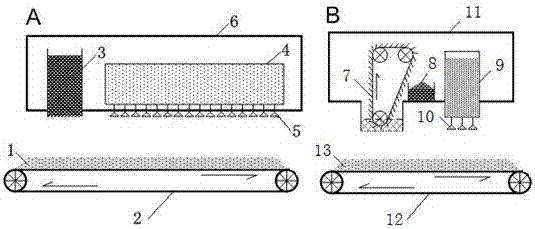

Full-automatic base material tray charging mechanism

ActiveCN103283526ALarge storage capacityReduce feeding timesCultivating equipmentsMaterial scatteringConveyor belt

Provided is a full-automatic base material tray charging mechanism. The full-automatic base material tray charging mechanism comprises a feeding bin, a horizontal material conveying system, an inclined material conveying system, a base material scattering system, a base material brushing-levelling system and a seedling tray arrangement working platform, wherein a feeding inlet is formed in one end of the feeding bin, the inclined material conveying system is arranged at the other end of the feeding bin, the horizontal material conveying system comprises the feeding bin, a left rotary shaft and a one-way shaft are arranged in the feeding bin, a conveyor belt is arranged on the left rotary shaft and the one-way shaft, one side of the one-way shaft is connected with the inclined material conveying system through a linkage mechanism, the linkage mechanism comprises a swing arm which is fixed with the one-way shaft, the upper portion of the swing arm is connected with one end of a connecting rod through a pin, a connecting hole is formed in the other end of the connecting rod, a connecting pin is installed in the connecting hole, the connecting rod is connected with an eccentric wheel through the connecting pin, the inclined material conveying system comprises a feeding frame which is arranged in an inclined mode, an upper rotary shaft and a lower rotary shaft are installed on the feeding frame, a discharging outlet is formed in the feeding frame, one end of the lower rotary shaft is connected with the eccentric wheel, the other end of the lower rotary shaft is driven by a motor, a feeding belt is arranged on the upper rotary shaft and the lower rotary shaft, a hopper is installed on the feeding belt, and base materials are conveyed to the base material scattering system from the discharging outlet through the hopper.

Owner:杭州赛得林智能装备有限公司

Method and system for repairing polycyclic aromatic hydrocarbon contaminated soil through fenton-like and microorganism combination

The invention discloses a method and system for repairing polycyclic aromatic hydrocarbon contaminated soil through fenton-like and microorganism combination. The method includes the following steps that (1) a mixture of carbon-coated porous foamed iron fine particles and sodium perborate or urea peroxide and citrate is scattered into the contaminated soil; (2) a hydrogen peroxide solution is evenly sprayed into the contaminated soil, polycyclic aromatic hydrocarbon pollutants are enriched and removed, and the foamed iron fine particles are recycled; and (3) mixed bacterium suspension is sprayed into the contaminated soil. The system comprises a material scattering device and a recovery device. The material scattering device comprises a material scattering crawler belt conveyor and a material scattering fixed frame. The material scattering fixed frame is provided with a mixture hopper, a hydrogen peroxide solution storage tank and a sprayer. The recovery device comprises a recovery crawler belt conveyor and a recovery fixed frame. The recovery fixed frame is provided with a magnetic recovery device, a recovery tank, a mixed bacterium suspension storage tank and a sprayer. By means of the method and system, the process is simple, cost is low, sustainability is high, damage to soil microorganisms and organic matter is avoided and the danger of secondary pollution is avoided.

Owner:QINGDAO AGRI UNIV

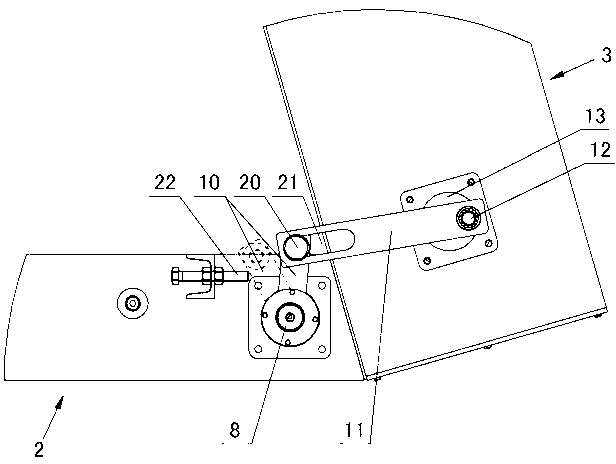

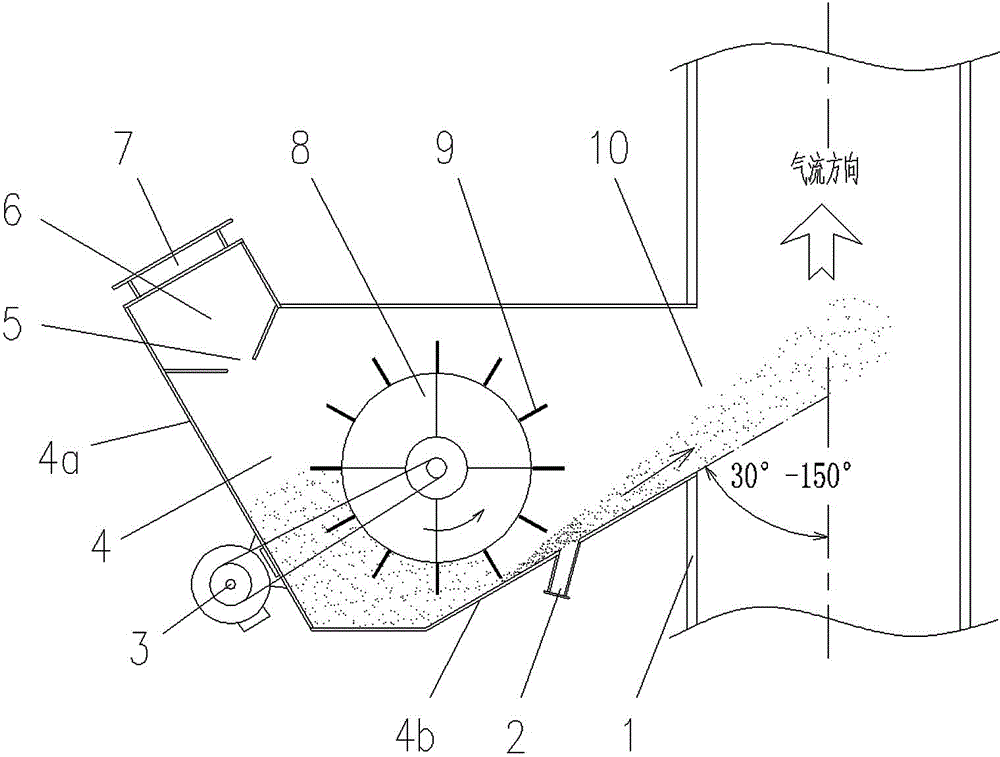

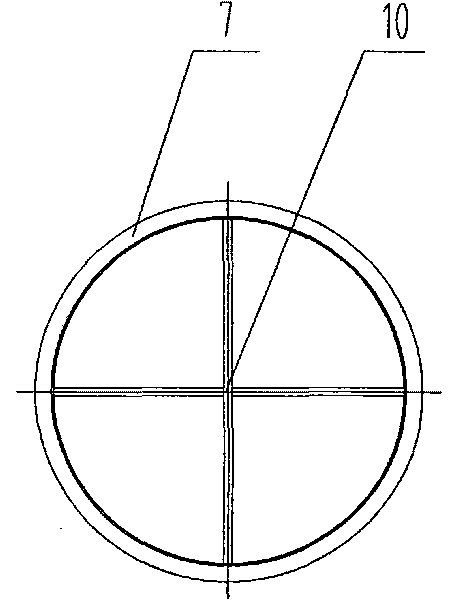

Material throwing type scattering device of cement production preheater

ActiveCN104154761APlay a role in raisingImprove the heating effectCharge manipulationPreheating chargesMaterial scatteringHeating effect

The invention relates to a material throwing type scattering device of a cement production preheater. The material throwing type scattering device comprises an air pipe (1), and a material scattering box (4) is arranged on the outer wall of one side of the air pipe and is provided with a feeding port (7), a discharging port (10) and a material poking hole (2). The material throwing type scattering device is characterized in that a material throwing wheel (8) is arranged in the material scattering box, a set of material scraping plates (9) are arranged on the outer circumference of the material throwing wheel, a buffering bin (6) and a material limiting port (5) are formed below the feeding port (7) in sequence, and the feeding port is communicated with the material scattering box through the buffering bin and the material limiting port. By means of the technical scheme, materials fed into the air pipe are scattered more evenly, the materials make full contact with hot air, the heating effect on the materials of the hot air is better, and the energy-saving effect of the device is obviously improved.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

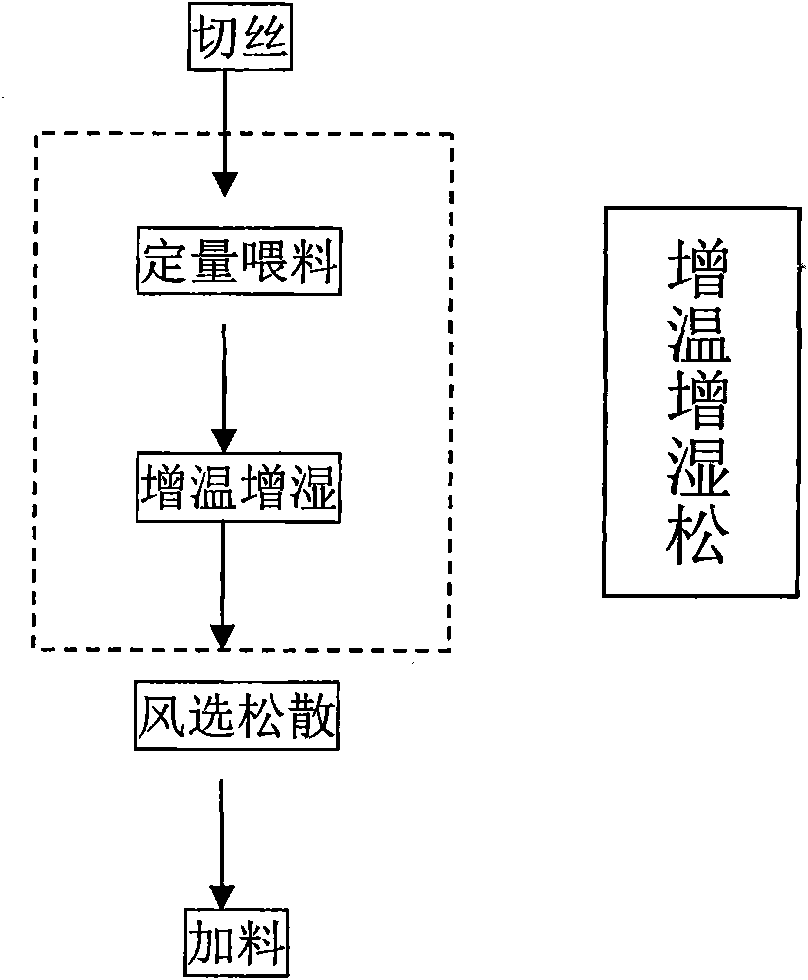

Leaf thread material feeding process and equipment

ActiveCN101773279AReduce sticking and drawingLoosely fullTobacco preparationTobacco treatmentVulcanizationMaterial scattering

The invention relates to a leaf thread material feeding process and equipment, which belong to the technical field of tobacco processing. The invention is characterized in that the leaf thread feeding process sequentially comprises the working procedures of thread cutting, temperature increasing and humidifying loosening, air separation loosening and material feeding. The equipment applicable to the process comprises a thread cutting machine, a quantitative material feeding machine, a vibration vulcanization bed, an air separation loosening device and a vertical material feeding machine which are sequentially ranged, wherein each equipment is connected through material conveying mechanisms, the vertical material feeding machine comprises a material feeding cavity, a material inlet airlock and a material outlet airlock are respectively arranged on the top and the bottom of the material feeding cavity, a material scattering mechanism is fixed on the upper part of the material feeding cavity, a material liquid atomizing system is communicated with the material feeding cavity through an air inlet pipe and a air return pipe of a hot air circulation system, and a sealed cyclic feeding system is formed. The process and the equipment can solve the problems of large thread cutting pulverization products of low-water-content tobacco flakes and material feeding aggregation of tobacco threads, the material liquid atomizing effect is good, the material liquid absorption velocity by the tobacco threads is high, the material feeding uniformity and the effectiveness are improved, in addition, the material storing time after the material feeding is shortened, and the production efficiency is high.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +1

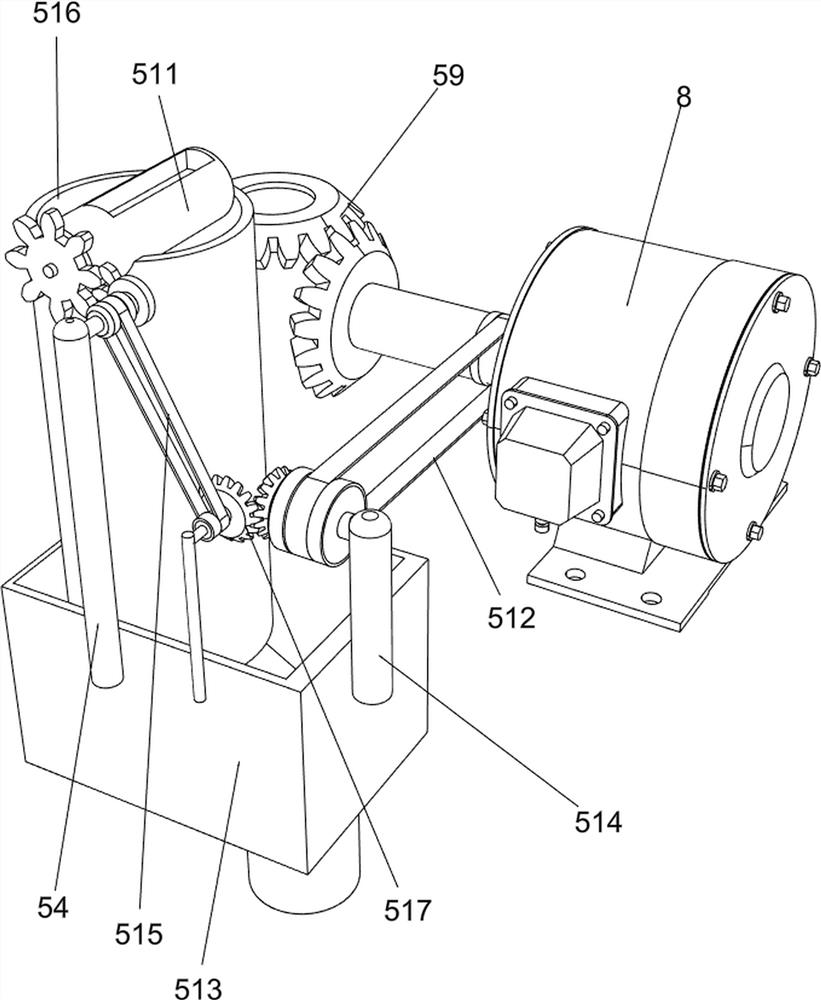

Agricultural field stirring fertilizer applicator

PendingCN111727711AUniform fertilization effectImprove work efficiencyTransportation and packagingRotary stirring mixersAgricultural engineeringMaterial scattering

The invention relates to a fertilizer applicator, in particular to an agricultural field stirring fertilizer applicator. The agricultural field stirring fertilizer applicator provided by the inventioncan continuously stir fertilizer, control blanking and realize uniform blanking. The agricultural field stirring fertilizer applicator comprises a supporting frame, wheels, a vibration material scattering mechanism, a stirring and discharging mechanism and a motor, wherein the wheels are rotationally connected to the four sides of the supporting frame; the supporting frame is connected with the vibration material scattering mechanism; the top of the supporting frame is connected with the stirring and discharging mechanism, and the stirring and discharging mechanism is connected with the vibration material scattering mechanism; the side part of the top of the supporting frame is connected with the motor; and an output shaft of the motor is connected with the stirring and discharging mechanism. Through cooperation of the motor, the stirring and discharging mechanism and the vibration material scattering mechanism, continuous stirring, fertilizer applying and intermittent fertilizer conveying can be achieved, the effect of uniform fertilizer applying can be achieved, and the working efficiency of people is improved.

Owner:丘春连

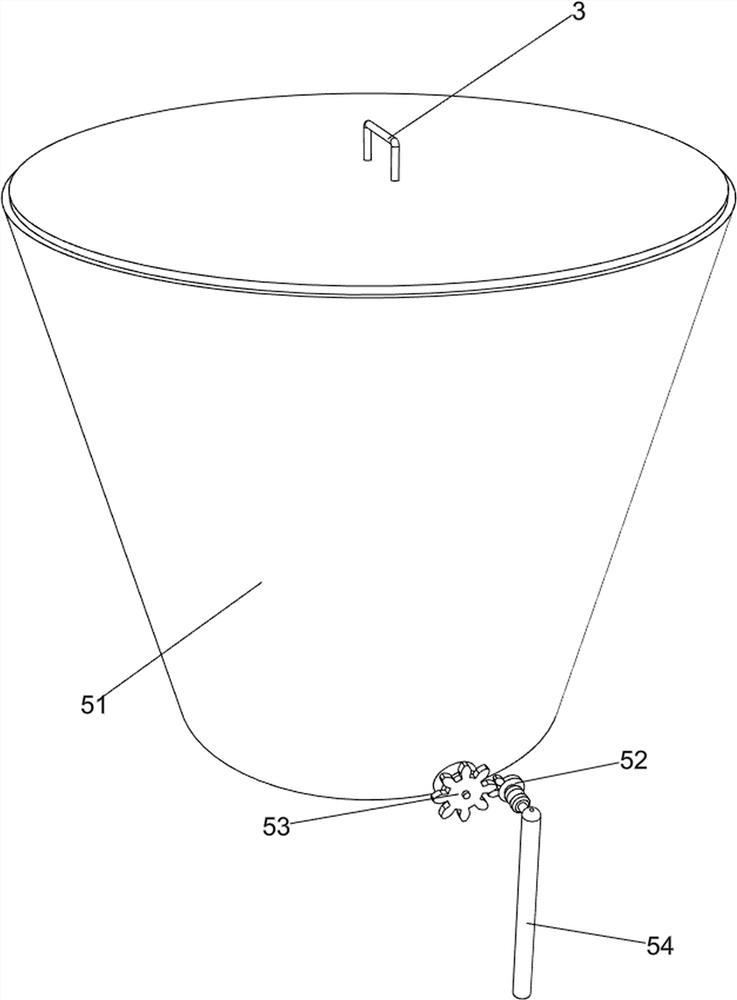

Material scattering device for aquaculture

PendingCN106973842APromote growthSimple structureClimate change adaptationPisciculture and aquariaAquatic productMaterial scattering

The invention discloses a material scattering device for aquaculture. The material scattering device comprises a culture pond and a storage box. A left sliding plate is fixedly arranged on the outer wall of a left side plate of the storage box in a welded mode. A right sliding plate is fixedly arranged on the outer wall of a right side plate of the storage box in a welded mode. The left sliding plate penetrates through a guiding slideway on a left L-shaped supporting plate in a sliding mode. A right sliding plate penetrates through a guiding slideway on a right L-shaped supporting plate in a sliding mode. A tension spring is connected between the right side plate of the storage box and a supporting vertical plate on the right L-shaped supporting plate. An inclined baffle is fixedly arranged on the lower surface of the right sliding plate in a welded mode. A first supporting rod is fixedly erected at the top end of a right supporting stand column in a welded mode, the top end of the first supporting rod is rotationally provided with a rotating cylinder in a bearing connection mode, and a plurality of shifting plates are fixedly arranged on the surface of the outer ring of the rotating cylinder in a welded mode. The material scattering device is simple in structure and convenient and rapid to operate, fish feed in an inner cavity of the storage box can uniformly fall down into the culture pond, aquatic products can grow better, and the practicability is high.

Owner:惠安县丽佳智能设备有限公司

Stereoscopic biscuit production line

ActiveCN106135330AEasy to installEasy to disassembleBaking plantsDough processingProduction lineCooking & baking

The invention belongs to the technical field of biscuit production equipment, and particularly relates to a stereoscopic biscuit production line. The biscuit production line is divided into a raw material preparation area, a biscuit making area and a cooling and packaging area, the raw material preparation area is located above the biscuit making area, and the biscuit making area is located above the cooling and packaging area. The biscuit production line is designed to be of a stereoscopic structure, the occupied area of a plant can be effectively reduced, meanwhile, the raw material preparation area is located above the whole biscuit production line, dough kneaded by a flour stirrer is loaded and transported by a carrier, the carrier is pushed to an automatic feeding machine, and the automatic feeding machine can pour the dough into a raw material pulverizer. The dough directly falls into the biscuit making area after being crushed by the raw material pulverizer for pressing, egg liquid coating, sugar spraying, material scattering and baking of biscuits, and the baked biscuits enter the cooling and packaging area for cooling and packaging. Little labor force is needed in the whole process, labor intensity is low, the automation degree is high, and production efficiency is high.

Owner:JINHUA YIYUAN FOOD CO LTD

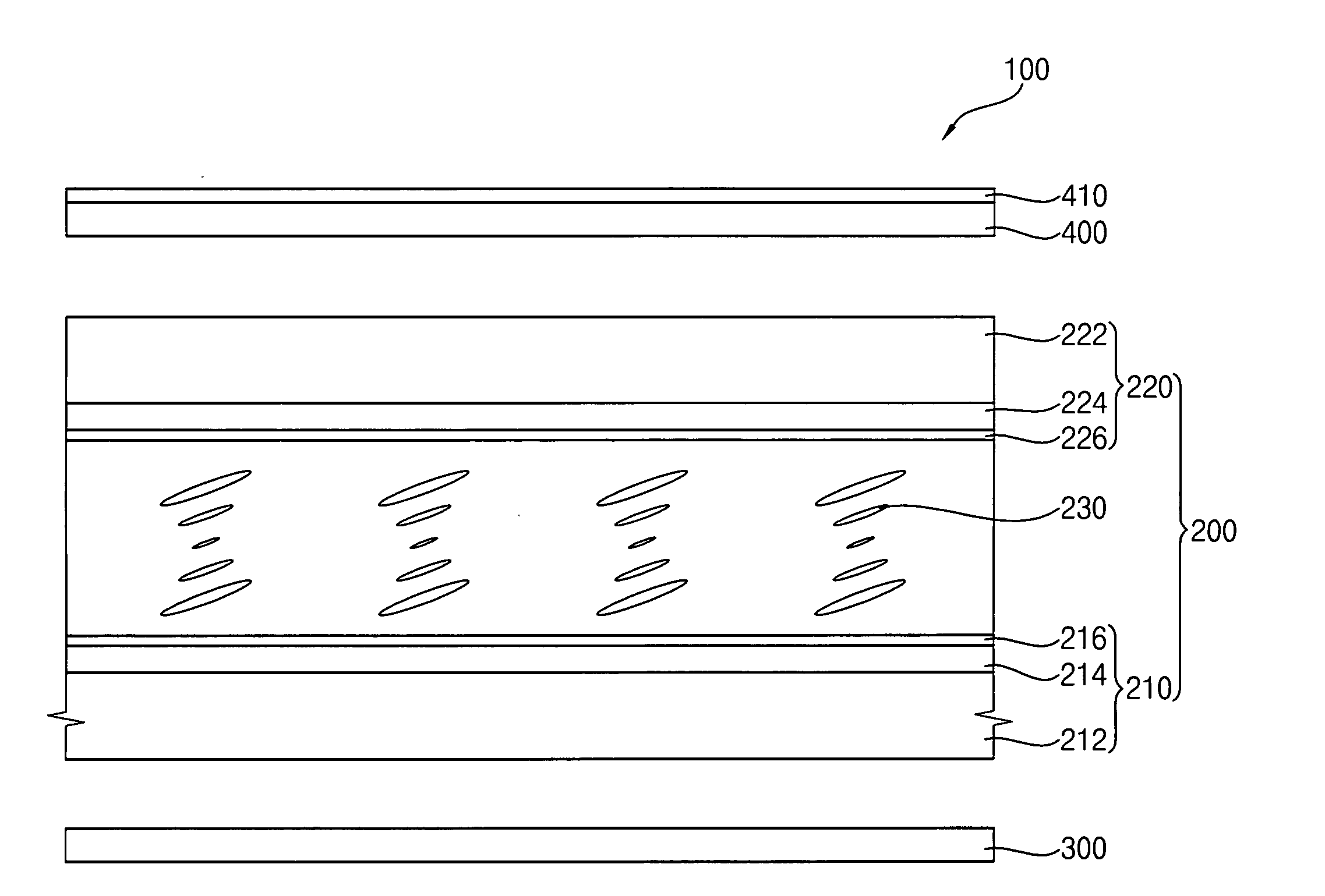

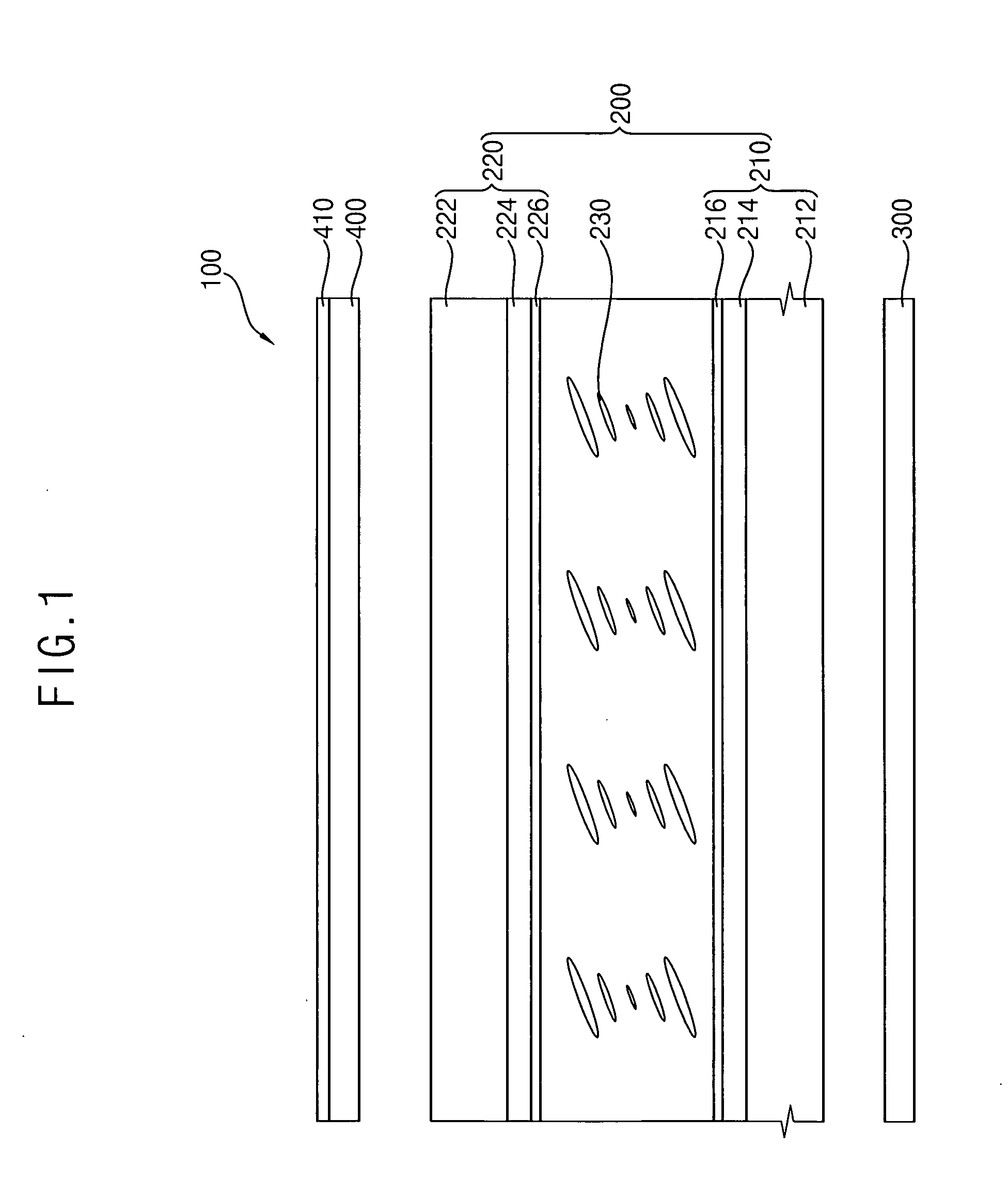

Polarizer and display apparatus having the same

InactiveUS20070171355A1Improve color reproducibilityExcellent surface hardnessPolarising elementsNon-linear opticsRefractive indexMaterial scattering

A polarizer includes a polarizing element, a first protective layer and a second protective layer and a surface treatment layer. The first and the second protective layer are formed on opposing sides of the polarizing element. The surface treatment layer is formed on the first protective layer and includes at least two kinds of scattering materials having different refraction indexes from each other. An inside haze value by the scattering materials is in a range of about 25% to about 50%. An outside haze value at the surface of the surface treatment layer is in a range of about 0.1% to about 1%.

Owner:SAMSUNG ELECTRONICS CO LTD

Medicinal material drying equipment

InactiveCN107702436AMaintain colorLow boiling pointDrying solid materials with heatDrying solid materials without heatVacuum pumpingBristle

The invention provides medicinal material drying equipment. The medicinal material drying equipment comprises a drying box, a feed hopper, a receiving box and a vacuum pumping device. The drying box is internally provided with a drying device, a material collection block and a lifting device. The drying device comprises a first drying unit and a second drying unit. The first drying unit and the second drying unit each comprises a material conveyor belt, ultrasonic transducers located below the material conveyor belt, a driving motor and an infrared ray lamp pole located above the material conveyor belt. A material scattering device is arranged above the first drying unit. Material retaining plates are arranged below the second drying unit. Limiting grooves and bristles are arranged above the material retaining plates. The lifting device is located on one side of the drying device. The medicinal material drying equipment conducts drying on medicinal materials through combination of ultrasound and infrared, is good in drying effect and capable of completely maintaining the original color, luster and flavor of the medicinal materials, conducts vacuum pumping on the interior of the drying box through the vacuum pumping device, can improve the drying efficiency and prevent vapor from wetting the medicinal materials again and is good in drying effect.

Owner:成都菲斯普科技有限公司

Online energy dispersive X-ray diffraction analyser

ActiveUS8311183B2Reduce voltageNeed long operating lifetimesX-ray spectral distribution measurementMaterial analysis using radiation diffractionLight beamMaterial scattering

An on-line EDXRD analyser including (i) a housing defining an analysis zone and having a passageway through it to allow transport of material in a process stream to pass through the analysis zone, (ii) a collimated source of polychromatic X-rays, (iii) an energy-resolving (ER)X-ray detector, (iv) a primary beam collimator disposed between the source of X-rays and the (ER)X-ray detector comprising an annular slit which defines an incident beam of polychromatic X-rays to irradiate a portion of the analysis zone, (v) a scatter collimator disposed between the primary beam collimator and the ERX-ray detector, the scatter collimator comprising an annular slit which defines a diffracted beam of X-rays scattered by the material to converge towards the ERX-ray detector, and (vi) a detector collimator comprising a conical opening which further defines the diffracted beam of X-rays scattered by the material. The ERX-ray detector measures an energy spectrum of the diffracted X-rays at a predetermined diffraction angle defined by the relative positioning of (ii) to (vi), and where one of (iv) and (v) comprises an aperture arranged to enable a detector to measure the transmission of a direct beam of X-rays through the material.

Owner:COMMONWEALTH SCI & IND RES ORG

Vertical mixing plant for processing sticky rice adhesive

InactiveCN106621912AStir wellGood dispersionRotary stirring mixersTransportation and packagingHeating timeVertical mixing

The invention discloses a vertical mixing plant for processing a sticky rice adhesive. The vertical mixing plant comprises a base; a mixing tank is arranged at the top of the base; a discharge pipe is arranged at the bottom of the mixing tank; a support plate is arranged at the top of the mixing tank; a thermal insulation layer, a first mixing device, a material scattering plate and a second mixing device are arranged in the mixing tank; a display device is arranged on the right side of the mixing tank; and a feed hopper, a rotating device and an exhaust pipe are arranged at the top of the support plate. The vertical mixing plant is simple in structure, reasonable in design and convenient in use; due to the arrangement of the first mixing device and the second mixing device, the material is fully mixed, a bottom scraper blade mixes the material at the bottom to avoid the mixing blind angles, a spiral mixing blade drives the material to turn up and down, so that the material is more sufficiently mixed; and due to the arrangement of a heating vertical rod, the material is heated, and the heating time and the temperature in the mixing tank can be controlled through the display device.

Owner:郑州吉音动漫科技有限公司

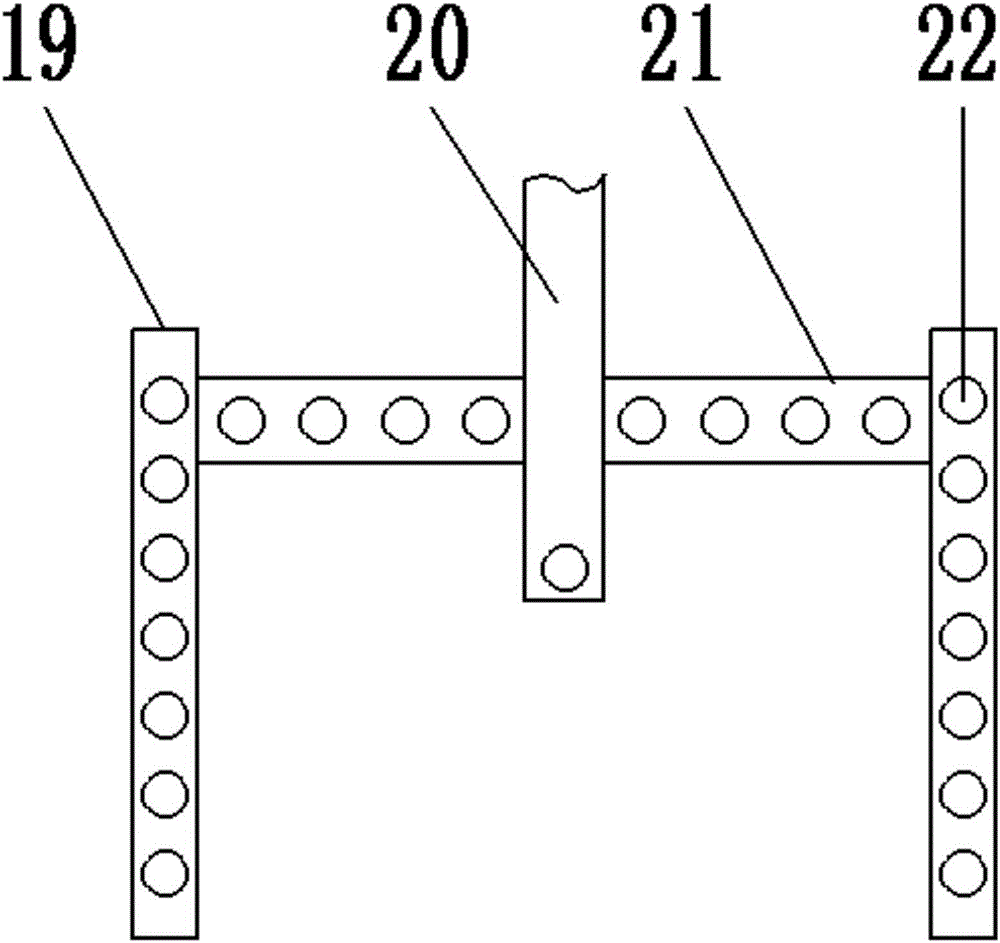

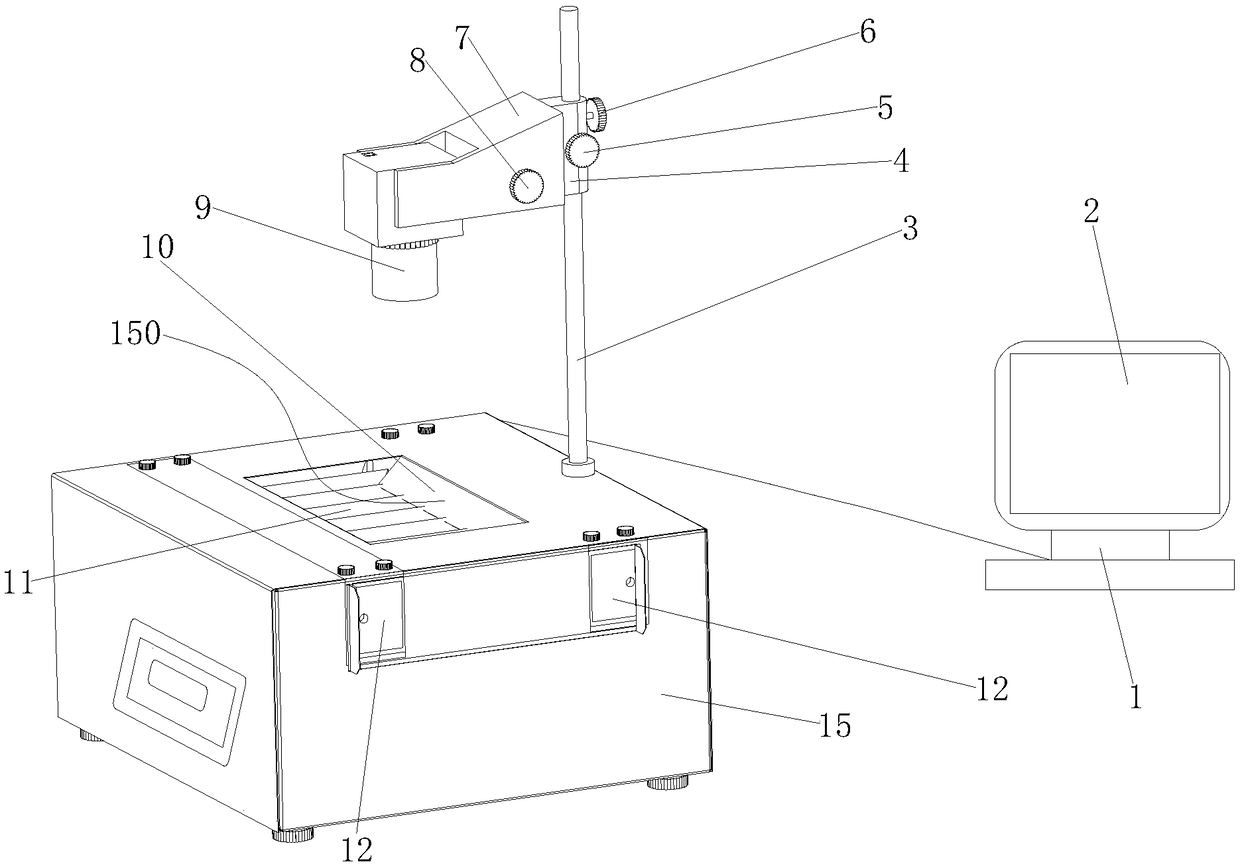

Machine vision-based tablet capsule counting device and method

InactiveCN108545265AHigh precisionImprove work efficiencyPackaging automatic controlColor imageImaging processing

The invention discloses a machine vision-based tablet capsule counting device and method. The machine vision-based tablet capsule counting device comprises a CCD camera mechanism. According to the machine vision-based tablet capsule counting device and method, the CCD camera mechanism capable of adjusting the height position up and down and adjusting the horizontal position front and back is adopted, an inclination angle adjusting mechanism is used for adjusting the inclination angle of a material scattering plate, and through the vibration function of a vibration mechanism on the material scattering plate, so that the plurality of tablet capsules are arranged in the groove bottom of the W-shaped grooves and form a row of queuing-shaped tablet capsule queues, and therefore the quality of true color images of the obtained tablet capsules is greatly improved; a MATLAB tool is adopted, image processing is carried out on the true color images of the tablet capsules through an image processing method, and accurately counting the tablet capsules according to the image processing result, so that the accuracy and the working efficiency of the tablet capsule counting are greatly improved; and the device is reasonable in overall design and compact in structure, a limited plane and a space position are fully utilized, the cost is low, and the method is suitable for popularization and application.

Owner:CHINA JILIANG UNIV

Magnetically driven deviation self-adjustment belt type conveyer

InactiveCN104760798AIncrease thickness costRealize automatic deviation adjustmentConveyorsRepulsion forceMaterial scattering

The invention belongs to the technical field of material conveying, in particular a magnetically driven deviation self-adjustment belt type conveyer. The magnetically driven deviation self-adjustment belt type conveyer is provided since a normal belt type conveyer has the disadvantages of increased cost of the conveying belt due to large hauling distance and large tension in a conveying process and has the risks of material scattering, environment pollution, conveying belt breakage and the like caused by deviation of the conveying belt in the conveying process. Specifically, a linear motor is adopted to drive the conveying belt, and magnetic force produced by electrifying a linear motor stator and magnetic force of a permanent magnet array coact to form driving force. The magnetic pole of a deviation adjustment magnet is the same as that of the permanent magnet array on the conveying belt; by means of repulsion force of permanent magnets, the deviation of the conveying belt in movement is adjusted. The conveyer has the beneficial effects that the concentrated force of single-point or multi-point rotary driving of the conventional conveying belt is uniformly distributed on the entire belt type conveyer, the cost of the conveying belt is reduced, and automatic deviation adjustment in operation of the conveying belt is realized by arranging the deviation adjustment magnet so as to prevent the problems of coal scattering and conveying belt breakage caused by deviation of the conveying belt.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

Construction equipment used for stone planting type interlayer treatment process

InactiveCN107034770AImprove construction qualitySpread evenlyIn situ pavingsRoads maintainenceComputer control systemInterface layer

The invention discloses construction equipment used for a stone planting type interlayer treatment process. The construction equipment comprises a material storage bin, a material scattering bin, a conveying belt, a stone scattering device, a stone vibration pressing device, a caterpillar-type chassis, a hydraulic lifting device and a computer control system. The construction equipment can conduct stone planting construction on initial set concrete without influence on the paving effect of a composite pavement base layer; the computer control system is adopted to automatically control operation; compared with a pavement adopting other existing interlayer treatment methods, the shear strength of an interface layer of the constructed composite pavement is improved obviously; and the current situation that for an existing stone planting method, matched construction equipment does not exist, working is complex, the construction quality is difficult to guarantee is solved.

Owner:CHANGAN UNIV

High-efficiency material distribution powder selector

InactiveCN101716574AImprove uniformityImprove quality and efficiencyGas current separationMaterial scatteringEngineering

The invention provides a high-efficiency material distribution powder selector which comprises a conical bucket, a cage type rotator, a primary air inlet, a powder selection shell, a slope-shaped material scattering disc, a bracket, an air outlet pipe, a spindle, a drive device, a vortex scattering blade, a window type feeding device, an air guide blade, a secondary air inlet, a secondary vortex scattering device and material distribution plates. The slope-shaped material scattering disc, which consists of an involute type slope-shaped material scattering plate, a material baffle and a reinforcing plate connecting device, is installed at the upper part of the cage type rotator and below the window type feeding device, the window type feeding device comprises a feeding pipe, an air inlet adjustment valve, an adjustable shutter and a square pipe, the square pipe is installed on the side surface of the feeding pipe, the air inlet adjustment valve is installed in the square pipe, an opening is arranged at the joint of the square pipe and the feeding pipe, the adjustable shutter is arranged at the opening part, a set of static material distribution plates is arranged above the material scattering disc, and the vortex scattering device is arranged at the air outlet part of the air outlet pipe.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com