Device for measuring scattering coefficients and absorption coefficients of laser working media

A technology of working medium and absorption coefficient, applied in the measurement of scattering characteristics, color/spectral characteristics, etc., can solve the problems of low accuracy, large transmittance measurement error, and no consideration of Fresnel loss, etc., to achieve good optical performance , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

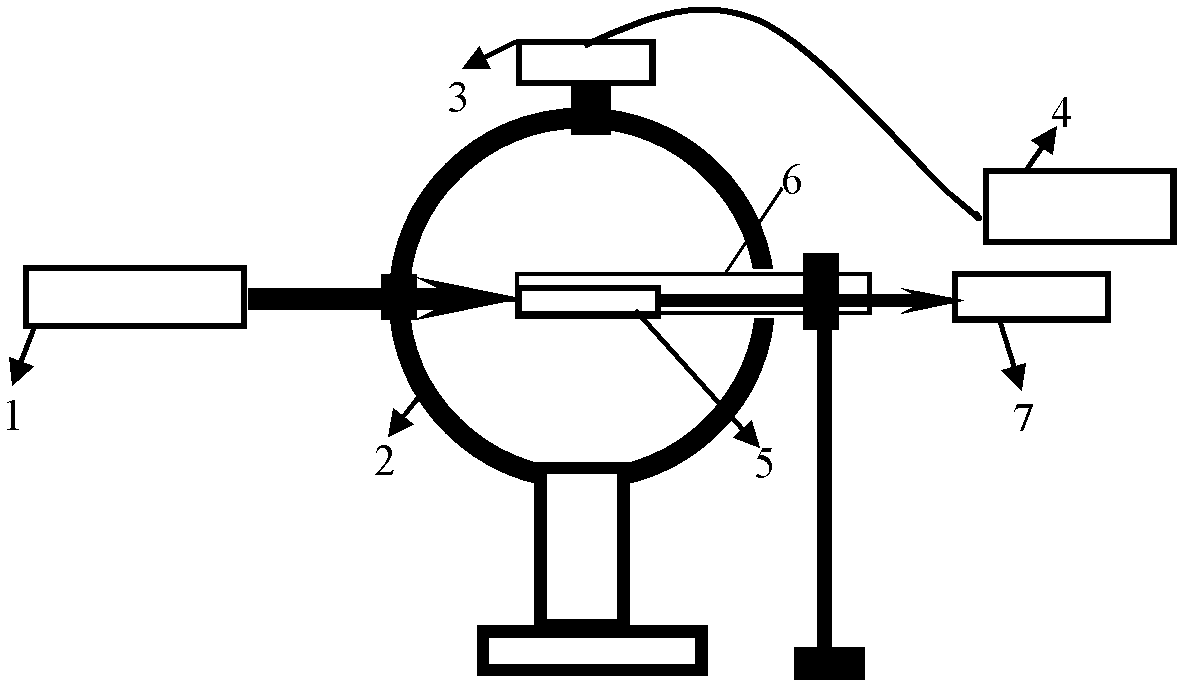

[0037] This embodiment provides an experimental device for measuring the scattering coefficient and absorption coefficient of a Nd:YAG ceramic laser working medium.

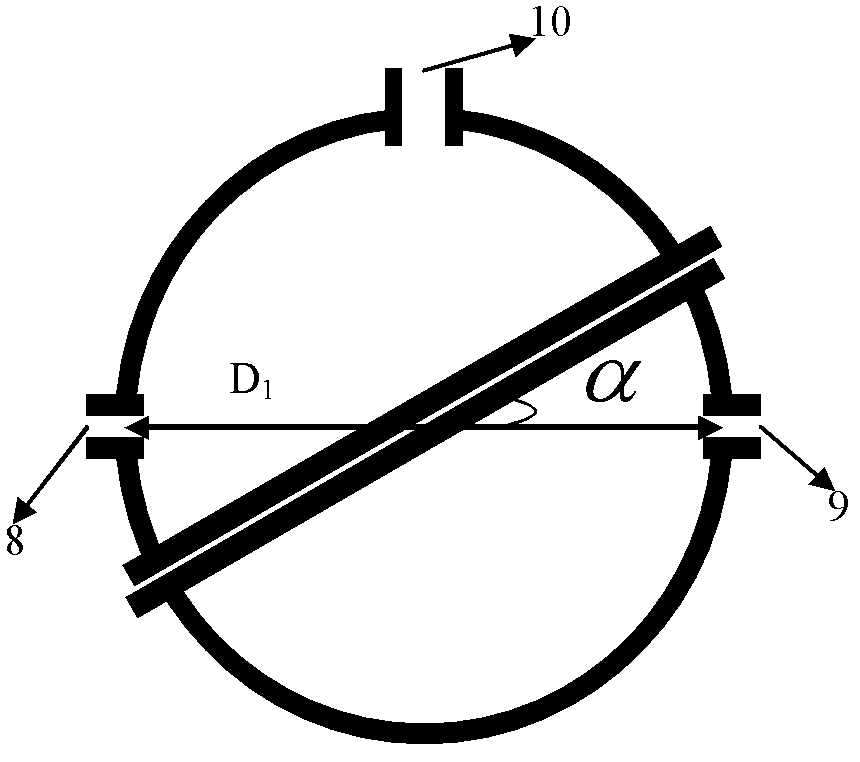

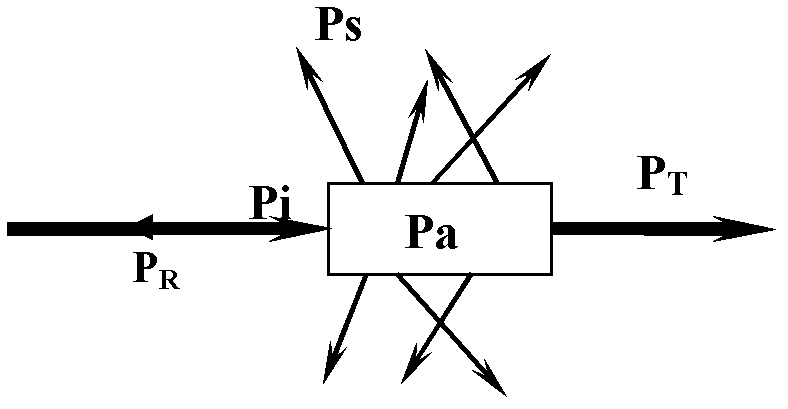

[0038]The specific structure of this embodiment refers to figure 1 The Nd to be measured: YAG ceramic material 5 (laser working medium to be measured) is placed and fixed on the center of the integrating sphere 2 by the fixed support device 6, and the test laser enters the integrating sphere through the light entrance 8 and is vertically incident from one end of the sample and transmitted through the other end , the incident laser power is P i After reflection from the incident end face of the sample, internal scattering and absorption of the sample, the transmitted power is P T , the total reflected power, total scattered power and total absorbed power are P R ,P s ,P a Before and after placing the sample, the incident laser power P is measured by the laser power meter 7 placed behind the light exit hole 9 p...

Embodiment 2

[0047] The present embodiment provides a kind of experimental device of measuring Yb:YAG laser crystal scattering coefficient and absorption coefficient, and present embodiment is similar to embodiment 1, and difference is:

[0048] 1. The output center wavelength of the test laser is 1 μm.

[0049] 2. The test sample is a Yb:YAG laser crystal with a size of 4.9mm×6.85mm×15mm.

[0050] The measurement result of this embodiment is: the sample scattering coefficient is 0.009cm -1 , absorption coefficient 0.007cm -1 , the total loss coefficient is 0.016cm -1 , the large loss coefficient of this sample is not conducive to high-performance laser output, and the scattering loss caused by pores and grain boundaries, and the extrinsic absorption loss caused by impurities are relatively large, and the optical properties of the material can be improved by reducing the pores and impurity content. performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scattering coefficient | aaaaa | aaaaa |

| absorption coefficient | aaaaa | aaaaa |

| scattering coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com