Material throwing type scattering device of cement production preheater

A material spreading device and preheater technology, which is applied in the direction of preheating costs, lighting and heating equipment, furnaces, etc., can solve the problems that affect the preheating effect of materials, cannot be eliminated, and cannot be evenly spread, so as to achieve the heating effect Good, energy-saving effect is improved, and the effect of material uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

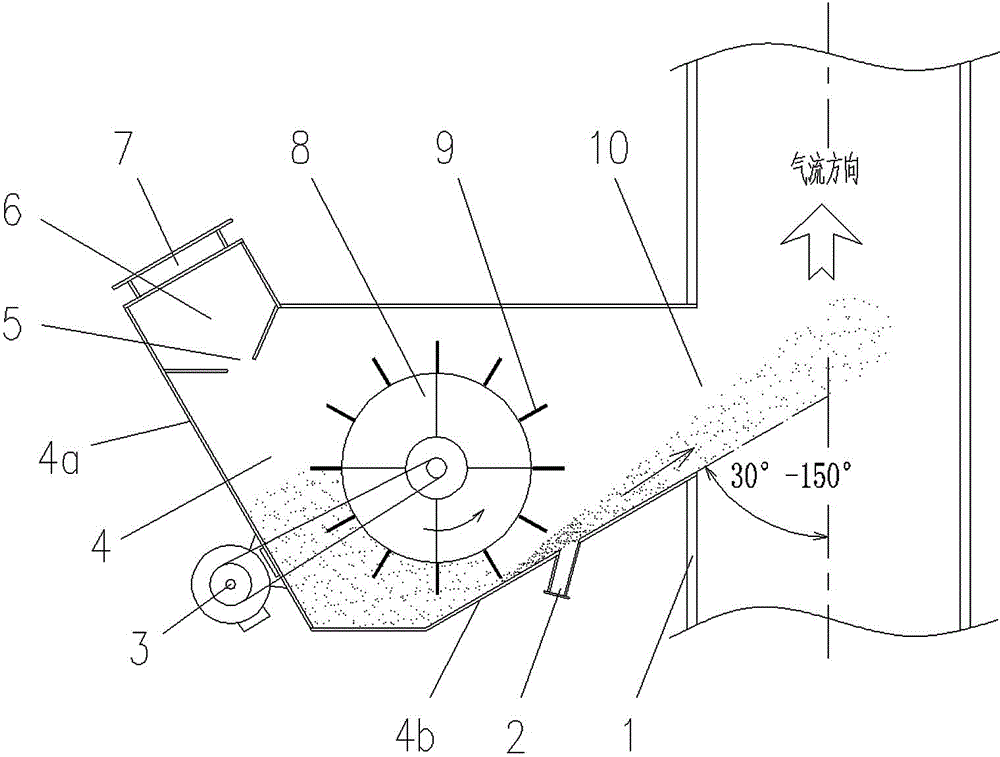

[0012] like figure 1 As shown, a cement production preheater throwing type material spreading device comprises: air duct 1, a material spreading box 4 arranged on the outer wall of one side of the air duct, and a material inlet 7 and a material outlet are arranged on the material spreading box 10 and poke material hole 2, it is characterized in that:

[0013] The material spreading box 4 is provided with a throwing wheel 8, and the outer circumference of the throwing wheel is axially provided with a group of scraper plates 9, and the throwing wheel and the two side plates of the spreading box rotate and cooperate, and the throwing wheel and the motor 3 drive cooperation, the motor 3 is a numerically controlled motor, and the throwing wheel is separated from the rear side plate 4a of the material spreading box by a certain distance, and is clearance-fitted with the lower side bottom plate 4b of the discharge port.

[0014] The lower side of the feed port 7 is provided with a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com