Stereoscopic biscuit production line

A production line, three-dimensional technology, used in baking, baking workshops, dough processing, etc., can solve the problems of laborious handling, indigestion, larger occupation, etc., to achieve simple installation and disassembly, and reduce the floor space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

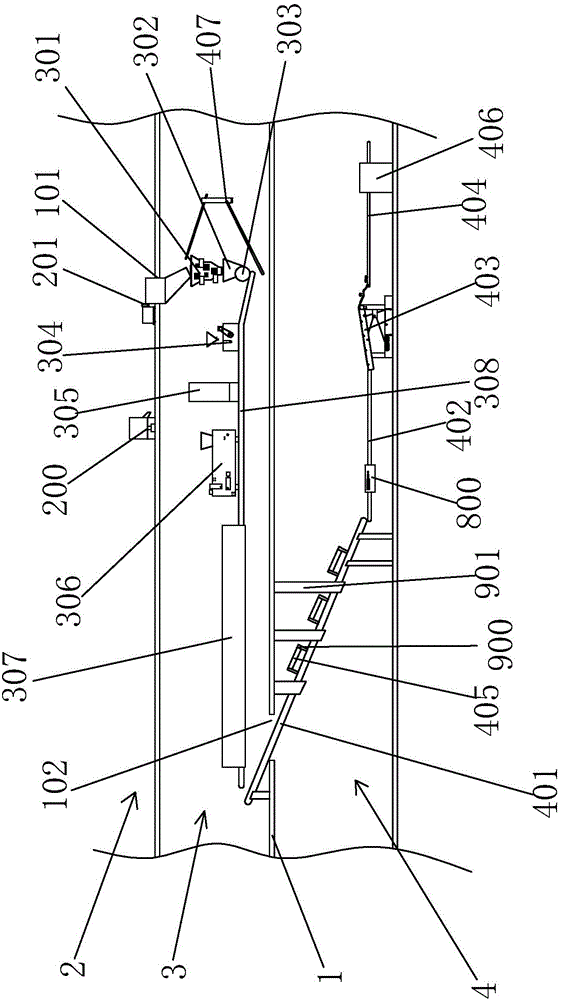

[0036] Such as figure 1 As shown, a three-dimensional biscuit production line includes a basic building 1, a raw material preparation area 2, a biscuit production area 3, and a cooling and packaging area 4. The raw material preparation area 2 is located on the third floor of the basic building 1, and the biscuit production area 3 is located on the foundation. On the second floor of building 1, the cooling and packaging area 4 is located on the first floor of the basic building 1. On the floor between the raw material preparation area 2 and the biscuit production area 3, there is a material inlet 101, the biscuit production area 3 and the cooling and packaging area 4 A through groove 102 is provided on the floor between;

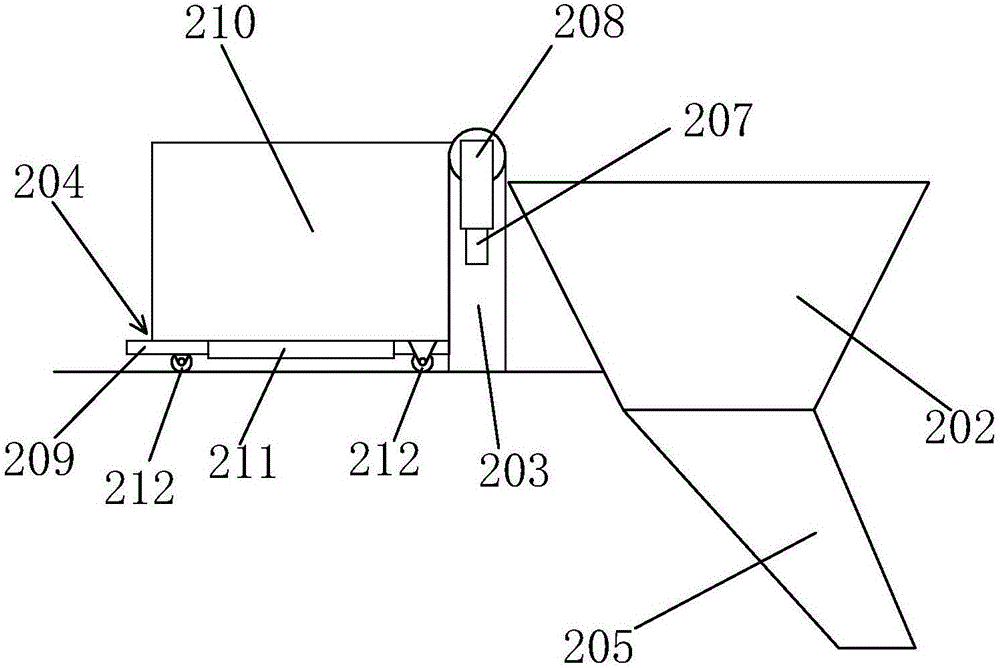

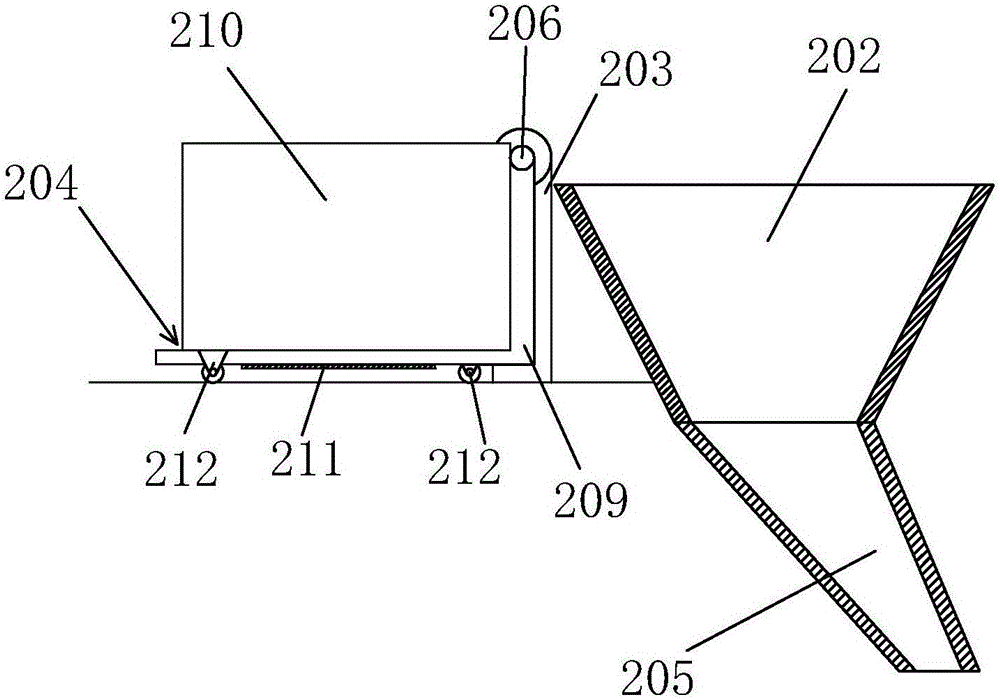

[0037] Such as Figure 1-4 As shown, the raw material preparation area 2 is provided with a flour mixer 200 and an automatic feeding machine 201, and the automatic feeding machine 201 includes a feeding hopper 202, a feeding machine frame 203, a feeding car ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com