Vertical mixing plant for processing sticky rice adhesive

A stirring device and a technology for glutinous rice glue, which are applied to mixer accessories, mixers with rotary stirring devices, dissolution and other directions, can solve problems such as the influence of heating temperature on the quality of glutinous rice glue, uneven mixing, etc., to shorten mixing time and improve work efficiency. , Reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

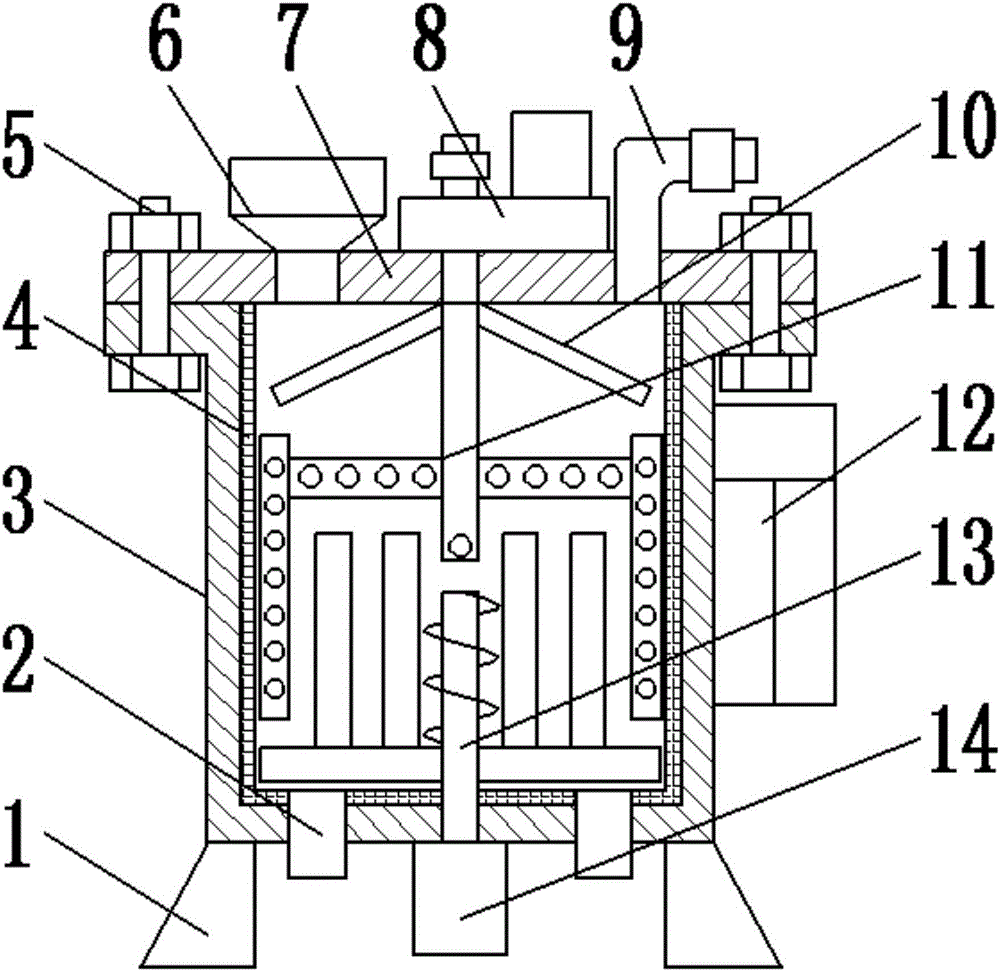

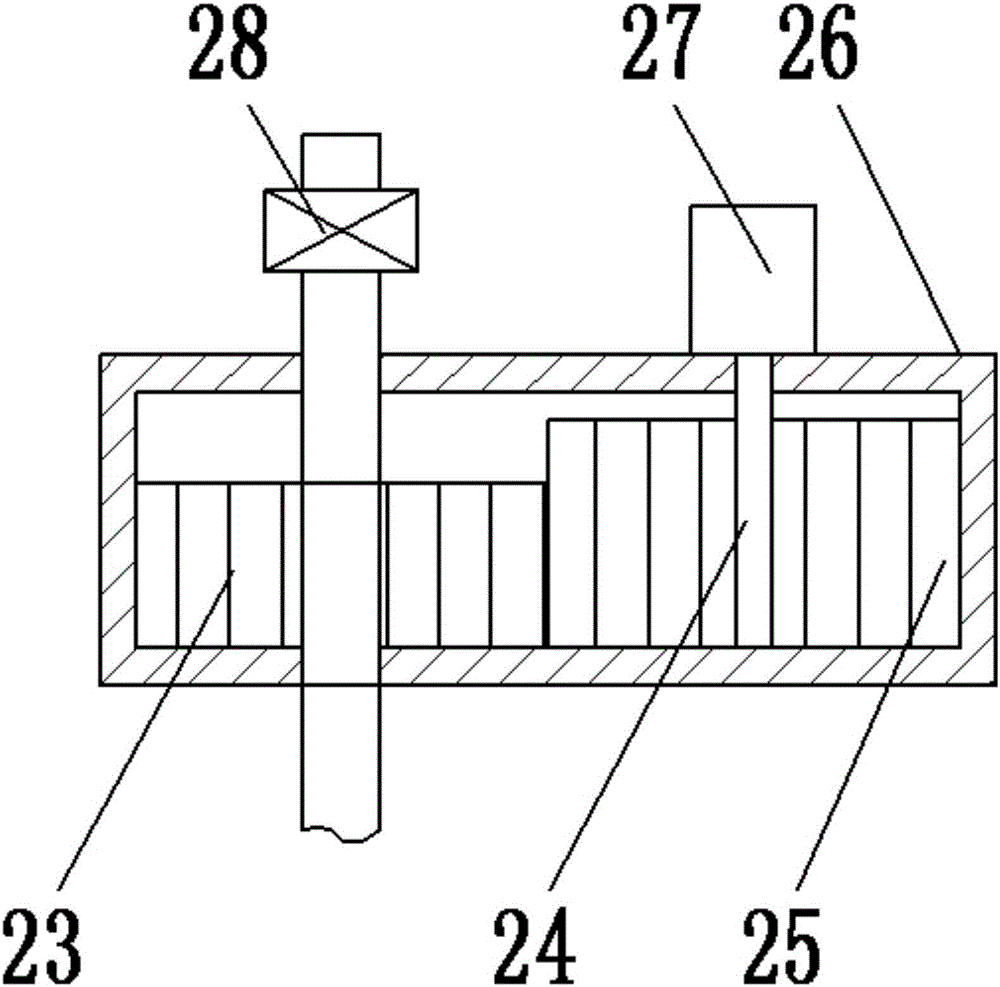

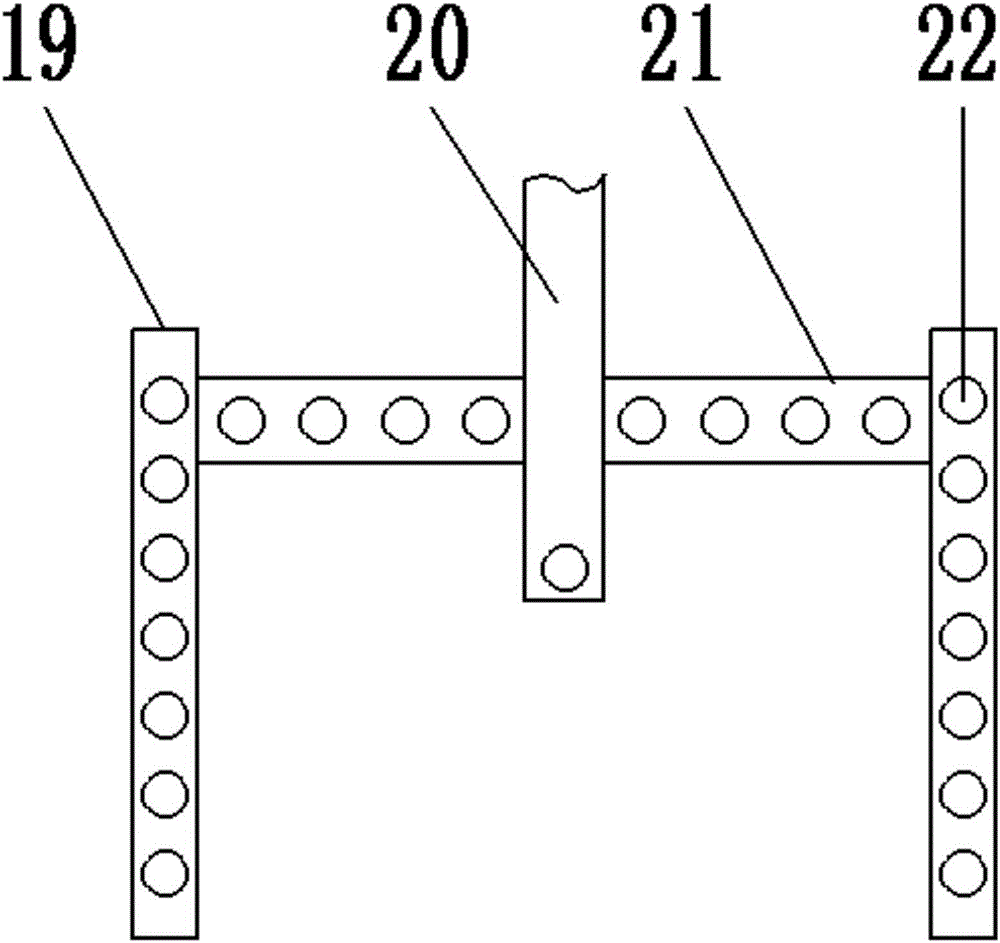

[0020] see Figure 1-4 , a kind of stirring equipment for vertical glutinous rice glue processing, comprises base 1; The top of described base 1 is provided with stirring box 3, is used to support this device, and can guarantee the stability of this device; The bottom of described stirring box 3 A discharge pipe 2 is provided; the top of the stirring box 3 is provided with a support plate 7; the inside of the stirring box 3 is provided with an insulating layer 4, a first stirring device 11, a spreading plate 10 and a second stirring device 13; The right side is provided with a display device 12, which is used to stir and mix the materials; the heat preservation layer 4 is arranged on the inner wall of the stirring box 3, and is used to ensure the temperature in the stirring box 3; the second stirring device 13 is formed by a bottom scraper 15. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com