Patents

Literature

132results about How to "Avoid Stirring Dead Angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

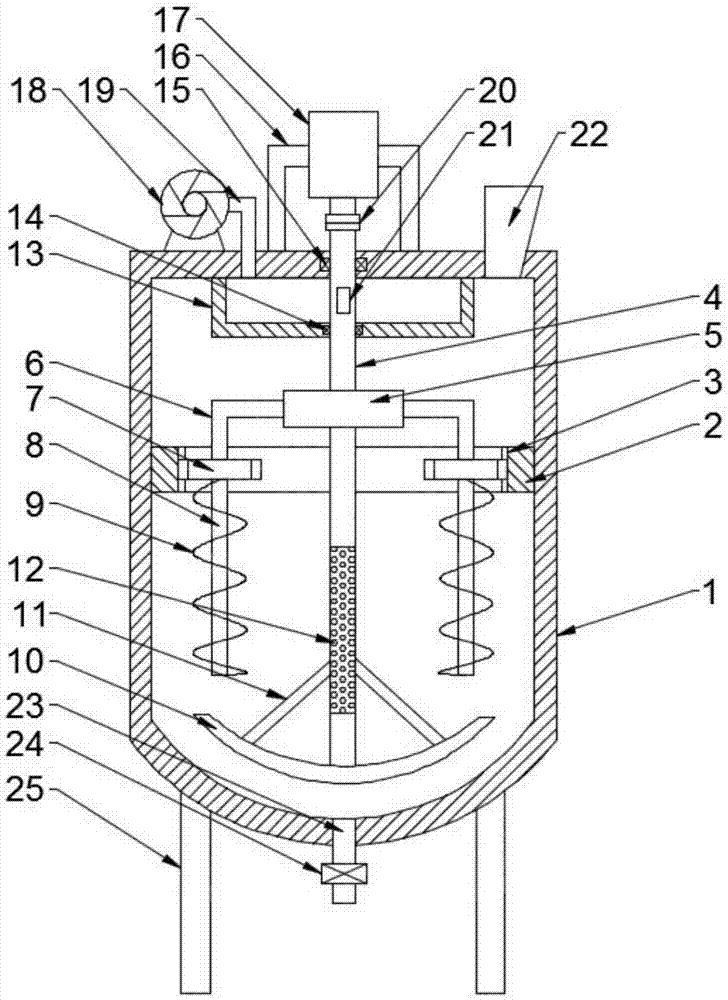

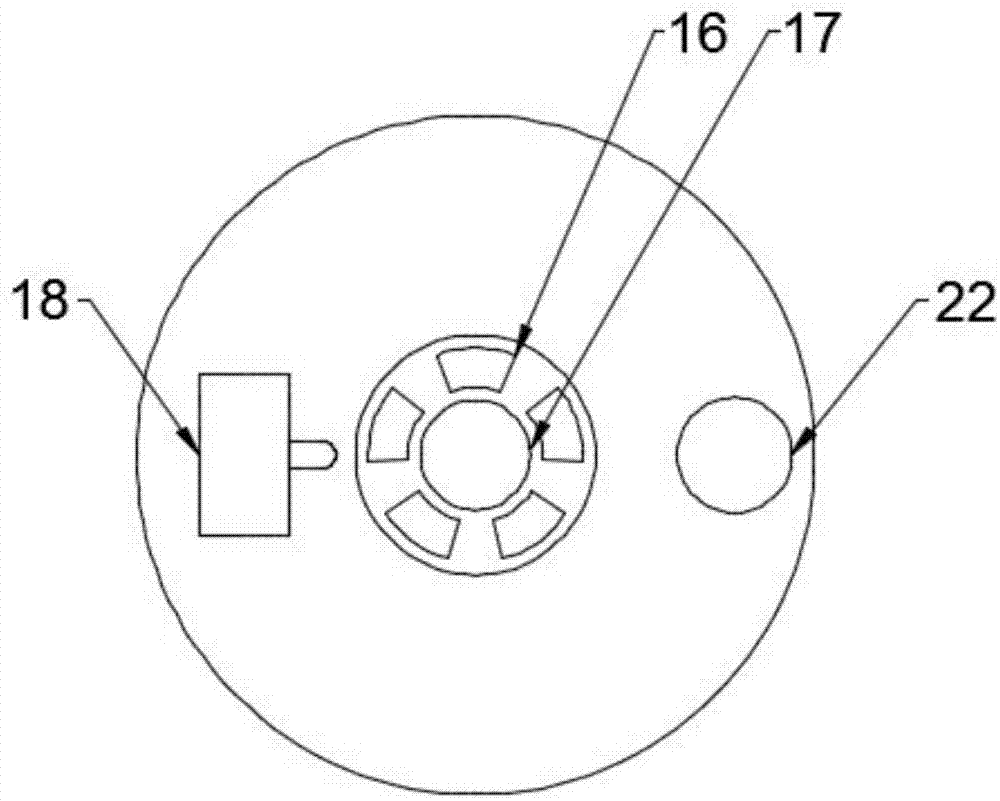

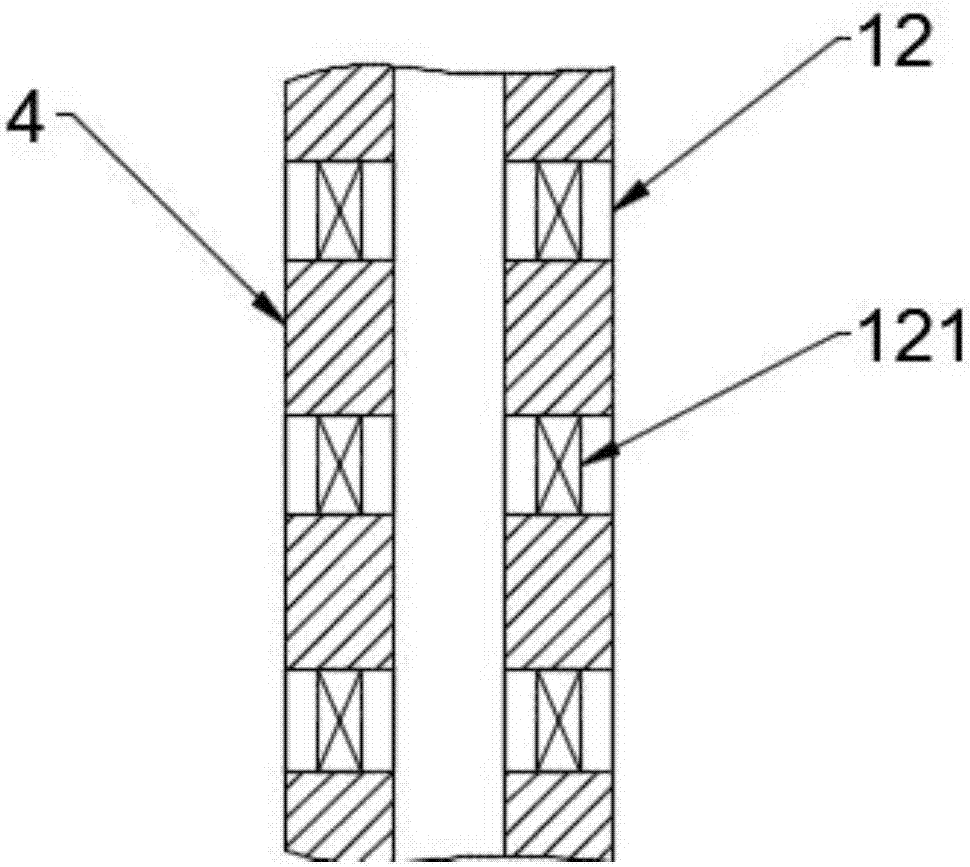

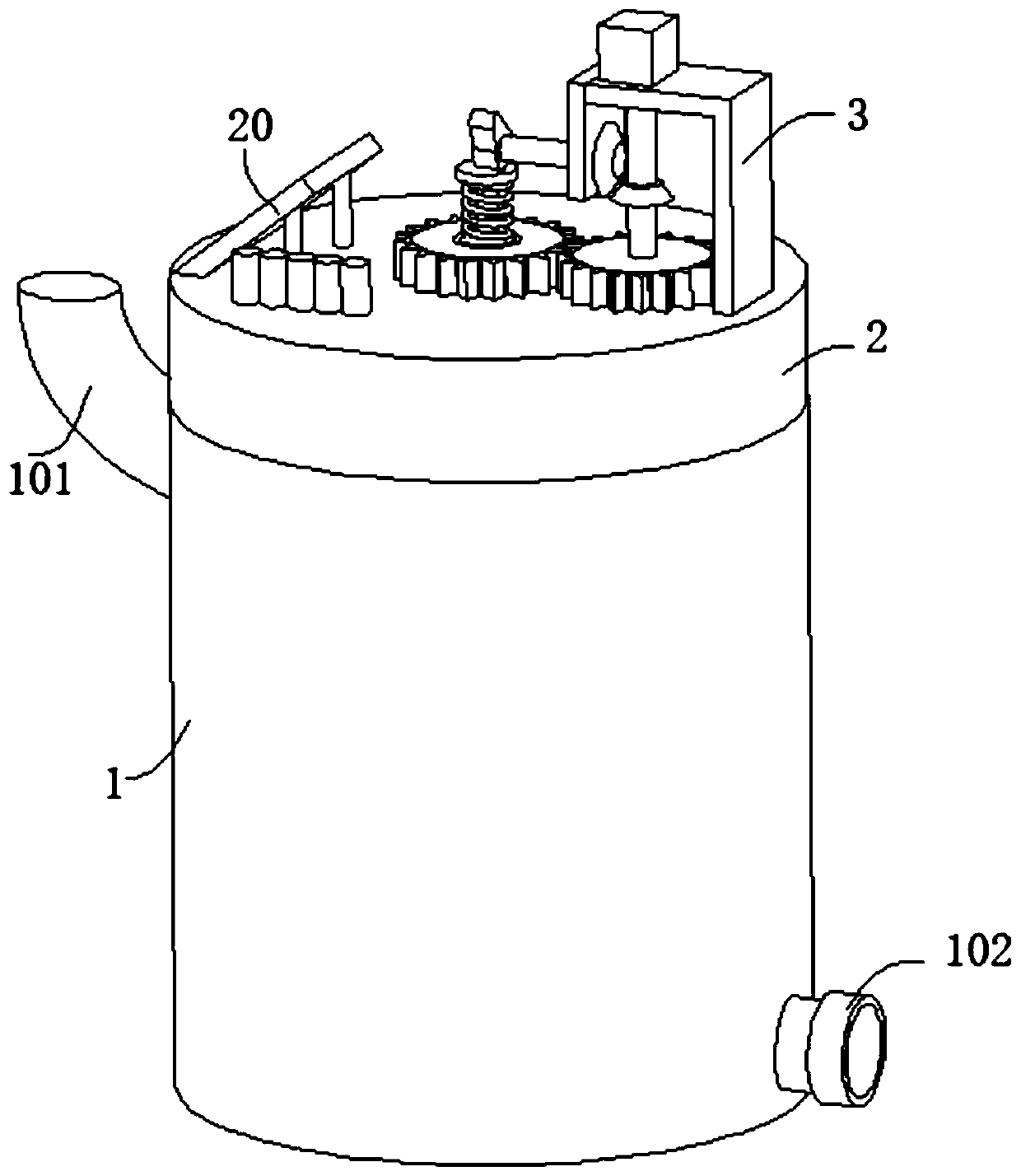

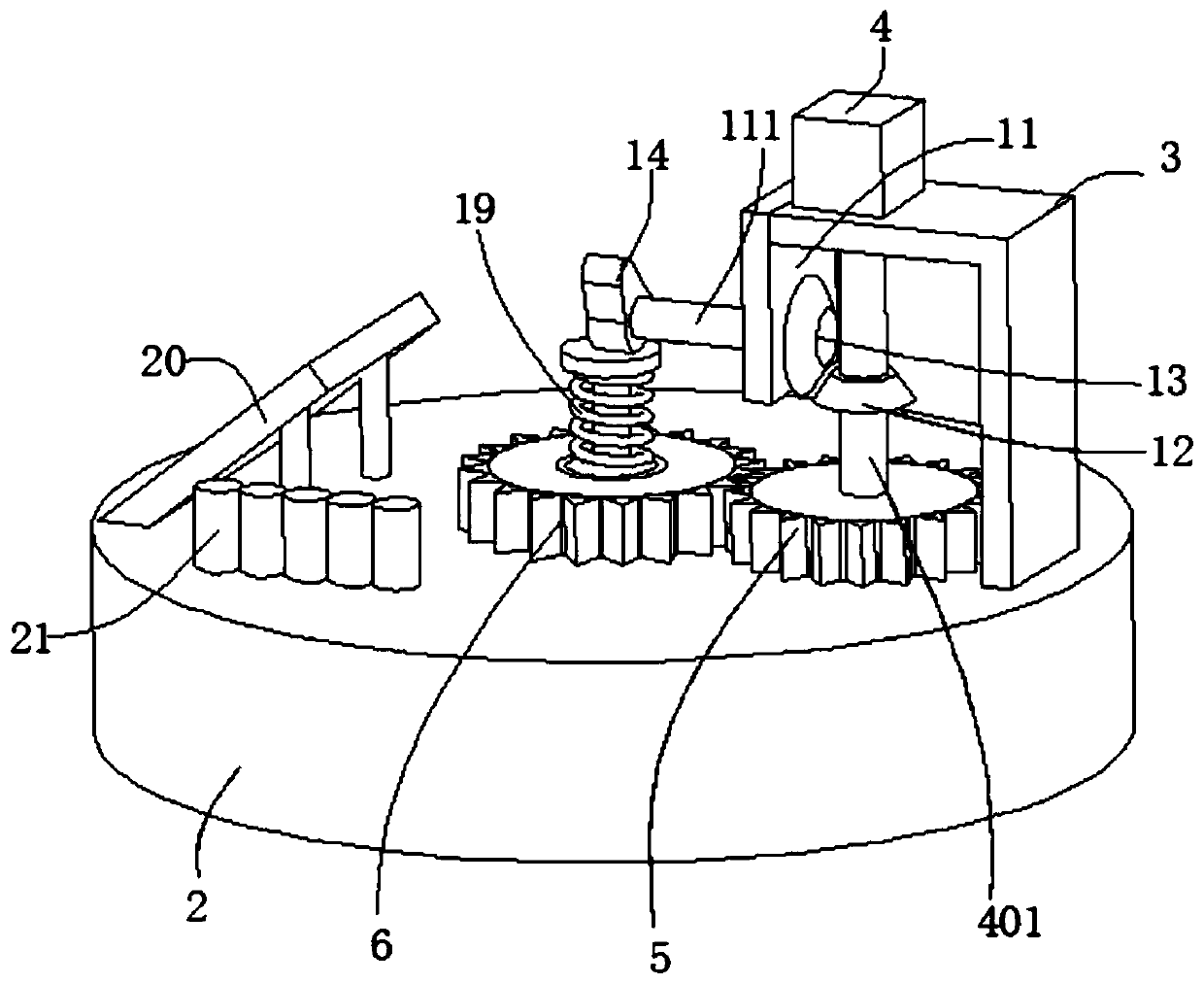

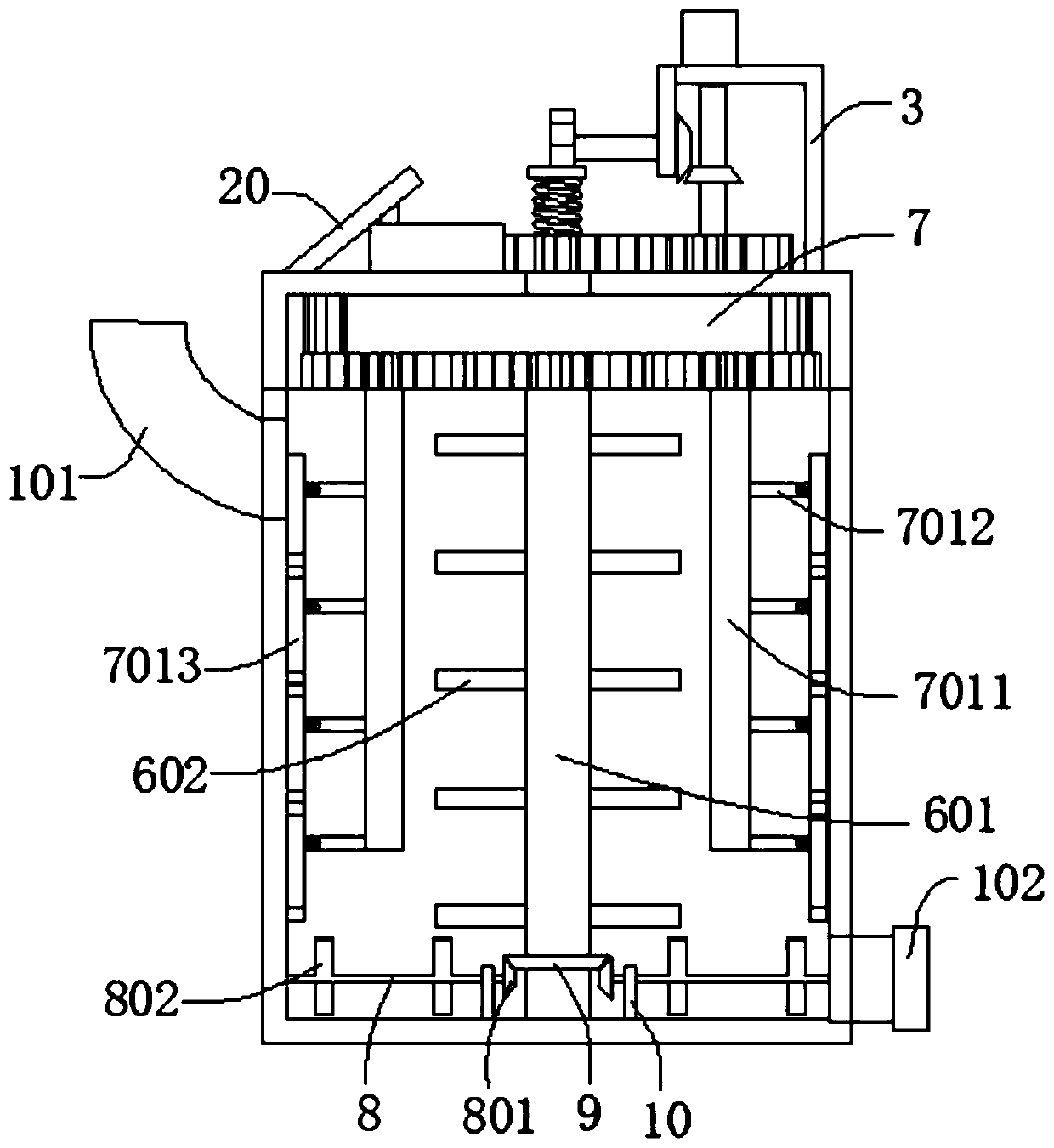

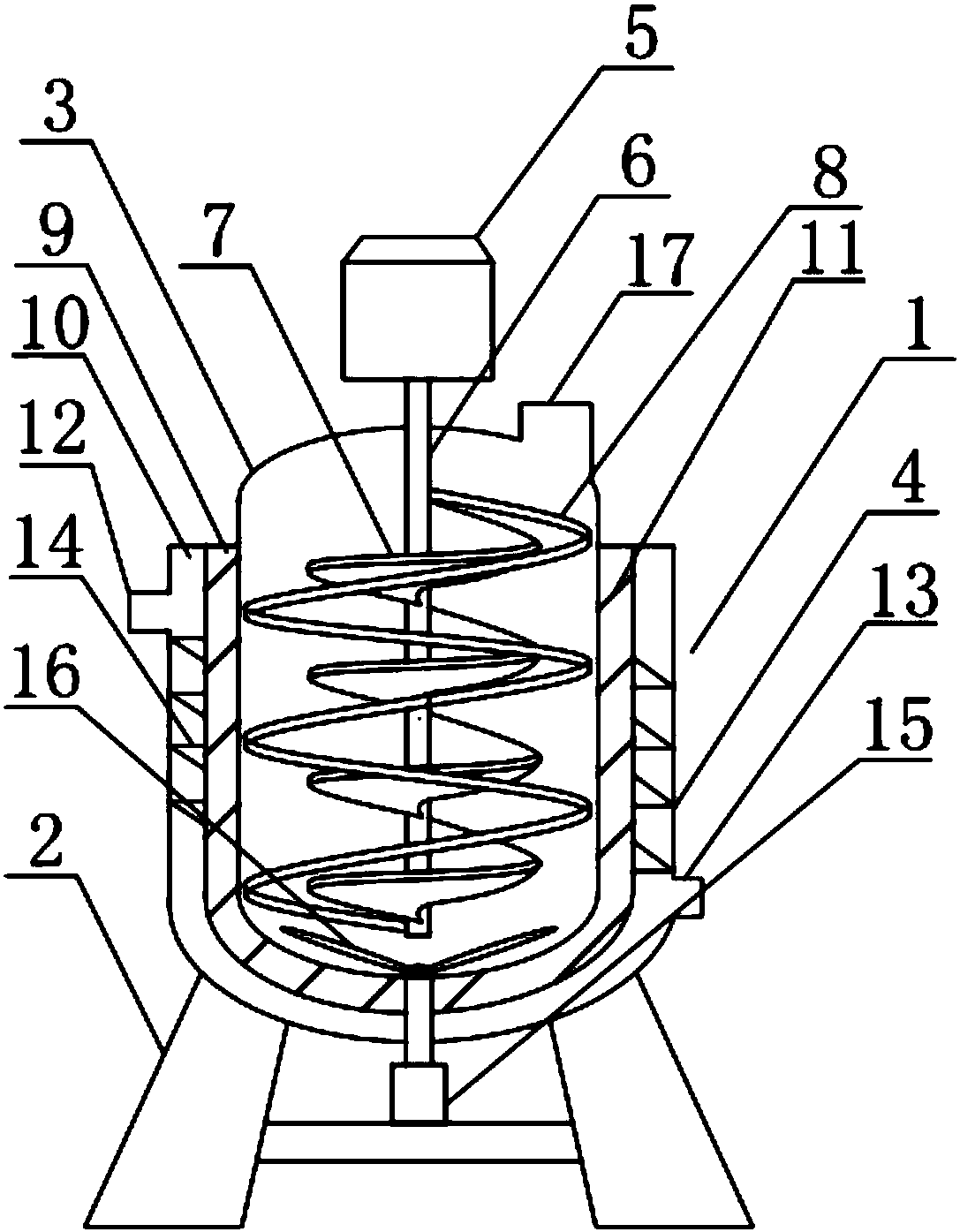

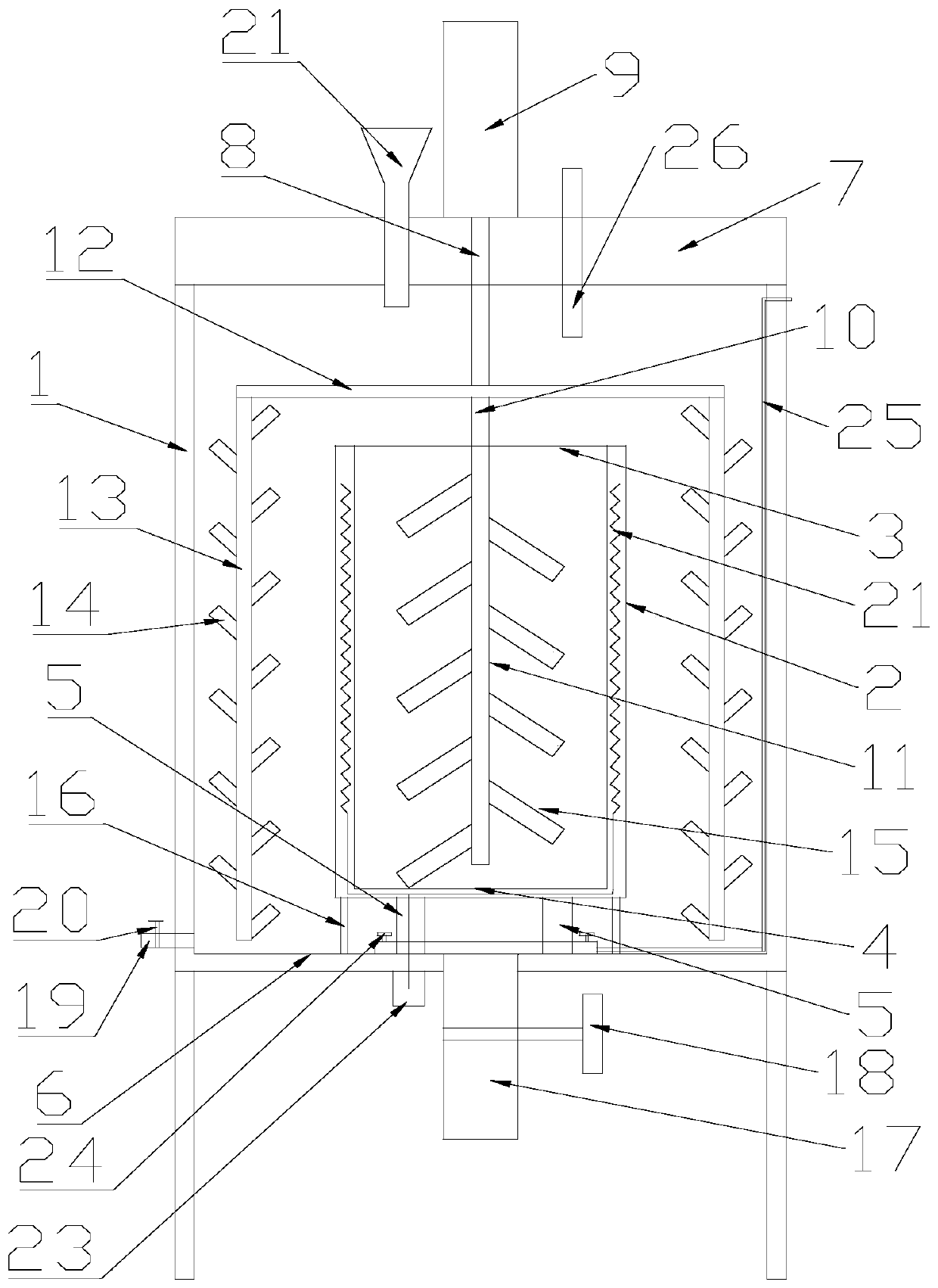

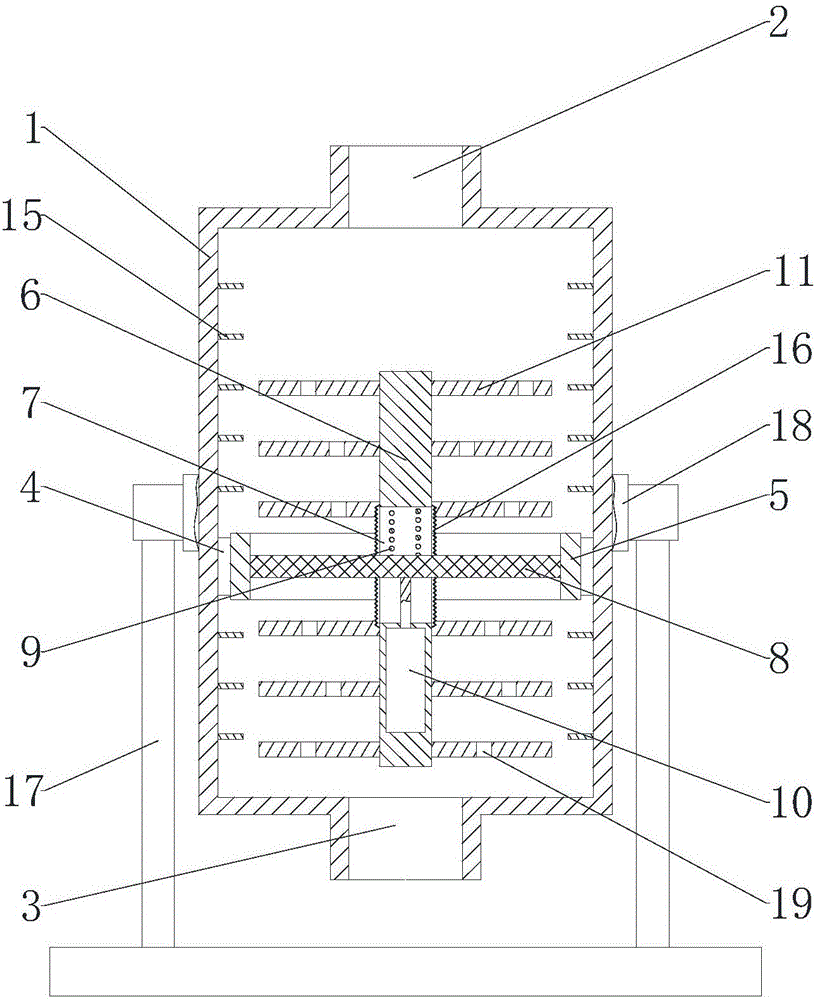

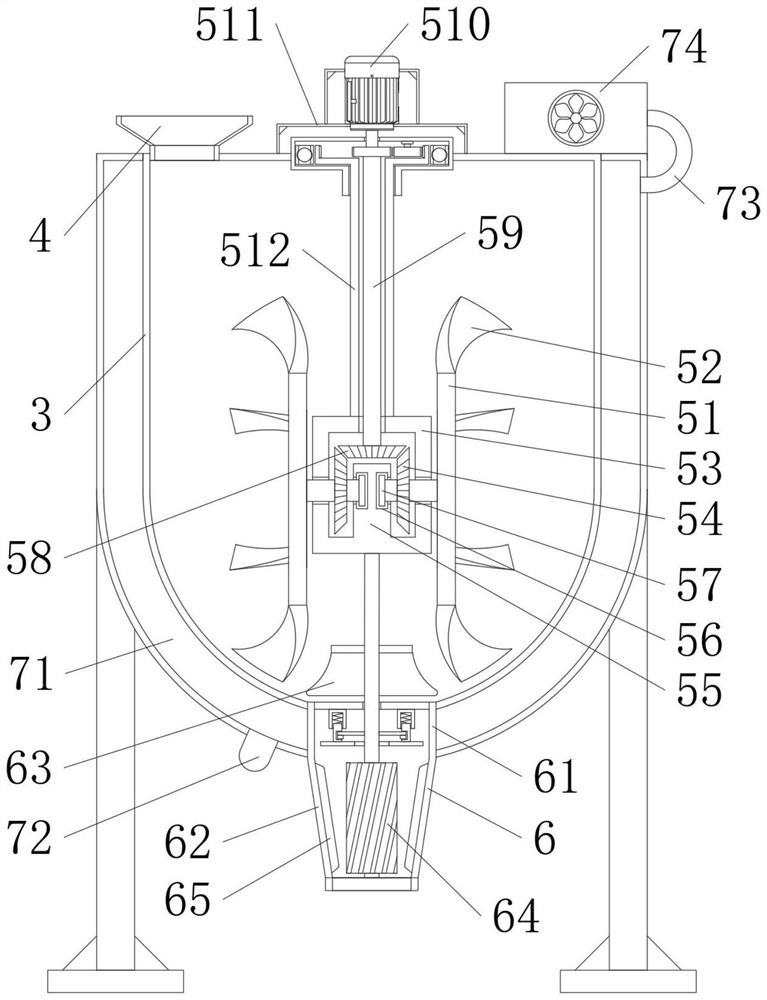

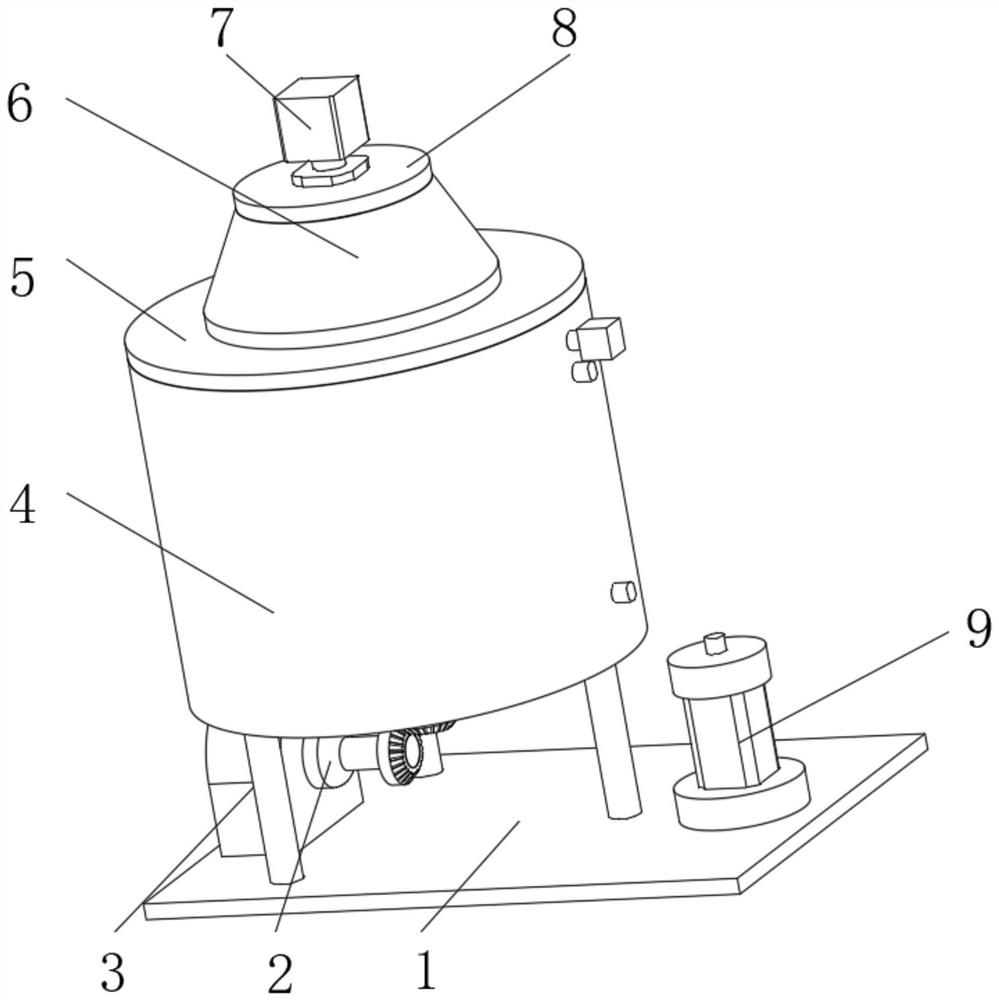

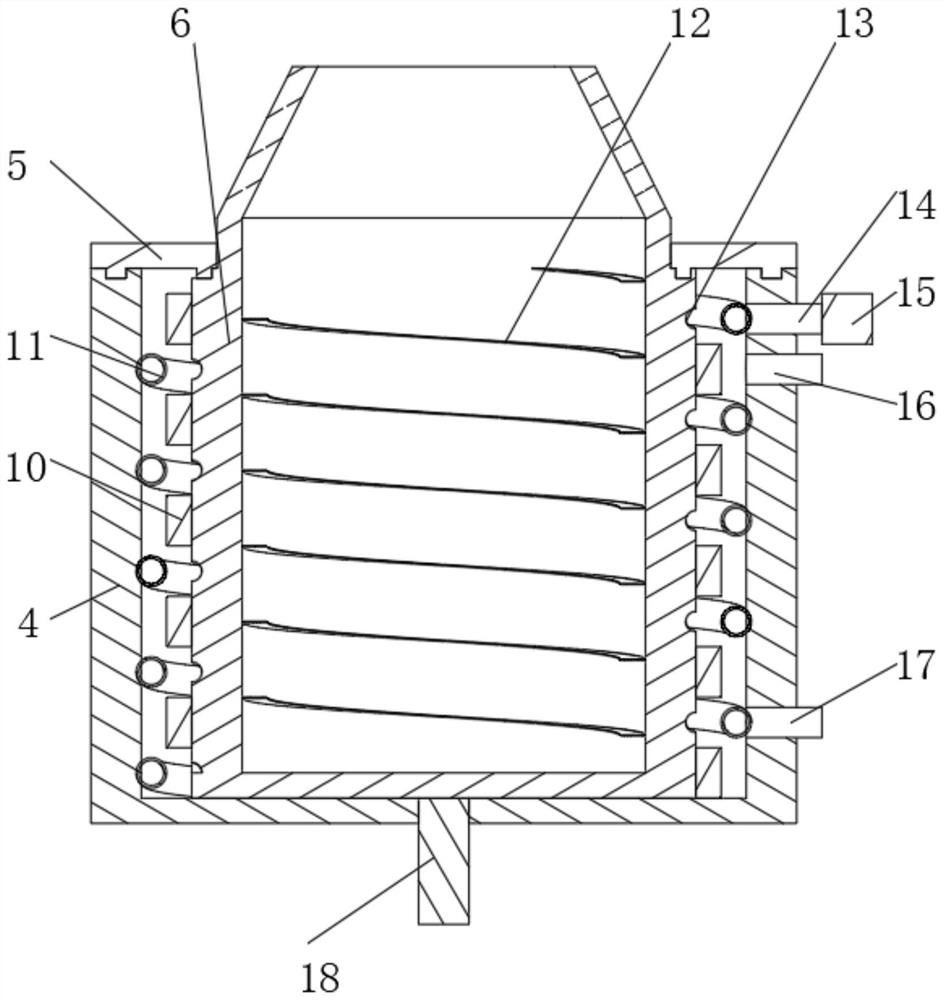

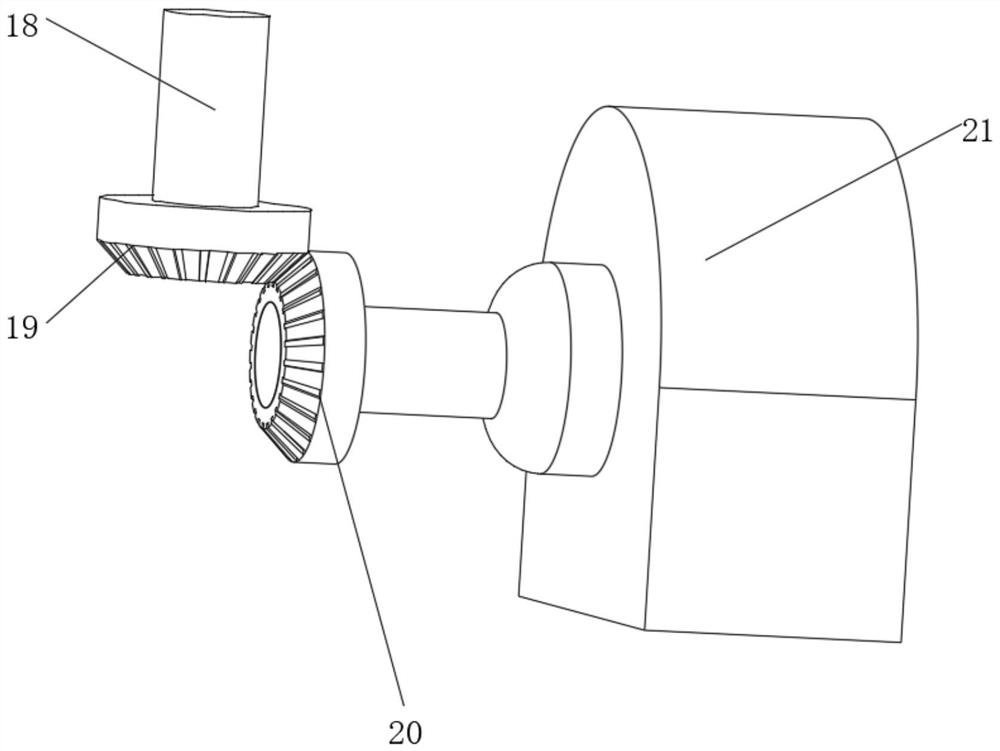

Efficient chemical reagent conditioning reaction kettle

InactiveCN107349893AGuaranteed mixing concentrationImprove mixing efficiencyRotary stirring mixersTransportation and packagingGear wheelCompound (substance)

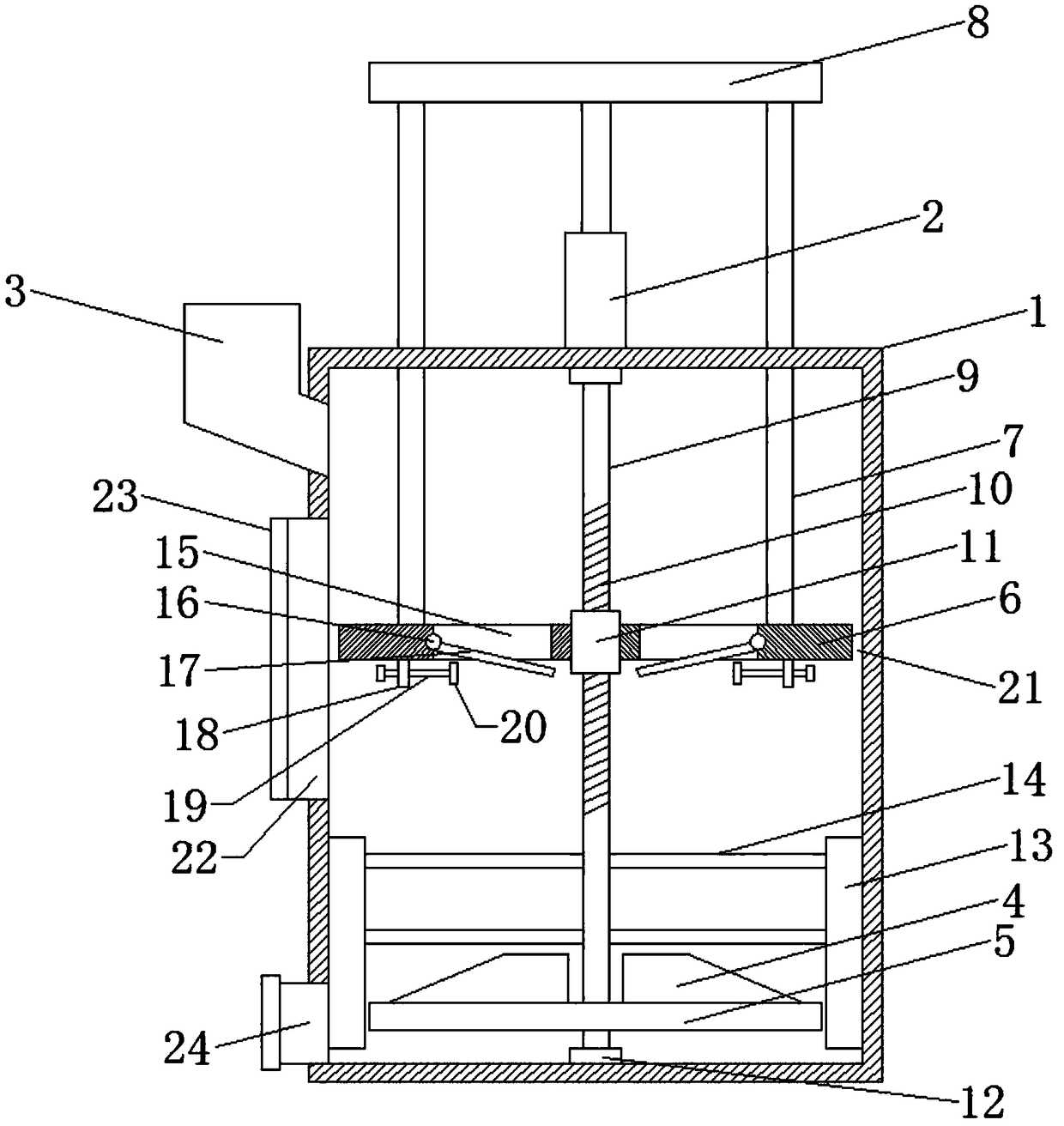

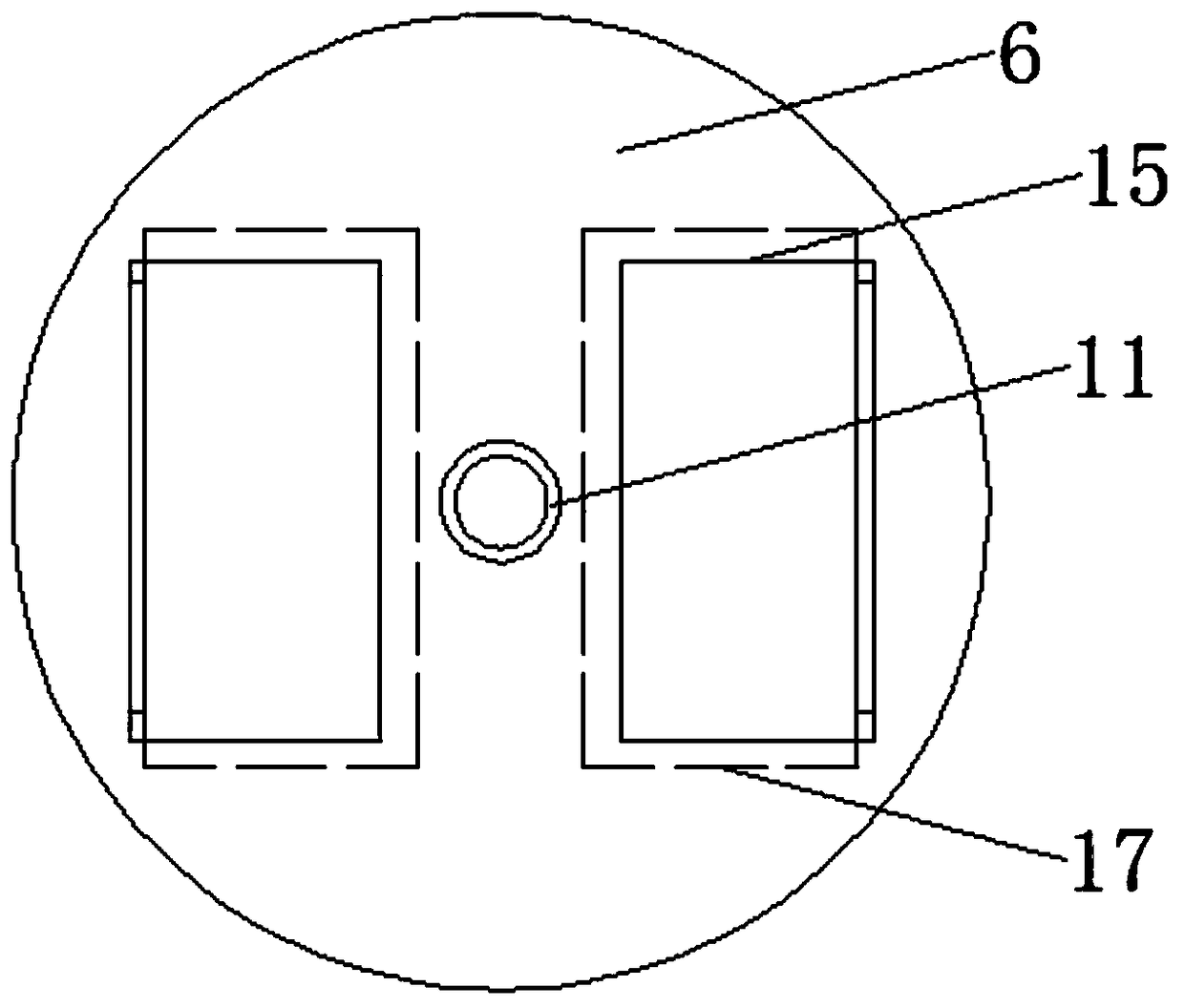

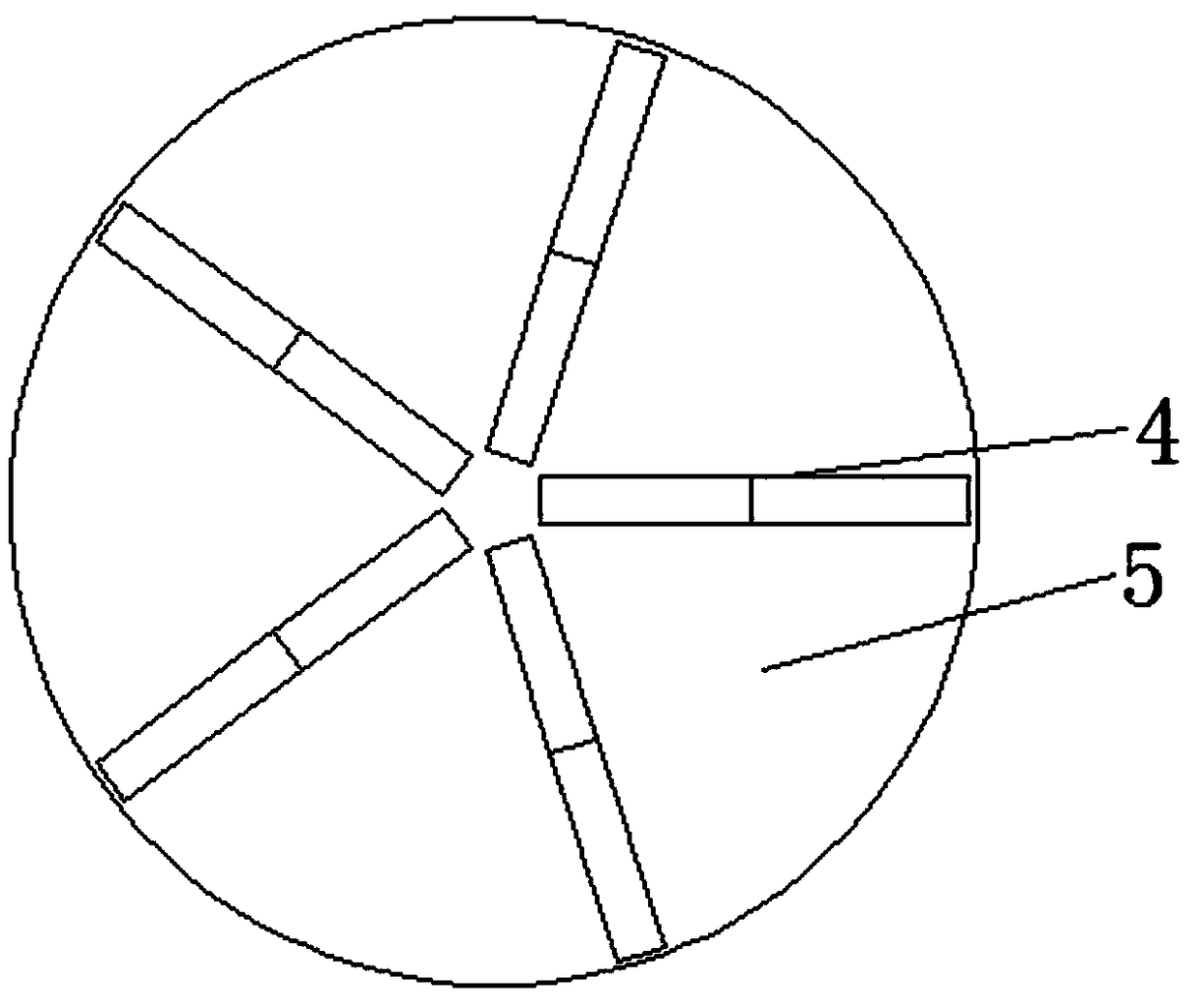

The invention discloses an efficient chemical reagent conditioning reaction kettle, which comprises a kettle body, wherein a guide rail is arranged at the upper part of an inner cavity of the kettle body; an inner gear is arranged on the inner circle surface of the guide rail; a rotating shaft is arranged in the inner cavity of the kettle body; a connecting disc is arranged in the middle part of the rotating shaft in a sleeving way; the bottom end of the rotating shaft is fixedly connected with a second stirring blade matched with the bottom wall of the kettle body; a plurality of connecting rods are uniformly arranged at the outer circle surface of the connecting disc; the other end of the connecting rod is rotationally connected with a gear matched with the inner gear; the bottom end of the gear is fixedly connected with a stirring rod; a first stirring blade is arranged on the stirring rod in a sleeving way; the bottom end of the kettle body is connected with a material discharging pipe in a penetrating way; a plurality of support legs are uniformly arranged at the bottom end of the kettle body. The second stirring blade arranged in the efficient chemical reagent conditioning reaction kettle is used for stirring the bottom of the inner cavity of the kettle body; the occurrence of the stirring dead corner is prevented; the mixing concentration of the solution is ensured; the second stirring blade does composite movement of autorotation and revolution around the rotating shaft under the driving of the gear, so that the stirring of the solution in the inner cavity of the kettle body becomes disordered; the reagent mixing efficiency is improved; the stirring quality is improved.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

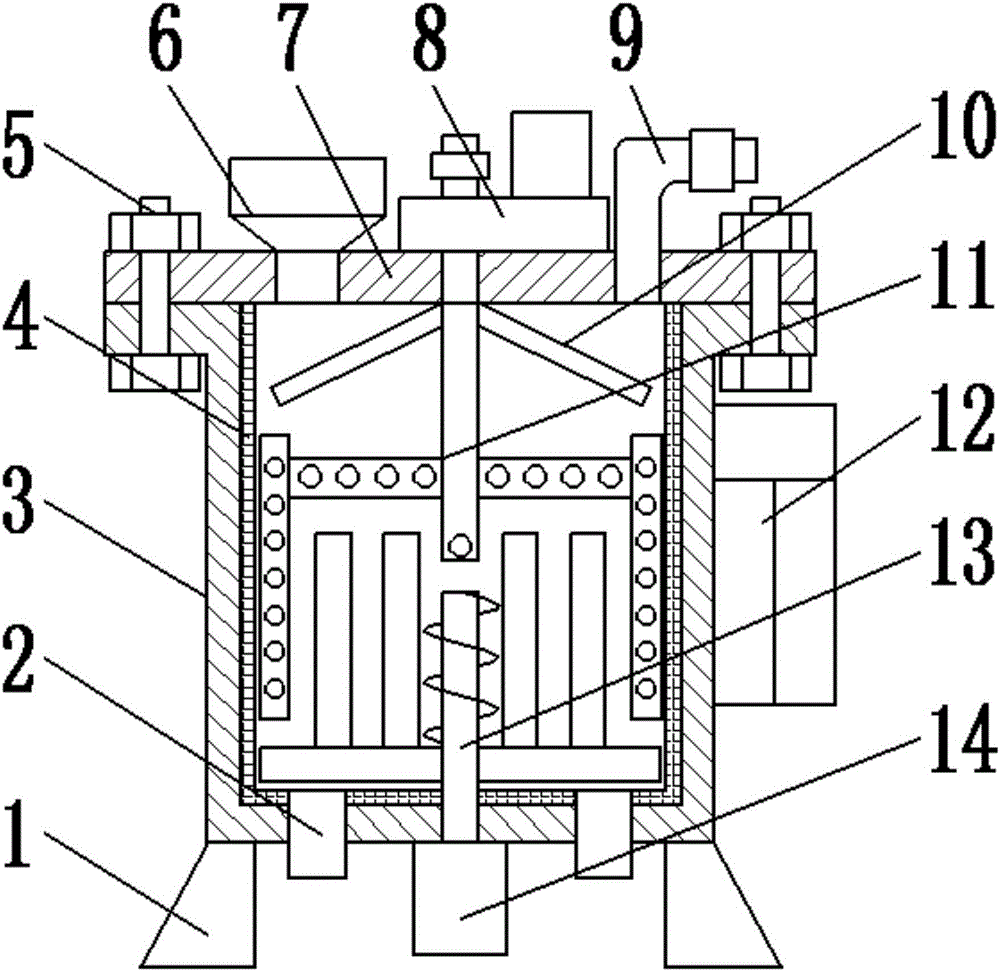

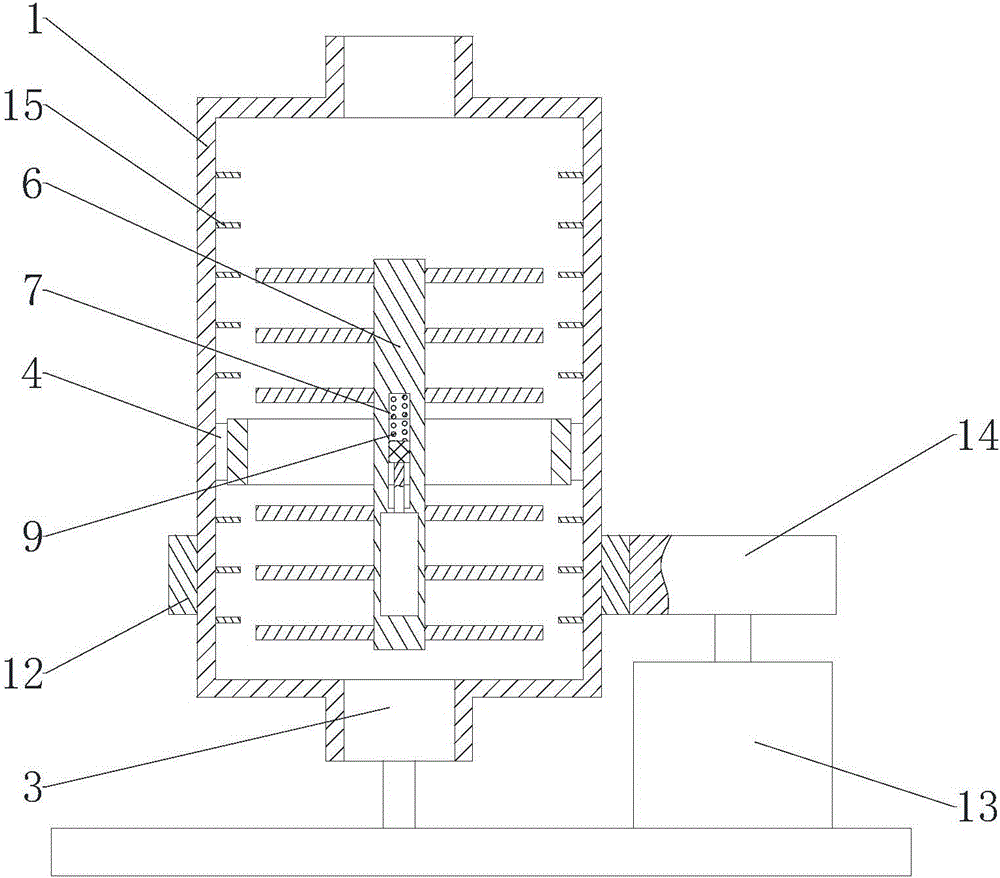

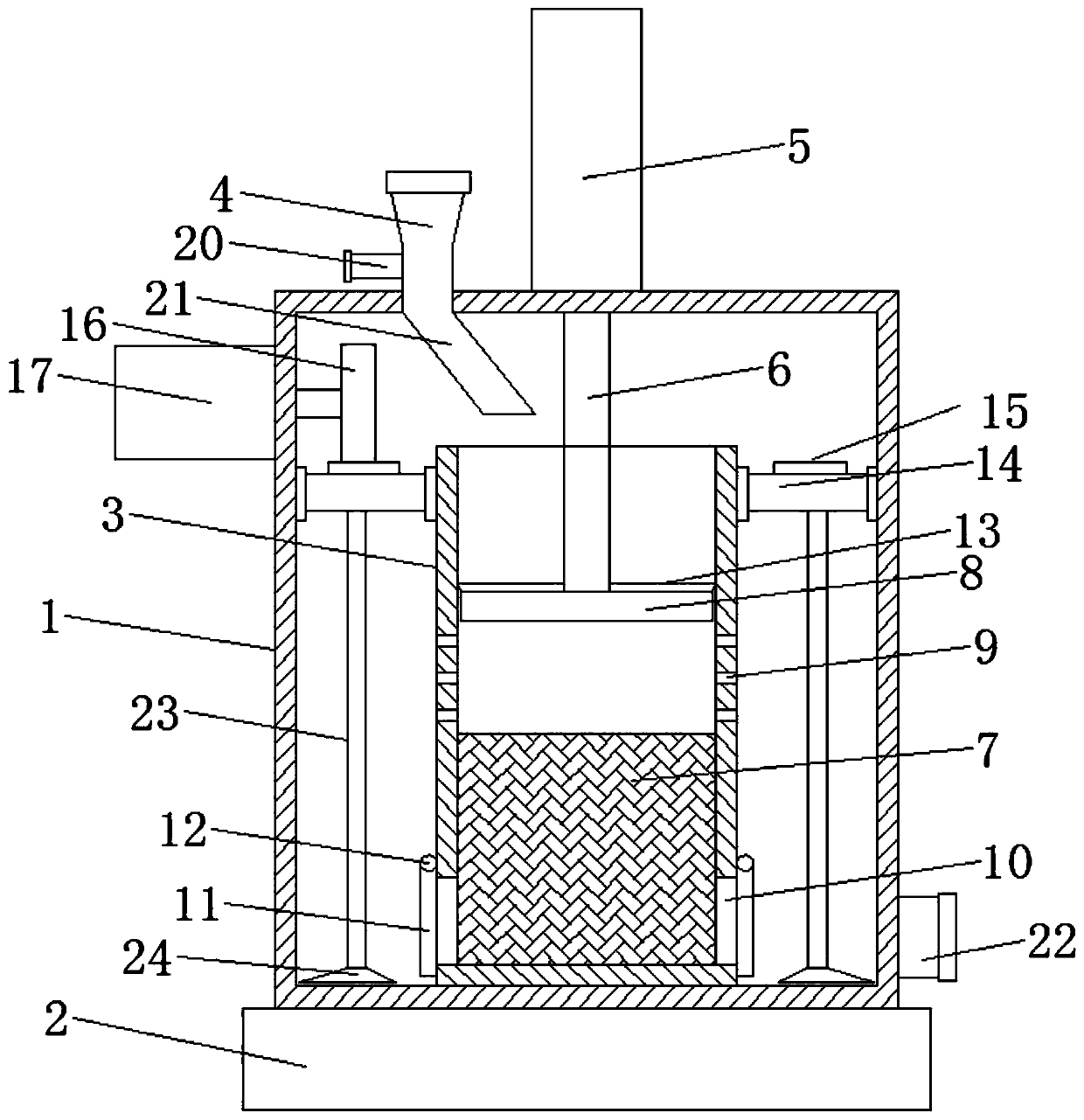

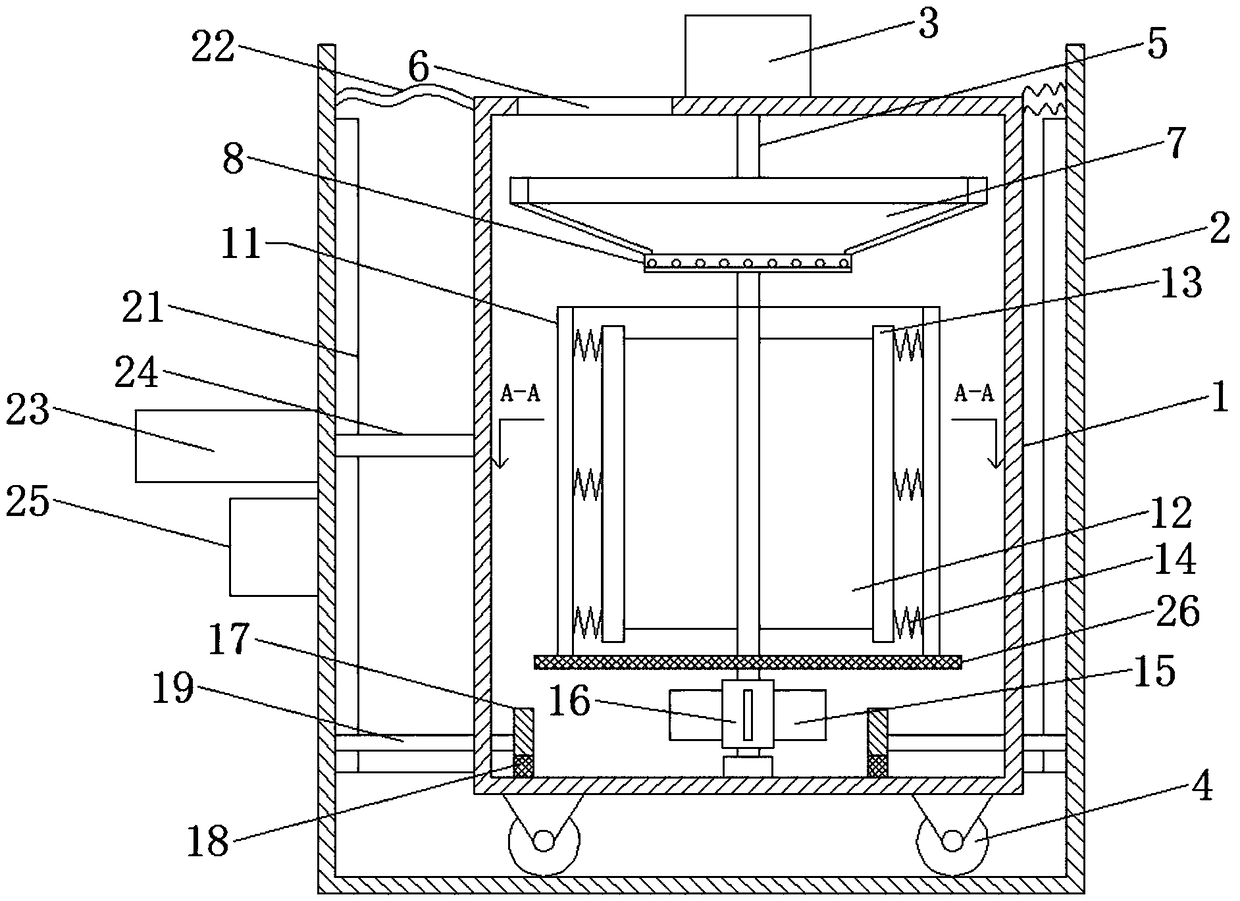

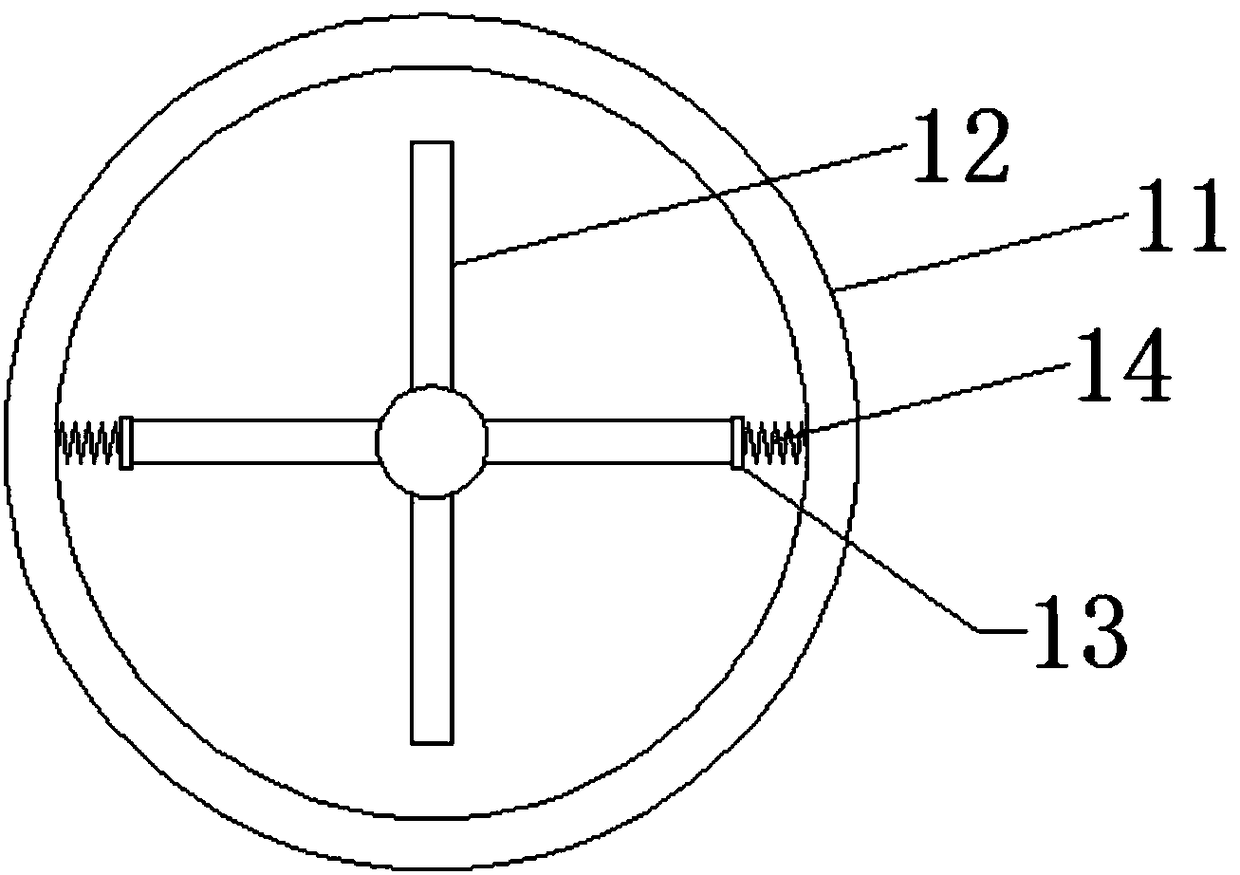

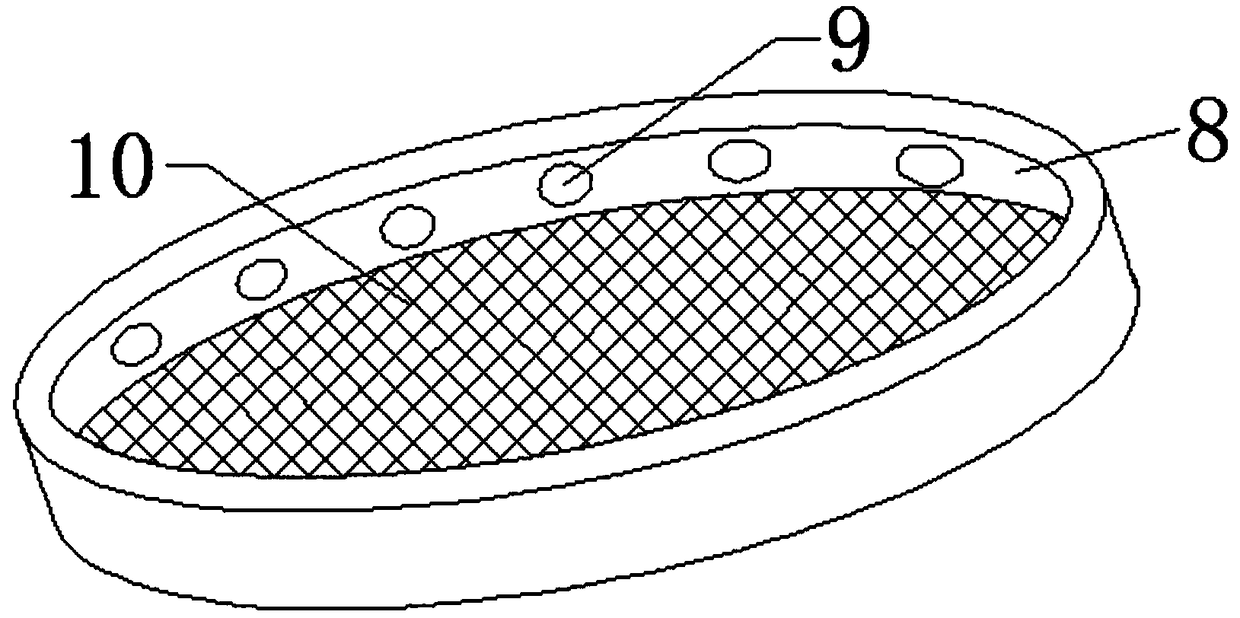

Self-cleaning efficient stirrer

InactiveCN105056808AAvoid Stirring Dead AngleEasy to moveRotary stirring mixersHollow article cleaningHydraulic cylinderPulp and paper industry

The invention discloses a self-cleaning efficient stirrer. The self-cleaning efficient stirrer comprises a stirrer body, a heat insulation material layer and hydraulic cylinders; a heating cavity is formed in the lower side of the stirrer body and internally provided with a heating furnace, the outer wall of the stirrer body is covered with the heat insulation material layer, a control panel is arranged on the outer wall at the left side of the stirrer body, a stirring rotating shaft is vertically arranged in the stirrer body, and stirring paddles are symmetrically arranged on outer walls at the two sides of the bottom end of the stirring rotating shaft. The self-cleaning efficient stirrer is good in lifting stirring effect and high in efficiency, in the stirring process, materials at the bottom in the stirrer are circularly pumped into the top to be mixed, the stirring effect and efficiency are greatly improved, and no dead angle exists in the stirring process; the materials are heated in the stirring process, the heat efficiency is high, the heat insulation effect is good, after stirring is finished, a nozzle is driven by a motor to rotate to clean the inside of the stirrer, the cleaning effect is good, and manual operation difficulty and intensity are reduced; in addition, the stirrer is convenient and fast to move and high in convenience.

Owner:岑立强

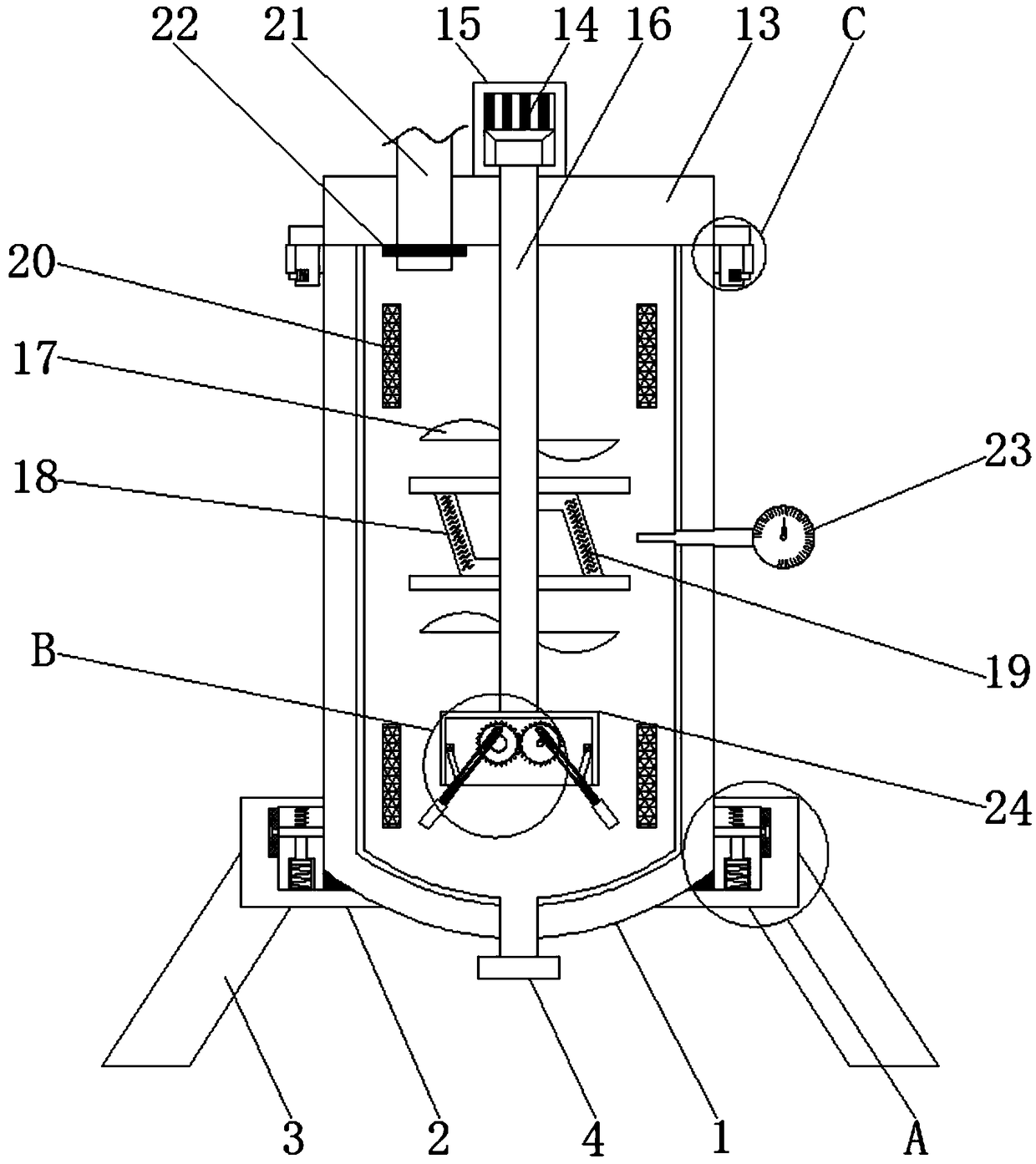

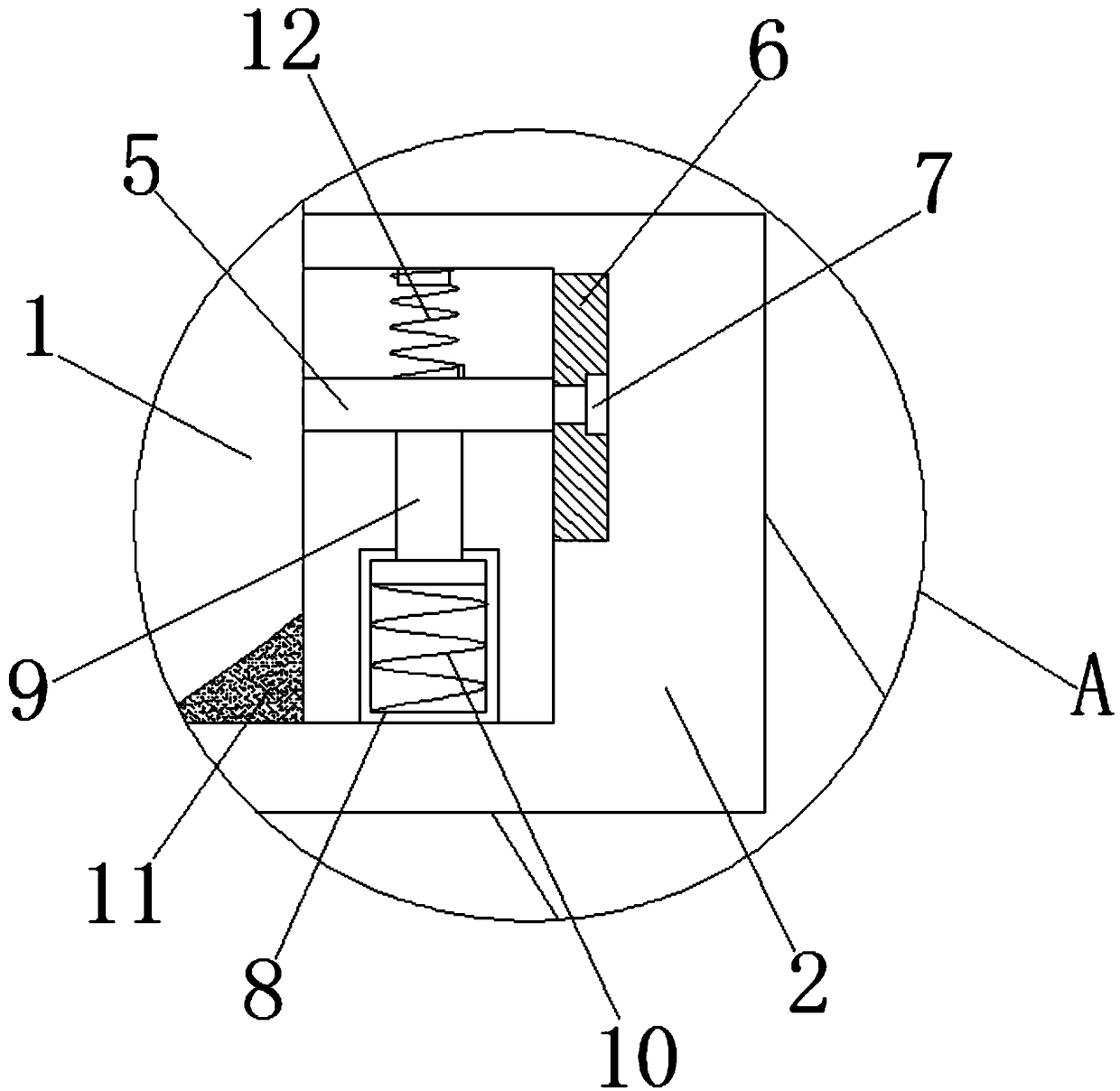

New energy stirring device and using method

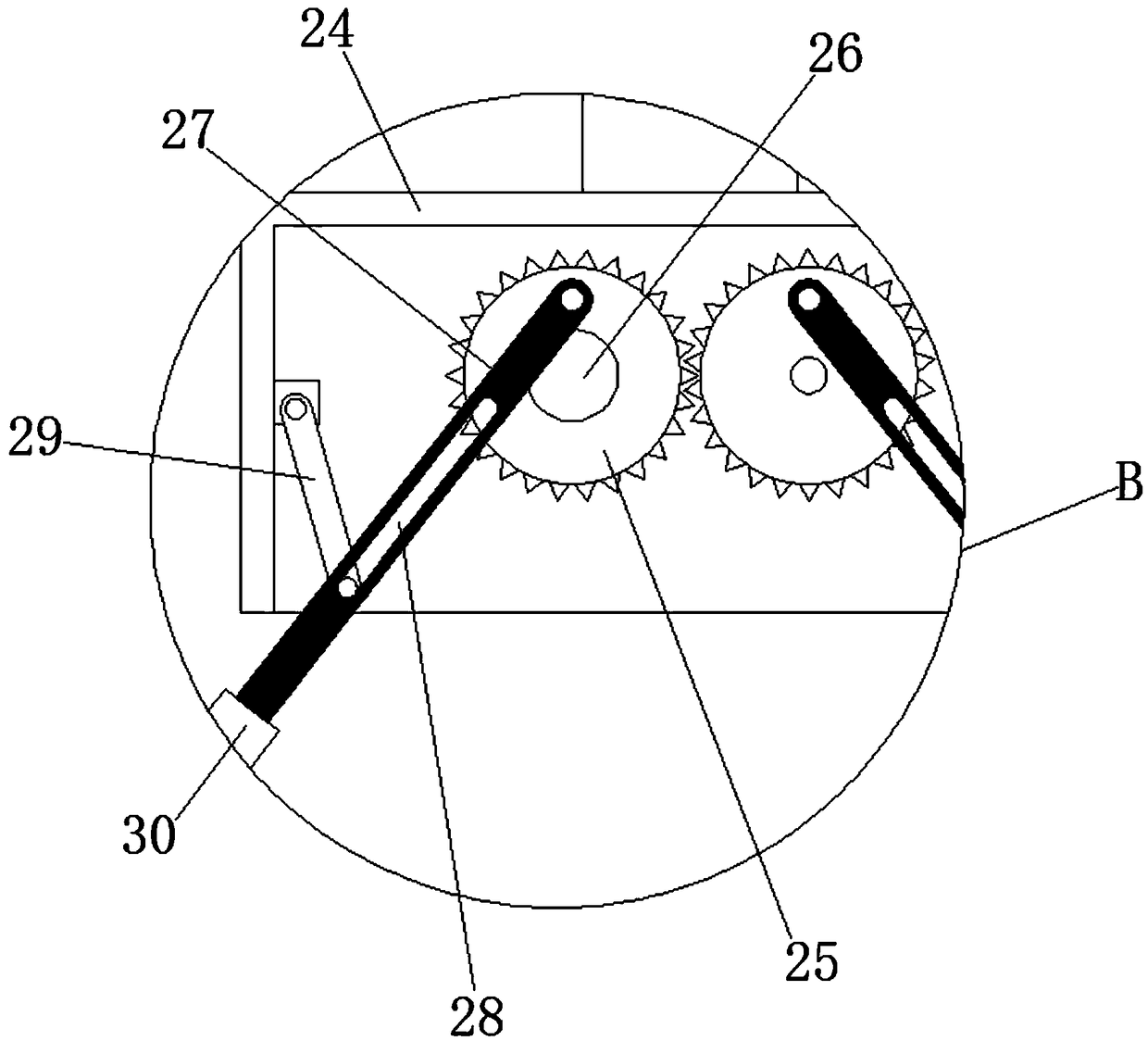

InactiveCN111450738AImprove stirring efficiencyImprove the mixing effectRotary stirring mixersTransportation and packagingElectric machineDrive shaft

The invention discloses a new energy stirring device and a using method, and belongs to the technical field of new energy. The new energy stirring device comprises a box body and a box cover, the boxcover is connected to the top of the box body; the outer wall of the box cover is connected with a support seat; the top of the support seat is connected with a motor; the output end of the motor is connected with a rotation shaft; the end, away from the motor, of the rotation shaft penetrates the support seat and is connected with a first gear, the outer wall of the first gear is in engaged witha second gear, the inner wall of the second gear is connected with a driving shaft, and the outer wall of the driving shaft is connected with a third gear, which is rotationally connected to the bottom wall of the box cover. The bottom wall of the box cover is also rotationally connected to a rotating disc. The inner wall of the box cover is connected to an annular rack. The interior of the box body is stirred through three stirring rods, the stirring efficiency and the stirring effect are improved, stirring dead corners are avoided, in the stirring process, materials adhered to the inner wallof the box body are scraped, the box body is convenient to clean, and the uniformity in the stirring process is further improved.

Owner:绍兴市亚索新能源科技有限公司

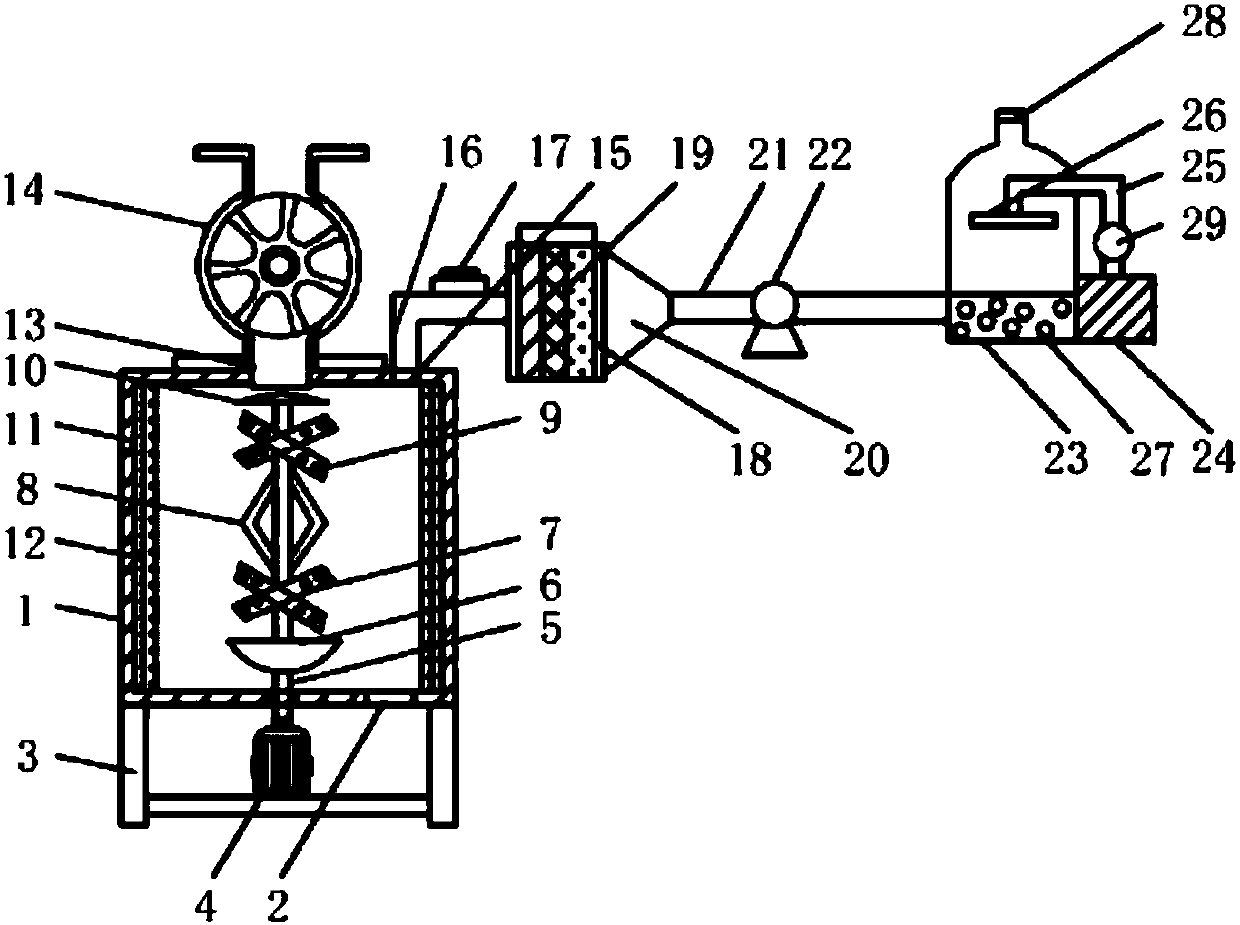

Chemical reactor with waste gas treatment device and using method of chemical reactor

InactiveCN108043347AEvenly heatedEqual accessProcess control/regulationCombination devicesChemical reactorFiltration

The invention discloses a chemical reactor with a waste gas treatment device in the technical field of chemical equipment. The chemical reactor comprises a reactor body; the bottom of the reactor bodyis provided with a supporting seat; the bottom of the supporting seat is provided with a motor; an output shaft of the motor is provided with a stirring shaft; the outer wall of the stirring shaft issequentially provided with a semispherical stirring head, a first stirring blade, a rhombic stirring blade and a second stirring blade from bottom to top; the center of the top of the reactor body isprovided with a feeding funnel; the top of the feeding funnel is provided with a quantifying device; an exhaust vent is formed in the right side of the top of the reactor body and is connected with afilter box by an exhaust pipe; the right side of the filter box is provided with a collecting hood; the collecting hood is connected with a purification box by a guide pipe; due to the arrangement ofthe quantifying device at the top of the reactor body, the equivalent feeding of a material can be realized, the material in the reactor body can be more sufficiently stirred, and no materials are wasted. The waste gas treatment device is low in cost and high in purification efficiency; and waste gases exhausted into the air after being subjected to multilayer filtration are pollution-free and odorless.

Owner:别名洋

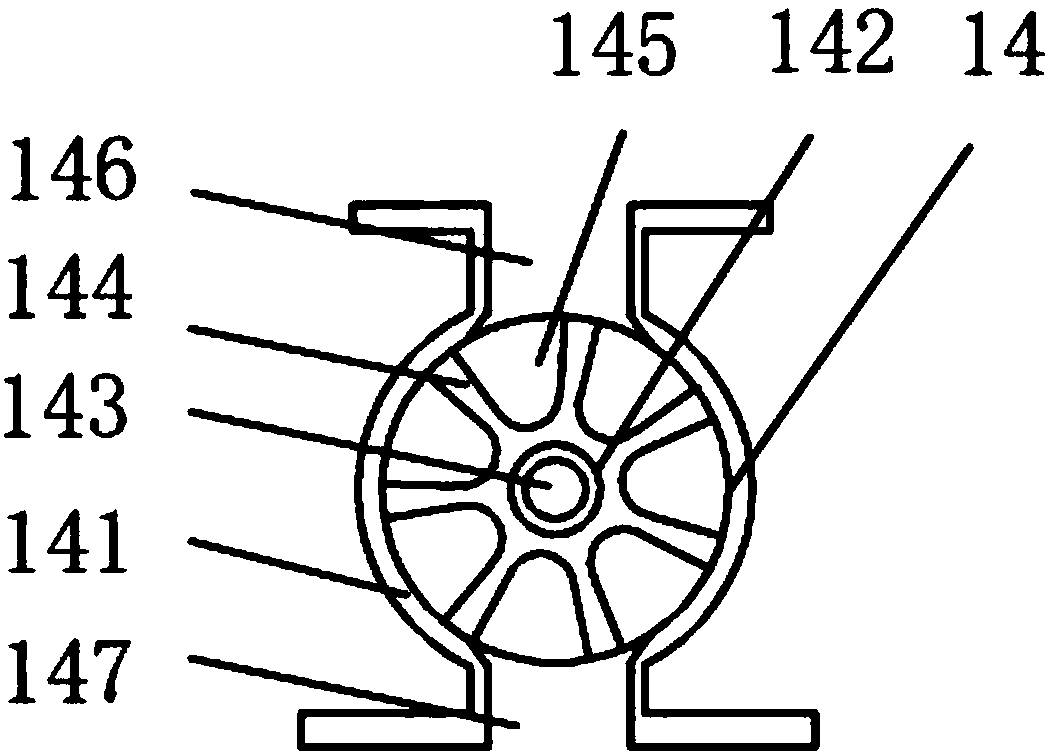

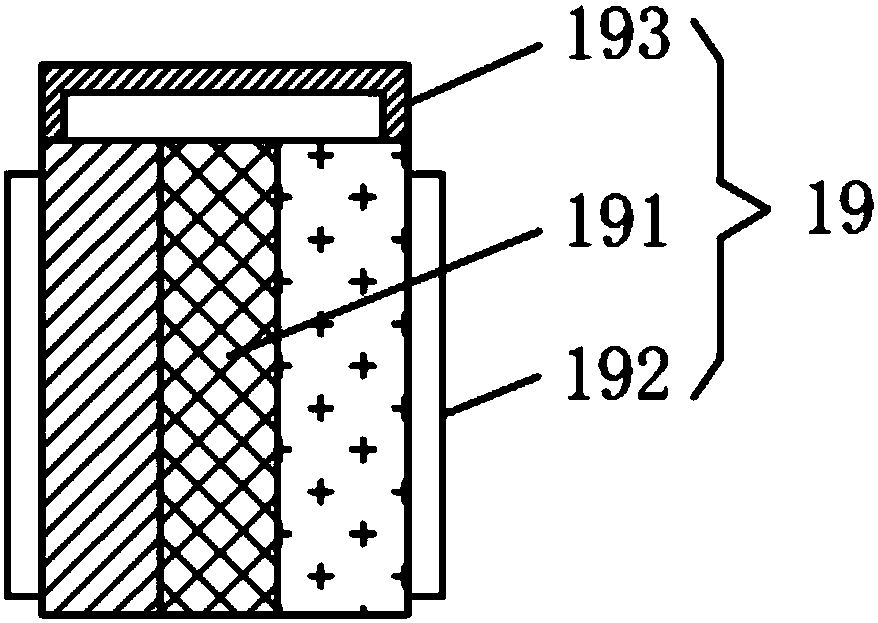

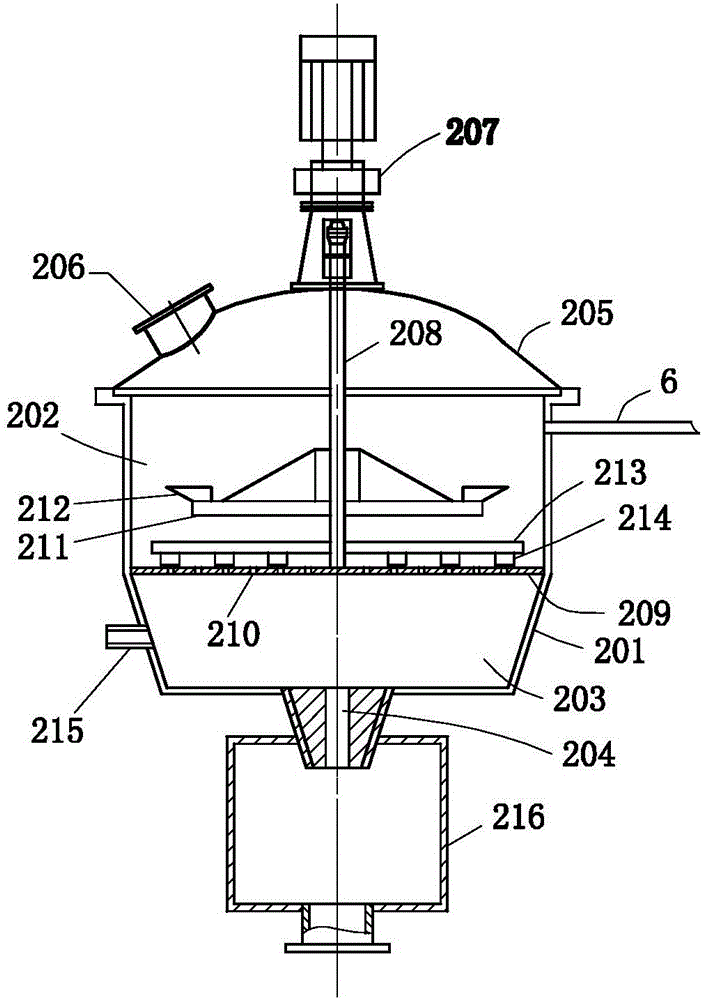

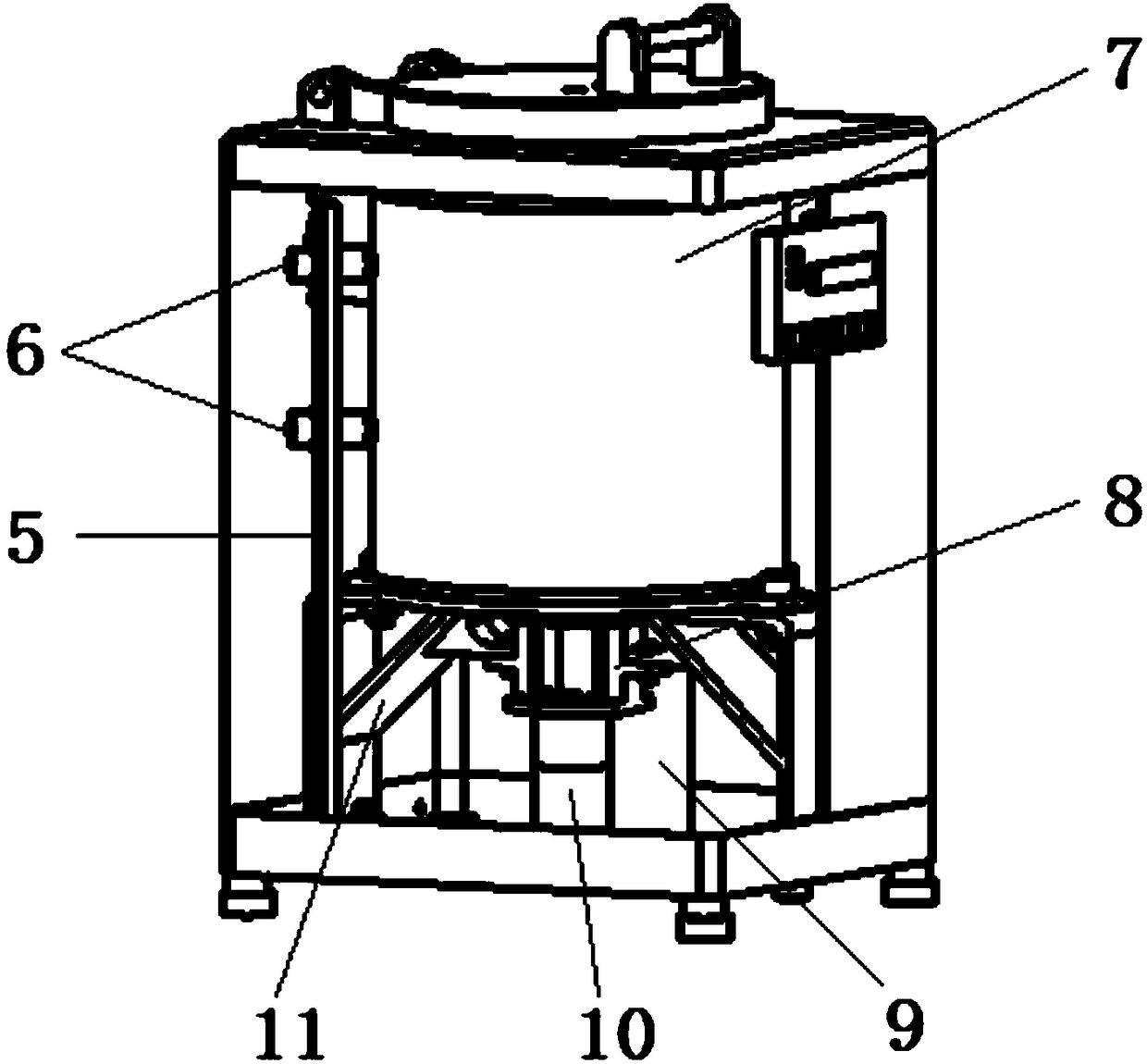

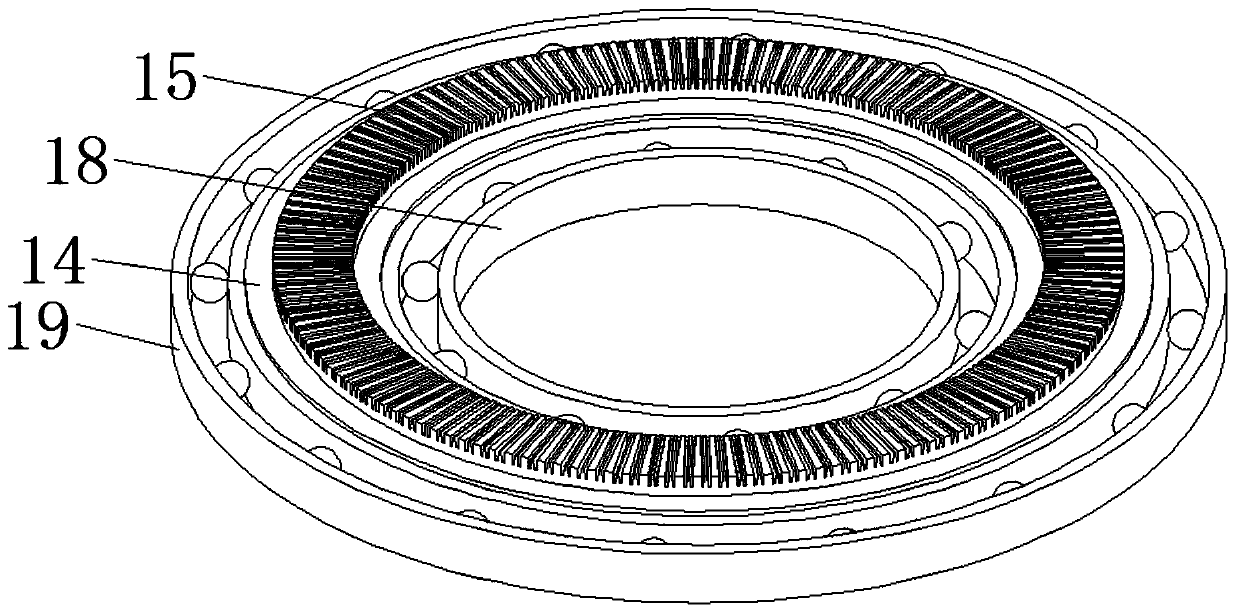

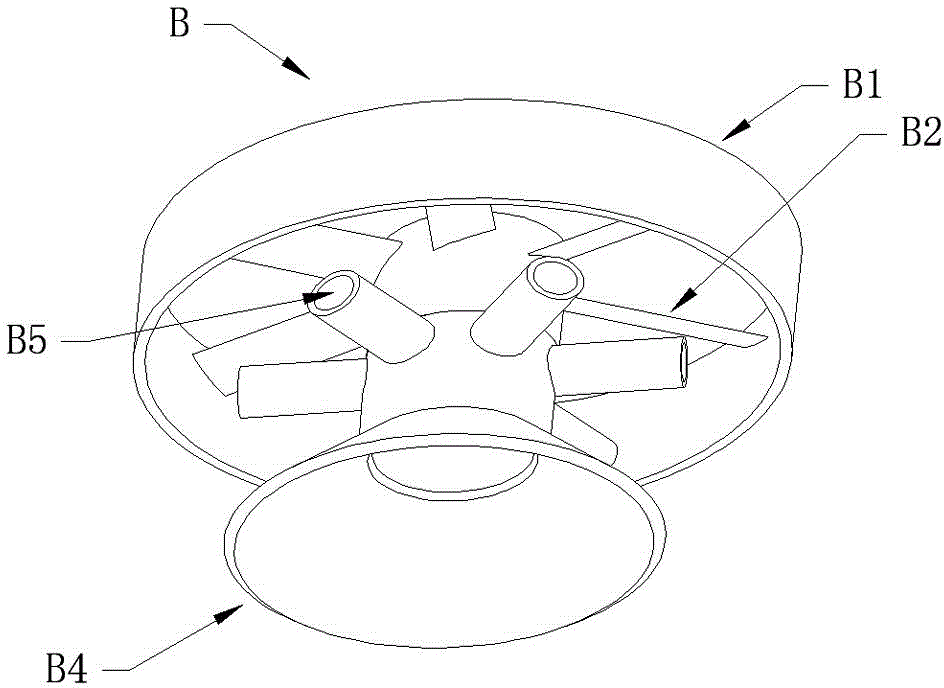

Lubricating grease blending kettle

PendingCN107774224AImprove liquidityAvoid blind spotsRotating receptacle mixersTransportation and packagingSpiral bladeFan blade

The invention provides a lubricating grease blending kettle. The lubricating grease blending kettle comprises a tank body of the blending kettle, wherein the tank body of the blending kettle is arranged on a support base and comprises a kettle body and a jacket; a stirring mechanism and a stirring motor are arranged at the top part of the kettle body; the stirring mechanism comprises a stirring shaft and spiral blades, and a circle of spiral scraping strips is arranged at the exterior of each spiral blade; the jacket comprises an inner jacket and an outer jacket, a heating wire is arranged inthe inner jacket, the outer jacket is provided with a cooling water inlet and a cooling water outlet, a flow guide plate is arranged in an inner cavity of the outer jacket, and a rotary motor is arranged at the bottom part of the jacket. The lubricating grease blending kettle has the beneficial effects that by arranging the spiral scraping strips at the outer side of each spiral blade on the stirring shaft, the lubricating grease which is attached to the inner wall of the kettle body can be driven, so that the integral fluidity is improved, and the dead corner at the inner wall of the kettle body is prevented; the rotary motor is used for driving the kettle body to rotate, the lubricating grease at the bottom part are stirred by fan blades, the dead corner at the bottom part of the kettlebody is prevented, and the stirring and blending effect is better.

Owner:天津市津冠润滑脂有限公司

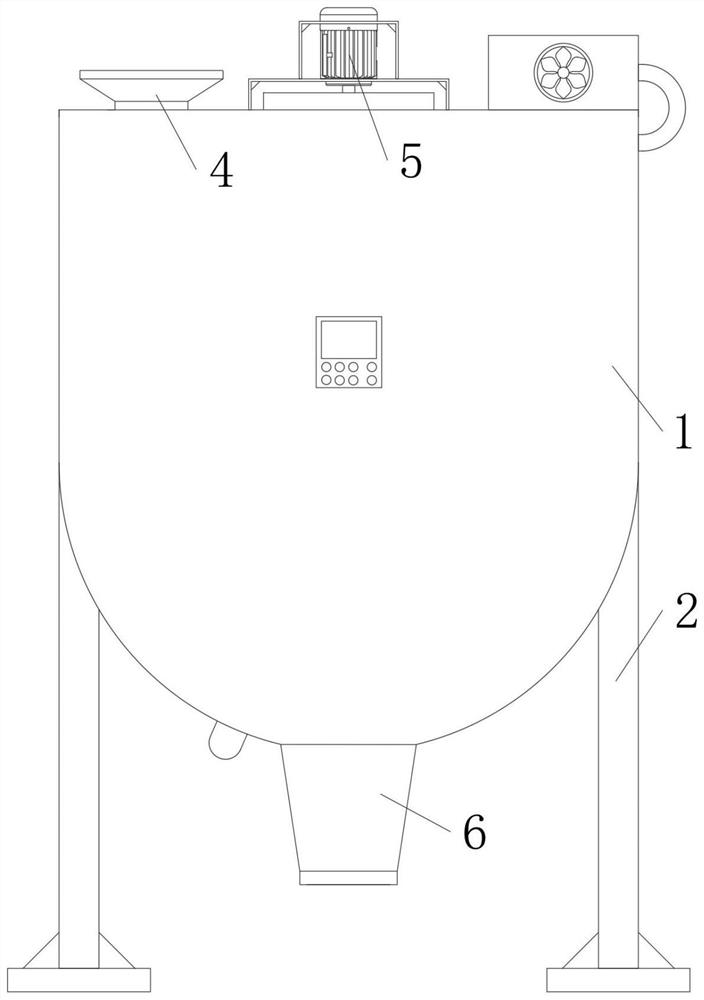

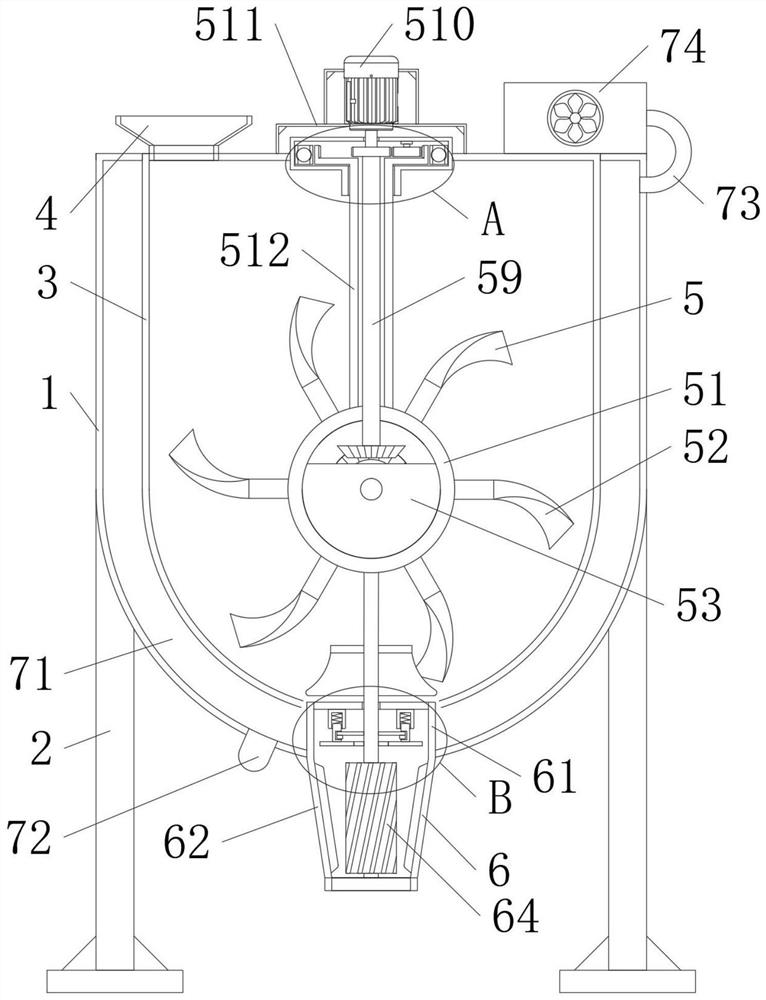

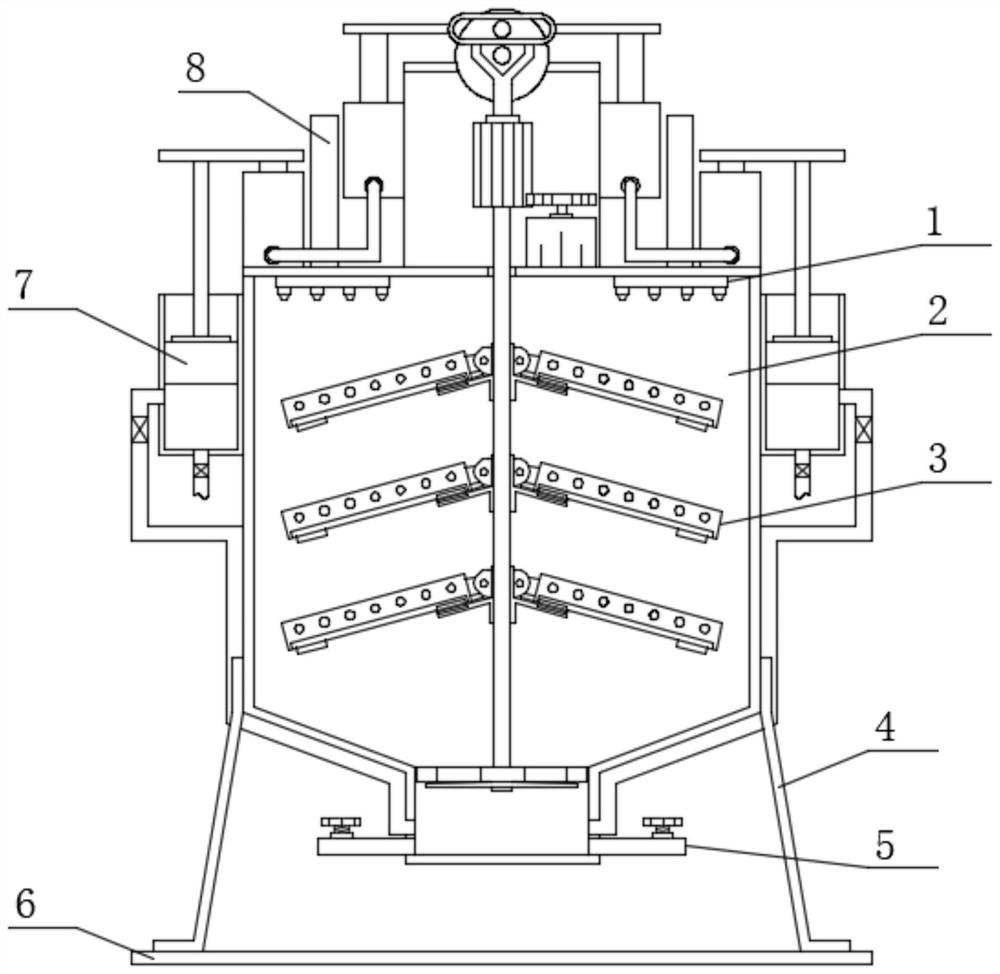

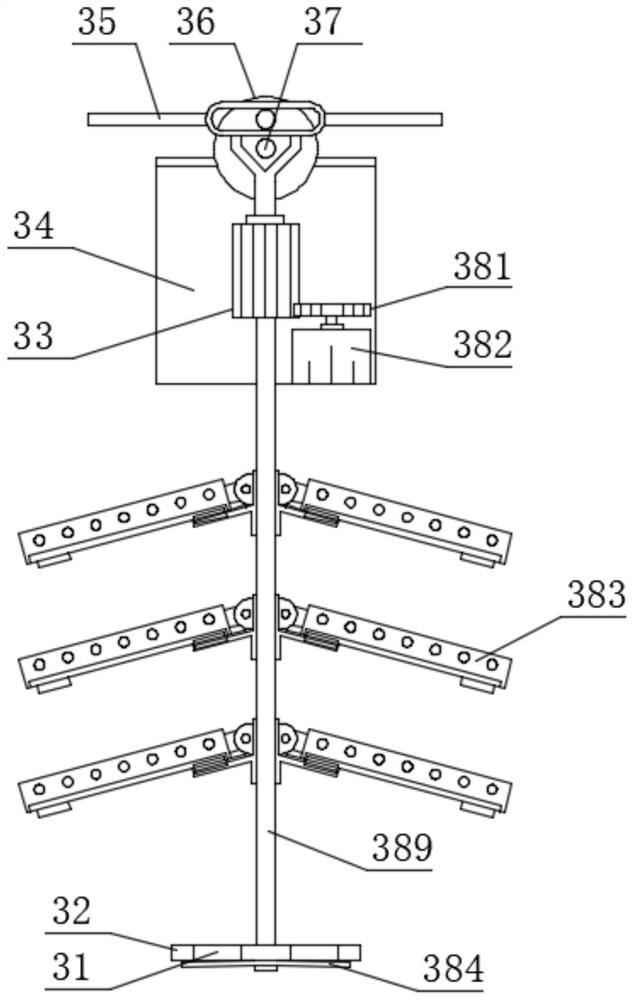

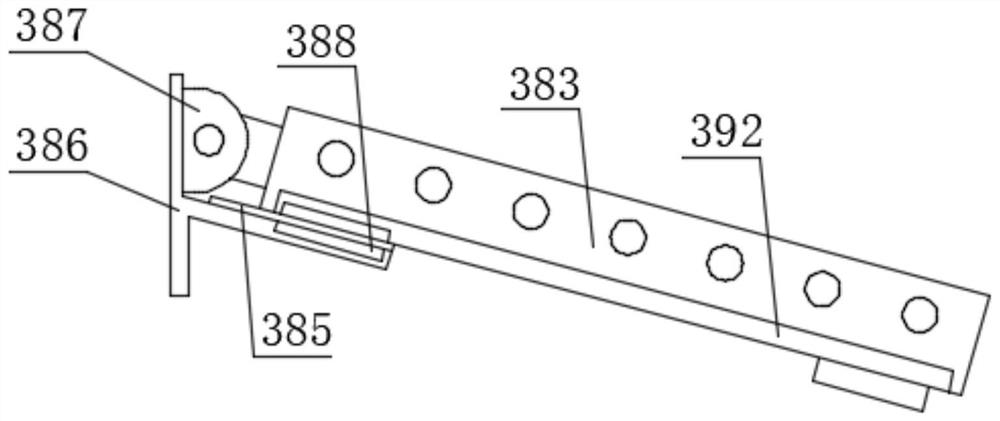

Vertical mixing plant for processing sticky rice adhesive

InactiveCN106621912AStir wellGood dispersionRotary stirring mixersTransportation and packagingHeating timeVertical mixing

The invention discloses a vertical mixing plant for processing a sticky rice adhesive. The vertical mixing plant comprises a base; a mixing tank is arranged at the top of the base; a discharge pipe is arranged at the bottom of the mixing tank; a support plate is arranged at the top of the mixing tank; a thermal insulation layer, a first mixing device, a material scattering plate and a second mixing device are arranged in the mixing tank; a display device is arranged on the right side of the mixing tank; and a feed hopper, a rotating device and an exhaust pipe are arranged at the top of the support plate. The vertical mixing plant is simple in structure, reasonable in design and convenient in use; due to the arrangement of the first mixing device and the second mixing device, the material is fully mixed, a bottom scraper blade mixes the material at the bottom to avoid the mixing blind angles, a spiral mixing blade drives the material to turn up and down, so that the material is more sufficiently mixed; and due to the arrangement of a heating vertical rod, the material is heated, and the heating time and the temperature in the mixing tank can be controlled through the display device.

Owner:郑州吉音动漫科技有限公司

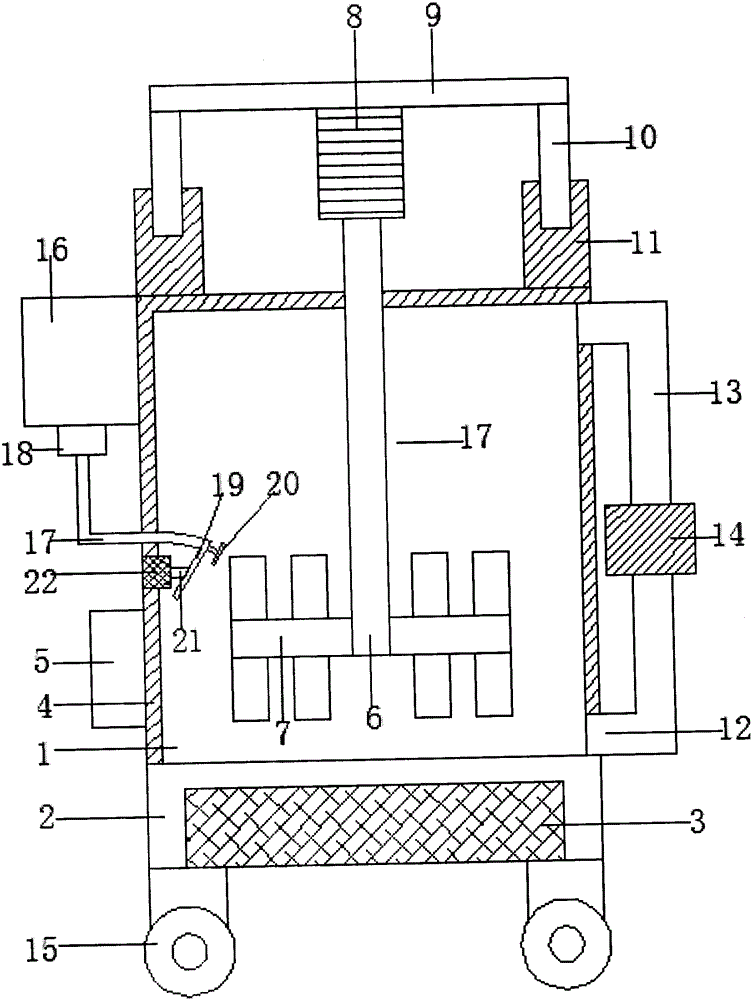

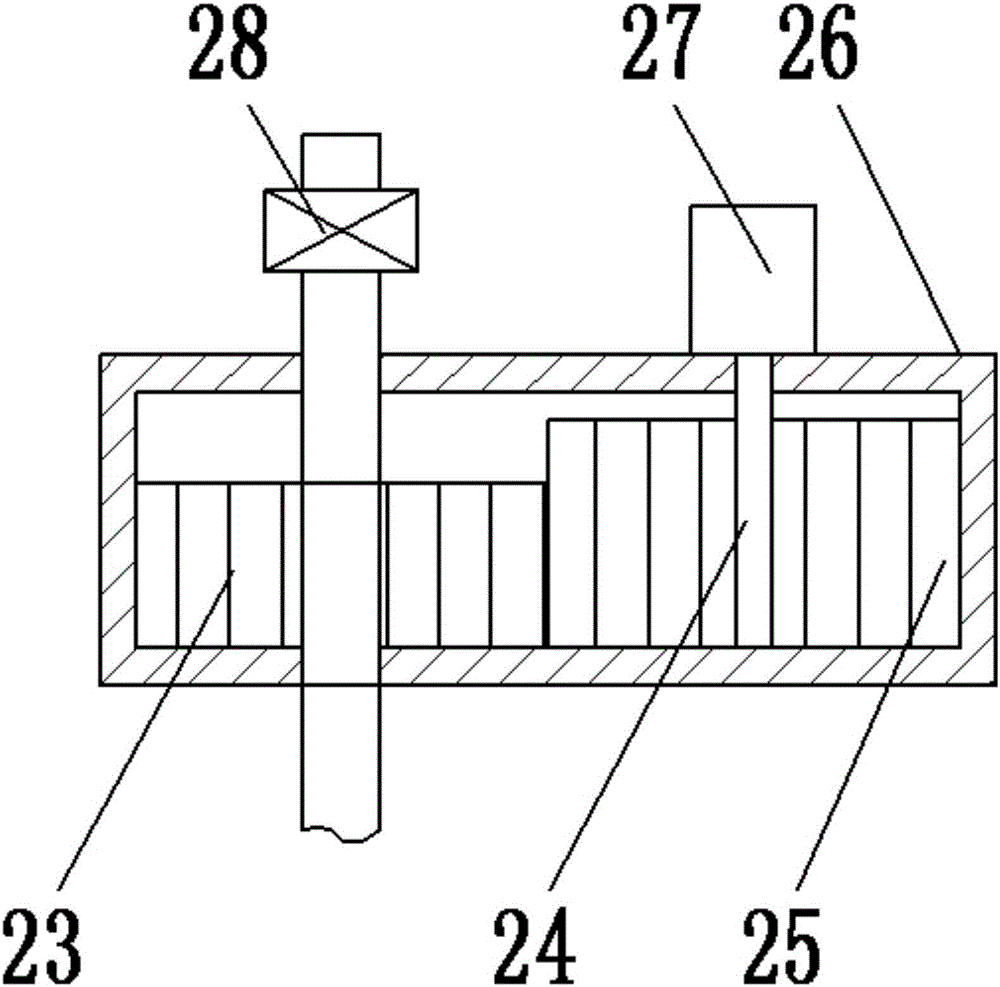

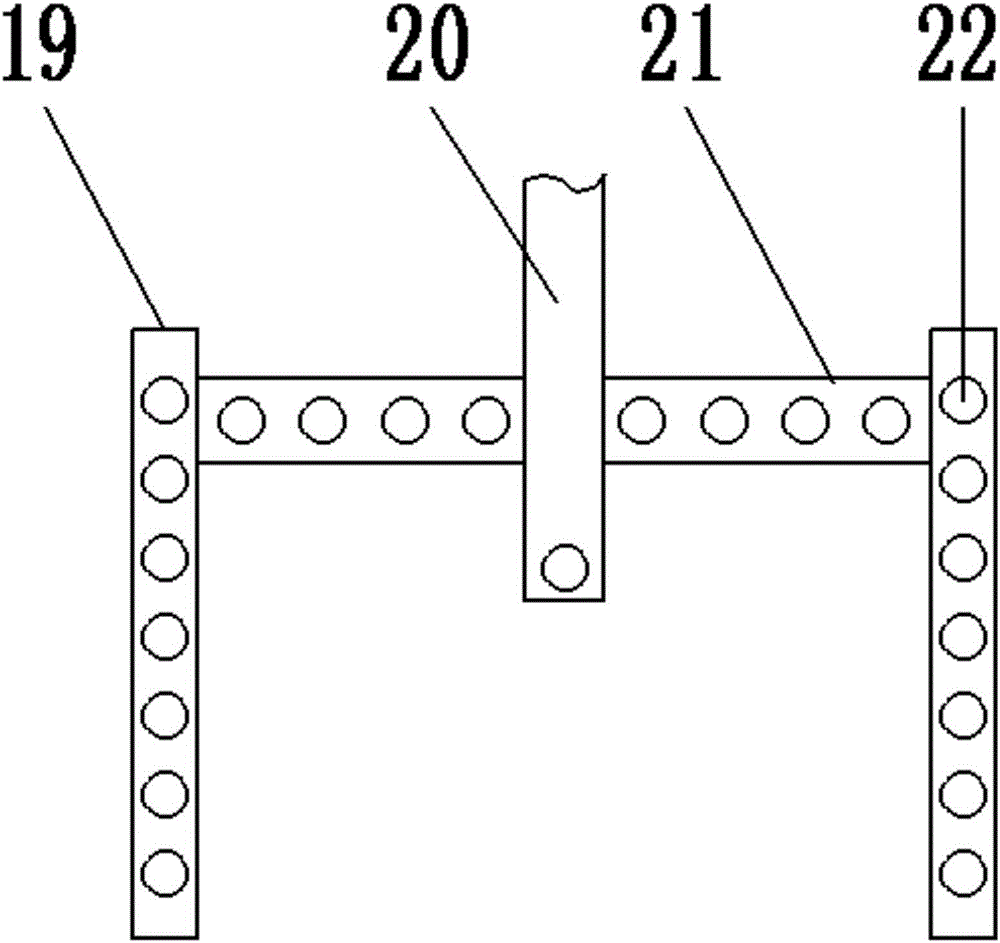

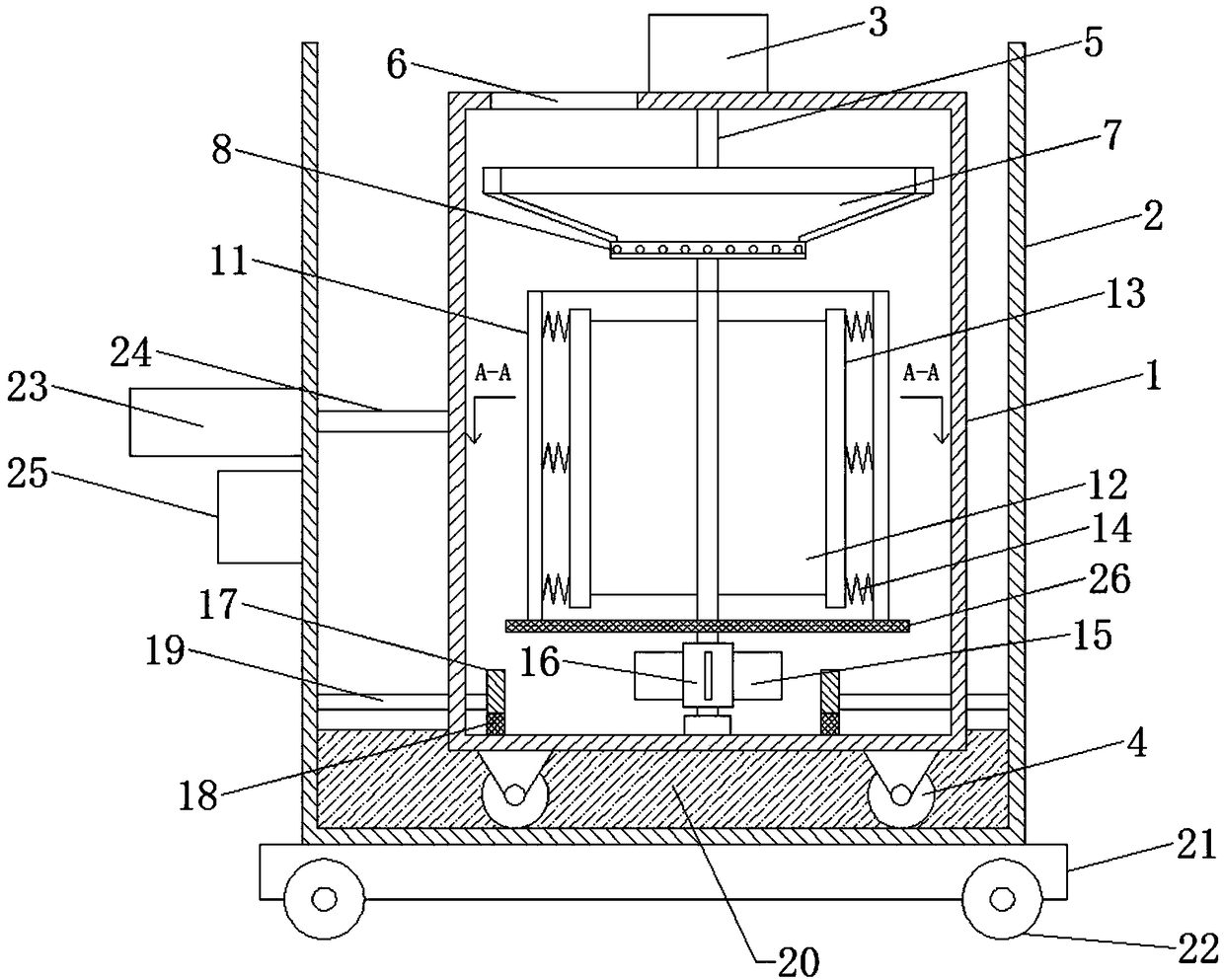

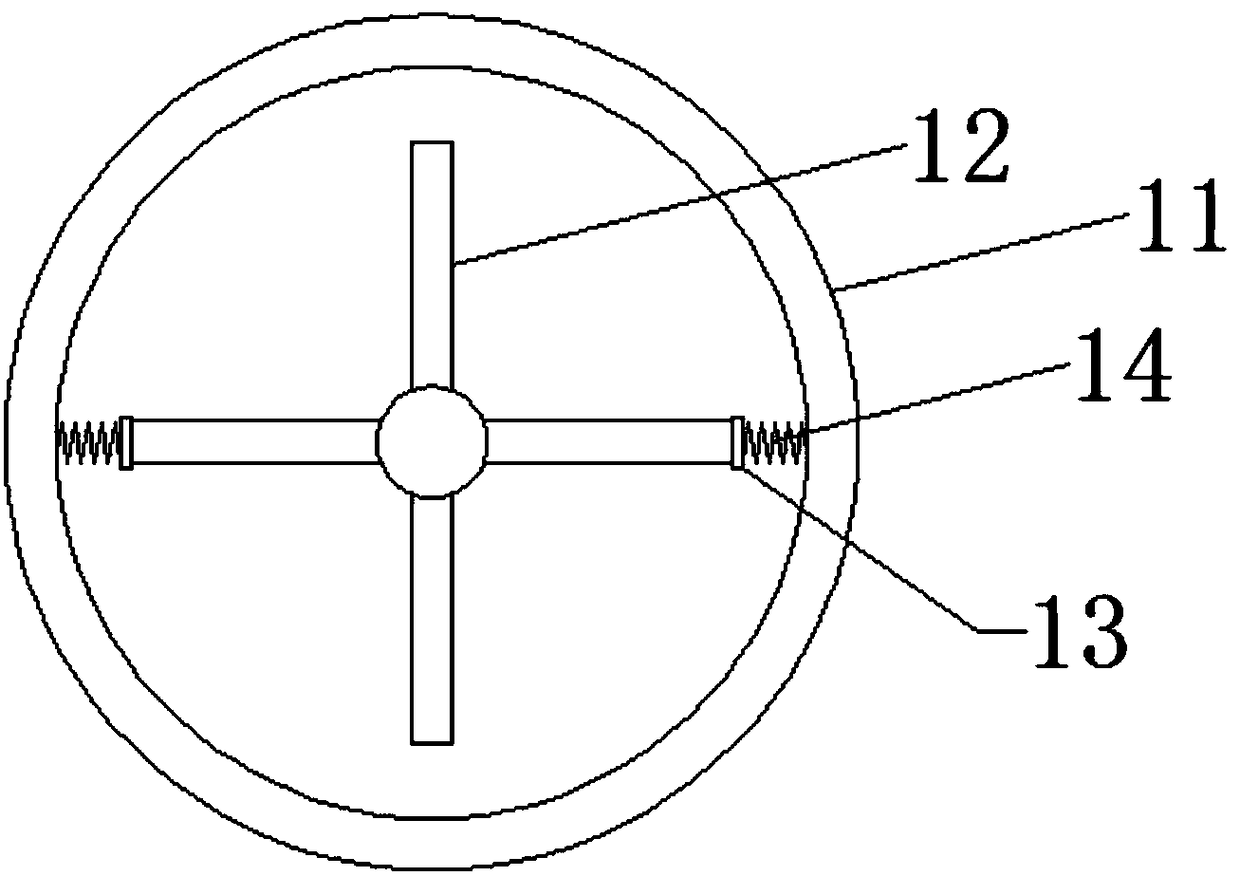

Movable material mixing equipment for building

InactiveCN108556139AAvoid Stirring Dead AngleLarge swingMixing operation control apparatusPretreatment controlPneumatic cylinderDrive shaft

The invention discloses movable material mixing equipment for building. The movable material mixing equipment comprises a cylinder body, a shell, a motor and a feeding opening. Multiple moving wheelsare fixedly installed on the bottom of the cylinder body. A horizontal connecting rod is fixedly connected to a piston rod of a pneumatic cylinder. The connecting rod extends into the tail end in theshell and is fixedly connected with the cylinder body. A horizontal material guide hopper is coaxially fixed to a transmission shaft. A horizontal dispersing disc is fixed to the lower end of the material guide hopper. A supporting screen plate is provided with a screen cylinder which is arranged on the outer side of a main stirring blade in a sleeving manner. A plurality of connecting springs arefixedly connected to the left side and the right side of the inner wall of the screen cylinder. According to the equipment, by means of the arranged material guide plate and the rotating dispersing disc, materials entering the equipment are spread in the cylinder body uniformly, the materials make contact with materials in the cylinder body uniformly, and the materials are stirred and mixed conveniently and fast. The cylinder body moving left and right enables the materials in the cylinder body to waggle left and right, the materials in the cylinder body can move conveniently in the horizontal direction, and the stirring dead angle is avoided.

Owner:南安泰达农业科技有限公司

Extruding type raw material mixing and stirring equipment for processing of new materials

InactiveCN108993273AAvoid incomplete mixingAvoid Stirring Dead AngleShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses extruding type raw material mixing and stirring equipment for processing of new materials. The extruding type raw material mixing and stirring equipment comprises a cylinder body, a hydraulic telescopic cylinder, a feeding hopper, stirring blades and a stirring circular disk, wherein a horizontal lifting disk is arranged at the middle part of the cylinder body; a vertical thread sleeve which is arranged on the outer side of a transmission rod in a sleeving manner is fixedly mounted on a center shaft of the lifting disk; the outer side of the transmission rod is in threaded connection with the thread sleeve through formed threads; discharging openings which adopt a rectangular structure are formed in the lifting disk; and a baffle plate is rotatably connected to eachdischarging opening through a corresponding mounted horizontal hinge. According to the extruding type raw material mixing and stirring equipment disclosed by the invention, through the lifting disk which moves up and down, interior liquid is pushed to flow, and the liquid is stirred; the liquid flows at the edge of the lifting disk and the discharging openings in the lifting disk, so that the situation that stirring of the interior liquid is not thorough is avoided; and when the lifting disk moves downwards, each baffle plate is attached to the corresponding discharging opening, when the lifting disk moves upwards, each baffle plate is separated from the corresponding discharging opening, and the material liquid on the lifting disk flows downwards from the discharging openings, so that the material liquid in the cylinder body flows in a large range.

Owner:YANCHENG BILLION CONNAUGHT MACHINERY CO LTD

Flocculation stirrer

PendingCN110642353AEasy to cleanAvoid flocculation effectsWater/sewage treatment by flocculation/precipitationFlocculationSludge

The invention discloses a flocculation stirrer. The stirrer comprises a stirring barrel, an inner barrel is mounted in the stirring barrel; the inner barrel is coaxial with the stirring barrel; the stirring barrel comprises a barrel cover; a stirring shaft is mounted on the barrel cover; the stirring shaft is driven by a motor to rotate; the stirring shaft comprises an upper stirring shaft and a lower stirring shaft; an outer stirring shaft is mounted on the upper stirring shaft; outer fan blades for generating upward vortexes are mounted on the outer stirring shaft, inner fan blades for generating downward vortexes are mounted on the lower stirring shaft, a filter screen is connected between the periphery of the lower barrel opening and the barrel bottom of the stirring barrel, a sludge discharging pipe which is vertically arranged downwards is arranged in the middle of the barrel bottom of the stirring barrel, and a water discharging pipe which is horizontally arranged is arranged atthe lower part of the barrel wall of the stirring barrel. According to the flocculation stirrer, flocs are filtered and intercepted in the stirring process, the influence of the flocs on the flocculation effect is avoided, sewage in the stirrer can form convection, stirring dead corners are avoided, and discharging of the flocs and cleaning of the stirrer are very convenient.

Owner:嘉兴港区工业污水处理有限公司

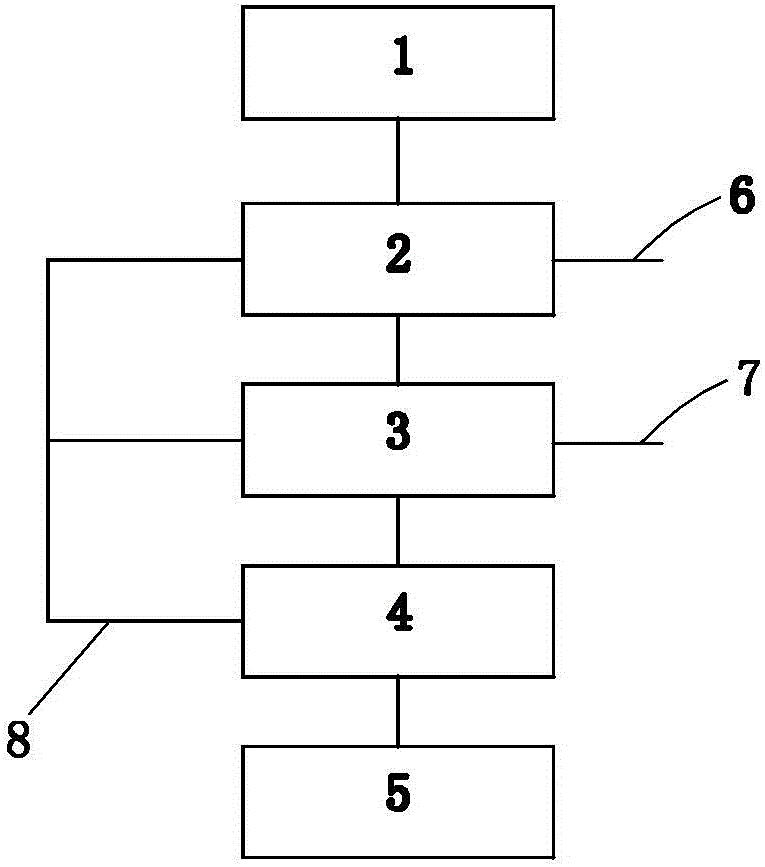

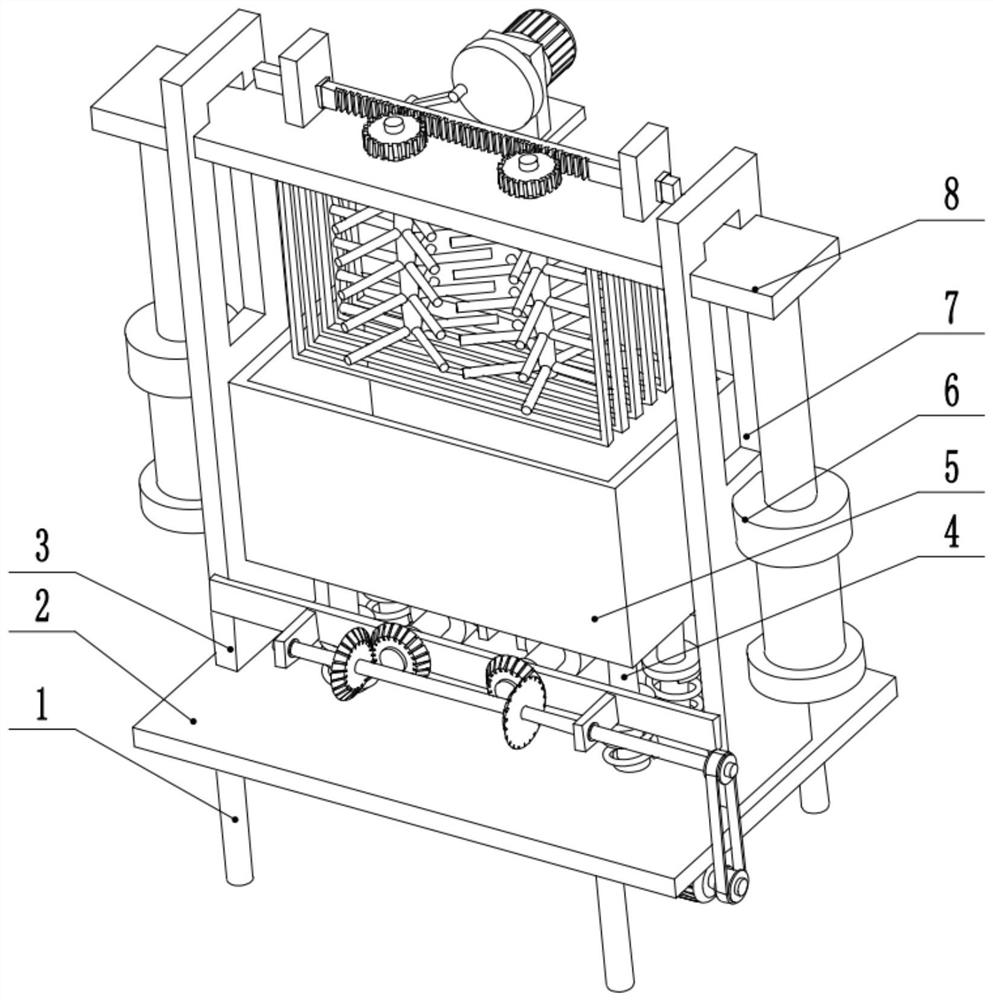

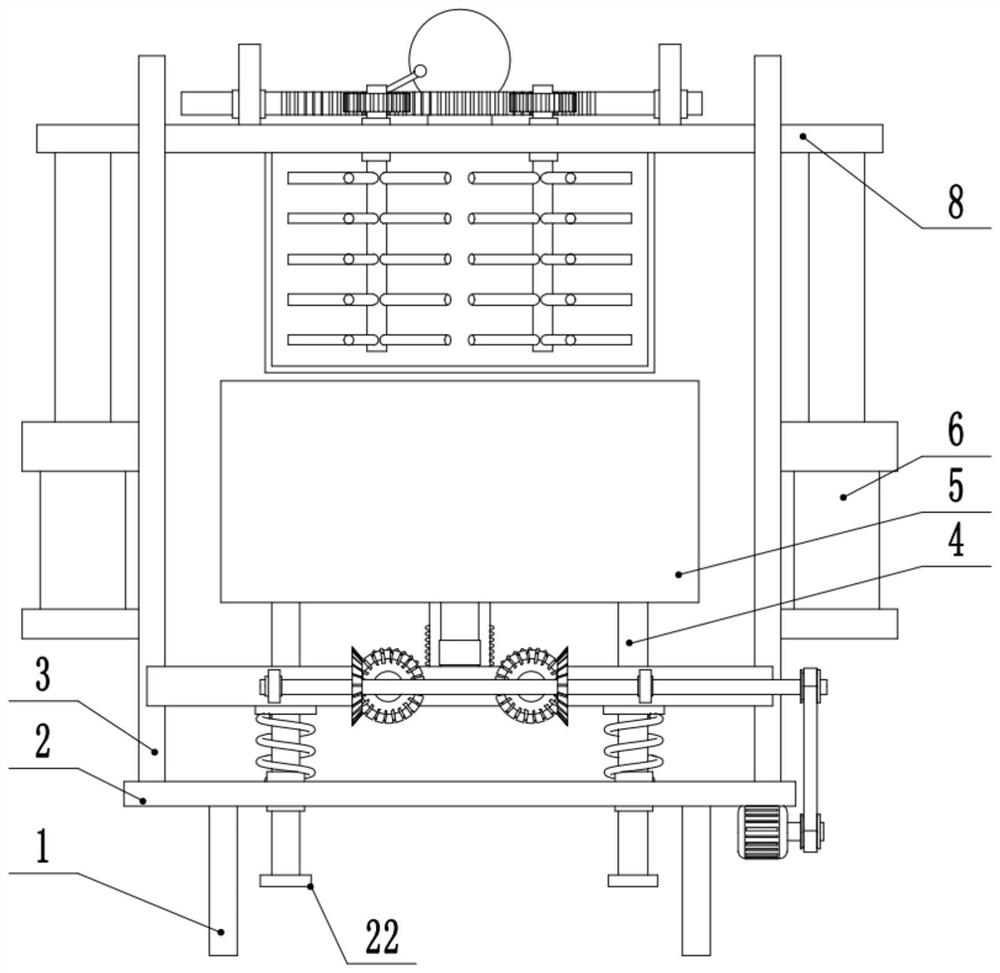

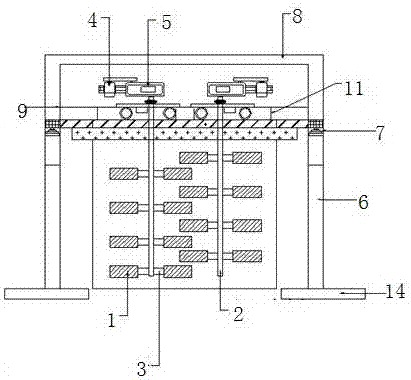

Treatment process and equipment of waste books

ActiveCN106149438AReduce power consumptionEmission reductionPaper recyclingPulp beating/refining methodsPulp and paper industryEnergy consumption

The invention discloses a treatment process and equipment of waste books and belongs to the technical field of waste paper recycling. The treatment process sequentially includes the steps, from top to bottom, of firstly, using an edge-cutting machine to cut off the edges, with glue or iron nails, of the waste books; secondly, using a hydrapulper to crush the waste books obtained after the first step, and using a ink-removing overflow pipe to discharge ink during the crushing; thirdly, using a pulping machine to make the crushed materials into pulp, performing ink removing while stirring during pulping, and discharging the removed ink through an ink discharge pipe; fourthly, using a concentrator to perform concentration; fifthly, storing the concentrated pulp in a pulp storage tank. The treatment process and equipment has the advantages that the process and equipment is simplified, energy consumption is lowered, the discharge of industrial waste liquid is reduced, the pulping efficiency and quality of the waste books are increased, and the process and equipment is widely applicable to waste paper treatment.

Owner:徐州市全鑫毛制品有限公司

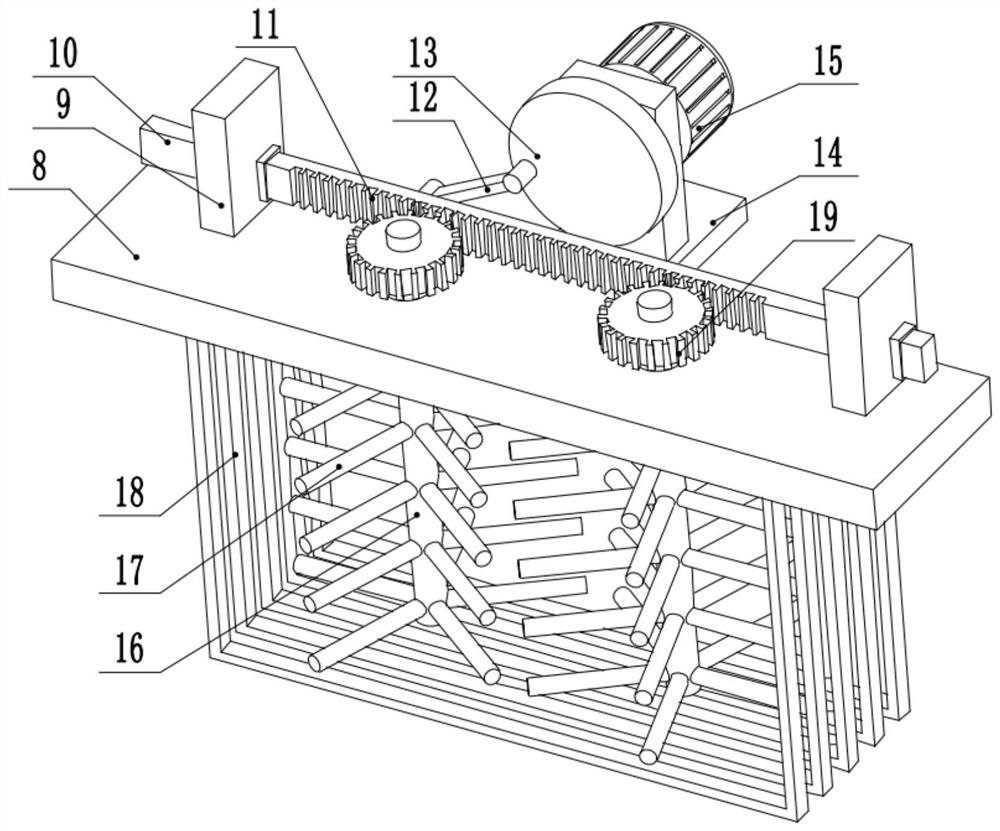

High efficiency type drum agitator

The invention discloses a high efficiency type drum agitator, which comprises a barrel, wherein the upper end of the barrel is provided with a charging opening; the lower end of the barrel is provided with a discharging opening; the inner wall of the barrel is provided with a connecting ring, which is located in an inner cavity of the barrel, through a first bearing; an agitating component is also arranged in the inner cavity of the barrel; the agitating component comprises a supporting rod and a connecting rod; the middle of the supporting rod is provided with a through opening which runs through the radial direction of the supporting rod; the connecting rod runs through the through opening; an elastic member which is located above the connecting rod is also arranged in the through opening; the supporting rod is also provided with an electromagnetic push rod; the outer wall of the barrel is connected with a gear ring in a sleeving manner; the high efficiency type drum agitator also comprises a driving component capable of driving the gear ring to rotate. When a raw material is more, the electromagnetic push rod is started to make a telescopic end of the electromagnetic push rod carry out repeated telescopic movement; in this way, the supporting rod can be controlled to carry out repeated up-and-down movement in the barrel; thus, the agitation coverage range of an agitating vane can be enlarged; an agitation dead angle is effectively avoided; the agitation of concrete is enabled to be more sufficient and uniform.

Owner:郑州市恒源建筑设备制造有限公司

Stirring machine for producing cleaning agent

InactiveCN108636168AAvoid Stirring Dead AnglePerformance impactRotary stirring mixersTransportation and packagingPistonMotor drive

The invention provides a stirring machine for producing a cleaning agent and relates to the field of stirring equipment. The stirring machine for producing the cleaning agent comprises a stirring box,wherein a bearing plate is inserted into the bottom of the stirring box; supporting legs are fixedly mounted at four corners of the bottom of the bearing plate; a valve is communicated with the bottom of the stirring box; baffle plates are fixedly mounted at two sides of the stirring box and are located in the bearing plate; sleeves are fixedly mounted at the bottom of an inner wall of the bearing plate; pistons are arranged in the sleeves. According to the stirring machine for producing the cleaning agent, a first motor drives stirring blades to rotate and the aim of stirring is realized; asecond motor drives a gear to rotate so that a transverse rod shakes leftward and rightward; meanwhile, a rotary rod drives a box body to rotate, and liquid at the bottom of the stirring box is stirred so that the uniform stirring effect is realized; a condition that the bottom of the stirring machine is not sufficiently stirred is avoided and conditions that a stirring dead angle is formed and the utilization performance of the cleaning agent is influenced are avoided.

Owner:新昌县盛南建材有限公司

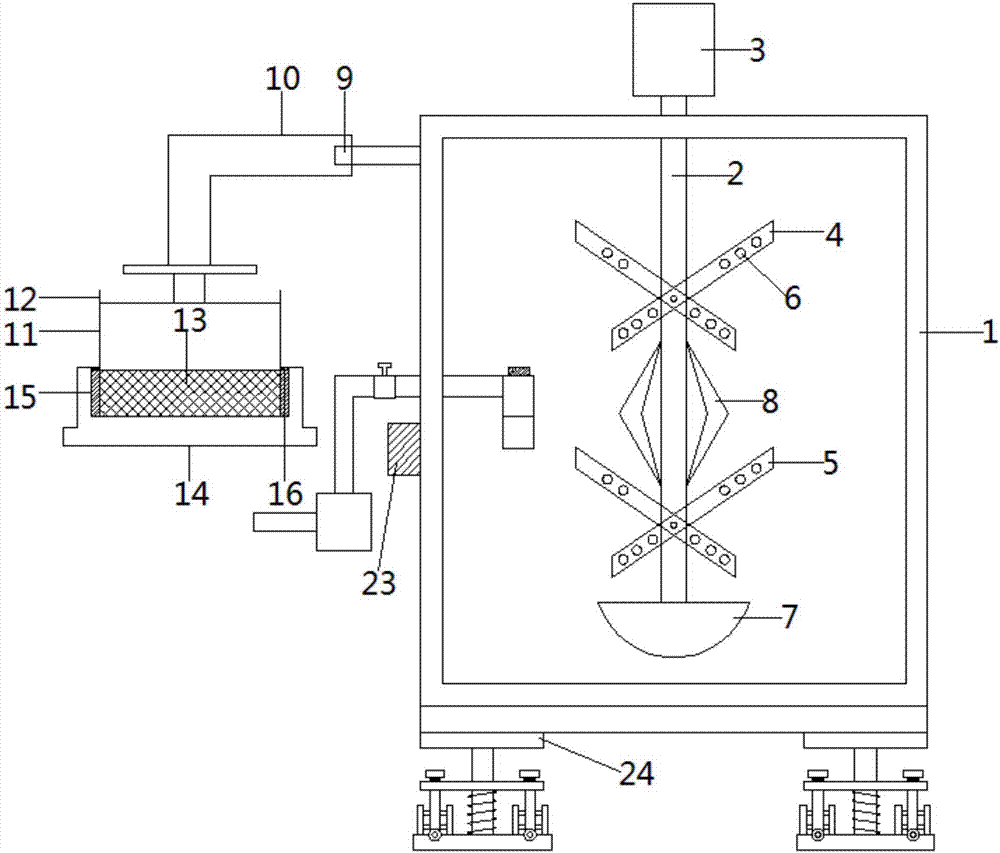

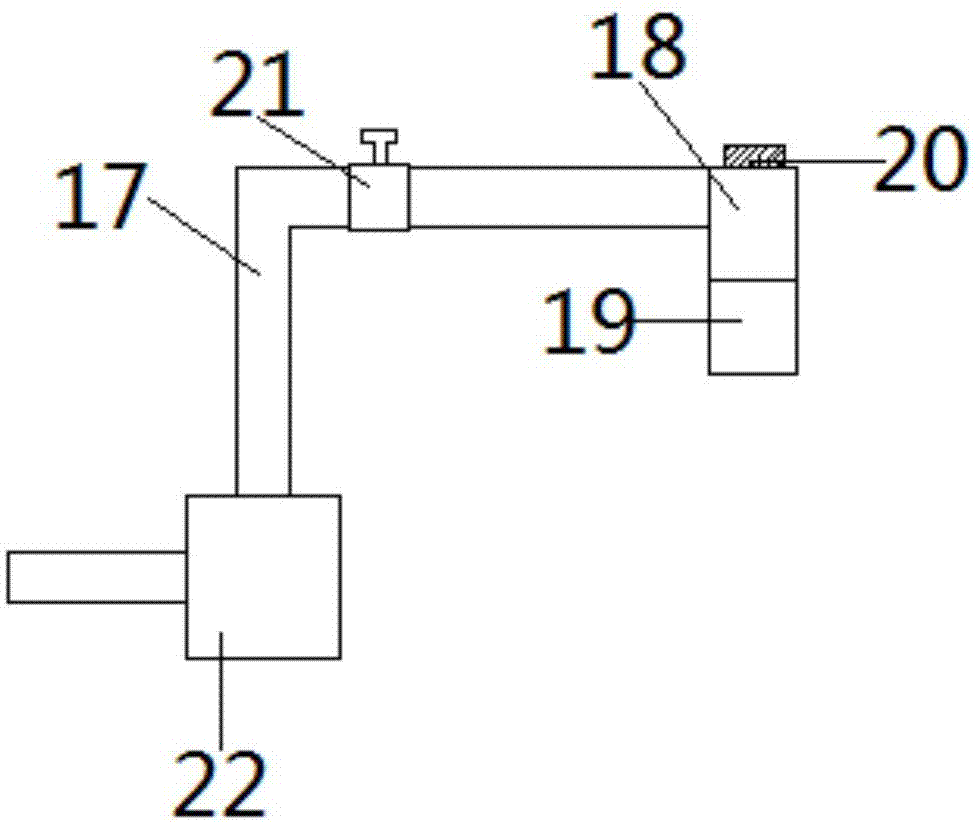

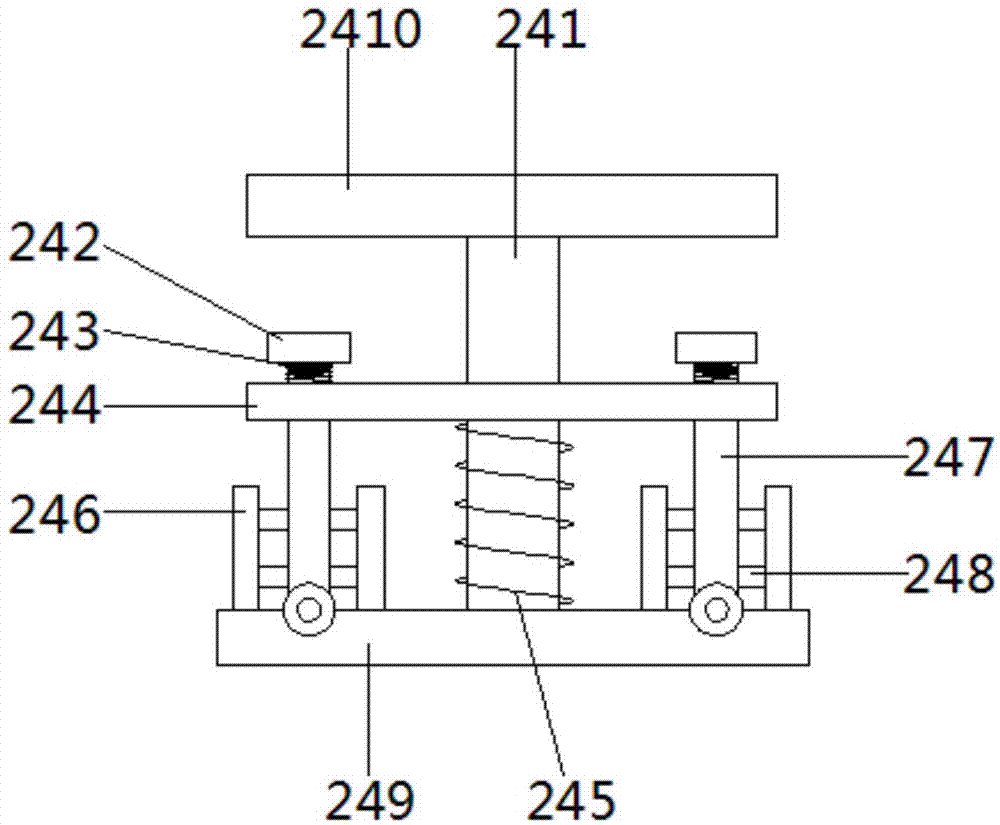

Chemical reaction device with waste gas collecting device

InactiveCN107570101AStir wellStir quicklyRotary stirring mixersChemical/physical/physico-chemical stationary reactorsChemical reactionDrive motor

The invention discloses a chemical reaction device with a waste gas collecting device. The chemical reaction device comprises a kettle. A stirring rotary shaft is vertically arranged in the center ofthe inside of the kettle, a driving motor is connected with the top of the stirring rotary shaft, first stirring blades and second stirring blades are arranged on the outer wall of the stirring rotaryshaft in the up-down directions, stirring through holes are formed in the first stirring blades and the second stirring blades, and a plurality of rhombic stirring blades are arranged in the middle section of the outer wall of the stirring rotary shaft. The chemical reaction device with the waste gas collecting device has the advantages that materials can be sufficiently stirred and mixed by thechemical reaction device, uniform reaction can be carried out on the materials, the reaction speeds can be increased, and the reaction time can be shortened; auxiliaries can be automatically added andcan be sufficiently mixed with the materials after being fed into the kettle, and accordingly the reaction efficiency further can be improved, waste gas generated in working procedures of a reactionkettle can be treated, and accordingly environments can be protected; vibration generated when the chemical reaction device works can be reduced to a great extent, noise can be lowered, and the stability can be improved.

Owner:宁波市江北区伊人宝贸易有限公司

Paint production mixing device provided with agitating tank

InactiveCN107537390AEasy to moveEnsure normal flowMixer accessoriesDrive shaftAgricultural engineering

The invention discloses a mixing device for paint production with a stirring tank, which comprises a shell, a base, a fixed seat, a motor and a feeding box; Stirring chamber; the lower end of the output shaft of the motor is fixedly connected with a transmission shaft that passes through the partition plate vertically; a distributing mechanism is coaxially fixed on the corresponding transmission shaft in the barrel, and evenly distributed on the side wall of the distributing mechanism. Several convex ribs; a downwardly recessed arc-shaped stirring tank is provided on the upper surface of the partition plate, and a circular stirring piece is vertically inserted in the stirring tank. The present invention pulverizes the freshly entered raw materials and the recycled raw materials through the material distributing mechanism, so that they are evenly distributed into the shell, and the material liquid above the partition plate is collected in the stirring tank, and is stirred by the stirring plate. The distance between the tank and the stirring plate is small, which avoids the dead angle of stirring, and the stirring tank is more conducive to the flow of the material liquid.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

Novel domestic kitchen garbage treatment equipment

InactiveCN108435759AReduce processing stepsReduce pollutionSolid waste disposalControl systemCoupling

The invention discloses novel domestic kitchen garbage treatment equipment. The novel domestic kitchen garbage treatment equipment comprises an outer shell and an internal assembly. A cover is arranged at the top of the outer shell and provided with multiple air inlet holes. The outer wall of the outer shell is provided with a control panel and a plug, wherein the plug is used for being connectedwith an external power source. The internal assembly comprises a fermentation vat, temperature sensors, a deodorization and ventilation device, a discharging device and a control system. A base support frame is fixedly connected to the bottom of the outer shell. The fermentation vat is fixedly connected to the base support frame and internally provided with a vertical type stirring tank. The vertical type stirring tank is fixedly connected with an output shaft of a motor and reducer through a coupling. The outer wall of the fermentation vat is coated with sound insulation and heat insulation cotton. A heating piece is arranged between the sound insulation and heat insulation cotton and the outer wall of the fermentation vat. The temperature sensors are in contact with the outer wall of thefermentation vat and arranged on a temperature sensor fixing bracket outside the fermentation vat. The novel domestic kitchen garbage treatment equipment is simple in structure, convenient and fast to operate and great in practicability; kitchen garbage treatment procedures can be effectively reduced; and the novel domestic kitchen garbage treatment equipment is short in cycle, high in efficiencyand good in effect and can be applied and popularized conveniently.

Owner:SHANGHAI INST OF TECH

Donkey-hide gelatin blood-nourishing granule raw material mixing process and mixing device thereof

PendingCN113694800AWell mixedImprove the mixing effectRotary stirring mixersMixer accessoriesMedicinal herbsColla corii asini

The invention discloses a donkey-hide gelatin blood-nourishing granule raw material mixing process and a mixing device thereof. The mixing device comprises a hollow mixing tank and a plurality of supporting legs installed at the lower end of the mixing tank, an inner tank is arranged in an inner cavity of the mixing tank, a feeding hopper is inserted in one side of the top wall of the inner tank in a penetrating mode, and a mixing mechanism is arranged in the inner cavity of the inner tank and penetrates through the top wall of the inner tank; a discharging mechanism connected with the mixing mechanism is also arranged in the inner cavity of the inner tank; the mixing mechanism comprises stirring wheels which are symmetrically and rotatably mounted in an inner cavity of the inner tank, a plurality of stirring claws are arranged on the stirring wheels at equal intervals, the center shafts of the stirring wheels extend towards the close sides and are rotatably connected with a rotating box in a penetrating mode, and the center shafts of the stirring wheels all penetrate through the side wall of the rotating box and are fixedly sleeved with driven bevel gears. The problems that in the prior art, the mixing efficiency is low, pasty raw materials cannot be mixed, medicinal raw materials are likely to splash out, mixing dead angles are likely to be generated, and the mixing quality is poor are solved. The device is especially suitable for fully mixing the donkey-hide gelatin blood-nourishing granules.

Owner:HUIYINBI GROUP ANHUI PHARMA

Pesticide mixing device for extruding and flow pushing for agriculture

InactiveCN110538605AGood dispersionImprove liquidityTransportation and packagingMixer accessoriesHydraulic cylinderEngineering

The invention relates to the field of agriculture, and particularly discloses a pesticide mixing device for extruding and flow pushing for agriculture. The pesticide mixing device for extruding and flow pushing for agriculture comprises a shell, a base, a feed hopper and a discharge pipe; a vertical extruding and flow pushing cylinder with an upward opening is coaxially fixed in the shell, a vertical downward hydraulic cylinder is fixed on the top of the shell, a vertical connecting rod is fixedly connected to the lower end of a piston rod of the hydraulic cylinder, and a horizontal extrudingand flow pushing plate matched with the inner wall of the extruding and flow pushing cylinder is fixed at the tail end of the hydraulic cylinder; and a plurality of liquid inlet holes are formed in the side wall of the middle of the extruding and flow pushing cylinder, and a liquid suction sponge is placed on the bottom of the extruding and flow pushing cylinder. According to the pesticide mixingdevice, liquid flows in the extruding and flow pushing cylinder, the extruding and flow pushing plate moves vertically to drive the liquid in the extruding and flow pushing cylinder to stir, meanwhile, the liquid flows in the liquid suction sponge in the extruding and flow pushing cylinder, a pesticide is easy to disperse by fine meshes in the sponge, the liquid continuously flows in and out of the pesticide mixing device through the extruding and flow pushing cylinder, and thus, the fluidity is improved.

Owner:陆璨

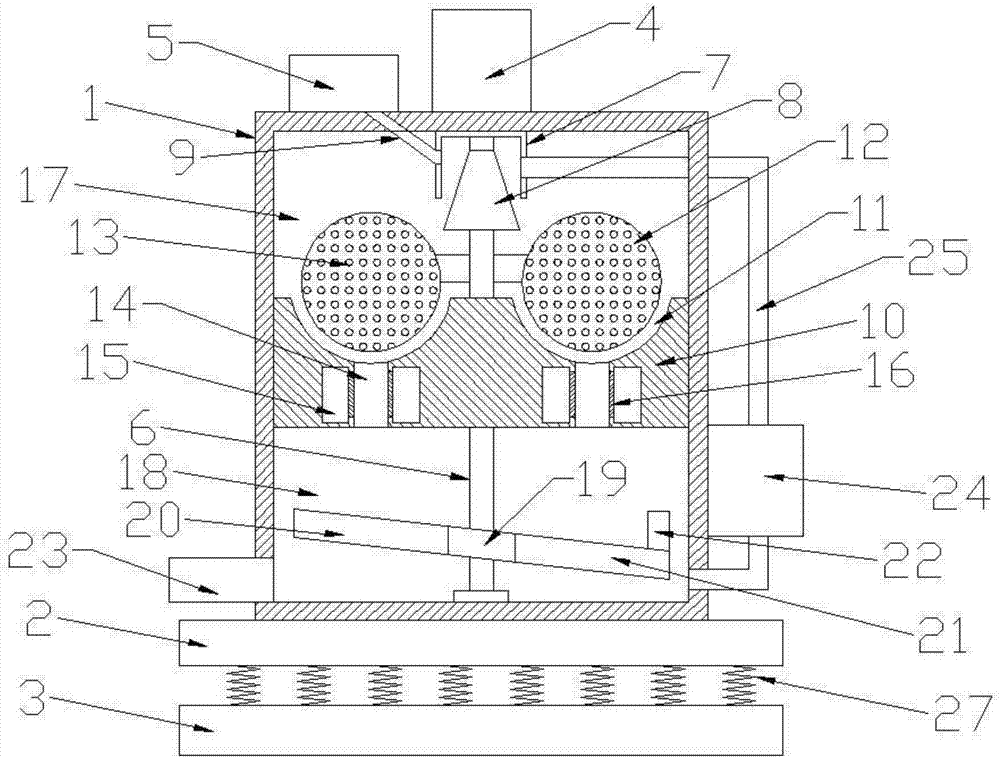

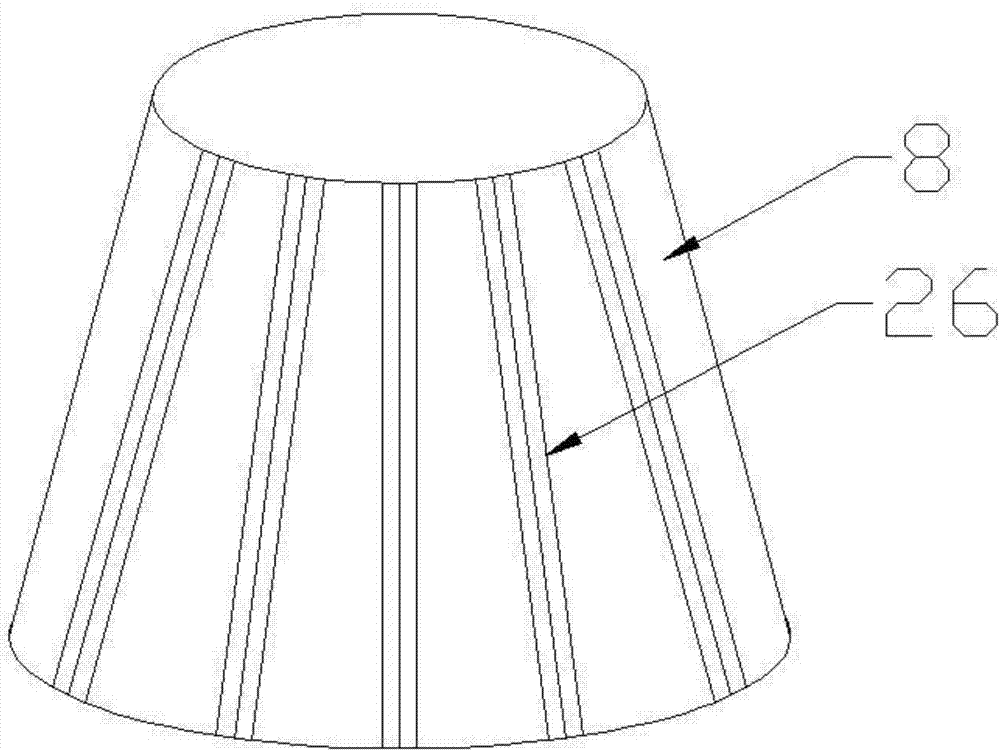

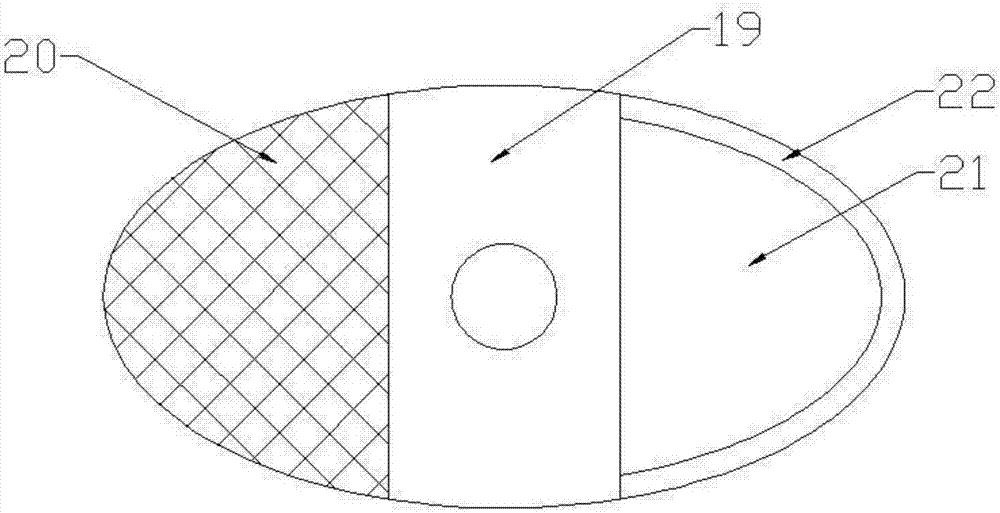

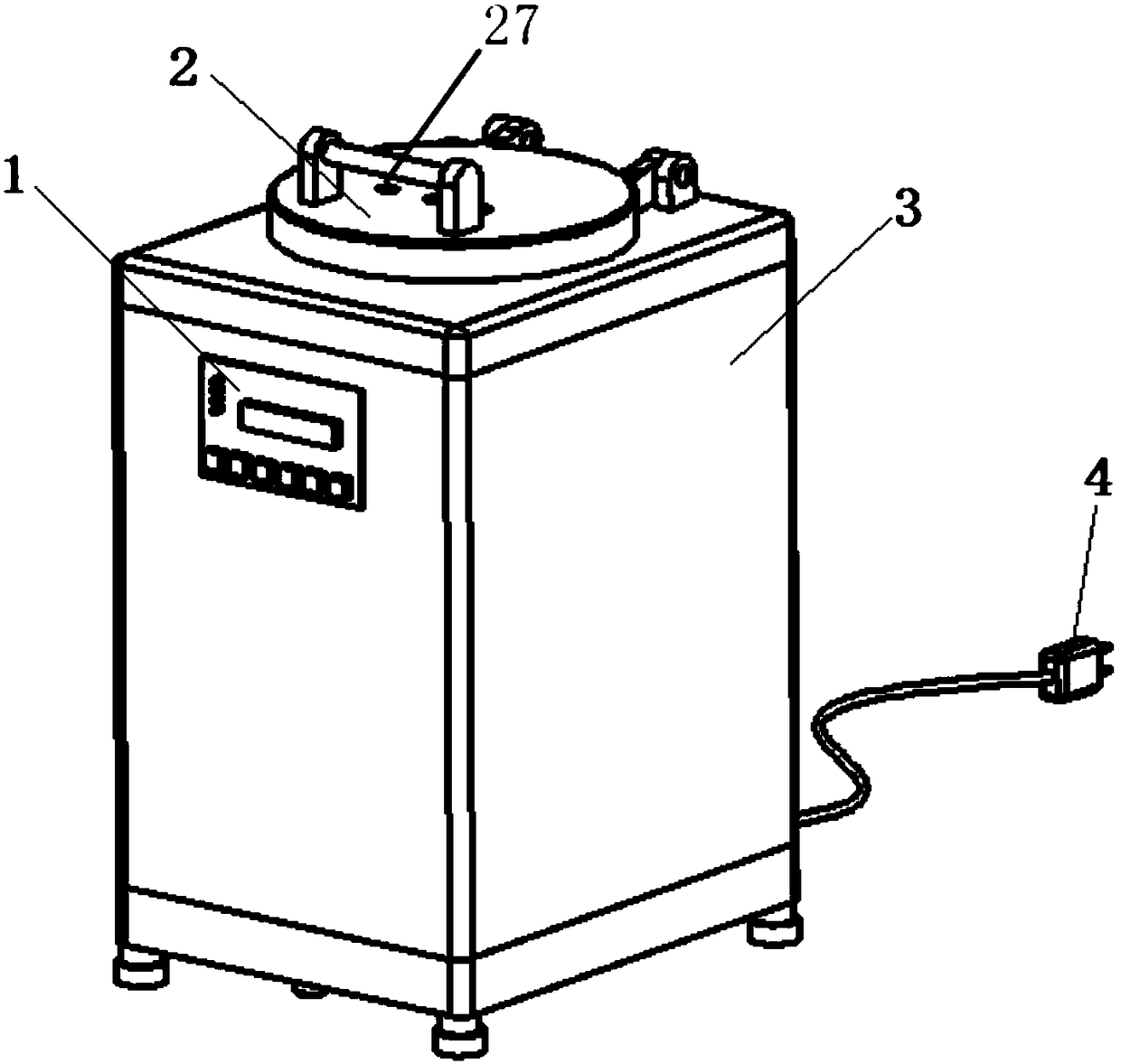

Circulating cooling system of nano-grinding and emulsifying machine

PendingCN112337332AIncrease contact areaImprove cooling efficiencyRotary stirring mixersTransportation and packagingHeat transmissionHelical blade

The invention discloses a circulating cooling system of a nano-grinding and emulsifying machine, belonging to the technical field of cooling. To invention aims to solve problems in achieving cooling efficiency. The circulating cooling system provided by the invention specifically comprises a base, wherein an outer shell is fixed to the outer wall of the top of the base through supporting legs, aninner shell is rotatably connected to the inner wall of the outer shell through a rotating shaft, a heat exchange pipe is fixedly installed on the inner wall of the outer shell, spiral blades are welded to the inner wall of the inner shell, space between the inner shell and the outer shell is filled with a heat transfer medium, a transmission assembly is arranged on the outer wall of the top of the base and connected with the rotating shaft in a matched mode, and a first connecting port and a second connecting port which are connected with the two ends of the heat exchange pipe respectively are arranged on the outer wall of one side of the outer shell. The heat transfer medium is liquid, and a contact area of the heat transfer medium and the inner shell is the surface area of the outer side of the inner shell, so the contact area is greatly increased and cooling efficiency is improved; and a groove is formed in the outer wall of the inner shell, so the contact area is further increased, and cooling effect is improved.

Owner:NANTONG FLECK FLUID EQUIP

Low-stibium multicomponent lead alloy and production technology and applications thereof

InactiveCN101792873AMake up for the shortcomings of insufficient mechanical strengthGood casting performanceIngotCobalt

The invention discloses a low-stibium multicomponent lead alloy and a production technology and applications thereof. The low-stibium multicomponent lead alloy contains 1.1-1.8% of stibium, 0.0009-0.004% of arsenic, 0.0009-0.005% of ytterbium and the balance lead. The alloy also contains at least one of cobalt, aluminum and selenium, and the weight percentages of cobalt, aluminum and selenium are separately 0.009-0.03%, 0.009-0.1% and 0.009-0.05%. The production technology of the alloy comprises the following steps: firstly placing electrolytic lead and antimony ingot in a pit-type resistance furnace to melt at 400-800 DEG C, secondly pumping liquid lead-antimony alloy with a lead pump to an alloy kettle, stirring and cooling while adding other alloys. The prepared low-stibium multicomponent lead alloy of the invention is used in the grid and bus of the lead-acid accumulator and is characterized by easy casting process, high strength and high corrosion resistance; and the prepared accumulator has less water loss and longer service life in use.

Owner:双登天鹏冶金江苏有限公司

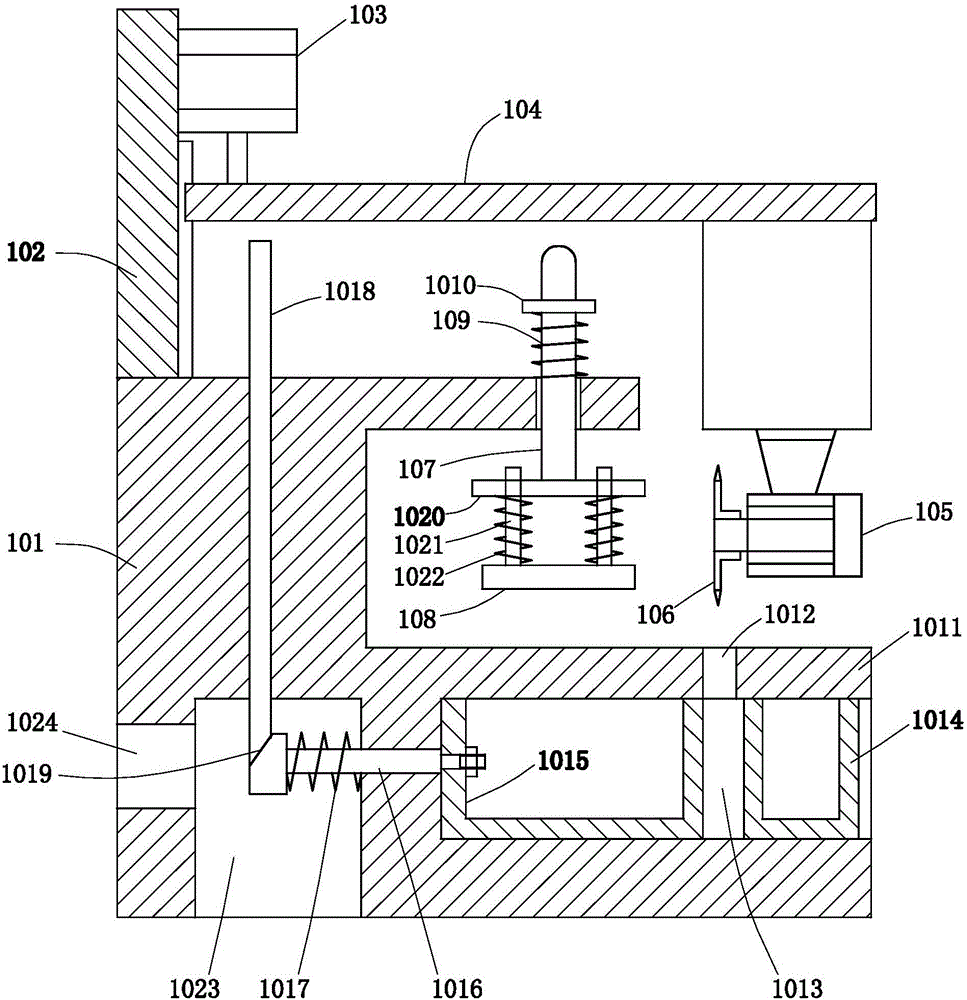

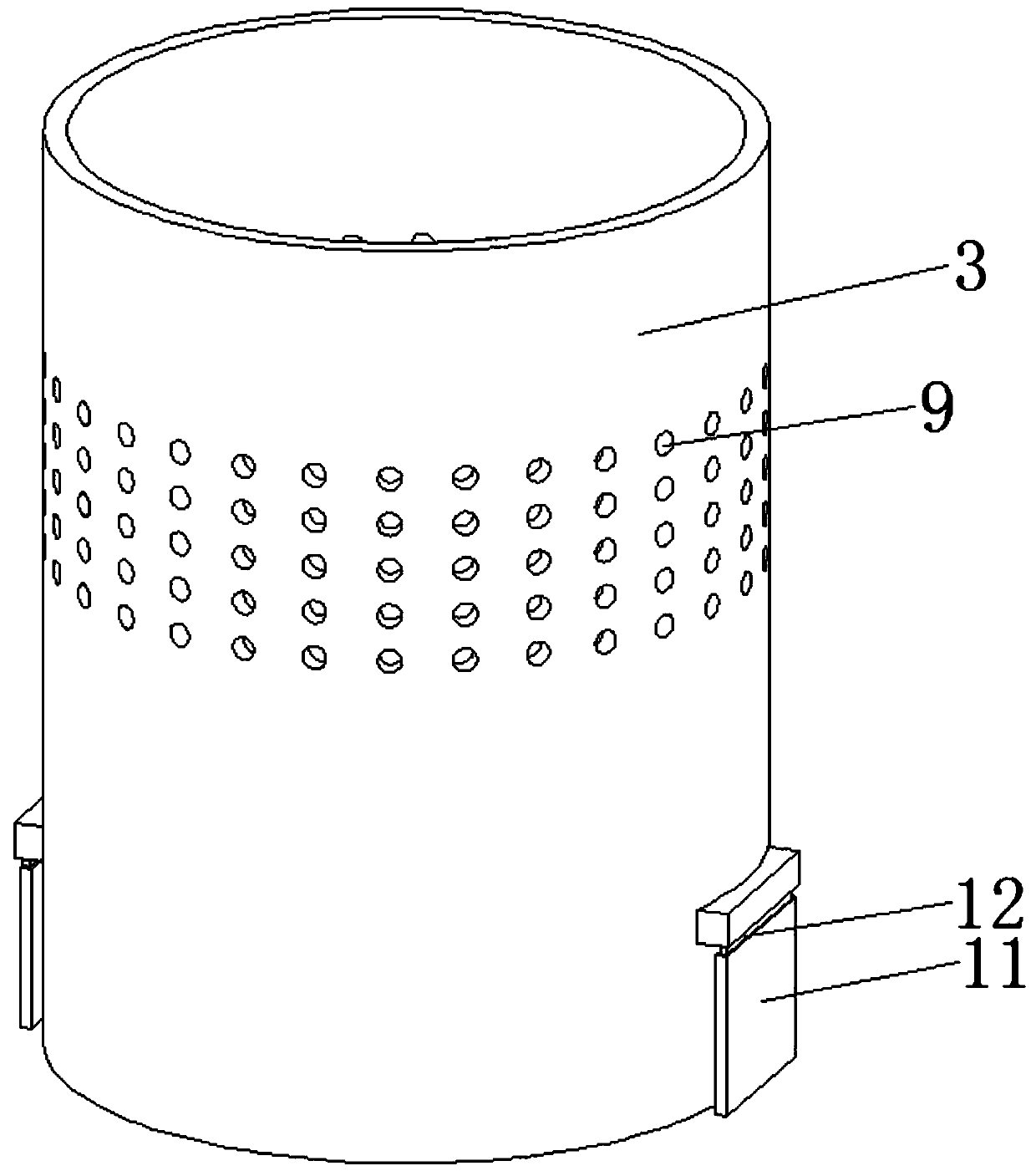

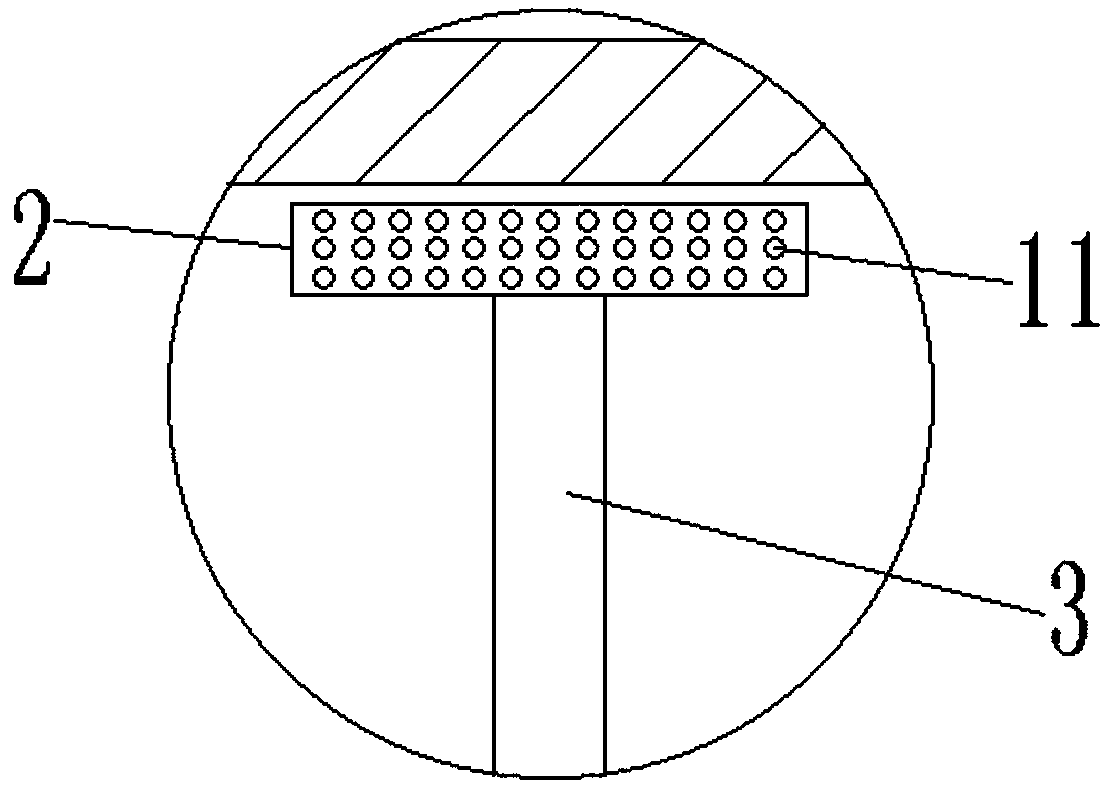

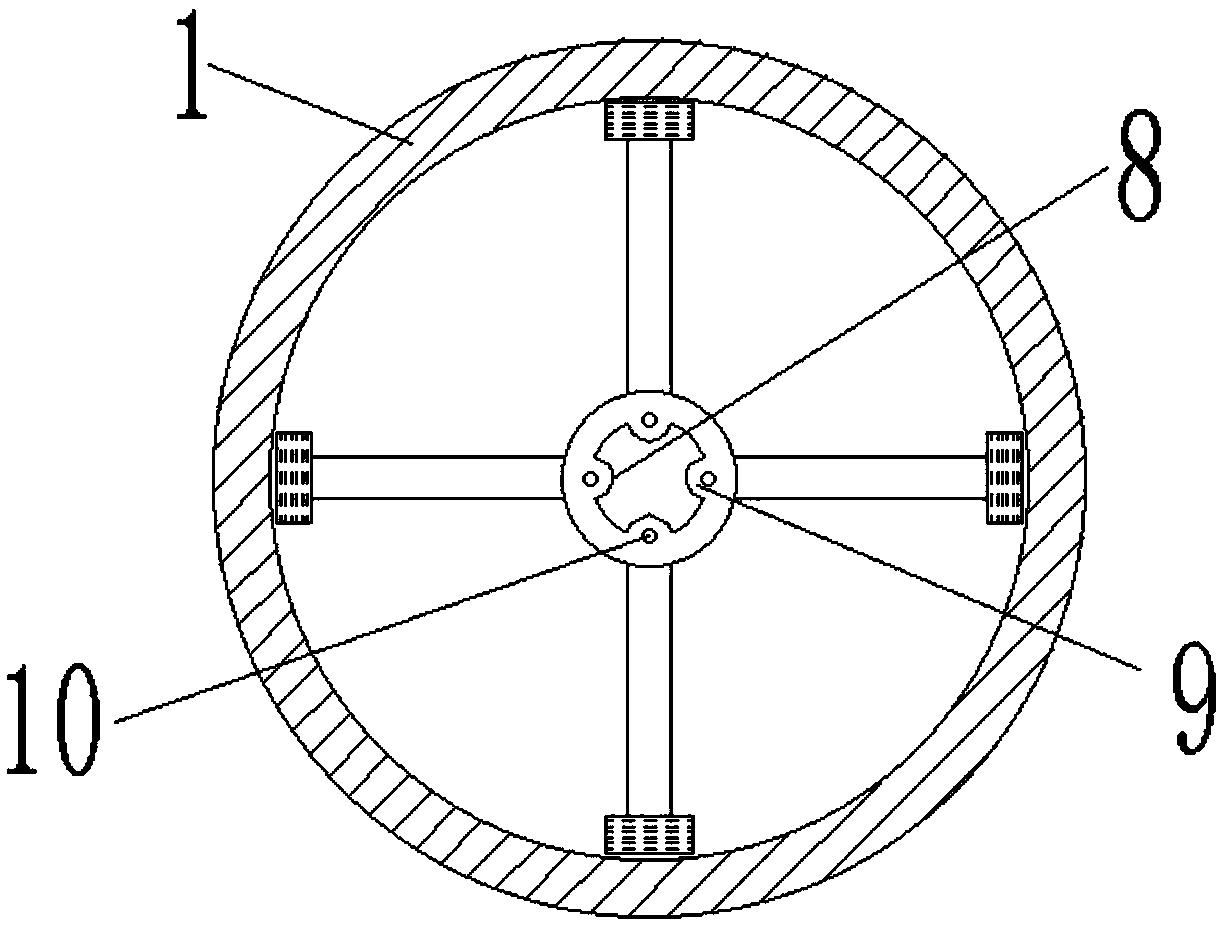

Stirring device for concrete block brick machine

InactiveCN109093845AAvoid Stirring Dead AngleStir wellHollow article cleaningCement mixing apparatusEngineeringMechanical engineering

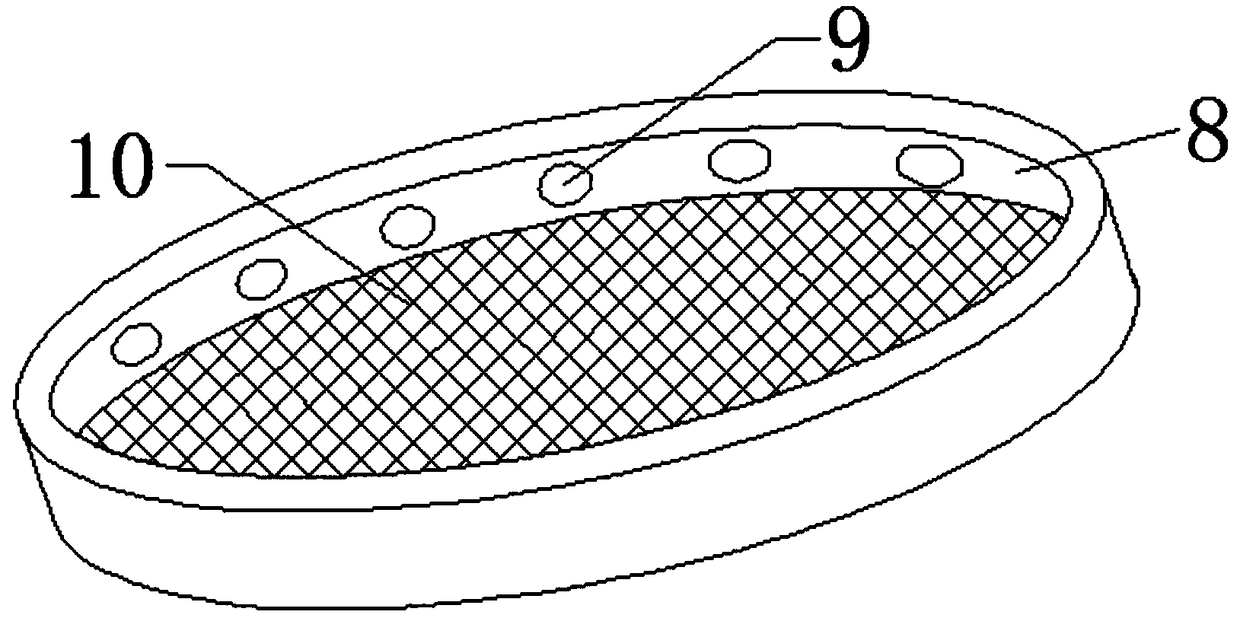

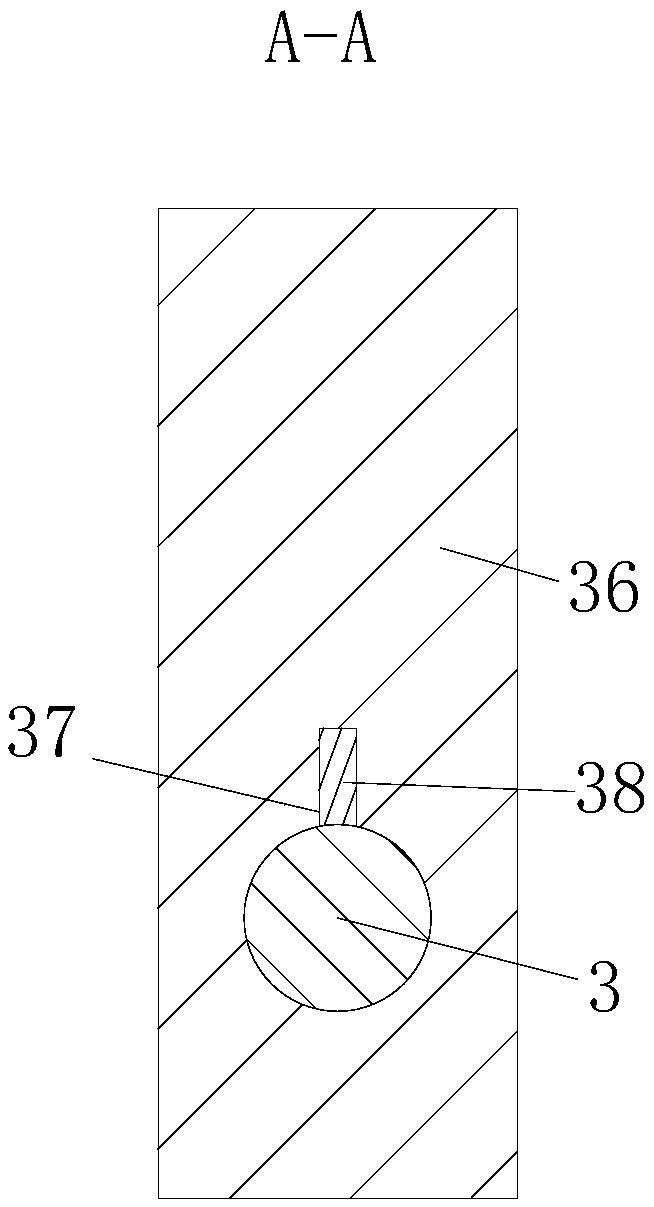

The invention discloses a stirring device for a concrete block brick machine. The stirring device for the concrete block brick machine comprises a stirring barrel (1), wherein a rotating rod (5) is arranged in the stirring barrel (1), a rotating motor (7) is arranged at one end of the rotating rod (5), a plurality of grooves (8) are formed in the rotating rod (5), and stirring rings (4) are connected on the periphery of the rotating rod (5) through the grooves (8); a plurality of bulges (9) which are glidingly connected with the grooves (8) are arranged on the inner circumference of the stirring rings (4), a plurality of stirring rods (3) are arranged on the outer circumference of the stirring rings (4), a stirring scraping plate (2) is arranged at one end, away from the circle center of each stirring ring (4), of each stirring rod (3), and a plurality of through holes (11) are formed in all the stirring scraping plates (2); linear motors (10) are arranged on all the bulges (9). The stirring device for the concrete block brick machine disclosed by the invention has the advantage of relatively uniform stirring of stirred materials.

Owner:湖州德海新型建材有限公司

Environment-friendly stone paperboard filler stirring device

InactiveCN111921429AStir wellAvoid Stirring Dead AngleShaking/oscillating/vibrating mixersTransportation and packagingGear wheelPaperboard

The invention relates to the technical field of environmental protection, and discloses an environment-friendly stone paperboard filler stirring device comprising a bottom plate, supporting plates arearranged on the left and right sides of the upper surface of the bottom plate. A chute is formed in the upper part of each supporting plate; the middle of the chute is slidably connected with a lifting plate; an air cylinder is arranged on the side, away from the device center, of the supporting plate. Piston rods of the cylinders are fixedly connected with left and right ends of the lower surface of the lifting plate; first fixing plates are arranged on the left and right sides of the upper surface of the lifting plate, the middle of each first fixing plate is slidably connected with a sliding rod, first racks are arranged on the front sides of the sliding rods, the left and right sides of the first racks are engaged with driven gears, the driven gears are fixedly connected with the upper end of a stirring shaft, and stirring rods are arranged at the lower end of the stirring shaft. According to the environment-friendly stone paperboard filler stirring device, raw materials in the stirring box are stirred more sufficiently through the stirring rod, the stirring position is continuously changed, stirring dead corners can be avoided and the stirring effect is improved.

Owner:陈方羽

Uniformly-heated raw material mixing device for chemical industry

InactiveCN108525632AEasy to moveLarge swingShaking/oscillating/vibrating mixersRotary stirring mixersChemical industryEngineering

The invention discloses a uniformly-heated raw material mixing device for the chemical industry. The uniformly-heated raw material mixing device comprises a barrel, a shell, a motor and a material inlet, wherein a plurality of moving wheels are fixedly installed on the bottom of the barrel, a heating cavity is arranged between the barrel and the shell, the inner wall of the shell is provided witha heating layer, and a sealing cover is arranged between the top of the barrel and the shell in a sealing manner; a piston rod of an air cylinder is fixedly connected with a horizontal connecting rod,and the tail end, entering the shell, of the connecting rod is fixedly connected with the barrel; a horizontal scattering disc is fixed on the lower end of a guiding hopper; and a supporting screen is provided with a mesh tube sleeving the outer side of a main stirring blade, and the left side and the right side of the inner wall of the mesh tube are respectively fixedly connected with a plurality of connecting springs. By arranging a guiding plate and the rotary scattering disc, a raw material is uniformly scattered in the barrel, so that the raw material can be rapidly stirred and mixed; and the heating layer can provide the appropriate temperature for the reaction, so that the mixing reaction of the chemical raw material is ensured to be performed normally.

Owner:南安泰达农业科技有限公司

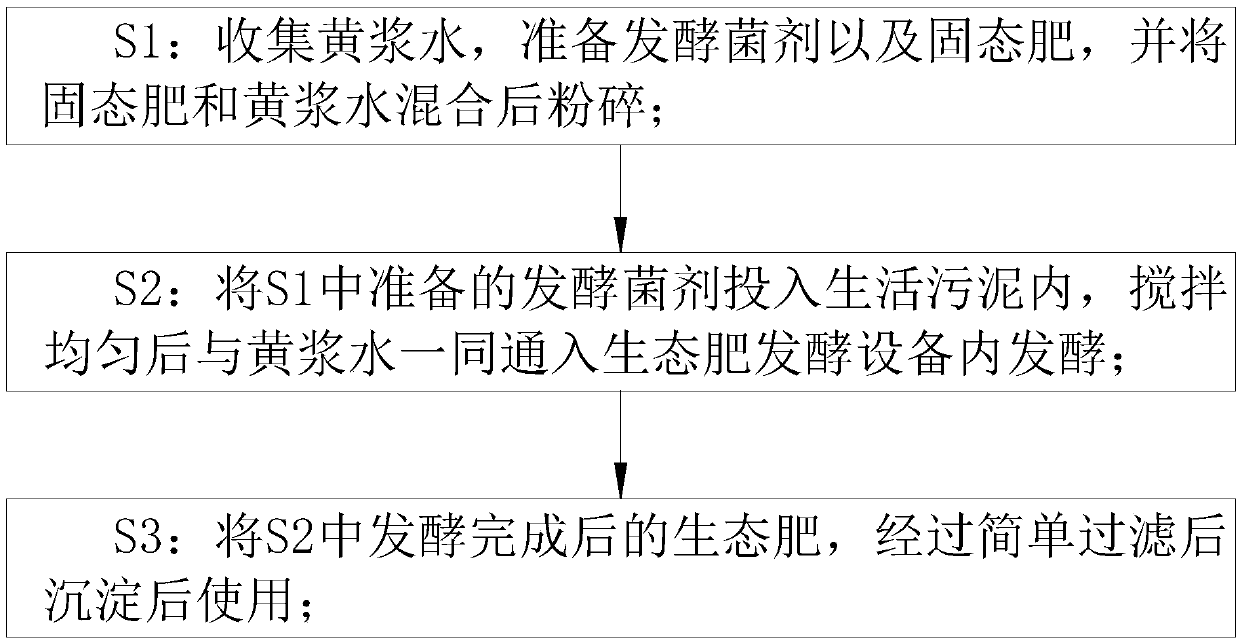

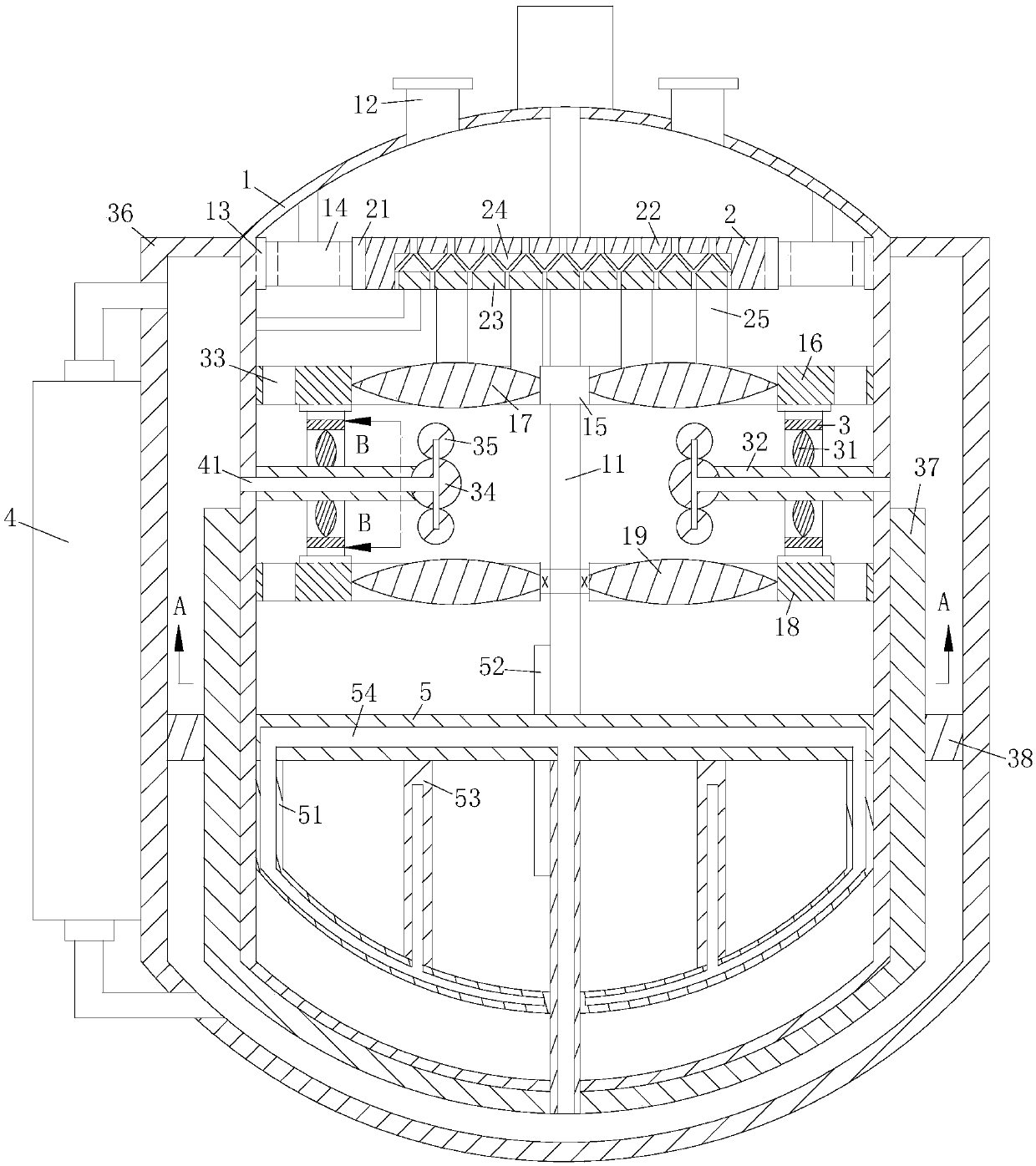

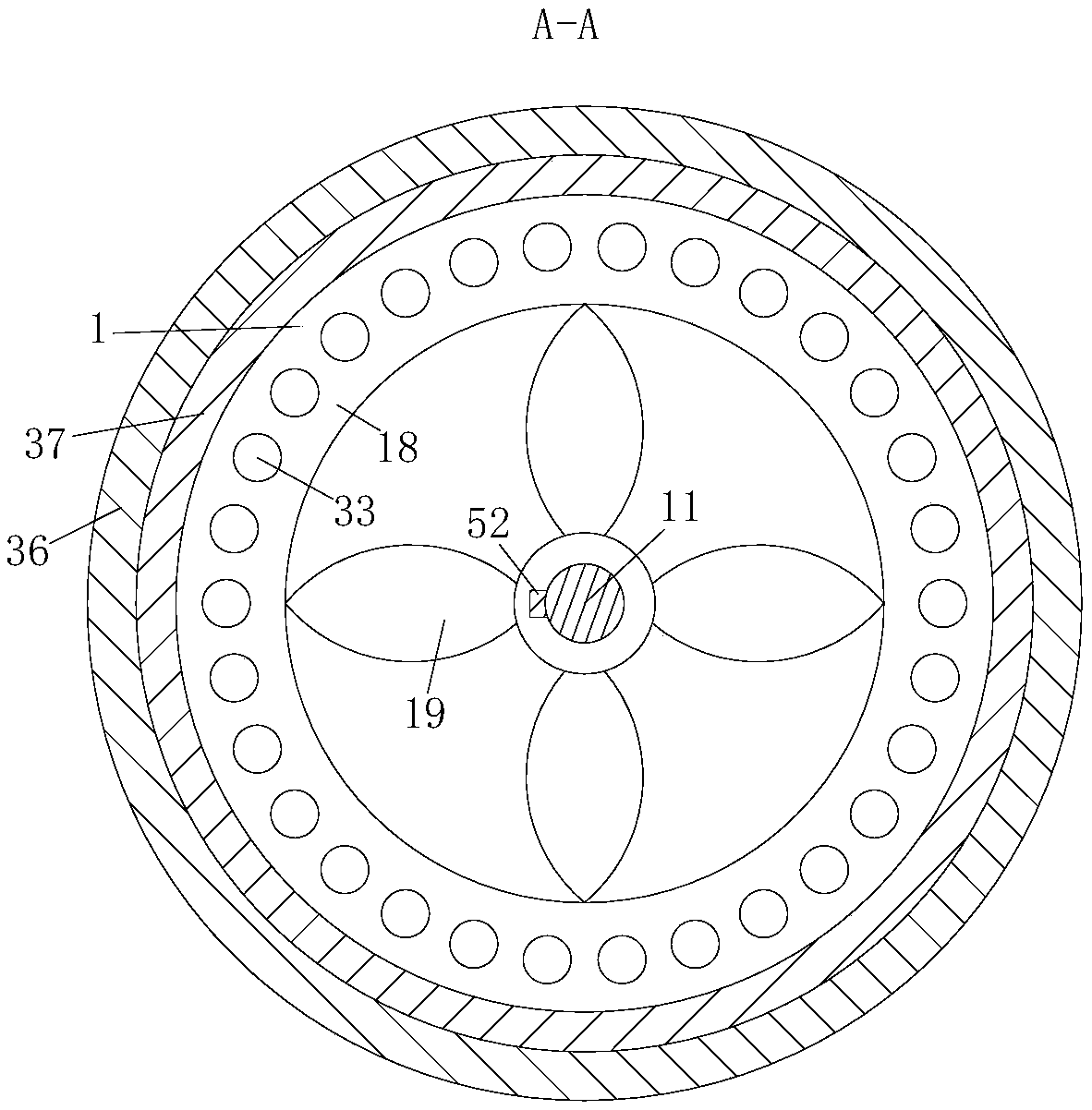

Ecological fertilizer fermentation process

ActiveCN109516848AMultiply fastWell mixedBio-organic fraction processingMicroorganism based treatmentSludgeFermentation

The invention belongs to the technical field of agricultural waste materials, and particularly relates to an ecological fertilizer fermentation process. Solid fertilizers and yellow serofluid are mixed and are then crushed, so that the mixing of the solid fertilizers and yellow serofluid is sufficient; the ecological fertilizer production through fermentation is facilitated. Fermentation bacterialagents are fed into domestic sludge to be uniformly stirred; the domestic sludge can provide proper adhesion points for bacteria, so that the breeding of bacteria is faster; the fermentation speed isaccelerated; used ecological fertilizer fermentation equipment comprises a frame body and a controller; one end, near a rotating shaft, of a second fixing rod is fixedly connected with a first aeration ball; the upper and lower ends of the first aeration ball are fixedly connected with second aeration balls; a heat insulation cabin is arranged outside the frame body. A heater is arranged on the outer surface of the frame body. A fourth stirring rod is made of magnetic materials. The ecological fertilizer fermentation process has the characteristics that the structure is simple; the operationis convenient; the stirring is uniform and thorough; the fermentation speed is high.

Owner:黑龙江信谷农业发展有限公司

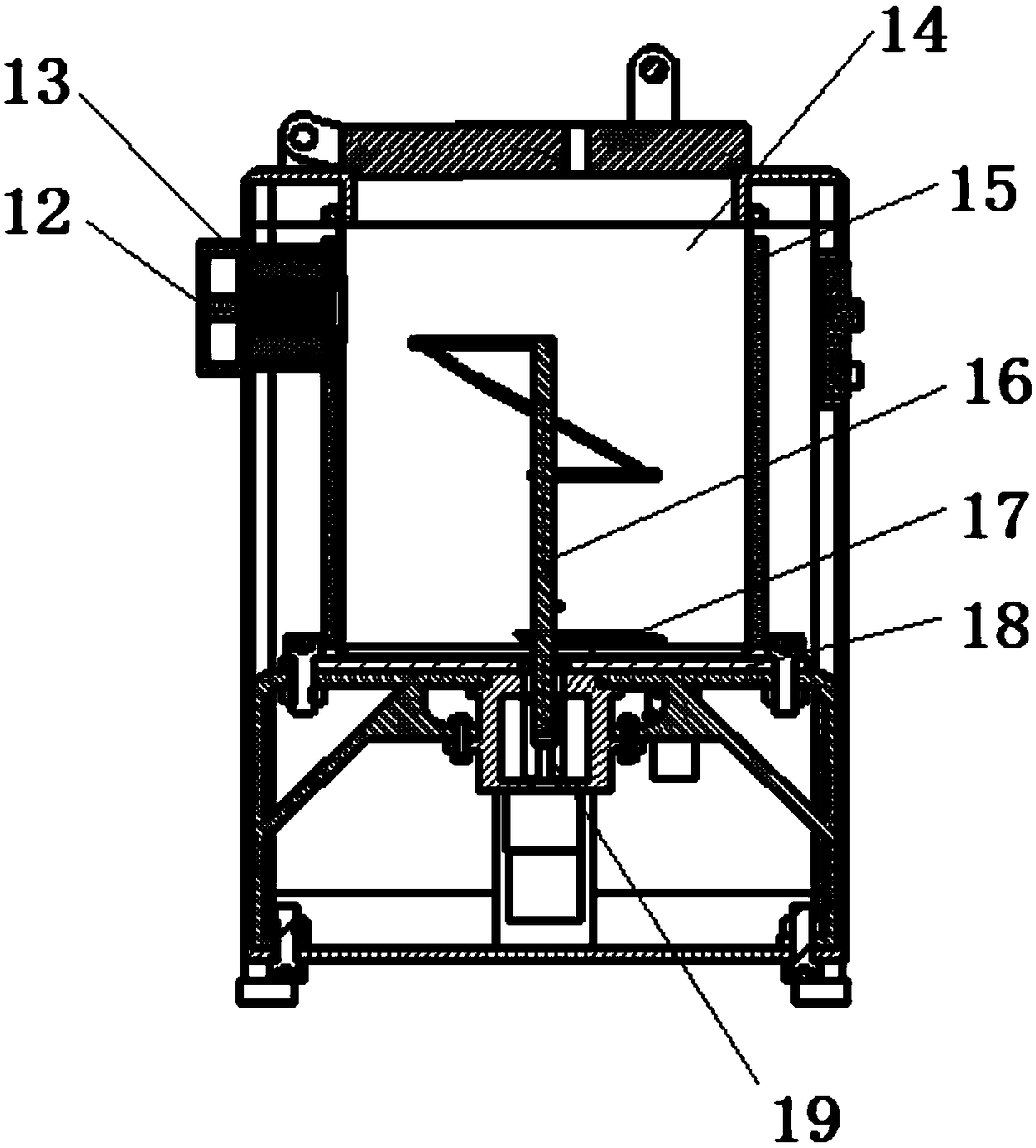

Double-shaft adjustable stirrer

PendingCN106890588AReduce overrunningAvoid overrunningRotary stirring mixersTransportation and packagingDrive shaftPulp and paper industry

The invention relates to a double-shaft adjustable stirrer which comprises a stirring tank, stirring components, a supporting component and a power component. The stirring components are positioned in the stirring tank, the power component is positioned on the supporting component and connected with the stirring components through stirring transmission shafts, each stirring component comprises stirring blades, one transmission shaft and blade connecting rods, each stirring blade is connected with the corresponding transmission shaft through the corresponding blade connecting rod, and the supporting component comprises a supporting frame, a hydraulic rod and a portal bridge frame; the supporting frame is fixed on a supporting frame foundation, one end of the hydraulic rod is fixed on the supporting frame while the other end of the same is connected with the portal bridge frame, and angle ranges of the stirring blades and the blade connecting rods are 20-70 degrees.

Owner:张惠琴

Vibratile heating type decoloring device

InactiveCN106190553AImprove the mixing effectImprove sealingTransportation and packagingMixersElectricitySlag

The invention discloses a vibratile heating type decoloring device, and belongs to the field of edible oil processing. The vibratile heating type decoloring device comprises a tower body which is provided with a stirring layer and a mixing layer, a separation plate is connected between the stirring layer and the mixing layer, the separation plate is provided with a pneumatic valve, the outer side wall of the stirring layer is provided with a slag discharge outlet, and the upper end face of the separation plate is provided with a monitor; the stirring layer is provided with a feed inlet and a sensor, the sensor is electrically connected with the pneumatic valve, the feed inlet is provided with a feed pipe, and a stirring shaft is rotatably arranged in the stirring layer; a disc is arranged on the stirring shaft in a sliding mode, and the bottom end of the disc is provided with an arc-shaped protrusion matched with the outer edge contour of the disc; the separation plate is provided with a support rod corresponding to the arc-shaped protrusion; the mixing layer is internally provided with tower plates, and a heating tube is arranged between every two adjacent tower plates; the outer side wall of the tower body is provided with vibrators, and the bottom of the tower body is provided with a support frame. The vibratile heating type decoloring device solves the problems that an existing decoloring tower is low in working efficiency and nonuniform in stirring, and dead angles exist in the decoloring tower.

Owner:罗奇

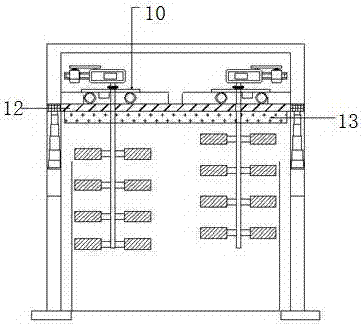

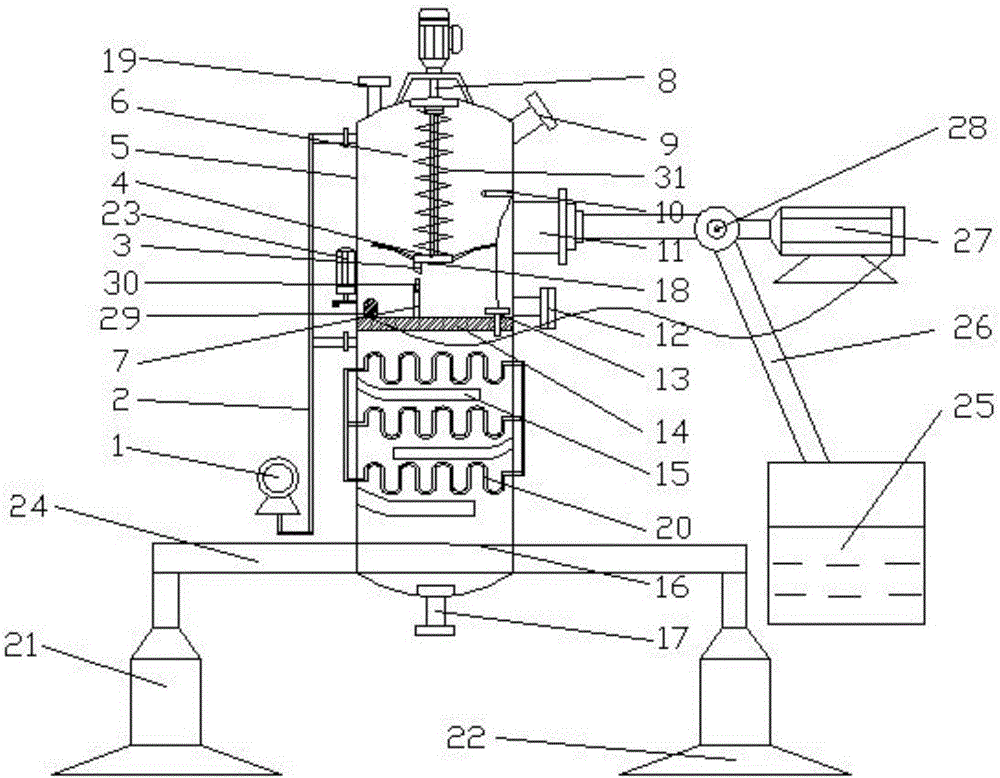

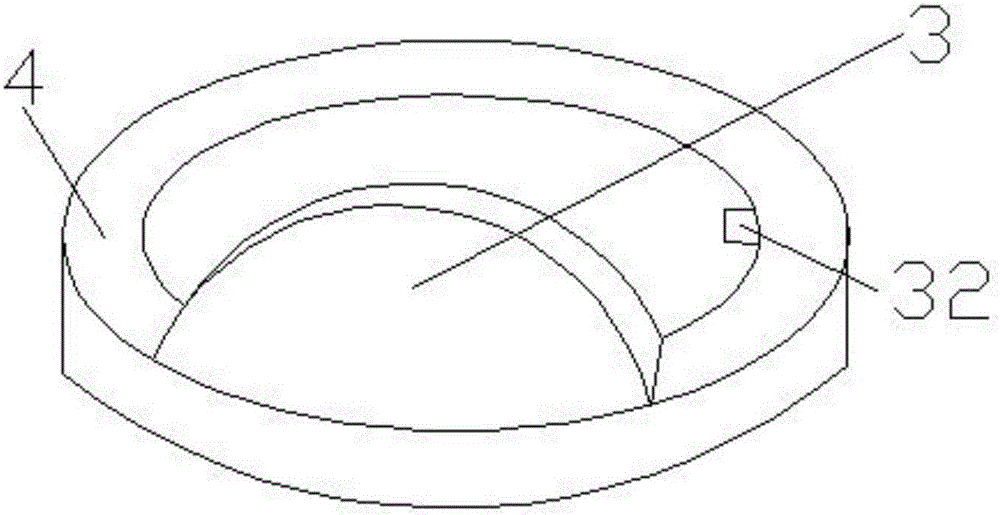

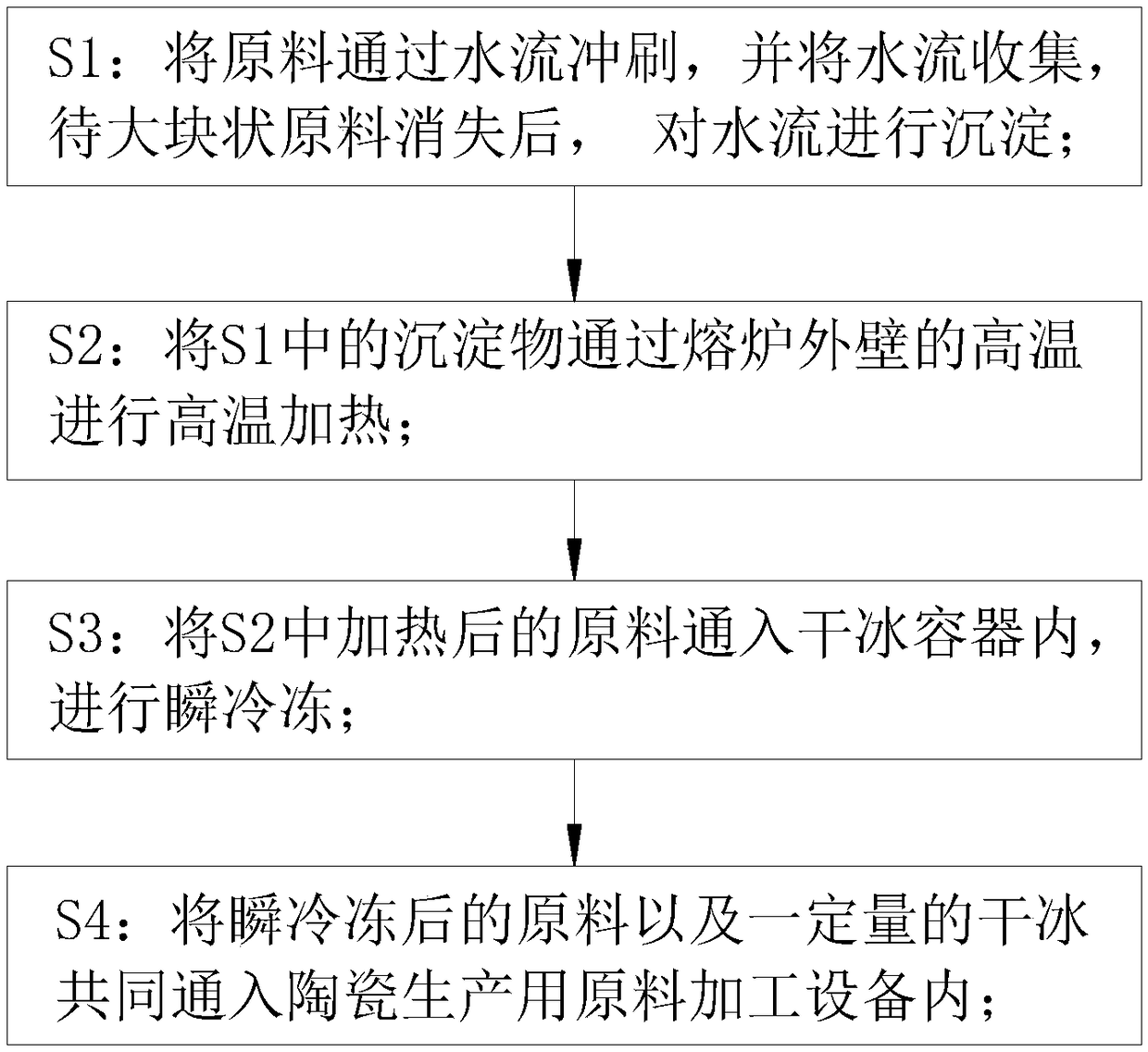

Raw material processing technology for ceramic production

The invention belongs to the technical field of ceramic production, in particular to a raw material processing technology for the ceramic production. The raw material processing technology for the ceramic production comprises the steps that raw materials are washed by water flow, the water flow is collected, and the water flow is precipitated after large block raw materials disappear; the precipitate is heated at high temperature through the high temperature of the outer wall of a melting furnace, and water in the raw materials is evaporated through the high temperature heating; then the heated raw materials are introduced into a dry ice container to carry out instantaneous freezing, and the block raw materials in the raw materials are crushed; and the instant frozen raw materials and a certain amount of dry ice are jointly introduced into a raw material processing device for the ceramic production, wherein the dry ice effectively prevents the device from generating heat when grindingand crushing the raw materials, the service life of the device is prolonged, and the dry ice is gasified when the raw materials are mixed with water to generate carbon dioxide gas to assist in stirring, so that the mixing is more sufficient. According to the raw material processing technology for the ceramic production, the operation is convenient, the crushing efficiency is high, the service lifeis prolonged, the raw materials are fully mixed, and the phenomenon that the raw materials adhere to the surface of the device and the precipitation is not occur .

Owner:徐州亚苏尔高新材料有限公司

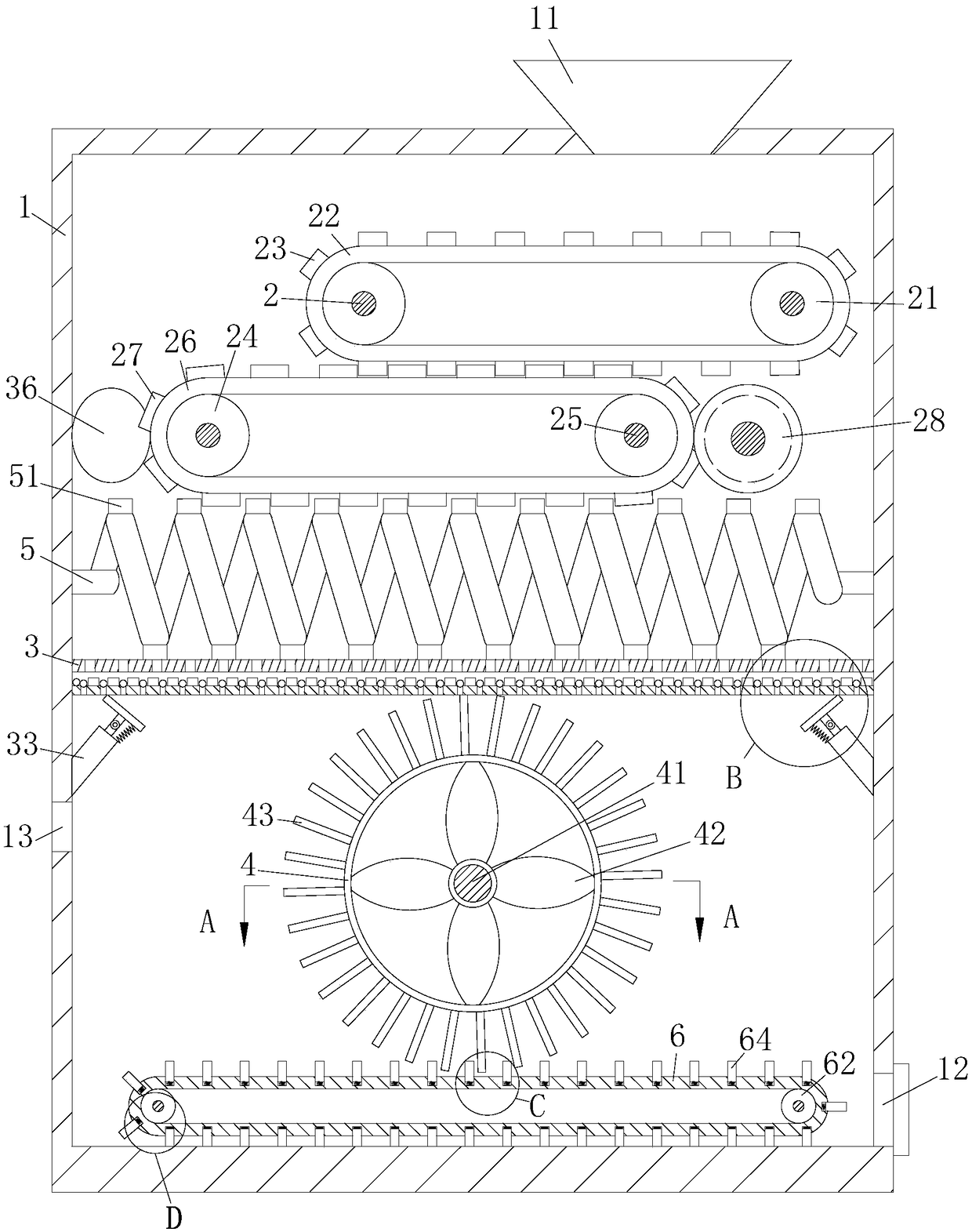

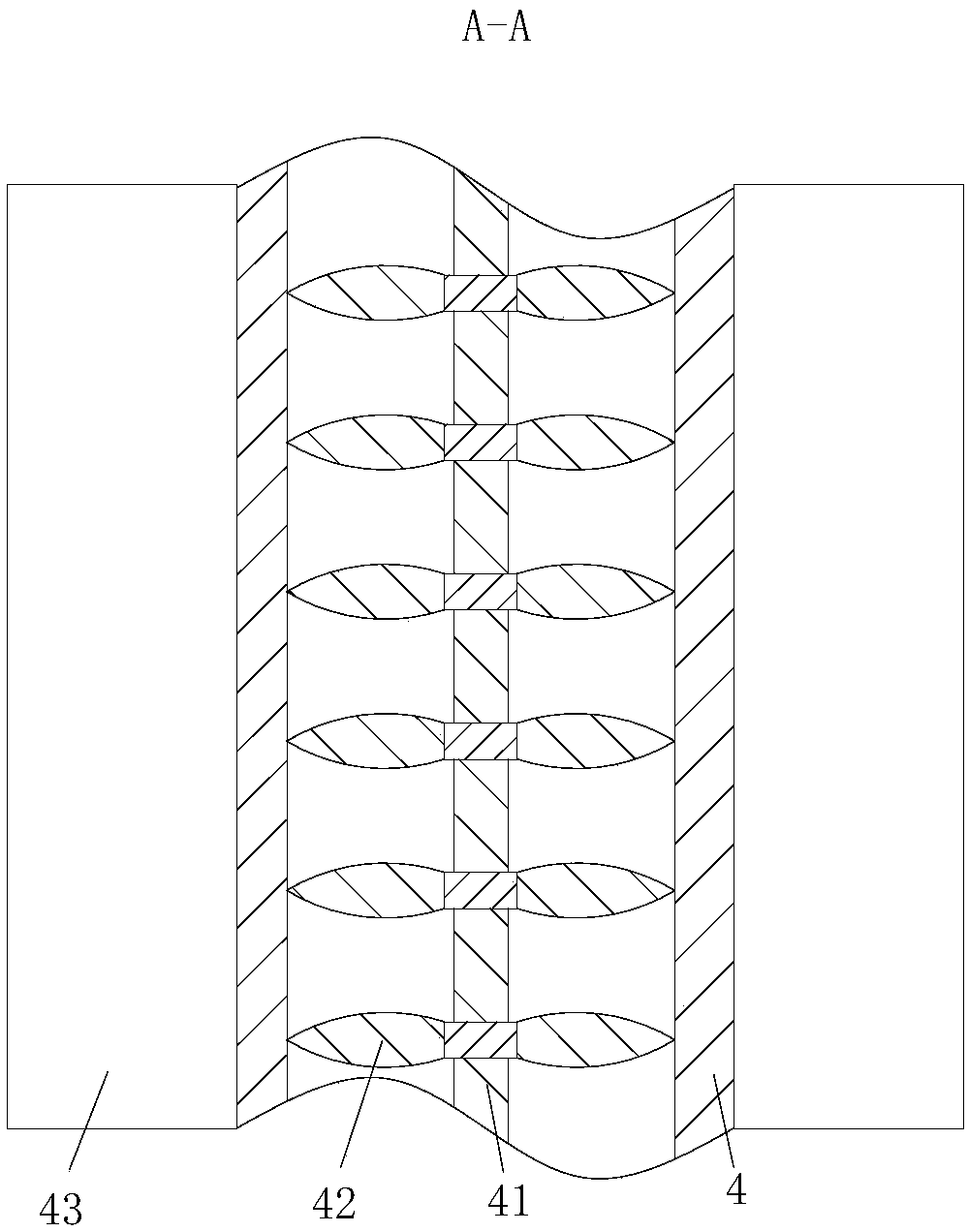

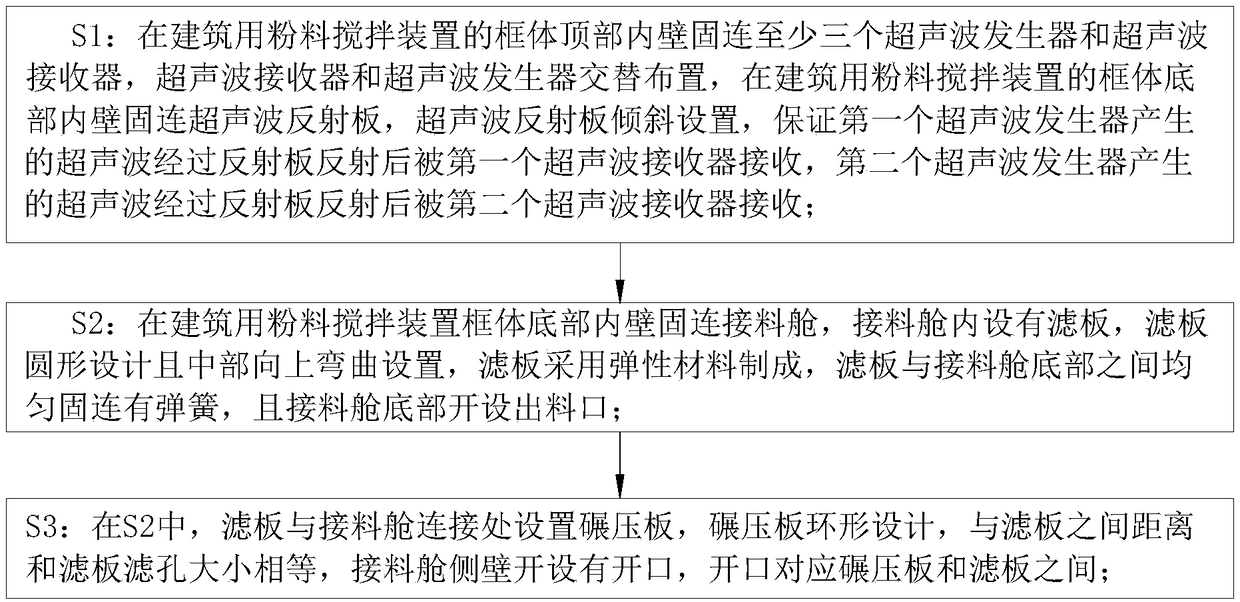

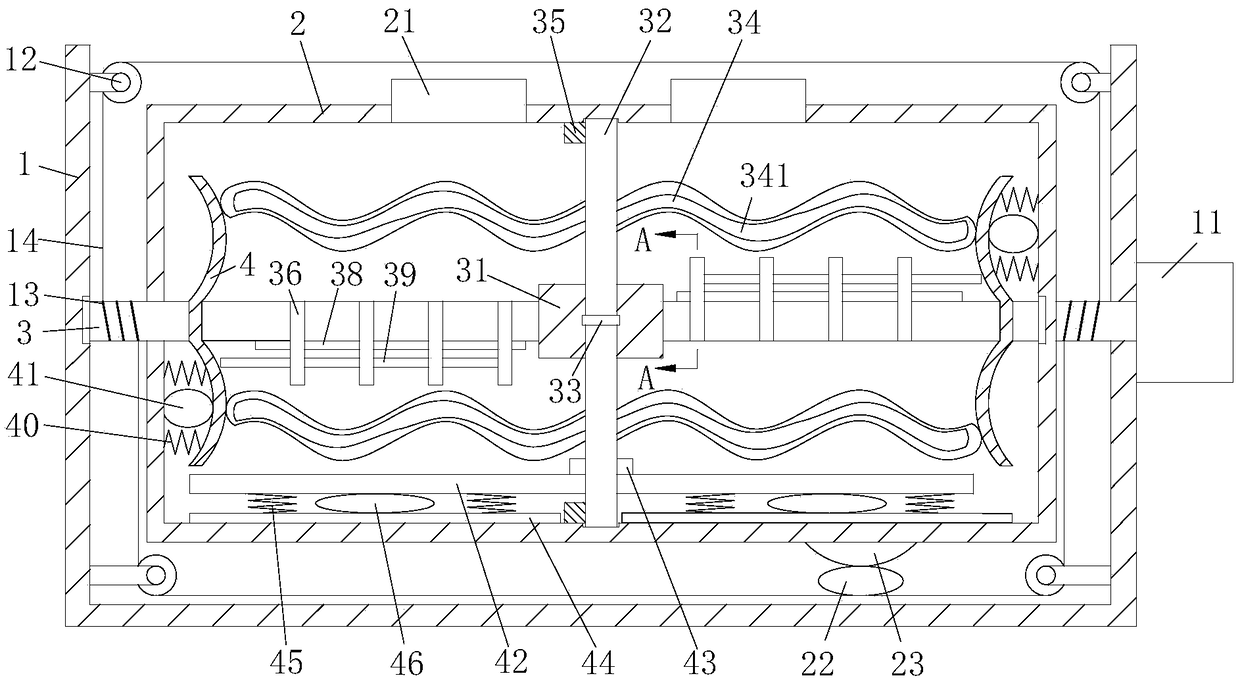

Building material mixing and stirring process

ActiveCN109224980AAvoid clumpingSmash thoroughlyRotating receptacle mixersTransportation and packagingDrive shaftFilter effect

The invention belongs to the technical field of building material mixing, and particularly relates to a building material mixing and stirring process. Through the matching of an ultrasonic wave generator and an ultrasonic wave reflecting plate, building materials in a rotating tube are crushed; the unthorough stirring due to adhesion agglomeration of the building materials can be prevented; the building materials fall down so that the filter plate vibrates; the filtering effect is enhanced; the filtering speed is accelerated; in addition, the filtering plate is in bent arrangement, so that theadhesionve and agglomerationve building materials can roll on the surface of the filtering plate to assist the crushing; uncrushed blocks can roll to the peripheral positions of the filtering plate;in the filtering plate vibration process, the building material can realize the further material mixing, so that the stirring of the filtered building materials is complete; in the filtering plate vibration process, the milling plate is matched for crushing building material agglomeration blocks on the periphery of the filtering plate; meanwhile, the ultrasonic waves can be used for assisting thecrushing, so that the crushing is faster and more thorough; a used building material powder stirring device comprises a frame body and a rotating tube; screw thread grooves are formed in the surfacesof a driving shaft and a motor rotating shaft; the screw thread directions are opposite. The stirring is sufficient and thorough; the building materials after the material mixing do not have an agglomeration phenomenon.

Owner:婺源县江湾建筑工程有限公司

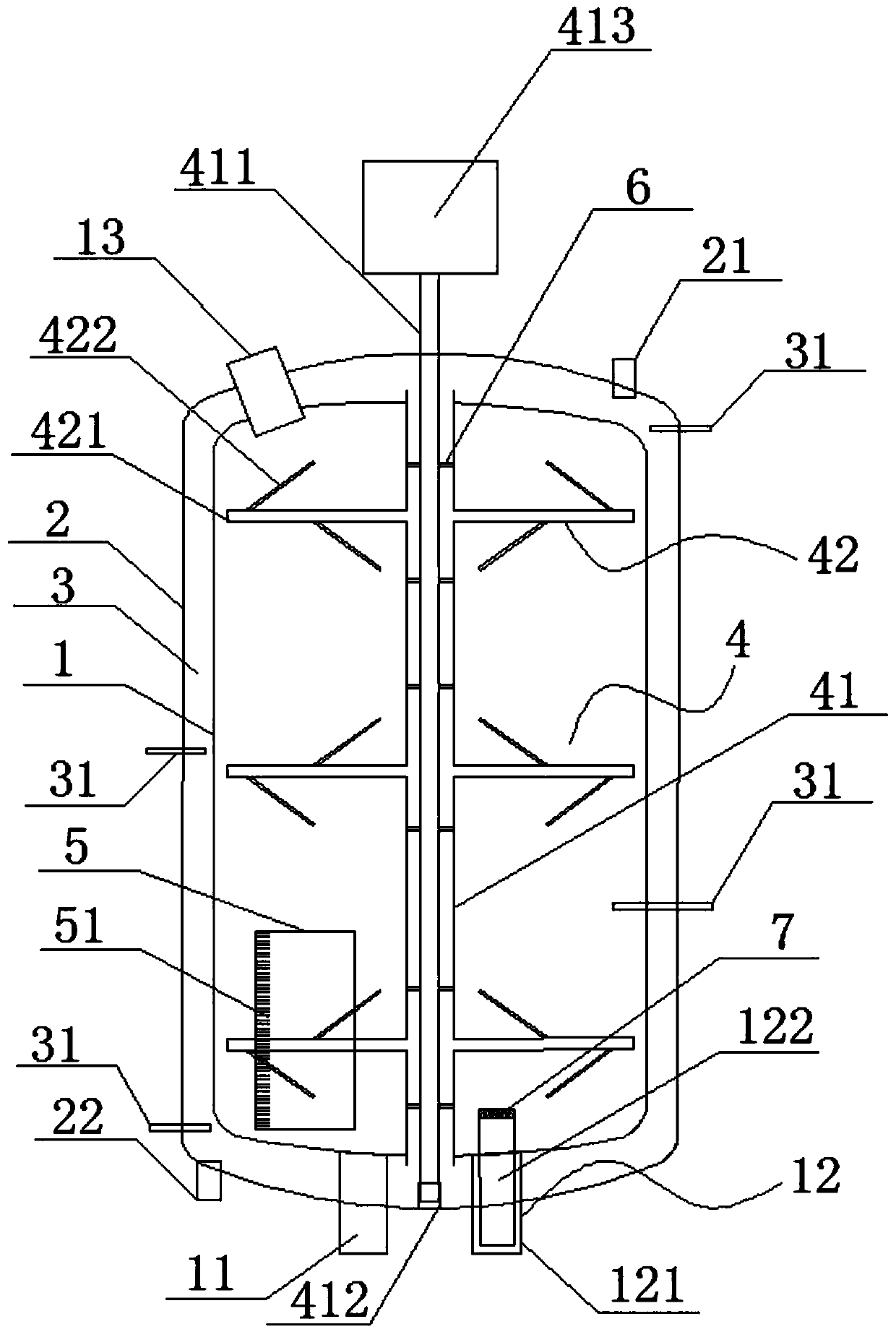

Crystallization reactor with high disperse stirring performance

InactiveCN110756143AStir wellAvoid disturbanceChemical/physical/physico-chemical stationary reactorsPhysical chemistryCooling chamber

The invention provides a crystallization reactor with high disperse stirring performance. The crystallization reactor comprises a reactor body and a reactor sleeve, a cooling chamber is formed betweenthe outer wall of the reactor body and the inner wall of the reactor sleeve, a high disperse stirring mechanism is arranged in the reactor body, the high disperse stirring mechanism comprises a hollow shaft rod and a plurality of disperse stirring units, both the upper end and the lower end of the hollow shaft rod extend out of the reactor body and communicate with the cooling chamber, the disperse stirring units are evenly distributed on the hollow shaft rod from top to bottom, and the lower end of the reactor body is provided with a first outlet and a second outlet. The crystallization reactor is provided with a main stirring rod and an inclined auxiliary stirring rod, stirring can be conducted in horizontal and vertical directions, the main stirring rod communicates with the cooling chamber and can be filled with a coolant, the mixing cooling effect is better, the crystallization efficiency is improved, and the crystal uniform dispersion is better.

Owner:陈永福

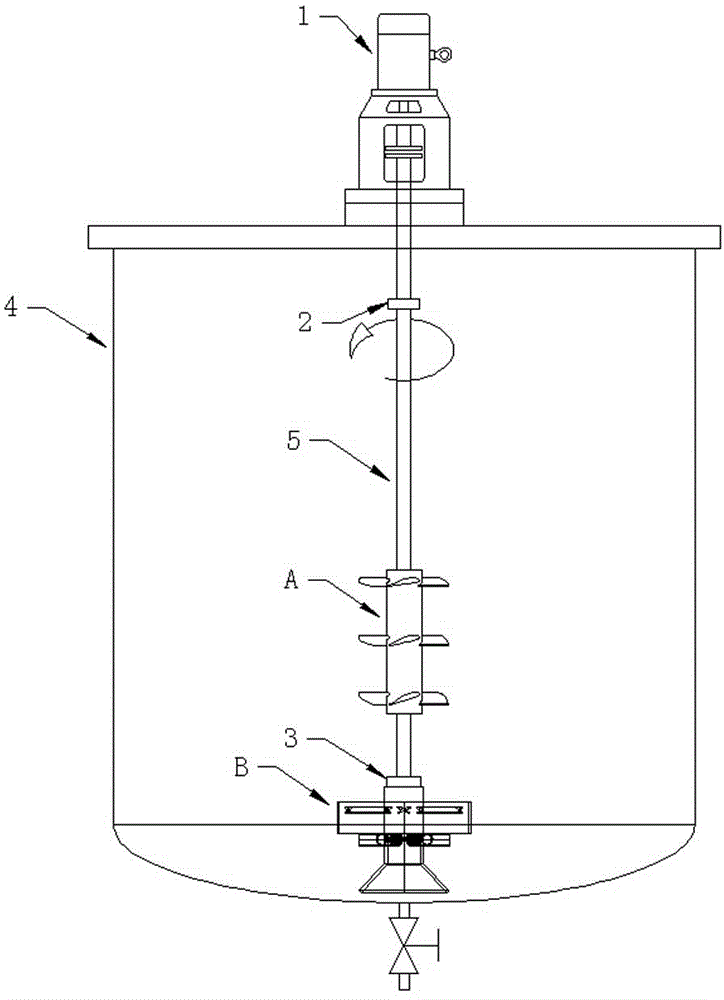

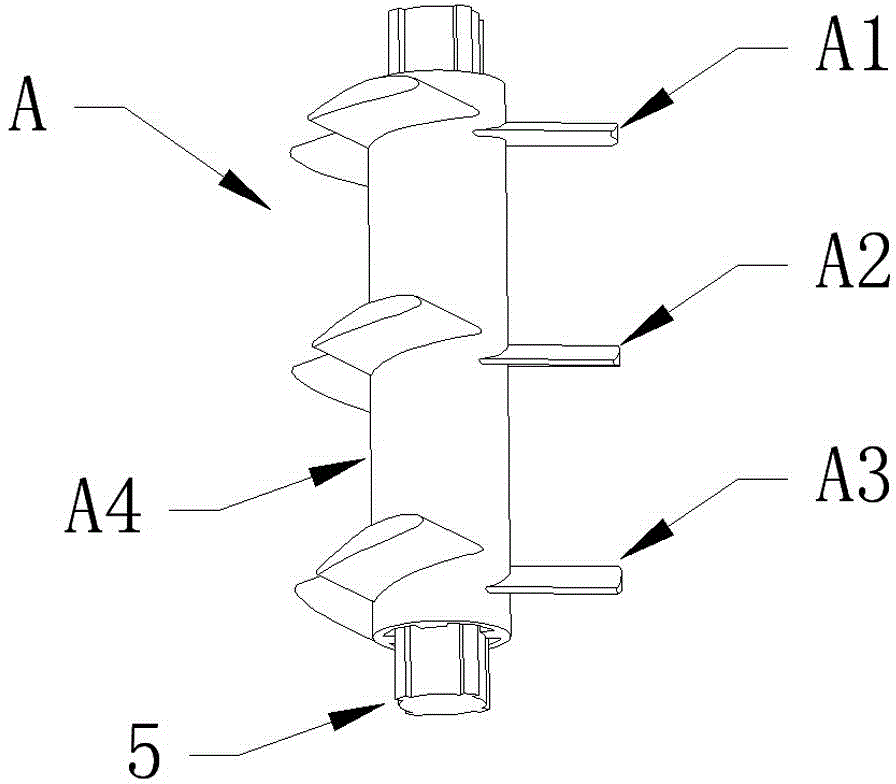

Low-energy-consumption lifting mixing barrel

ActiveCN104624097AUniform solid-liquid distributionReduce energy consumptionMixersStaringEngineering

The invention discloses a low-energy-consumption lifting mixing barrel. A mixing shaft is inserted into a barrel body, a motor and a reducer drive the mixing shaft to rotate, the mixing shaft is sequentially provided with a lower suspension spraying mixer and a bottom sweeping mixer from top to bottom, wherein the lower suspension spraying mixer is limited by an upper positioning step and a lower positioning step and can float up and down; the lower suspension spraying mixer comprises a mixing shaft, a shaft sleeve and a paddle, wherein the mixing shaft is a spline shaft, the shaft sleeve is also a spline shaft sleeve, the spline shaft sleeve can move on the spline shaft, and the paddle is welded on the spline shaft sleeve; the bottom sweeping mixer comprises a mixing shaft and an outer barrel, the mixing shaft and the outer barrel are welded into a whole by virtue of a paddle, the mixing shaft extends downward and forms a hollow cylinder, then the hollow cylinder extends to form a cone, and the outer wall of the cylinder is communicated with a jet pipe; and a blade tilt is gradually increased from top to bottom. The low-energy-consumption lifting mixing barrel has the characteristics that energy consumption is low, material circulation is good, deposition at the bottom is hardly caused, no mixing dead angle is formed, and light-load staring can be still realized even materials are sedimented due to long-time power failure, so that the low-energy-consumption lifting mixing barrel has a broad application prospect.

Owner:湖北省泽瀚实业有限公司

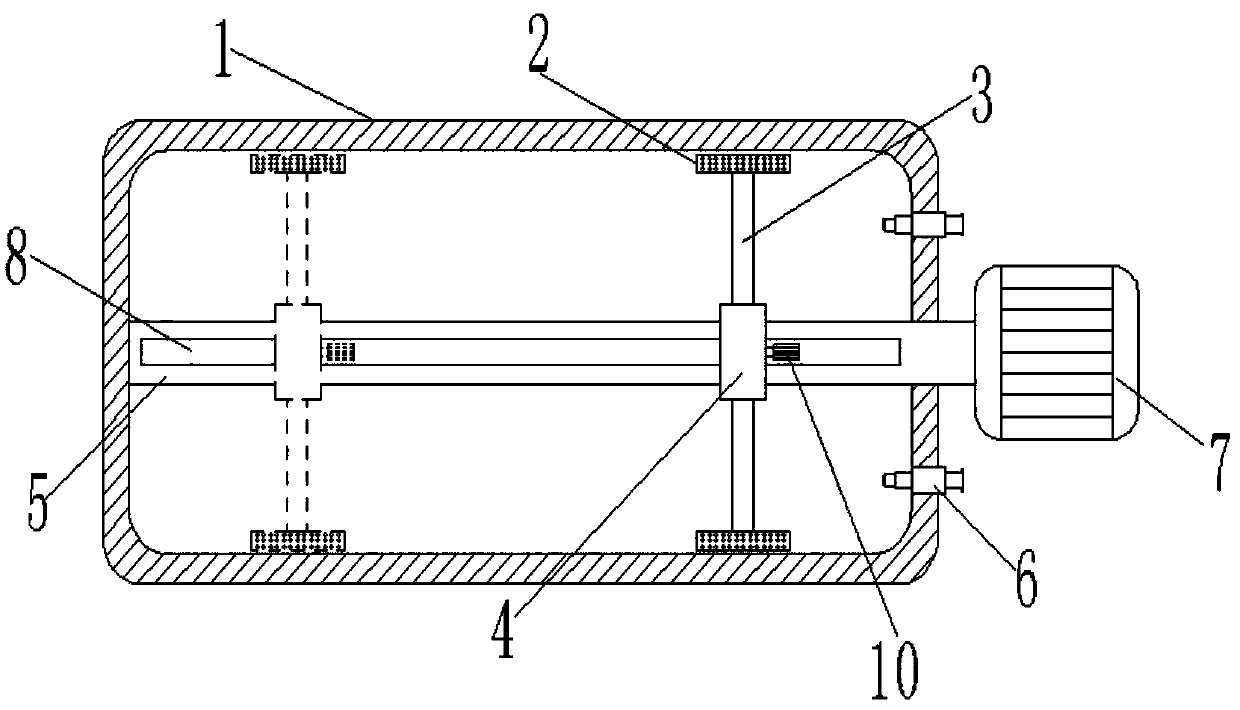

Chemical reaction kettle premixing device

ActiveCN113385072AImprove the mixing effectSimple structureFlow mixersRotary stirring mixersEngineeringMechanical engineering

The invention discloses a chemical reaction kettle premixing device, and belongs to the technical field of chemical production. The chemical reaction kettle premixing device comprises a kettle body, a discharge pipe and a feed pipe, the feed pipe is arranged at one end of the kettle body, the discharge pipe is arranged at the other end of the kettle body, and a stirring mechanism is arranged at the end, away from the discharge pipe, of the kettle body. The stirring mechanism comprises a turbulent flow assembly used for conveying and mixing materials in the kettle body, a driving assembly used for driving the turbulent flow assembly to move and a power assembly used for driving the turbulent flow assembly to intermittently rotate at a high speed, and a material spraying pipe is arranged on the inner wall of the kettle body. The premixing device is simple in structure and convenient to use, the posture of the turbulent flow assembly is periodically changed through mutual cooperation of the driving assembly and the power assembly during use, materials in the kettle body are stirred and mixed in all directions through cooperative use of the mixing assembly and the transmission assembly, stirring dead angles are avoided, and the material mixing effect of the premixing device is obviously improved.

Owner:重庆化工职业学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com